Patents

Literature

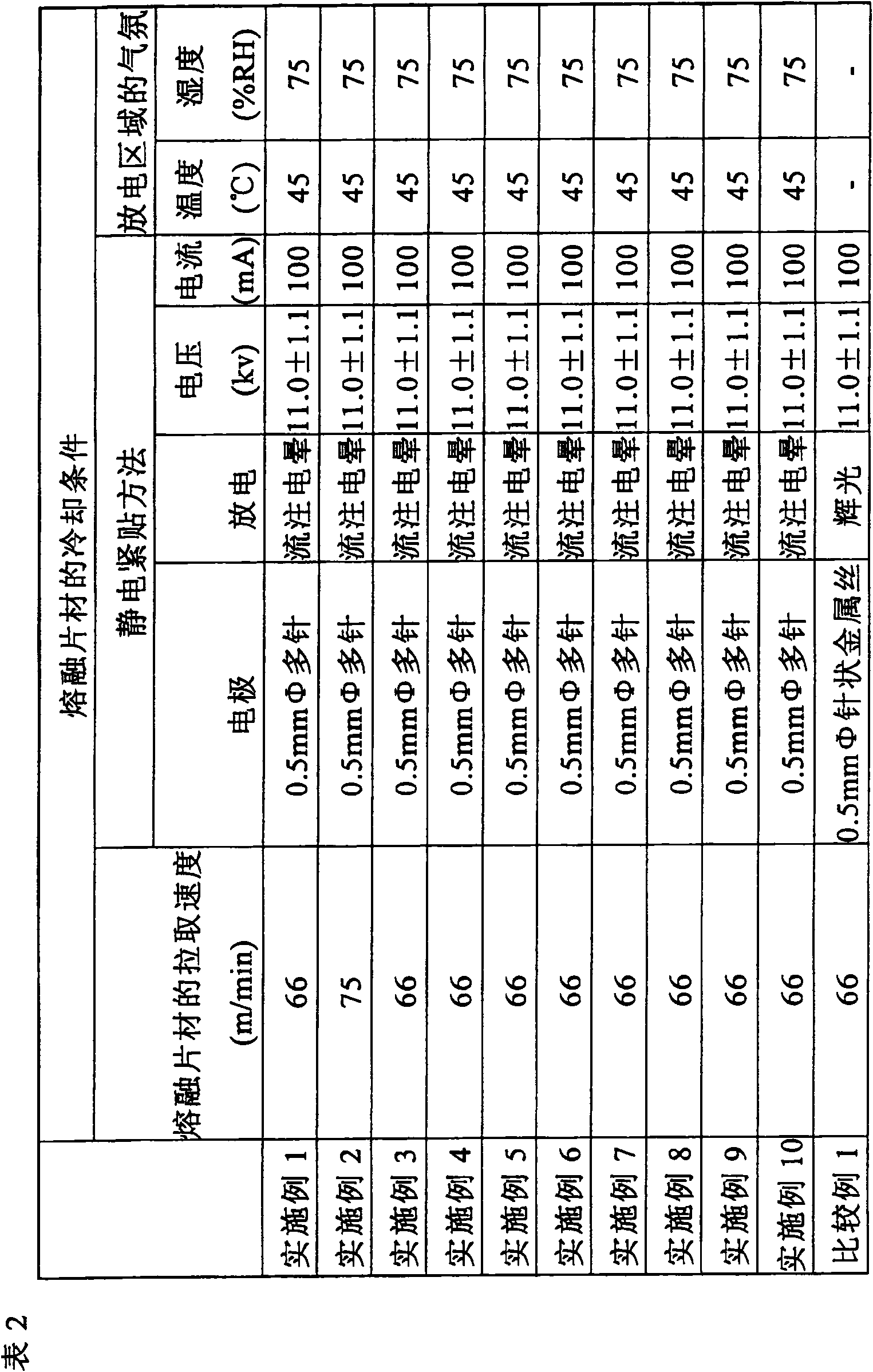

48results about How to "Excellent pinhole resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

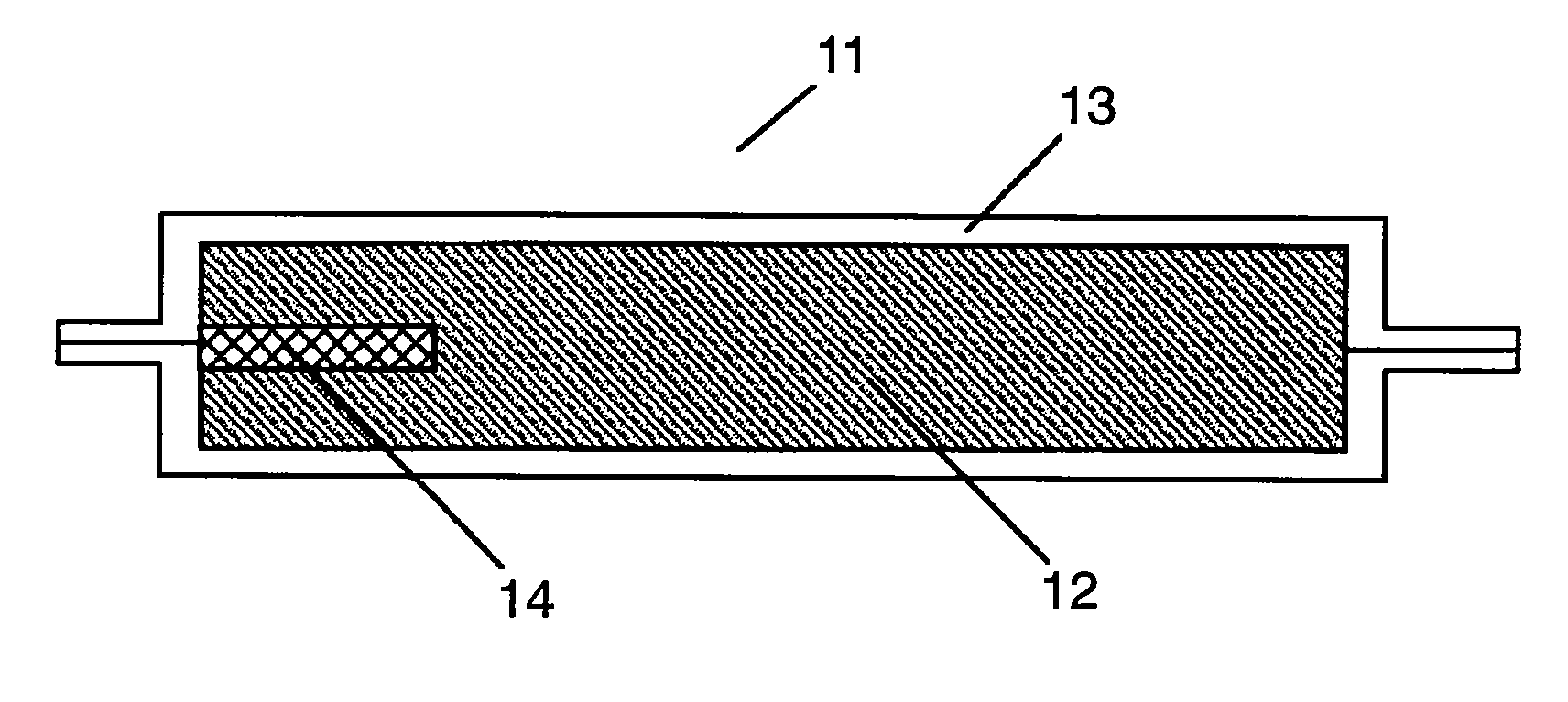

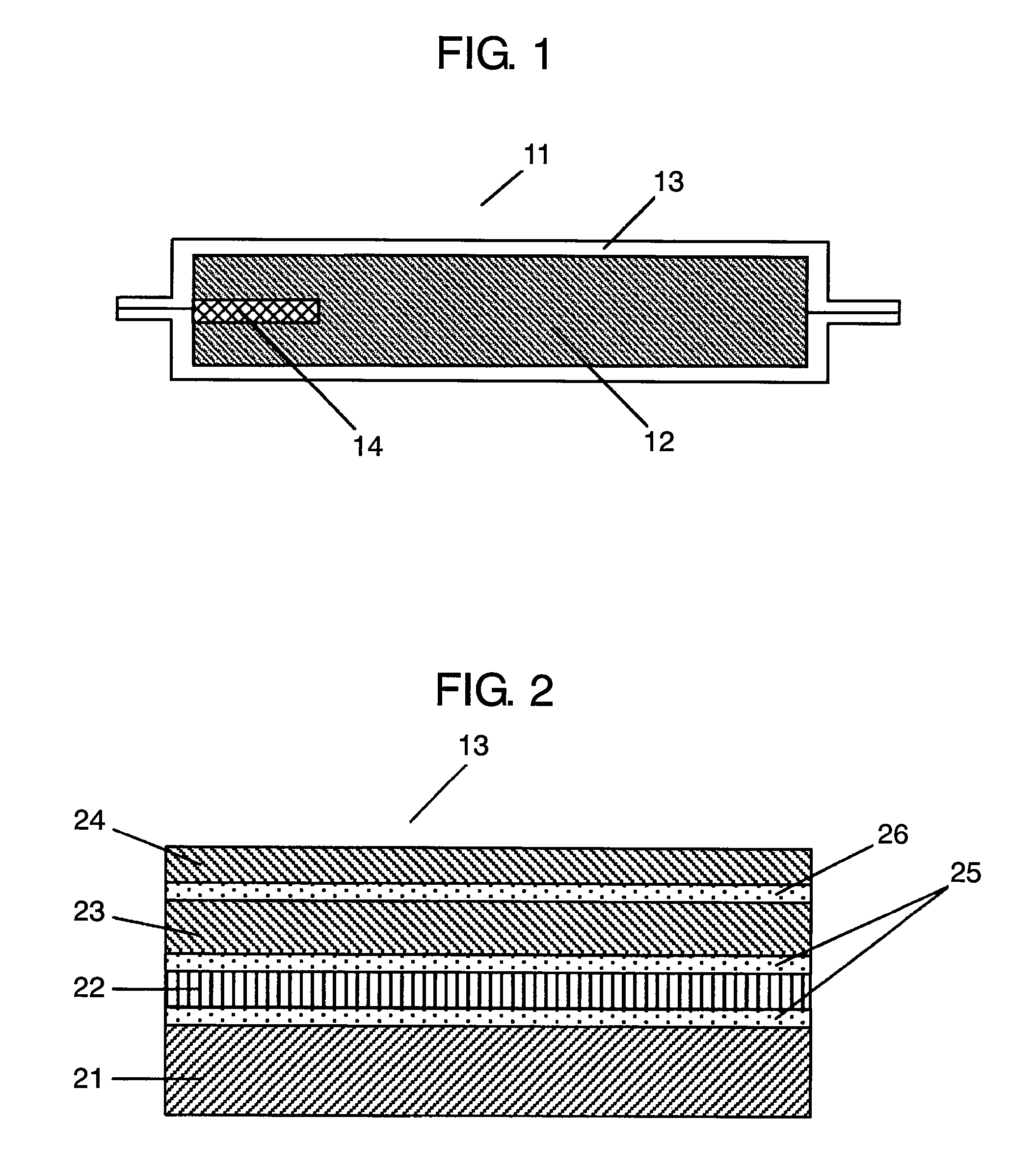

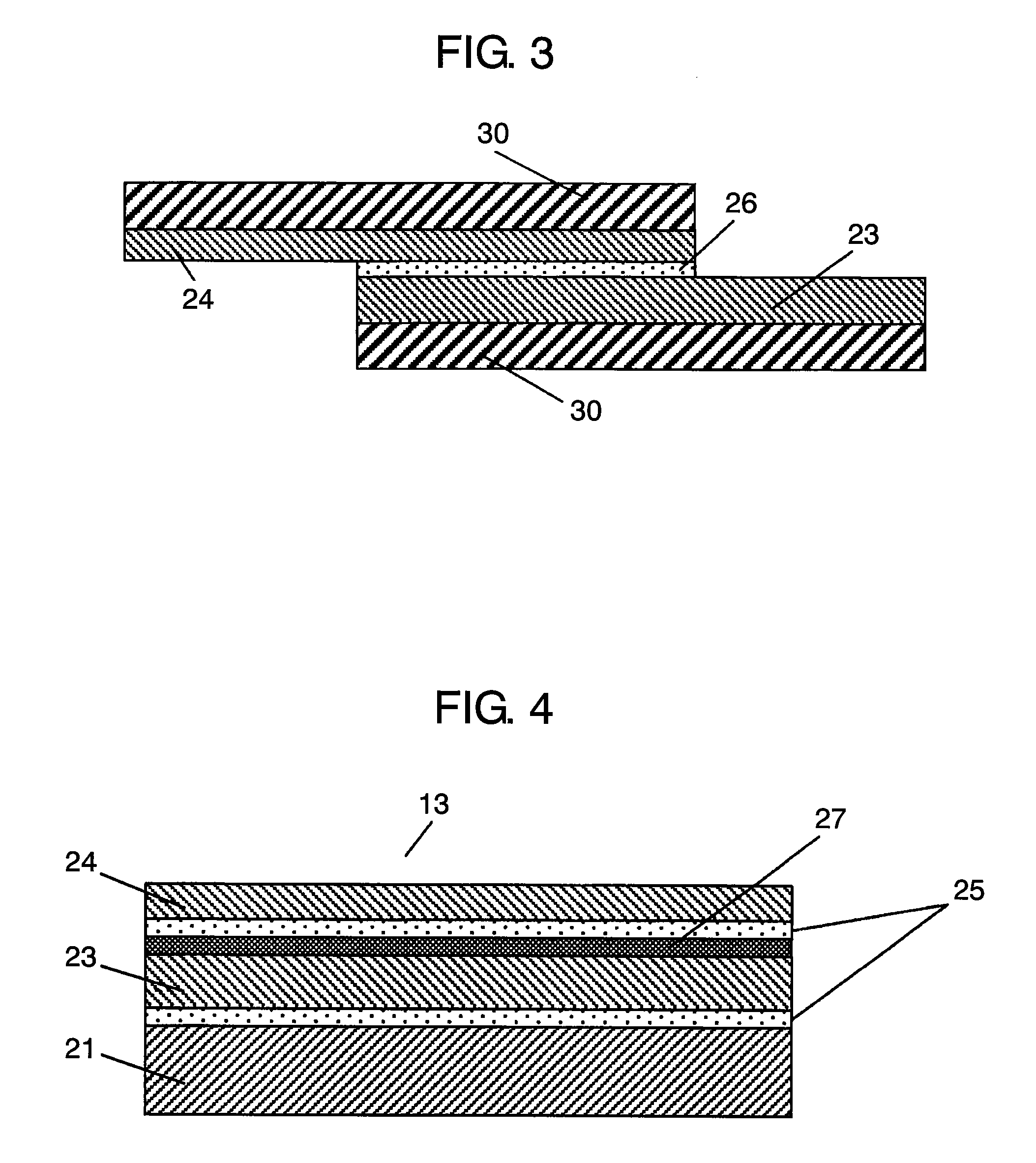

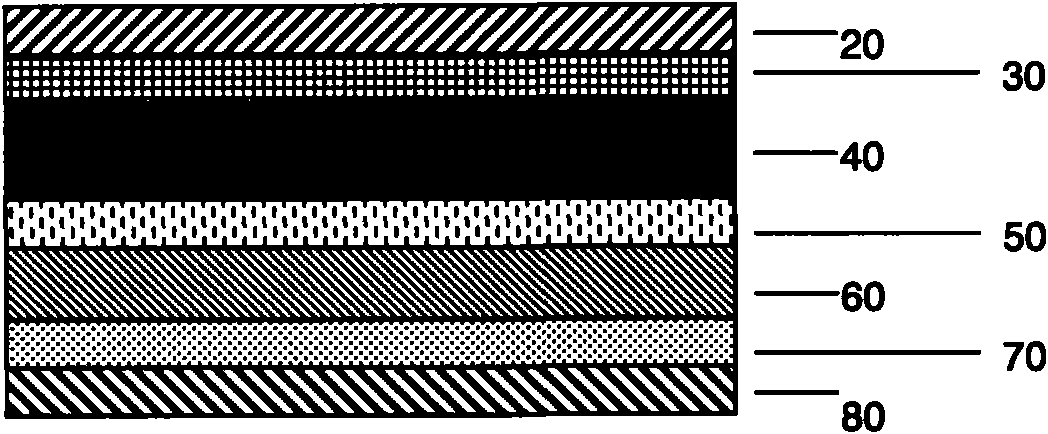

Vacuum heat insulation material and cold reserving apparatus with the same

ActiveUS7762634B2Long-lasting performanceExcellent pinhole resistanceThermal insulationSynthetic resin layered productsForeign matterMetal foil

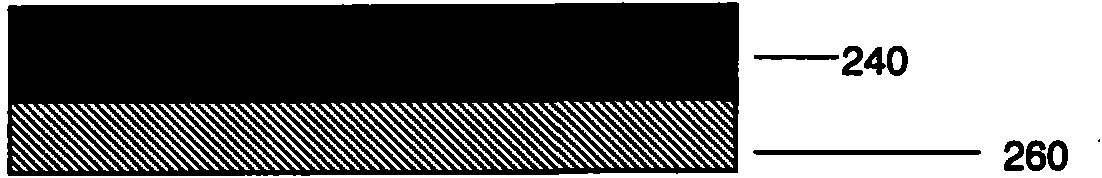

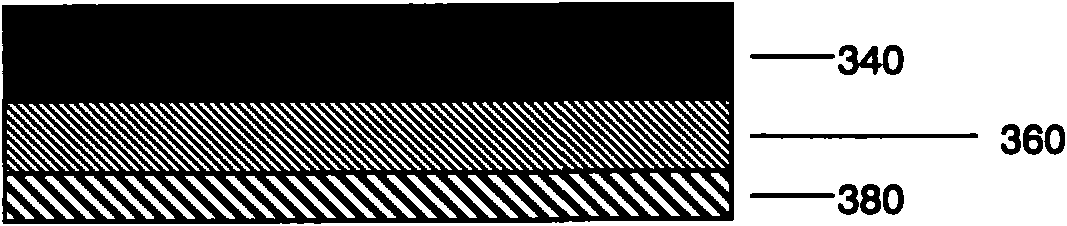

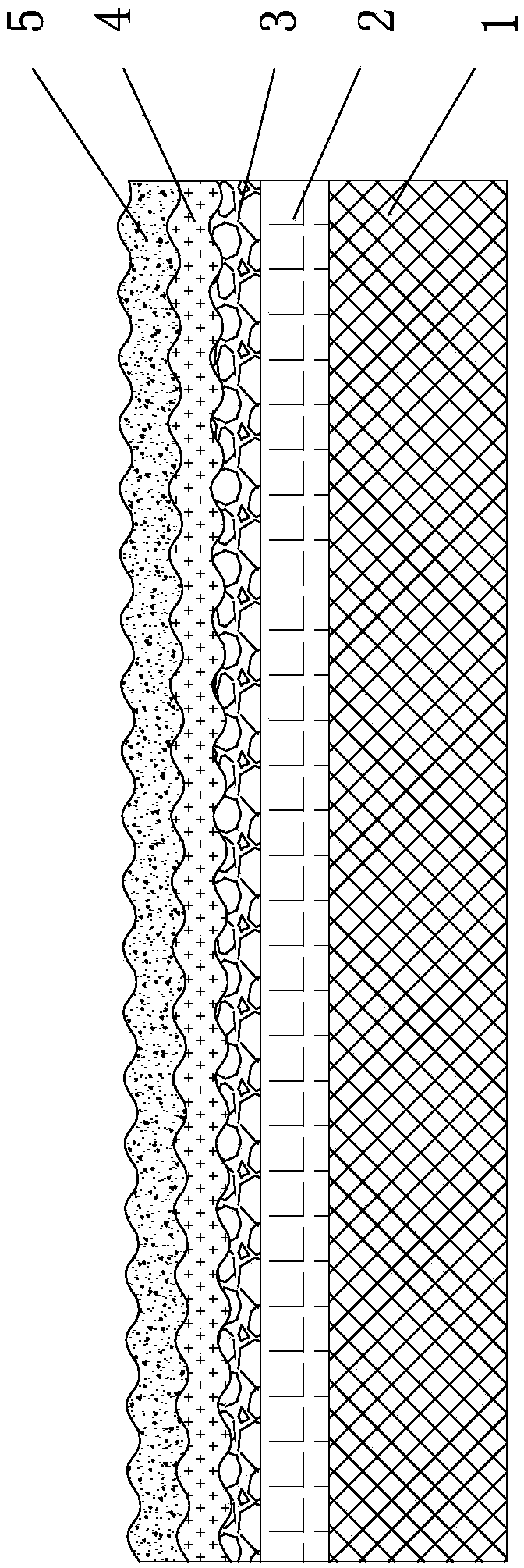

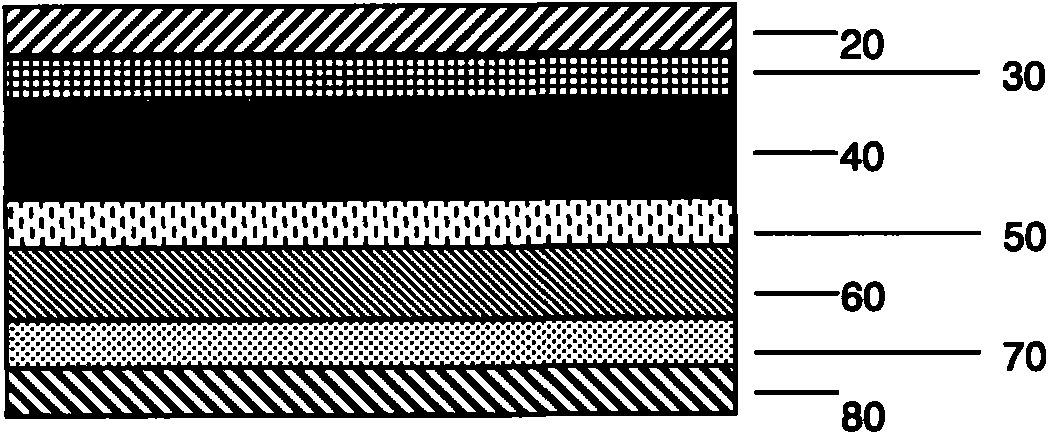

A vacuum heat insulation material has a covering material which is a lamination body including a sealant layer, a metal foil layer, a first plastic film layer, and a second plastic film layer which are laminated in this order from inside to outside via adhesive layers. When a foreign body is pierced into the vacuum heat insulation material, the propagation of breakage caused by the piercing is blocked somewhere inside the lamination body, thereby preventing the formation of through-pinholes. This results in the provision of a high-quality vacuum heat insulation material with excellent long-term insulation performance by using a covering material excellent in gas barrier properties and pinhole resistance to the piercing of minute foreign bodies.

