Patents

Literature

310results about How to "Guaranteed impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

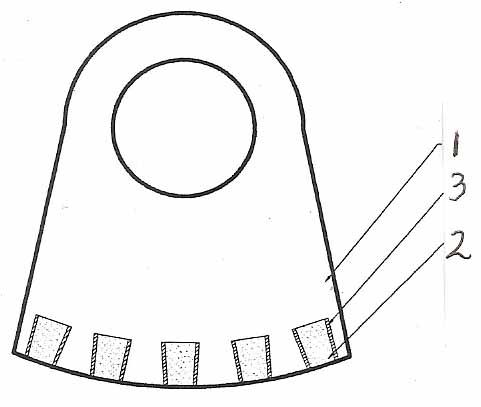

Protection mat and its fabrication process

InactiveCN101385576AGuaranteed impact resistanceGood bending performanceLamination ancillary operationsLaminationElastic membraneEngineering

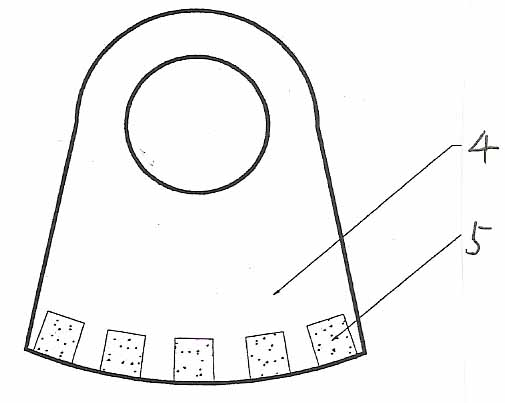

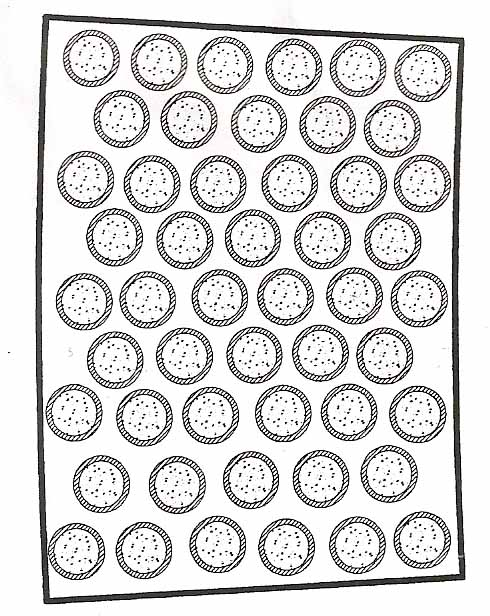

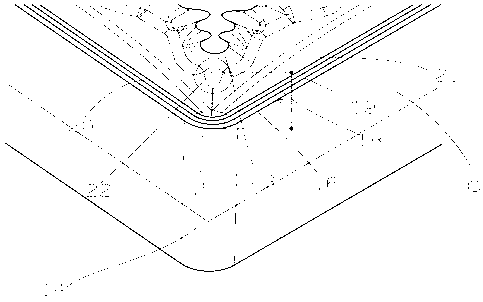

The invention discloses a supplementary mat which has good bending property along all the directions to well joint wit the protected part, and a manufacturing method thereof; the supplementary mat comprises an outer layer which is elastic membrane material that is soft and has stretching performance, an intermediate layer that is composed of a plurality of buffer cells that are mutually independent and arranged in a staggered form, and base material that is soft elastic membrane material with stretching performance; wherein, the two ends of each of the buffer cells are respectively agglutinated with the outer layer and the base material. The supplementary mat also include adhesive sticker which is coated on the outward side of the base material and used for fixing the supplementary mat to the part needed to be protected.

Owner:3M INNOVATIVE PROPERTIES CO

Ceramic reinforced metal matrix abrasion-resisting compound material and preparation method

The invention discloses a ceramic reinforced metal matrix abrasion-resisting compound material and a preparation method. The compound material comprises a metal matrix abrasion-resisting component body, wherein a plurality of blind holes are formed on the surface of the metal matrix abrasion-resisting component body, and self-fluxing alloy powder metallurgically bonded with the metal matrix abrasion-resisting component body and ceramic sintering bodies are arranged in the blinding holes. At a sintering temperature of a vacuum furnace, the self-fluxing alloy powder is fused and is metallurgically bonded with the abrasion-resisting component body while the abrasion-resisting component body and the ceramic are not deformed. The process is simple and the prepared material with a required hardness can be acquired without being subjected to the heat treatment. By using the preparation method, the problem that the ceramic is difficult to be bonded with a metal substrate is solved and the defect caused by a pouring process is avoided. The ceramic, alloy and metal on the surface of the abrasion-resisting component are regularly distributed, the abrasion resistance of the abrasion-resisting component is ensured and the shock resistance is also ensured.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

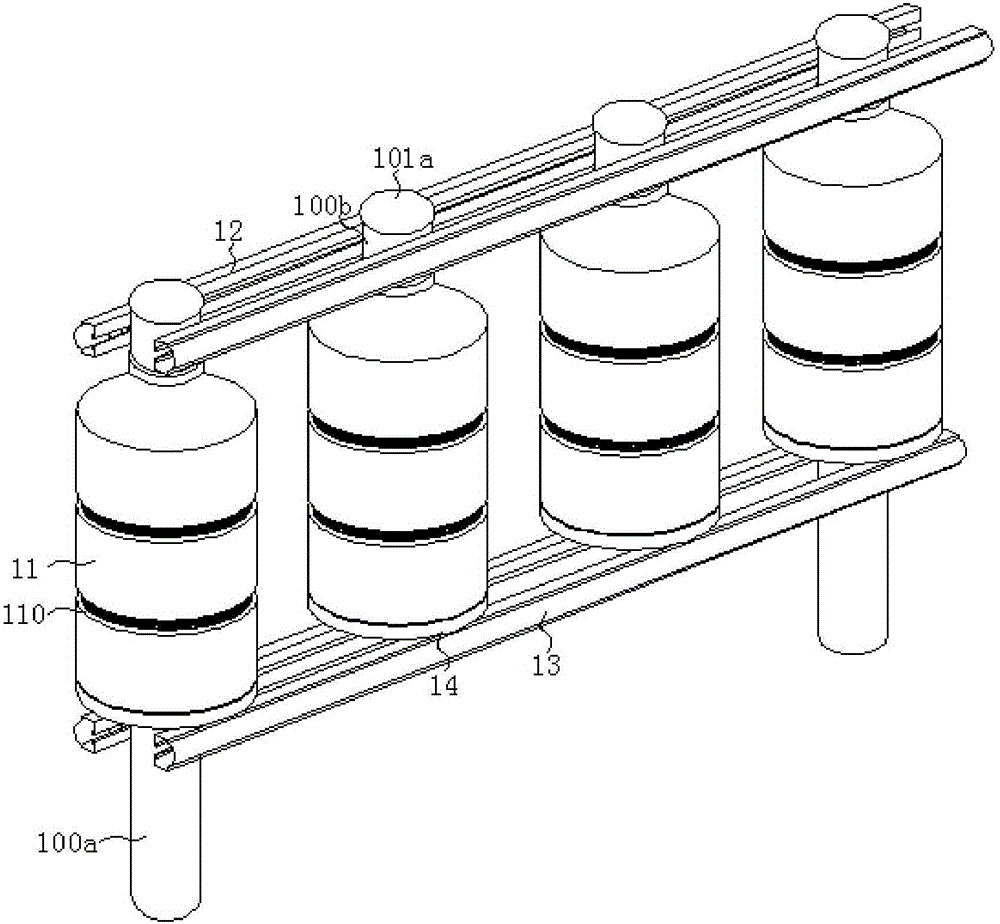

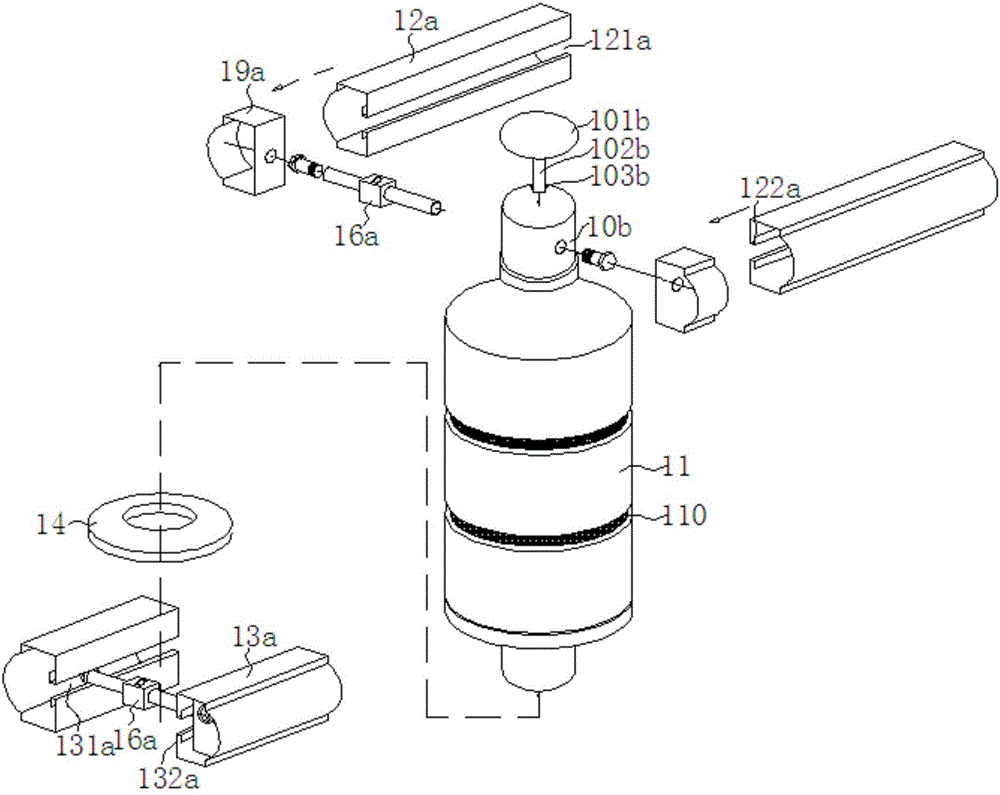

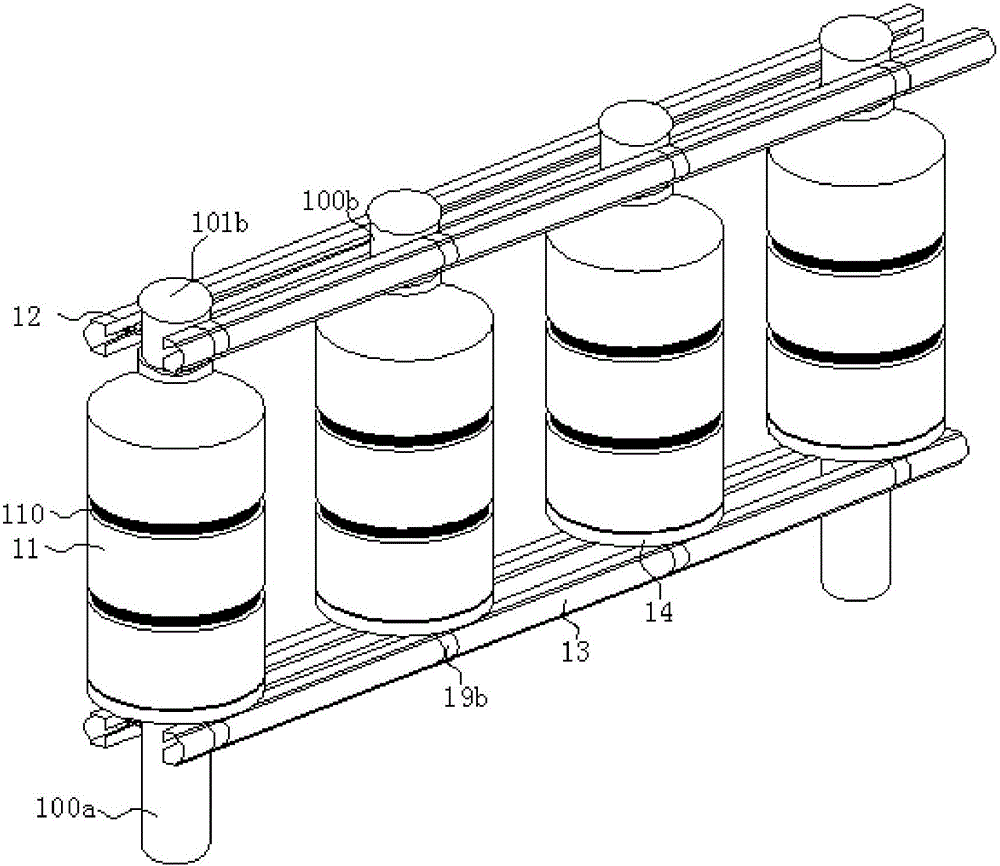

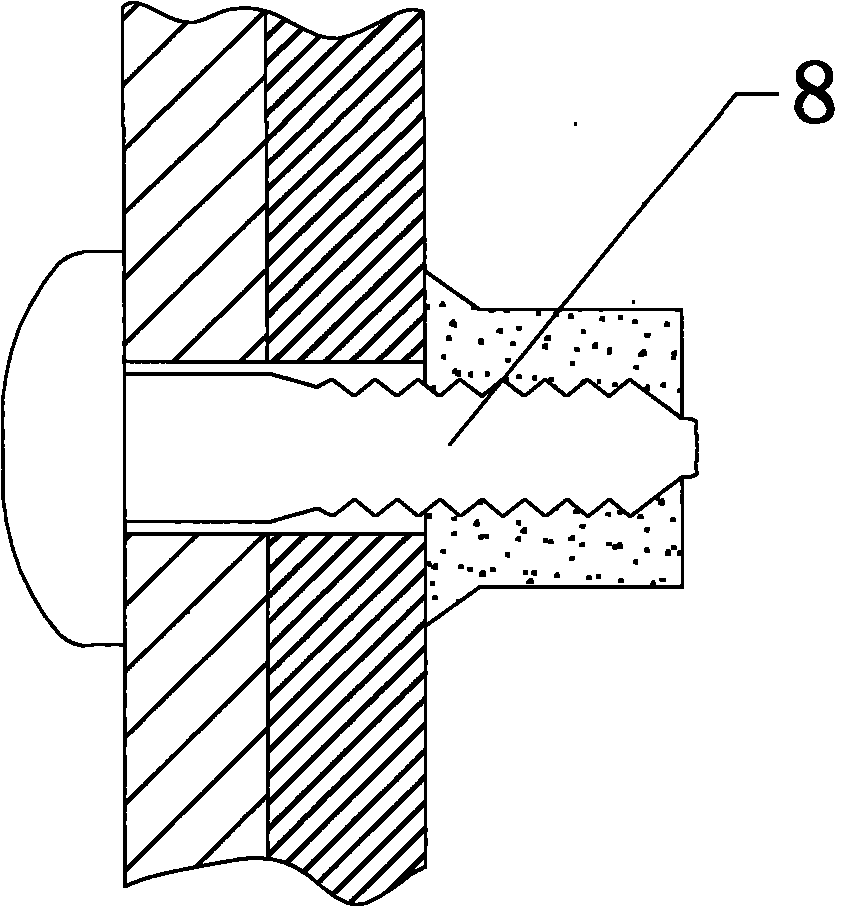

Road traffic guardrail capable of buffering and absorbing impact

The invention discloses a road traffic guardrail capable of buffering and absorbing impact. The road traffic guardrail is characterized by comprising fastening pieces; each fastening piece is provided with two ends and a connecting part used for connecting the two ends, wherein the two ends are used for applying force to an upper horizontal column or a lower horizontal column; power is transmitted to the connecting part from the two ends; and the upper horizontal column or the lower horizontal column is subjected to the force and moves relative to a corresponding round tube stand column, so that the upper horizontal column or the lower horizontal column is fixed to the round tube stand column. The road traffic guardrail capable of buffering and absorbing impact is simple in structure; the fastening pieces are adopted for fixing the upper horizontal column and the lower horizontal column; on the one hand, the fastening pieces are high in strength and guarantee the anti-impact performance of the upper horizontal column and the lower horizontal column, on the other hand, the upper horizontal column and the lower horizontal column can move relative to the round tube stand columns only by applying force to the connecting parts of the fastening pieces in the mounting process, and therefore, fixation is achieved; mounting is convenient and fast, and the labor efficiency is greatly improved; and at the same time, a smaller number of screw rods are used, and the production cost is lowered.

