Patents

Literature

132results about How to "Excellent retort resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam-resistant solvent-free laminating adhesive and preparation method thereof

ActiveCN102604583ALow viscosityImprove heat resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides steam-resistant solvent-free laminating adhesive applicable to compound soft package, which comprises a component A and a component B. The component A is isocyanate terminated polyurethane polymer formed by reacting polyhydroxy compound and polyisocyanate terminated compound. The component B is formed by mixing more than one type of plant oil polyalcohol, curing accelerator and synthetic modifier. The polyhydroxy compound in component A is formed of polyester polyol and / or polyether polyol with more than two degrees of functionality and a molecular weight range of from 600-2000, and more than one type of plant oil polyalcohol. The curing accelerator in the component B is formed of small molecular polyalcohol with more than two degrees of functionality. The synthetic modifier is formed by reacting more than one type of silane coupling agent and polyalcohol. The steam-resistant solvent-free laminating adhesive is low in viscosity and fast in curing speed, has high peel strength after boiled in water at 100 DEG C, and is especially suitable for soft packages requiring long-term high temperature sterilization (such as soft packages for foods, drugs and baby products). The invention further provides a preparation method of the steam-resistant solvent-free laminating adhesive.

Owner:SOUTH CHINA UNIV OF TECH +1

Low viscosity solvent-free polyurethane laminating adhesive and preparation method thereof

ActiveCN103215006AIncrease crosslink densityHigh functionalityFilm/foil adhesivesPolyureas/polyurethane adhesivesAdhesiveSolvent based

The invention discloses a low viscosity solvent-free polyurethane laminating adhesive, which includes component A and component B. The component A is an isocyanate terminated compound, and the component B is a hydroxyl terminated compound. The component A and the component B are mixed according to that the isocyanate terminated group and the hydroxyl are in a mole ratio of 1.3-1.75, thus obtaining the bicomponent polyurethane laminating adhesive. The invention also discloses a preparation method of the low viscosity solvent-free polyurethane laminating adhesive. The low viscosity solvent-free polyurethane laminating adhesive prepared by the invention has the advantages of low viscosity, fast curing speed, high peel strength and resistance to 100DEG C cooking.

Owner:SOUTH CHINA UNIV OF TECH +1

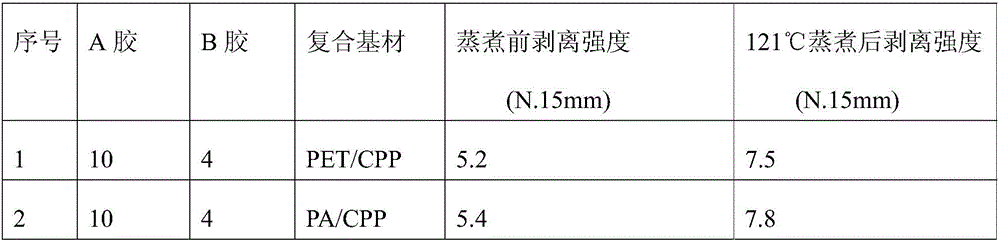

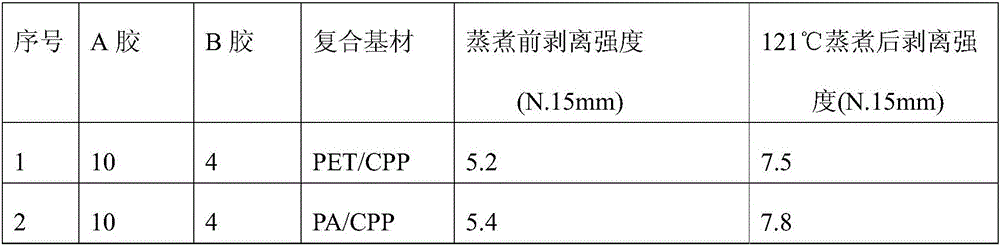

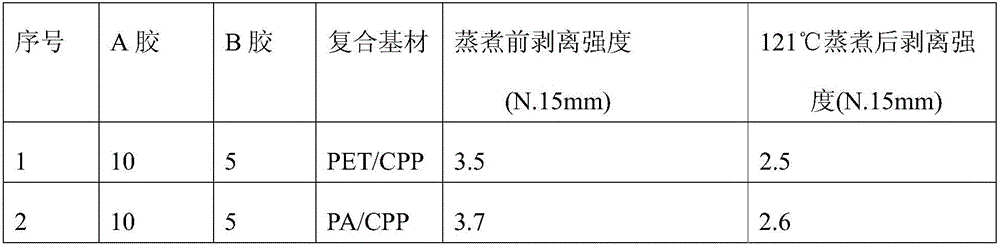

Solvent-free two-component polyurethane cooking adhesive and preparation method thereof

InactiveCN106675499AImprove temperature resistanceImprove media resistancePolyureas/polyurethane adhesivesPolyesterPolyol

The invention provides a heat-resistant solvent-free two-component polyurethane cooking adhesive. Through introducing a bisphenol A structure polyether and synthesizing appropriate polyester polyol, the temperature resistance and the medium resistance of the adhesive are improved, and the problems of low peeling strength and easiness in delaminating of a common solvent-free adhesive after cooking are solved. The heat-resistant solvent-free two-component polyurethane cooking adhesive is formed by an adhesive A and an adhesive B, wherein the adhesive A is formed by polyester polyol, liquidated-MDI and polyether polyol through an reaction; the adhesive B is formed by bisphenol A structure-contained polyether polyol, a coupling agent and castor oil; the matching ratio of the adhesive A and the adhesive B is 10 to (4 to 5).

Owner:JIANGSU LIHE ADHESIVE

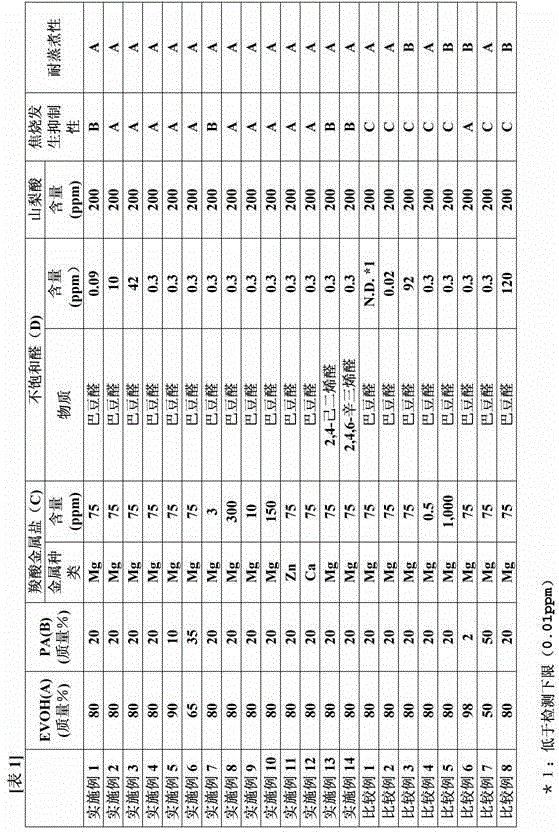

Ethylene-vinyl alcohol resin composition, multilayer structure, multilayer sheet, container, and packaging material

ActiveCN104350102AScorch suppressionSuppress uneven stretchingSynthetic resin layered productsFood preservationPolymer sciencePolyamide

The purpose of the present invention is to provide a resin composition exhibiting excellent retort resistance and property to inhibit burning in an operation lasting a long period of time. The present invention is a resin composition containing an ethylene-vinyl alcohol copolymer (A) having an ethylene content between 20 and 60 mol%, a polyamide resin (B), a carboxylic acid metal salt (C), and an unsaturated aldehyde (D), wherein the mass ratio of the ethylene-vinyl alcohol copolymer (A) relative to the polyamide resin (B) is between 60 / 40 and 95 / 5 when A / B, the content of the carboxylic acid metal salt (C) relative to the resin content is between 1 and 500 ppm in terms of metal element, and the content of the unsaturated aldehyde (D) relative to the resin content is between 0.05 and 50 ppm.

Owner:KURARAY CO LTD

Aluminium foil sealing film and preparation method thereof

ActiveCN102700819ADoes not affect ease of peelingImprove cooking temperatureSynthetic resin layered productsSealingPolymer sciencePolyethylene terephthalate glycol

The invention provides an aluminium foil sealing film and a preparation method thereof and belongs to the technical field of plastic packaging. The aluminium foil sealing film comprises a protective layer, a separation layer and a heat-seal layer, wherein the protective layer is a gloss oil layer or a PET (Polyethylene Terephthalate) film layer; the separation layer is an aluminium foil layer; and the heat-seal layer comprises the materials as follows: 15 to 25 wt% of polybutene, 25 to 35 wt% of ethylene-propylene copolymer and 40 to 60 wt% of HDPE (high-density polyethylene). As a sealing film for the bottle mouth of a polypropylene plastic bottle, the aluminium foil sealing film provided by the invention has the excellent properties of cooking resistance and easiness for uncovering, and when the cooking-resistant temperature is 121 DEG C, the sealing film is unchanged in color and is not stratified. The opening force is 5 to 25 N after the sealing film and the polypropylene bottle are heat-sealed at 200 DEG C, and the heat-seal strength of a heat-seal strip with the width of 15 mm is 5 to 25 N, which shows that the aluminium foil sealing film has the excellent properties of cooking resistance and easiness for uncovering at the same time.

Owner:ZHEJIANG GOLDSTONE PACKING

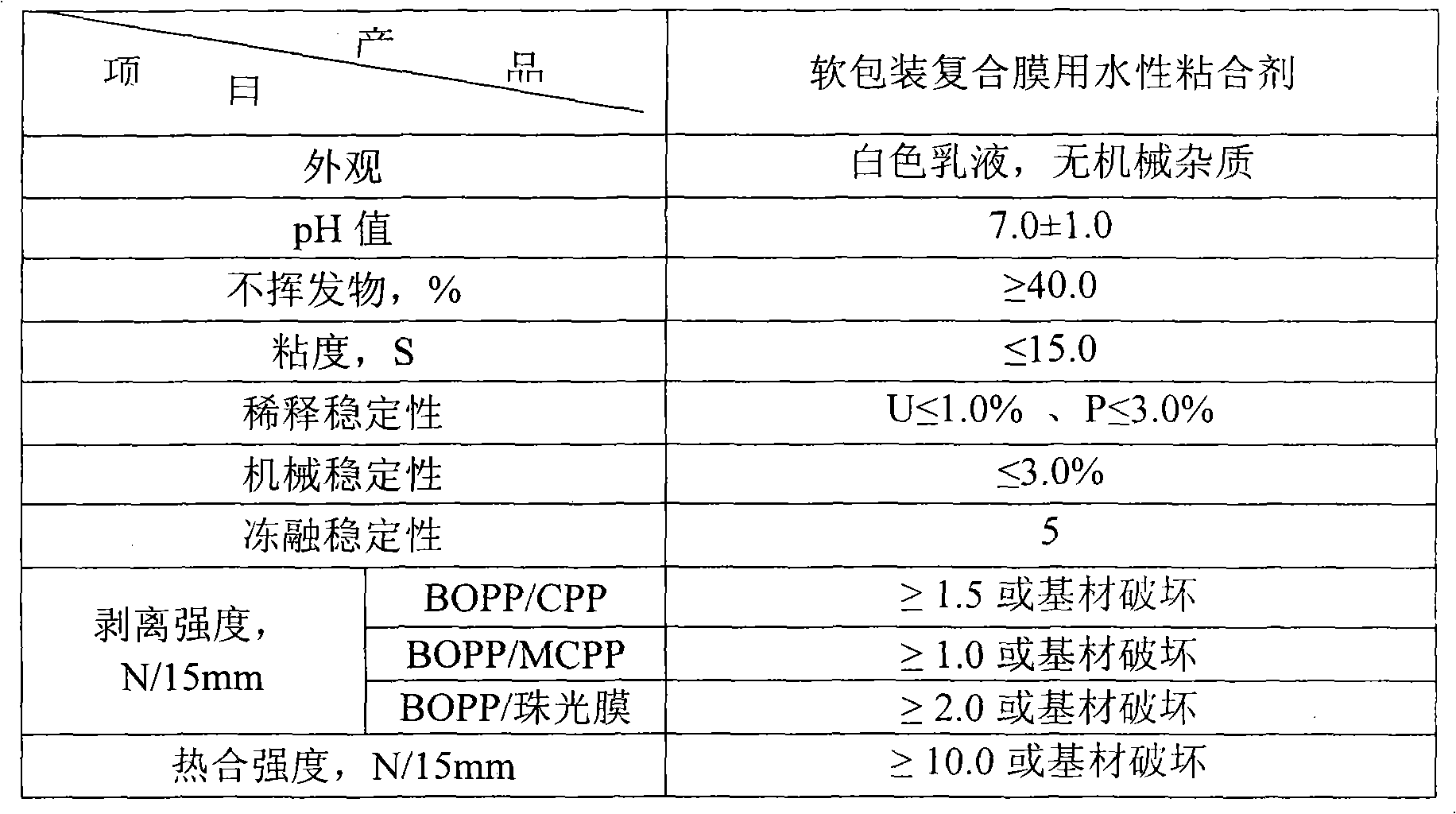

Preparation method of polyacrylate microgel emulsion and application thereof

InactiveCN101864025AReduce electrolyte levelsImprove performance such as water resistanceEster polymer adhesivesEmulsionAdhesive

The invention provides a method for synthetizing polyacrylate microgel emulsion in a soap-free emulsion polymerization mode, which comprises the following processes: (1) pre-emulsification: mixing a variety of monomers for emulsification to prepare pre-emulsified liquid; (2) seed polymerization: carrying out a polymerization reaction on a small amount of pre-emulsified liquid after the activation of an initiator to prepare seed solution; (3) polymerization: continuing to drip the pre-emulsified liquid in the seed solution to prepare microgel; and (4) ammonification: dripping hartshorn to regulate PH to prepare the polyacrylate microgel emulsion. The process is simple, the condition is easy to control, the emulsion is easy for scale production and can be used as the main constituent of aqueous adhesive used for flexible package plastic-plastic composition, and the prepared polyacrylate microgel aqueous adhesive has strong binding power on base materials, is waterproof, resists heat, is environmental-friendly, and has high drying speed.

Owner:HITEK POLYMER MATERIAL

Photosensitive composition, method for forming pattern, and permanent pattern

InactiveCN101116035AExcellent soldering heat resistanceImprove folding resistanceSemiconductor/solid-state device manufacturingPolyurea/polyurethane coatingsHeat resistanceDiol

The object of the present invention is to provide a photosensitive composition, a method for forming a pattern, and a permanent pattern. The flexibility is greatly improved, and it is suitable for the manufacture of flexible printed circuit boards. Therefore, the photosensitive composition contains at least (A) a polyurethane resin having a carboxyl group, (B) a polymerizable compound, (C) a photopolymerization initiator, and (D) a thermal crosslinking agent, and the (A) polyurethane resin having a carboxyl group The resin is preferably a form obtained by reacting a diisocyanate compound represented by the following structural formula (I) and a diol compound represented by either the following structural formula (II) or the following structural formula (III).

Owner:FUJIFILM CORP

Water-based high-barrier coating liquid and high-barrier film thereof

ActiveCN109266123AImprove stabilityGuaranteed normal applicationFilm/foil adhesivesCoatingsWater basedPolymer science

The invention discloses water-based high-barrier coating liquid and a high-barrier film thereof. The coating liquid is prepared from a water-soluble polymer, nanometer oxide, a coupling agent and a delaying cross-linking agent, and is specifically prepared from the following components in percentage by weight: 0.5-15% of water-soluble polymer, 0.1-15% of nanometer oxide, 0.01-5% of a coupling agent, 0.01-3% of a delaying cross-linking agent, 0.01-1.5% of an auxiliary agent and 60.5-99.37% of a solvent, wherein the water-soluble polymer is a water-soluble polymer with hydroxyl, the nanometer oxide is prepared by carrying out hydrolysis-condensation on metal alkoxide by adopting a sol-gel method under an acid catalysis condition, and the coupling agent is an organic siloxane coupling agent.The prepared high-barrier coating liquid is excellent in performance and can be used as a barrier layer independently or can be used in combination with an inorganic deposition layer, so that excellent barrier performance can be achieved, and the coating liquid can be used for food packaging, medicine packaging, electronic packaging and the like.