Owner:PANASONIC CORP

Laminated material without metal foil for blocking package

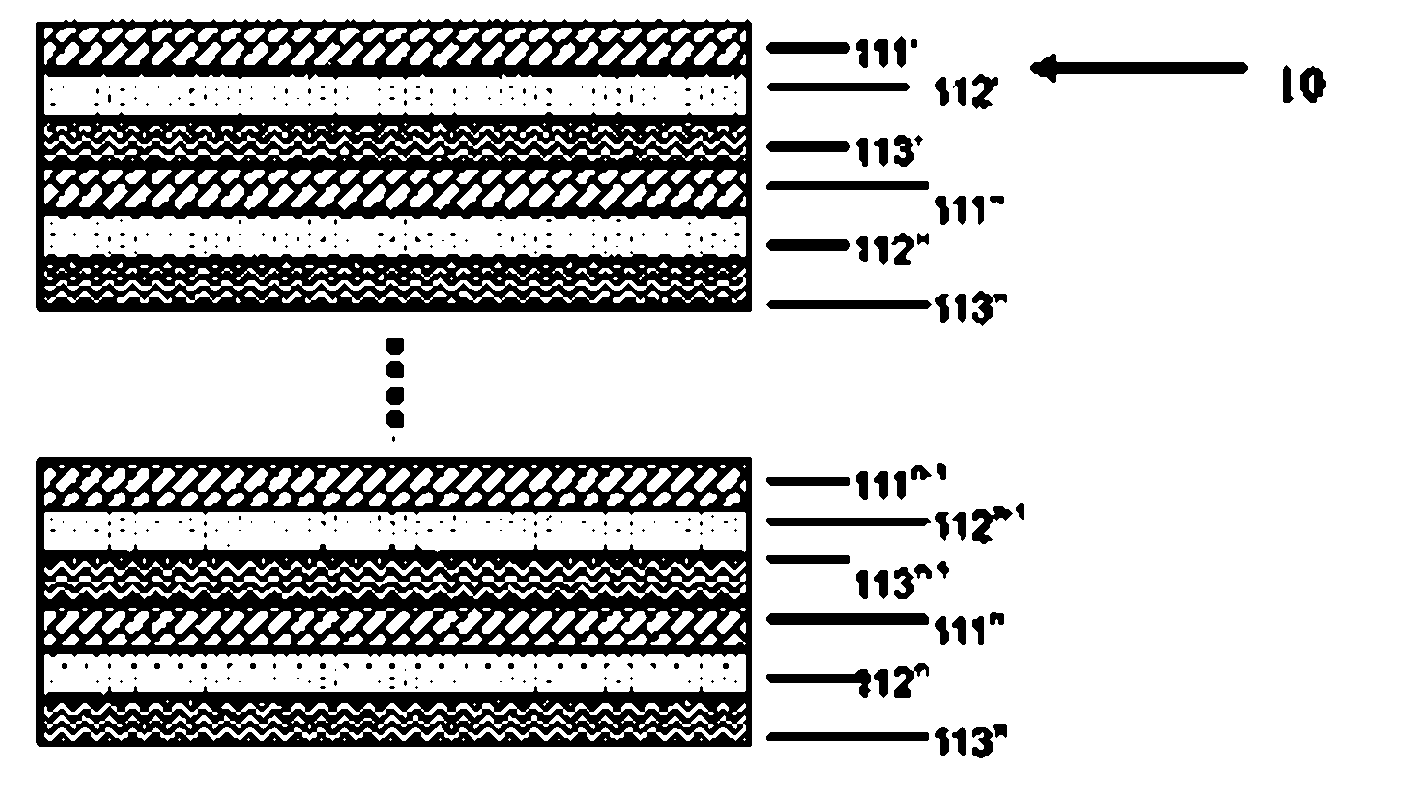

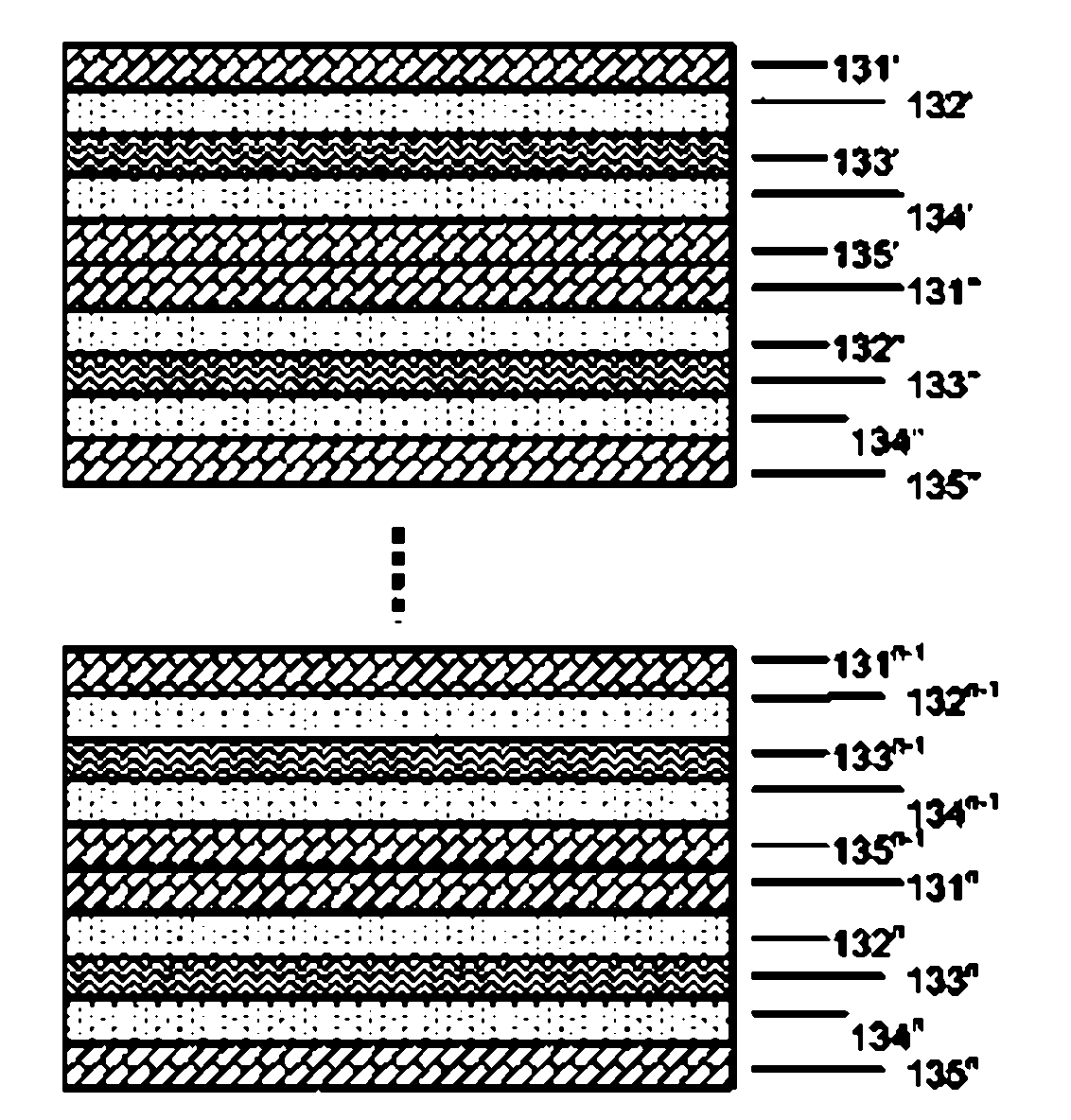

The invention discloses a laminated material without metal foil for a blocking package. The material at least comprises a substrate layer assembly and a composite blocking layer assembly, wherein the substrate layer assembly and the composite blocking layer assembly are laminated together; the substrate layer assembly has the effect of supporting; and the composite blocking layer assembly comprises at least one composite blocking layer which is prepared through a partition-laminated confluence layer multiplication and coextrusion method and comprises a plurality of repeated units. The material is characterized in that each repeated unit at least comprises three polymer constitutes, and each polymer constitute can form an individual layer or more than one individual layer; and only one of the polymer constitutes is a blocking polymer constitute which can block gas.

Owner:厦门天策材料科技有限公司

Barrier-property lapped polymer film packaging material

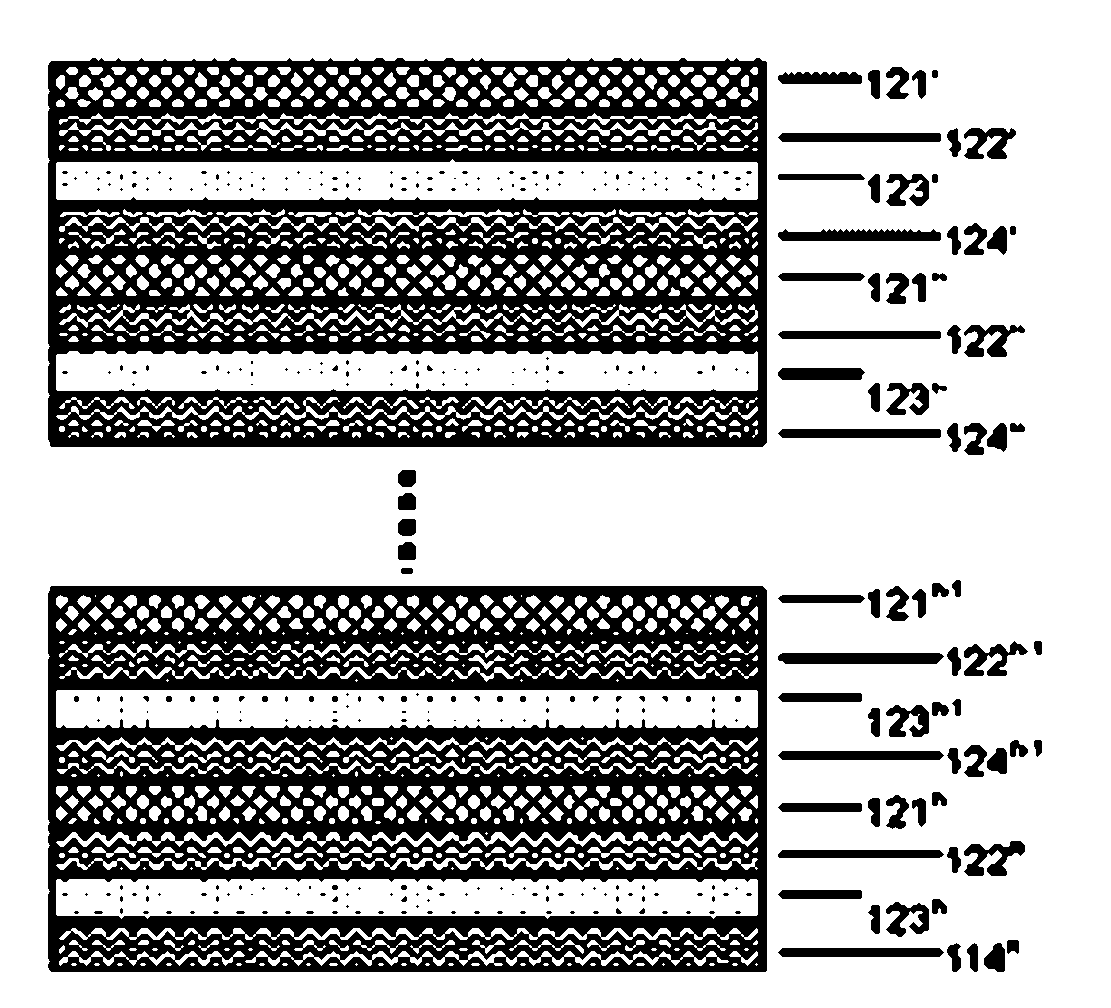

ActiveCN102001486AReduce dosageOne less contains at least dosageFlexible coversWrappersPolymer thin filmsEngineering

The invention discloses a barrier-property lapped polymer film packaging material comprising at least one layer-multiplied and coextruded lapped barrier compound layer. Each barrier compound layer comprises a plurality of repeating units which comprise at least two individual layers; each individual layer corresponds to one of two different polymers; at least one repeating unit of the lapped barrier compound layer at least comprises three individual layers; each of the individual layers corresponds to one of three different polymers; and at least one of the at least three polymers forms at least one barrier-property polymer part which can separate gas.

Owner:厦门天策材料科技有限公司

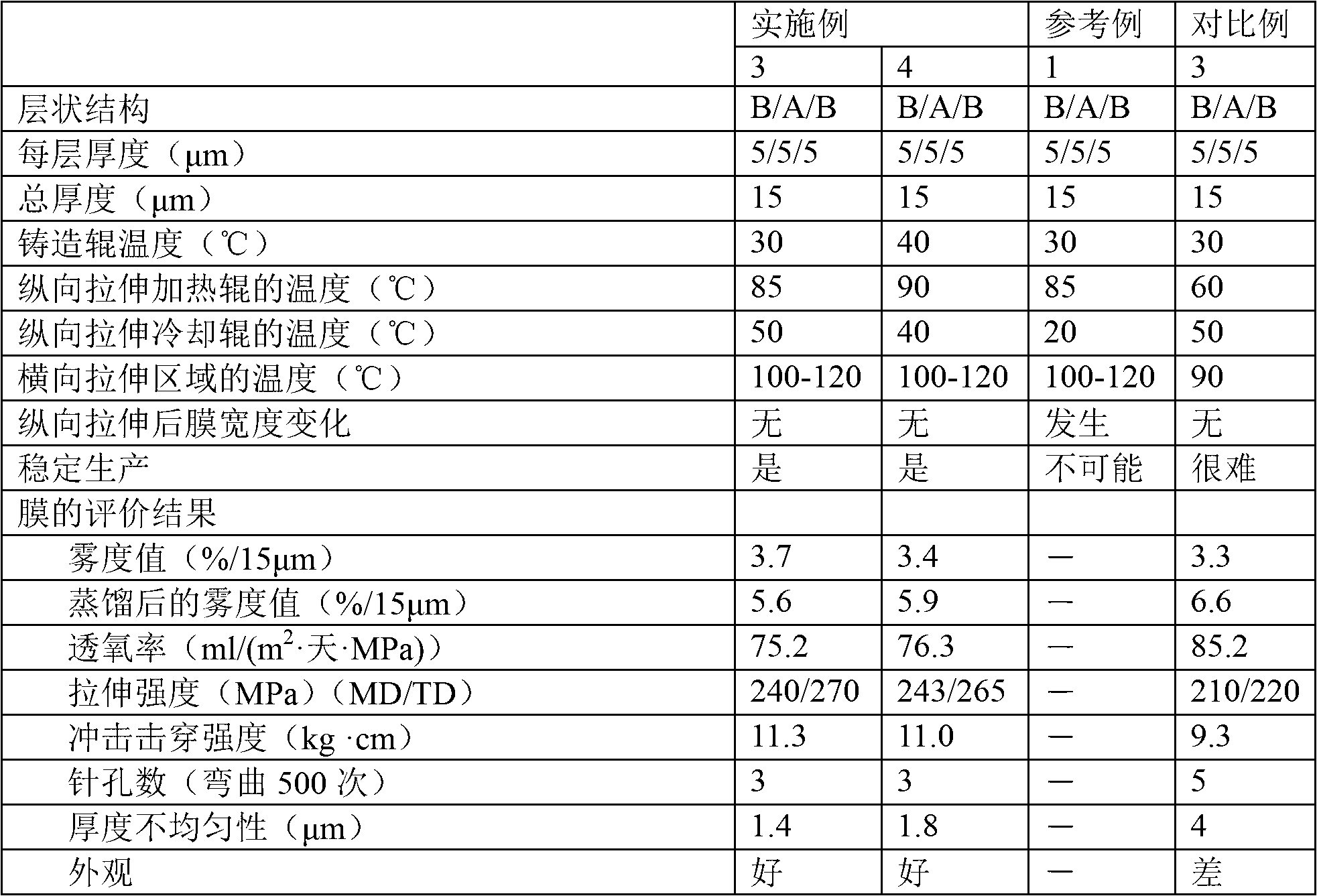

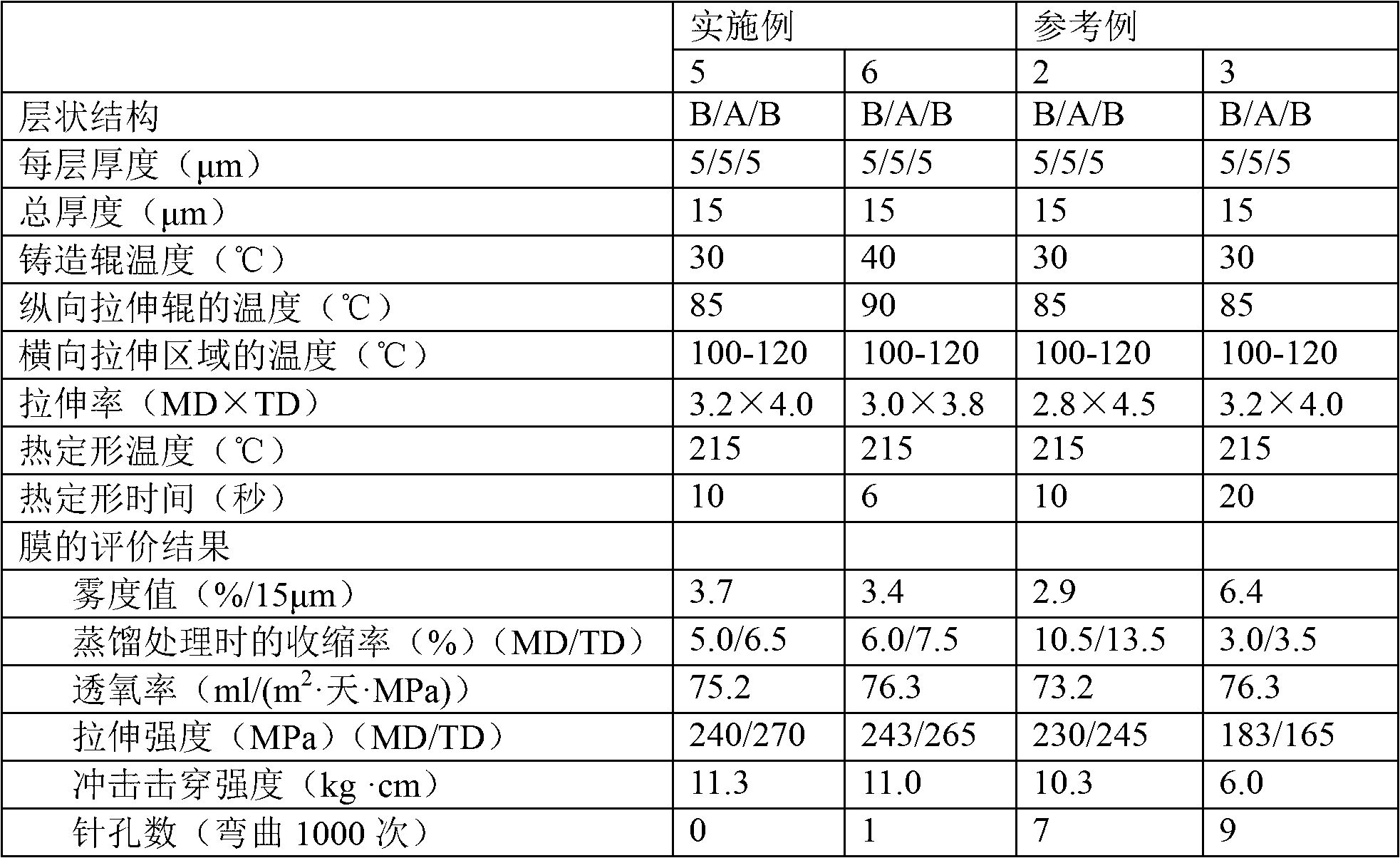

Polyester film

ActiveCN1835994AHigh mechanical strengthImprove heat resistanceFlexible coversWrappersPolyesterHeat resistance