Owner:ANHUI MINGXIN METAL PROD CO LTD

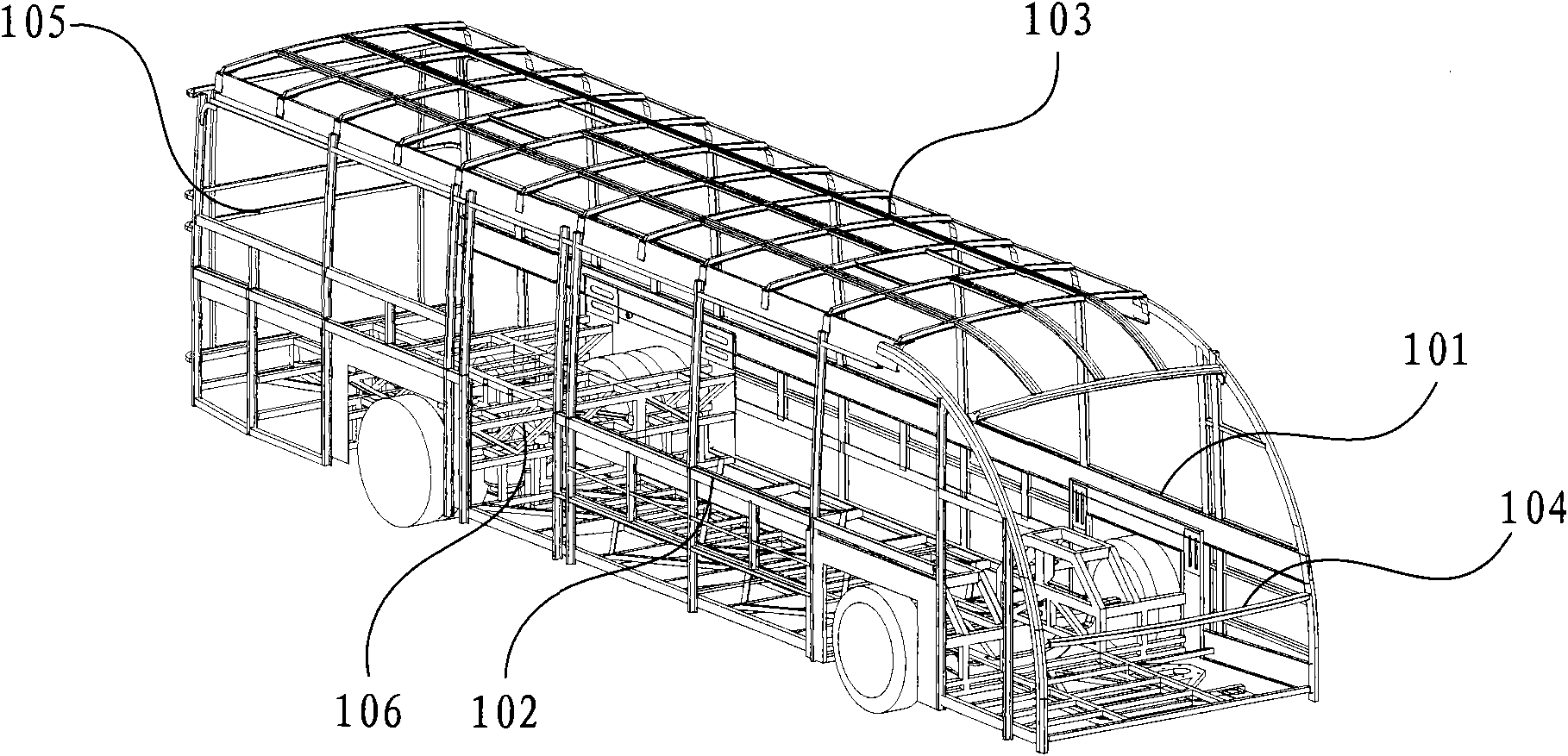

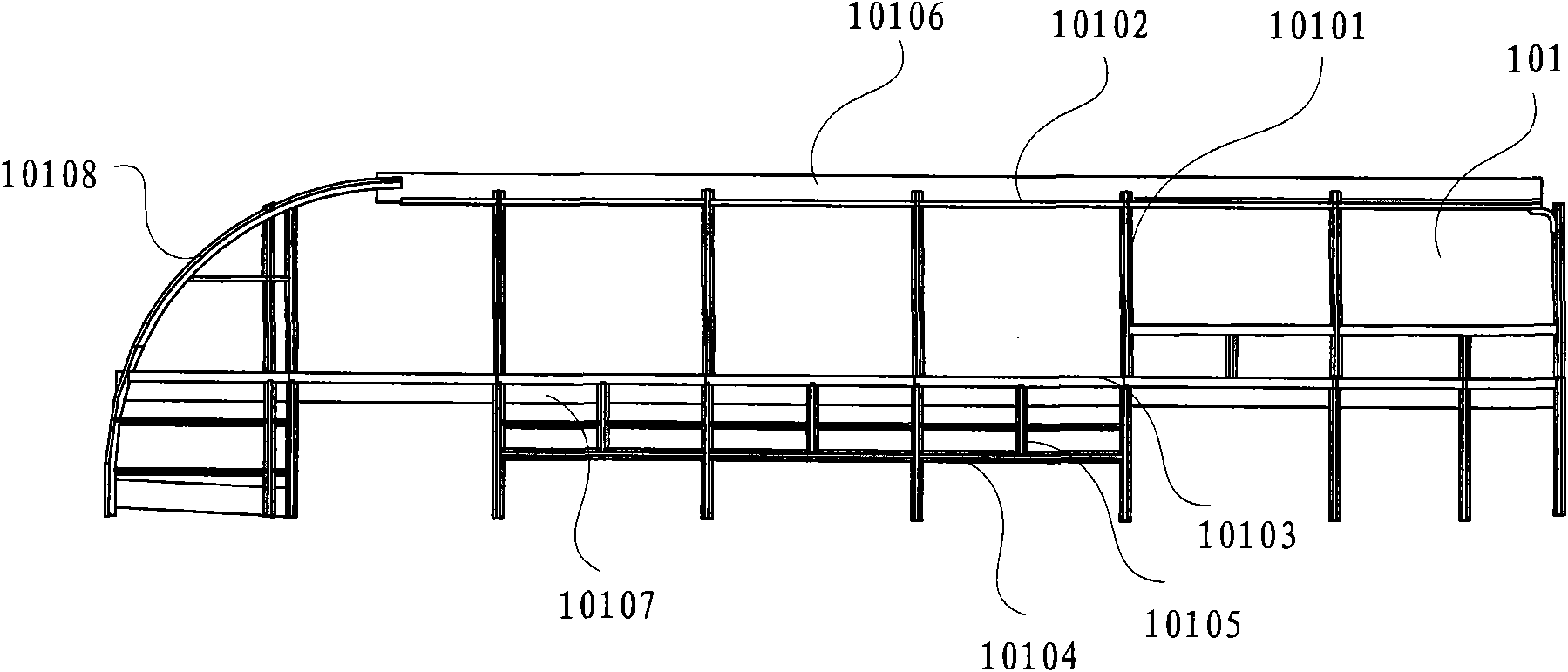

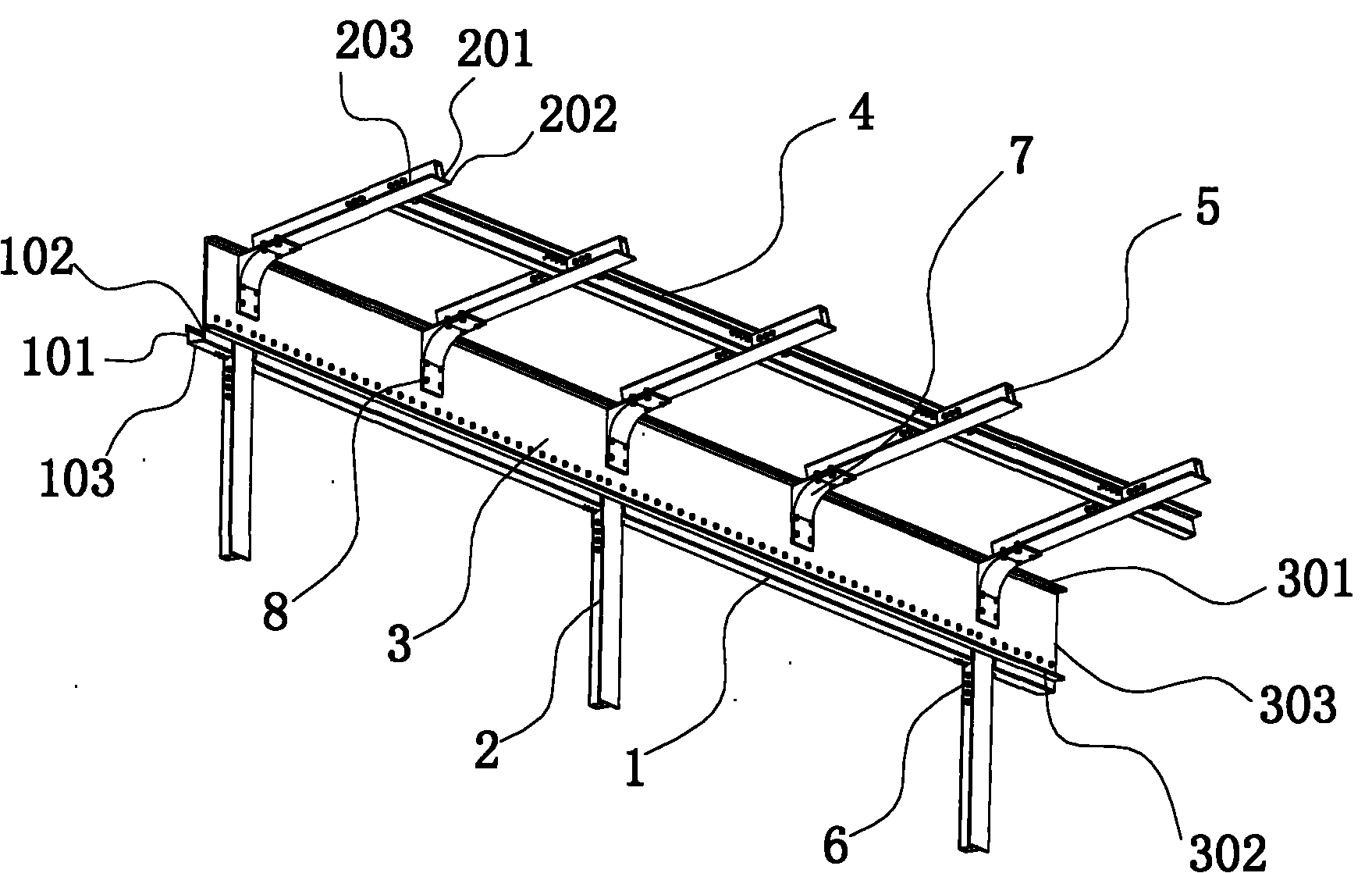

Lightweight total-bearing body frame structure

ActiveCN101863290AReduce weightExtended service lifeSuperstructure connectionsPassenger vehicle superstructuresSteel frameUltimate tensile strength

The invention relates to a lightweight total-bearing body frame structure, which comprises a side wall frame, a roof frame, a front wall frame, a rear wall frame and an interlayer frame. The lightweight total-bearing body frame structure is made of an aluminum alloy or magnesium alloy material, and is riveted with lockbolts so as to ensure that the weight of the body frame is greatly reduced while the whole strength of the body is not lower than the conventional steel body frame. The parts forming the body frame has a unique design, so that well balance between weight reduction and strength maintenance can be achieved. The lightweight total-bearing body frame structure saves more energy than the conventional steel frame.

Owner:北京绿程锦绣能源科技有限公司

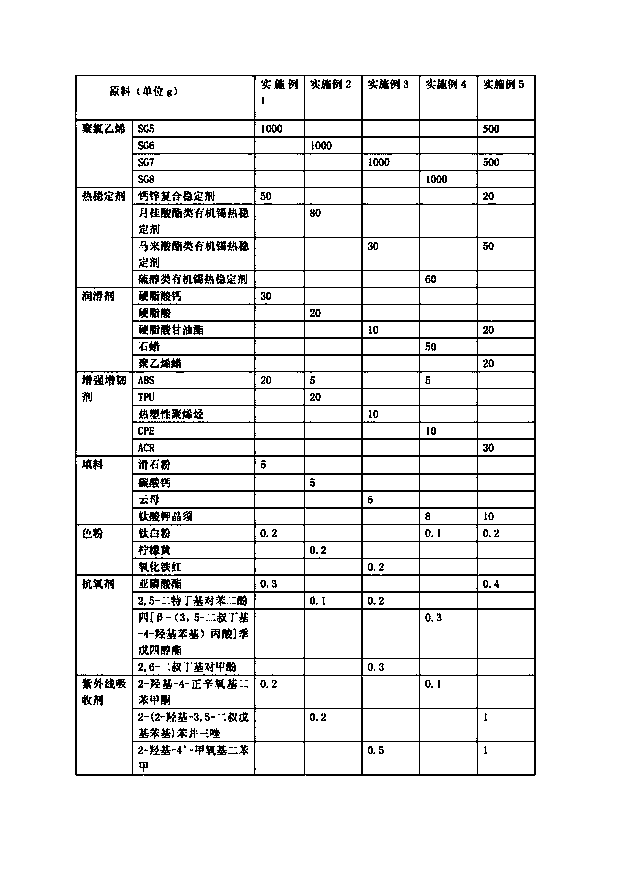

Environmental thermoplastic PVC table tennis material and its preparation method of table tennis

An environmental thermoplastic PVC table tennis material comprises the following materials, by weight, 100 parts of polyvinyl chloride, 3-8 parts of a heat stabilizer, 1-5 parts of a lubricant, 10-30 parts of a reinforcing flexibilizer, 5-10 parts of a filling material, 0.1-0.2 part of a toner, 0.1-0.5 part of an anti-oxidant and 0.1-2 parts of an ultraviolet ray absorber. The preparation method of the environmental thermoplastic PVC table tennis comprises the following steps: firstly carrying out injection moulding to form two hemispheres, splicing the two hemispheres by the use of an adhesive to form a complete sphere, polishing, swelling in a die cavity to form a uniform table tennis, and carrying out aftertreatment to prepare a finished product ball. Thickness of the hemispheres, from top to bottom, is divided into five stages. The environmental thermoplastic PVC table tennis material has advantages of low cost, high hardness, excellent elastic modulus, good eccentricity and good environmental protection property, and can meet requirements of a game ball.

Owner:JIANGNAN UNIV +1

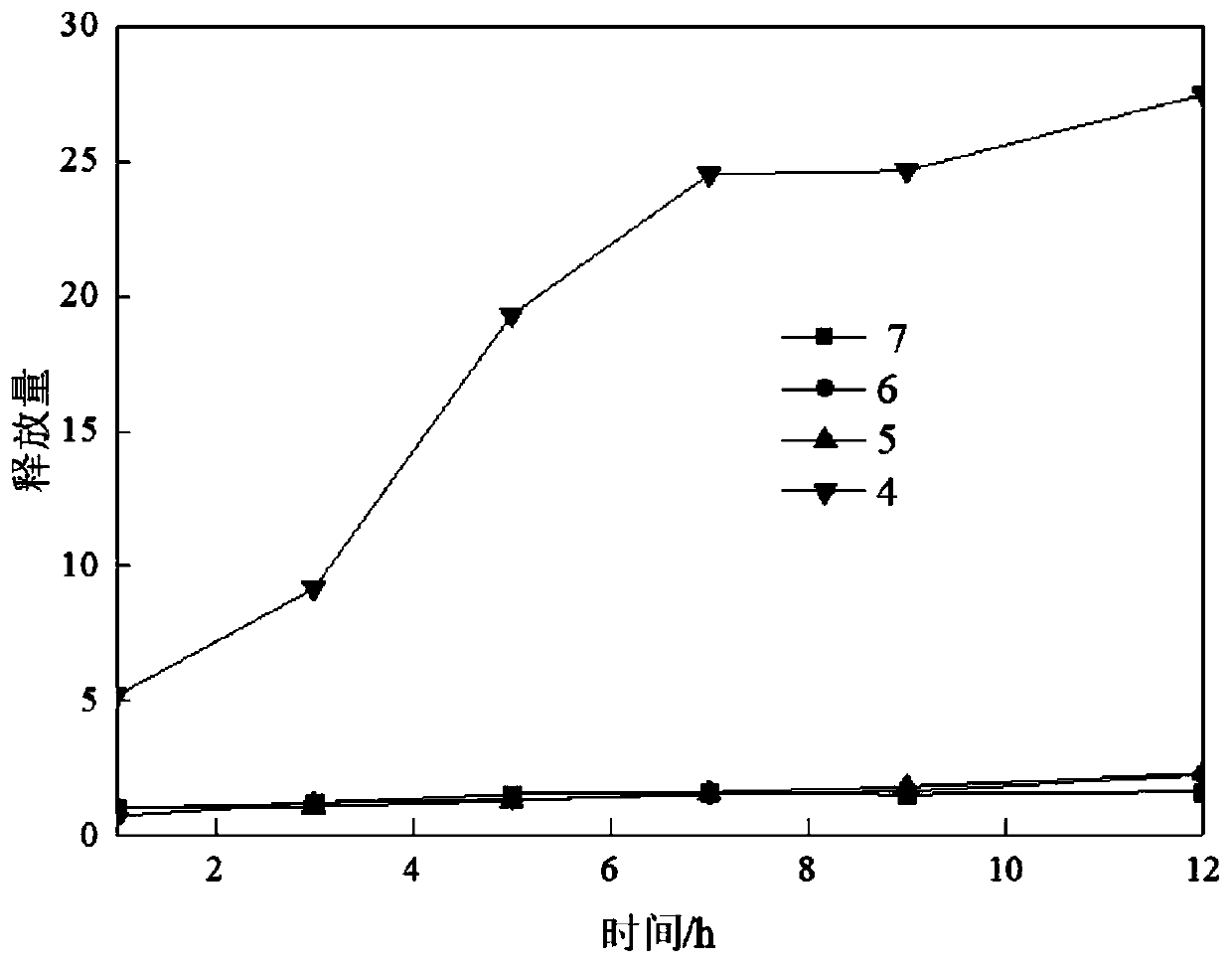

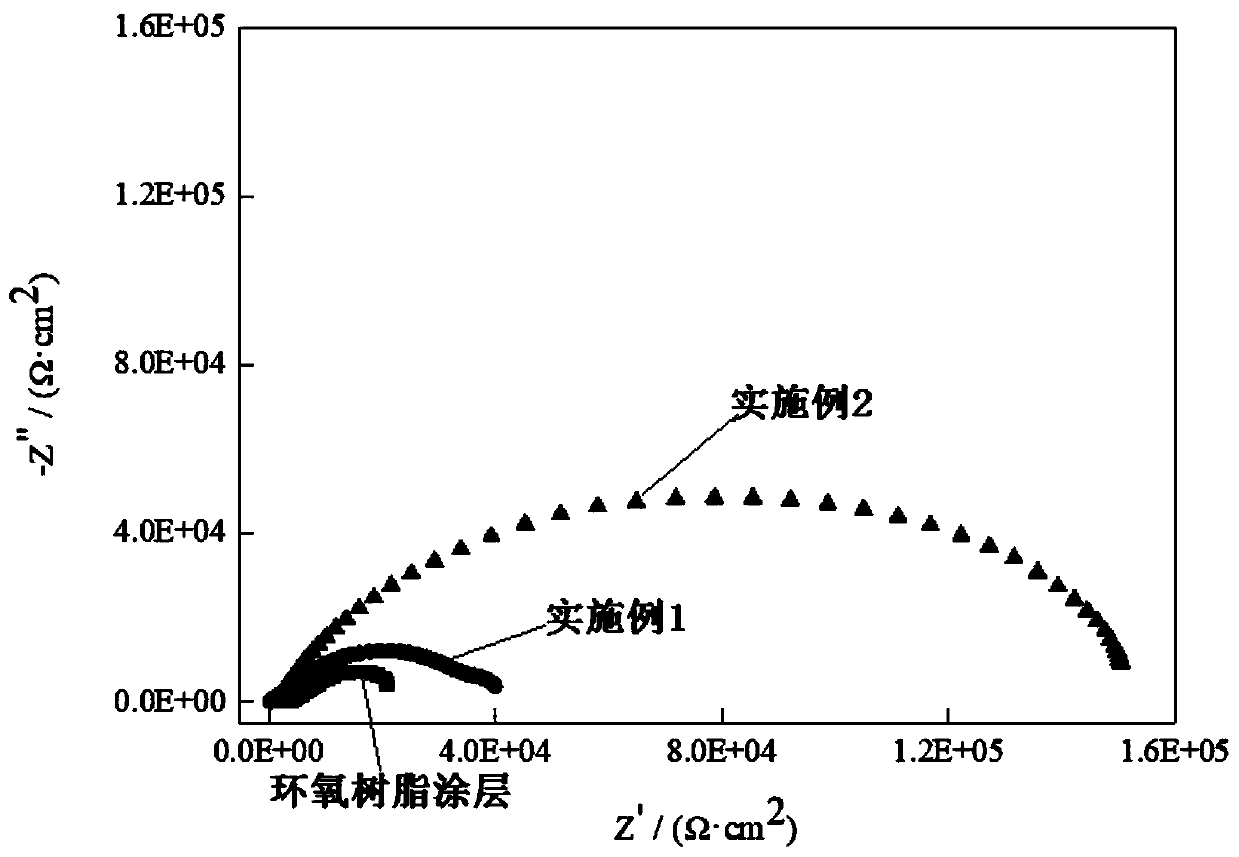

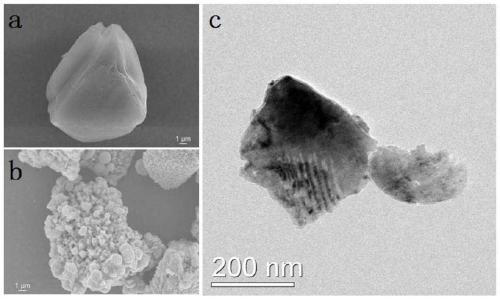

Stimulus-responsive self-repair anticorrosive coating material and preparation method

ActiveCN110105843AImprove anti-corrosion performanceIncrease load rateAnti-corrosive paintsEpoxy resin coatingsCationic polyelectrolytesLayer by layer self assembly

The invention discloses a stimulus-responsive self-repair anticorrosive coating material and a preparation method. The coating material comprises a CuO microcapsule and a coating matrix. The CuO microcapsule comprises a capsule core and a capsule core carrier, the capsule core is a corrosion inhibitor, and the capsule core carrier is porous CuO; and the surface of the CuO microcapsule is coated byan anionic polyelectrolyte layer and a cationic polyelectrolyte layer alternately. The invention successfully constructs the anticorrosive coating material with ph responsiveness and self-repair dualefficacy. The porous CuO can improve the loading rate and encapsulation rate of the capsule core substance; at the same time, the anionic polyelectrolyte can be adsorbed on the surface by means of layer-by-layer self-assembly, under the action of Coulomb force, then cationic polyelectrolyte can be adsorbed on the surface, thus improving the dispersibility of the microcapsule in the coating, solving the agglomeration problem of the porous substance CuO, and at the same time improving the bonding performance of the capsule core carrier and the coating matrix, and the anticorrosion performance of the coating material can be further improved.

