High-scratch-resistant plastic surface printing extinction oil and preparation method thereof

A technology of plastic watch and matting oil, applied in inks, household appliances, applications, etc., can solve the problems of poor temperature resistance and anti-adhesion, odor adhesion fastness, not environmental protection, etc., to improve scratch resistance, improve retort resistance, outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

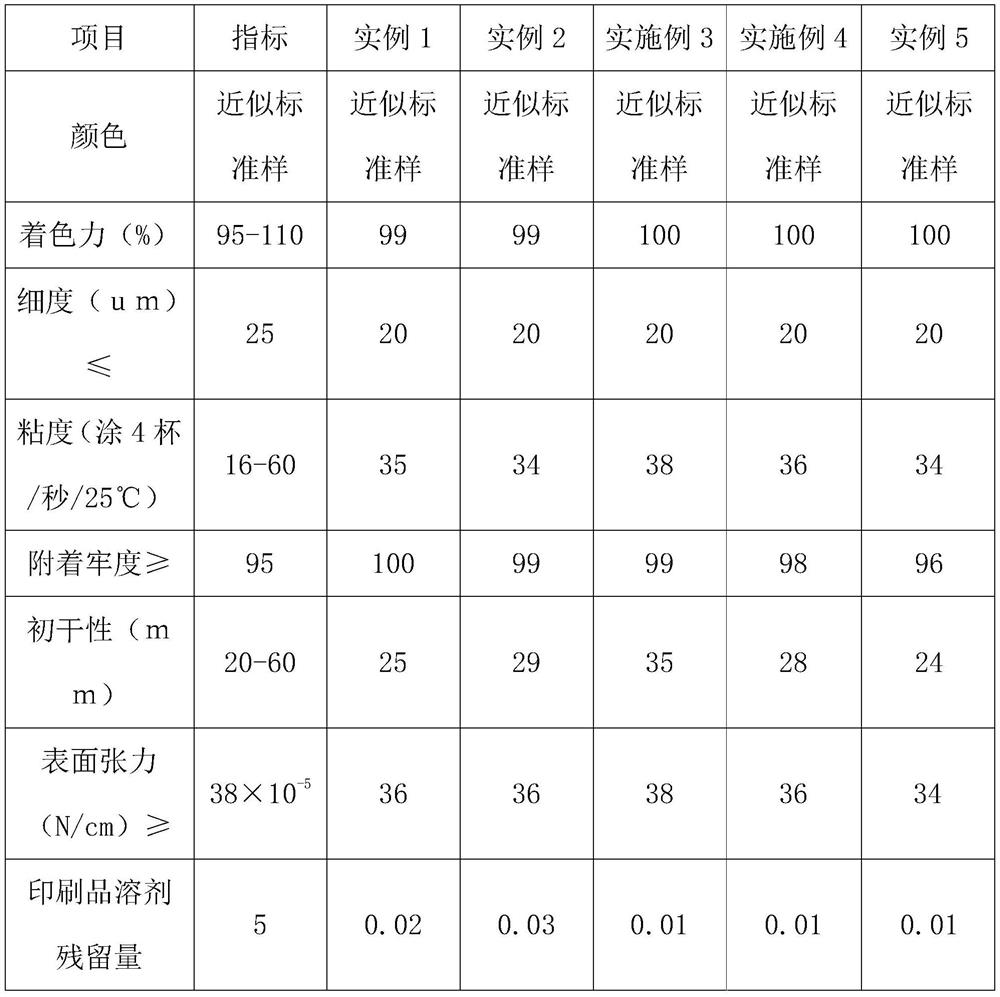

Examples

Embodiment 1

[0030] A scratch-resistant plastic surface printing matting oil, comprising the following components:

[0031] 30% Vinyl Resin Solution 23%

[0032] 70% surface printing polyurethane solution 22%

[0033] Anti-scratch agent 1%

[0034] Kaolin 12%

[0035] Polyethylene wax 2%

[0036] Ethyl acetate: 20%

[0037] n-Propyl acetate: 20%.

[0038] Furthermore, the model of the vinyl acetate resin in the 30% vinyl acetate resin solution is 555.

[0039] A preparation method of scratch-resistant plastic surface printing matting oil, the specific steps are as follows:

[0040] S1. Preparation of mixed solvent: Accurately measure ethyl acetate and n-propyl acetate, add the two into the mixing tank, stir with a high-speed disperser at a stirring rate of -2000r / min for 20 minutes to fully mix, and take out part of the mixed solvent;

[0041] S2. Configure resin solution: Add vinyl vinegar resin solution, polyurethane solution, filler, polyethylene wax and additives into the mixing...

Embodiment 2

[0046] A scratch-resistant plastic surface printing matting oil, comprising the following components:

[0047] 30% Vinyl Resin Solution 23%

[0048] 70% surface printing polyurethane solution 22%

[0049] Anti-scratch agent 1%

[0051] Polyethylene wax 2%

[0052] Ethyl acetate: 20%

[0053] n-Propyl acetate: 20%.

[0054] Furthermore, the model of the vinyl acetate resin in the 30% vinyl acetate resin solution is 555.

[0055] A preparation method of scratch-resistant plastic surface printing matting oil, the specific steps are as follows:

[0056] S1. Preparation of mixed solvent: Accurately measure ethyl acetate and n-propyl acetate, add the two into the mixing tank, stir with a high-speed disperser at a stirring rate of 1500r / min for 45min to fully mix, and take out part of the mixed solvent;

[0057] S2. Configure resin solution: Add vinyl vinegar resin solution, polyurethane solution, filler, polyethylene wax and additives into the mixi...

Embodiment 3

[0062] A scratch-resistant plastic surface printing matting oil, comprising the following components:

[0063] 30% Vinyl Resin Solution 23%

[0064] 30% surface printing polyurethane solution 22%

[0065] Anti-scratch agent 1%

[0067] Polyethylene wax 2%

[0068] Ethyl acetate: 20%

[0069] n-Propyl acetate: 20%.

[0070] Furthermore, the model of the vinyl acetate resin in the 30% vinyl acetate resin solution is 555.

[0071] A preparation method of scratch-resistant plastic surface printing matting oil, the specific steps are as follows:

[0072] S1. Preparation of mixed solvent: Accurately measure ethyl acetate and n-propyl acetate, add the two into the mixing tank, stir with a high-speed disperser at a stirring rate of 1800r / min for 35min to fully mix, and take out part of the mixed solvent;

[0073] S2. Configure resin solution: Add vinyl vinegar resin solution, polyurethane solution, filler, polyethylene wax and additives into the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com