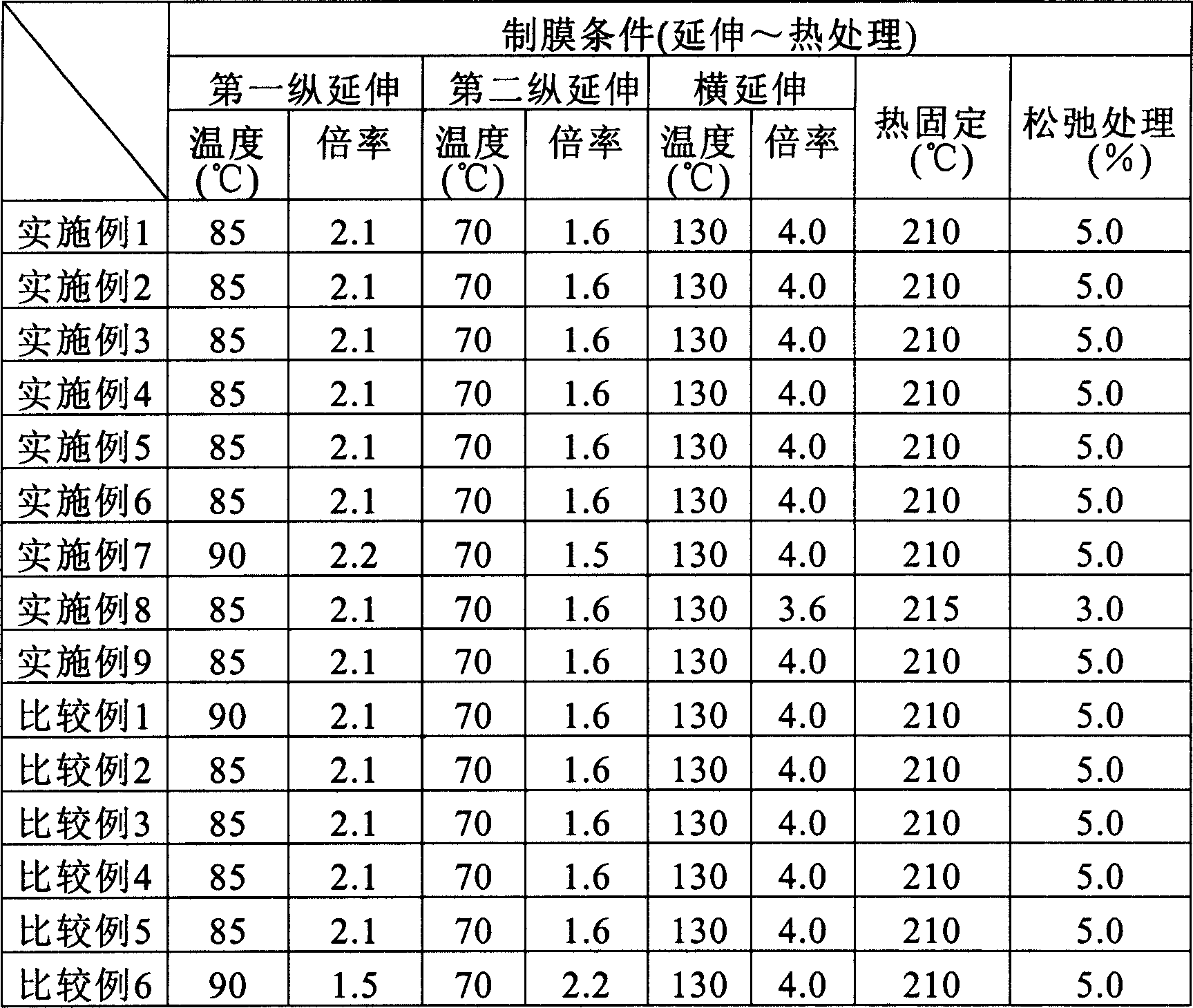

Provided is a polyester film which is excellent in heat resistance, chemical resistance, insulating characteristics, dimensional stability at elevated temperatures, and is suitable for use in a variety of fields of application such as those needing a boiling or retort treatment which requires satisfactory levels in toughness, the resistance to pin-holing, the resistance to flexing, the resistance to the breakage of a bag by dropping, impact resistance and the like, those practicing thermal molding or vacuum molding, those of bags for packaging foods containing water or drugs. A polyester film, characterized in that it exhibits an initial modulus of elasticity at least in one direction of 2.5 to 10 GPa, an impact strength of 40 to 10000J / mm, a thermal shrinkage at 150 DEG C at least in one direction of -0.5 to 6 %, a haze of 0.001 to 7 %, and an absolute value of the difference between the thermal shrinkage percentages in the longitudinal direction and in the transverse direction of 1.1 % or less.

Owner:TOYOBO CO LTD

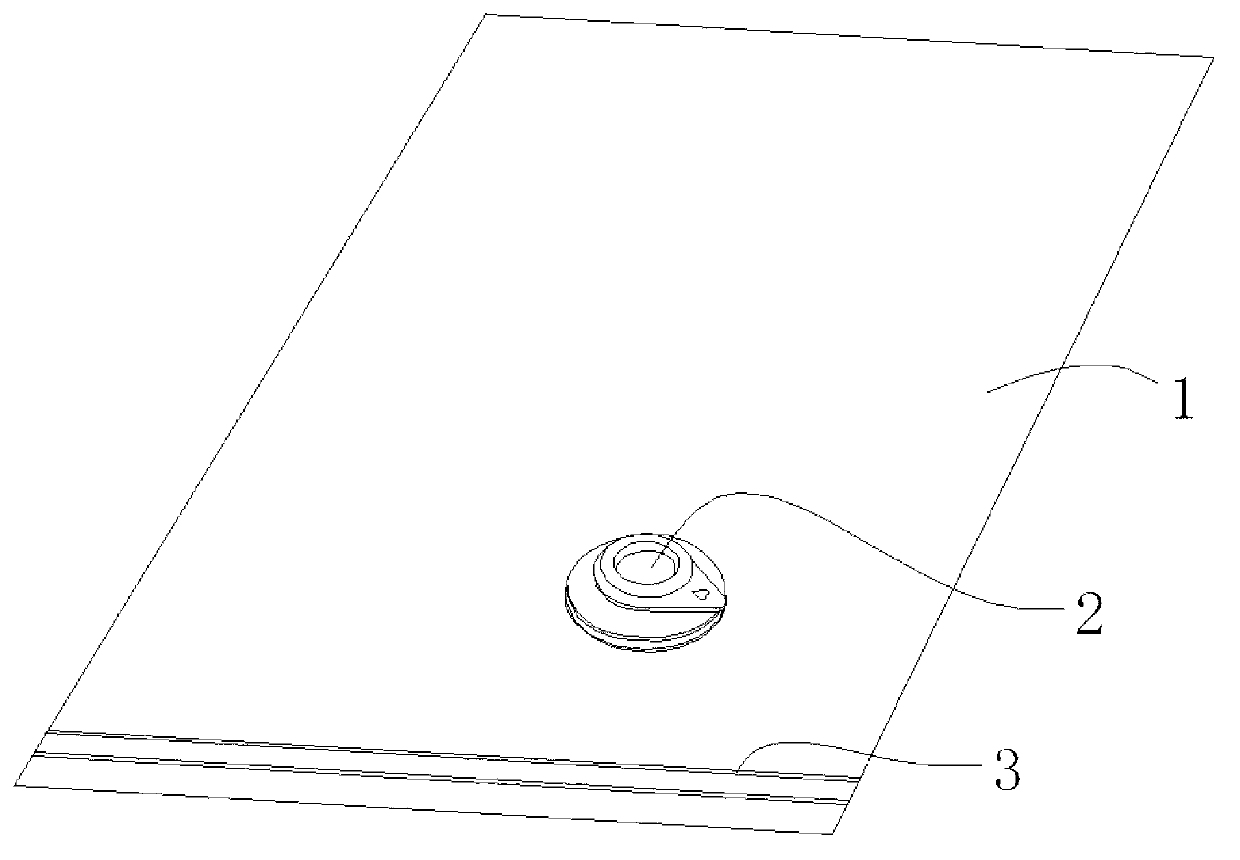

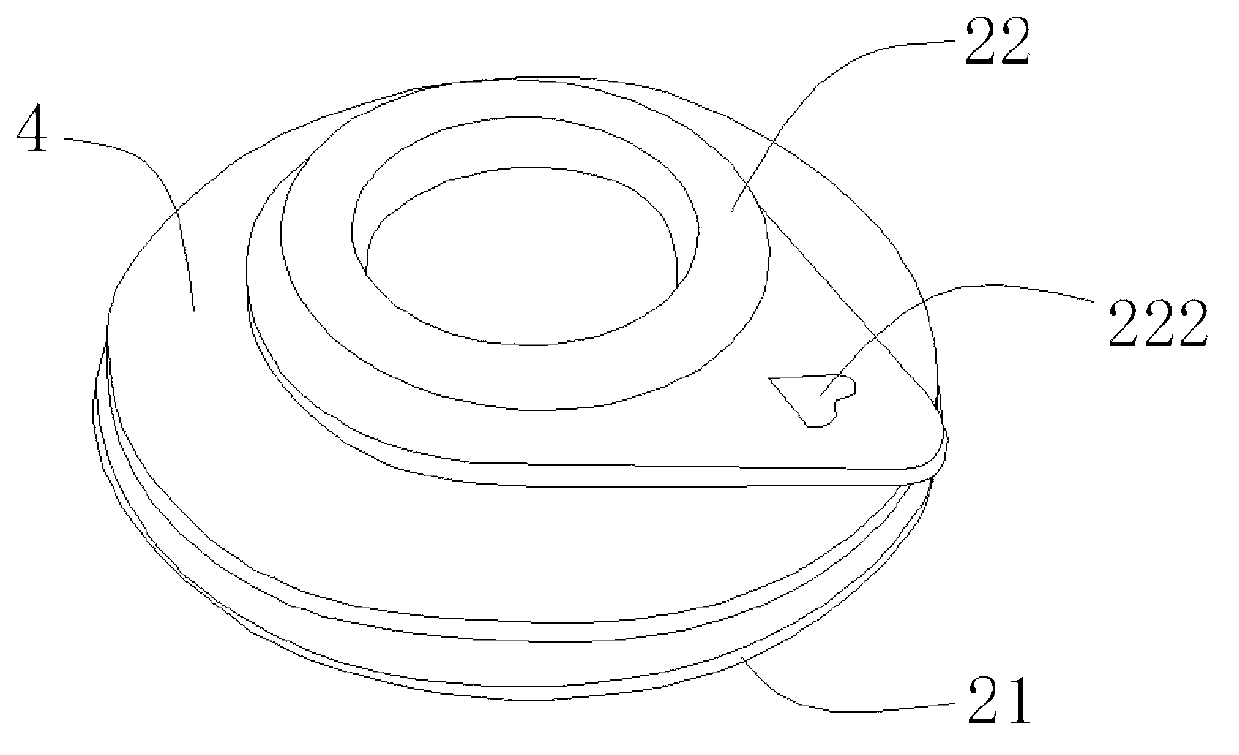

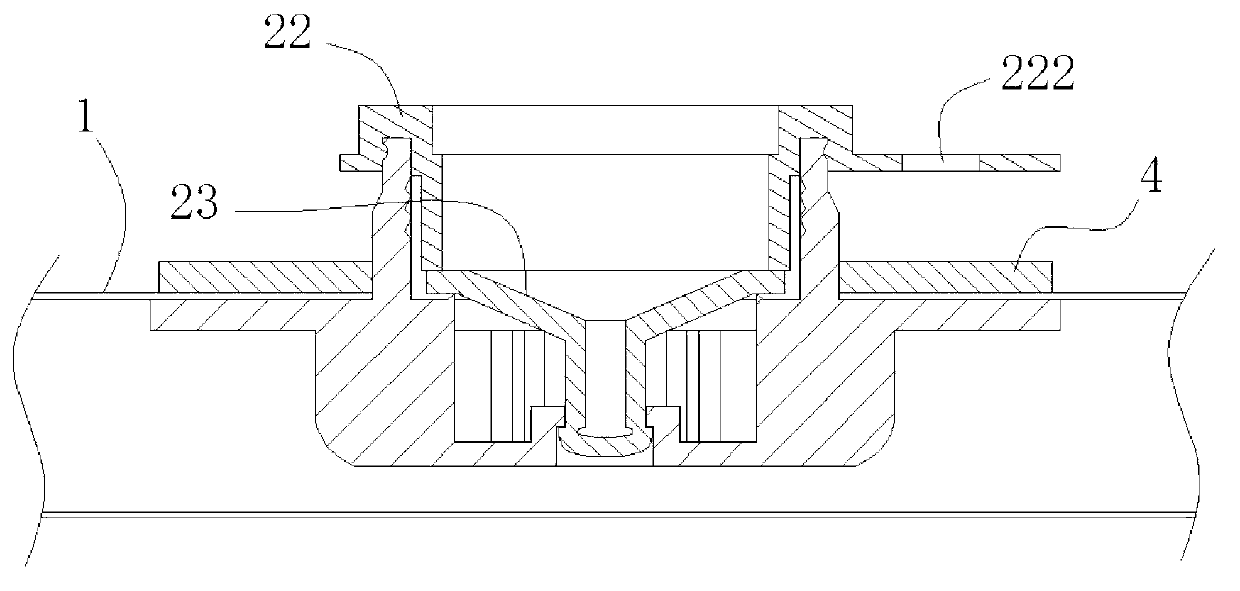

Vacuum bag manufacturing method and product of the same

The invention discloses a vacuum bag manufacturing method, and further discloses a product obtained by adopting the method. The vacuum bag manufacturing method and the product of the vacuum bag comprise a bag body and a vent valve. The vent valve comprises a valve seat, a valve cover and a cone-shaped soft plug. The method is easy in manufacturing procedure, easy to realize, and capable of being used for quickly manufacturing the vacuum bag product which is good in sealing effect and convenient to use. The vacuum bag product is ingenious and reasonable in structural design. The cone-shaped soft plug and an opening of an accommodating cavity are matched for sealing air, an operator just needs to cover the valve cover to ensure that the cone-shaped soft plug is tightly attached on the opening, and accordingly sealing effects are achieved. The valve cover is plugged out to ensure that air freely enters and leaves the bag body to bring convenience to air pumping and use. Furthermore, a flange is arranged on the opening to further strengthen sealing effects, and articles can be beneficially stored for a long period. A bag opening can be quickly opened or sealed through concave-convex seals. The vacuum bag manufacturing method and the product of the vacuum bag are convenient to use and simple and easy to operate, bring great convenience to the steps of taking and putting the articles and life of people, and facilitate wide promotion and applications.

Owner:广东树业环保包装有限公司

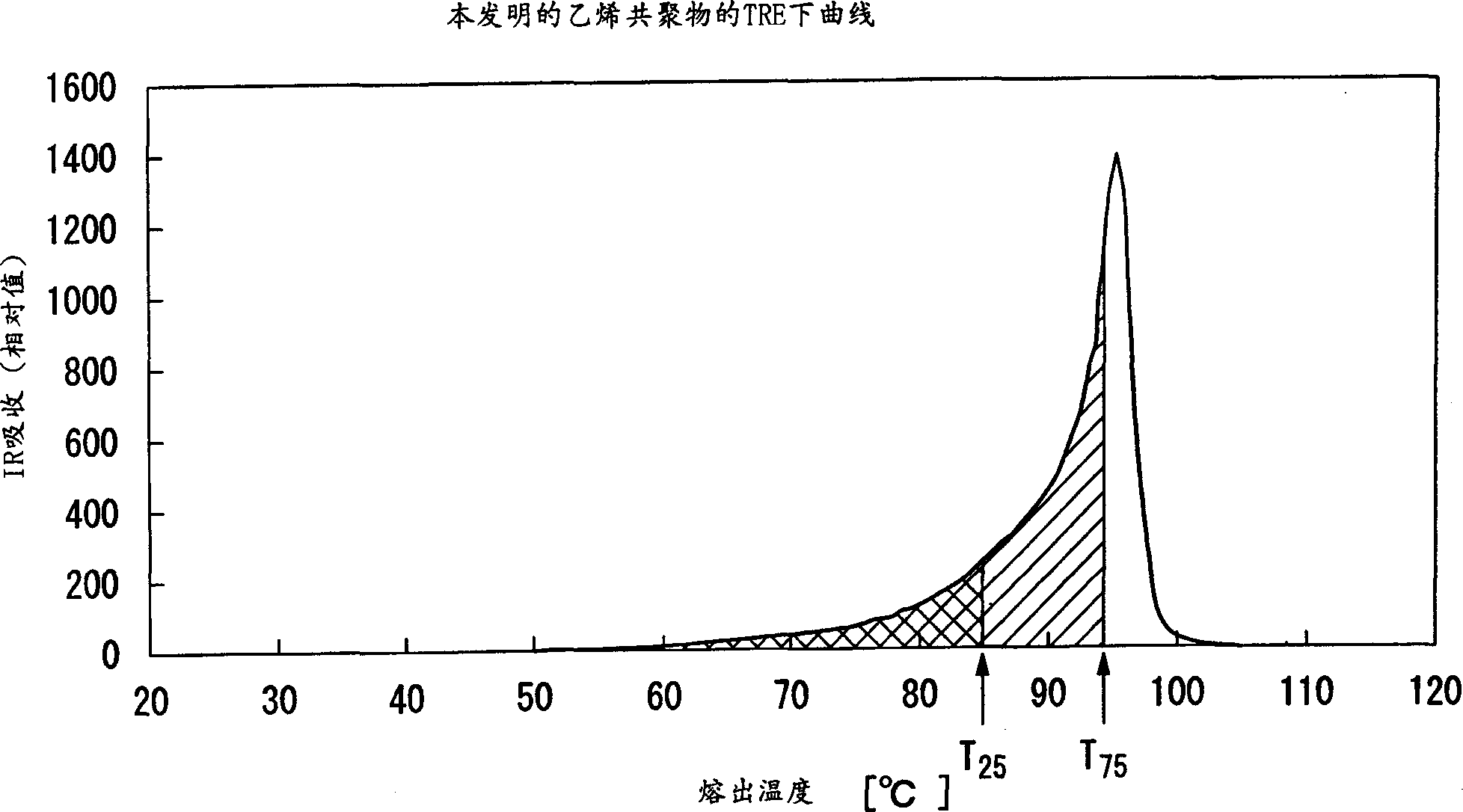

Ethylene/alpha-alefin copolymer, composition thereof, film thereof and uses of these