Owner:SUN YAT SEN UNIV

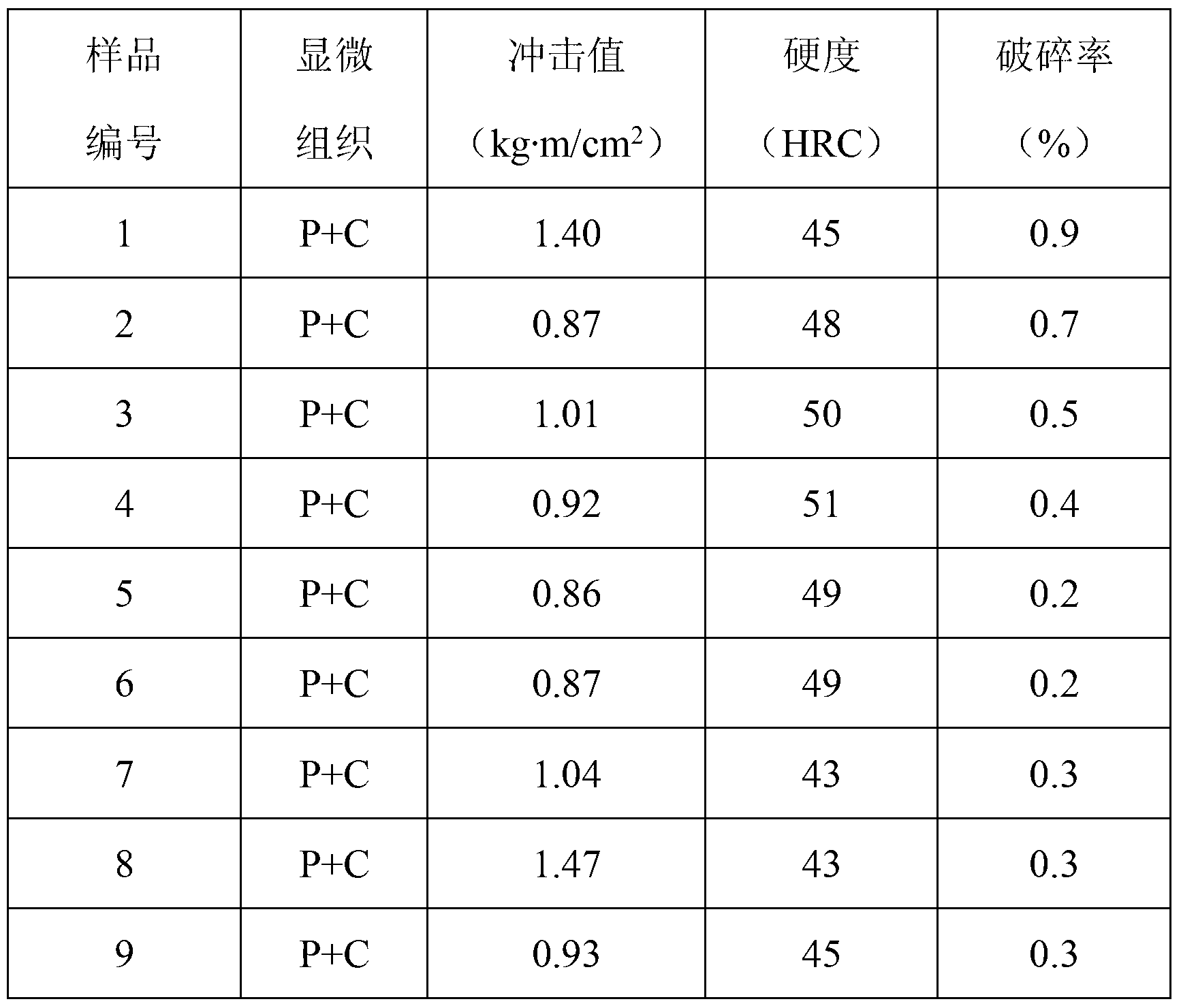

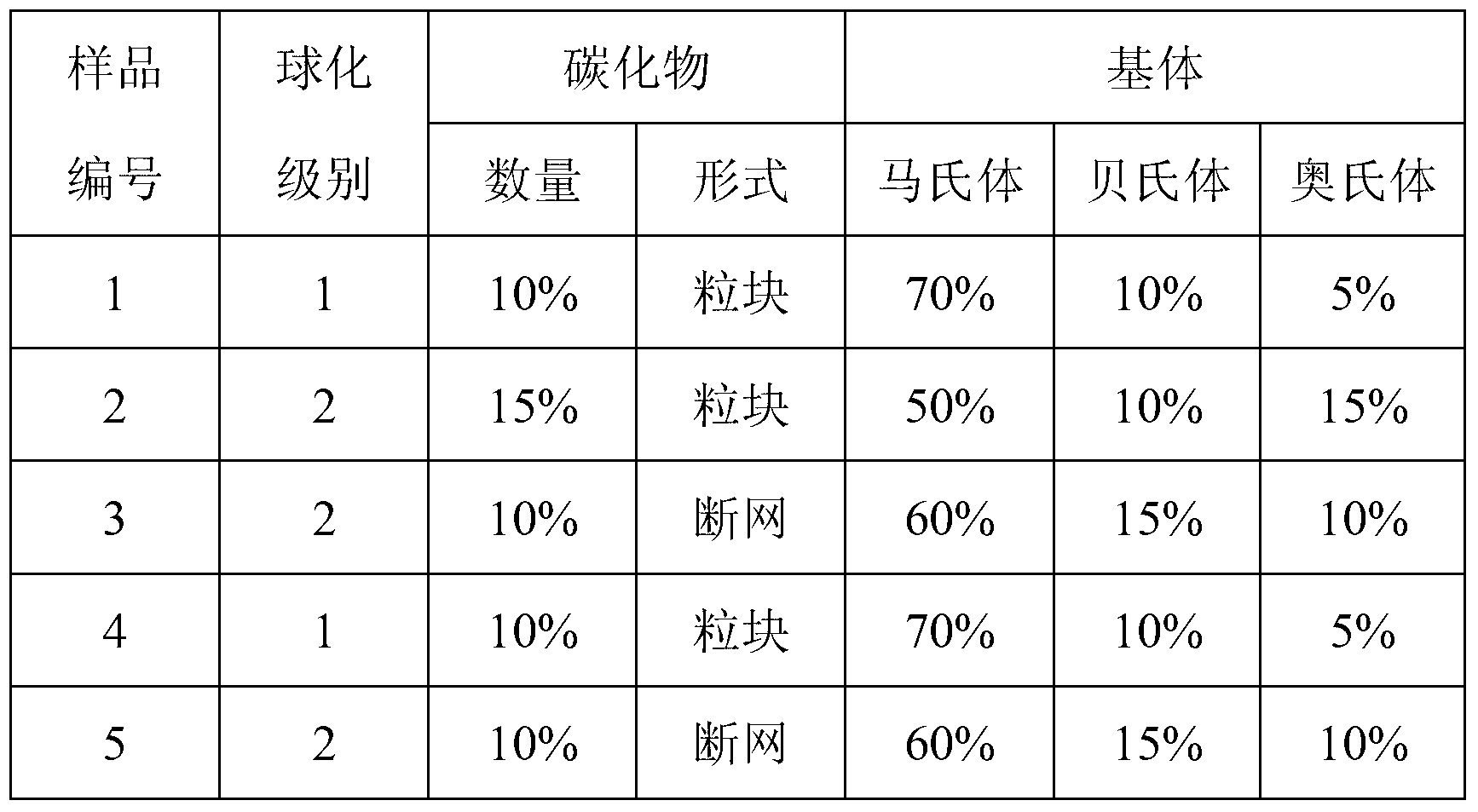

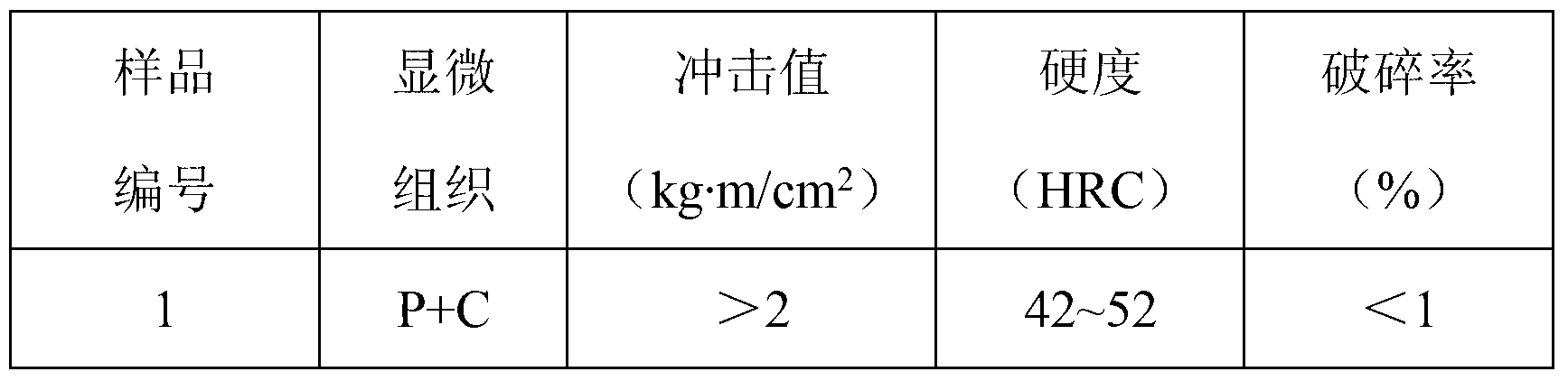

Multi-component alloy casting ball

The invention discloses a multi-component alloy casting ball which comprises the following main chemical components in percentage by weight: 1.8-3.2% of carbon (C), 0.5-1.0% of silicon (Si), 0.4-0.8% of manganese (Mn), 2.0-3.8% of chromium (Cr), no more than 0.5% of molybdenum (Mo), no more than 0.5% of copper (Cu), no more than 0.5% of nickel (Ni), no more than 0.2% of niobium (Nb), no more than 0.5% of zirconium (Zr), no more than 0.5% of vanadium (V), no more than 0.01% of boron (B), no more than 0.15% of phosphorus (P), no more than 0.15% of sulfur (S), 0.5-0.6% of rare earth yttrium (Y-Re) and the balance of iron (Fe). According to the invention, the cost is saved, the corrosion resistance and high temperature resistance of the multi-component alloy casting ball in a wet grinding environment can be improved, the breakage rate can be reduced, and the hardness and shock resistance of the multi-component alloy casting ball in a dry grinding environment can be ensured.

Owner:贵州省遵义市永力机电安装有限公司

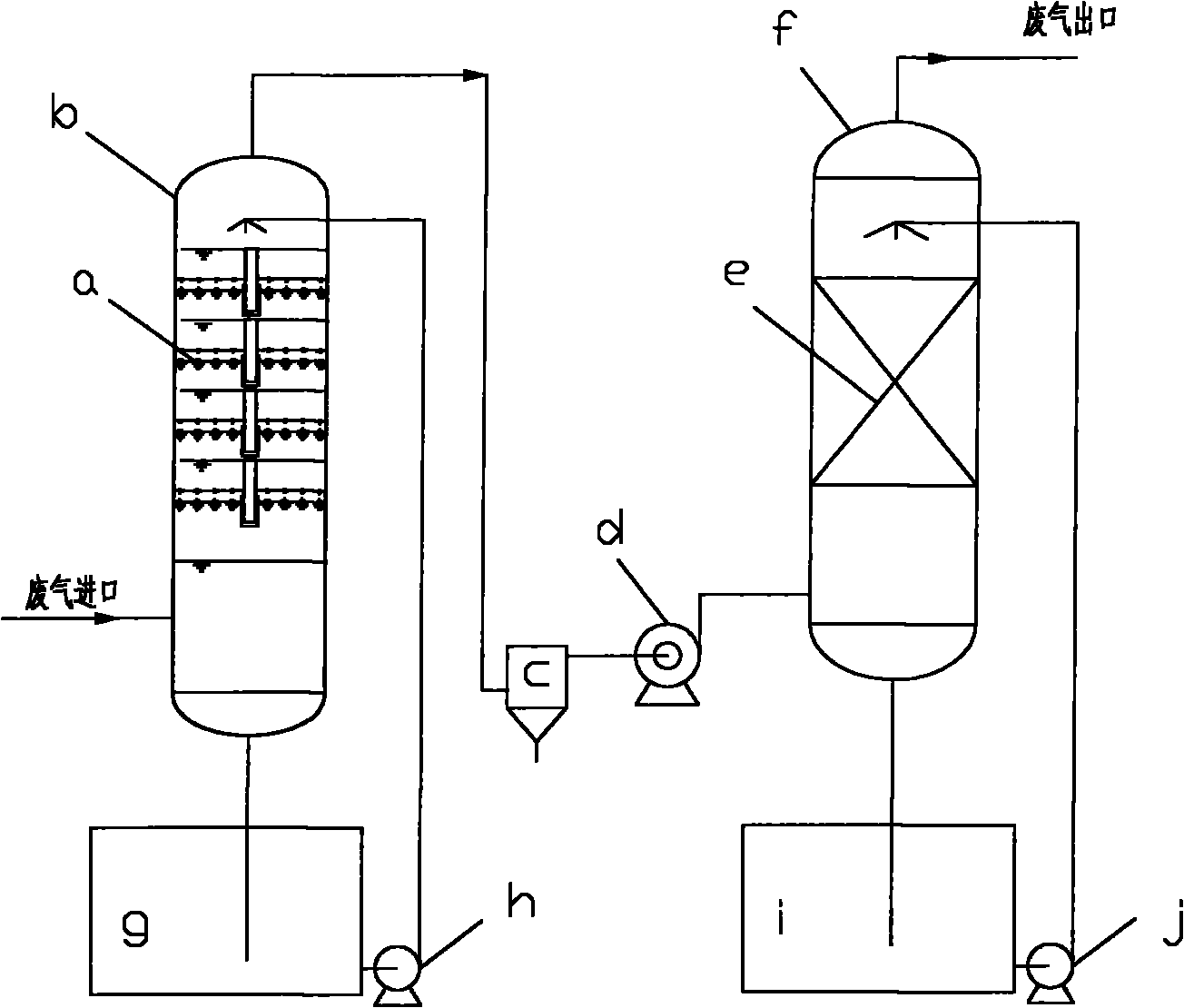

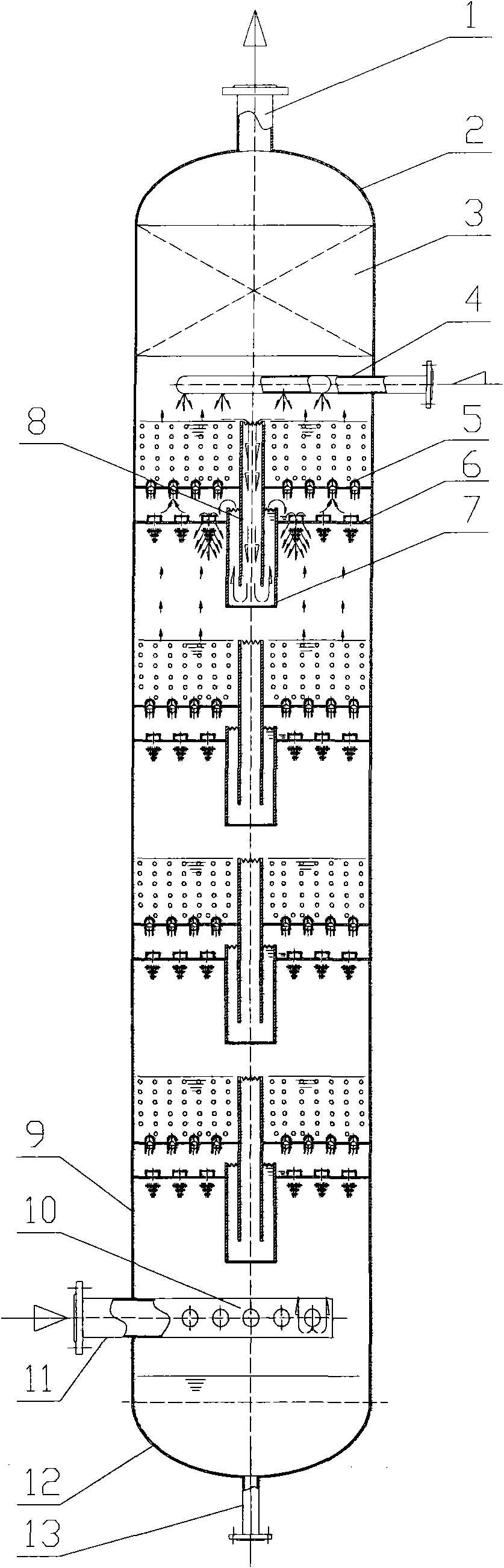

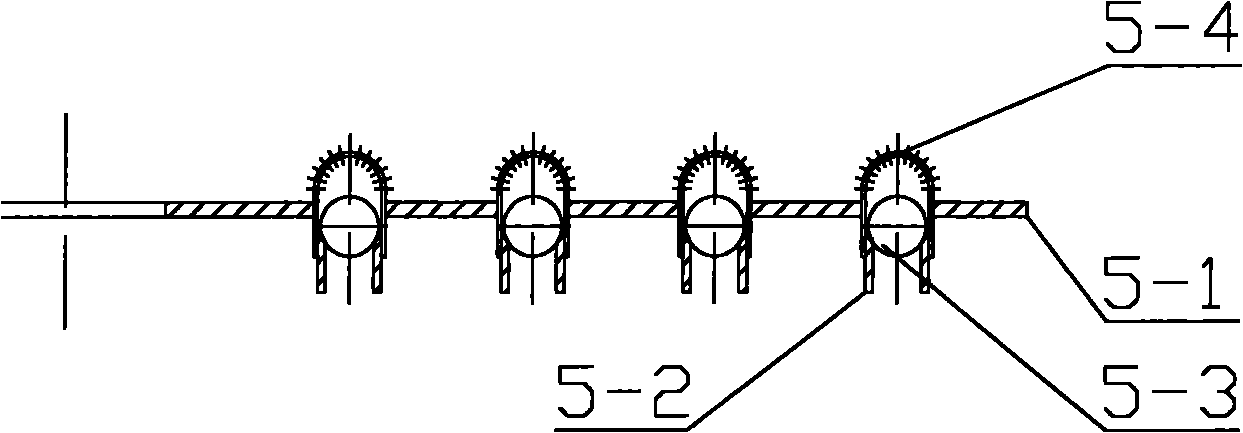

Multi-component stink exhaust gas biological purifying method

ActiveCN101898084AImprove purification effectGreat operating flexibilityDispersed particle separationLarge containersExhaust gasFoul odors

The invention discloses a multi-component stink exhaust gas biological purifying method which adopts two-stage biological purifying treatment. The method comprises the steps of: treating exhaust gas firstly through a biological bubble column and then through a biological filter column; and discharging tail gas after two-stage biological treatment. The biological bubble column utilizes microbe fungicide containing microbe thallus. Exhaust gas is diffused through a nozzle of the bubble column, and then stink components in the exhaust gas are purified and treated with the microbe fungicide in a bubble reaction district. The nozzle of the bubble column is in a bubble pulse valve structure. Absorption liquid containing thallus is used in the bubble absorption column, which not only can purify hydrogen sulfide and organic sulfide, but also can chemically absorb ammonia-class alkaline exhaust gas components in the exhaust gas; and thus, the purifying effect is improved. The invention has theadvantages of large operation flexibility and impact resistance, and the formal stable operation of the succession biological filter columns is ensured. The invention can be used for efficiently purifying the exhaust gas containing mixed stink components, such as sulfide, ammonia, VOCs (volatile organic chemcials), and the like, and is suitable for effusing stink exhaust gas in various sewage treatment plants and effusing exhaust gas in pump stations, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

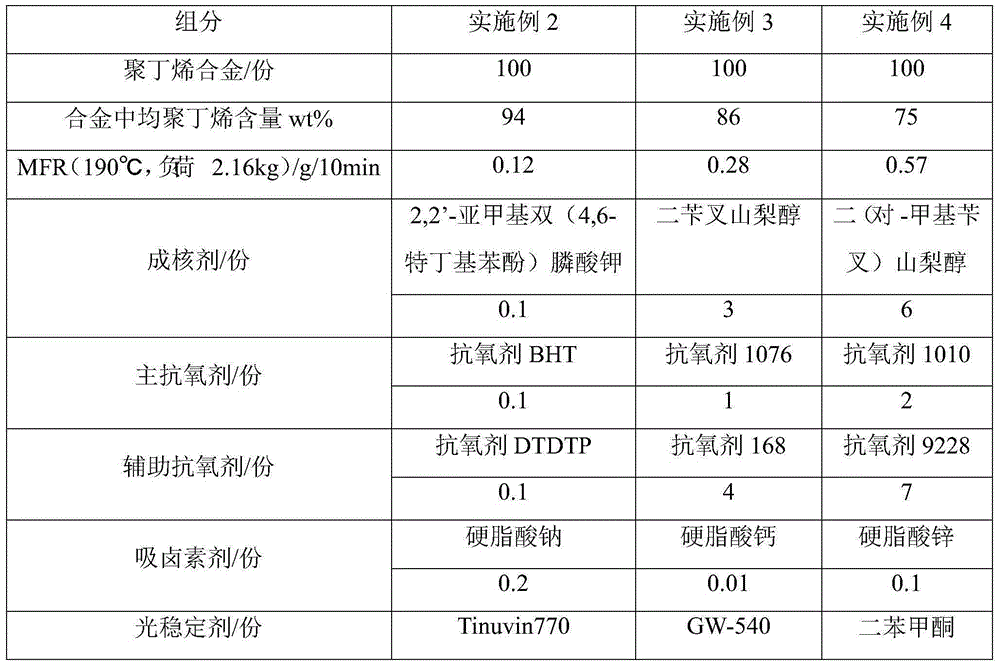

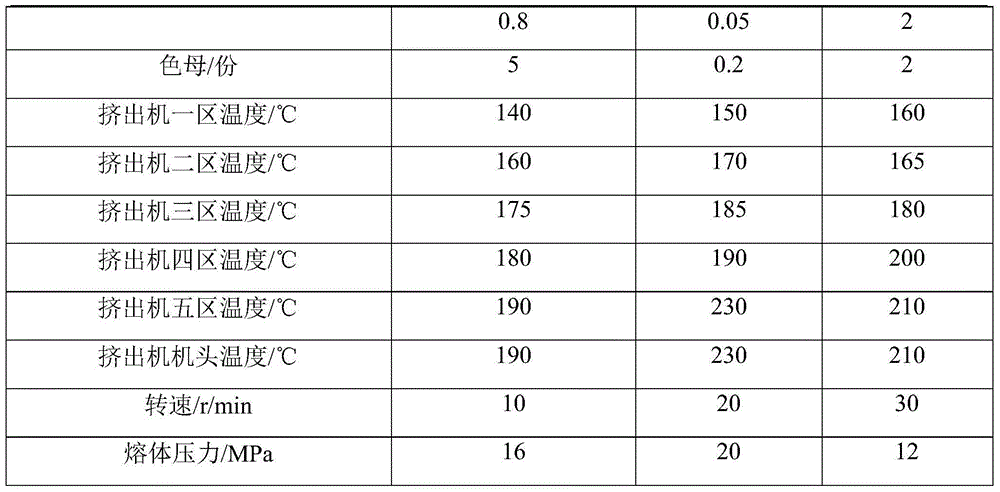

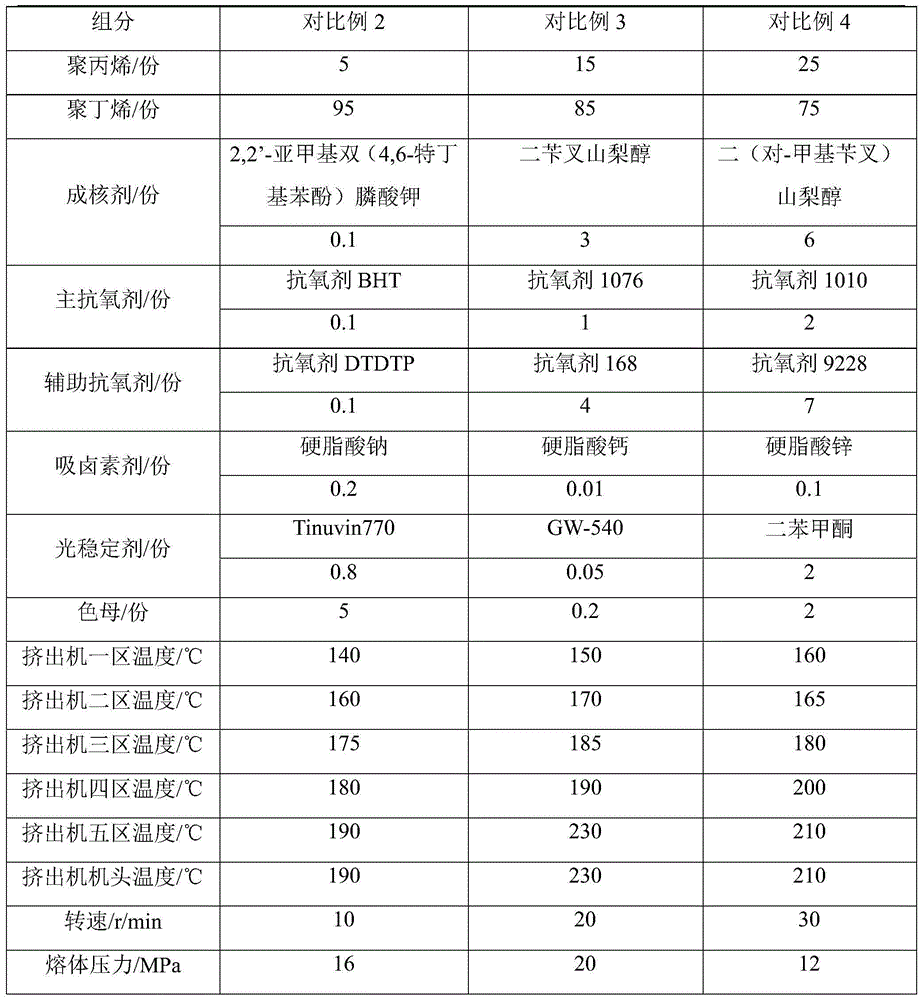

Special polybutylene alloy pipe material for cold/hot water pipe and preparation method of special polybutylene alloy pipe material

The invention relates to a special polybutylene alloy pipe material for a cold / hot water pipe and a preparation method of the special polybutylene alloy pipe material, belonging to the field of high polymer materials. The special polybutylene alloy pipe material comprises the following components: polybutylene alloy, an antioxidant, a halogen absorber, a light stabilizer, a color masterbatch and a nucleating agent. The preparation method comprises the steps of uniformly mixing the polybutylene alloy, the antioxidant, the halogen absorber, the light stabilizer, the nucleating agent and the color masterbatch by using a high-speed mixer; and extruding and pelleting to obtain the special polybutylene alloy pipe material for the cold / hot water pipe. The tensile strength and bending modulus of the special polybutylene alloy pipe material are greatly improved on the basis that the impact resistance, excellent environment stress crack resistance and thermal creep resistance of polybutylene are kept, and the special polybutylene alloy pipe material can be used as a cold / hot water pipe and pipe fitting material.