Owner:CHINA LUCKY FILM CORP +1

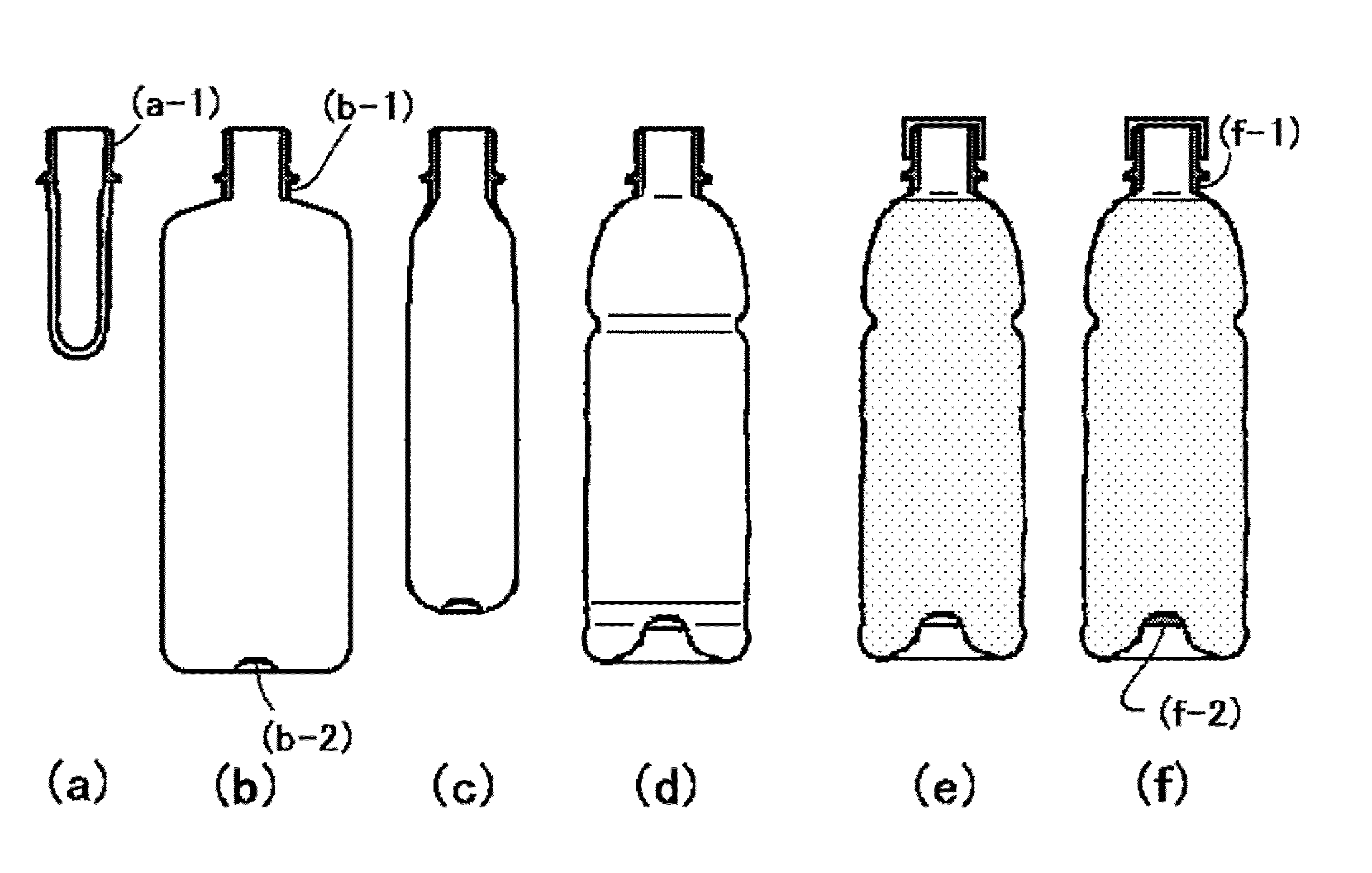

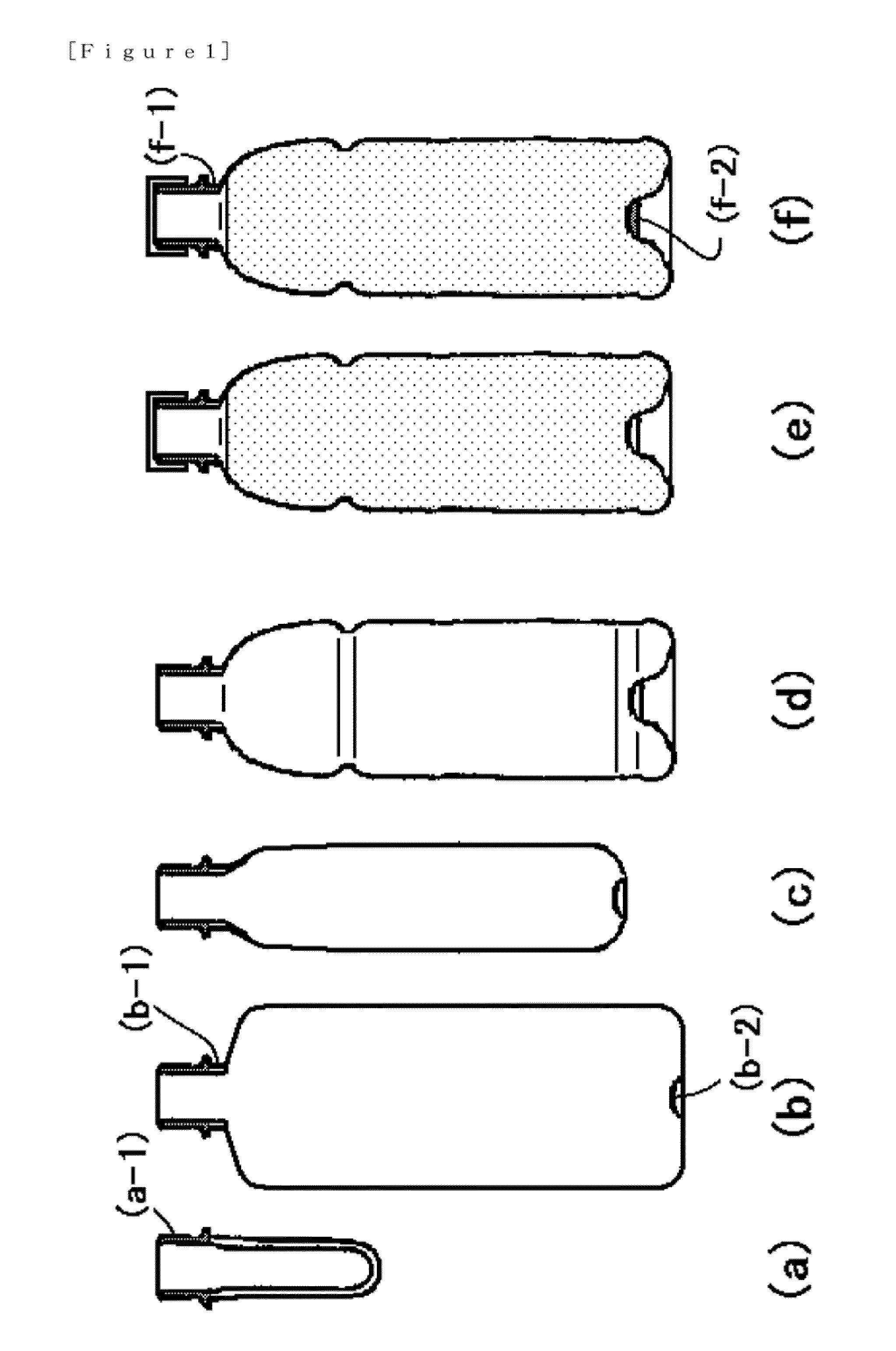

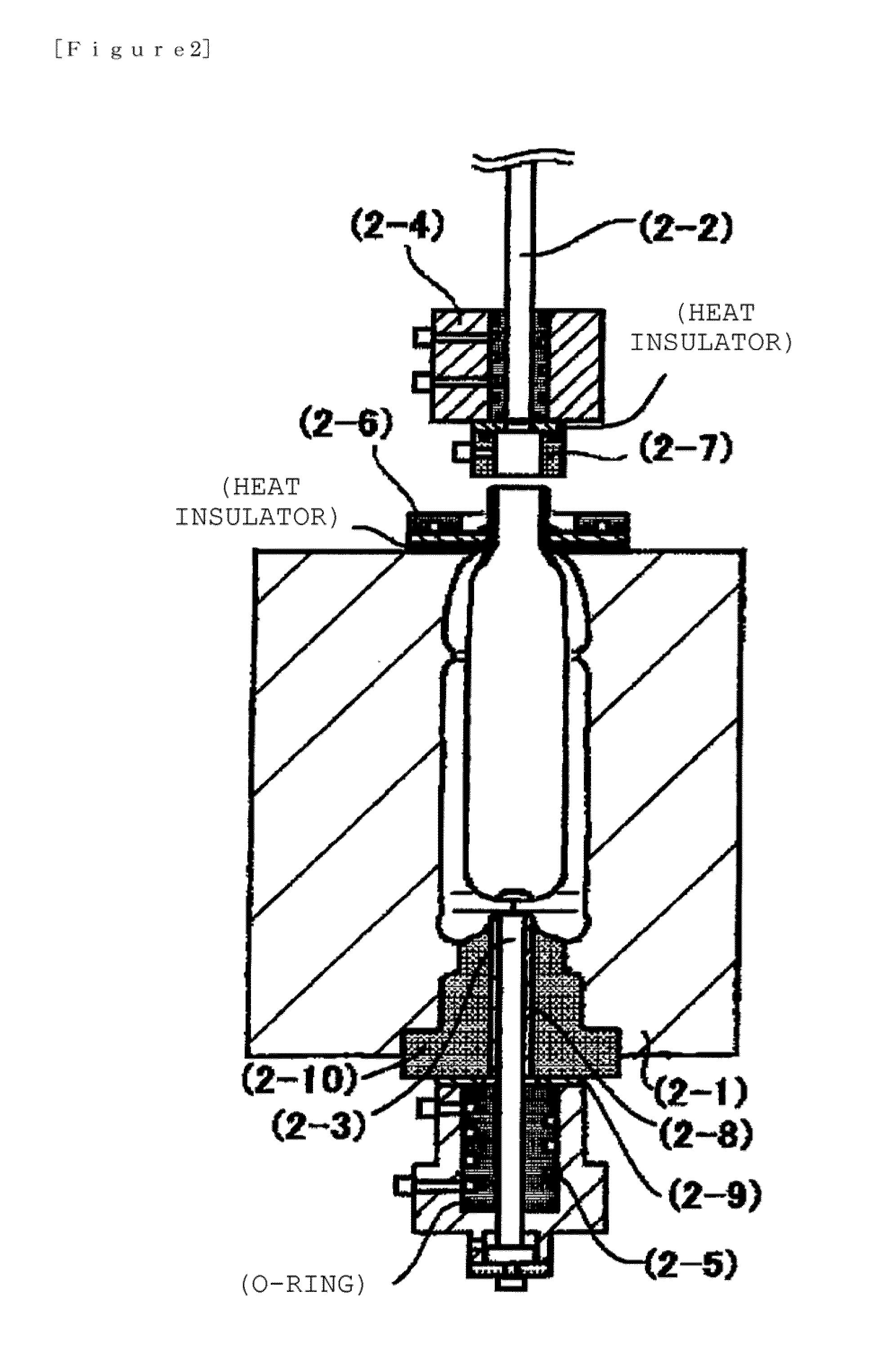

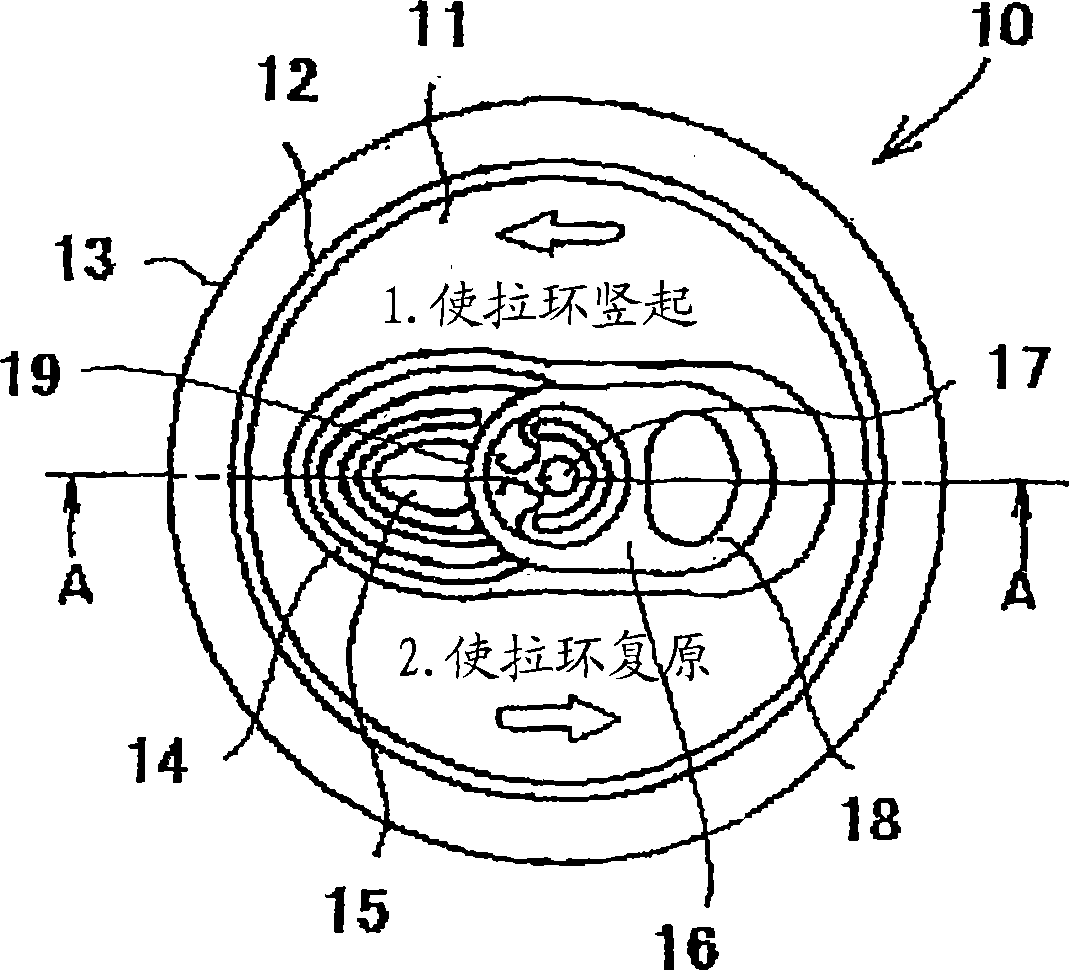

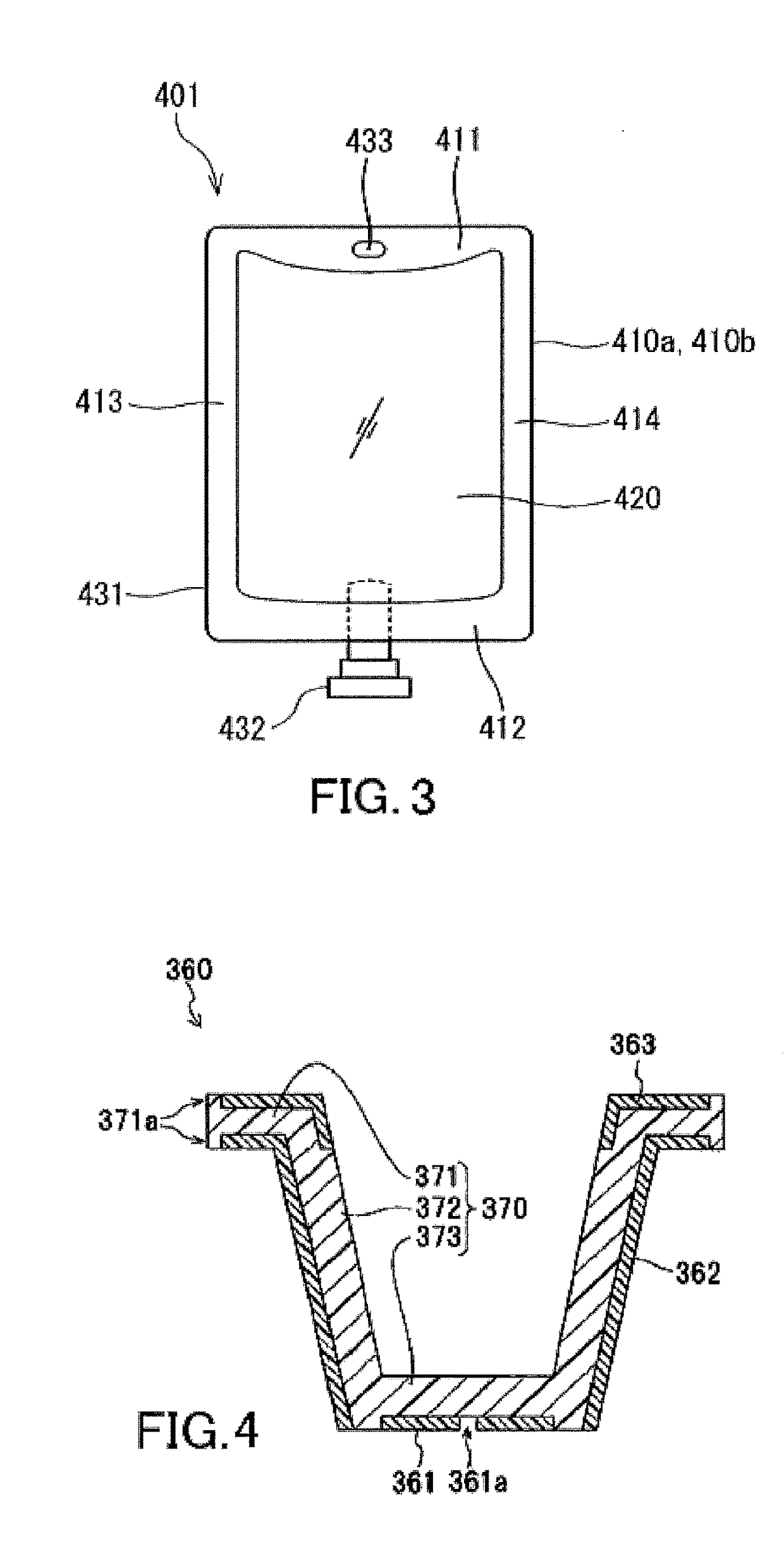

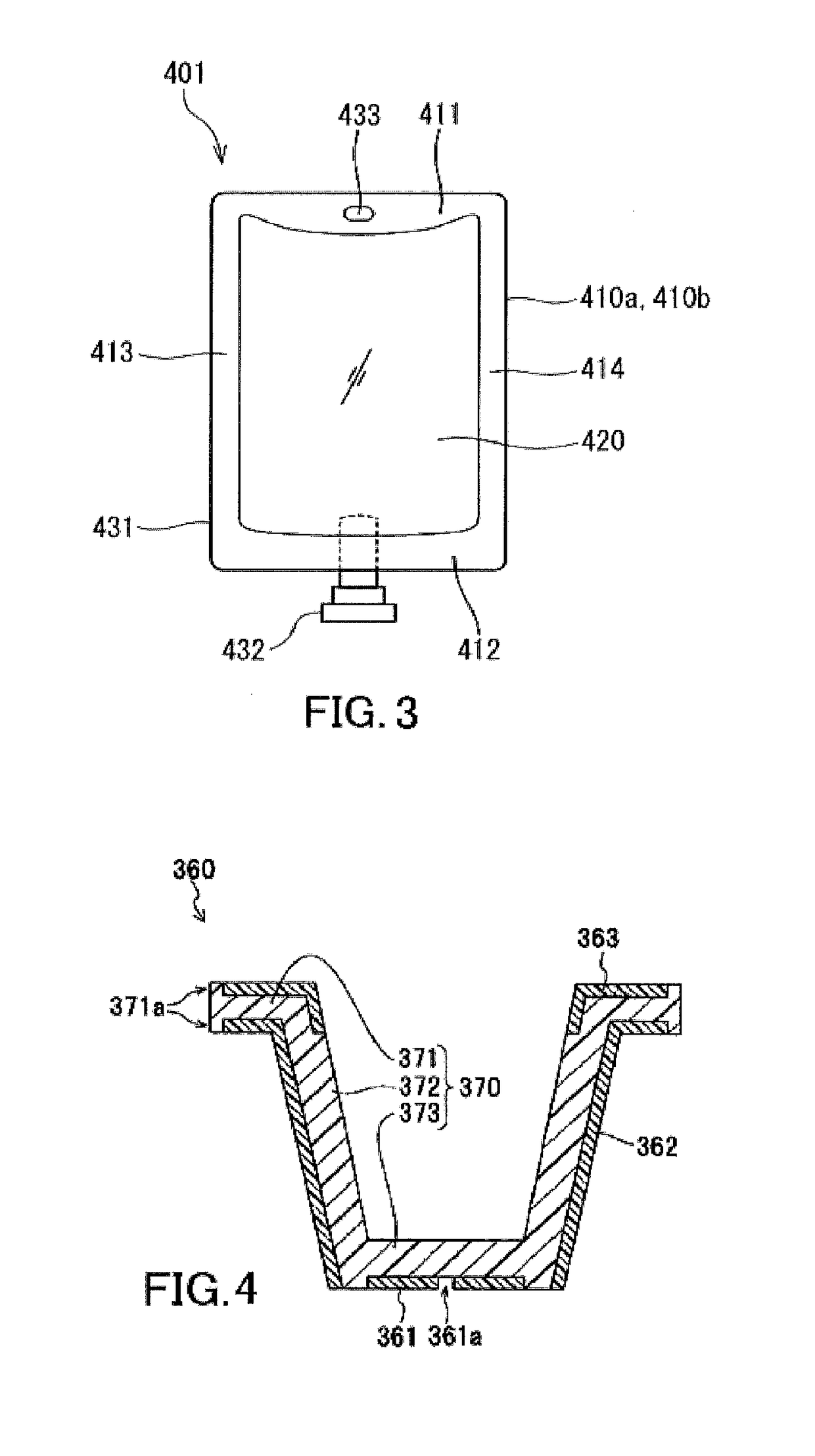

Thermoplastic resin container for which completion of retort processing can be confirmed and method for producing the same