InactiveCN1305502AHigh mechanical strengthImprove heat resistancePlastic/resin/waxes insulatorsSynthetic resin layered productsElutionAlkene

Owner:JAPAN POLYOLEFINS CO LTD

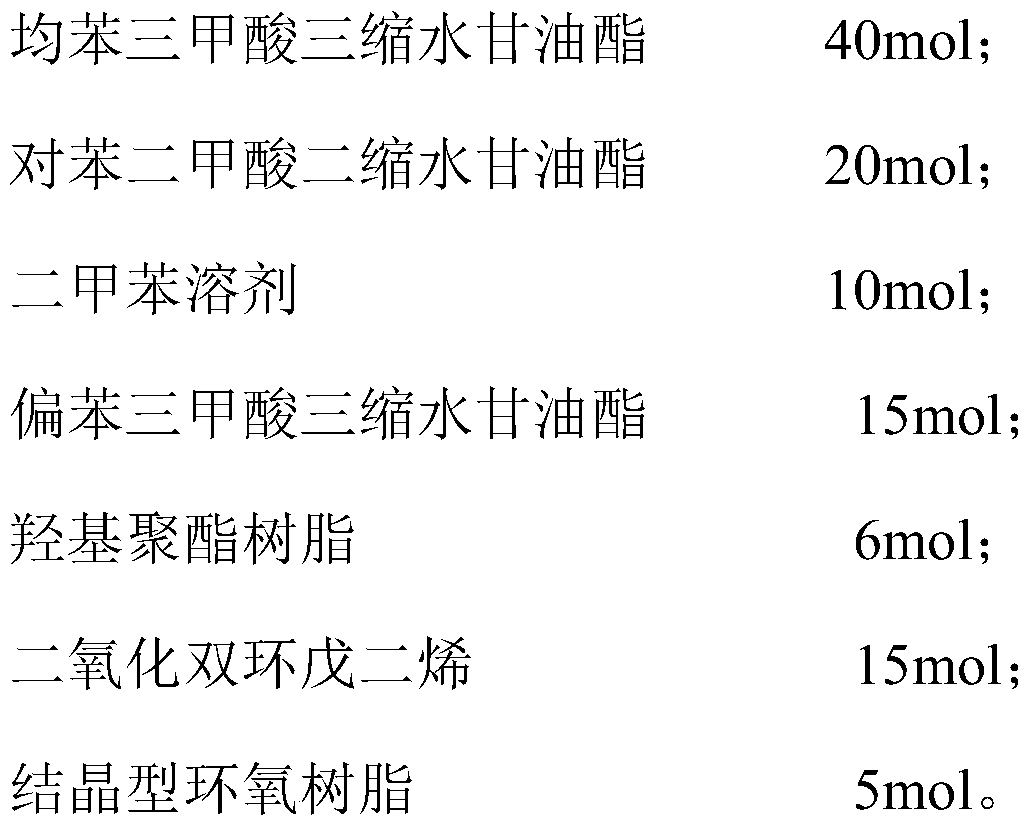

Compound curing agent used for polyester-type powder paint and production method and application thereof

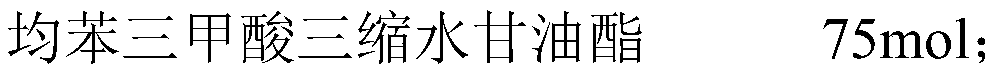

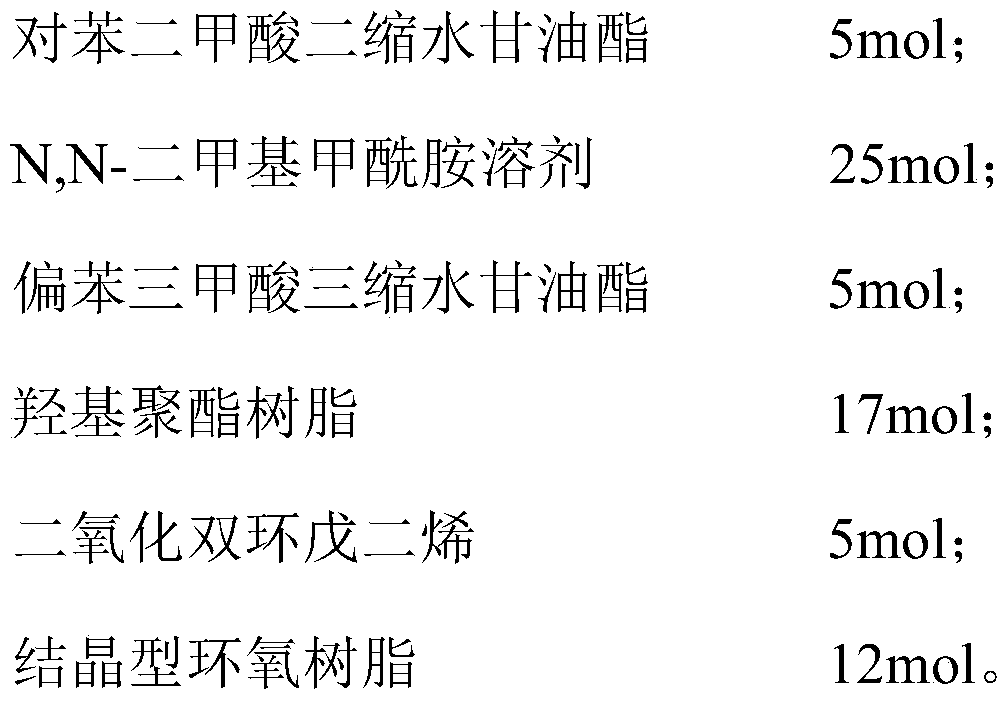

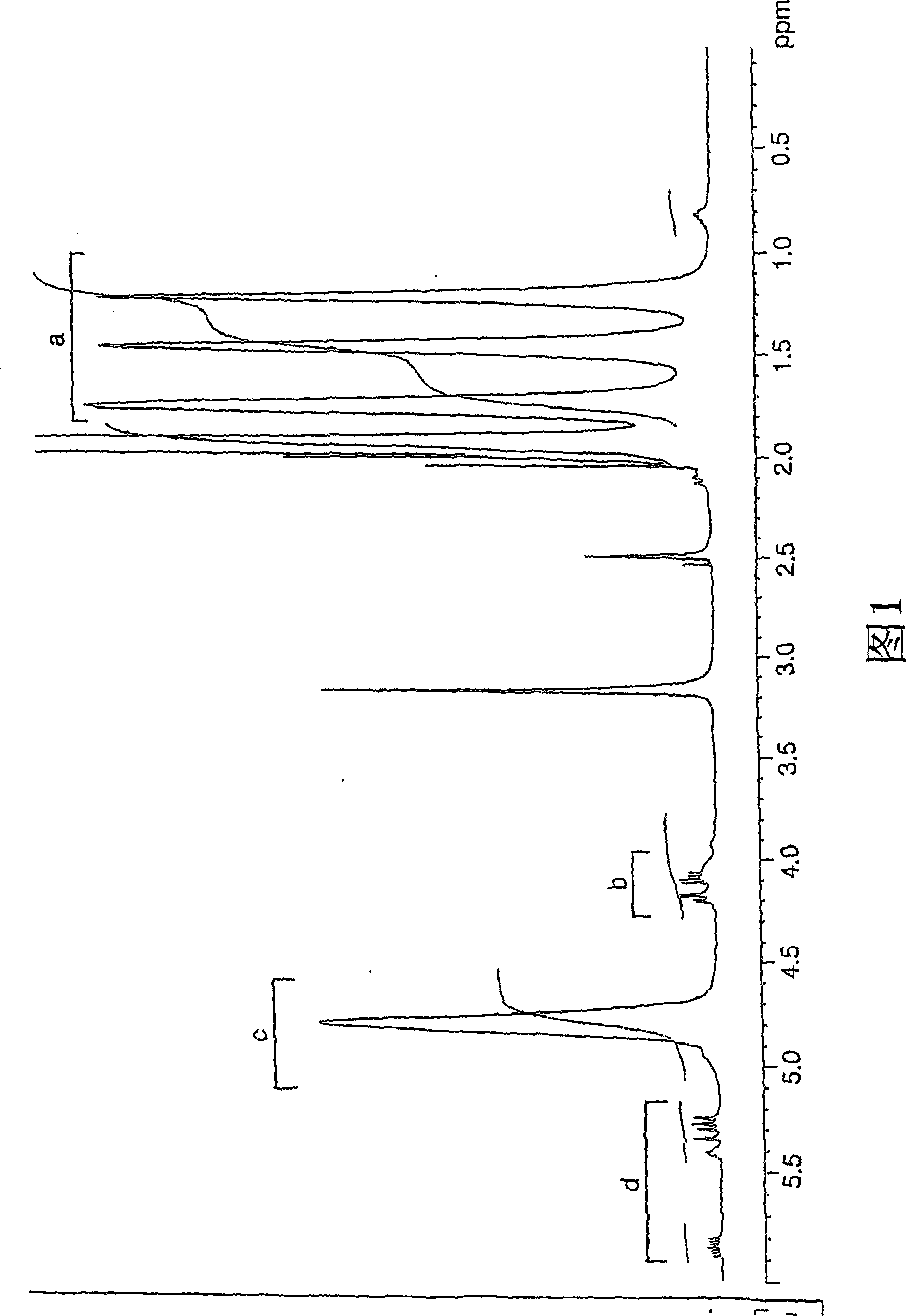

ActiveCN109852127AGood curing effectHigh epoxy equivalentPowdery paintsPolyester coatingsEpoxyTrimellitic acid

The invention belongs to the technical field of powder paint, particularly relates to a compound curing agent used for polyester-type powder paint, and further discloses a production method and application of the compound curing agent used for the polyester-type powder paint. The compound curing agent used for the polyester-type powder paint is mainly produced by using trimesic acid,tris(2,3-epoxypropy)ester and diglycidyl terephthalate as main raw materials and selectively adding 1,2,4-benzenetricarboxylic acid,tris(2,3-epoxypropy)ester, hydroxy polyester resin, bicyclopentadiene dioxide and / or crystalline epoxy resin for mixing reaction. The compound curing agent used for the polyester-type powder paint has a good curing effect, the mechanical performance of a produced coating is stable,and meanwhile, the coating has good boiling-resistant performance; and when the compound curing agent used for the polyester-type powder paint and polyester resin are cured, the performance of a product of the compound curing agent used for the polyester-type powder paint and the polyester resin totally reaches curing effects of current TGIC and HAA curing agents, and the compound curing agent used for the polyester-type powder paint and an existing TGIC or HAA product can be mixed for use, so that the comprehensive performance is more excellent.

Owner:安徽泰达新材料股份有限公司

Resin composition and multilayer structure body using the same

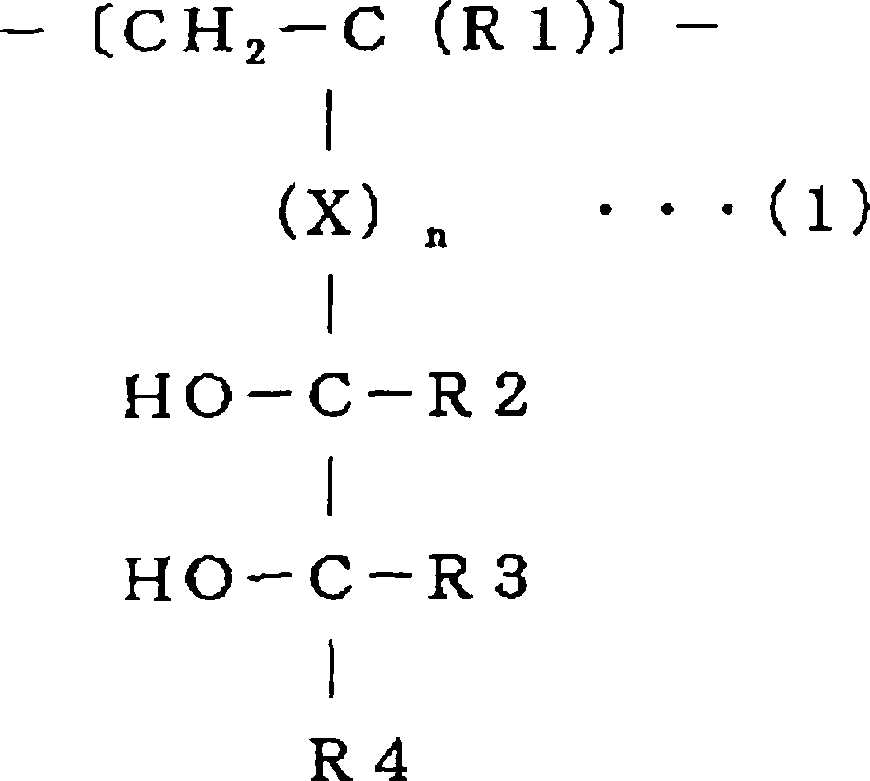

InactiveCN101432355AExcellent pinhole resistanceExcellent retort resistanceSynthetic resin layered productsDomestic containersPolyamideEther

A resin composition that excels in high-temperature retort resistance and gas barrier and further excels in pinhole prevention after retort; and a multilayer structure making use of the same. There is provided a resin composition comprising ethylene / vinyl alcohol copolymer (A) and polyamide resin (B), characterized in that the ethylene / vinyl alcohol copolymer (A) is an ethylene / vinyl alcohol copolymer containing the following structural unit (1), preferably one obtained by copolymerization of 3,4-diacetoxy-1-butene, a vinyl ester monomer and ethylene and saponifying the resultant copolymer. Further, there is provided a multilayer structure having a layer comprising the above resin composition. (1) wherein X is any bonding chain excluding ether bonds; each of R1 to R4 independently is an arbitrary substituent; and n is 0 or 1.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

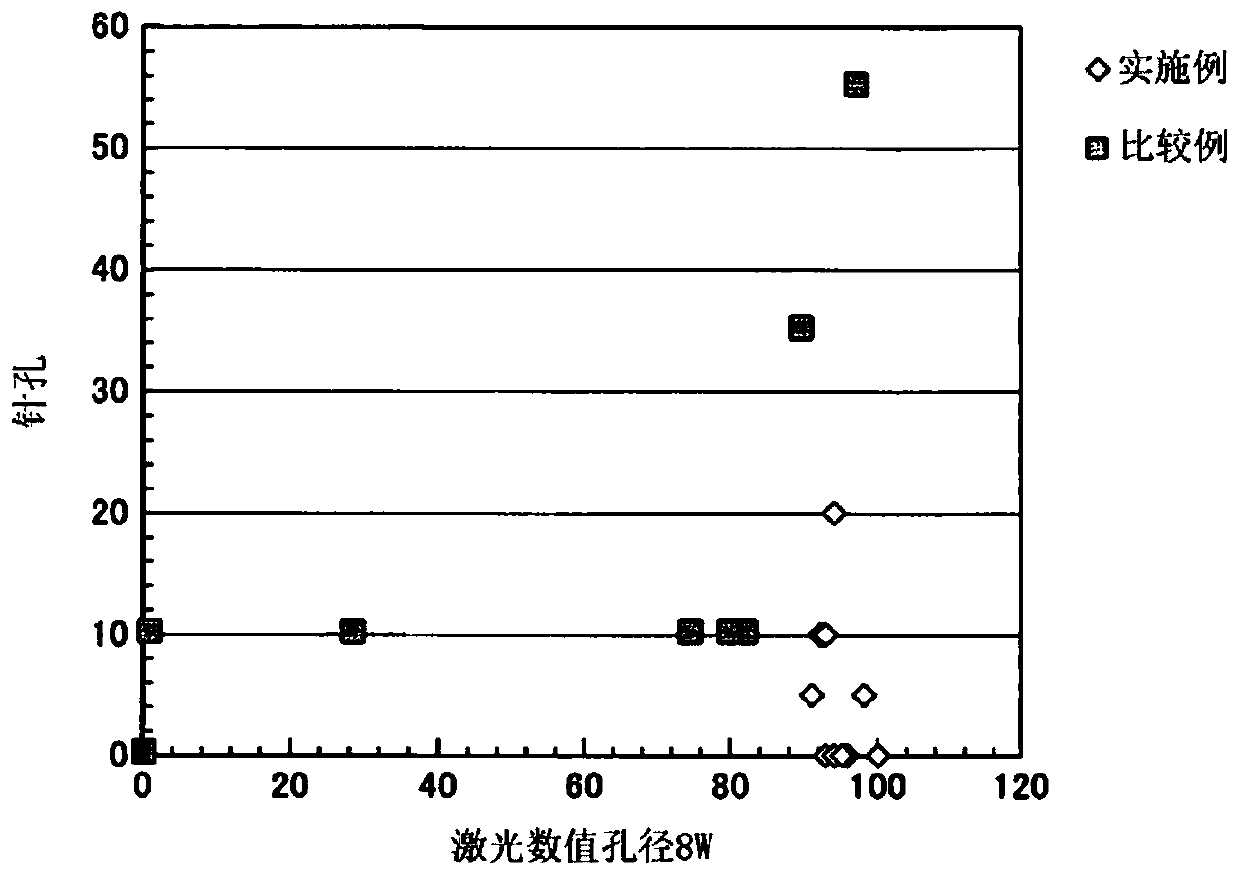

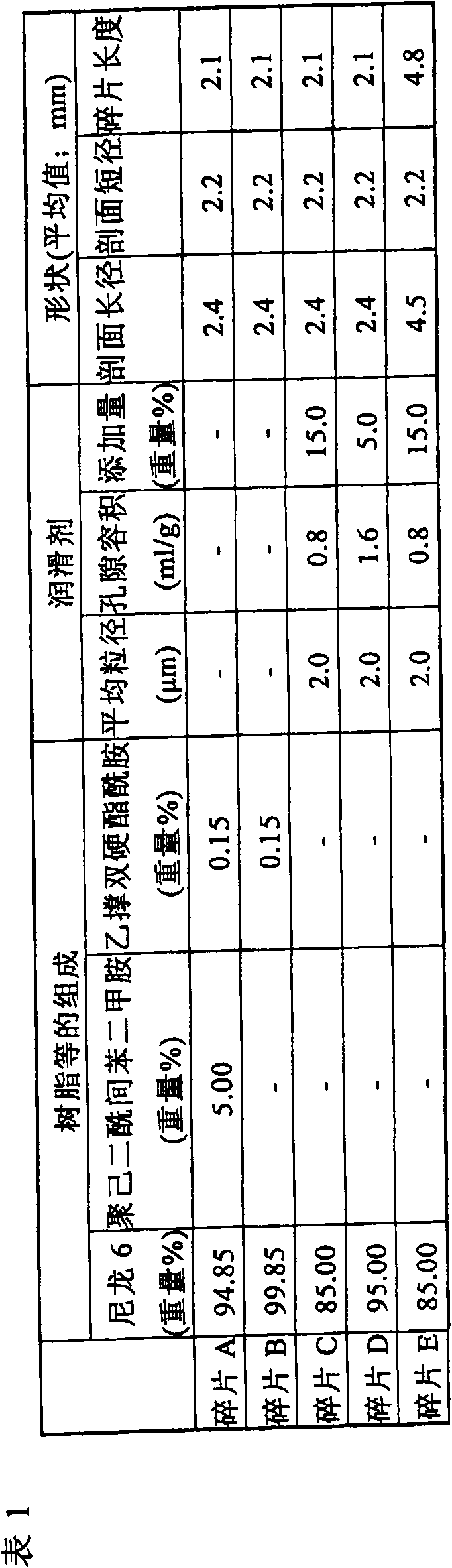

Polyamide Resin Film Roll, and Production Method Therefor

ActiveUS20070259164A1High yieldExcellent pinhole resistanceFlexible coversWrappersPolyamideRefractive index

A polyamide based resin film roll is provided. The polyamide based resin film roll comprising: a first sample cutout portion within 2 m from the winding end of film; and a final cutout portion within 2 m from the winding start of film, wherein when a sample cutout portion is set up in approximately every 100 m from the first sample cutout portion, in all samples cut out from each of the cutout portions, mechanical properties such as boiling water shrinkage percentage and refraction index in the thickness direction are adjusted within a given range of variation width.