Owner:QINGDAO UNIV OF SCI & TECH +2

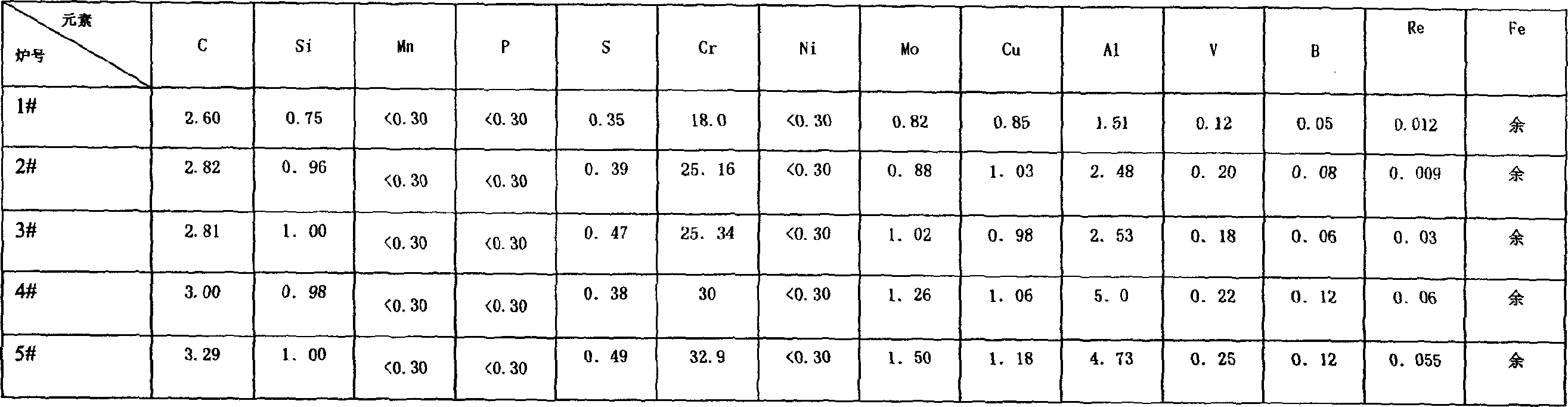

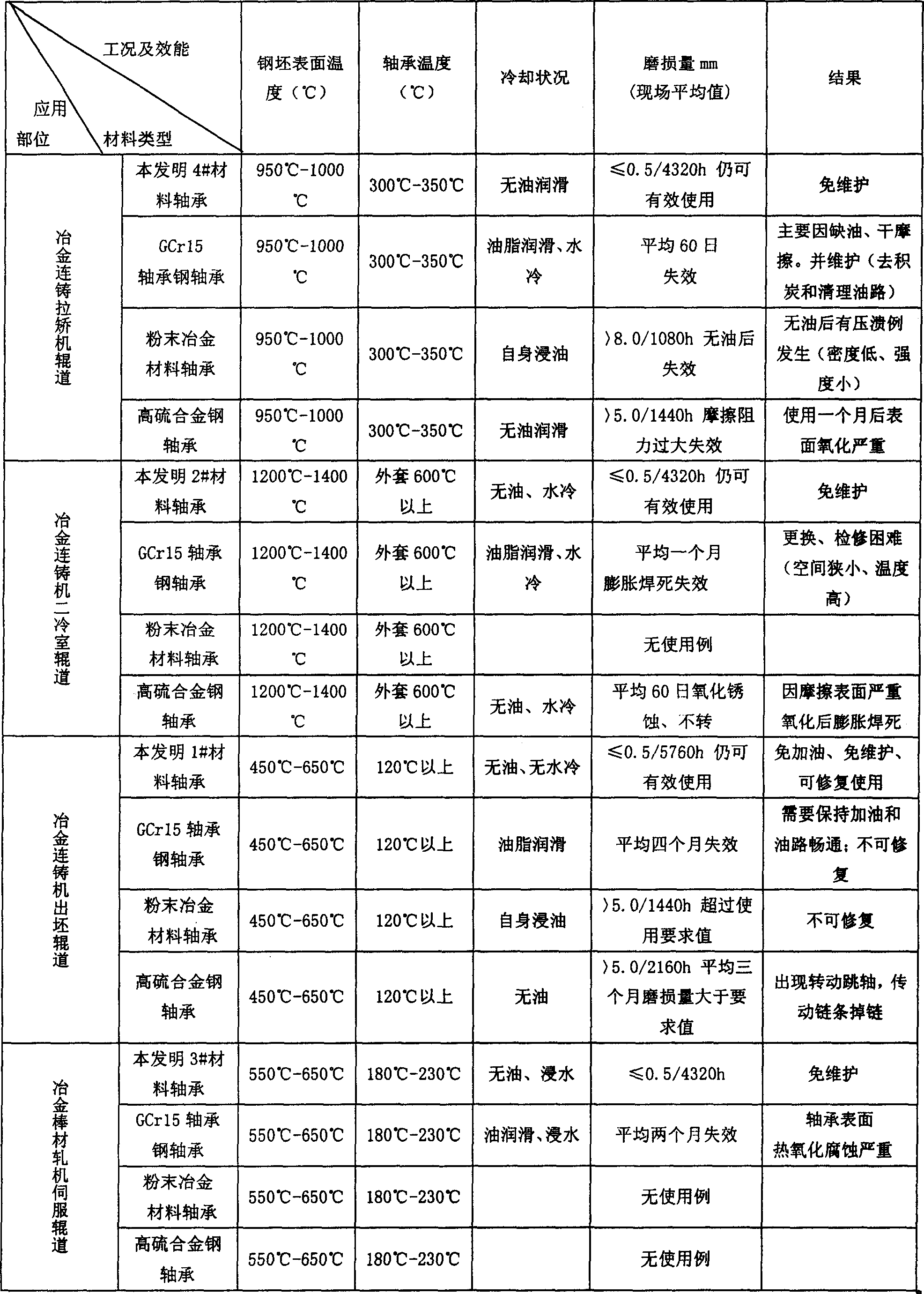

Self-lubricating heat-resistnat and wear-resistant materials

InactiveCN1818117AHigh temperature strength and hardnessIncreased high temperature strength and hardnessBearing componentsOxidation resistantWear resistant

The invention opened a heat-proof and wearing self-lubricating material. It can be used to the shafting bearing, bearing bush, axile bush and the other break-away friction parts of the metallurgy, mining area and machine, especially for the parts of the high temperature (350 DEG C-800 DEG C).the weight ration of the composition is C 2.6-3.%, S 0.35-0.49%, Si 0.5-1.0%, Cr 18-35%, Mo 0.8-1.5%, Cu 0.8-1.2%, Al 1.5-5.0%, V 0.1-0.25%, B 0.05-0.15%, RE 0.008-0.08%, P<=0.3%, Ni<=0.3%, Mn<=0.3%, the residue is Fe. The weight ratio of Cr / C is 5.5-10. The material has the good resistance to heat and wearing character, also it can resist the corrosion of the CO2 and SO2.

Owner:BEIJING CISRI GAONA TECH

Adjustable finishing broach of wheel disc and tenon slot combination surface

InactiveCN102717149AMaintain and improve geometric accuracyEliminate size deviationBroaching toolsTongue and grooveGas turbines

The invention discloses an adjustable finishing broach of wheel disc and tenon slot combination surface. The adjustable finishing broach comprises a mounting section, a cutting section and an adjusting section, wherein the cutting section consists of two halves of separate contour line blade elements and fixed on the mounting section through the adjusting section, and the adjusting section is a replaceable element to adjust the position of the contour line of the cutting section. According to the invention, the dimensional deviation of reground cutting edge can be removed; the geometric accuracy of precisely processed contour line is kept; the tool cost is reduced, and the service life of the tool is prolonged; and the adjustable finishing broach is suitable for broaching machining of the wheel disc and the tenon slot of a heavy gas turbine rotor.

Owner:SHANGHAI JIAO TONG UNIV

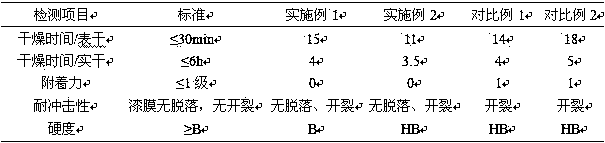

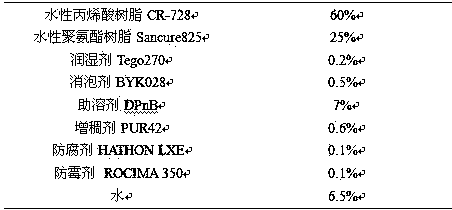

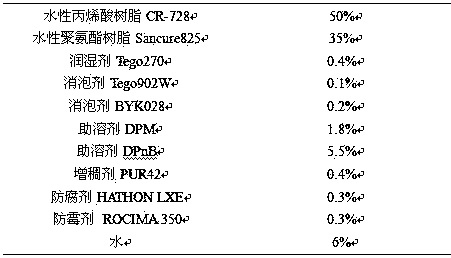

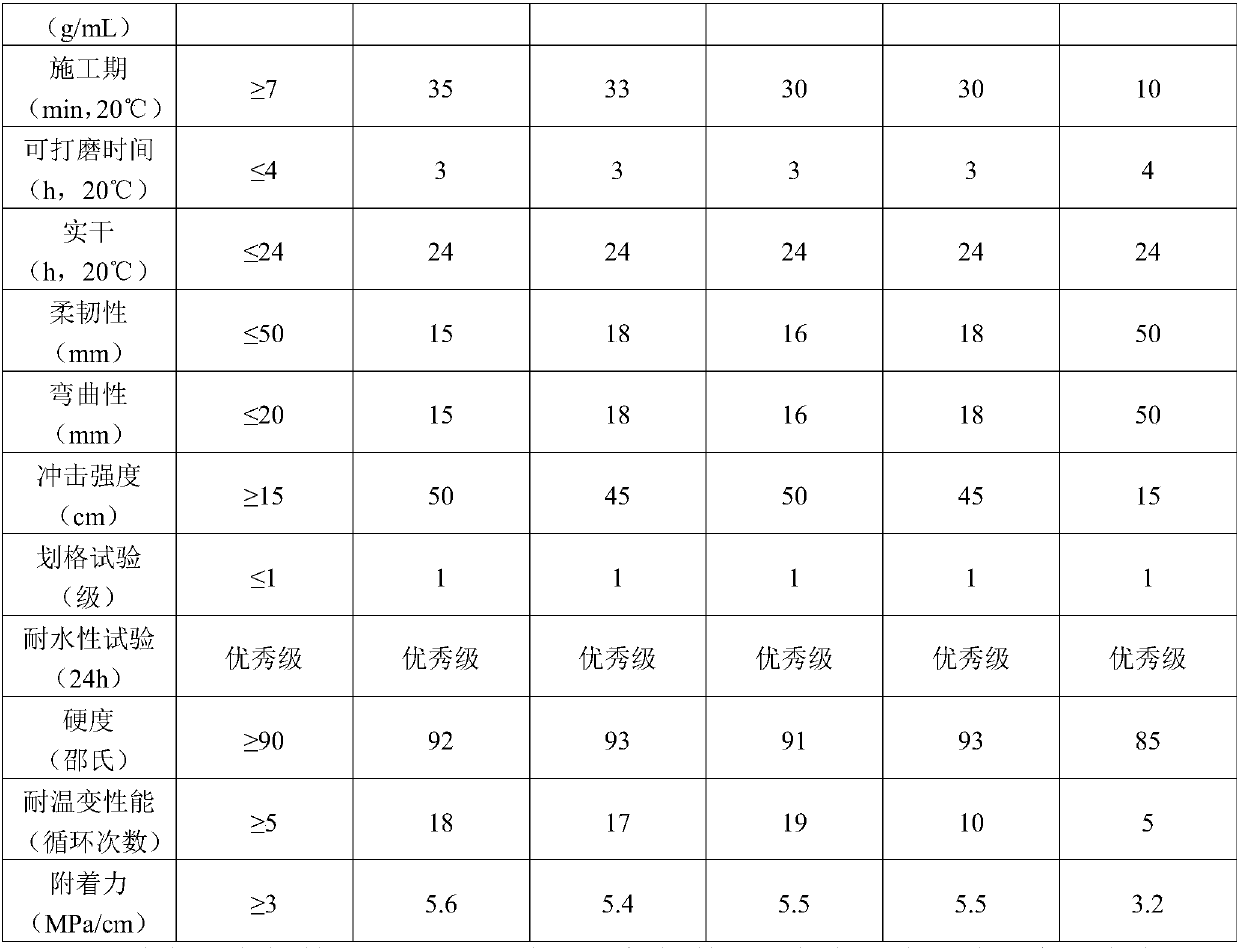

Single-component waterborne finishing coat and preparation method thereof

The invention provides single-component waterborne finishing coat and a preparation method thereof. According to coating performance requirements of existing soft wood and rattan wood products, technical problems that a coating material is poor in flexibility, poor in elasticity and easy to crack are solved by utilizing performances of waterborne acrylic resin and waterborne polyurethane resin, and adjusting a use ratio, so that technical requirements of a client for coating the soft material are satisfied. The single-component waterborne finishing coat comprises the following main components in percentage by weight: 50%-60% of waterborne acrylic resin, 25%-35% of waterborne polyurethane resin, 0.2%-0.5% of a wetting agent, 0.3%-0.5% of a defoaming agent, 6%-8% of a cosolvent, 0.4%-0.6% of a thickener, 0.1%-0.3% of a preservative, 0.1%-0.3% of a mildew preventive and 6%-8% of water.

Owner:GUANGDONG BADESE CHEM

High manganese steel and preparation method thereof

InactiveCN102534405AGuaranteed impact resistanceGuaranteed wear resistanceProcess efficiency improvementQuenching agentsHigh resistanceManganese

The invention discloses high manganese steel, which consists of the following components in percentage by weight: 0.9-1.2 % of C, 11-14 % of Mn, 0.3-0.6 % of Si, 1.5-2.5 % of Cr, less than or equal to 0.04 % of P, less than or equal to 0.04 % of S, and the balance of ferrum. A preparation method for the high manganese steel comprises the following steps of: selecting raw materials; performing smelting, namely preparing molten steel only after the components are ensured to be qualified, and controlling the temperature of the molten steel to be 1,650 DEG C for casting; performing modeling, painting after the modeling is finished, and performing mold assembly and casting; performing cleaning, namely deburring castings, and polishing and checking the castings; performing thermal treatment, namely stacking the cleaned castings in a high-temperature thermal treatment furnace, sealing a furnace door, raising the temperature to 1,100 DEG C, preserving the heat for 4 hours, quickly discharging the castings out of the furnace, and placing the castings into water for quenching; and cleaning the surfaces again, and checking and accepting, warehousing, stacking and classifying the castings. The invention has the advantages that the high manganese steel has high impact resistance and abrasion resistance; and the preparation method is simple, the production cost is low, and the market prospect is good.

Owner:TONGLING ANDONG CAST STEEL

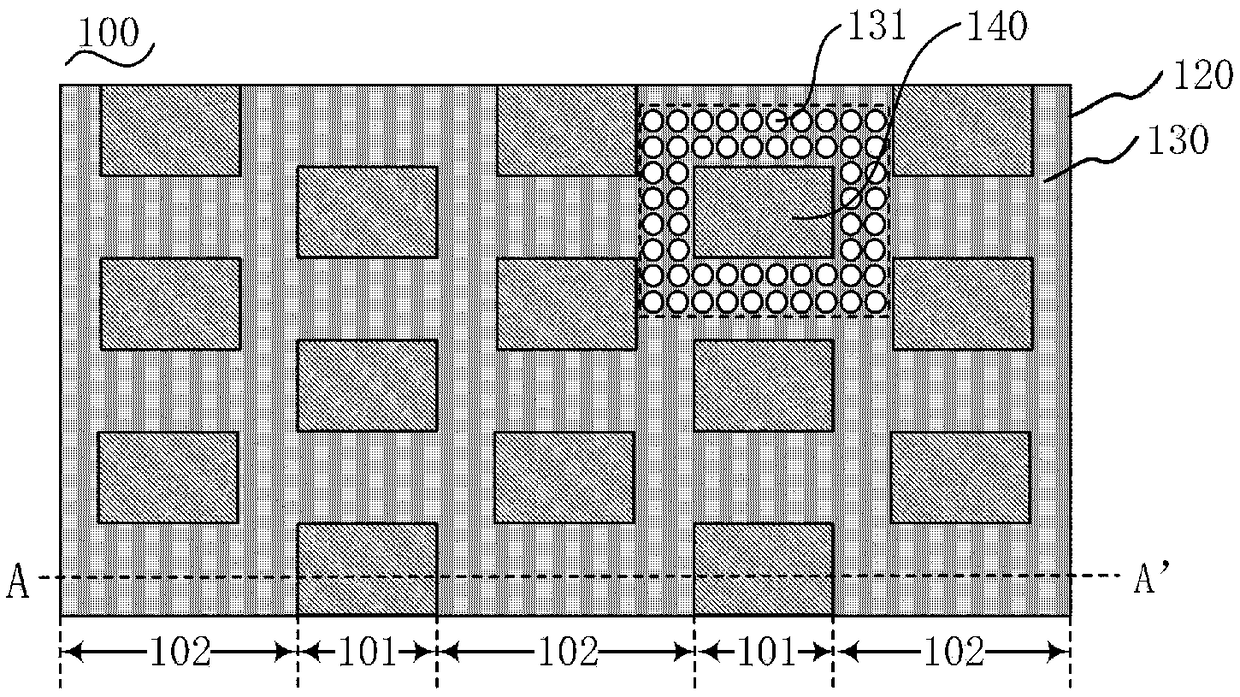

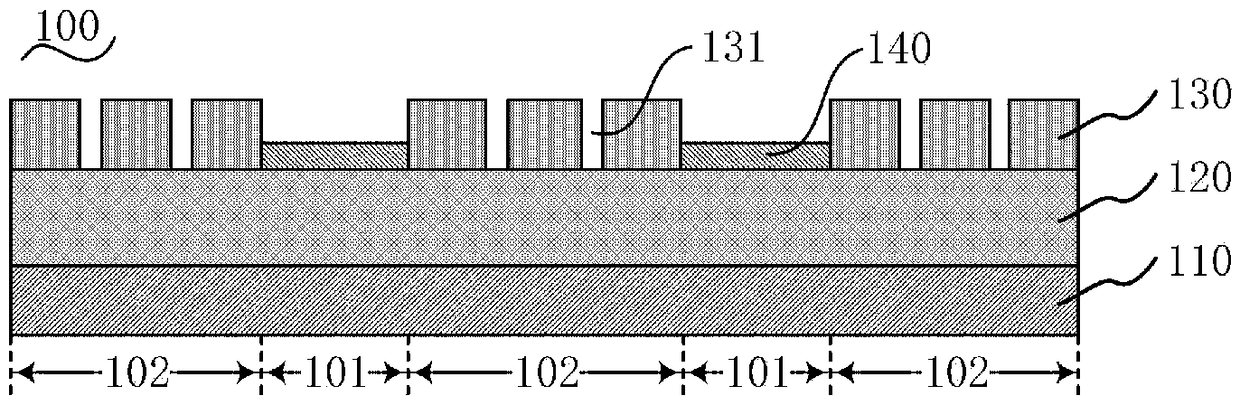

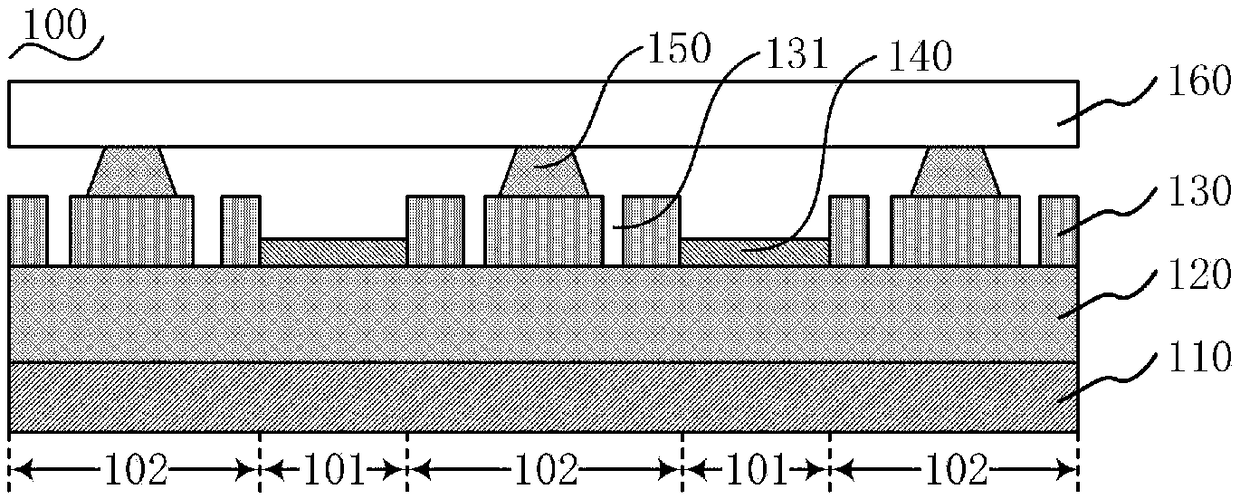

Display panel, display device, and method for manufacturing display panel

ActiveCN109148531AGuaranteed impact resistanceImprove display failureSolid-state devicesPhotovoltaic energy generationCushioningDisplay device

The invention relates to a display panel, a display device and a preparation method of the display panel. At first, a display panel is provided, which includes an array substrate and a pixel defininglay, wherein the pixel defining layer is arranged on the array substrate and defines a plurality of pixel regions, a plurality of groove structures are arranged on the pixel defining layer, and the groove structures do not overlap with the pixel regions. As that groove structure is arrange at the peripheral position of the pixel area, the display panel can disperse and release the stress inductivity increased instantaneously in the groove structure when the display panel is subject to external impact, thereby improving the impact resistance of the display panel and achieving the purpose of protecting the pixel area unde the impact of external force. In addition, the display panel needs no additional cushioning material, the thickness of the display panel is reduced, and the bending performance of the display panel is improved.