ActiveUS20110076432A1Excellent retort resistanceReliable confirmationLayered productsBottlesBlow moldingEngineering

To provide a thermoplastic resin container that contains food or drink subjected to a retort processing for which completion of the retort processing can be confirmed and supervised with simple means without the need of an expensive member or facility, not only whether the temperature of the retort processing is reached but also whether the retort processing is performed as specified can be confirmed, and the consumer also can easily confirm completion of the retort processing of the product. The container is produced by two-stage stretch blow molding of a preform made of a thermoplastic resin in such a manner a part that is not stretched or is insufficiently stretched is formed at a part of the container, and the part that is not stretched or is insufficiently stretched is whitened to form a retort processing completion confirming part by heating in the retort processing after a content is packed and sealed in the container.

Owner:TOYO SEIKAN KAISHA LTD

General purpose plastic priming paint for automobile and preparation method thereof

The invention relates to a general plastic auto primer and the preparation method thereof, pertaining to the coating technical field. The invention solves the universality of plastic auto primer and is characterized in that the primer comprises the components with certain weight portions, modified thermoplastic acrylic resin of 55-65wt portions, paint of 20-25wt portion, dispersion agent of 0.3-1.0wt portions, flow agent of 0.1-0.3wt portions and solvent of 15-30wt portions. The components are mixed and grinded for preparing the primer. The product of the invention is mainly characterized in that the product is applicable for primer coating of various auto plastic components and for plastic components of different materials, thereby, the product can reduce waste and trouble which are caused by frequent exchange of paint and dramatically improve work efficiency. In addition, the product of the invention has excellent boiling resistance and hot-cold alternation resistance. The product is proved to have better index of pencil hardness, adhesive, impact strength and water resistance, etc. over than the prior product and is expected to replace the prior plastic auto primer product.

Owner:唐山威克涂料化工有限公司

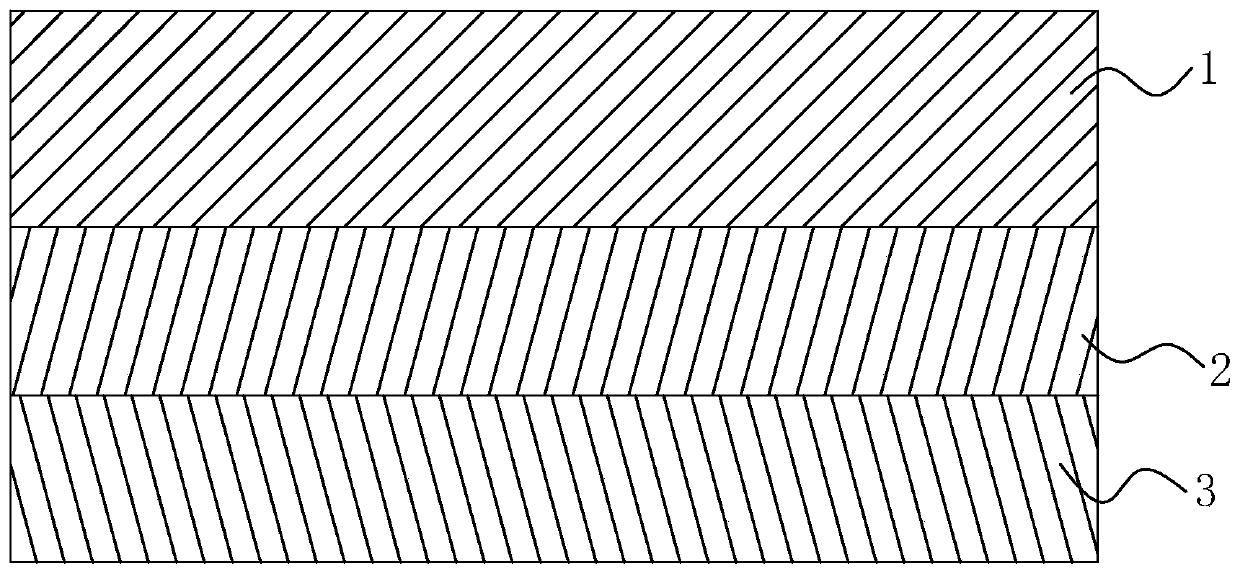

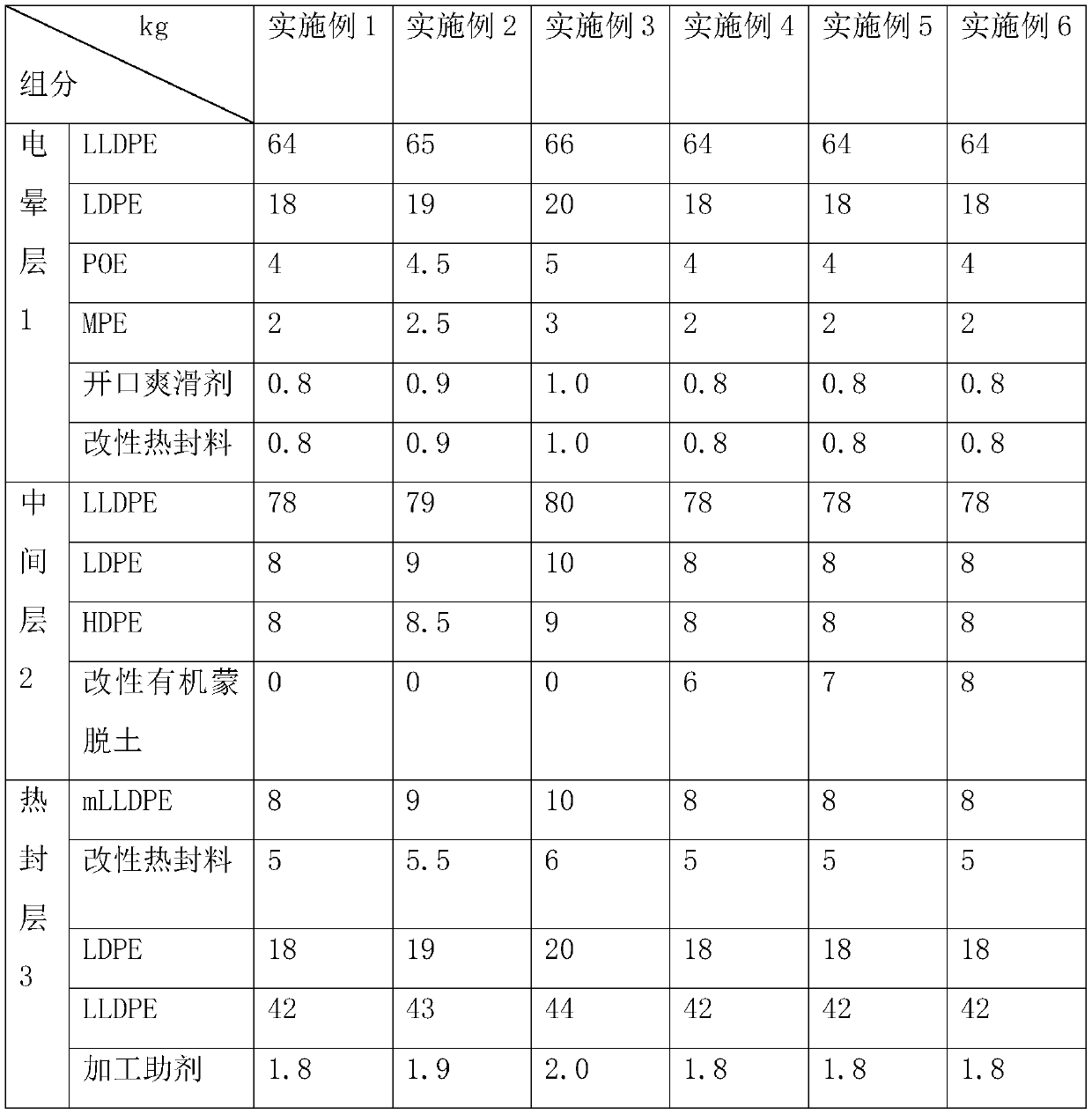

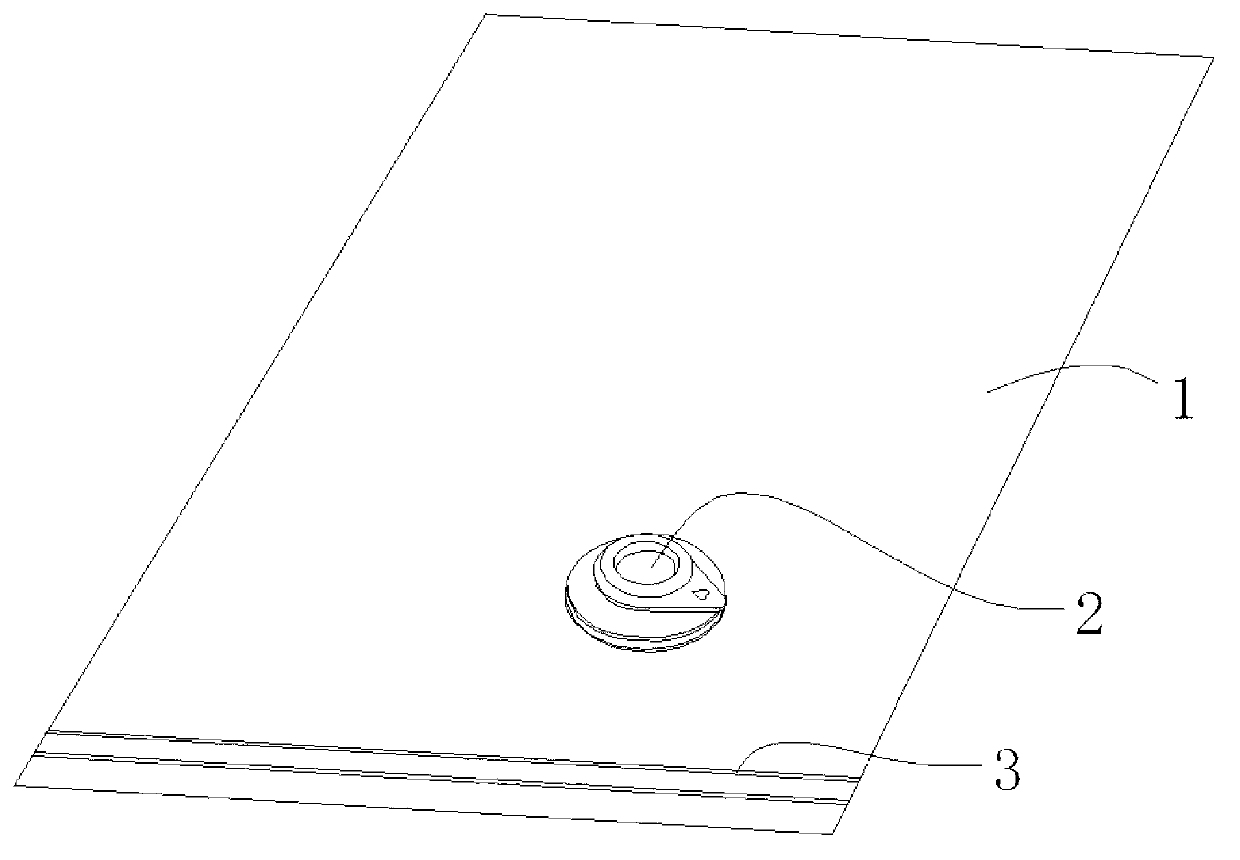

CPE heat-sealing composite film and preparation method thereof

ActiveCN110466225AHigh impact strengthHigh tensile strengthSynthetic resin layered productsComposite filmMaterials science

The invention discloses a CPE heat-sealing composite film and a preparation method thereof. The CPE heat-sealing composite film includes a corona layer, an intermediate layer and a heat-sealing layerconnected in sequence. The corona layer includes the following components by weight: 64-68 parts of LLDPE, 18-22 parts of LDPE, 4-6 parts of POE, 2-4 parts of MPE, 0.8-1.2 parts of an anti-block slipping agent and 0.8-1.2 parts of a modified heat-sealing material. The intermediate layer includes the following components by weight: 78-82 parts of LLDPE, 8-12 parts of LDPE and 8-10 parts of HDPE. The heat-sealing layer includes the following components by weight: 8-12 parts of mLLDPE, 5-7 parts of a modified heat-sealing material, 18-22 parts of LDPE, 42-46 parts of LLDPE and 1.8-2.2 parts of aprocessing aid. The CPE heat-sealing composite film of the invention has the advantages of good heat-sealing performance in overlapping sealing, good drop resistance, and low bag breaking rate.

Owner:福建立邦包装有限公司

Preparation method of polyurethane resin for single-component steaming and boiling resistant composite ink

InactiveCN102796242AExcellent retort resistanceGood adhesionInksPolyesterPolyethylene terephthalate glycol

The invention discloses a preparation method of a polyurethane resin for a single-component steaming and boiling resistant composite ink. The method comprises the following steps of: first, reacting a mixed acid of dimer acid and aliphatic dibasic acid with aliphatic dibasic alcohol with a branched chain, so as to synthesize polyester diol; and then adding a trimer mixture of aliphatic or alicyclic diisocyanate and isocyanate, a diamine chain extender and a molecular weight regulator to the polyester diol to react with the polyester diol, so as to prepare the polyurethane resin for the single-component steaming and boiling resistant composite ink. According to the invention, the prepared polyurethane resin obtains better steaming and boiling resistance; and the single-component ink prepared by the polyurethane resin can resist steaming and boiling at 100-125 DEG C, obtains good adhesion to various plastic base materials with different polarities, such as PET (Polyethylene Terephthalate), NYLON, BOPP (Biaxially-oriented Polypropylene) and the like, and obtains perfect pigment wetting and dispersing property. According to the invention, the prepared polyurethane resin has the advantage of no aromatic isocyanate curing agent damage; and as ethanol and ethyl acetate are used as a solvent, no benzene and no ketone of the polyurethane resin for the ink are achieved, and environment friendliness and safety are also achieved.

