Laminated material without metal foil for blocking package

A technology of packaging materials and laminated materials, which is applied in the field of laminated materials without metal foil, can solve the problems that the performance of co-extruded films cannot be continuously improved, the number of layers of co-extruded films is limited, and the number of construction layers is high, so as to facilitate processing and reduce The effect of dosage and rich structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

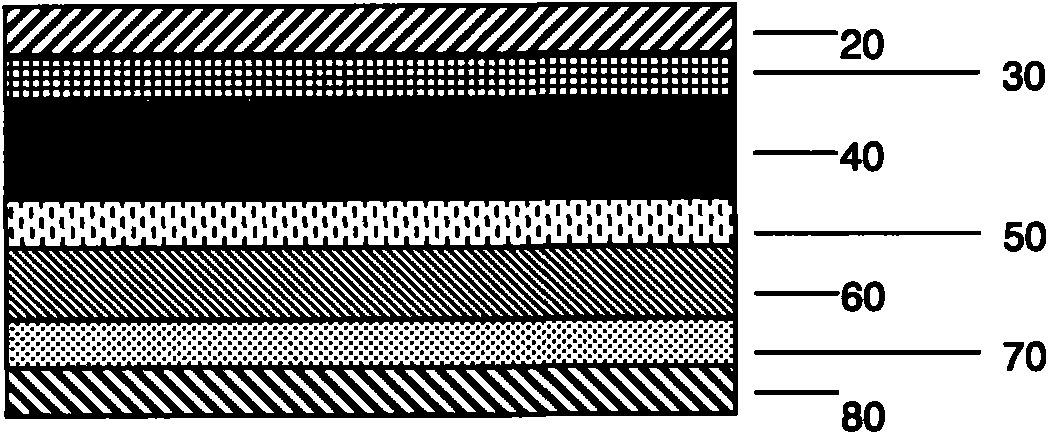

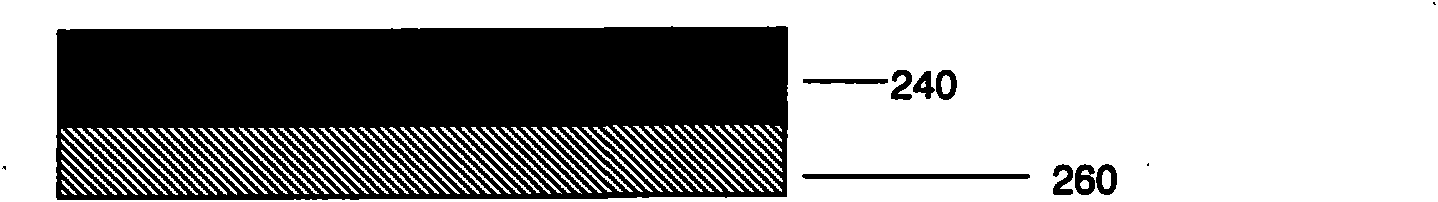

[0051]In this embodiment, the overall structure of the packaging material is outer layer / substrate layer / barrier layer, wherein the outer layer is low-density polyethylene, the substrate layer is cardboard, and the barrier layer is composed of only three polymers and repeated The unit is a composite layer of layer multiplication extrusion of five layers. Wherein the non-barrier polymer composition A in the barrier composite layer is low-density polyethylene, and the non-barrier polymer composition B is maleic anhydride modified low-density polyethylene. The barrier polymer composition C is modified melt-processable polyvinyl alcohol.

[0052] First, cast low-density polyethylene on a thick cardboard (paper weight is about 400g / m2) at about 325°C 2 ) with a printed layer on the outer surface, the coating thickness is about 20 microns.

[0053] A barrier composite extruded by the layer doubling method was coextruded on the inner surface of a coated low density polyethylene lam...

Embodiment 2

[0056] In this example, the overall structure of the packaging material is outer layer / substrate layer / barrier layer, wherein the outer layer is low-density polyethylene (LDPE), the substrate layer is tissue paper, and the barrier layer component is composed of three polymers A layer multiplied extruded composite layer consisting of four layers with repeating units. Wherein the non-barrier polymer composition A in the barrier composite layer is ethylene acrylic acid copolymer (EAA), and the non-barrier polymer composition B is a copolymer of 95wt% low density polyethylene and 5wt% maleic anhydride modified low density polyethylene Blend, barrier polymer composition C is extrusion grade ethylene-vinyl alcohol copolymer (EVOH) and commercial grade nanoclay filled nylon 6.

[0057] First, at about 325°C, cast low-density polyethylene on a thick cardboard (paper weight is about 150g / m 2 ) with a printed layer on the outer surface, the coating thickness is about 20 microns.

[00...

Embodiment 3

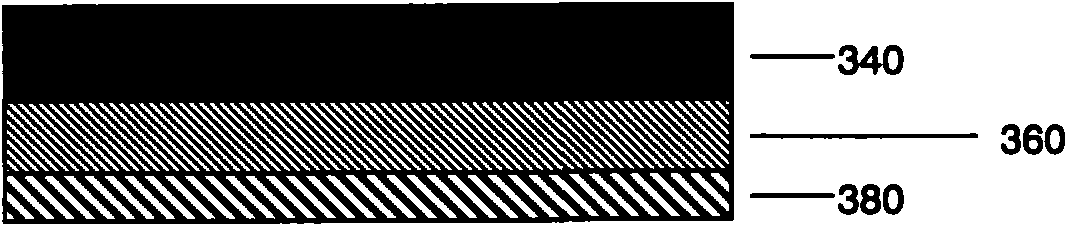

[0061] In this embodiment, the overall structure of the packaging material is outer layer / substrate layer / barrier layer / inner layer, wherein the outer layer is linear low density polyethylene (LLDPE), the substrate layer is cardboard, and the barrier layer component is composed of The composite layer is composed of three polymers and the repeating unit is three layers, and the inner layer is LLDPE filled with nano-calcium carbonate. Wherein the non-barrier component A in the barrier composite layer is ethylene-vinyl acetate copolymer (EVA), and the non-barrier component B is a blend of 95wt% low-density polyethylene and 5wt% maleic anhydride-modified low-density polyethylene , The barrier polymer composition C is a blend of extrusion-grade polyvinyl alcohol copolymer (PVA) and MXD6 nylon.

[0062] Firstly, linear low density polyethylene is cast-coated on thick cardboard (paper weight is about 320g / m2) at about 350°C. 2 ) with a printed layer on the outer surface, the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com