Inductive positioning code-spurting device

A technology of inductive positioning and inkjet coding, which is applied to printing devices, printing, typewriters, etc., can solve the problems of different sizes of packaging, poor printing quality, and different package sizes, etc., and achieve the goal of reducing labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

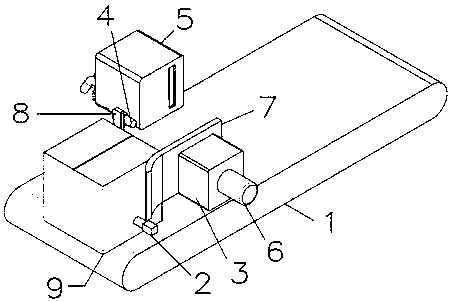

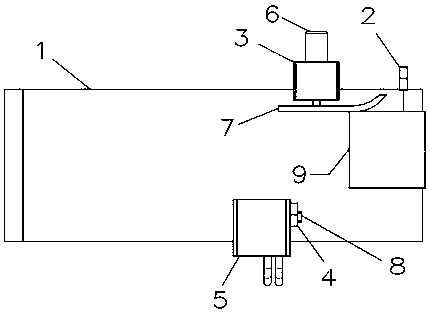

[0034] Such as figure 1 and figure 2 As shown, the inductive positioning coding device includes a conveyor belt 1 along which a position sensor 2 , a limit assembly 3 , a first ultrasonic sensor 4 and a printer 5 are sequentially arranged.

[0035] The coding machine 5 is used for coding the items 9 to be coded on the product in the back-end coding process of the e-commerce sorting industry. The coding quality is affected by the distance between the surface of the object 9 to be coded and the surface of the inkjet printer 5, and the invention of the rigid positioning coding device is to ensure that the printing distance is within a constant range, so that the coding quality can be guaranteed.

[0036] The inductive sensor 8 is used to sense whether the object 9 to be coded is close to the inkjet printer 5. The inductive sensor 8 is electrically connected to the controller, and the inductive signal is fed back to the controller for logic control. When the inductive sensor 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com