Owner:YUNGU GUAN TECH CO LTD

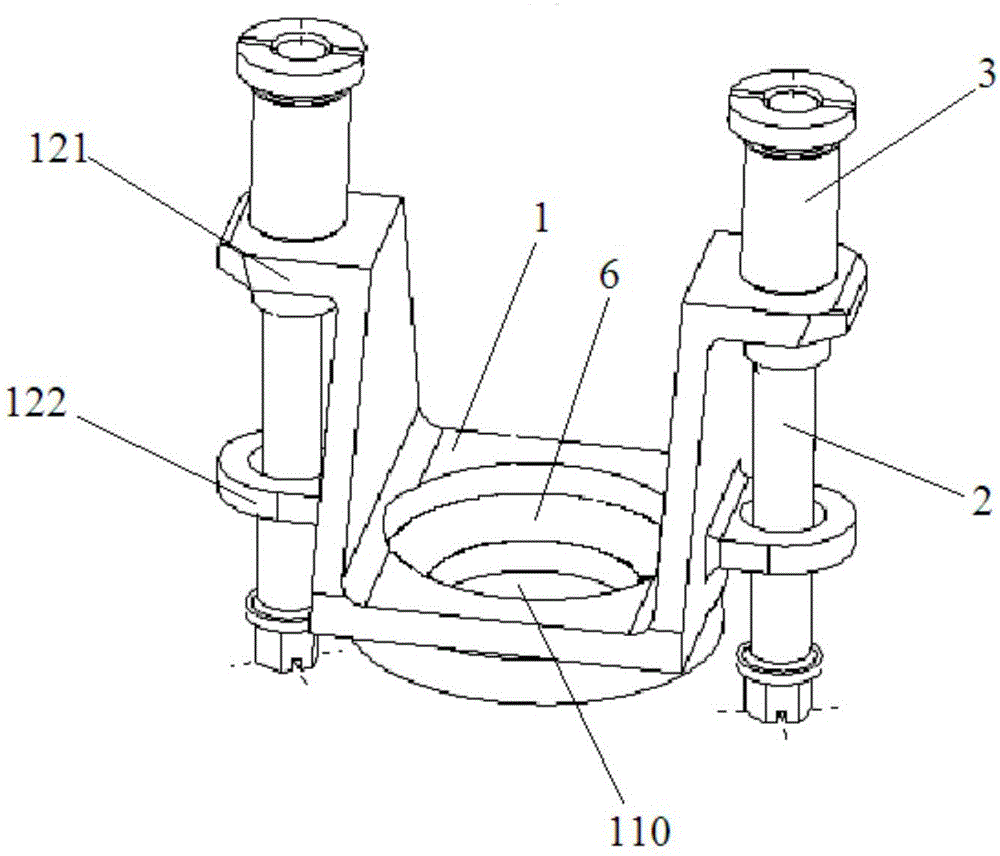

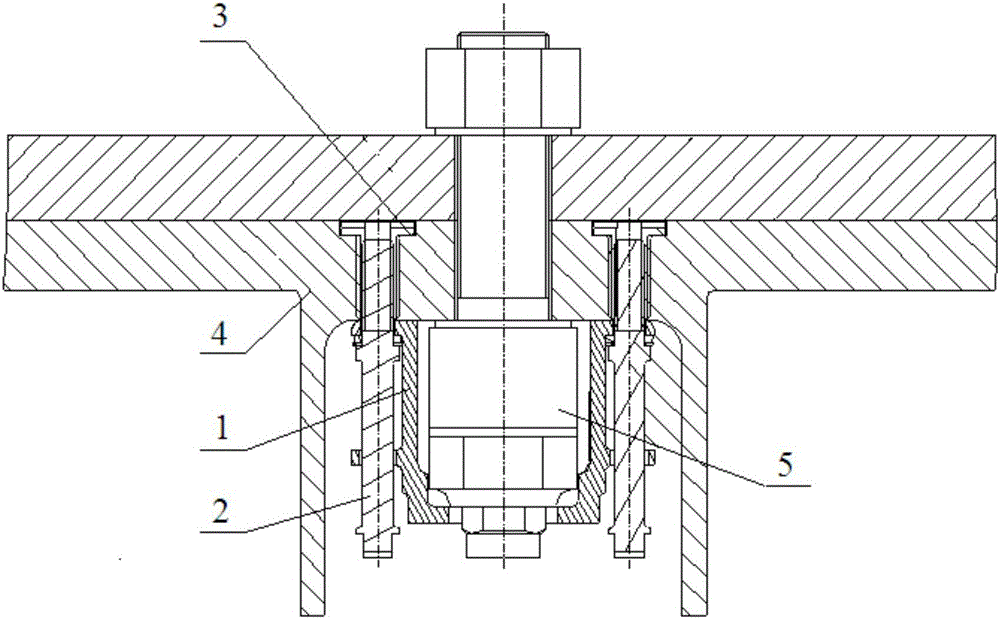

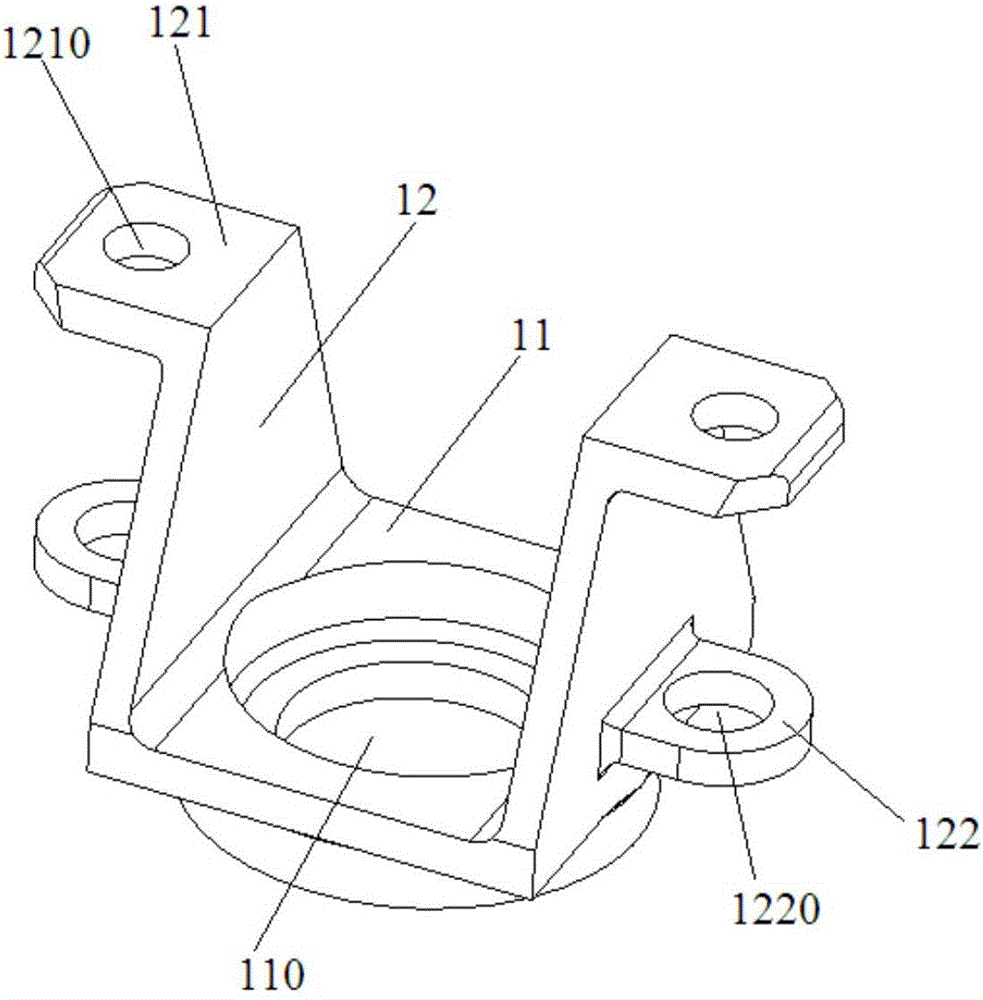

Explosive bolt acquirer

InactiveCN106403733AGuaranteed impact resistanceEasy to installSelf-propelled projectilesHigh volume manufacturingEngineering

The invention relates to the technical field of projectile body structural design, in particular to an explosive bolt acquirer. The explosive bolt acquirer comprises a support and an installation bolt, the support is in an inversed-n shape and comprises a base plate and two side plates, the side plates and the two ends of the base plate are integrally molded, the upper ends of the side plates extend to the outer sides to be provided with end edges, and installation holes are formed in the end edges; the installation bolt penetrates the installation holes to be connected with a shell end frame so that the support can be fixed to the lower surface of the shell end frame, the base plate is provided with a buffer hole, and a bolt head of an explosive bolt is located between the two side plates and is embedded into the buffer hole. Compared with a traditional explosive bolt acquiring structure, the explosive bolt acquirer is convenient and rapid to install, the design, analyzing and testing cost is reduced, projectile body structural design quick response and cost reduction are achieved, material selecting and machining can be separated from material selecting and machining of a projectile body overall bin, the machining difficulty is reduced, selectable materials are many, the production efficiency is improved, productization is facilitated, and the large-batch production efficiency is high.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

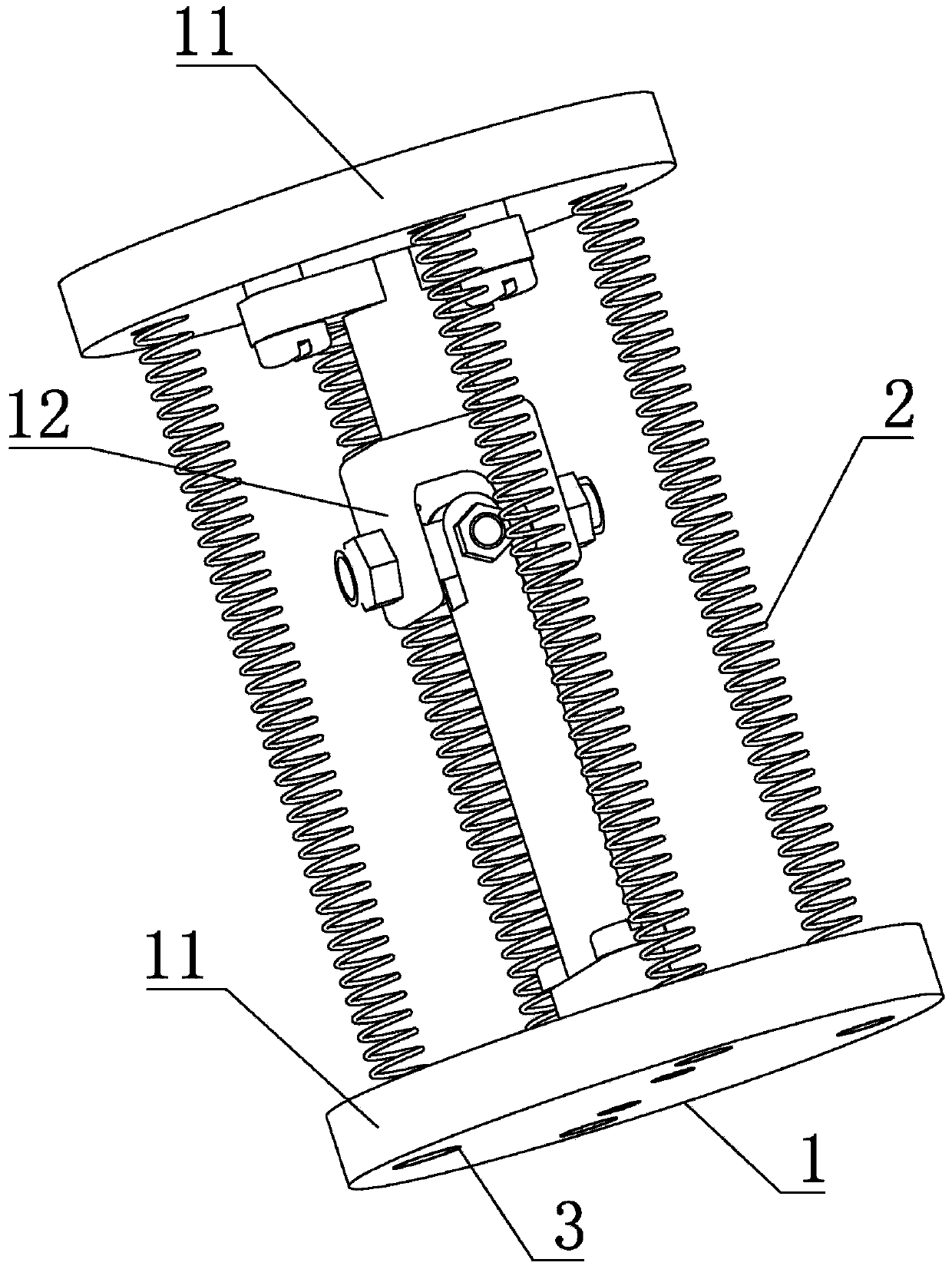

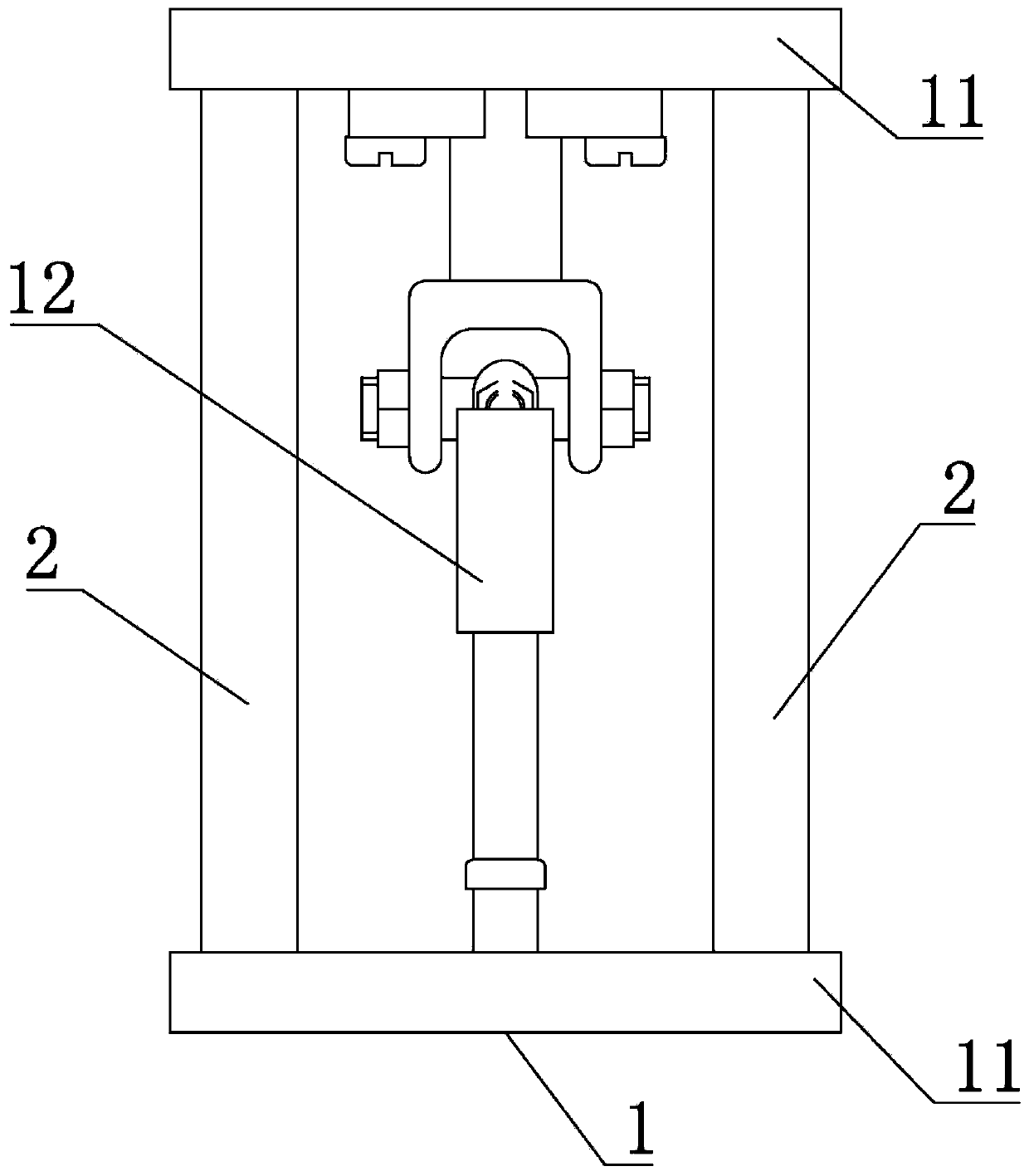

Posture control device

The invention discloses a posture control device. The device comprises a supporting frame; the supporting frame comprises more than two spring seats which are arranged in the vertical direction; more than two springs, which are manufactured through two-way memory alloy, are vertically arranged between every two adjacent spring seats; the upper end and the lower end of each spring are respectively fixedly connected to every two adjacent upper and lower spring seats; every two adjacent spring seats are integrally connected through a universal coupling; the upper end and the lower end of each universal coupling are respectively fixedly connected to the upper and lower spring seats. The posture control device has the advantages of being large in driving force, simple in structure, recyclable, high in reliability, capable of working for a long time, being small in cost, small in noise, and convenient to mount; in addition, the outstanding performances of biological posture control and the concise and compact structure are brought; the two-way memory alloy springs are high in flexibility and can ensure the impact resistance of the posture control device.

Owner:湖北三江航天红林探控有限公司

Antistatic ABS (acrylonitrile-butadiene-styrene) modified material and preparation method thereof

ActiveCN104497472AGuaranteed impact resistanceImprove antistatic performanceSurface resistivityCarbon black

The invention relates to the technical field of ABS (acrylonitrile-butadiene-styrene) materials, and in particular relates to an antistatic ABS modified material and a preparation method thereof. The modified material comprises the following raw materials in parts by weight: 62-94 parts of ABS resin, 8-12 parts of an antistatic agent, 8-12 parts of a toughening agent, 0.8-1.6 parts of zinc stearate, 0.05-0.15 part of PETS, 0.3-0.7 part of PMI, 0.3-0.7 part of a diffusant and 0.1-0.6 part of an antioxidant, wherein the antistatic agent is a mixture consisting of carbon black and carbon fiber in a weight ratio of 1:(0.8-1.2). According to the preparation method provided by the invention, the antistatic property, processability and shock resistance of the modified material are improved by adding the antistatic agent, the toughening agent, the PETS and the PMI to perform co-blending modification, so that the surface resistivity of the modified material reaches 5-7 orders of magnitude, and is significantly improved in comparison with that of the existing antistatic ABS material.