Owner:TOYOBO CO LTD

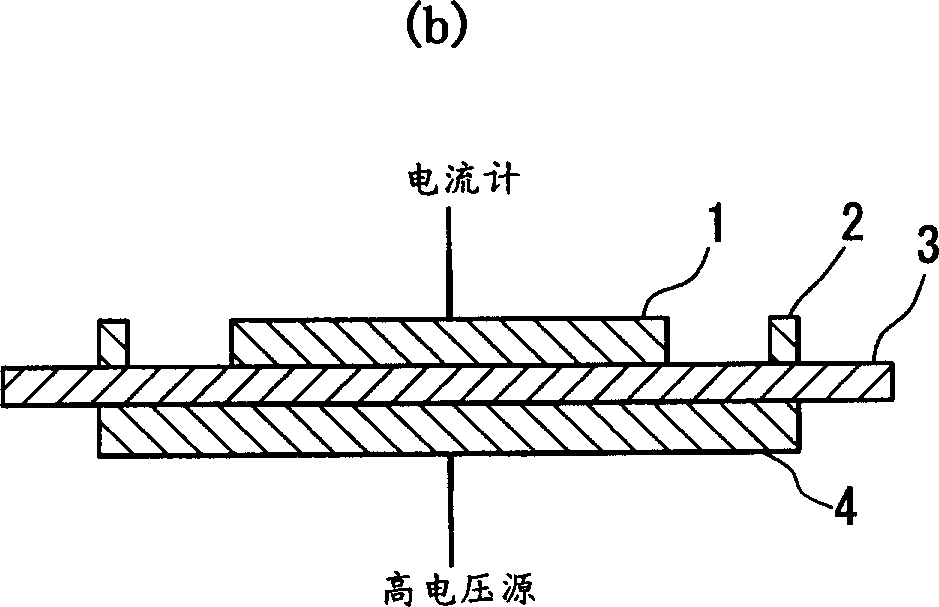

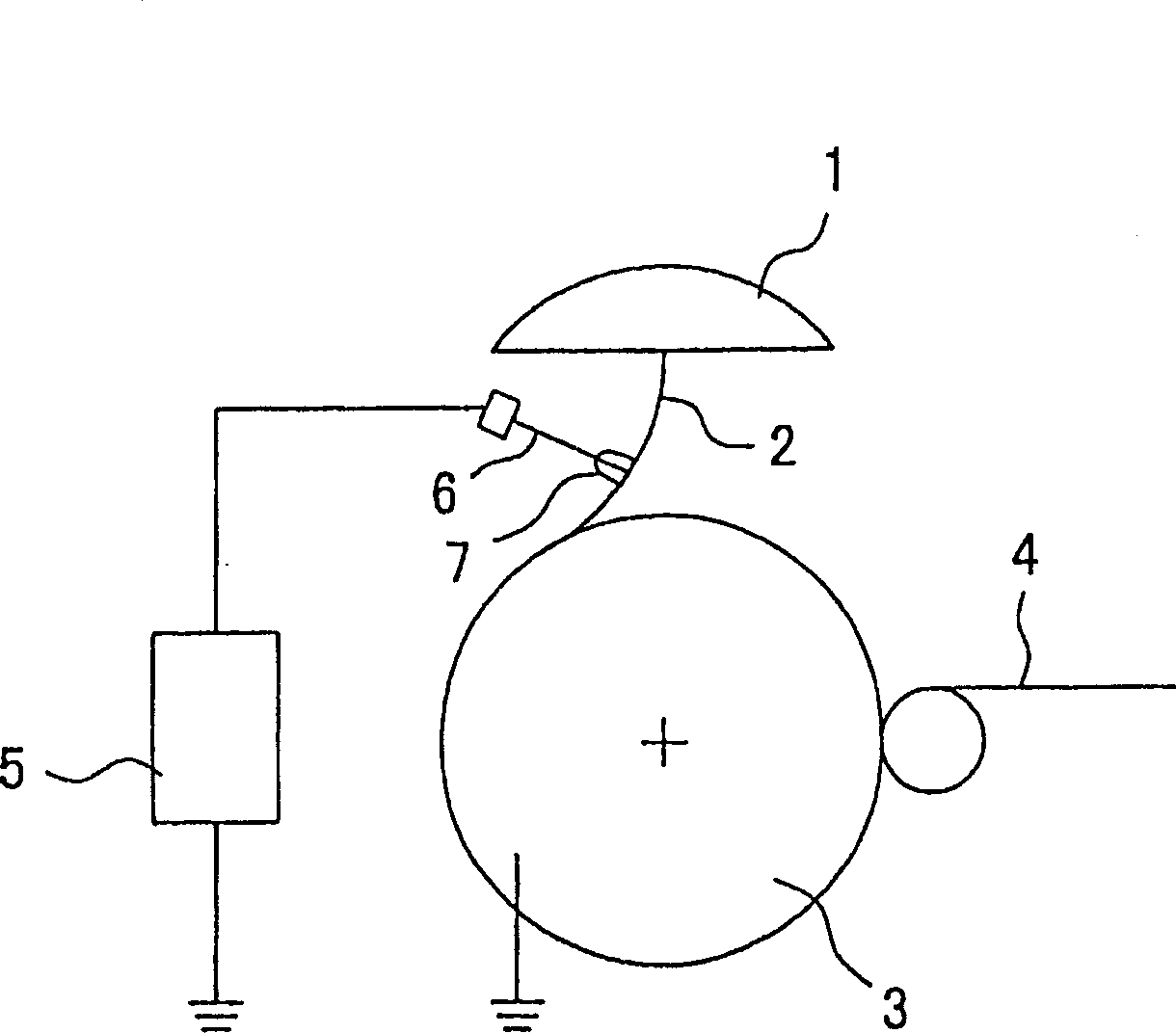

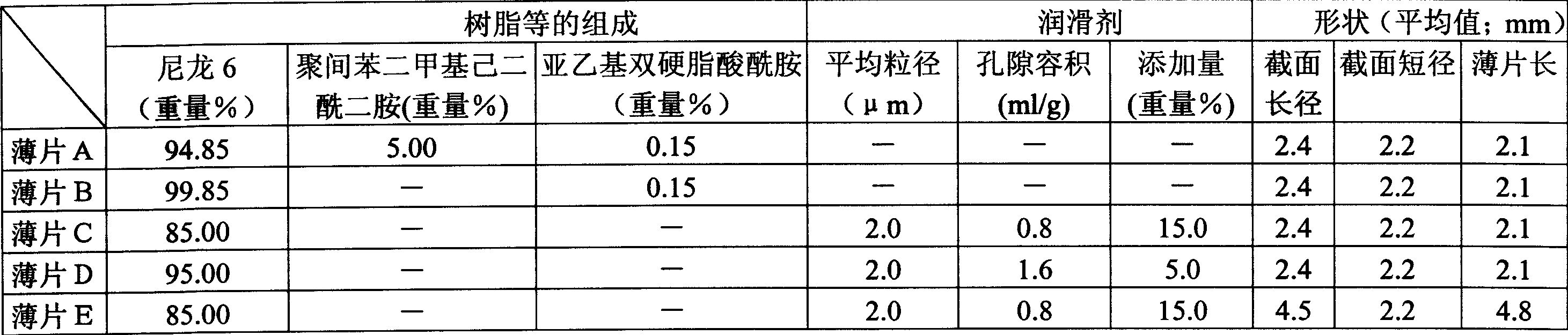

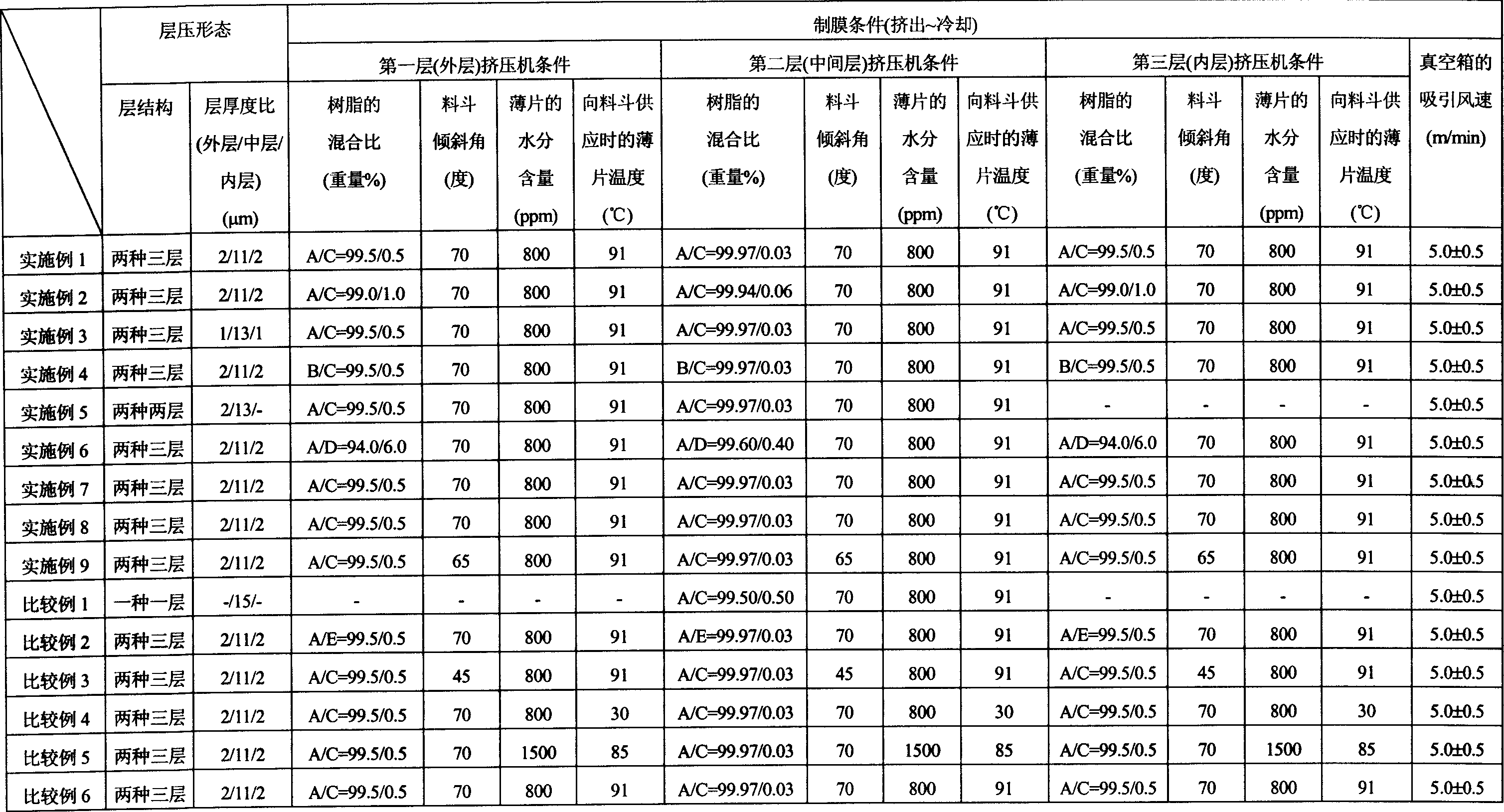

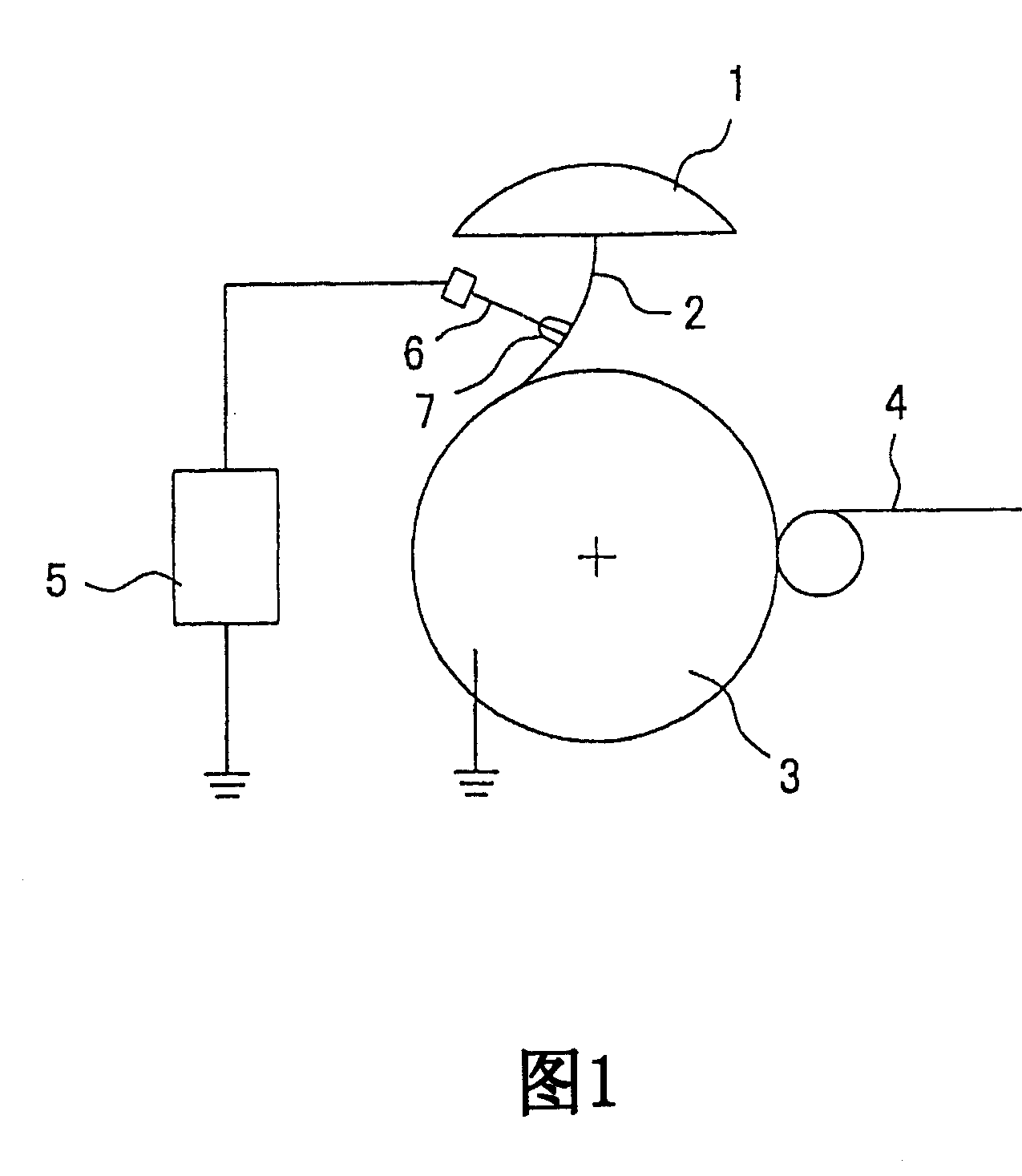

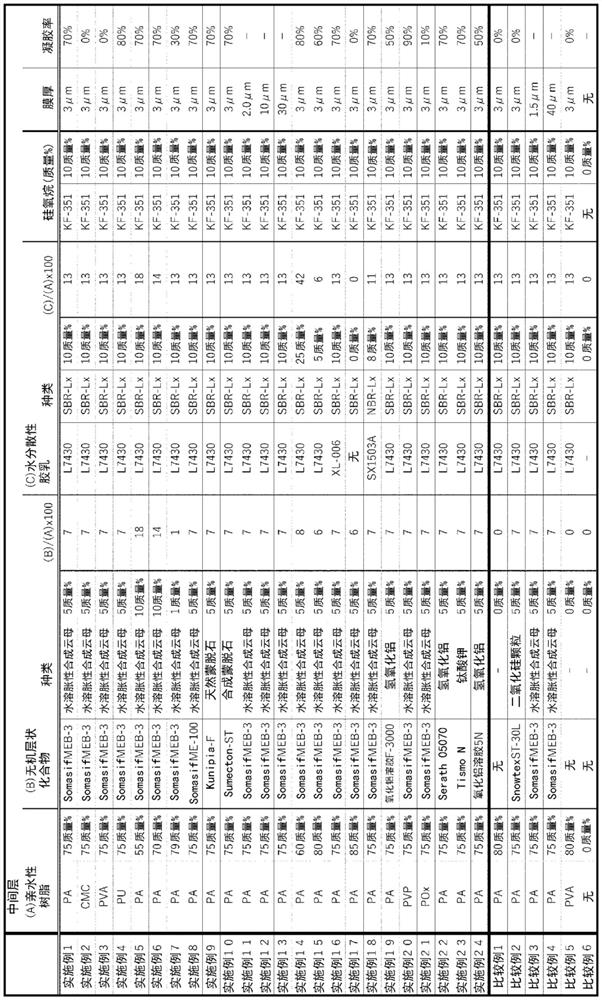

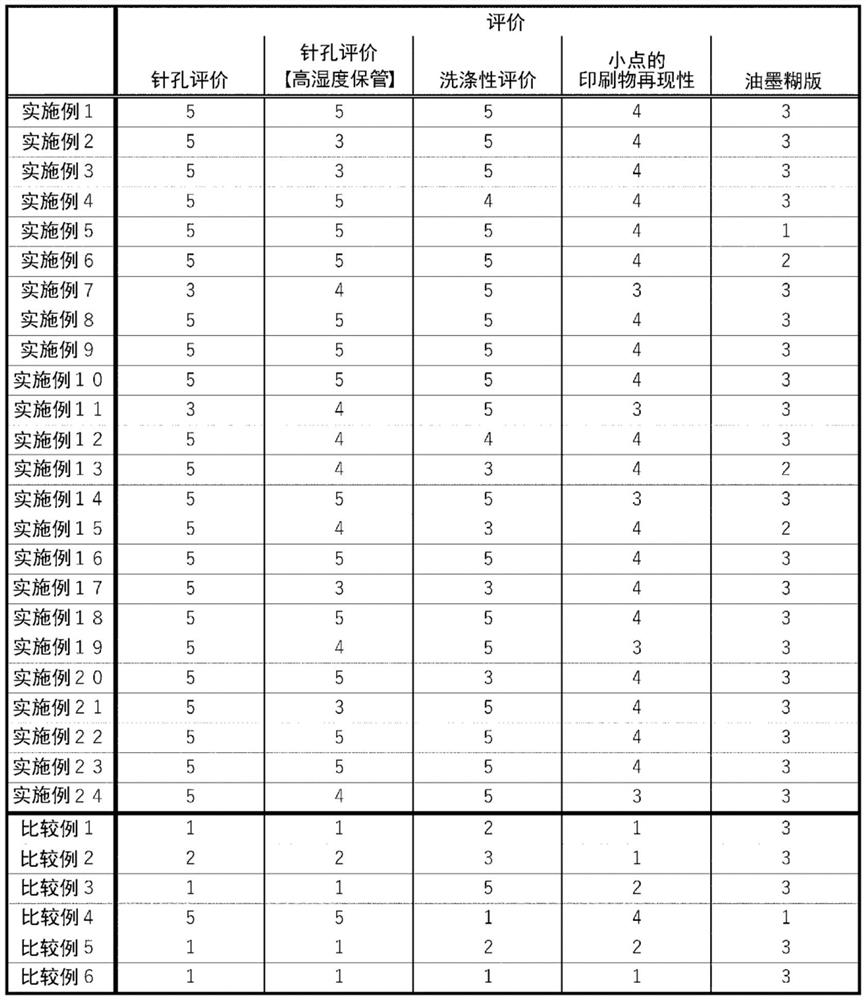

Method for manufacturing polyamide resin laminated film roll

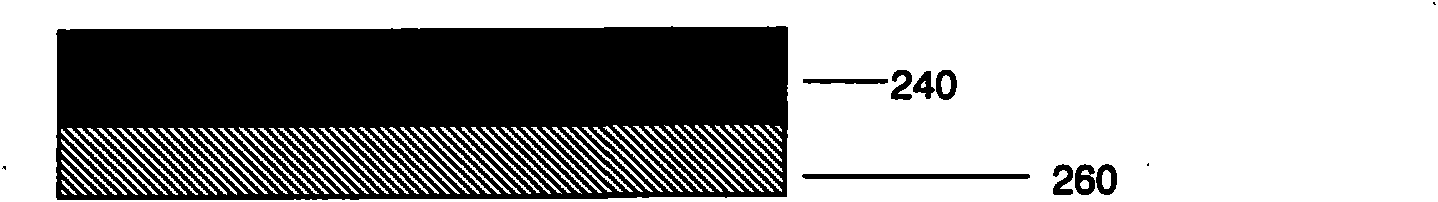

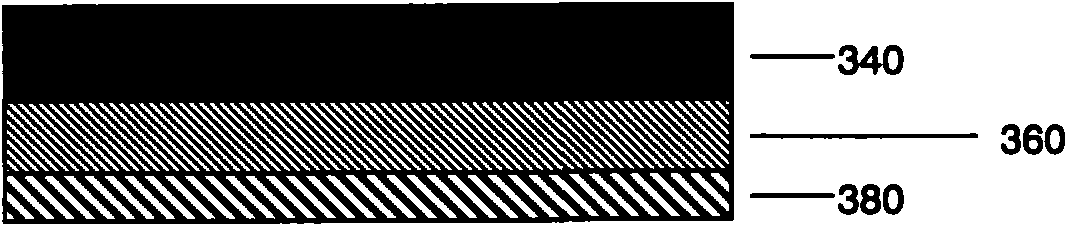

The present invention provides a method for producing a polyamide-based resin laminated film roll, which can be smoothly laminated to a bag with a good yield even under high humidity, and is useful for efficiently producing a polyamide-based resin that can be biaxially oriented. A method of manufacturing a resin laminated film roll. The manufacturing method of the film roll of the present invention includes: melting and extruding the polyamide resin onto the surface of the moving cooling body to form a sheet and cooling to obtain a melt extrusion cooling process of an unstretched sheet; A biaxial stretching step of biaxial stretching in the longitudinal direction and a transverse direction; and a winding step of winding the biaxially stretched film into a roll. Moreover, in the melt extrusion cooling process, when the polyamide resin is melt extruded and cooled on the surface of the moving cooling body, flow is carried out between the electrode to which the DC high voltage is applied and the polyamide resin laminated sheet in the molten state. The corona discharge in the corona state gives the polyamide resin laminated sheet in the molten state enough charge to make it closely adhere to the moving cooling body.