Owner:山西省应用化学研究所

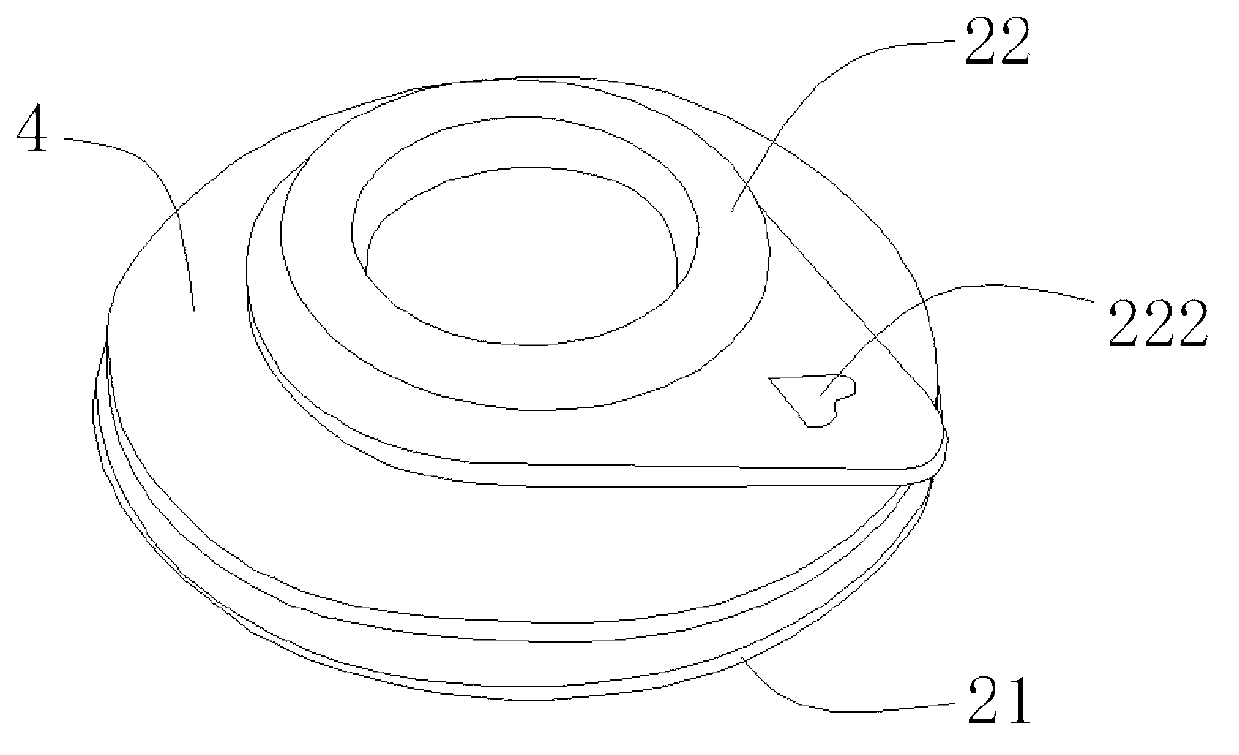

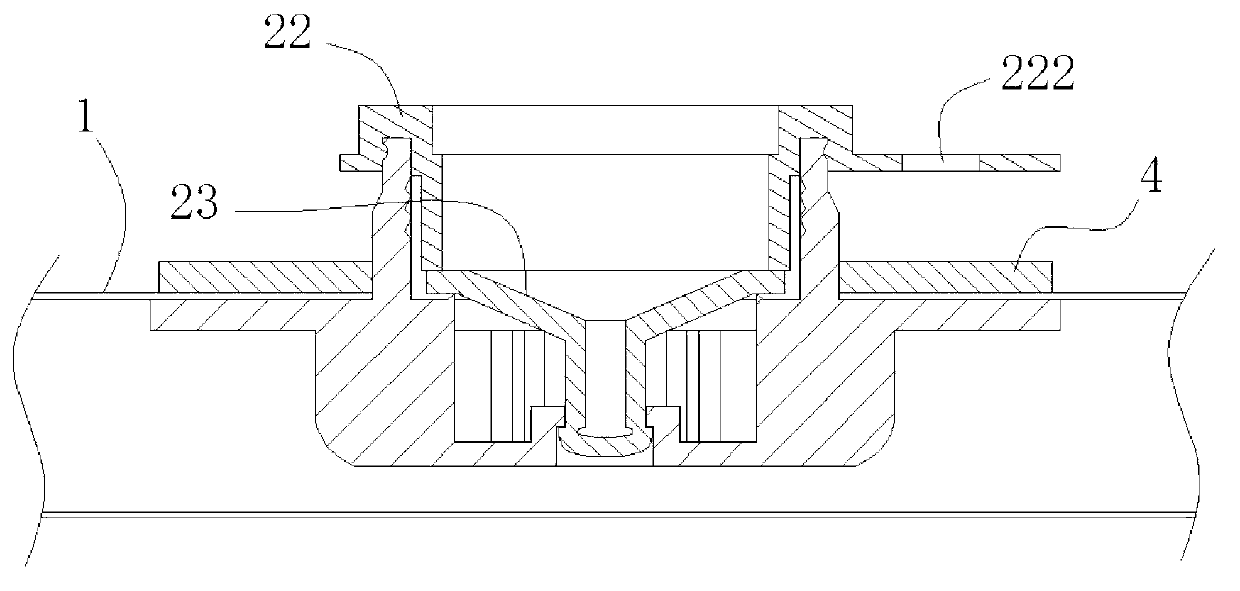

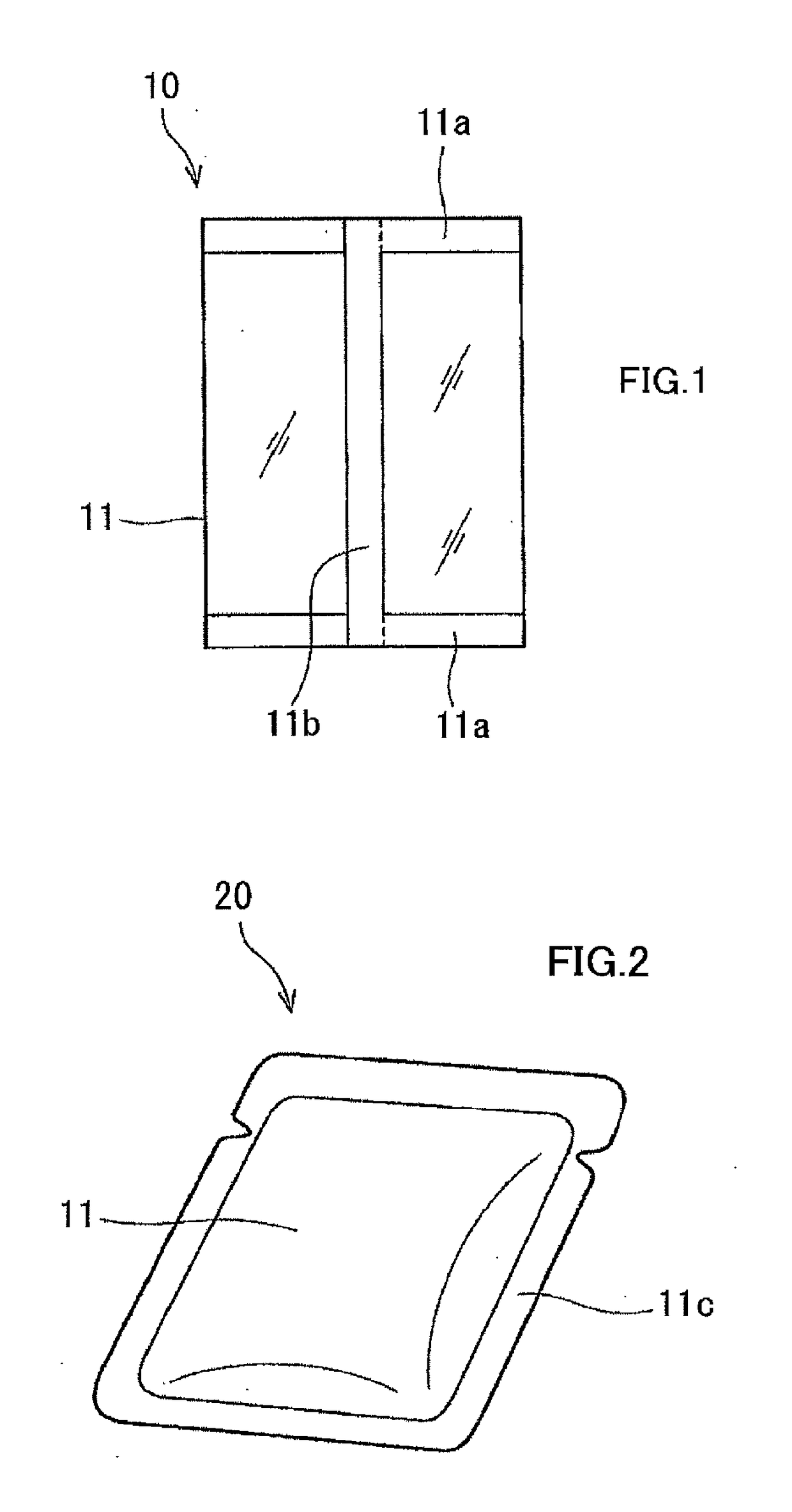

Vacuum bag manufacturing method and product of the same

The invention discloses a vacuum bag manufacturing method, and further discloses a product obtained by adopting the method. The vacuum bag manufacturing method and the product of the vacuum bag comprise a bag body and a vent valve. The vent valve comprises a valve seat, a valve cover and a cone-shaped soft plug. The method is easy in manufacturing procedure, easy to realize, and capable of being used for quickly manufacturing the vacuum bag product which is good in sealing effect and convenient to use. The vacuum bag product is ingenious and reasonable in structural design. The cone-shaped soft plug and an opening of an accommodating cavity are matched for sealing air, an operator just needs to cover the valve cover to ensure that the cone-shaped soft plug is tightly attached on the opening, and accordingly sealing effects are achieved. The valve cover is plugged out to ensure that air freely enters and leaves the bag body to bring convenience to air pumping and use. Furthermore, a flange is arranged on the opening to further strengthen sealing effects, and articles can be beneficially stored for a long period. A bag opening can be quickly opened or sealed through concave-convex seals. The vacuum bag manufacturing method and the product of the vacuum bag are convenient to use and simple and easy to operate, bring great convenience to the steps of taking and putting the articles and life of people, and facilitate wide promotion and applications.

Owner:广东树业环保包装有限公司

Easy-to-open lid with excellent suitability for high-temperature opening

InactiveCN101394999AGood mouthEasy open operationSynthetic resin layered productsThin material handlingEpoxyPolyester resin

An easy-to-open lid which comprises a resin-coated metallic sheet obtained by coating a metallic base with a polyester film through a primer, wherein the primer comprises an epoxy resin or polyester resin and a resol resin, the resol resin having 0.2-2.0 methylol groups per benzene ring. When an end of the opening tab is plunged to break the score for opening, no opening failure occurs and the opening operation can be conducted lightly. In particular, even when the lid is in the state of being heated at a high temperature, it has excellent suitability for high-temperature opening and does not pose that problem. It is excellent also in corrosion resistance, resistance to the contents, and retortion resistance.

Owner:TOYO SEIKAN KAISHA LTD

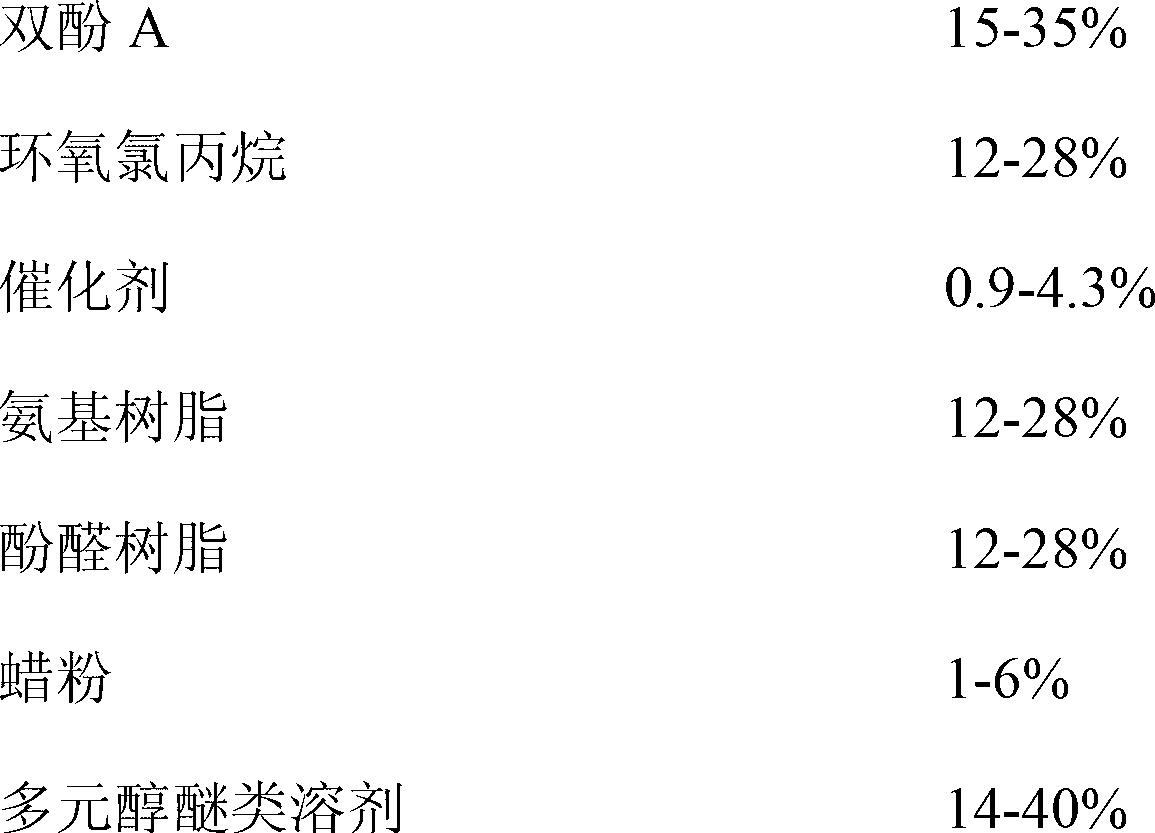

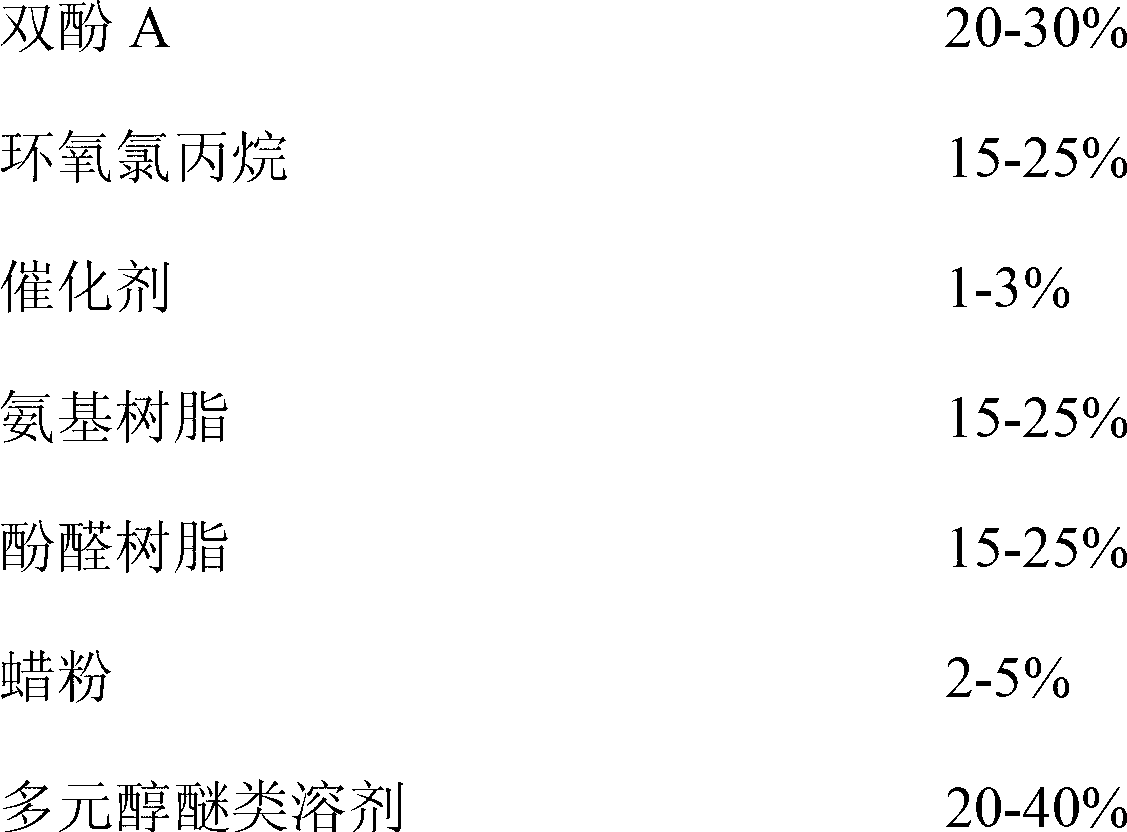

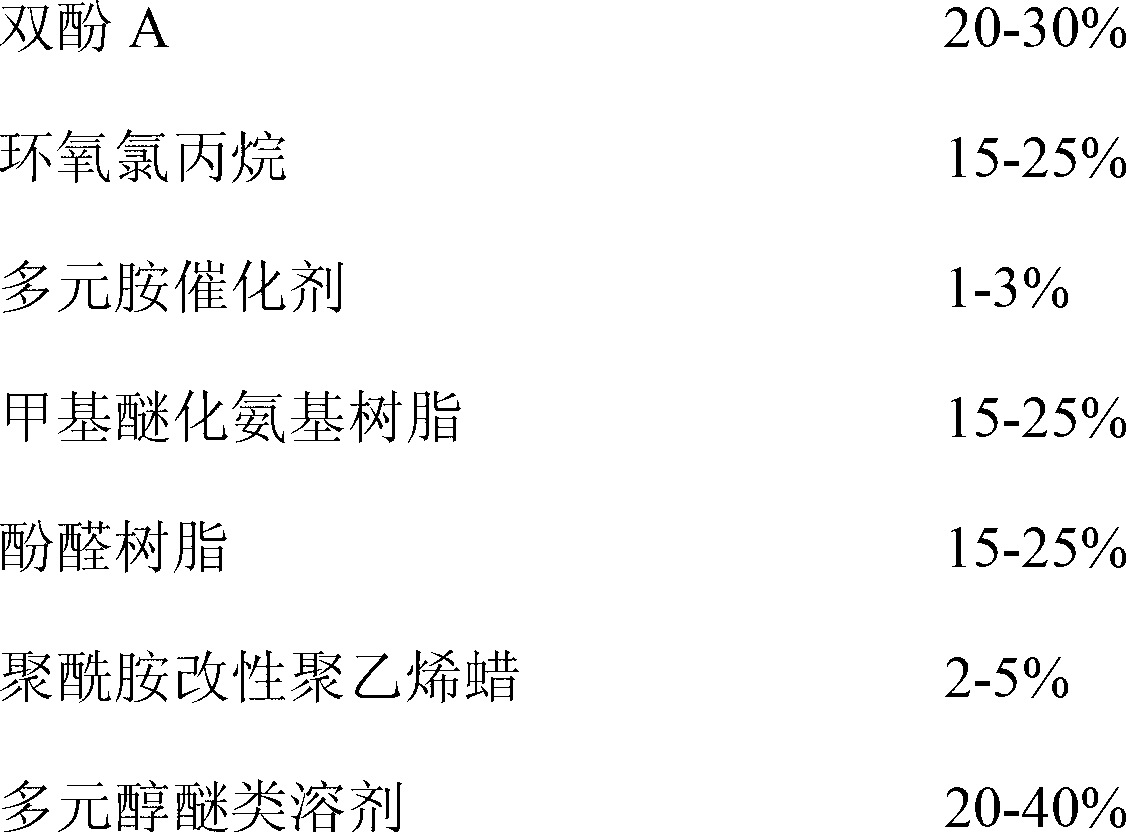

Inner iron printing paint for food packaging

ActiveCN103122201ARealize continuous printing and coatingShort curing timePretreated surfacesInksWaxSolvent

The invention relates to inner iron printing paint for food packaging, which comprises (a) bisphenol A, epoxy chloropropane and a catalyst; (b) an amino resin crosslinking agent; (c) phenolic resin; (d) solvent; and (e) wax powder, wherein the catalyst is a bisphenol A epoxy resin catalyst which is prepared from bisphenol A and epoxy chloropropane, the mass ratio of the bisphenol A to the epoxy chloropropane is (0.8-2):1, and the catalyst accounts for 0.9-4.3w%. According to the inner iron printing paint provided by the invention, the curing time is only 25-120 seconds, and continuous printing and coating can be performed; and meanwhile, the inner iron printing paint has favorable corrosion resistance, boiling resistance and flexibility.