Owner:广东省天行健新材料股份有限公司

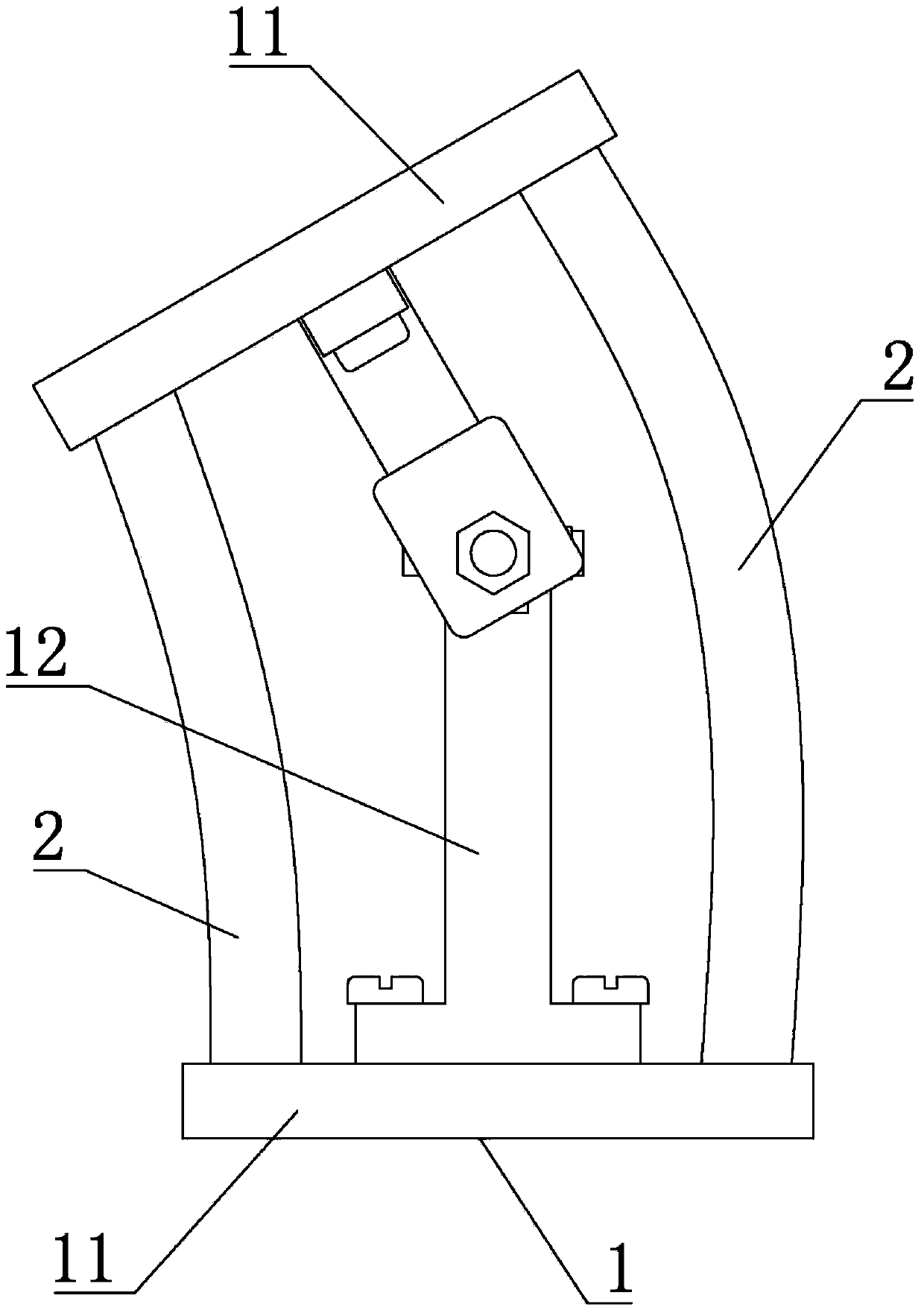

Frit suitable for color development as well as colored vitreous enamel product and preparation method

The invention relates to a frit suitable for color development as well as a colored vitreous enamel product and a preparation method. The frit suitable for color development comprises the following components in parts by weight: 20-35 parts of feldspar, 10-45 parts of quartz, 0.5-5 parts of Suzhou clay, 2-6 parts of calcium borate, 1-7 parts of aluminium hydroxide, 12-32 parts of light calcium carbonate, 1-8 parts of barium carbonate, and 1-8 parts of borax. The preparation method for the colored vitreous enamel product comprises the following steps: (1), preparing enamel slurry; (2), enameling the product; (3), sintering. The colored vitreous enamel product comprises an inner enamel layer and an outer enamel layer, wherein the ceramic carcass is high-end ceramic, the inner enamel layer is a transparent frit enamel layer, and the outer enamel layer is a colored enamel layer made from the frit suitable for color development. The frit suitable for color development is appropriate in frit expansion factor, relatively wide in sintering range, bright and flat in enamel surface, and can be used for various colored decoration of various high-end ceramic products. The preparation method of the colored vitreous enamel product and the colored vitreous enamel product can be used for producing various high-end enamel products for hue decoration.

Owner:山东省淄博华洋陶瓷有限责任公司

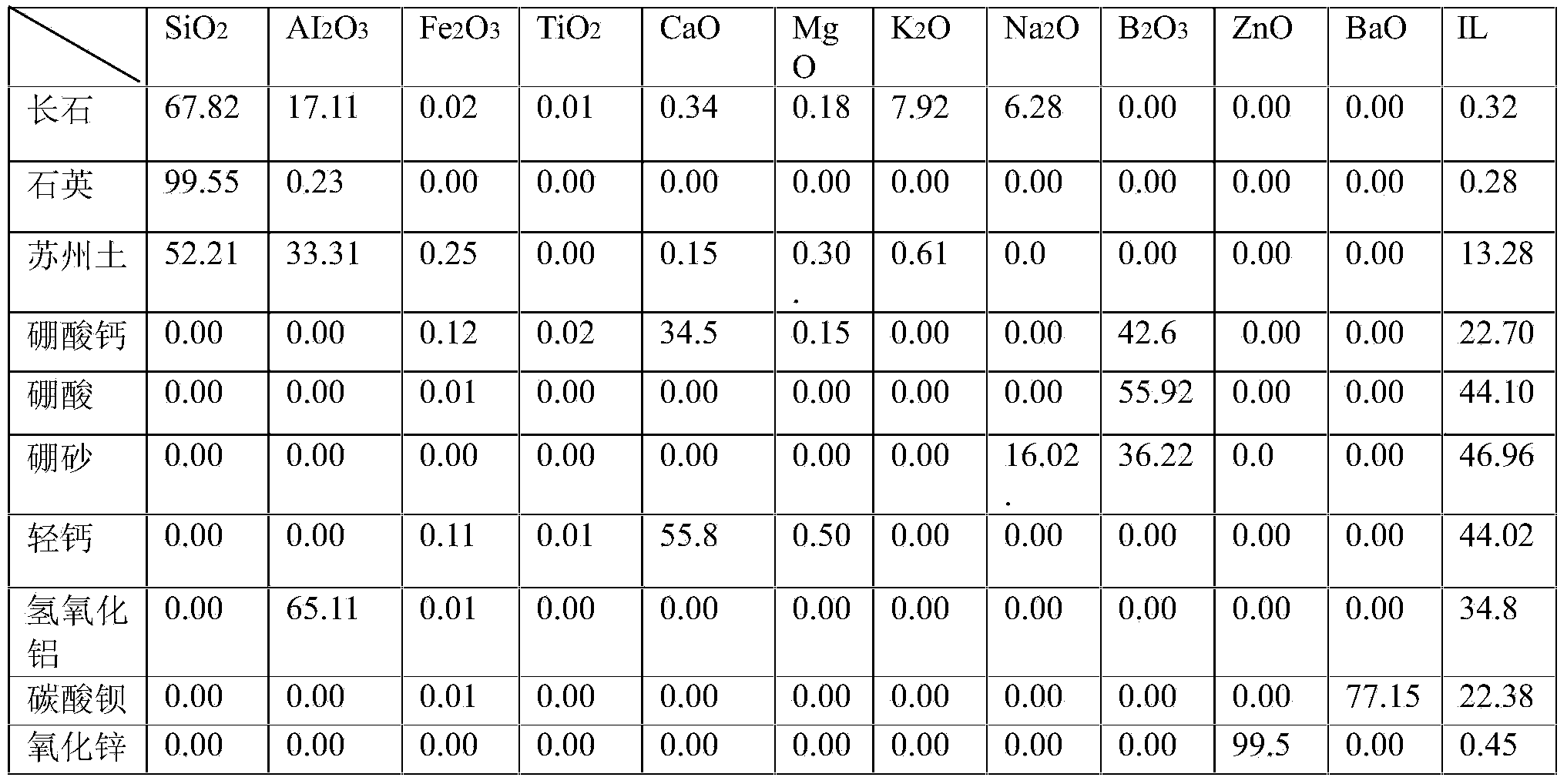

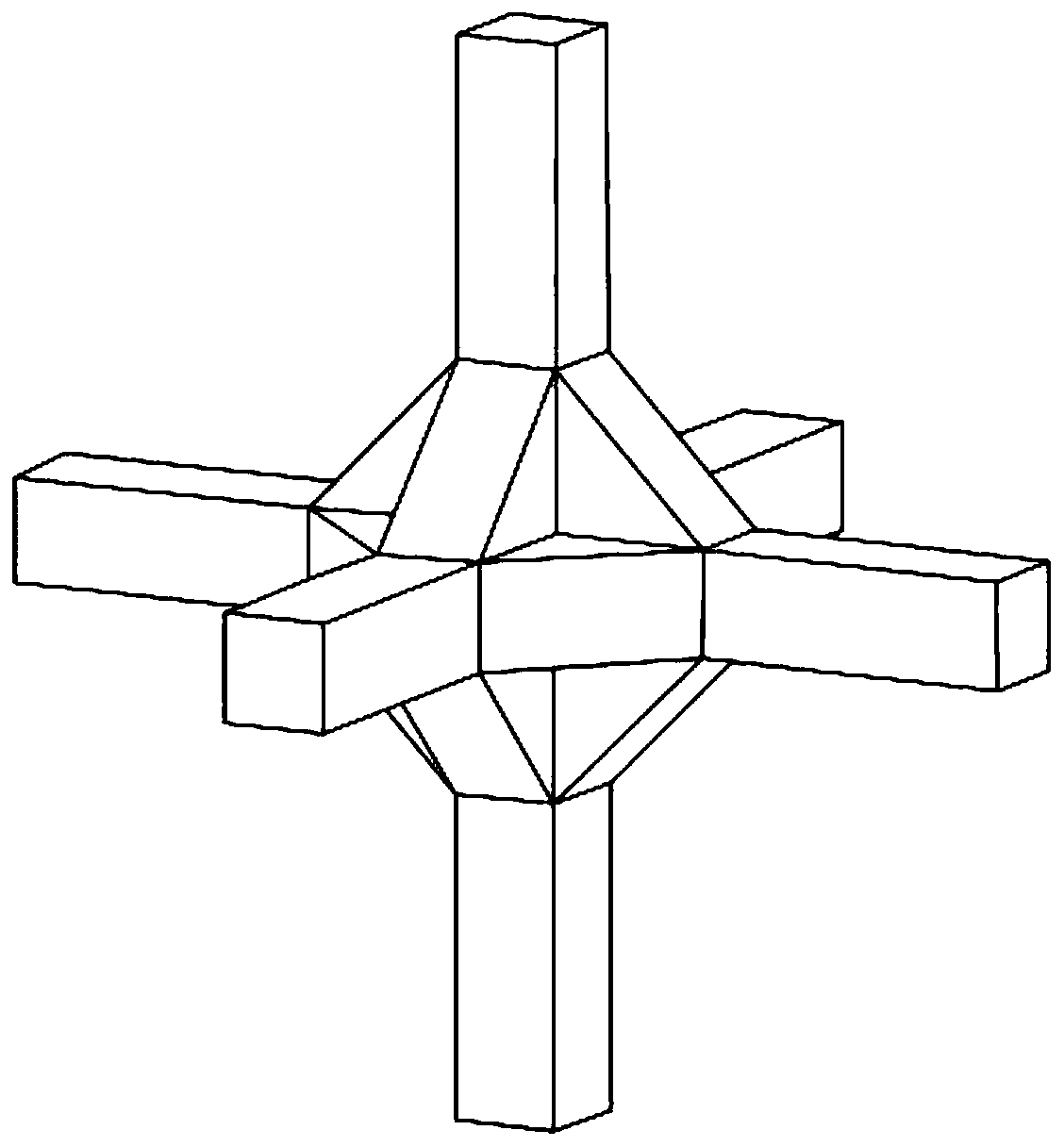

Indexable cutting insert for rough machining

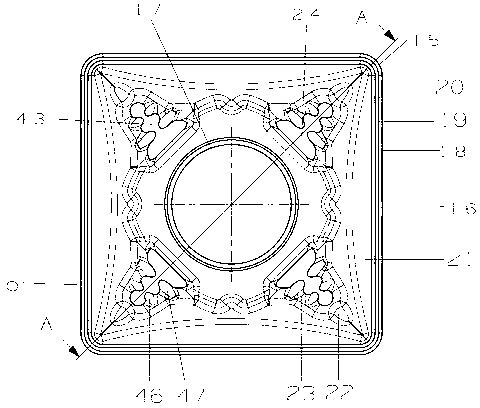

ActiveCN103009333AImprove impact resistanceGuaranteed impact resistanceMetal-working hand toolsEdge strengthEngineering

The invention discloses an indexable cutting insert for rough machining. An insert body is a polygonal body, the geometrical center is provided with a mounting through hole, a chip breaker body is arranged around the mounting through hole, and cutting units are respectively distributed at the included angle between each two neighboring sides. The indexable cutting insert is characterized in that each cutting unit consists of a main cutting edge and an auxiliary cutting edge; each of the main cutting edge and the auxiliary cutting edge is provided with a chamfer plane and an arris plane, and a first front insert face and a second front insert face are connected with the chip breaker body through concave bottoms; at each cutting unit, the chip breaker body is provided with a boss, the surface of the boss gradually rises to form a first chip breaker and a second chip breaker, a first concave is formed between the ridge of the first chip breaker and the ridge of the second chip breaker, a second concave is formed between the second chip breaker and the chip breaker body, and both the first concaves and the second concaves are smoothly connected with the concave bottoms. Under the premise of guaranteeing the edge strength of the insert, the cutting resistance is decreased, the indexable cutting insert has high chip-breaking ability, and the overall cutting performance is good.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

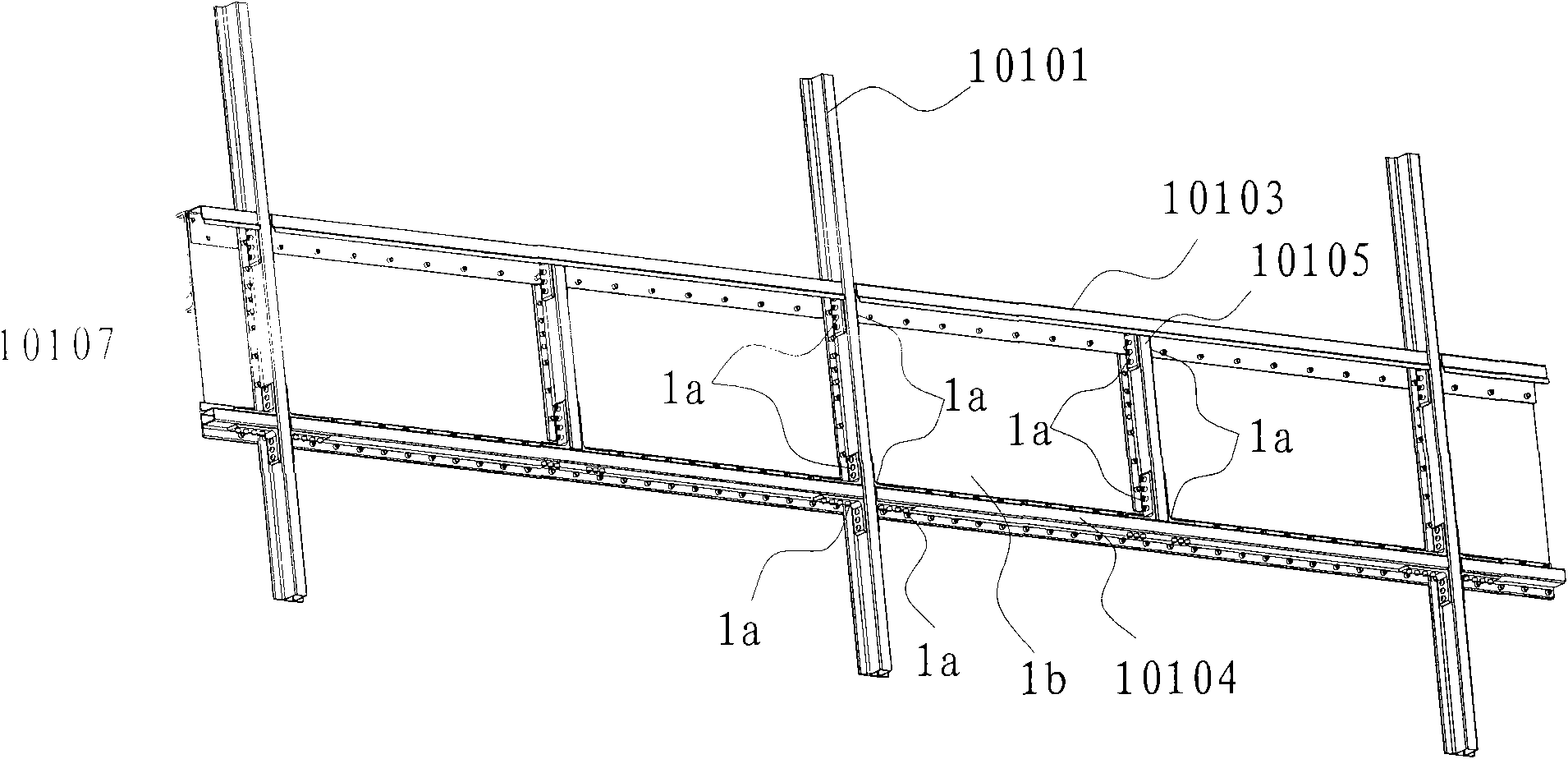

Car frame connecting structure

ActiveCN102009698AReduce intensityNo drop in strengthSuperstructure connectionsPassenger vehicle superstructuresStress concentrationVehicle frame

The invention relates to a car frame connecting structure comprising a side window longitudinal beam, an upright column, a stiffening beam, a top cap longitudinal beam and a top cap horizontal beam, wherein the side window longitudinal beam is riveted with the upright column through a medium corner; the side window longitudinal beam is riveted with the lower part of the stiffening beam; the upright column is riveted with the stiffening beam; the upper part of the stiffening beam is riveted with the top cap horizontal beam through a large corner; and the top cap longitudinal beam is riveted with the top cap horizontal beam through the medium corner. The car frame connecting structure is made of aluminium alloys or magnesium alloys. The invention achieves the effect on reducing weight approximate to a half under the conditions of same or similar strength of steels by adopting the car frame connecting structure made of the aluminium alloys or the magnesium alloys, thereby greatly reducing the weight of a car body without reducing the strength; and in addition, the invention has the advantages of reduced manufacturing and operating cost, long service life and more energy saving and environmental protection, prevents the stress concentration caused by adopting a welding mode through riveting connection and has firm connection without generating cracks.

Owner:北京绿程锦绣能源科技有限公司

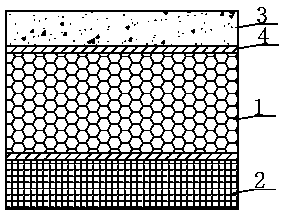

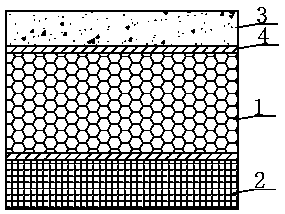

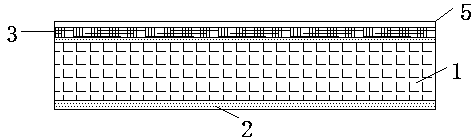

Cast-in-situ type polyurethane micro-foaming runway surface layer and construction technology thereof

InactiveCN110004794AHigh foaming ratioPromote absorptionGround pavingsEpoxy resin coatingsWater basedPolycarbonate

The invention discloses a cast-in-situ type polyurethane micro-foaming runway surface layer and a construction technology thereof, and particularly relates to the field of sports materials. The cast-in-situ type polyurethane micro-foam runway surface layer comprises an elastic layer, and the elastic layer is prepared from a component A and a component B in a reaction mode, wherein the component Ais prepared from the following adopted main materials in parts by weight: 10-20 parts of polyether polyol, 10-20 parts of a diluent and 60-70 parts of HDI tripolymer, and the component B is prepared from the following adopted main materials in parts by weight: 20-30 parts of polycarbonate diol (PCDL), 5-10 parts of a chain extender, namely dimethylolpropionic acid (DMPN), 20-30 parts of MDI, 2-10parts of triethylamine (TEA), 10-30 parts of deionized water, 5-10 parts of a pigment, 20-25 parts of a filter and 0.1-0.2 part of an additive. By correspondingly preparing the component A and the component B, prepared polyurethane glue and a polyurethane sizing agent are mixed and stirred, a water-based polyurethane foaming body is obtained by adding a foaming agent, a foam stabilizing agent anda thickener, inert gas is introduced in the stirring process, the foaming rate of the elastic layer is increased, an uniformly-dispersed microporous structure is quickly formed, the effect of buffering impact force is achieved, the impact absorption property and the overall performance of the surface layer structure can be improved, the quality is stable, and construction is convenient.

