Low-cost, pinhole-resistant and high-hardness polyester resin for HAA system and preparation method of polyester resin

A polyester resin and system technology, used in the field of preparing powder coatings, can solve the problems of difficult to control the degree of reaction, low softening point of polyester resin, fast reaction speed, etc., and achieve outstanding pinhole resistance, good storage stability, and reduced effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

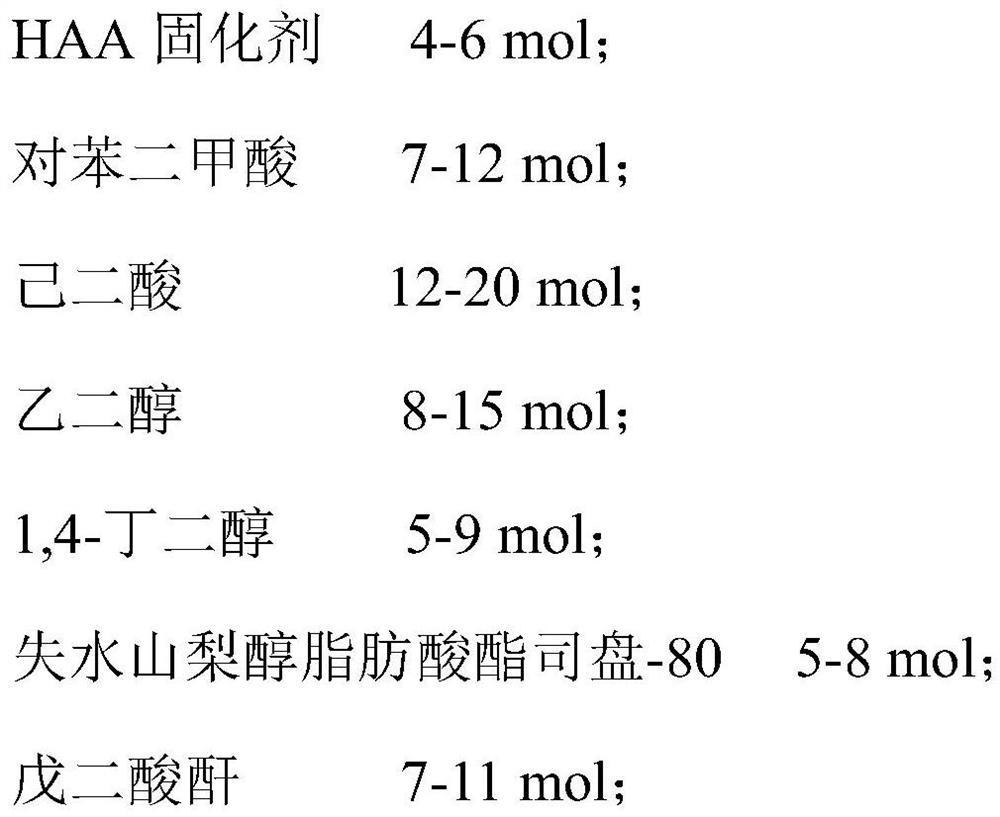

[0022] A low-cost, pinhole-resistant, high-hardness type polyester resin for HAA systems, based on the total amount of raw materials for preparing the polyester resin, it includes the following raw material components in molar percentages:

[0023]

[0024]

[0025] The hydroxyl value of Span-80 is 190-210 mgKOH / g, purchased from Jiangsu Haian Petrochemical Plant.

[0026] In addition, it further includes a catalyst monobutyl tin oxide, the amount of which is 0.1% of the total molar weight of raw materials; antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) ] Pentaerythritol ester), consumption is 0.1% of the total molar weight of raw materials.

[0027] A method for preparing the polyester resin for the above-mentioned HAA system, comprising the steps of:

[0028] A. Add the catalyst and HAA curing agent in the formula amount into the reaction kettle, and fully melt at 138°C;

[0029] B. Then add the formulated amount of terephthalic acid and adipic acid in...