Owner:TOYOBO CO LTD

Biaxially oriented polyester film and preparation thereof

A biaxially oriented polyester film of the present invention which comprises a polyester resin prepared by polymerizing a glycol component mainly comprising 1,3-propanediol and an acid component mainly comprising terephthalic acid or dimethyl terephthalate, said polyester film having an unit impact absorption energy of 1.0 or more, can be advantageously used for packaging.

Owner:爱思开迈克沃有限公司

Food packaging bag material for storing dehydrated vegetables

PendingCN111607155AAntioxidantImprove antioxidant capacityFlexible coversWrappersLinear low-density polyethyleneNano al2o3

The invention discloses a food packaging bag material for storing dehydrated vegetables. Thefood packaging bag material comprises the following components in parts by weight: 25-45 parts oflinear lowdensity polyethylene, 20 to 35 parts of a composite filler, 10 to 16 parts of polyoxyethylene, 6-10 parts of white latex, 3-5 parts of tributyl citrate, 3-5 parts of montmorillonite, 3-5 parts of maleic anhydride grafted compatilizer, 5 to 10 parts of nanometer aluminium oxide, 4 to 6 parts of mica powder, 3-5 parts of epoxy resin, 2-6 parts of zinc stearate, 2-8 parts of tri epoxidized soybean oil, 1-6 parts of white carbon black, 2-6 parts of hydroxypropyl acrylate, 4-6 parts of an oxidant, 2-4 parts of boron nitride, 1-2 parts of polyvinylpyrrolidone, 3-5 parts of a flexibilizer, 1-3 partsof asbestos powder, 0.5-3.5 parts of tungsten carbide, 0.5-2.5 parts of cerium oxide and 3-5 parts of anthocyanin. The invention relates to the technical field of food packaging bags, and particularlyprovides thefood packaging bag material for storing dehydrated vegetables.

Owner:徐州东创重工机械有限公司

Surface-treated copper foil and copper-clad laminate using same

ActiveCN110475909AGood etchingExcellent laser processabilityPrinted circuit manufactureElectroforming processesFine lineCopper foil

Provided is a surface-treated copper foil which has fine line-to-line spaces or line widths, has excellent etching properties, laser processability, and thin foil handling properties, and has less pinholes and a higher tensile strength. The surface-treated copper foil has a tensile strength of 400-700 MPa, a tensile strength of 300 MPa or more after heating at 220 degrees centigrade for 2 hours, afoil thickness of 7 [mu]m or less, a developed area ratio (Sdr) of one side thereof being 25-120%, and the number of pinholes with a diameter of at least 30 [mu]m being 20 / m2 or less.

Owner:FURUKAWA ELECTRIC CO LTD

Waterproof high-temperature-resistant food packaging bag material

The invention discloses a waterproof high-temperature-resistant food packaging bag material, made from the following materials according to parts by weight: 80 parts of maleic anhydride grafted polypropylene, 20 parts of foamed polystyrene, 10 parts of vermiculite powder, 1-5 parts of anti-stress whitening agent, 2-6 parts of 3-aminopropytriethoxysilane, 1-5 parts of glass fiber, 3-7 parts of propylene glycol monomethyl ether acetate, 1-3 parts of triphenyl phosphite, 2-6 parts of nano calcium carbonate, 1-5 parts of chlorinated paraffin, 3-7 parts of zinc stearate, 2-6 parts of hexatetramethylenetetramine, 1-5 parts of organosilicon microparticles, 4-8 parts of white latex, 1-3 parts of asbestos powder, and 1-6 parts of white carbon black. The waterproof high-temperature-resistant food packaging bag material provided herein has reasonable component formulation, has the advantages of good water resistance, high temperature resistance, impact resistance, pinhole resistance and the like, and is widely applicable.

Owner:明光市永德包装有限公司

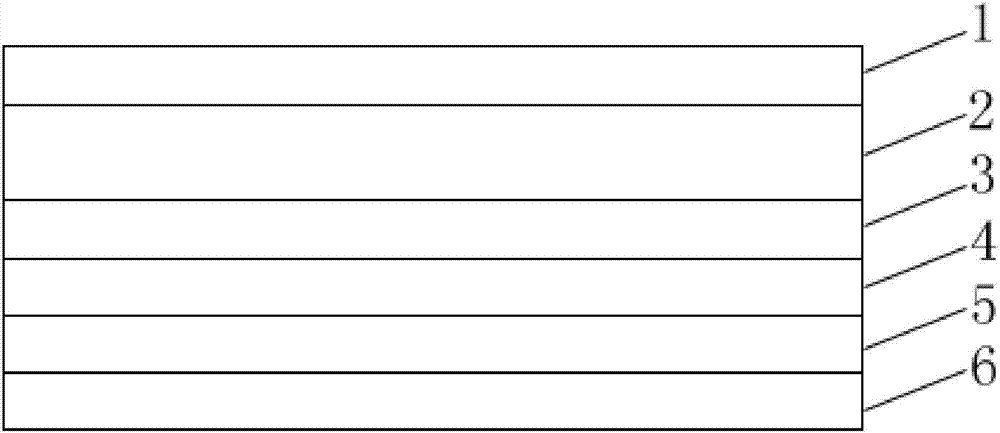

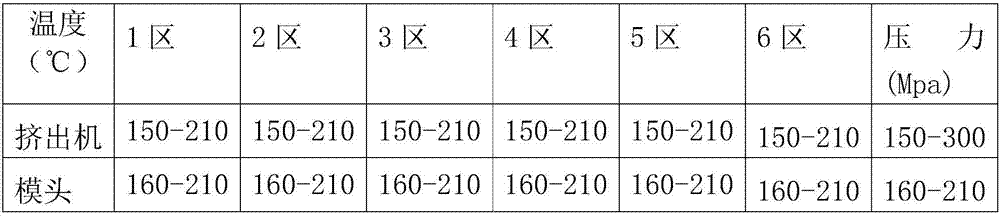

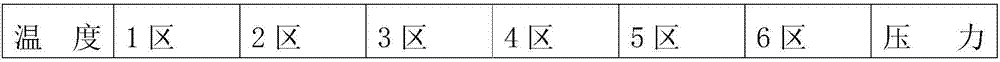

Paper-plastic-aluminum package material used for boiling-resistant sterilization technology as well as preparation method thereof

InactiveCN107351482AImprove bonding fastnessImprove heat resistanceFlexible coversWrappersCardboardPolymer science

The invention relates to a paper-plastic-aluminum package material used for boiling-resistant sterilization technology as well as a preparation method thereof. The packaging material has a six-layer composite structure, the package material comprises a polymer coating layer with high peeling intensity, a cardboard layer, a composite layer, an aluminium foil layer, a bonding layer and a polymer film heat-sealing layer with good heat resistance in order from outer to inner, and the polymer coating is a mixed coating layer of medium-density polyethylene resin and caking property polyethylene resin. The preparation method comprises the followings steps: the composite layer is extruded between the cardboard layer and the aluminium foil layer through an extruder; the bonding layer is extruded between the aluminium foil layer and the polymer film heat-sealing layer through the extruder; the polymer coating layer is extruded at the outside of the cardboard layer, so that an integral structure is formed by bonding. The method enhances the combination fastness of an external layer material and the cardboard, avoids disconnection of four angles after moulding of the paper-plastic-aluminum package material, the paper-plastic-aluminum package material has advantages of heat resistance and pin hole resistance, and the preparation cost is reduced.

Owner:SHANGHAI JIELONG YONGFA PRINTING & PACKING

Polyamide multi layer film

ActiveCN1849212AExcellent retort resistanceExcellent high temperature cooking resistanceSynthetic resin layered productsLaminationPolymer sciencePolyamide

The present invention provides a polyamide-based multilayer film with excellent retort resistance and high-temperature retort resistance and a manufacturing method thereof. The polyamide-based multilayer film contains at least one layer each of an ethylene-vinyl acetate copolymer saponified product layer and a polyamide layer. .

Owner:GUNZE LTD

Novel PET (polyethylene terephthalate) strap with multi-layer structure

InactiveCN105882089AImprove wear resistanceImprove folding resistanceSynthetic resin layered productsDomestic articlesPolyesterPolyethylene terephthalate

The invention discloses a novel PET (polyethylene terephthalate) strap with a multi-layer structure. The novel PET strap comprises a PET polyester layer, a PETN (pentaerythritol tetranitrate) polyester layer, a PET modified layer and a PET film sequentially from outside to inside. The novel PET strap has excellent wear resistance, folding resistance, pinhole resistance, tear resistance and the like; the heat shrinkage is quite low and is only 1.25% after the strap is placed at the temperature lower than 120 DEG C for 15 min; the PET strap has good antistatic property. The novel PET strap with the structure has very high toughness, high wear resistance and good antistatic property, can still guarantee work in a complex environment and is particularly suitable for packaging products such as electronic products, high precision instruments and the like.

Owner:铜陵永泰包装材料科技有限公司

Polyamide resin laminate roll and process for producing the same

ActiveCN1876516AImprove efficiencyExcellent pinhole resistanceFlexible coversWrappersSurface roughnessRefractive index

To provide a biaxially oriented polyamide resin laminate film roll that permits performing of smooth bag-making processing by laminating with high yield, enabling efficiently obtaining of a packaged matter free from S-shaped curling. There is provided a polyamide resin laminate film roll wherein in the event of disposing of a first specimen cutout portion within 2 m from film winding end and disposing of a final specimen cutout portion within 2 m from film winding startand further in the event of disposing specimen cutout portions every about 100 meters from the first specimen cutout portion, with respect to all the specimens cut out from the cutout portions, properties, such as boiling water shrinkage factor, surface roughness and refractive index along thickness direction, are regulated so as to fall within a fluctuation band of given range.

Owner:TOYOBO CO LTD

A novel three-proofing fabric

InactiveCN109532161AIncreased optionalityGood printing adhesionSynthetic resin layered productsClothingsPolyesterTear resistance

The invention provides a novel three-proofing fabric and belongs to the technical field of textiles. The fabric includes an oil-proof nanometer base cloth on which an elastic layer is braided. A waterproof layer is on the elastic layer, a PVDC layer is on the waterproof layer, and a polyester film is on the PVDC layer. Through arrangement of the polyester film and the PVDC layer, the fabric has extremely good transparency, abrasion resistance, folding resistance, pinhole resistance and tear resistance, enhanced barrier properties, reduced infiltration of water, oil and stains, and prolonged service lifetime and the three-proofing effect is further improved through cooperation with the oil-proof nanometer base cloth and the waterproof layer. In addition, the fabric is made of non-toxic materials and is safe and highly environmentally friendly.

Owner:海宁市华成纺织有限公司

High-performance food packaging bag material for storing dehydrated vegetables

The invention discloses a high-performance food packaging bag material for storing dehydrated vegetables. The high-performance food packaging bag material is prepared from, by weight, 60 parts of biaxial polypropylene, 25 parts of polyoxyethylene, 5 parts of 3-aminopropyl triethoxy silane, 4 parts of butyl acrylate, 3 parts of montmorillonite, 2 parts of boron nitride, 3-7 parts of nano alumina, 1-5 parts of mica powder, 1-5 parts of polyacrylamide, 2-6 parts of zinc stearate, 1-5 parts of aluminium oxide, 2-8 parts of epoxidized soybean oil, 6-10 parts of white latex, 2-6 parts of hydroxypropyl methacrylate, 0.5-3.5 parts of tungsten carbide and 0.5-2.5 parts of cerium oxide. The high-performance food packaging bag material is specifically researched for the dehydrated vegetables, the packaging bag has the advantages of being good in heat sealing performance, waterproof, resistant to high temperature and impact, resistant to porosity and the like, the preservation time of the dehydrated vegetables is long, and the high-performance food packaging bag material is suitable for wide-range popularization.

Owner:明光市永德包装有限公司

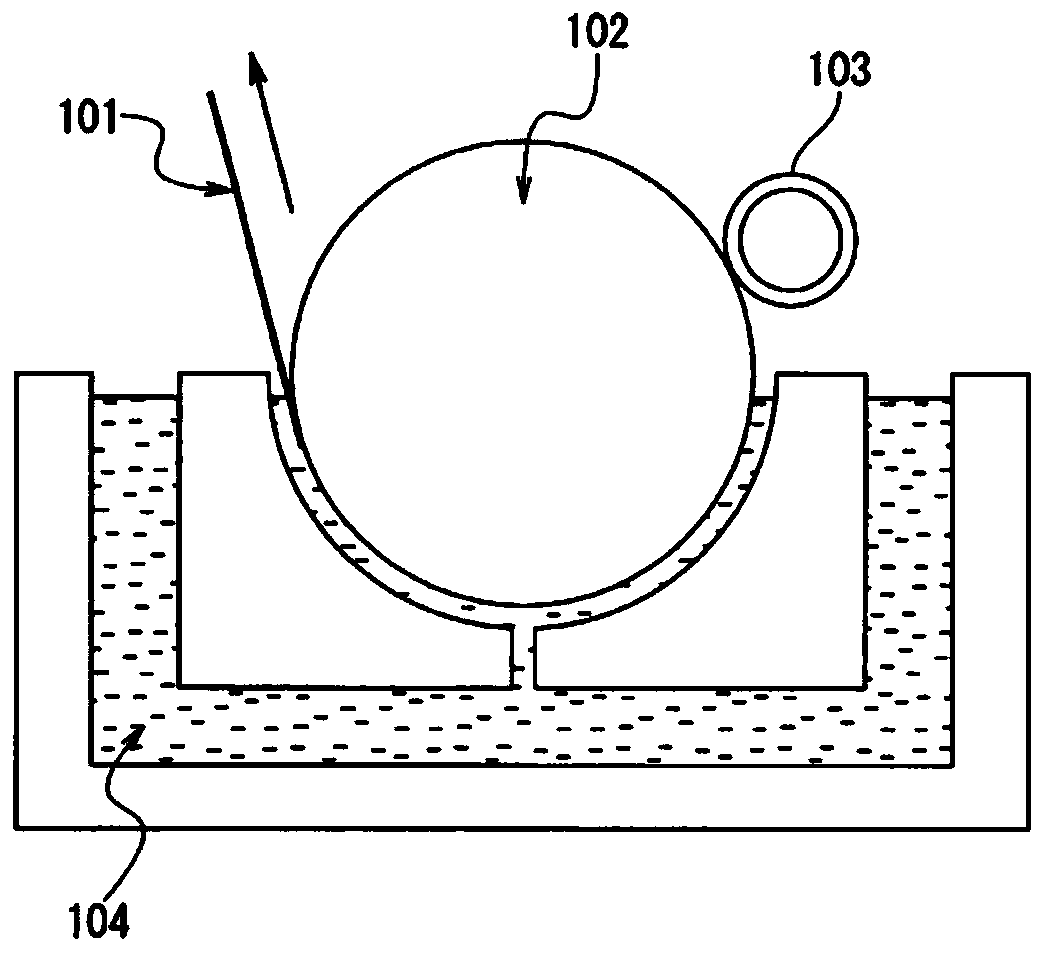

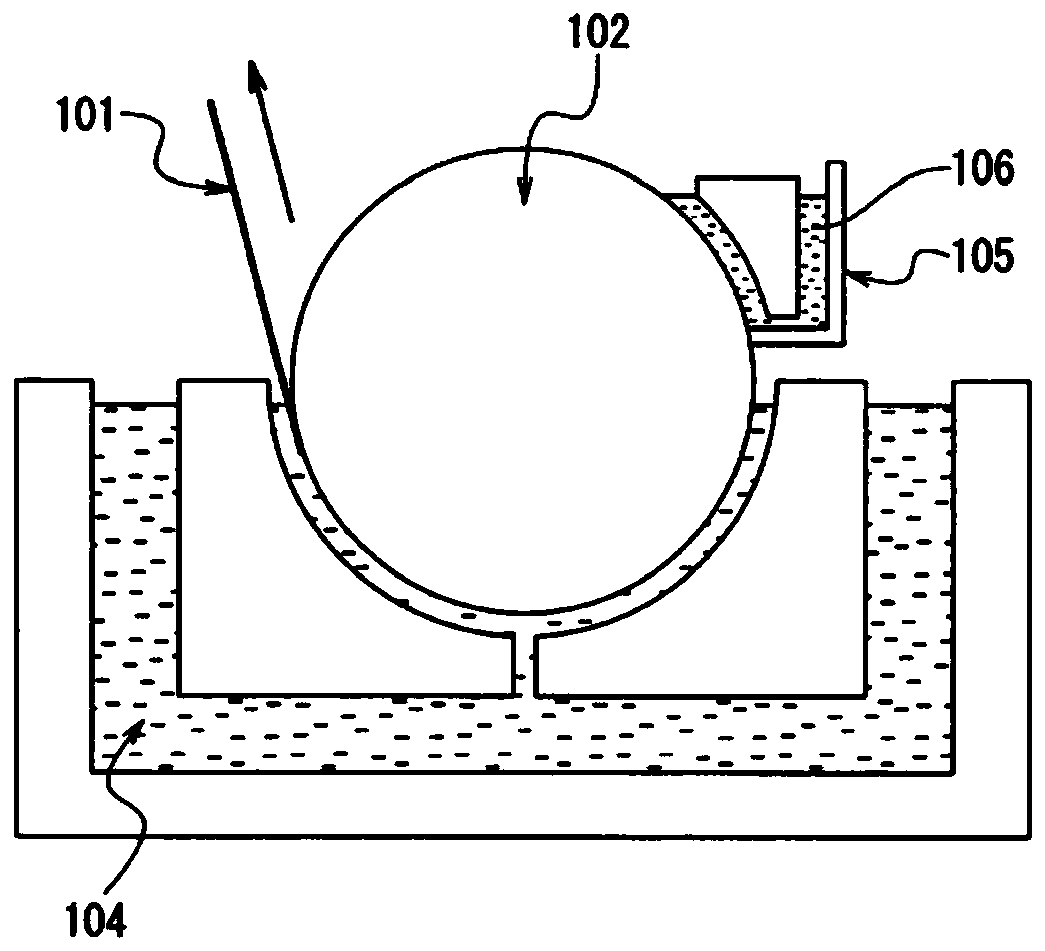

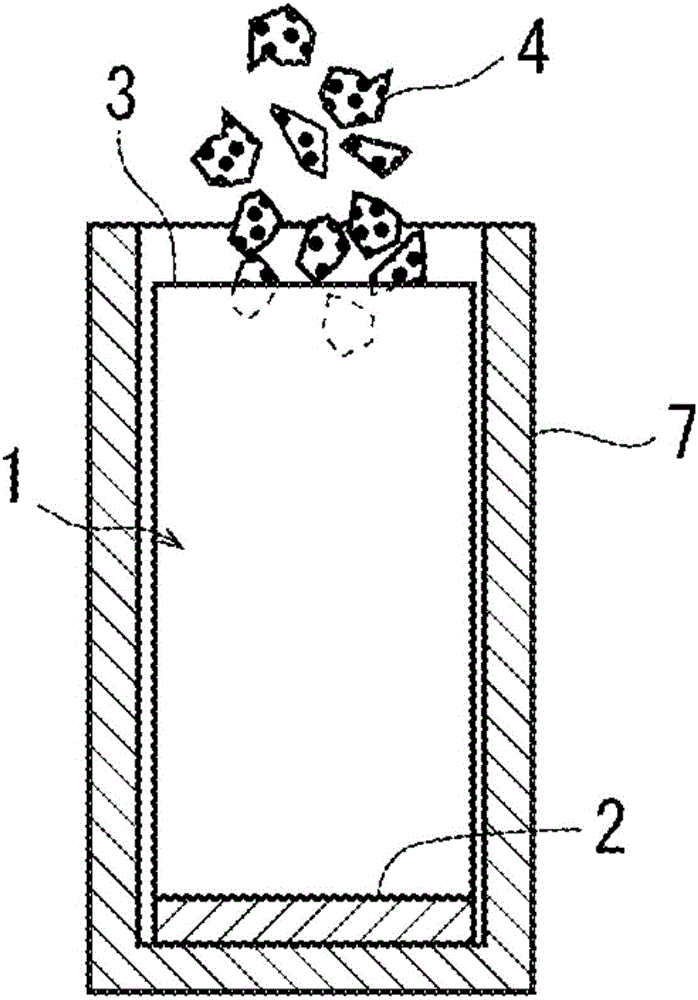

Polysilicon package

ActiveCN106660694AAvoid loss of tightnessReduced puncture strengthPackaging foodstuffsDamagable goods packagingGround contactPolycrystalline silicon

