Polyamide resin laminate roll and process for producing the same

A polyamide-based, resin-layered technology applied in the field of high-quality film rolls to achieve excellent pinhole resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

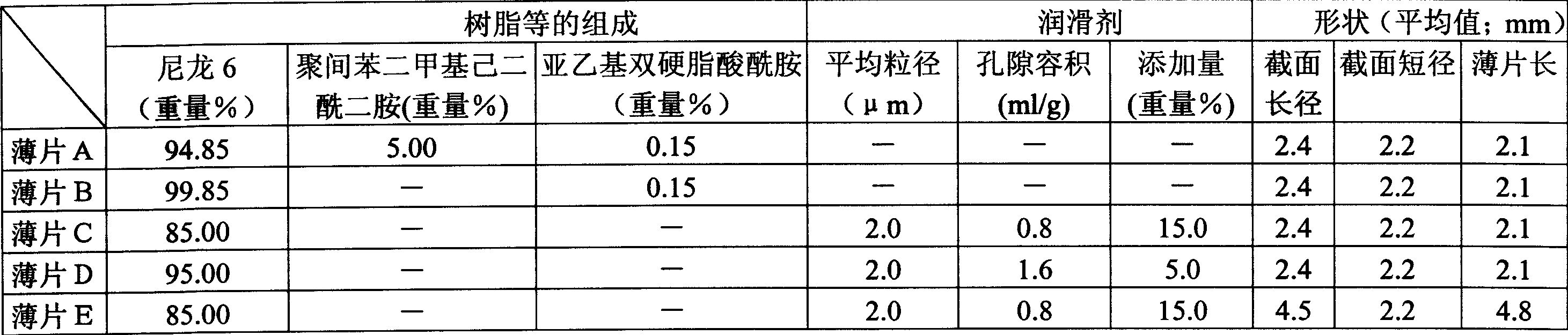

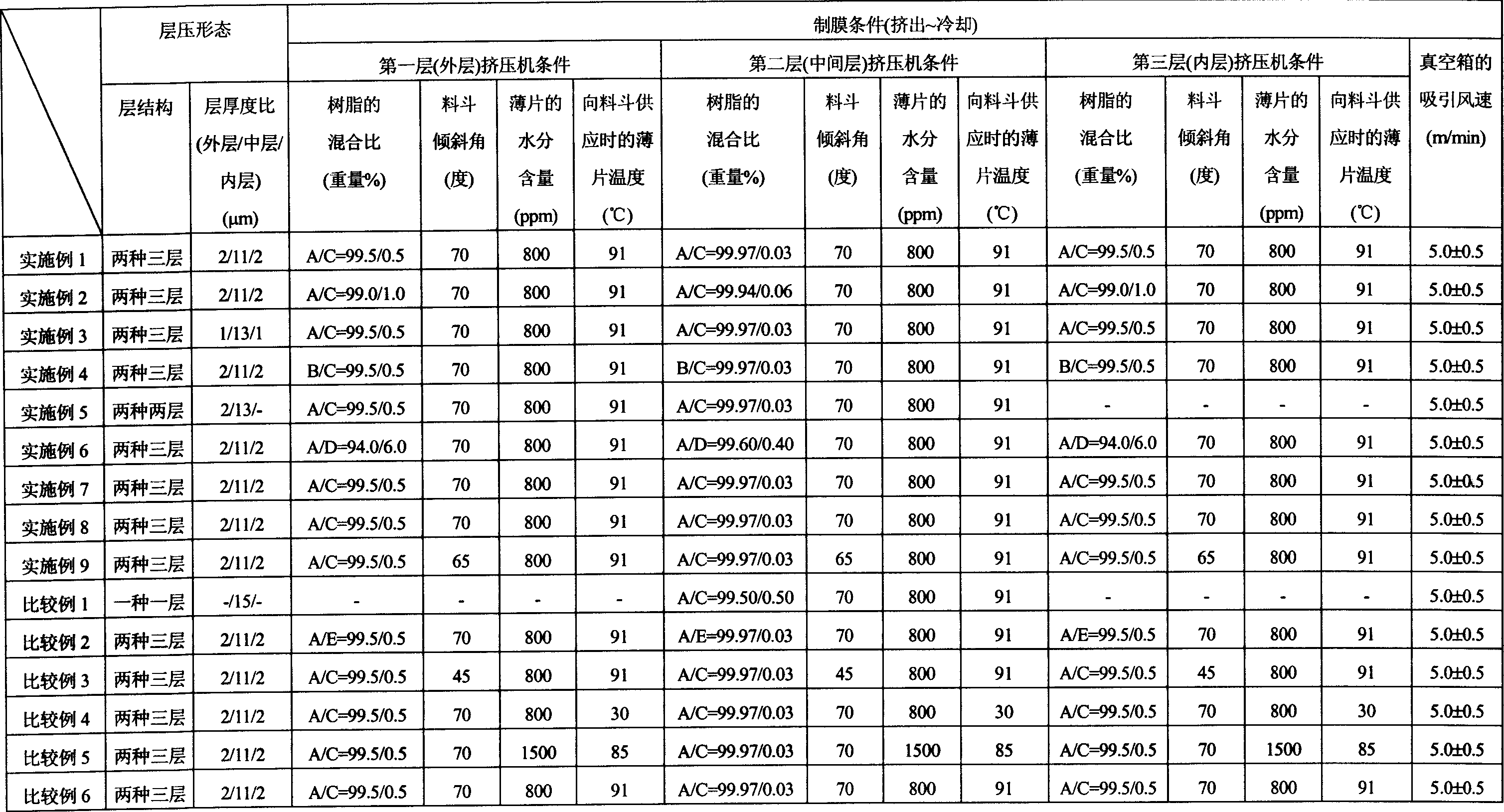

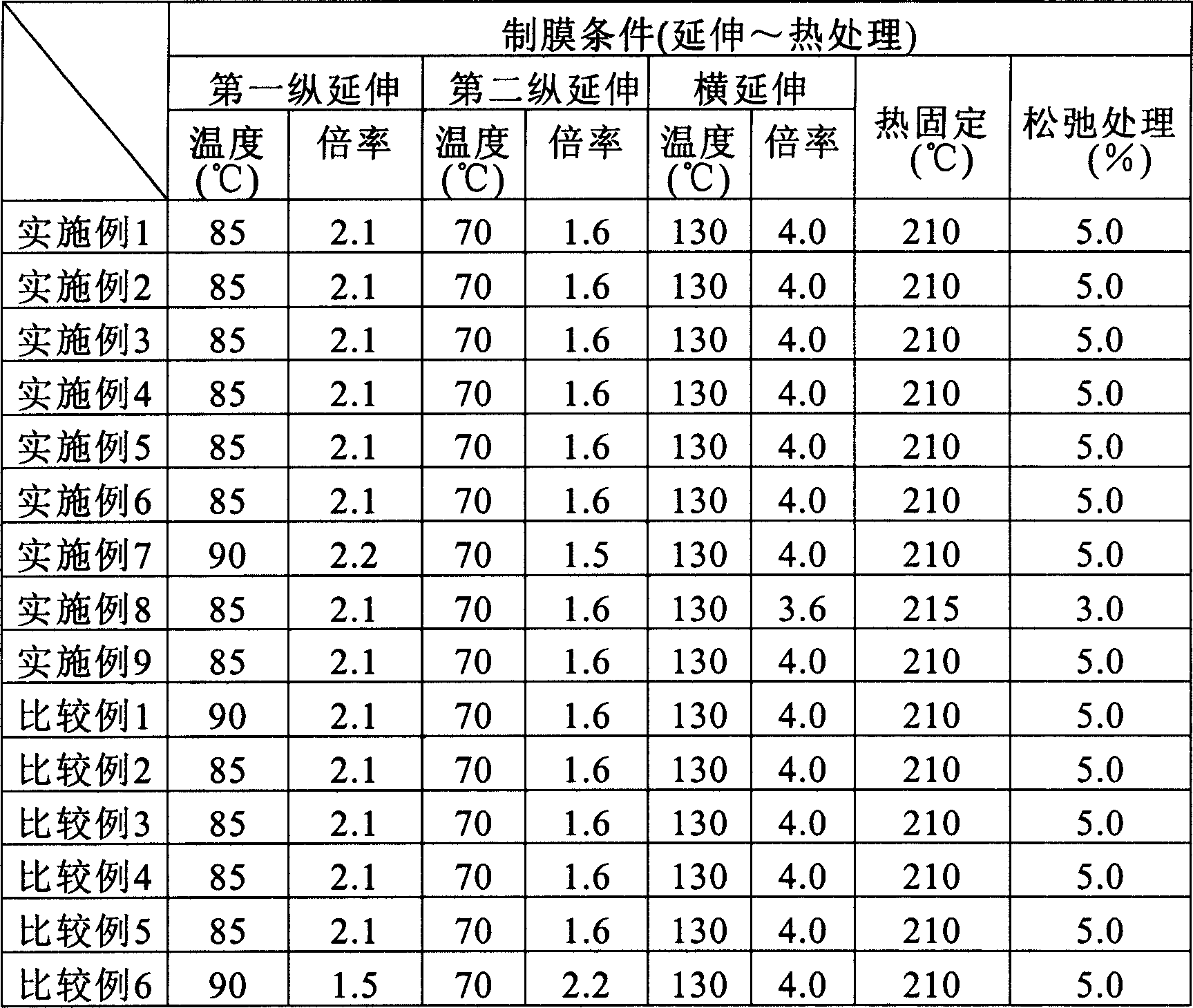

Embodiment 1

[0157] Using the co-extrusion method, melt-extrude polyamide-based resins from three extruders (first to third extruders) (laminate extrusion in a die), and wind them in a rotating machine cooled to 17°C. Rapid cooling was performed on a metal roll to obtain an unstretched film (polyamide-based resin laminated sheet) having a thickness of 257 μm and two types of three-layer structures. The method of forming each layer of the unstretched film (steps up to melt extrusion) is as follows. In addition, in the following description, the surface layer of the polyamide-based resin laminated sheet is referred to as the first layer, the second layer, and the third layer in order (that is, the surface of the third layer is the metal roll contact surface).