Owner:无锡品源科技咨询有限公司

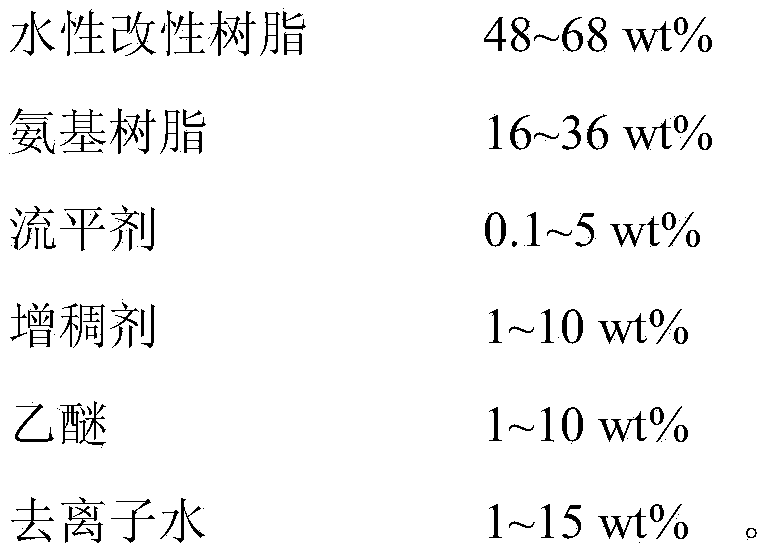

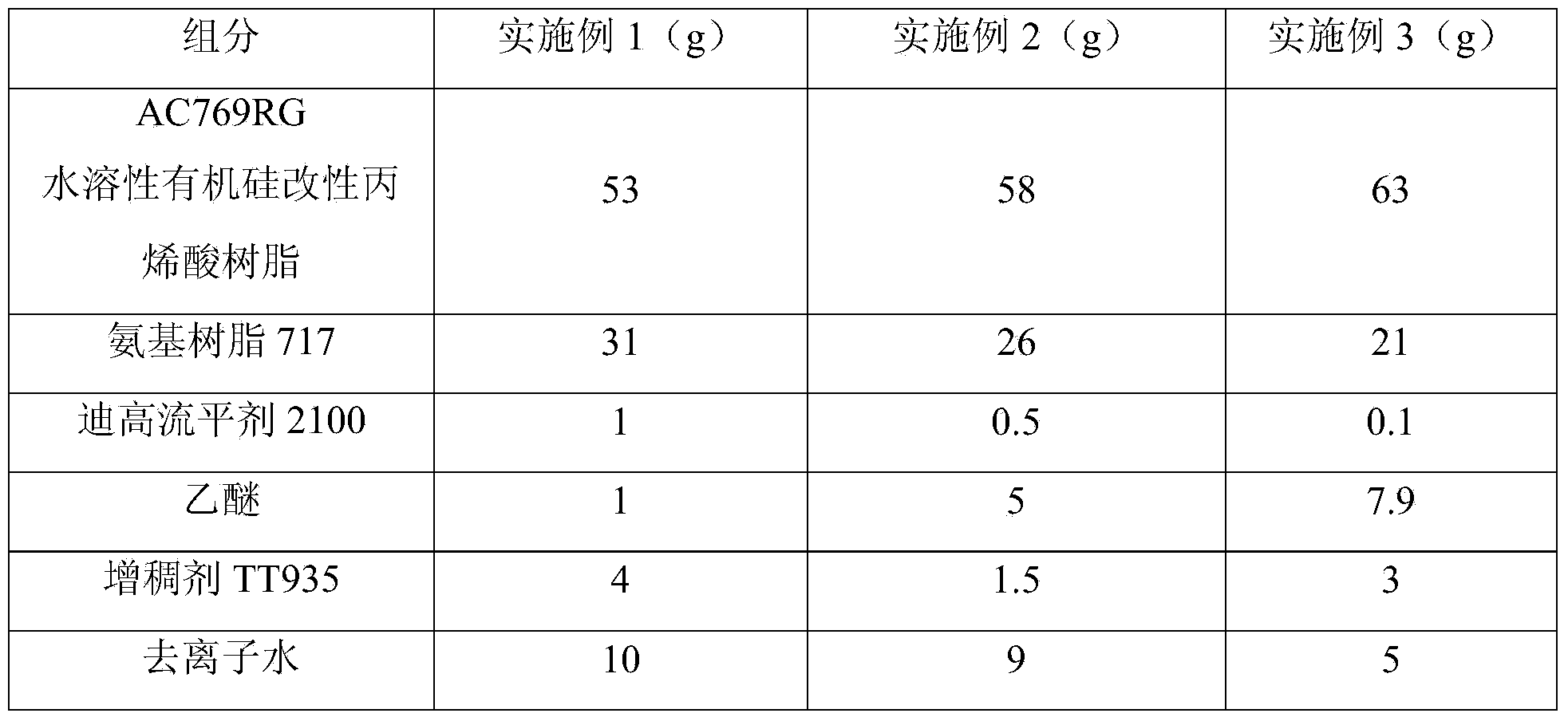

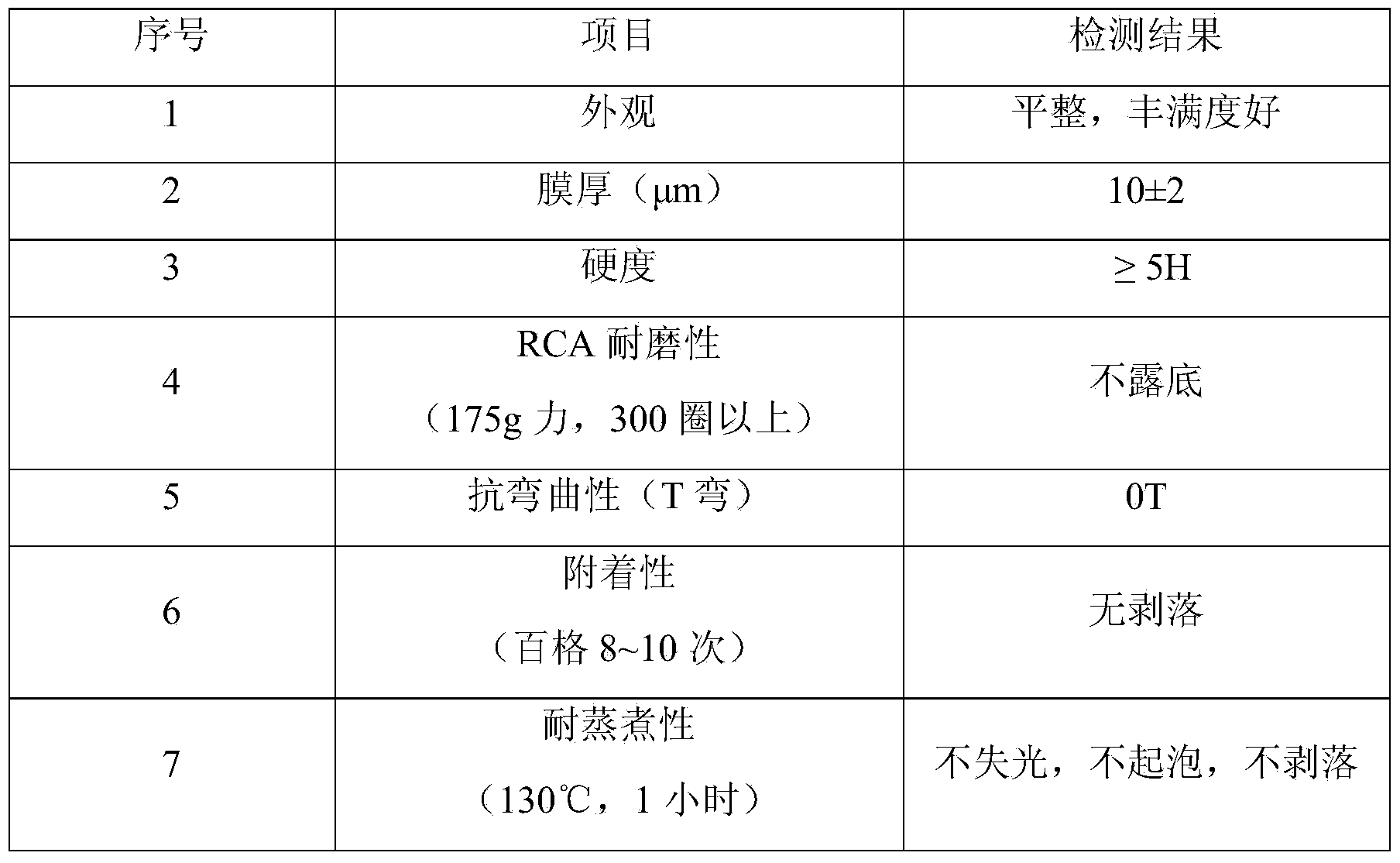

Water-based paint for surface of pop-top can and preparation method of water-based paint

The invention discloses water-based paint for the surface of a pop-top can and a preparation method thereof, which belongs to the technical field of paint. The paint is prepared by uniformly mixing water-base modified resin, ammonia-base resin, a leveling agent, a thickening agent, ether and deionized water. The prepared water-based paint which is attached on the surface of the pop-top can is good in RCA abrasion resistance (the substrate is no exposed for more than 300 circles at the force of 175g) and high in hardness (more than or equal to 5H); in addition, the pop-top can is also excellent in boiling durability, the paint on the surface of the pop-top can which is boiled for 1h under the condition of 130 DEG C is free from losing brightness, bubbling and stripping.

Owner:江苏巨珩新材料科技有限公司

Boiling-resistant aqueous composite ink and preparation method thereof

InactiveCN102532997AGood resolubilityExcellent retort resistanceInksPolymer sciencePigment dispersion

The invention discloses boiling-resistant aqueous composite ink and a preparation method thereof. The boiling-resistant aqueous composite ink mainly comprises raw materials including aqueous polyurethane resin, a pigment and water, and a surface wetting agent, a wetting dispersing agent and a defoaming agent are additionally added. The preparation method of the boiling-resistant aqueous composite ink comprises the following steps of: firstly, adding partial aqueous polyurethane resin into a stirring reaction kettle; secondly, slowly adding the surface wetting agent, the wetting dispersing agent and partial defoaming agent, and adding the pigment after stirring and dispersing; thirdly, stirring and dispersing at high speed, and grinding after dispersing; fourthly, adding the residual aqueous polyurethane resin and defoaming agent and stirring and dispersing, and adding the water until the required viscosity is obtained through regulation; and at last, stirring, dispersing, filtering and packaging. The boiling-resistant aqueous composite ink, provided by the invention, is prepared by taking the high-performance aqueous polyurethane resin as a connecting material, and has the advantages of good pigment dispersibility, wide use range, lower film forming temperature, better mechanical property of formed film, more uniform particle size distribution and the like, and can be used for soft retort packages.

Owner:ZHENGZHOU LETONG NEW MATERIAL TECH

Preparation process of composite packing film with very high oxygen inhibition and boiling resistance performance

InactiveCN100503237CImprove oxygen barrier performanceImprove moisture resistanceFlexible coversWrappersPolyesterComposite film

Owner:ZHEJIANG UNIV

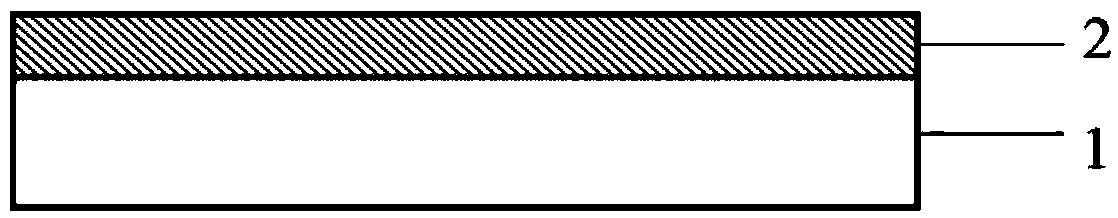

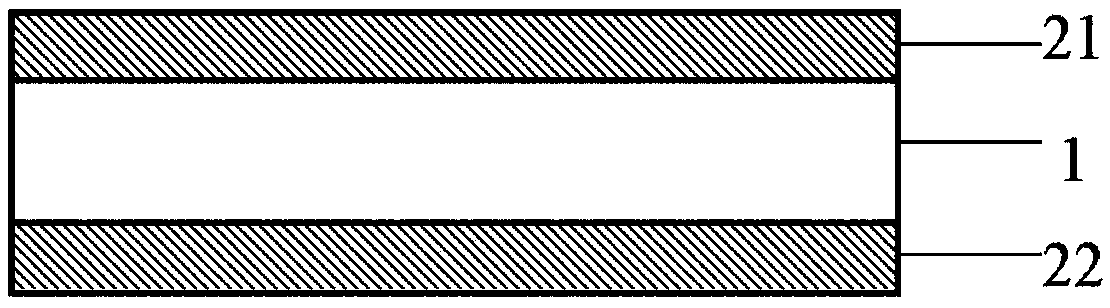

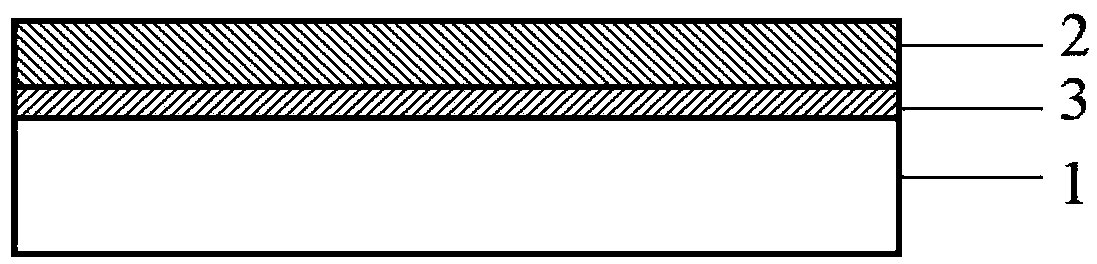

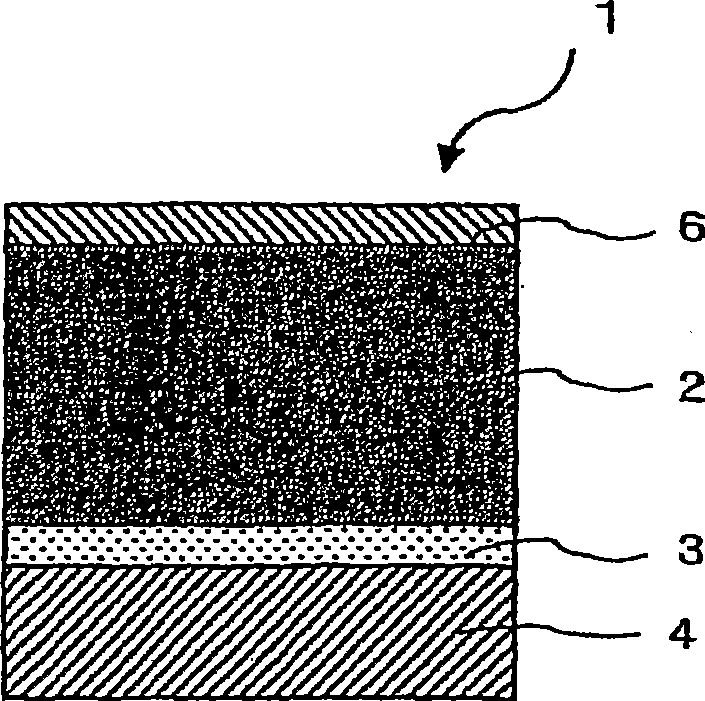

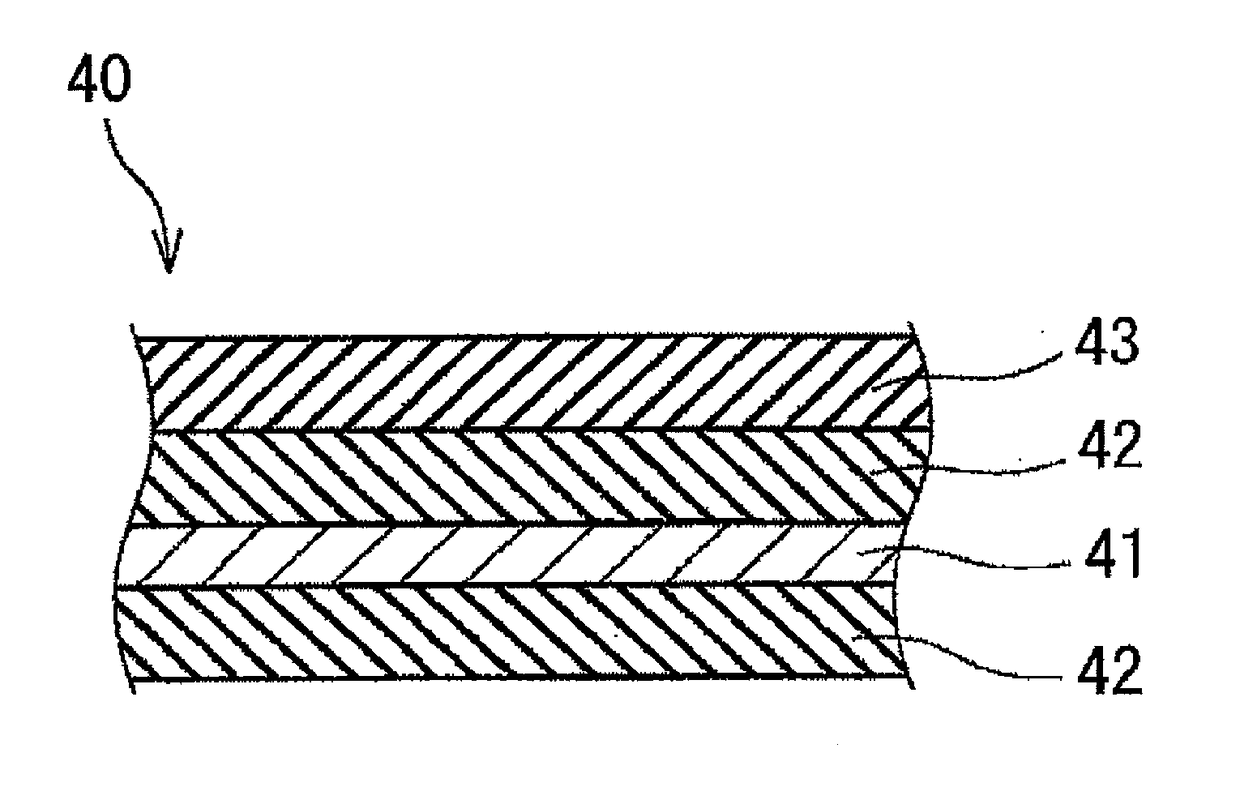

Multilayer structure, method for producing same, packaging material and product including same, and protective sheet for electronic device

ActiveUS20180015713A1Excellent retort resistanceImprove water vapor barrier performanceWrappersSolid-state devicesPhosphorusReaction product

The present invention relates to a multilayer structure including a base (X) and a layer (Y) stacked on the base (X). The layer (Y) contains a reaction product (D) of an aluminum-containing compound (A) and a phosphorus compound (B), and the reaction product (D) has an average particle diameter of 5 to 70 nm.