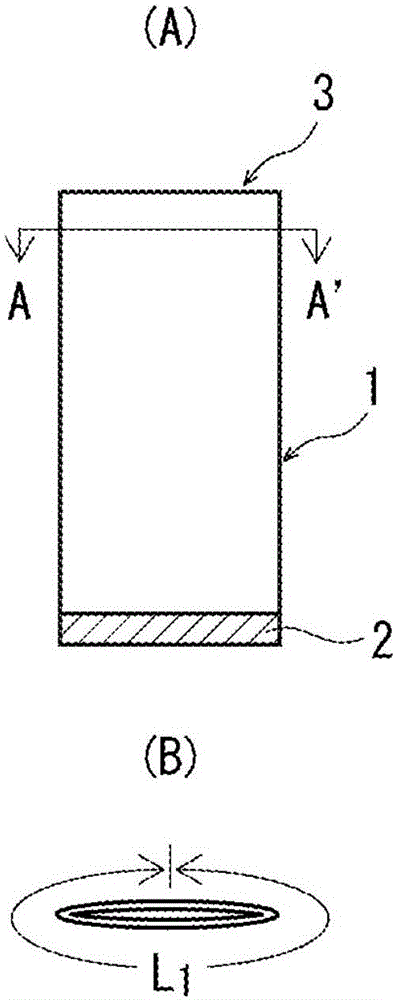

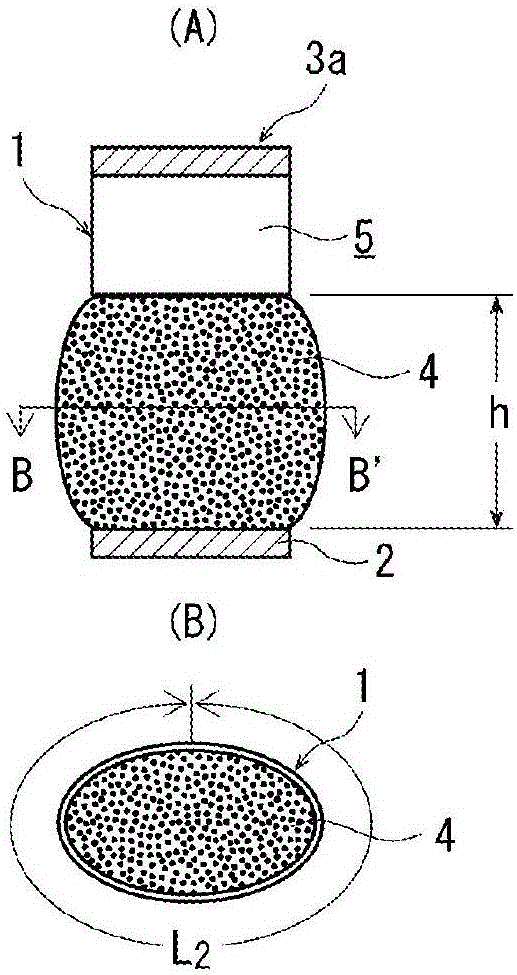

The present invention addresses the problem of providing a package in which a bag formed from a polyethylene resin film having a thin thickness, more specifically, a thickness of 300 [mu]m or less, is filled with polysilicon chunks (Si chunks), wherein damage to the bag caused by the Si chunks is effectively prevented. The present invention provides a polysilicon package in which a bag (1) formed from a polyethylene resin film having an average thickness of 300 [mu]m or less is filled with Si chunks (4), said polysilicon package characterized in that the bag (1) has, at the bottom thereof, a section (2) joined by heat sealing, and the Si chunks (4) fill the bag (1) such that the maximum expansion of the bag (1) when the bag (1) is maintained in an upright state with the bottom thereof serving as a ground contact surface is 5% or less.

Owner:TOKUYAMA CORP

Co-extrusion hot-pressing functional film for disposable sugarcane paper pulp container

InactiveCN107877960AImprove deep drawing performanceImprove temperature resistanceSynthetic resin layered productsEngineeringCo extrusion

The invention discloses a co-extrusion hot-pressing functional film for a disposable sugarcane paper pulp container. The functional film comprises a polyethylene resin layer with a three-layer structure, a polypropylene resin layer with a three-layer structure, and a multilayer co-extrusion film with a structure having at least three layers. The functional film has excellent deep drawability, paper pulp adhesive property, waterproof performance, oil resistant performance, and temperature resistant performance, and also has excellent transparency, puncture resistant performance, impact resistant performance, gas barrier property, tensile strength, and heatproof performance. All functions of the functional film all meet the industrial production standards. The produced co-extrusion hot-pressing functional film has excellent adhesive force and acupuncture resistant performance, and oil leakage is prevented.

Owner:JIANGMEN PENGJIANG HUALONG PACKING MATERIAL

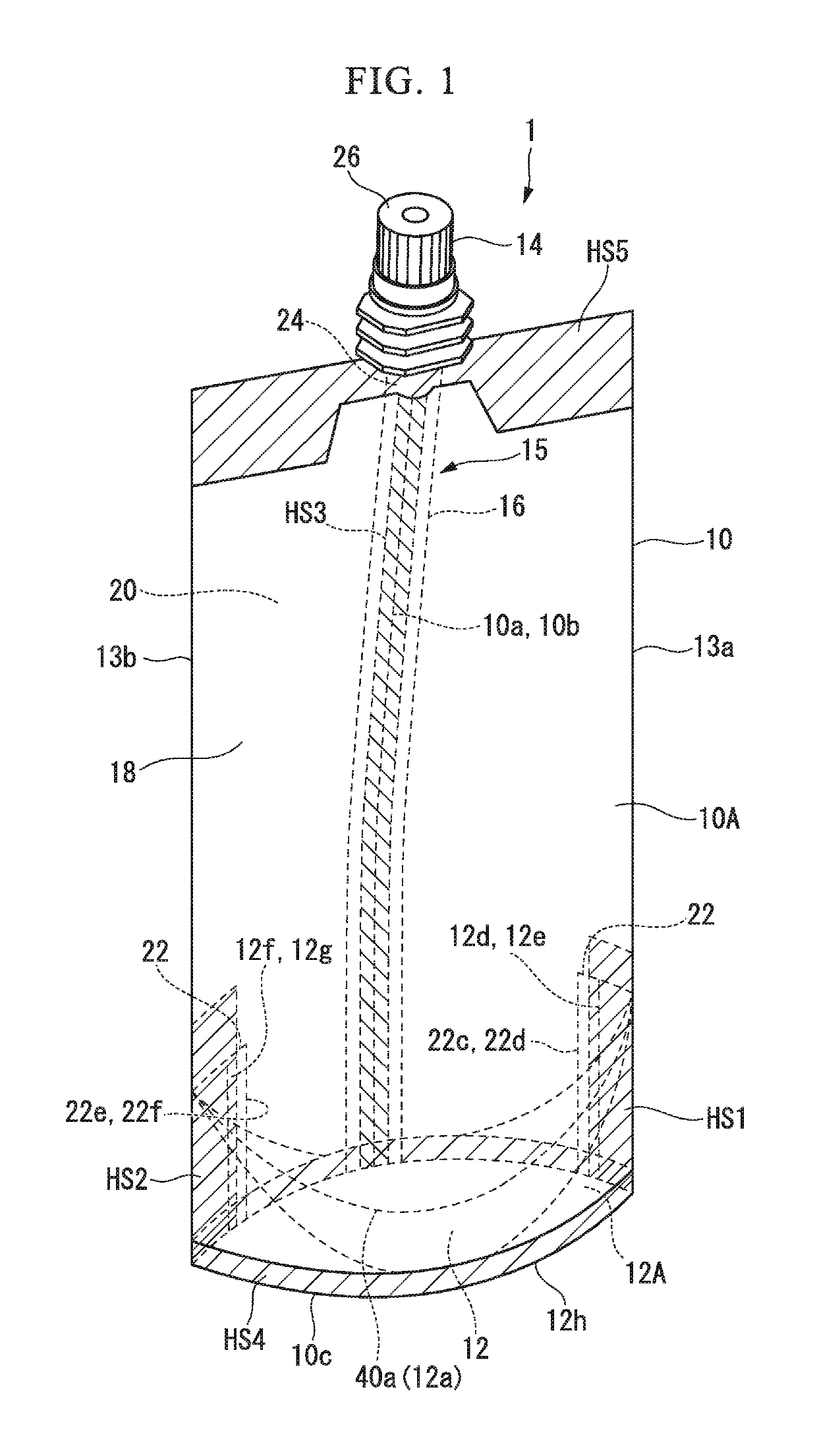

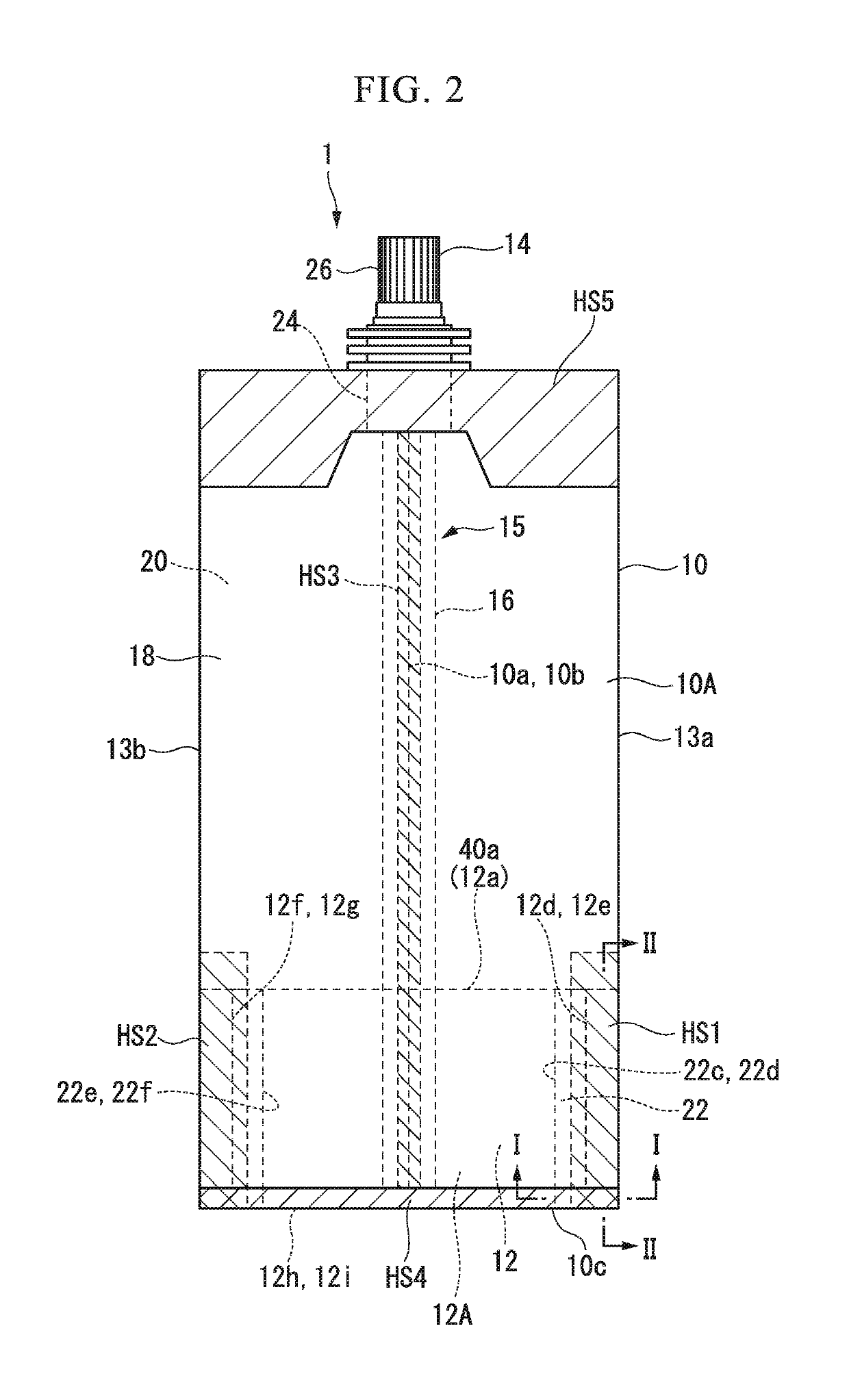

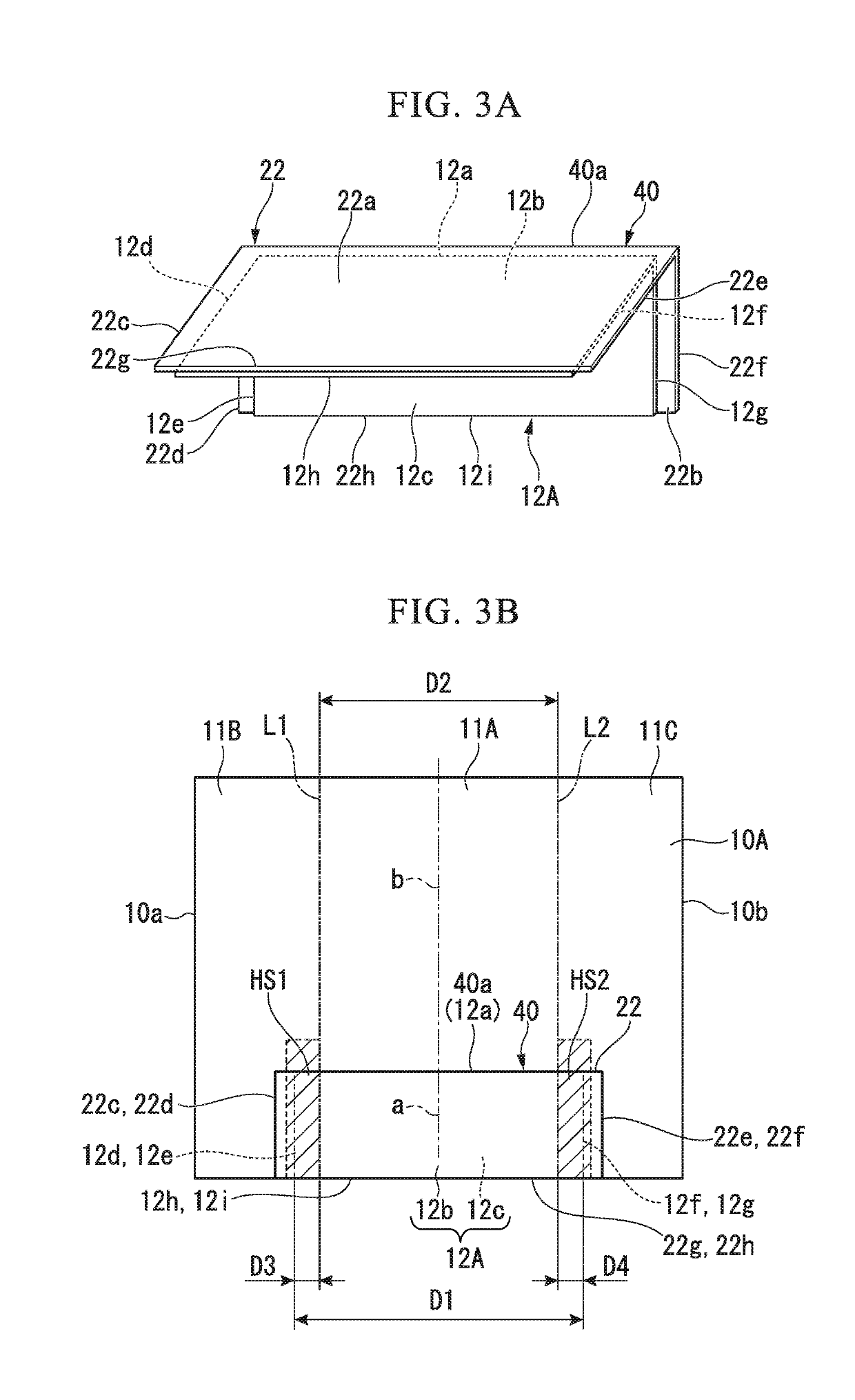

Self-standing bag and method for manufacturing the same

A self-standing bag (1) is provided, including: a body portion (10) formed of a body member (10A) in a tubular shape; and a bottom portion (12) formed of a half-folded bottom member (12A), in which each of side ends of the bottom member (12A) is bonded to an inner surface of a rear surface portion (20) of the body portion (10), a lower end of the bottom member (12A) is bonded to a lower end of the body portion (10) on an entire circumference of the body portion (10), on the body portion (10) side of the bottom member (12A), an adhesive film (22) for bonding a side end of the bottom member (12A) to the body portion (10) is laminated to cover the entire bottom member (12A), both side ends of the adhesive film (22) respectively protrude from both the side ends of the bottom member (12A) in a width direction, and bonding of the side end of the bottom member (12A) to the inner surface of the body portion (10) is achieved by the adhesive film (22).

