Regeneration of ink box for ink-jetting printer

A technology of inkjet printers and ink cartridges, which is applied in printing and other directions, and can solve problems such as easy to be diluted printing, expanding drilling air holes, deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

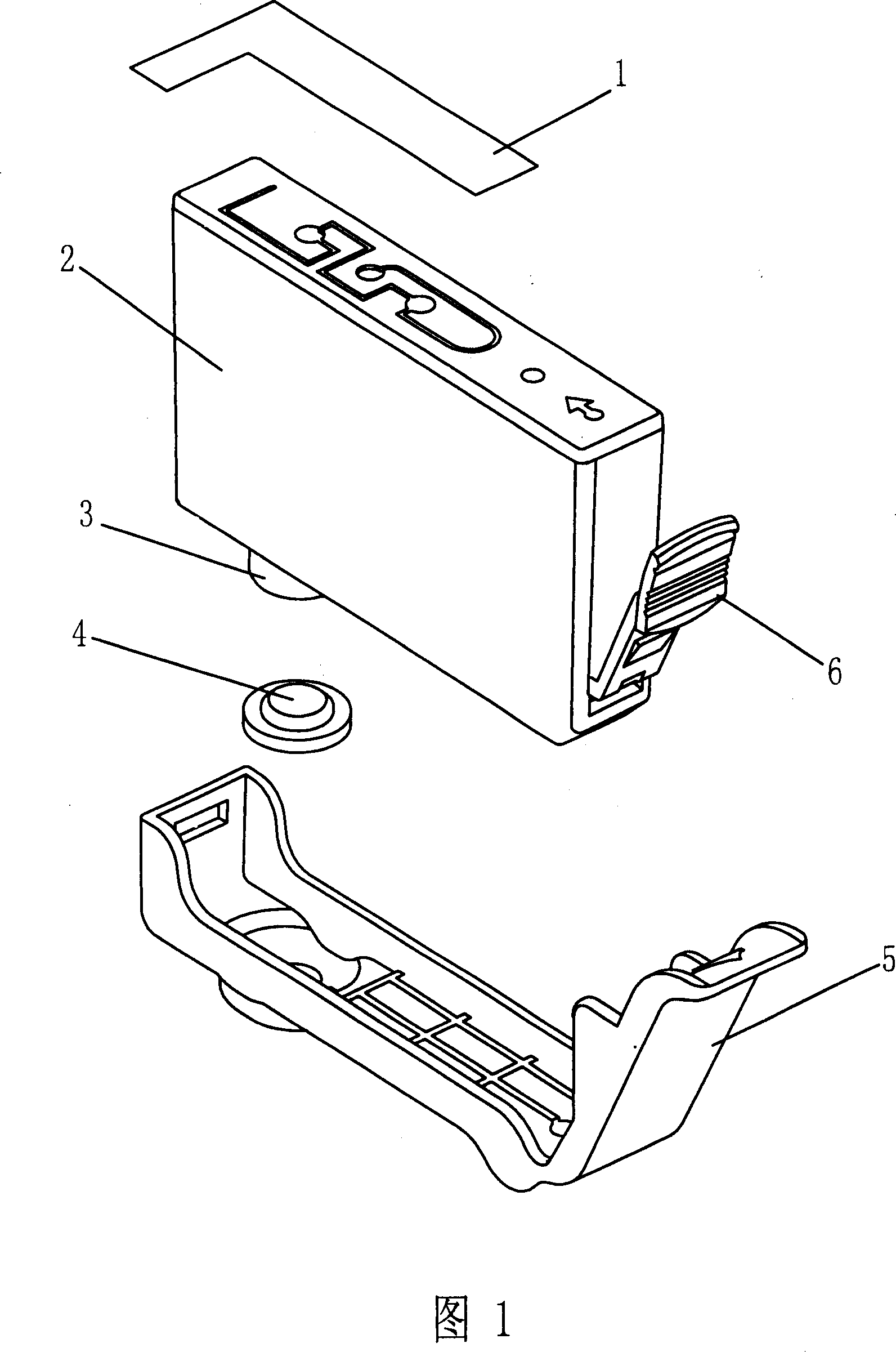

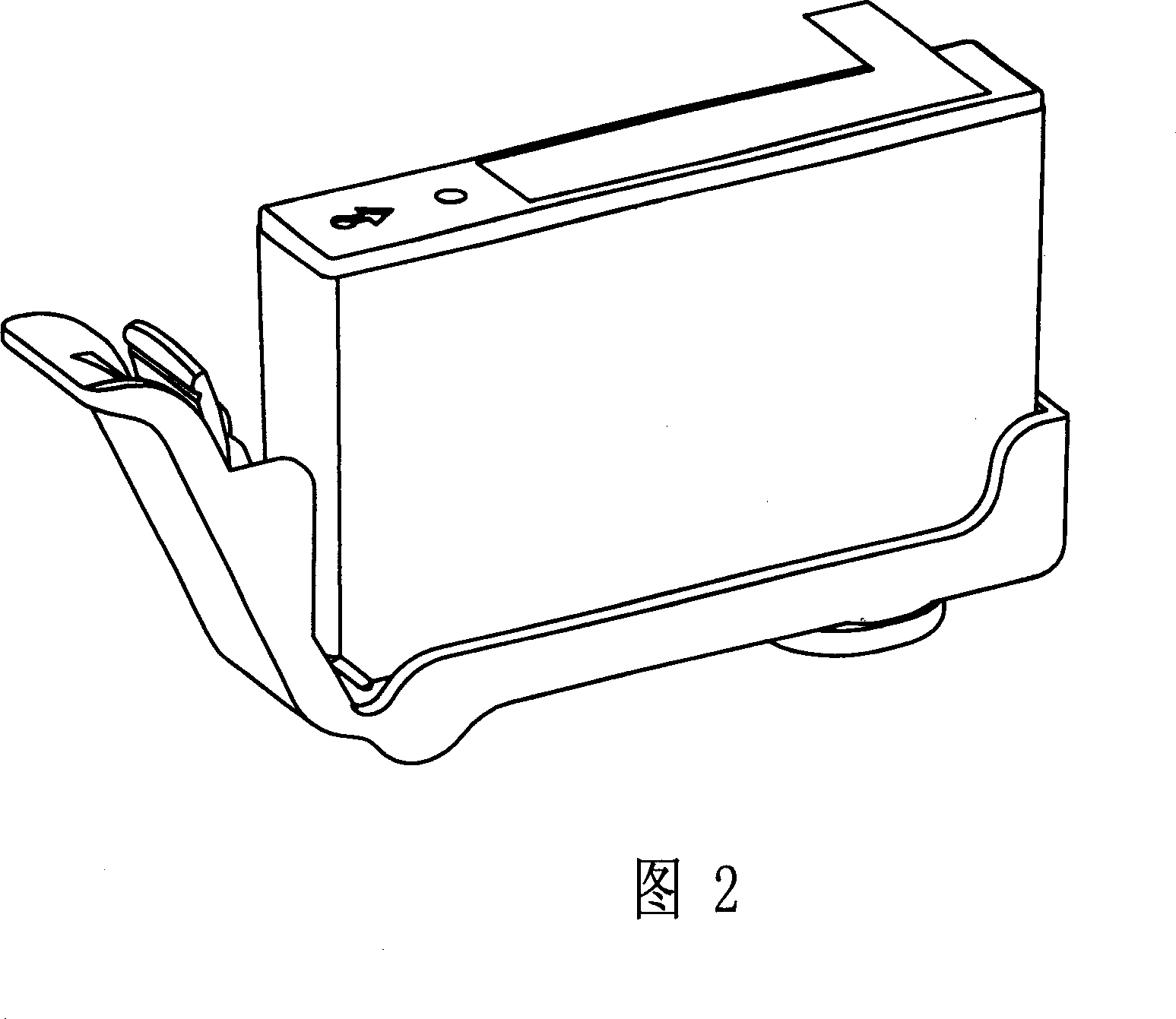

[0010] The exploded structure diagram of the ink cartridge is shown in Figure 1. The regeneration process steps for recycling the ink cartridge are: remove the old air-conducting film 1 on the ink container 2; clean the old cotton core in the ink outlet 3; Ink; inject ink into the ink container 2 from the ink outlet 3; install the silica gel pad 4 and the protective cover 5 at the ink outlet 3 successively, as shown in Figure 1, the convex part of the silica gel pad 4 contacts the ink outlet 3, Act as a seal to prevent ink leakage. The protective cover 5 has a long groove for accommodating the bottom of the ink container, and an oblique handle on the groove is used to accommodate and fix the pull bar of the ink container in the handle. The protective cover 5 can be separately installed as a whole with the bottom surface of the ink container 2 and the pull rod 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com