Owner:江苏长诺运动场地新材料有限公司

Composite car panel and preparation method thereof

PendingCN107825792AGood compatibilityHigh strengthSynthetic resin layered productsLaminationThermoplasticEngineering

The invention relates to a composite car panel and a preparation method thereof. The composite car panel comprises a panel core made from a thermoplastic resin material, wherein the upper surface andthe lower surface of the panel core are respectively connected with surface layers, and each surface layer is formed by laying a single or multiple continuous fiber reinforced thermoplastics resin prepreg sheet layers; the surface of the surface layer at one side is connected with an adhesive medium layer, and the surface of the adhesive dielectric layer is coated with a PUR hot melt adhesive layer; a peeling-resistant layer is laid on the PUR hot melt adhesive layer, and the adhesive medium layer is made from a porous breathable material; one surface, facing the PUR hot melt adhesive layer, of the adhesive medium layer is partially embedded into the PUR hot melt adhesive layer, and one surface, facing the continuous fiber reinforced thermoplastics resin prepreg sheet layer, of the adhesive medium layer is partially embedded in the continuous fiber reinforced thermoplastics resin prepreg sheet layer. The composite car panel not only has relatively high anti-scratch performance, anti-aging performance and wear resistance, but also has low water absorption performance, and ensures the overall strength and impact resistance of the composite car panel.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

Environment-friendly plastic material

The invention discloses an environment-friendly plastic material. The plastic material comprises the following components in parts by weight: 30-40 parts of degradable plastic master batches, 15-30 parts of modified starch, 8-12 parts of copolymerization type polypropylene, 2-4 parts of glycidyl methacrylate, 3-5 parts of carbon black, 1-3 parts of glass fiber, 1-3 parts of plant fiber, 0.6-0.8 parts of ethylene terephthalate, 2-4 parts of stearic acid and 0.3-0.5 parts of an anti-oxidant. The environment-friendly plastic material has the beneficial effects that the plastic package material which is prepared by degradable plastic master batches as raw materials has degradability, and shock resistance, oxidation resistance and corrosion resistance of the package material in prior art are kept; after usage, the plastic material is composted and degraded in the environment, so that environment pollution is substantially alleviated; the packaging material has a wide usage range and a wide application prospect.

Owner:JIANGSU DAOQ NEW MATERIAL TECH CO LTD

Medium manganese steel and preparation method thereof

The invention discloses medium manganese steel. The medium manganese steel comprises the following components in percentage by weight: 0.9 to 1.1 percent of carbon (C), 6 to 8 percent of manganese (Mn), 0.3 to 0.6 percent of silicon (Si), 1.0 to 1.2 percent of chromium (Cr), 0.2 to 0.4 percent of percent (MO), less than or equal to 0.04 percent of phosphorus (P), less than or equal to 0.04 percent of sulphur (S), and the balance of Fe. A preparation method comprises the following steps of: selecting raw materials; smelting, and yielding water after ensuring that the components are qualified, wherein the water yielding temperature is controlled at 1,650 DEG C, and casting; molding, coating after molding, assembling molds and casting; removing sand: cleaning cast burrs, and performing polishing inspection; preserving the heat, stacking casts with sand cleaned in a high-temperature heat treatment furnace, sealing a furnace door, raising the temperature, preserving the heat after the temperature is raised to 1,100 DEG C, preserving the heat for 6 hours, quickly discharging the casts, and putting the casts into water for quenching; and cleaning surfaces again, and inspecting, accepting, warehousing, stacking, classifying and warehousing products. The medium manganese steel has the advantages of ensuring high impact resistance and abrasion resistance of manganese steel; having a simple production process, low production cost and a good market prospect.

