Circular screen printer adjusting mechanism adopting magnetic bar printing mechanism

A technology of adjusting mechanism and printing machine, applied in screen printing machine, printing machine, rotary printing machine and other directions, can solve the problems of limited control effect, leakage of slurry, affecting printing effect, etc., to ensure printing effect and good printing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

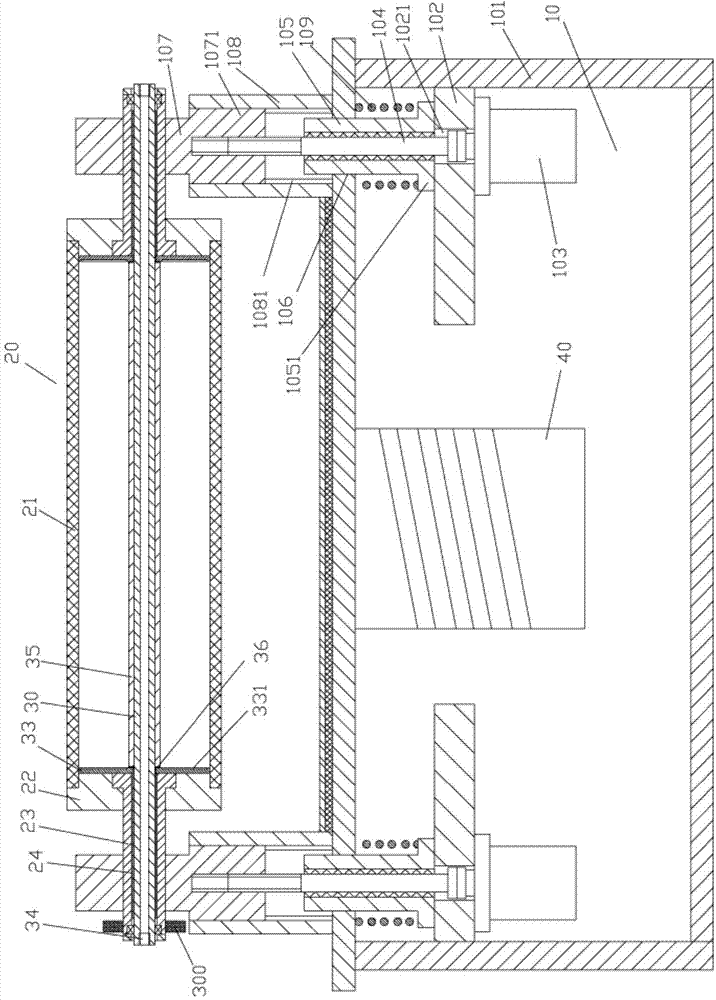

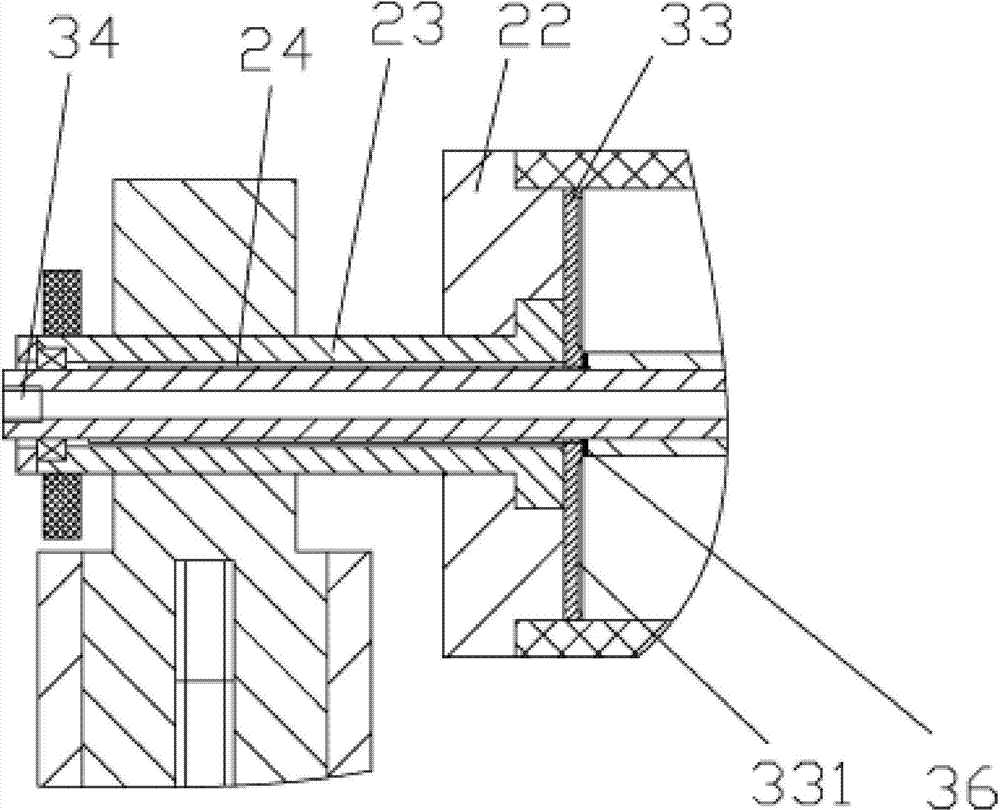

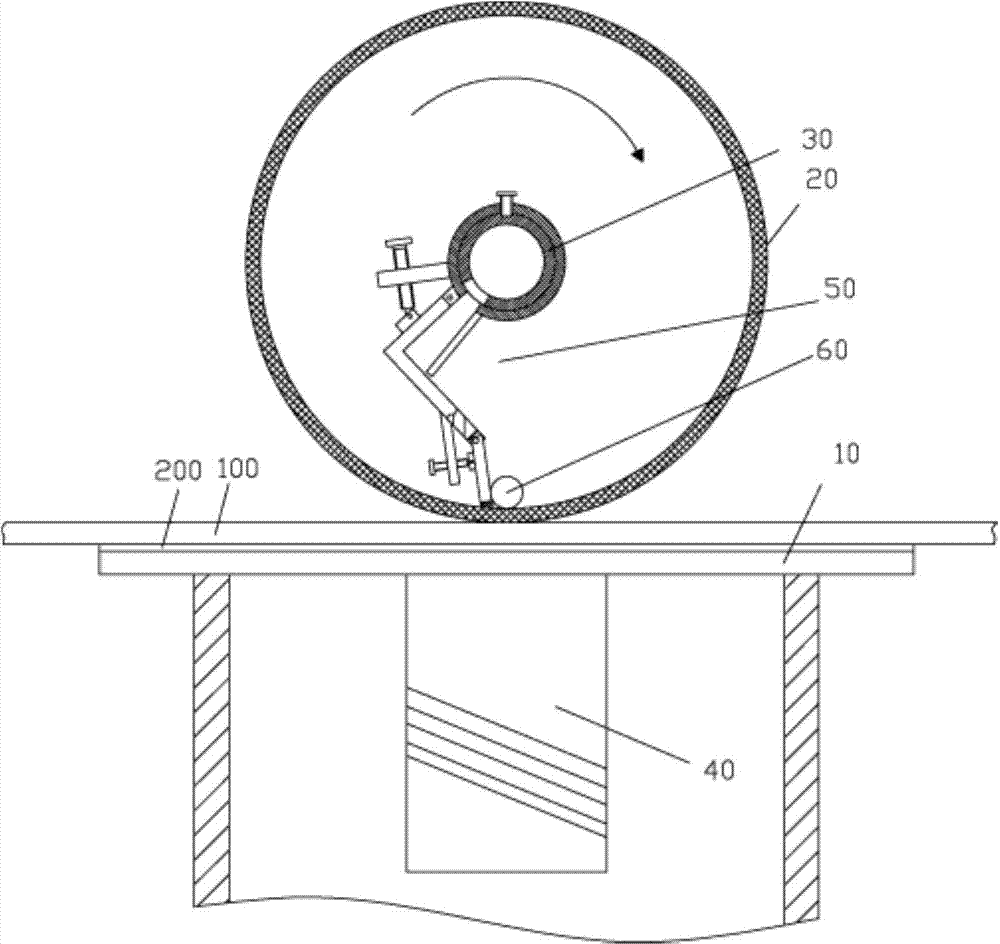

[0024] Example: see Figures 1 to 4 As shown, a rotary screen printing machine adjustment mechanism using a magnetic rod scraping mechanism includes a stand 10, and support plates 102 are fixed on the side plates 101 on both sides below the stand 10, and the top plate of the stand 10 The back is fixed with a magnetic table 40, and the support plate 102 is fixed with a drive motor 103. The output shaft of the drive motor 103 is inserted in the jack 1021 provided on the support plate 102, and the output shaft of the drive motor 103 is connected to the vertical shaft through a coupling. The adjustment rod 104 is fixed, the lower end of the vertical adjustment rod 104 and the coupling are in the socket 1021, the vertical adjustment rod 104 is inserted into the adjustment sleeve 105, and the adjustment sleeve 105 is inserted on the top plate of the stand 10 In the through hole 106 provided, the top end of the vertical adjustment rod 104 extends out of the adjustment sleeve 105, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com