Owner:KURARAY CO LTD

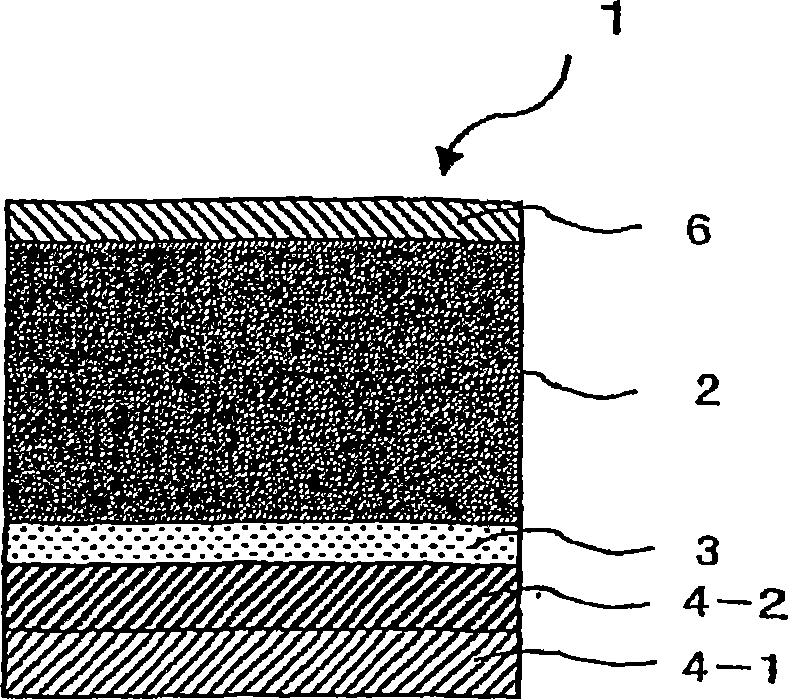

Multilayer structure, packaging material and product including same, and protective sheet for electronic device

ActiveUS20180022073A1Maintain good propertiesImprove interlayer adhesionFlexible coversWrappersEtherOrganic phosphorus

The present invention relates to a multilayer structure including a base (X) and a layer (Y) stacked on the base (X). The layer (Y) contains an aluminum-containing compound (A), an organic phosphorus compound (BO), and a polymer (F) having an ether bond and having no glycosidic bond.

Owner:KURARAY CO LTD

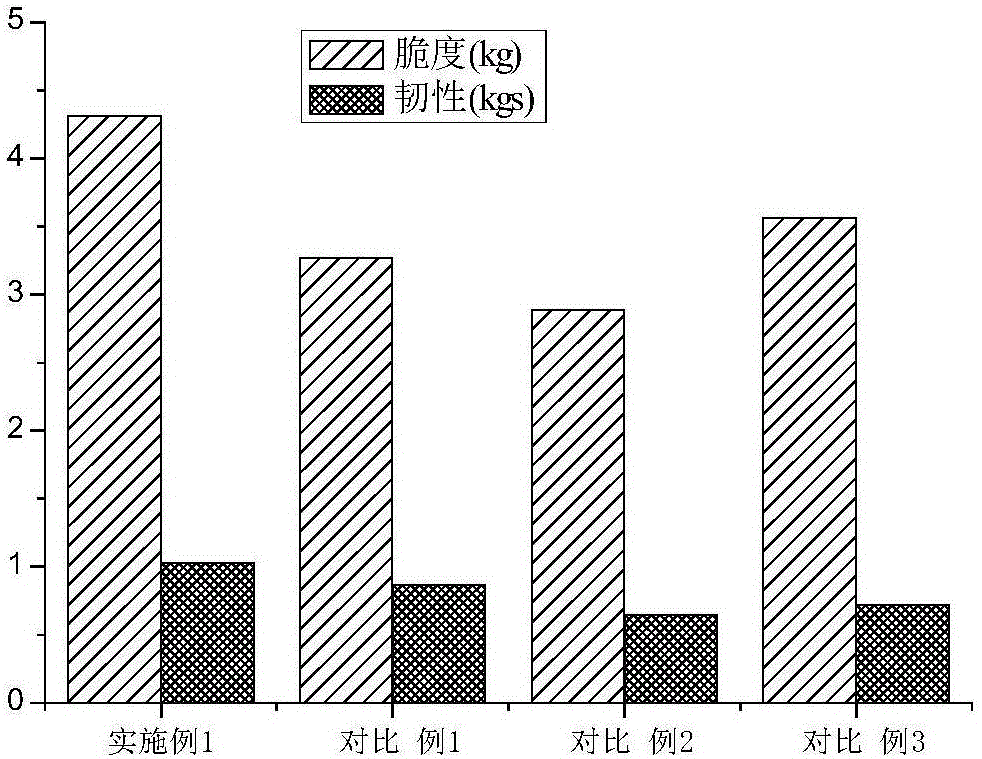

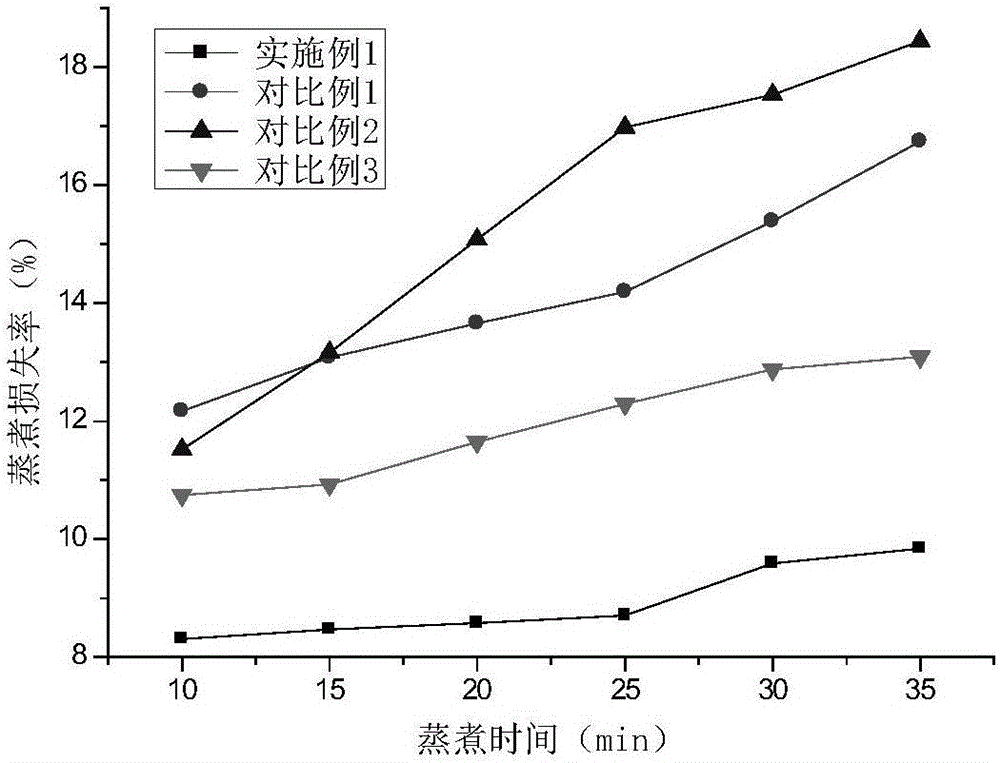

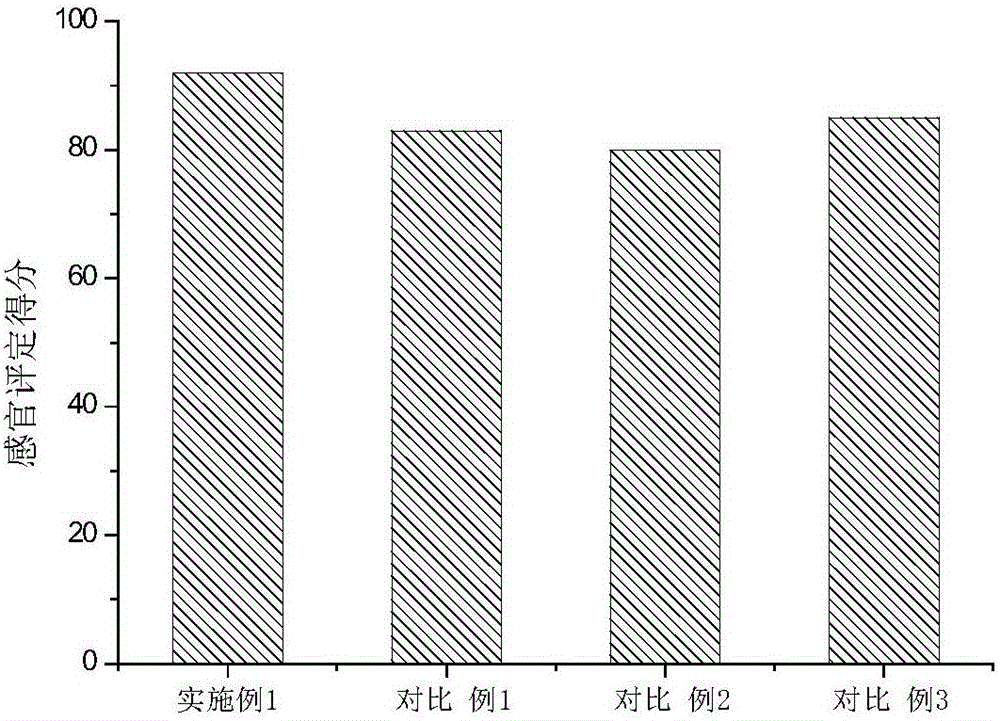

High-tenacity pork wonton wrapper and preparation method thereof

ActiveCN106722381AImprove gel qualityImprove crispnessFood freezingFood ingredient as mouthfeel improving agentIce waterPhosphate

The invention discloses a high-tenacity pork wonton wrapper. According to the high-tenacity pork wonton wrapper, minced fillet is used as a main raw material, and the pork wonton wrapper comprises the following raw materials in parts by weight: 60-80 parts of frozen minced fillet, 10-20 parts of potato modified starch, 50-70 parts of ice water, 5-10 parts of mixed colloid mortar, 0.3-0.6 part of TG enzymes, 0.5-1.5 parts of edible salt, 0.5-2.5 parts of white granulated sugar, 0.03-0.06 part of composite phosphate, and 0.03-0.1 part of sorbitol. The pork wonton wrapper is rich in nutrition, and fresh and crisp in mouth feel, and has high tenacity and high elasticity. The invention further discloses a preparation method of the high-tenacity pork wonton wrapper. The method is simple and convenient in technology, and feasible to operate, the gel coagulation intensity of the fish meat pork wonton wrapper is improved, the product quality of the fish meat pork wonton wrapper is improved, and the cooking resistance of the pork wonton wrapper is improved.

Owner:福州百洋海味食品有限公司

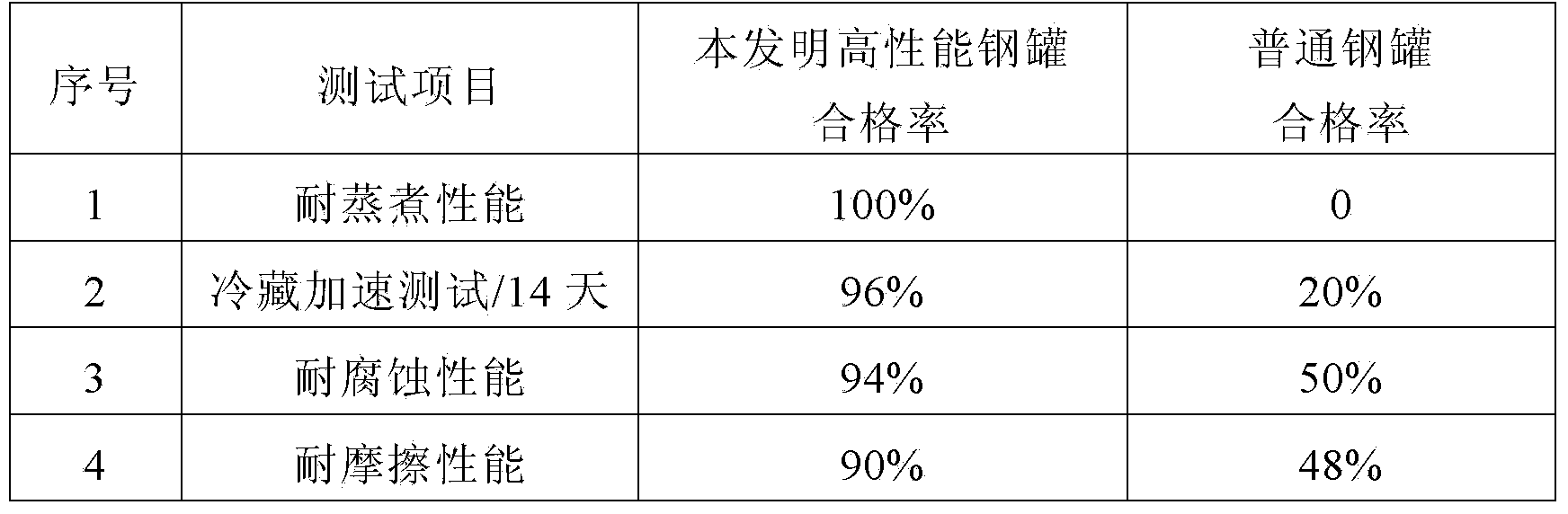

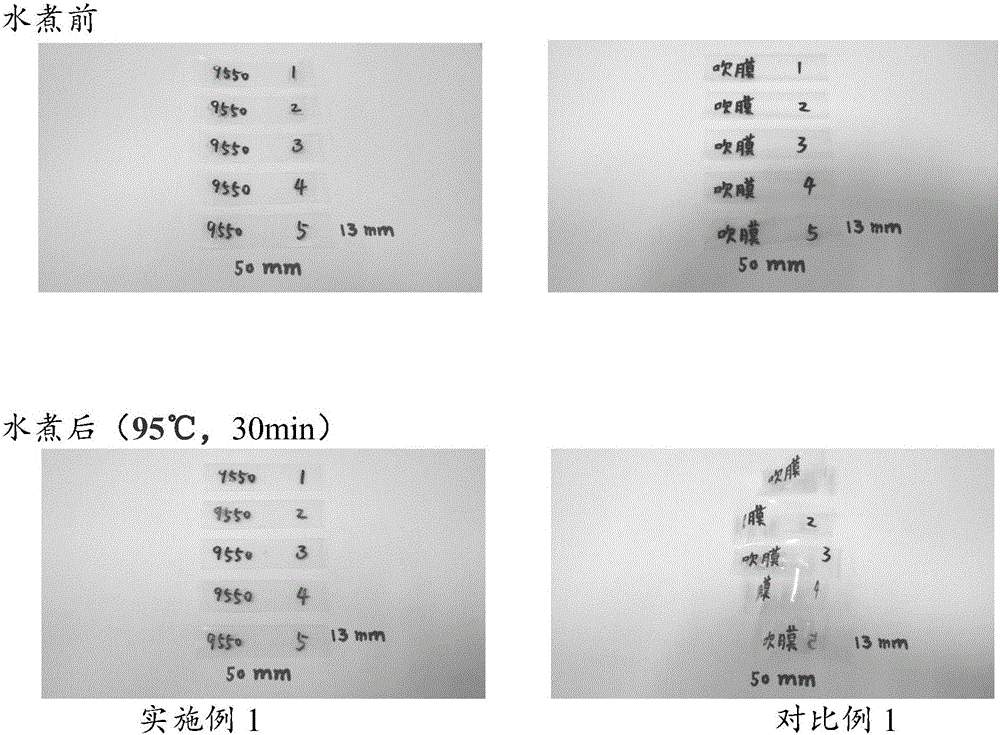

Manufacturing technology of two-piece-type steel high-performance zip-top cans

ActiveCN103920628AExcellent retort resistanceImprove environmental adaptabilityPretreated surfacesCoatingsManufacturing technologyColor printing

A manufacturing technology of two-piece-type steel high-performance zip-top cans includes forming, cleaning, bottom printing, first-time bottom edge coating, color printing, second-time bottom edge coating, first-time internal spraying, neck-shrinking edge turning, bottom coating, second-time internal spraying, light inspection and finished product packaging, wherein the bottom coating technology includes the steps that first, a can body is fixed; second, coating is performed; after coating is fed to a checkered steel roller, the coating is conveyed to a soft coating roller through a scraper, and steel can feet are evenly coated with the coating; third, surface dry curing is performed, the steel cans are conveyed through a magnetic or vacuum conveying belt to be irradiated through an UV lamp, and the surface dry curing of the coating is achieved; fourth, cooling is performed, blowing cooling is adopted, and the temperature of coated areas of the steel can feet is lowered to be lower than 80 DEG C of softening temperature of the UV coating; fifth, conveying is performed, the steel cans are conveyed to a next-procedure inlet through a common conveying belt; sixth, complete curing is performed, the steel cans enter a drying furnace after second-time internal spraying and dried for three minutes to four minutes at the temperature of 190 DEG C to 220 DEG C, the coating on the can feet can be completely cured, the bottom coating technology is ended, and subsequent procedures are started.