Owner:HOSOKAWA YOKO CO LTD

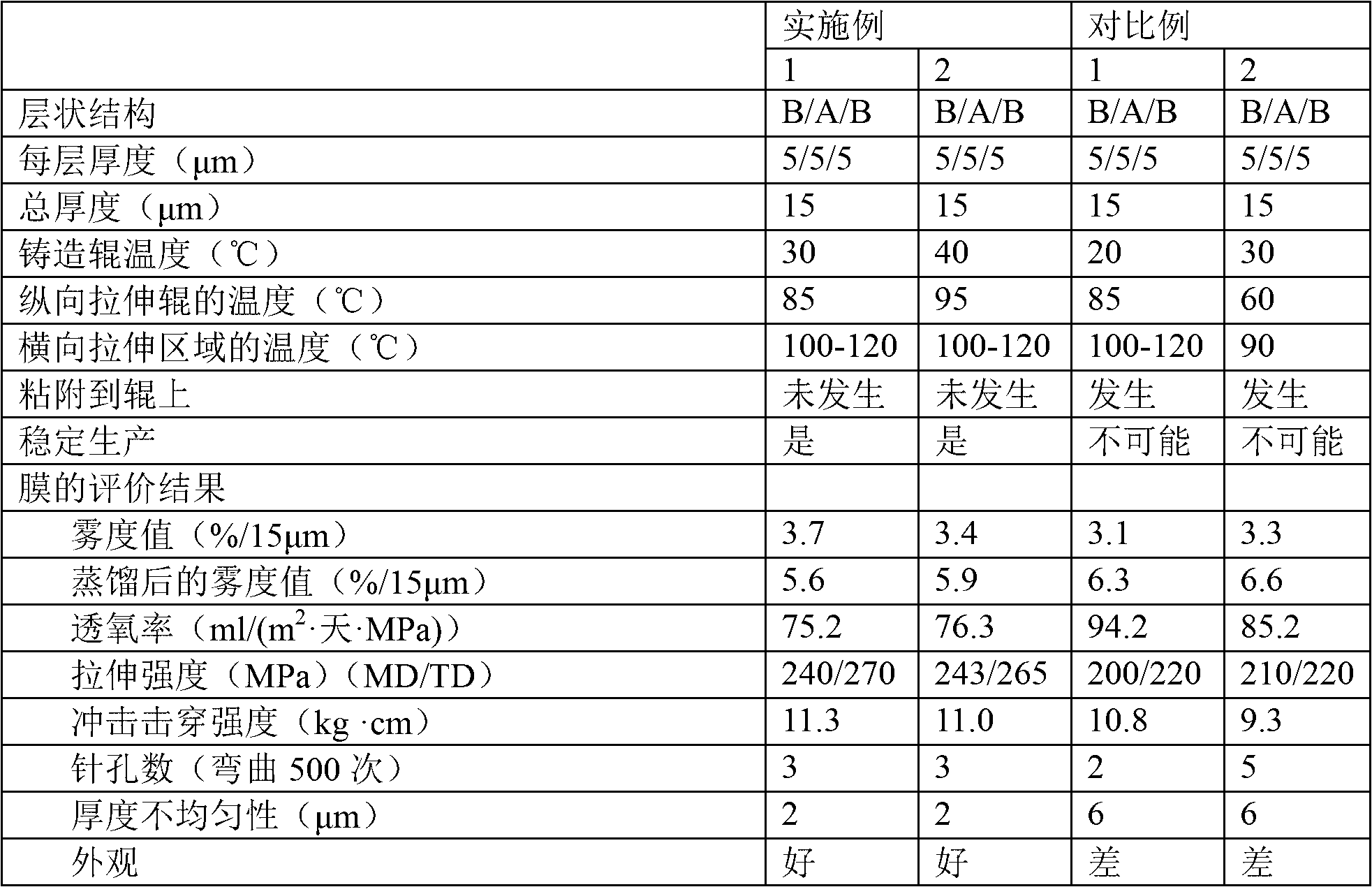

Biaxially stretched, multi-layereded polyamide film and production method thereof

ActiveCN101152764BHigh transparencyExcellent pinhole resistanceSynthetic resin layered productsPolyamideDicarboxylic acid

A method of producing a biaxially stretched, multi-layered polyamide film which includes a step of biaxially stretching a non-stretched laminate film composed of a layer mainly made of a polyamide resin and a layer mainly made of an aliphatic polyamide resin. The biaxial stretching is made by a roll / tenter successive biaxial stretching method. The polyamide resin is composed of a diamine constitutional unit mainly made of m-xylylenediamine units and a dicarboxylic acid constitutional unit mainly made of units derived from an alpha,omega-aliphatic dicarboxylic acid having 6 to 12 carbon atoms.The non-stretched laminate film is cooled by a cooling roll having a temperature within a limited range and then successively and biaxially stretched. With such a production method, the biaxially stretched, multi-layered polyamide film is excellent in the gas barrier properties, pinhole resistance, flexibility, and impact resistance.

Owner:MITSUBISHI GAS CHEM CO INC

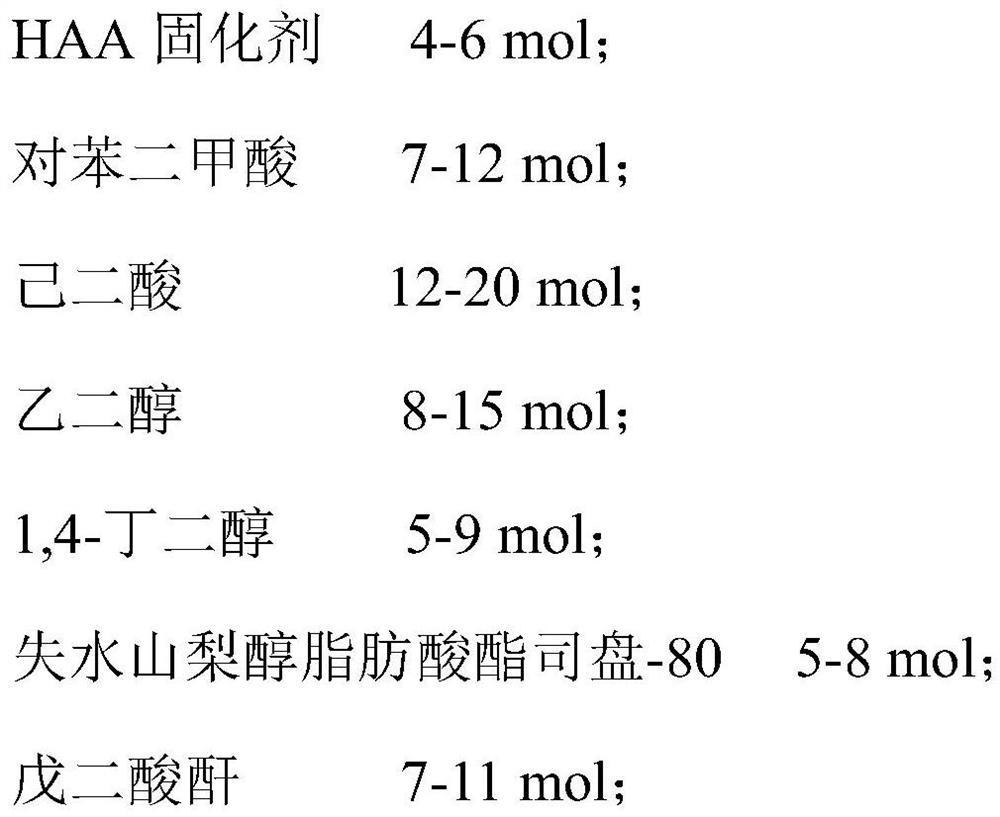

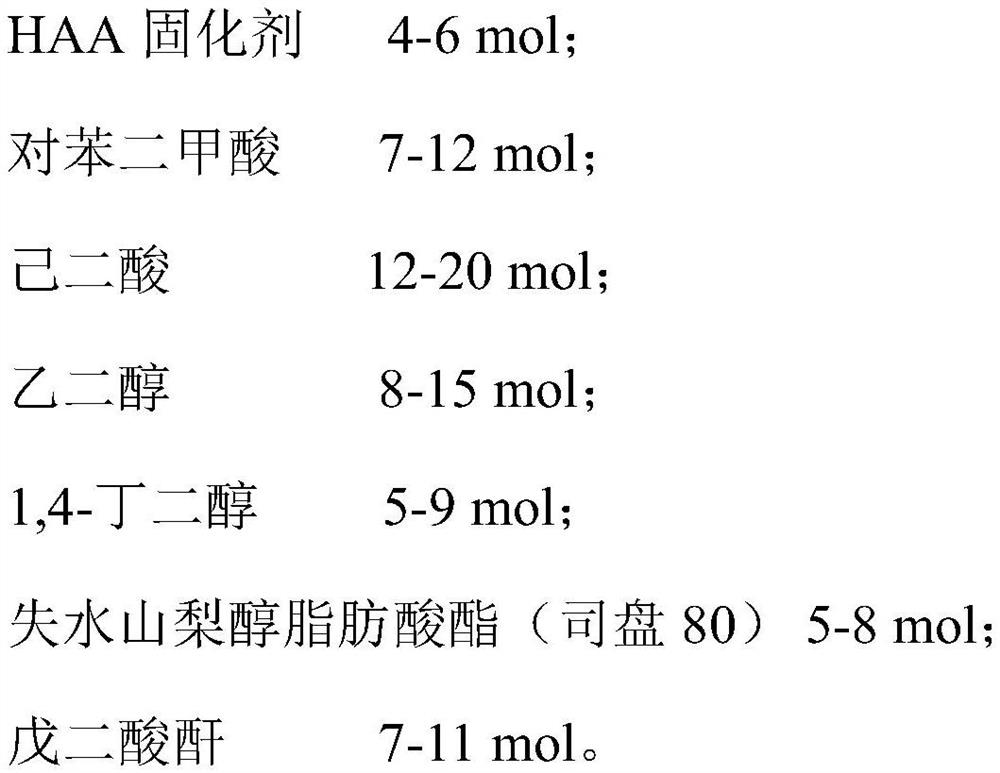

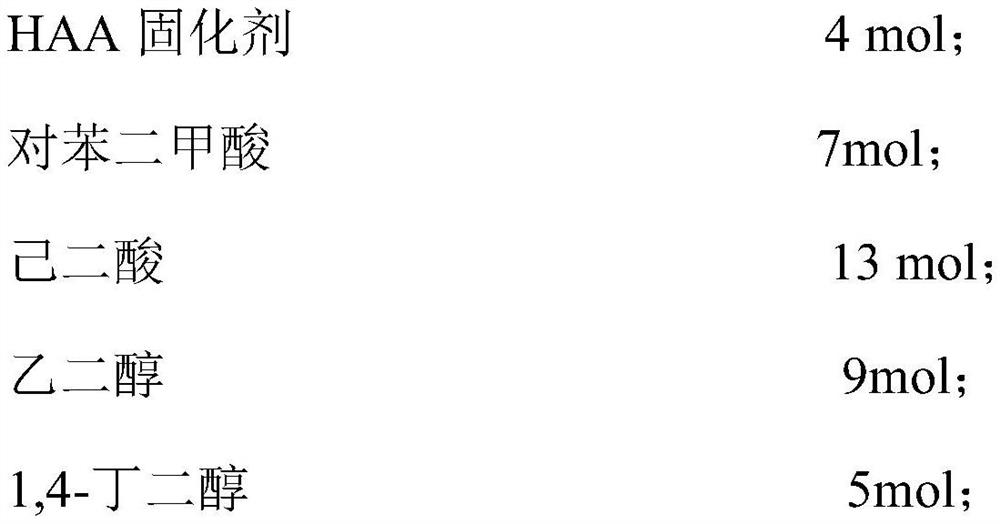

Low-cost, pinhole-resistant and high-hardness polyester resin for HAA system and preparation method of polyester resin

ActiveCN114181384AGuaranteed impact resistanceHigh hardnessPowdery paintsPolyester coatingsGlutaric anhydridePolymer science

The invention relates to the technical field of powder coatings, in particular to a low-cost, pinhole-resistant and high-hardness polyester resin for an HAA system and a preparation method of the polyester resin. An HAA curing agent, terephthalic acid, adipic acid, ethylene glycol, 1, 4-butanediol, sorbitan fatty acid ester span-80 and glutaric anhydride are mainly used as raw materials for polymerization; and finally, a coating film with relatively good leveling property can be obtained. The acid value of the polyester resin is 8-12 mgKOH / g and is far lower than that of common HAA curing polyester resin, so that the use amount of an HAA curing agent is greatly reduced during subsequent preparation of a powder coating, the pinhole resistance of a final coating film is outstanding, and the cost is extremely low; and moreover, rapid curing can be realized, energy is saved, and various properties are relatively good and meet the use requirements of the polyester resin powder coating.

Owner:HUANGSHAN HUIZHOU KANGJIA CHEM CO LTD

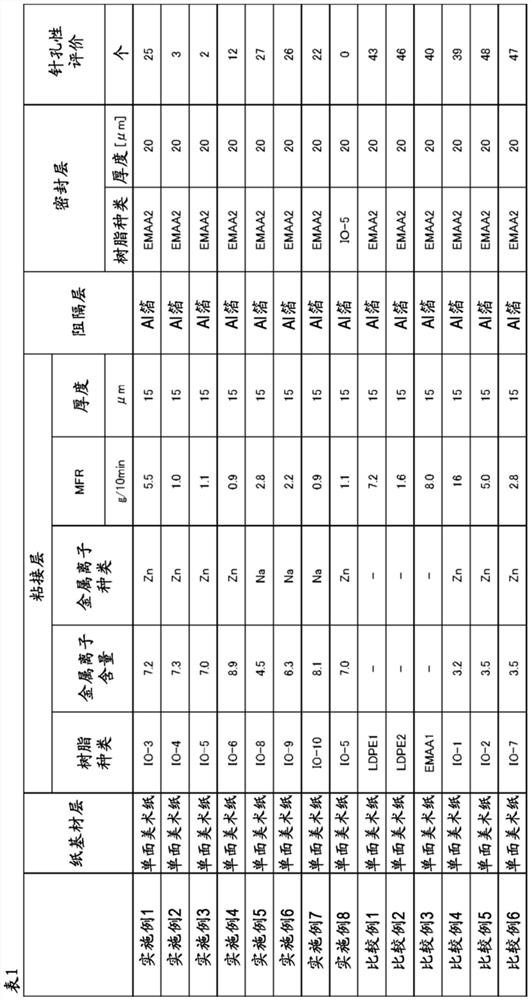

Layered product for soft packaging, soft packaging material, and soft package

A layered product for soft packaging comprises at least a paper base layer, an adhesive layer, a barrier layer, and a sealant layer, stacked together in this stated order, wherein the adhesive layer contains an ionomer (A) of an ethylene-unsaturated carboxylic acid copolymer, and the contained amount of metal ions represented by X * Y / 100 is 4.0-20.0, where X [mass%] represents the contained amount of an unsaturated carboxylic acid in the ethylene-unsaturated carboxylic acid copolymer (A1) included in the ionomer (A) of the ethylene-unsaturated carboxylic acid copolymer, and Y [mol%] represents the degree of neutralization of the ionomer (A) of the ethylene-unsaturated carboxylic acid copolymer.

Owner:MITSUI LTD

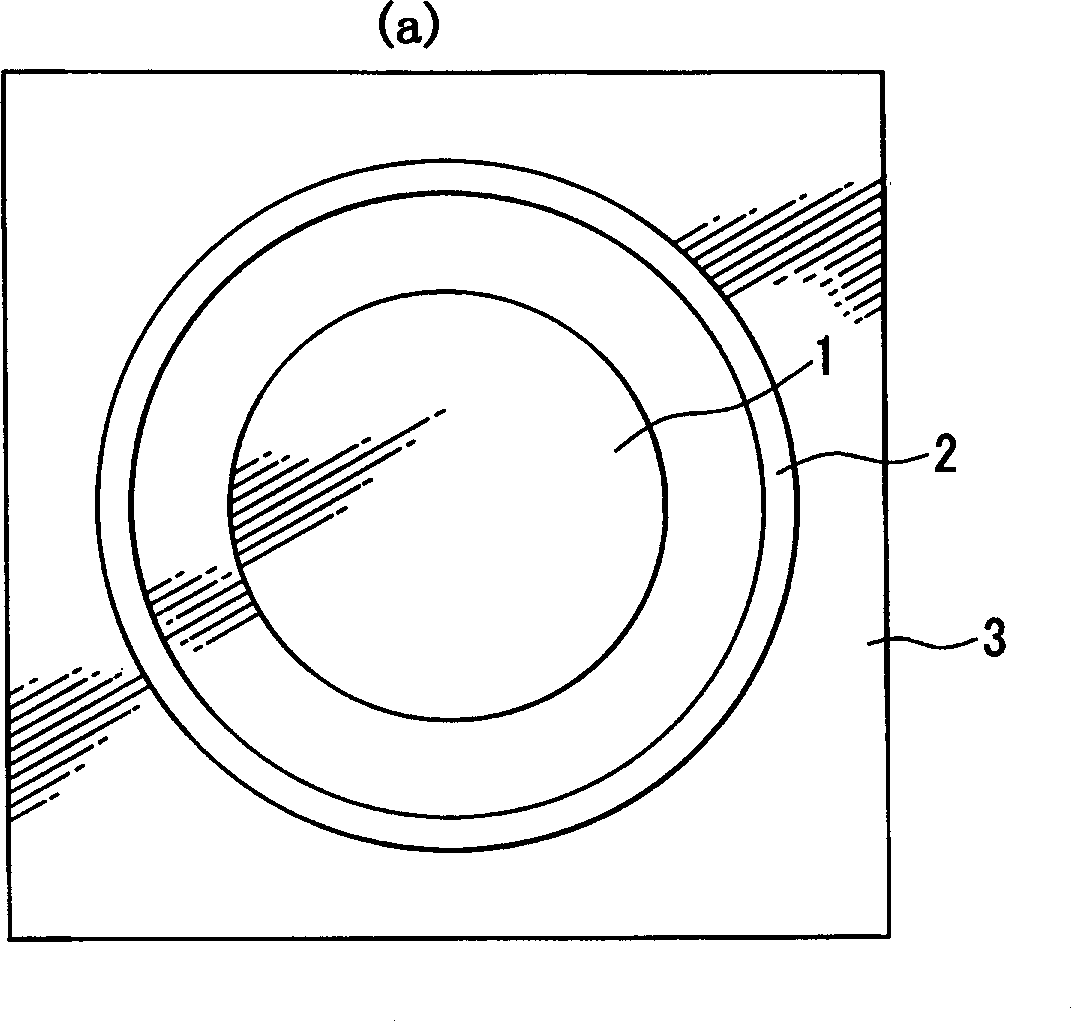

Method for manufacturing polyamide resin laminated film roll

InactiveCN1785657BUniform thicknessReduce crystallinityFlexible coversWrappersPolymer scienceHigh humidity

This invention provides a process for efficiently producing a biaxially oriented polyamide resin laminated film roll that can realize bag making by lamination with high efficiency at high yield even under high humidity conditions. The production process of a film roll comprises a melt extrusion-cooling step of melt extruding a polyamide resin onto the surface of a movable cooling material into a sheet form and cooling the extrudate to form an unstretched sheet, a biaxially stretching step of biaxially stretching the unstretched sheet in longitudinal and transverse directions, and a winding step of winding the biaxially stretched film into a roll form. In the melt extrusion-cooling step, in melt extrusion-cooling of the polyamide resin on the movable cooling material surface, corona discharge in a streamer corona state is carried out between an electrode, to which a direct current high voltage has been applied, and the polyamide resin laminated sheet in a melted state to impart, to thepolyamide resin laminated sheet in a melted state, charges sufficient for adhesion to the movable cooling material surface.

Owner:TOYOBO CO LTD

Laminated material without metal foil for blocking package

The invention discloses a laminated material without metal foil for a blocking package. The material at least comprises a substrate layer assembly and a composite blocking layer assembly, wherein the substrate layer assembly and the composite blocking layer assembly are laminated together; the substrate layer assembly has the effect of supporting; and the composite blocking layer assembly comprises at least one composite blocking layer which is prepared through a partition-laminated confluence layer multiplication and coextrusion method and comprises a plurality of repeated units. The material is characterized in that each repeated unit at least comprises three polymer constitutes, and each polymer constitute can form an individual layer or more than one individual layer; and only one of the polymer constitutes is a blocking polymer constitute which can block gas.

Owner:厦门天策材料科技有限公司

A kind of magnetic insulation pad and preparation method thereof

The invention discloses a magnetic insulating rubber cushion and a preparation method thereof, and belongs to the field of special cable or wire installation and maintenance methods. The magnetic insulating rubber cushion and the preparation method solve the problems that an existing insulating rubber cushion has no magnetism and can not fix small parts. The magnetic insulating rubber cushion at least comprises an upper rubber cushion body and a lower rubber cushion body which are bonded through adhesives, wherein at least one of the rubber cushion bodies is a magnetic rubber cushion body, and each magnetic rubber cushion body is prepared from magnetic micropowder and foaming polycurethane powder according to the weight ratio of 1 to 2-4. The prepared magnetic insulating rubber cushion has certain magnetism, small tools such as iron screws can be attracted to the rubber cushion when the rubber cushion needs to be used for installation or overhaul devices, and especially during high-place operation, the small tools can be prevented from falling, and installation and overhaul can be more convenient.

Owner:陈炳宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com