Embodiment 2

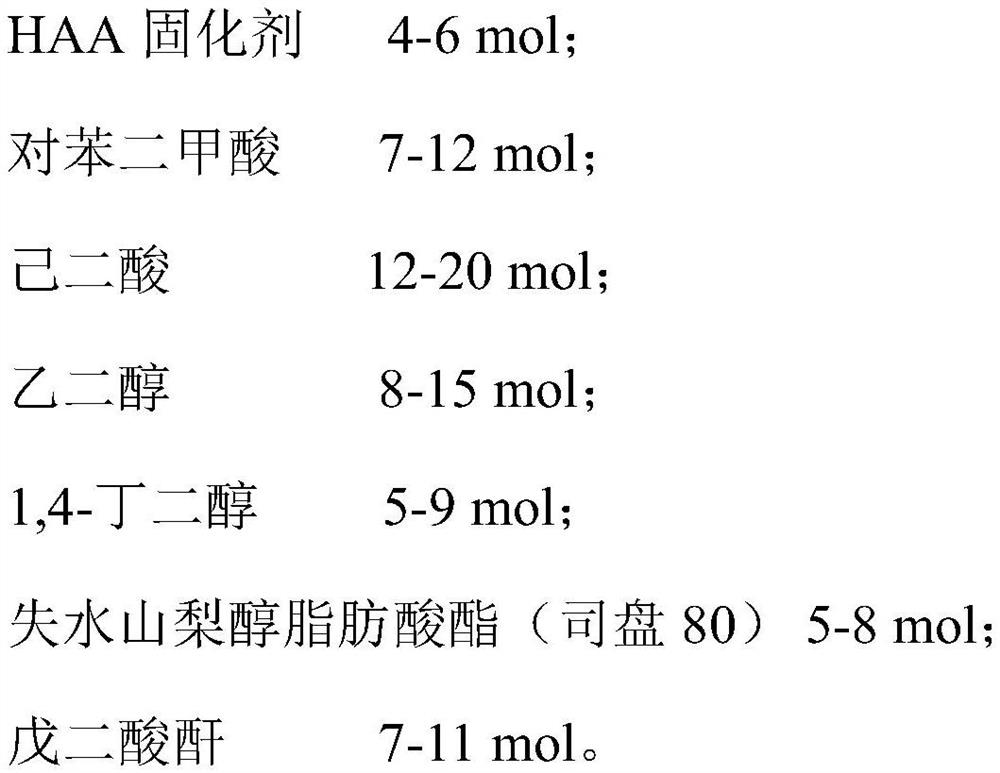

[0036] A low-cost, pinhole-resistant, high-hardness type polyester resin for HAA systems, based on the total amount of raw materials for preparing the polyester resin, it includes the following raw material components in molar percentages:

[0037]

[0038] The hydroxyl value of Span-80 is 190-210 mgKOH / g, purchased from Jiangsu Haian Petrochemical Plant.

[0039] It also further includes catalyst monobutyl tin oxide, and the consumption is 0.15% of the total molar weight of raw materials; ester), consumption is 0.2% of the total molar weight of raw materials.

[0040] A method for preparing the polyester resin for the above-mentioned HAA system, comprising the steps of:

[0041] A. Add the amount of catalyst and HAA curing agent into the reaction kettle, and fully melt at 139°C;

[0042] B. Then add the formulated amount of terephthalic acid and adipic acid into the reaction kettle, and gradually raise the temperature to 180°C under the protection of nitrogen, and contro...

Embodiment 3

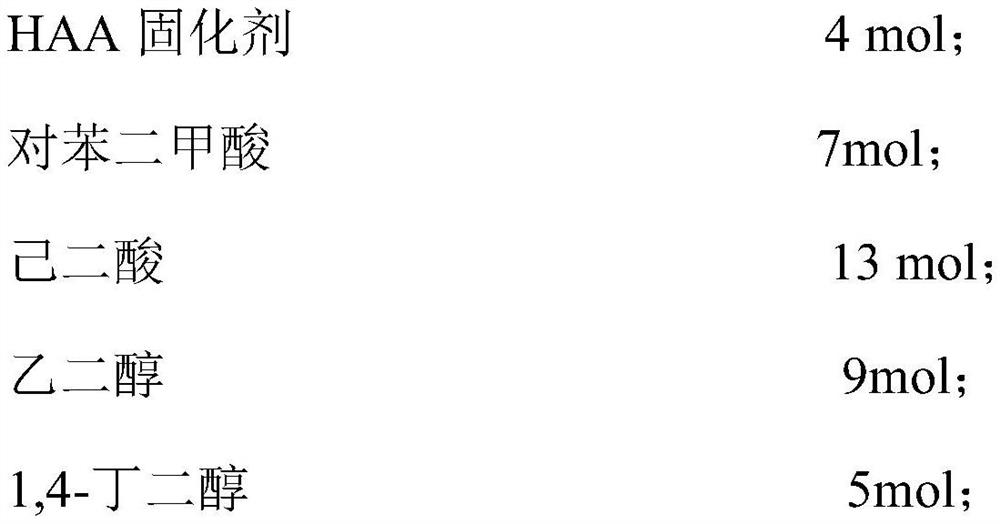

[0049] A low-cost, pinhole-resistant, high-hardness type polyester resin for HAA systems, based on the total amount of raw materials for preparing the polyester resin, it includes the following raw material components in molar percentages:

[0050]

[0051] The hydroxyl value of Span-80 is 190-210 mgKOH / g, purchased from Jiangsu Haian Petrochemical Plant.

[0052] It also further includes catalyst monobutyl tin oxide, and the consumption is 0.1% of the total molar weight of raw materials; antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester), consumption is 0.2% of the total molar weight of raw materials.

[0053] A method for preparing the polyester resin for the above-mentioned HAA system, comprising the steps of:

[0054] A. Add the catalyst and HAA curing agent in the formula amount into the reaction kettle, and fully melt at 138°C;

[0055] B. Then add the formulated amount of terephthalic acid and adipic acid into the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com