Owner:SHANGHAI BAOYIN METAL DECORATION

White coating for ultraviolet light polymerization tinplate and preparation method of white coating

ActiveCN103805040AImprove adhesionImprove physical performancePolyester coatingsPolyesterPolymer science

The invention discloses a white coating for an ultraviolet light polymerization tinplate and a preparation method of the white coating. The white coating comprises the following raw materials in parts by weight: 25-30 parts of polyester acrylic resin, 35-40 parts of titanium dioxide, 25-30 parts of activated monomer, 4-8 parts of photosensitizer, 0.5-1 part of adhesion promoter, 0.5-1 part of base material wetting agent, 0.3-0.5 part of flatting agent and 0.2-0.5 part of antifoaming agent. The preparation method comprises the steps: after fully dispersing the polyester acrylic resin and the titanium dioxide by a dispersing machine, grinding, then respectively adding the activated monomer and the photosensitizer, and finally adding the adhesion promoter, the base material wetting agent, the flatting agent and the antifoaming agent; and fully stirring and mixing the obtained mixture under the dispersing machine to obtain the white coating. The obtained white coating is high in adhesion for the tinplate, strong in etching resistance, good in steaming and boiling resistance capacity, and high in curing rate, and is energy-saving and environment-friendly, so as to be more efficient and convenient in use.

Owner:JIANGSU HIMONIA TECH

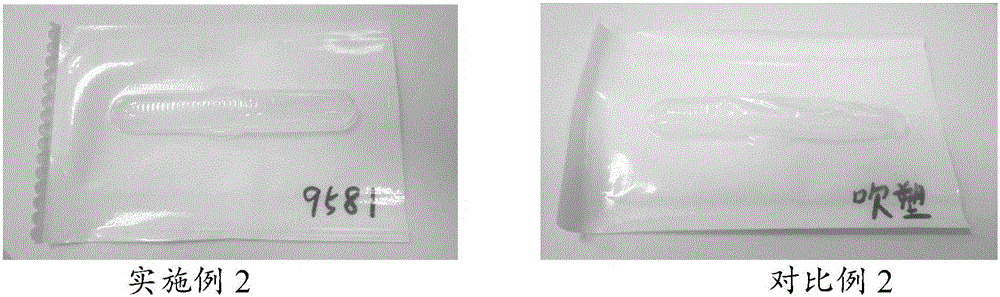

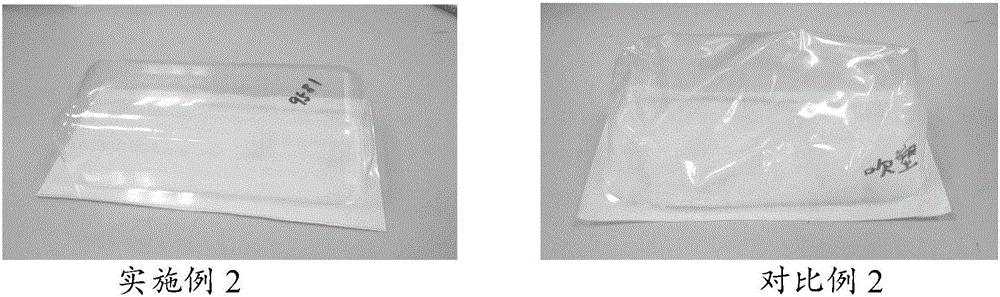

Composite film

ActiveCN106393834AHigh transparencyExcellent retort resistanceFlexible coversWrappersBlow moldingComposite film

The invention relates to a composite film. The composite film is characterized by comprising at least one layer of casting film, at least one layer of blow-molding film and an adhesive layer located between the casting film and the blow-molding film. The invention also relates to a preparation method and application of the composite film.

Owner:东莞奇妙包装有限公司

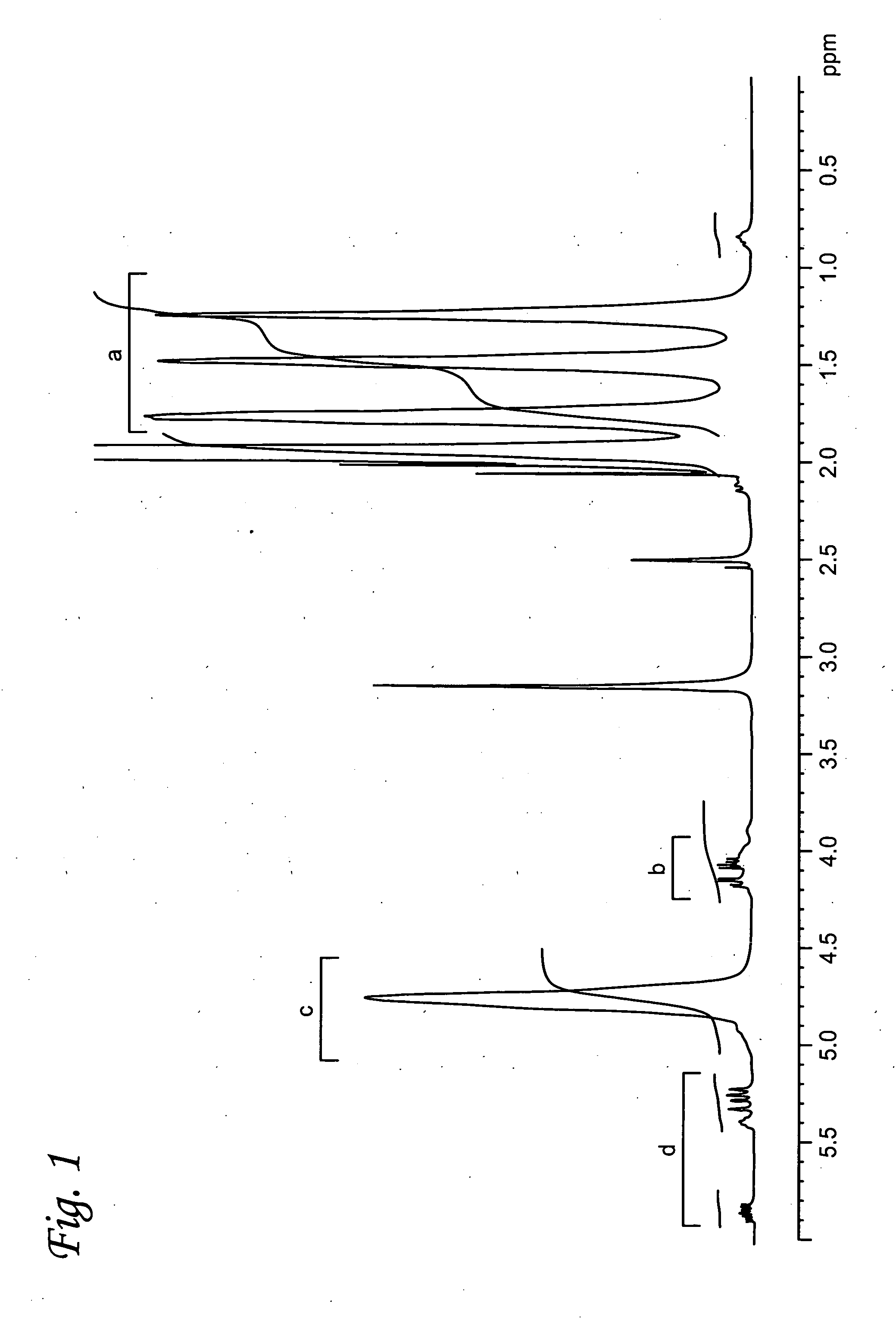

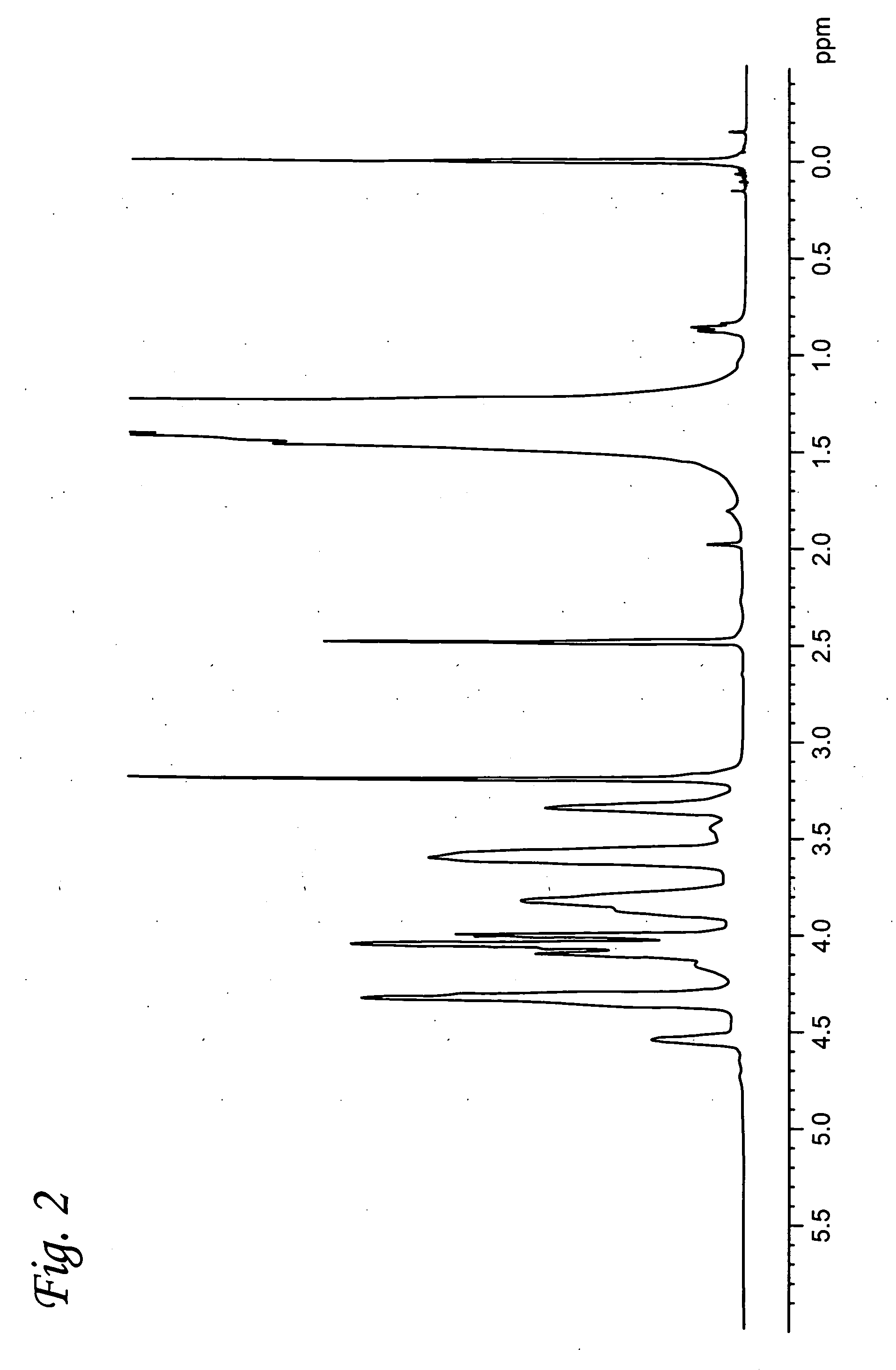

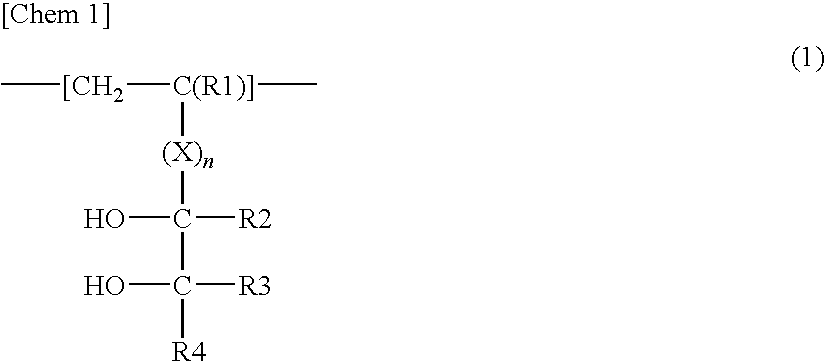

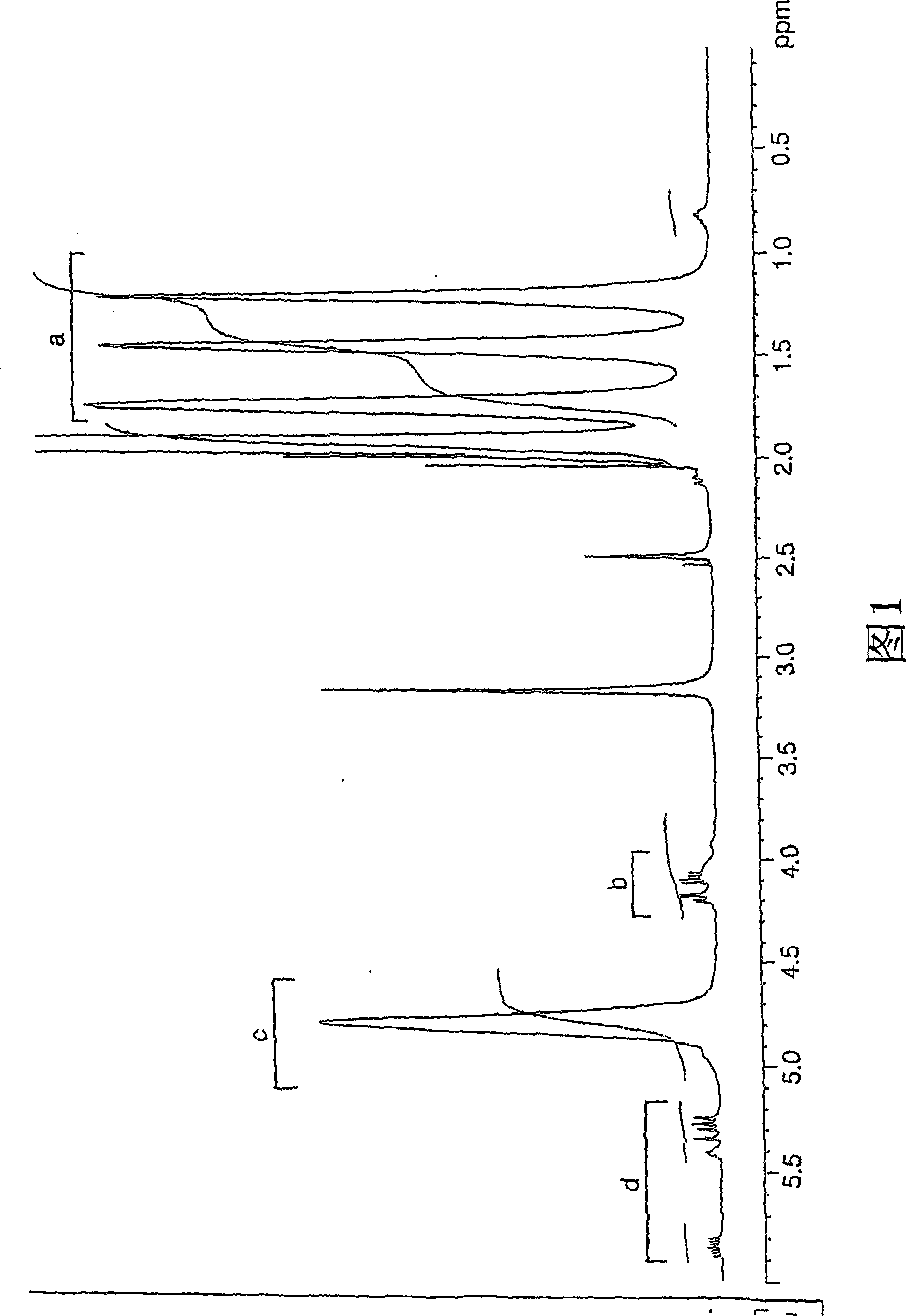

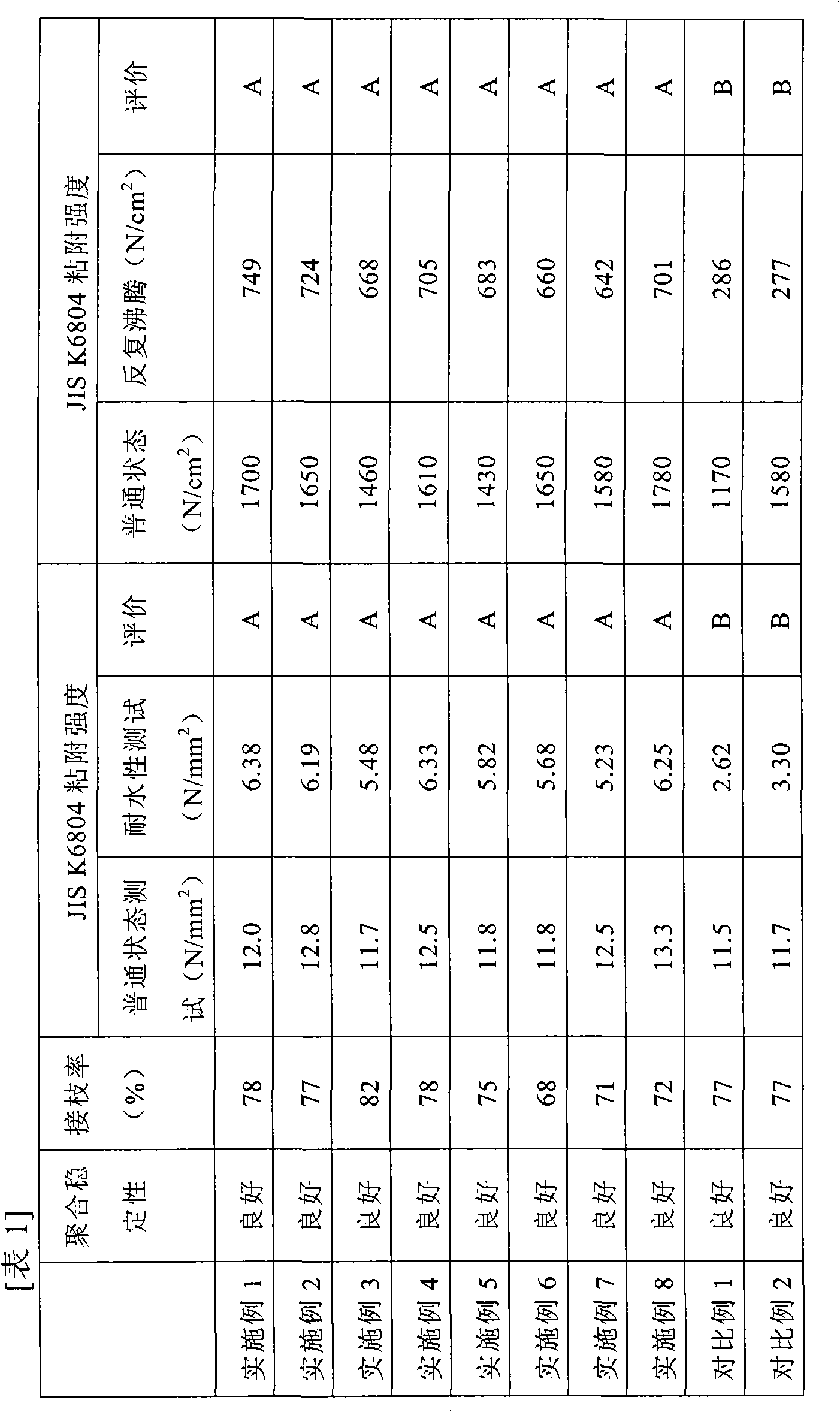

Resin Composition and Multi-Layer Structure Using the Same

InactiveUS20100055482A1Excellent in retort resistanceGood anti pinhole propertyAgricultural articlesSynthetic resin layered productsPolyamideVinyl ester