[0158] ・Formation of the first layer (outer layer)

[0159] The above flakes A and C were pre-dried while raising the temperature to about 120° C. with a 15 kl stirring device over about 8.0 hours. A certain amount of each flake was...

Embodiment 2

[0207] For the formation of the first layer and the third layer, when the flakes A and C in each mixer are supplied to the hopper directly above the first extruder and the third extruder, the supply amount of the flake A is 99.0% by weight, The supply amount of flake C was 1.0% by weight. For the formation of the second layer, when the flakes A and C in each mixer were supplied to the hopper directly above the second extruder, the supply amount of flake A was 99.94% by weight, The supply amount of the sheet C was 0.06% by weight, and in the same manner as in Example 1, a roll of a polyamide-based resin laminated film was obtained. Then, the properties of the obtained film roll were evaluated by the same method as in Example 1. The evaluation results are shown in Tables 4-7.

Embodiment 3

[0209] When the first to third extruders melt and extrude the raw material flakes, adjust the output of the first to third extruders so that the thickness ratio of the first layer / second layer / third layer is 1 / 13 / 1 , and in the same manner as in Example 1, a polyamide-based resin laminated film roll was obtained. When the obtained biaxially stretched laminated film was sliced in the thickness direction and observed with an electron microscope, the thicknesses of the first layer, the second layer, and the third layer were about 1 μm, about 13 μm, and about 1 μm, respectively. Then, the properties of the obtained film roll were evaluated by the same method as in Example 1. The evaluation results are shown in Tables 4-7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com