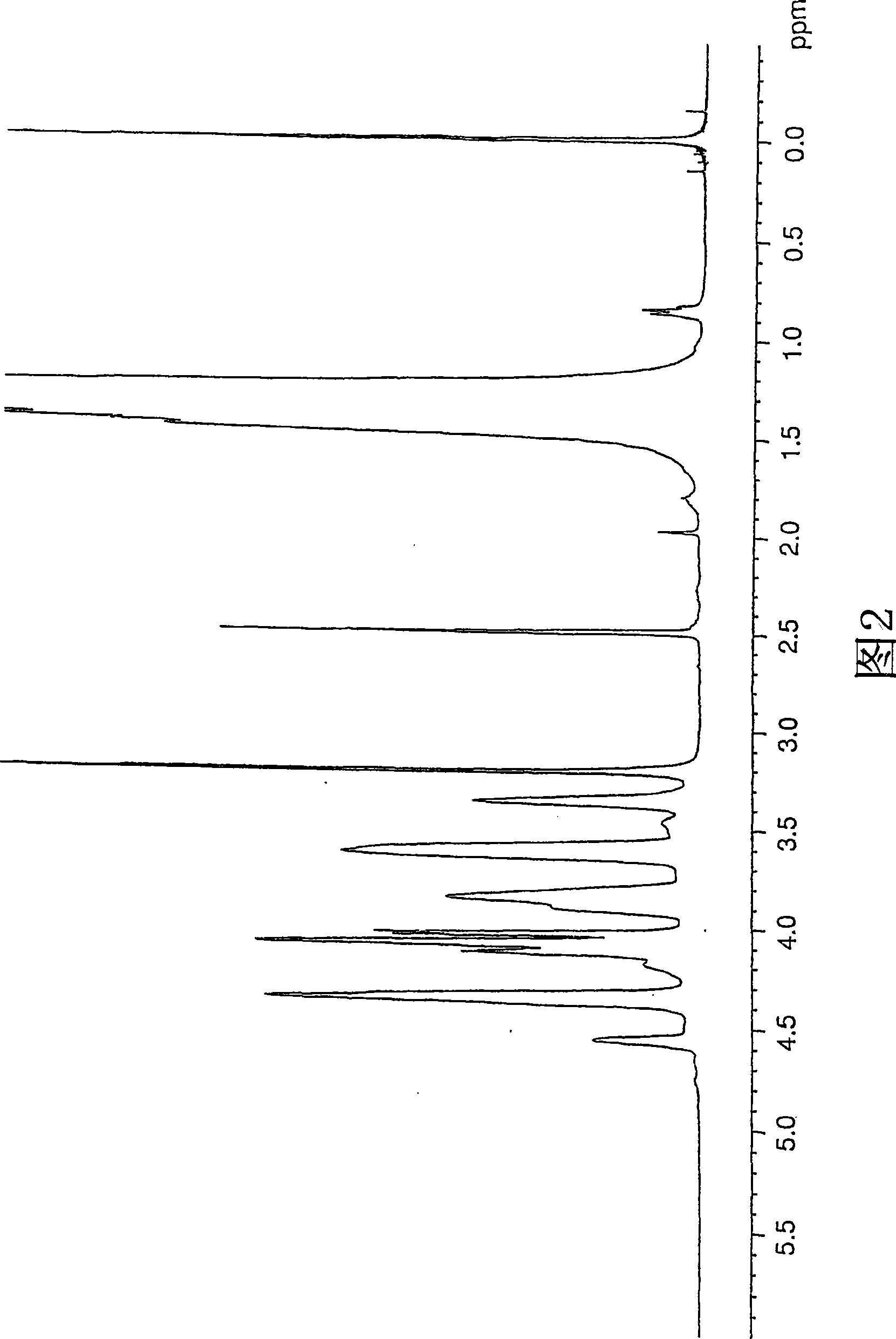

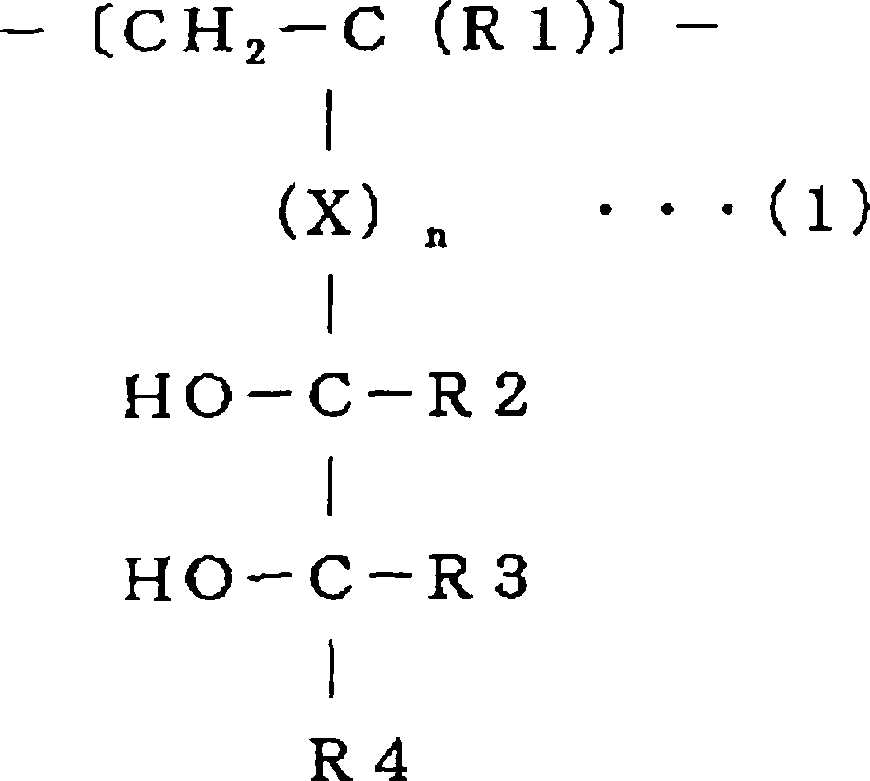

An object of the present invention is to provide a resin composition excellent in retort resistance at high temperature, gas barrier property, and anti-pinhole property as well as a multi-layer structure using the same. The invention relates to a resin composition comprising an ethylene-vinyl alcohol copolymer (A) and a polyamide-based resin (B), wherein the ethylene-vinyl alcohol copolymer (A) is an ethylene-vinyl alcohol copolymer comprising the following structural unit (1), preferably obtained by saponifying a copolymer of 3,4-diacetoxy-1-butene, a vinyl ester-based monomer, and ethylene:wherein X is a bonding chain which is an arbitrary bonding chain excluding an ether bond, R1 to R4 each independently represents an arbitrary substituent, and n represents 0 or 1.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

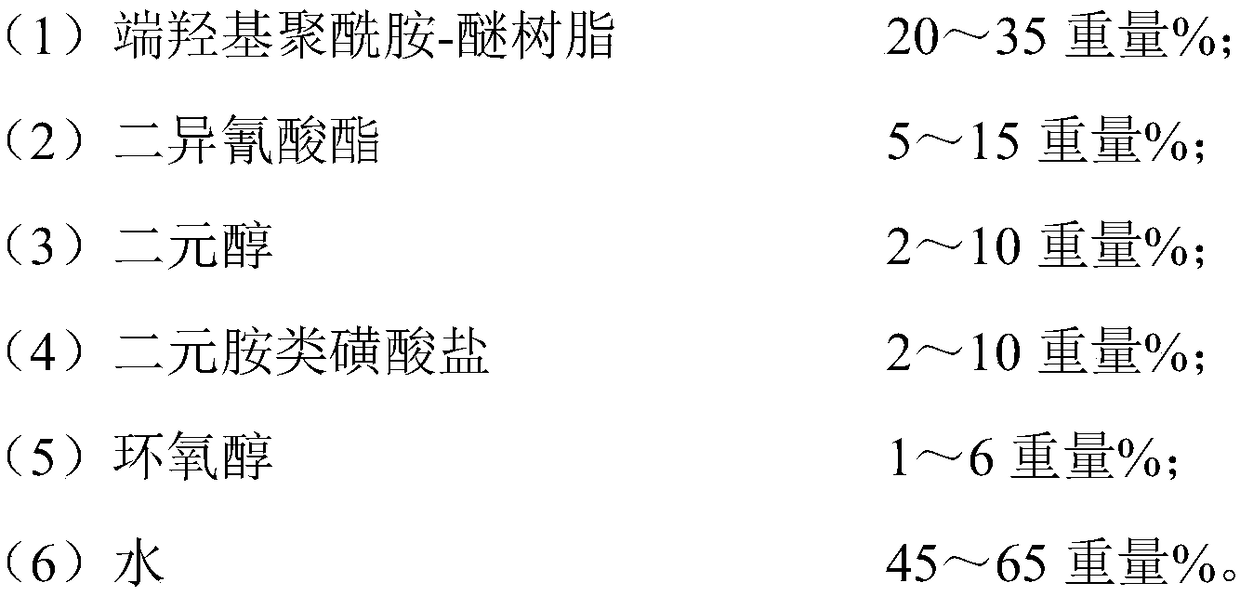

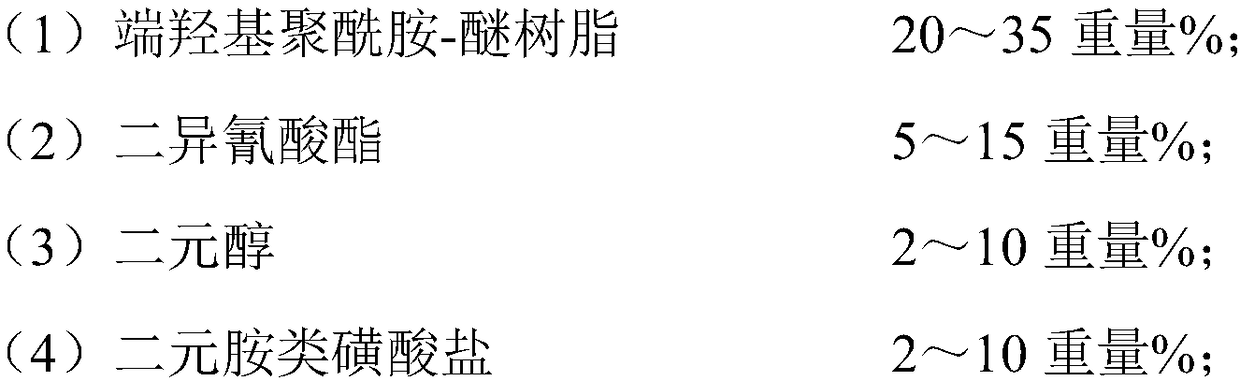

Water-based ink composition, water-based ink resin and preparation method and application thereof

ActiveCN108840992AImprove adhesion fastnessImprove water resistancePolyureas/polyurethane adhesivesInksEpoxySulfonate

The invention relates to the field of water-based ink, and discloses a water-based ink composition, water-based ink resin and a preparation method and application thereof. The water-based ink composition comprises the following components in percent by weight: (1), 20-35wt% of hydroxy-terminated polyamide-ether resin; (2), 5-15wt% of diisocyanate; (3), 2-10wt% of diol; (4), 2-10wt% of diamine sulfonate; (5), 1-6wt% of epoxy alcohol; (6), 45-65wt% of water. The water-based ink resin prepared from the water-based ink composition is good in adhesion and good in printability. After water-based inkprepared from the water-based ink resin is printed onto a packaging substrate, the water-based ink has the advantages of water boiling resistance and steam boiling resistance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ultraviolet (UV) base oil metal tank UV printing and coating method

ActiveCN103909754AGood flexibilityImprove impact resistancePolyurea/polyurethane coatingsOther printing apparatusUltravioletSolvent

The invention relates to an ultraviolet (UV) base oil metal tank UV printing and coating method which includes the following steps: 1) pre-printing computer direct platemaking; 2) inner coating which includes adopting inner coating to coat the inner surface; 3) conducting instantaneous high temperature processing on the surface of a base material; 4) instantaneous continuous completion of UV base oil coating, UV base oil solidification through a UV lamp and UV ink printing; 5) follow-up continuous solidification of a UV ink layer through a UV lamp group; 6) conducting polishing and coating to protect printed patterns from being scrapped and damaged. By means of the method, the UV base oil outer coating replaces the traditional solvent type base oil outer coating, the film layer is thin, natural gas energy consumed by tunnel type drying room drying and solidification and waste gas discharged to the nature are greatly reduced, the energy is saved, and the environment is protected. In addition, the new process that the UV base oil coating and UV ink printing are finished together continuously is achieved, the printing and coating production efficiency can be greatly improved, and meanwhile coating capacity of a coating line is released.

Owner:SHANGHAI BAOYIN METAL DECORATION

Steam-resistant solvent-free laminating adhesive and preparation method thereof

ActiveCN102604583BLow viscosityImprove heat resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides steam-resistant solvent-free laminating adhesive applicable to compound soft package, which comprises a component A and a component B. The component A is isocyanate terminated polyurethane polymer formed by reacting polyhydroxy compound and polyisocyanate terminated compound. The component B is formed by mixing more than one type of plant oil polyalcohol, curing accelerator and synthetic modifier. The polyhydroxy compound in component A is formed of polyester polyol and / or polyether polyol with more than two degrees of functionality and a molecular weight range of from 600-2000, and more than one type of plant oil polyalcohol. The curing accelerator in the component B is formed of small molecular polyalcohol with more than two degrees of functionality. The synthetic modifier is formed by reacting more than one type of silane coupling agent and polyalcohol. The steam-resistant solvent-free laminating adhesive is low in viscosity and fast in curing speed, has high peel strength after boiled in water at 100 DEG C, and is especially suitable for soft packages requiring long-term high temperature sterilization (such as soft packages for foods, drugs and baby products). The invention further provides a preparation method of the steam-resistant solvent-free laminating adhesive.

Owner:SOUTH CHINA UNIV OF TECH +1

Resin composition and multilayer structure body using the same

InactiveCN101432355AExcellent pinhole resistanceExcellent retort resistanceSynthetic resin layered productsDomestic containersPolyamideEther

A resin composition that excels in high-temperature retort resistance and gas barrier and further excels in pinhole prevention after retort; and a multilayer structure making use of the same. There is provided a resin composition comprising ethylene / vinyl alcohol copolymer (A) and polyamide resin (B), characterized in that the ethylene / vinyl alcohol copolymer (A) is an ethylene / vinyl alcohol copolymer containing the following structural unit (1), preferably one obtained by copolymerization of 3,4-diacetoxy-1-butene, a vinyl ester monomer and ethylene and saponifying the resultant copolymer. Further, there is provided a multilayer structure having a layer comprising the above resin composition. (1) wherein X is any bonding chain excluding ether bonds; each of R1 to R4 independently is an arbitrary substituent; and n is 0 or 1.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

Re-emulsifiable resin powder, aqueous emulsion and adhesive composition using same

InactiveCN101313028AImprove water resistanceExcellent retort resistancePolyureas/polyurethane adhesivesUnsaturated alcohol polymer adhesivesSolubilityEmulsion

Disclosed is a re-emulsifiable resin powder which is characterized in that the physical properties after being re-emulsified in water are substantially the same as those of the emulsion from which the resin powder is formed. A film formed by using an emulsion obtained by re-emulsifying such a re-emulsifiable resin powder is improved in water resistance. Specifically disclosed is a re-emulsifiable resin powder obtained from an aqueous synthetic resin emulsion which is dispersion-stabilized by a polyvinyl alcohol resin, wherein a hydrophobic monomer having a solubility in water at 20 DEG C of 0.1% or less is contained, as a copolymerizable monomer for constituting the aqueous synthetic resin, in an amount of not less than 30% by weight relative to the total weight of the copolymerizable monomers.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com