Owner:TONGLING ANDONG CAST STEEL

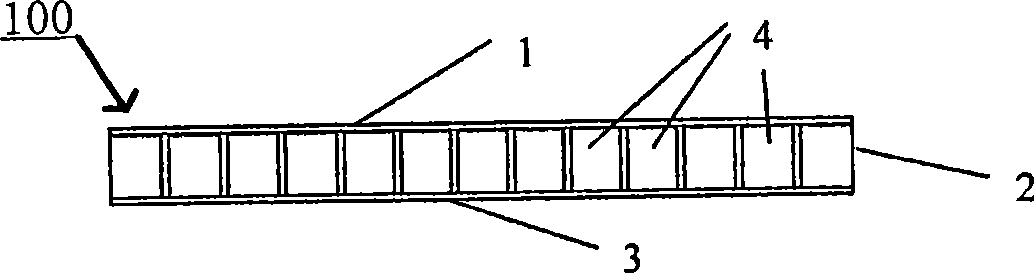

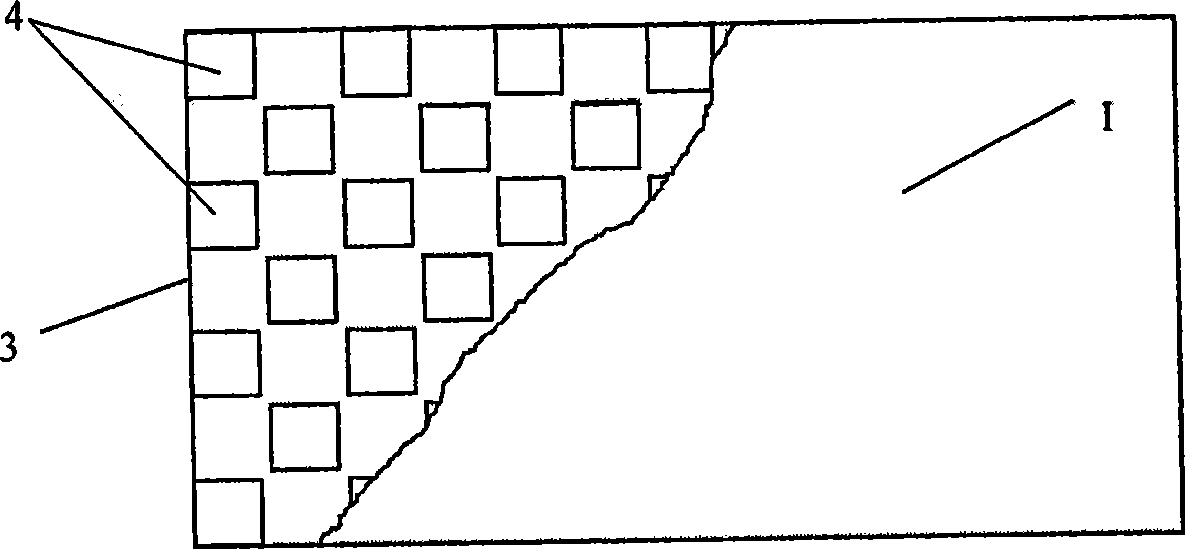

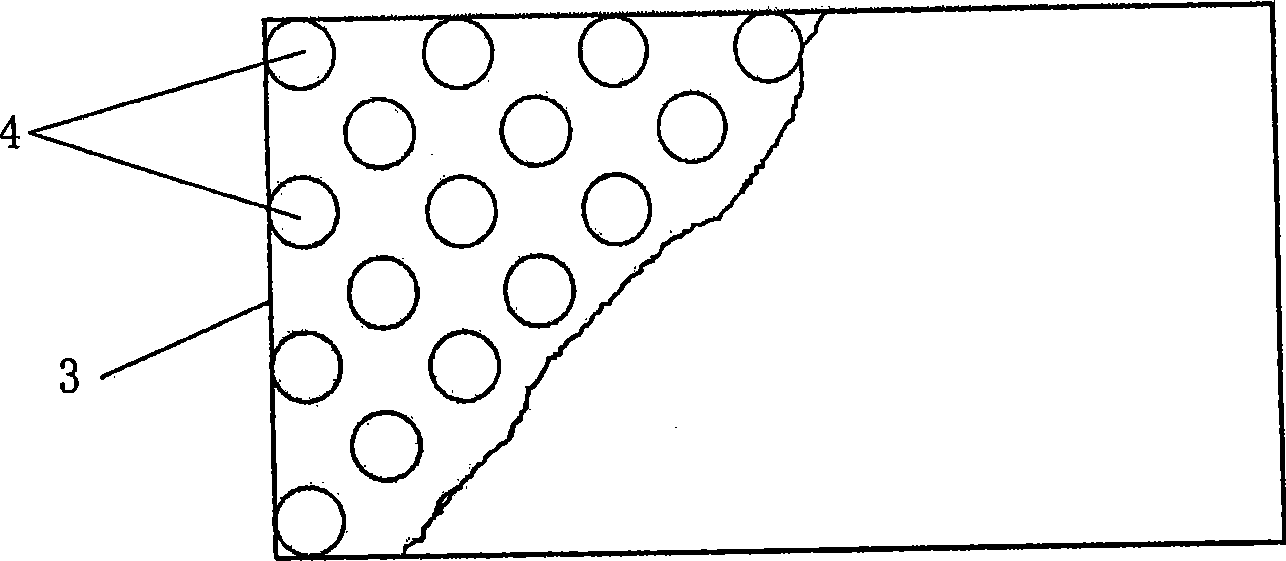

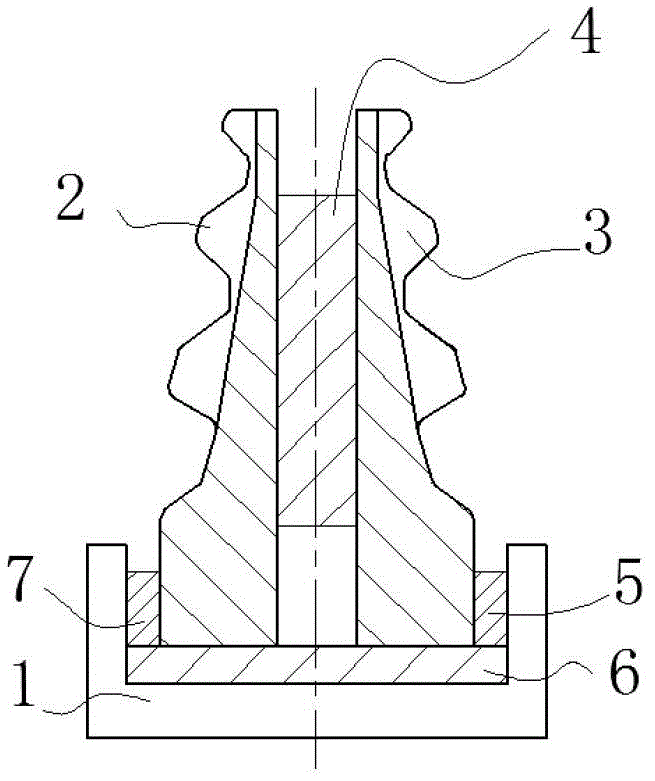

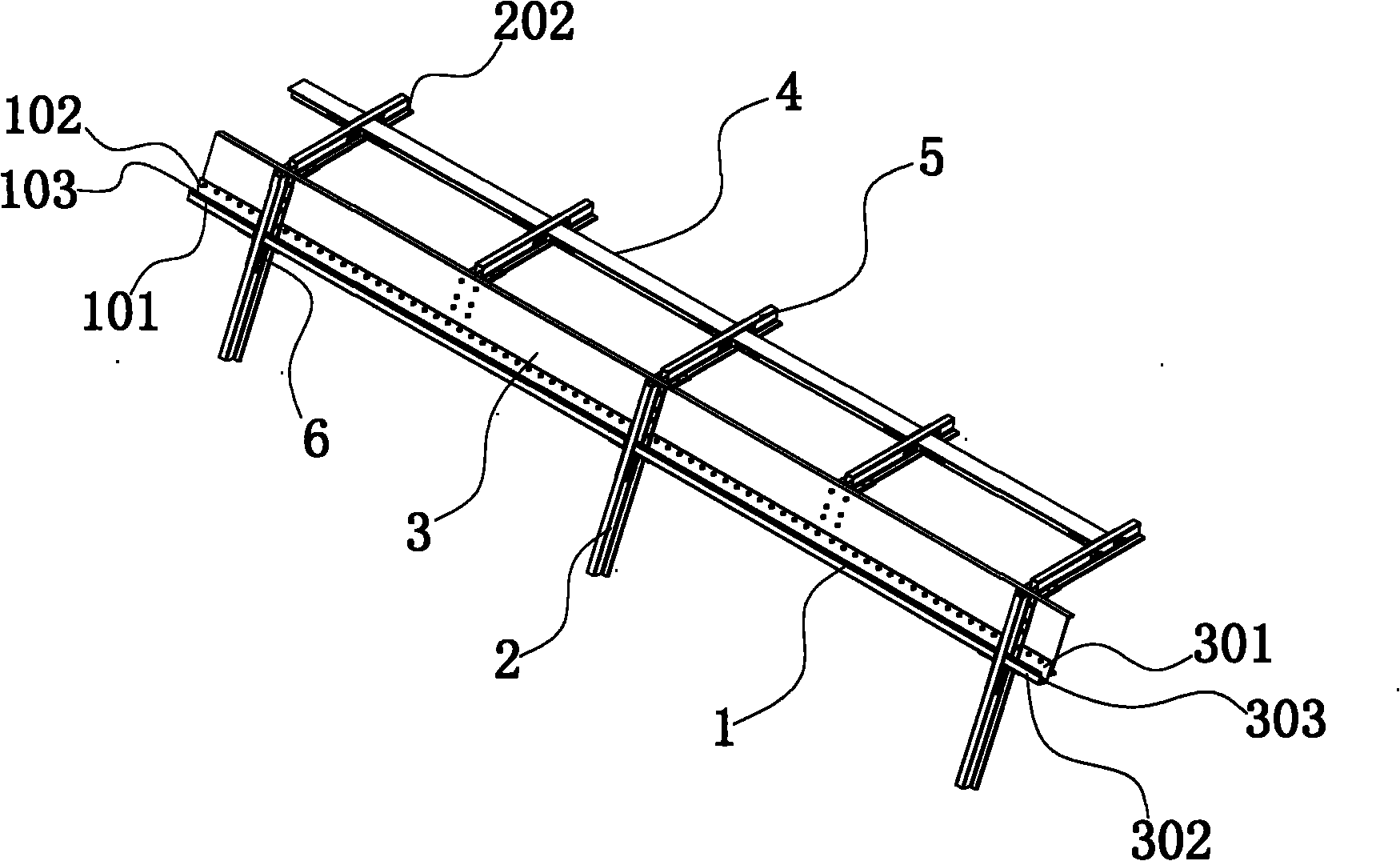

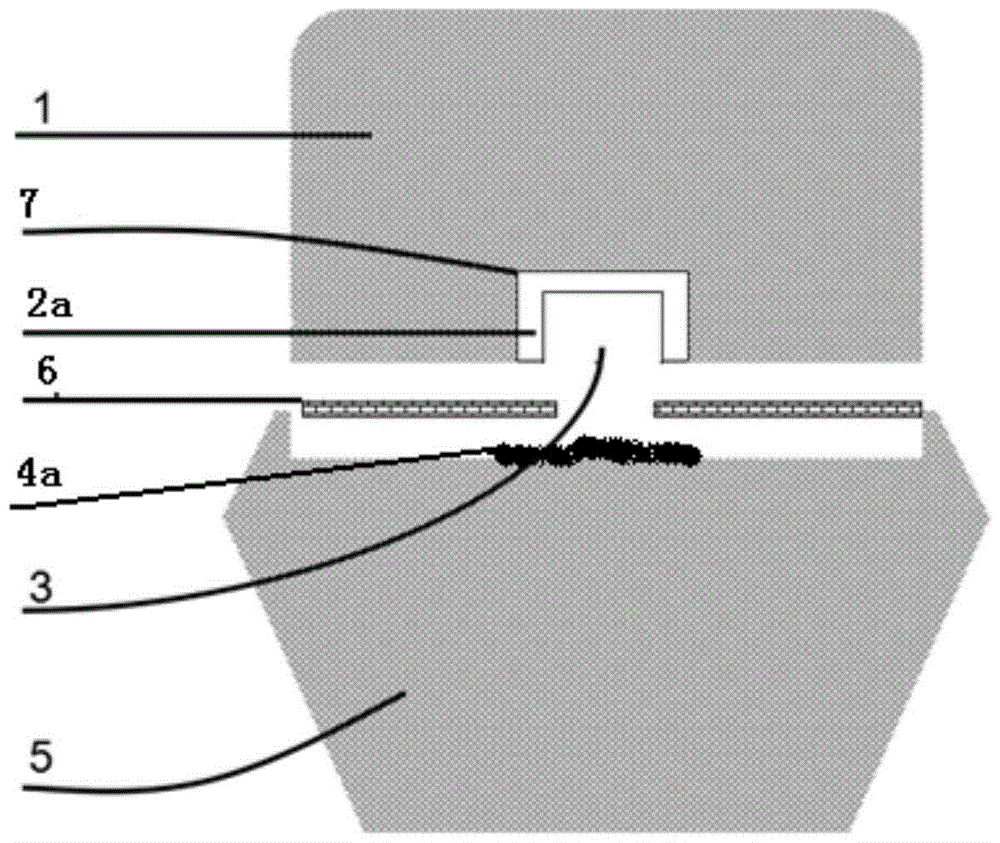

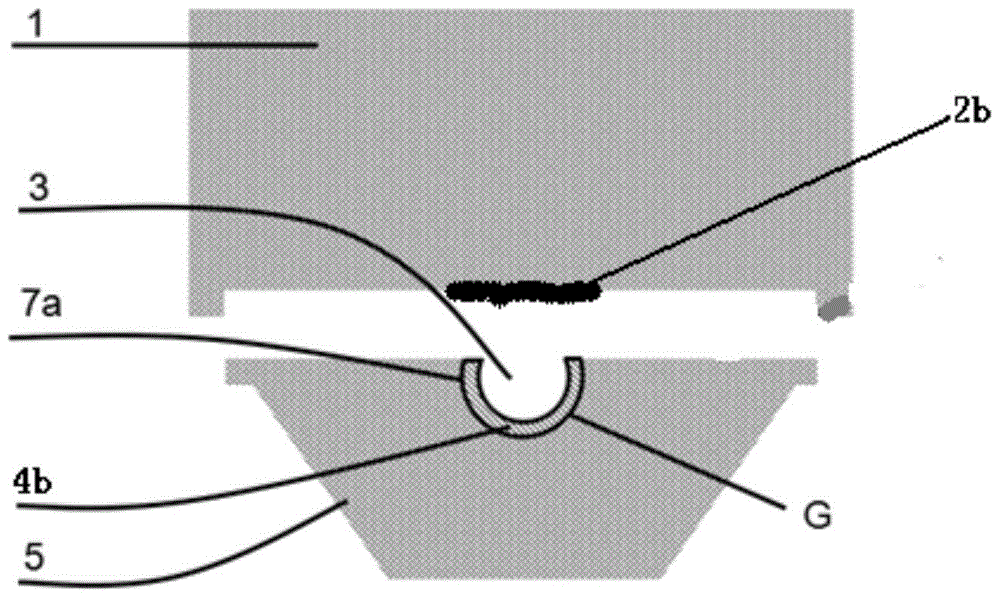

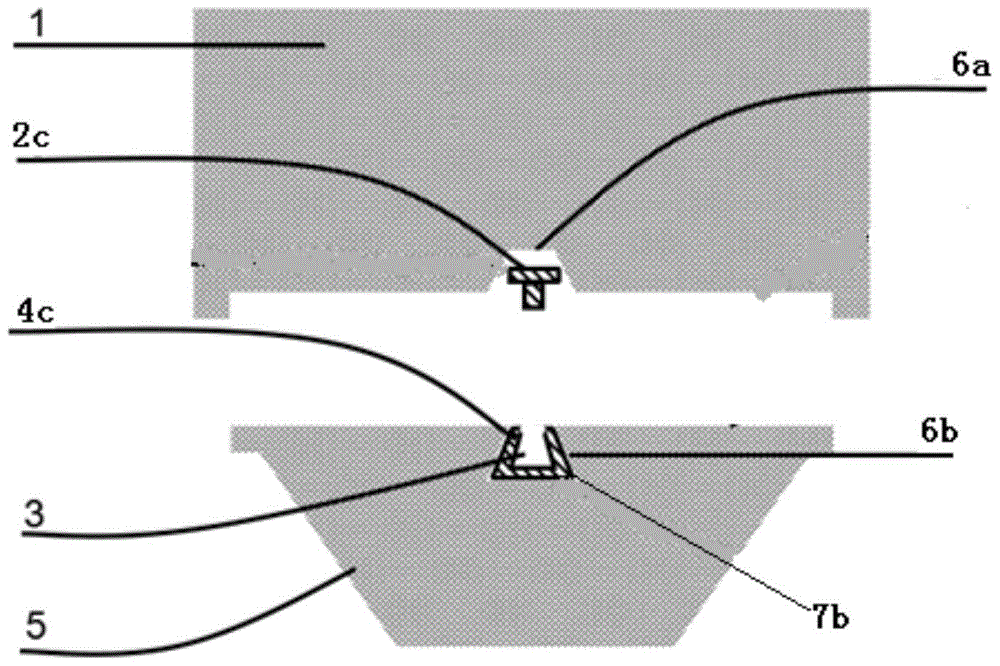

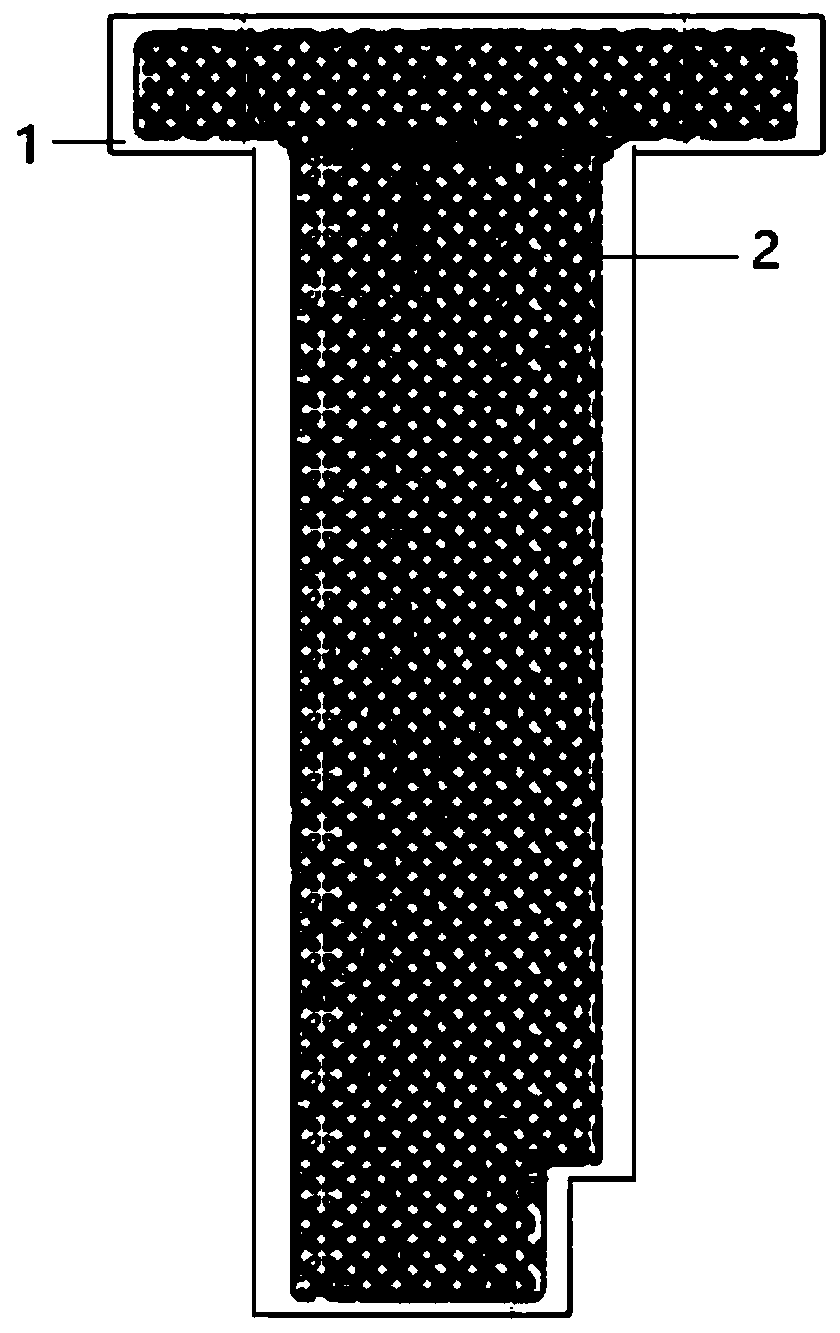

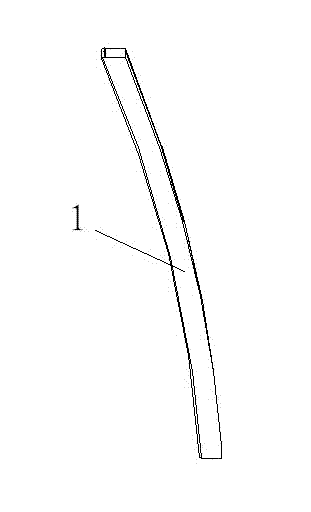

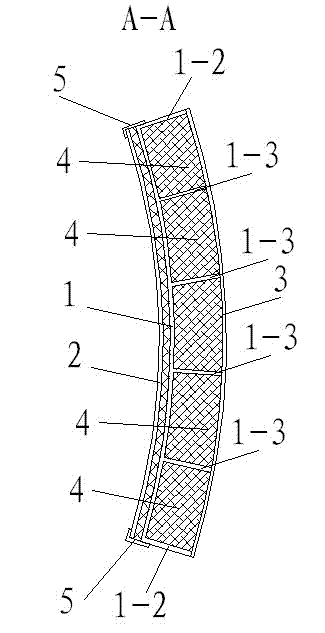

A carbon fiber reinforced carbon integrated pantograph skateboard for high-speed railway EMUs

The invention relates to a carbon fiber enhanced carbon integrated pantograph slide plate for high-speed railway multiple units. The pantograph slide plate comprises a sliding block (1), a bracket (5) and an air flue (3), wherein the bracket (5) and the sliding block (1) are made of C / C composite materials; in the pantograph slide plate, the carbon fiber enhanced carbon sliding block (1) is adhered to the bracket (5); a groove is formed in at least one of the carbon fiber enhanced carbon sliding block (1) and the bracket (5) along the length direction and is formed in a joint of the carbon fiber enhanced carbon sliding block (1) and the bracket (5); a high-temperature resistant sealing layer (2) is adhered to the groove wall of the groove formed in the carbon fiber enhanced carbon sliding block (1); when the carbon fiber enhanced carbon sliding block (1) and the bracket (5) are adhered integrally, the air flue (3) communicated with an air flue of a fast pantograph reduction device is formed by the high-temperature resistant sealing layer (2) and the bracket (5).

Owner:CENT SOUTH UNIV

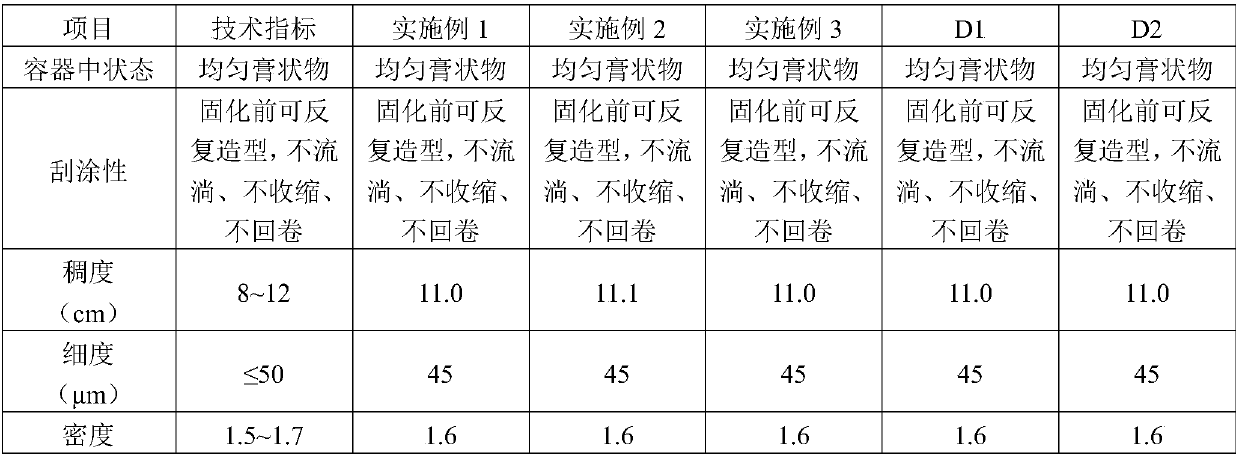

Poly putty specially used for multiple unit train as well as preparation method and application thereof

ActiveCN107641365AGood flexibilityImprove bending performanceFilling pastesCopper naphthenatePliability

The invention discloses poly putty specially used for a multiple unit train. The poly putty comprises main putty and a curing agent, wherein the main putty comprises the following components in partsby weight: 38-42 parts of unsaturated polyester resin, 0.7-0.8 part of cobalt isooctanoate with a weight fraction of 8%, 2-5 parts of styrene, 0.2-0.5 part of a composite auxiliary agent, 5-8 parts offumed silica, 5-10 parts of titanium dioxide, 25-30 parts of talcum powder with 325 meshes, and 8-15 parts of talcum powder with 600 meshes; and the composite auxiliary agent is composed of TBC, 1,4-naphthoquinone, antioxidant 264, copper naphthenate, and methyl ethyl ketoxime. The poly putty provided by the invention has the characteristics of high flexibility, high bendability, high impact resistance and very good temperature variation resistance, and the poly putty can withstand long-term high-low temperature change, is not easy to crack or fall, and fully meets the long-term operating requirements of the multiple unit train in areas with a high temperature difference.

Owner:河北新盾合成材料有限公司

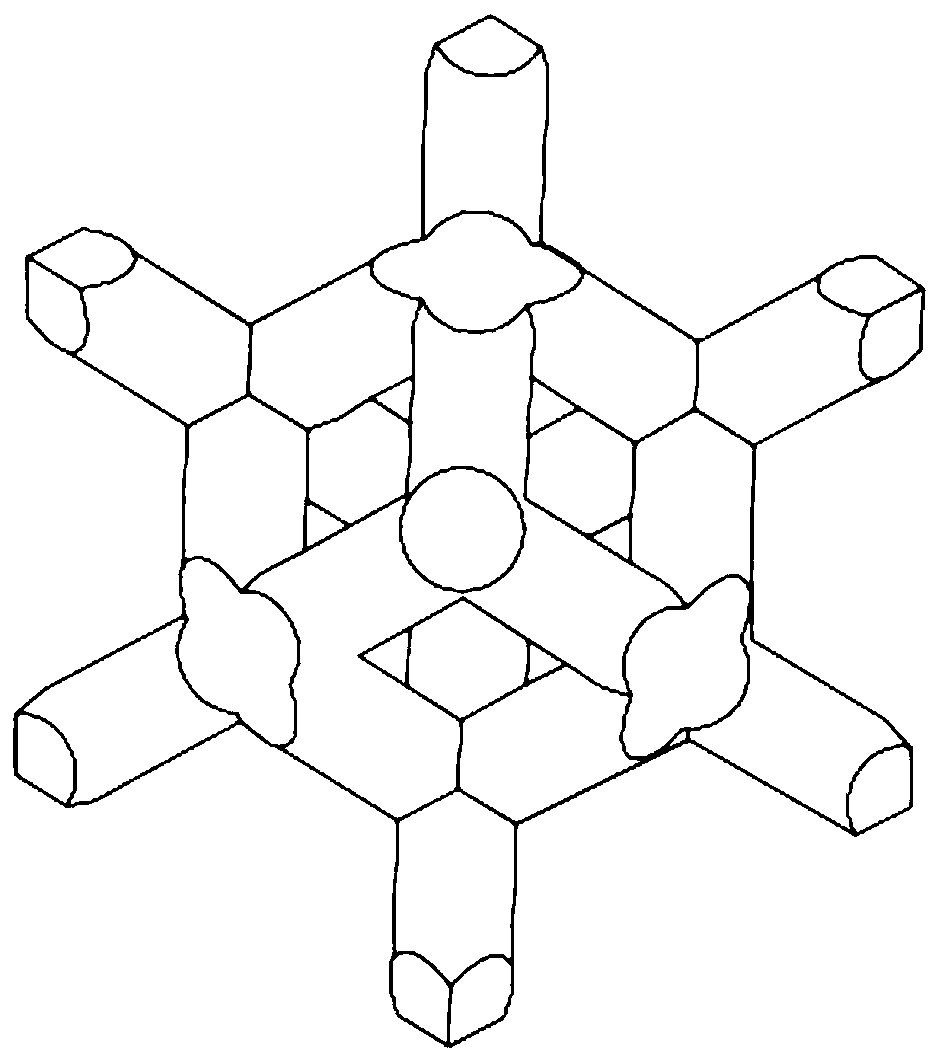

Hollow blade easy-to-remove aluminum oxide ceramic core and preparation method thereof

ActiveCN110773700AEasy to removeGuaranteed impact resistanceAdditive manufacturing apparatusFoundry mouldsOxide ceramicSlurry

The invention provides a hollow blade easy-to-remove aluminum oxide ceramic core and a preparation method thereof. According to the ceramic core, a shell and a space lattice structure in the shell arecombined, and when the relative density of the space lattice structure is 20 to 50 percent and the thickness of the shell is 0.4 to 0.5 mm, high void ratio of the ceramic core is realized and the deflection and the bending resistance of the ceramic core are guaranteed; and according to the preparation method, stable printing is facilitated by high flowability and low viscosity of ceramic slurry,the properties of the ceramic core are improved well by cooperating with the space lattice structure, the ceramic slurry is printed into a needed forming green body by 3D printing equipment, and the formed ceramic core is obtained by degreasing and sintering the formed green body. The ceramic core has high strength and short core removing time, saves ceramic materials, shortens process flow and provides an efficient solution for the problem about removal of the aluminum oxide ceramic core.

Owner:武汉因泰莱激光科技有限公司

Coating material and process method for repairing main bearing of shield tunneling machine

ActiveCN109706449AImprove crevice corrosion resistanceImprove hardenabilityMetallic material coating processesShield tunnelingImpurity

The invention discloses a coating material and process method for repairing a main bearing of a shield tunneling machine, and belongs to the technical field of surface treatment. The coating materialfor repairing the main bearing of the shield tunneling machine is prepared from the following components in percentage by mass: 0.53-0.60% of C, 0.8-1.1% of Si, 0.5-0.8% of Mn, 0.9-1.2% of Cr, 0.15-0.30% of Mo, 0.10-0.20% of W, 0.05-0.1% of Cu and the balance of Fe and inevitable impurities, wherein the mass percentage of the components adds up to 100%. The powder is used for repairing the main bearing of the shield tunneling machine through a laser cladding process, so that an abrasion-resistant, corrosion-resistant and fatigue-resistant coating is laser-clad on the raceway surface of the main bearing, the service life of the main bearing is prolonged, the service life of the shield tunneling machine is prolonged, and a good effect is played on reducing the production cost.

Owner:沈阳大陆激光工程技术有限公司

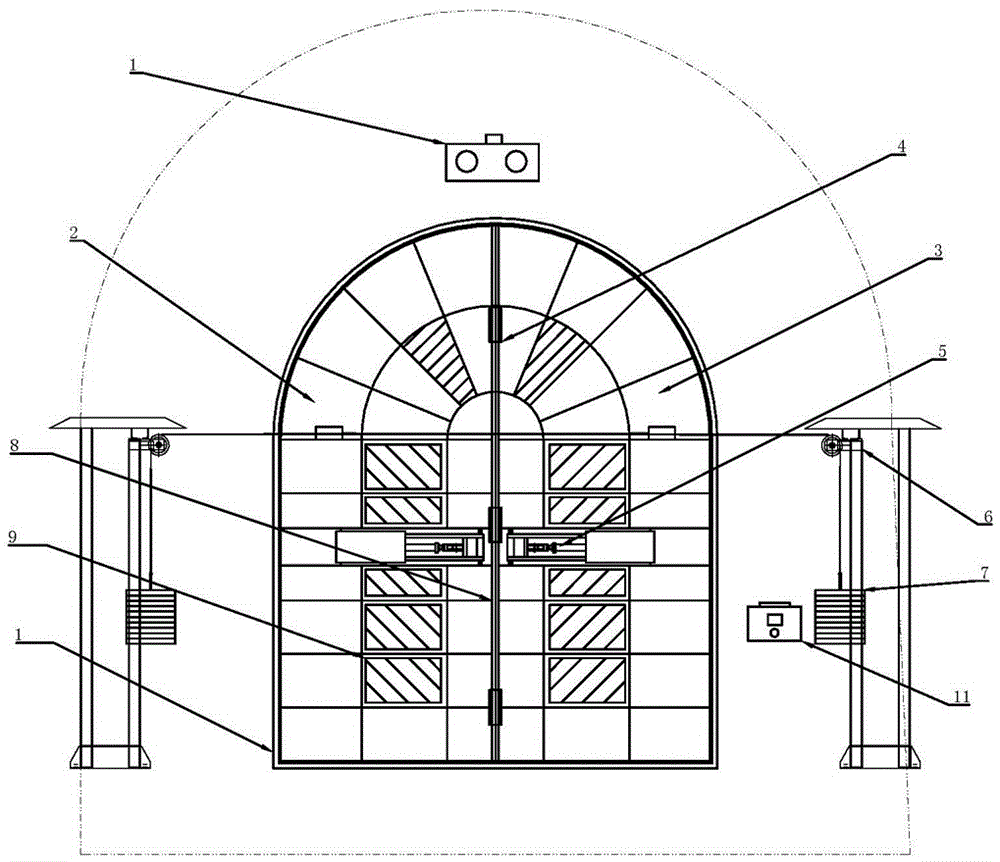

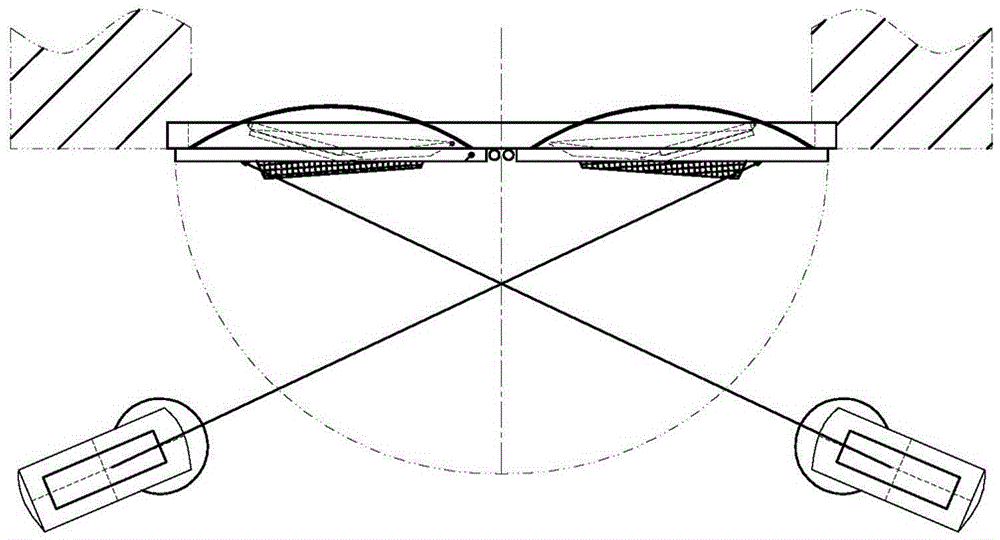

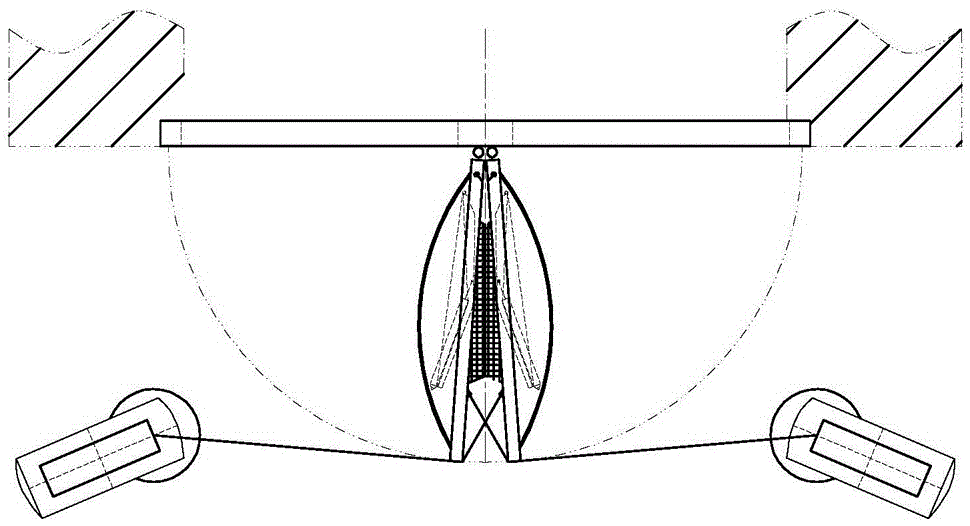

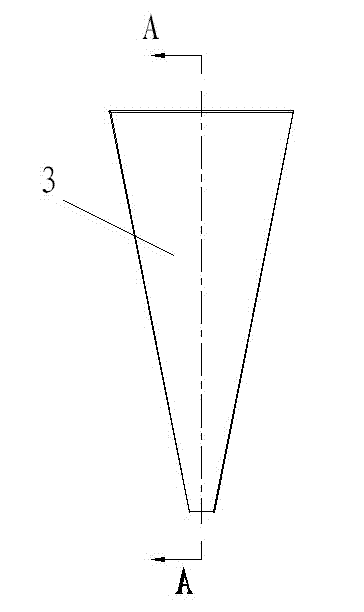

Self-restoring type explosion door applied to inclined shaft and horizontal shaft

InactiveCN105927274ARealize self-lockingBack to normalMining devicesWar-like protectionBlock and tackleSelf locking

The invention discloses a self-restoring type explosion door applied to an inclined shaft and a horizontal shaft. A door frame is fixed on a shaft opening chamber foundation; a support column is fixed on the door frame; a left explosion door leaf and a right explosion door leaf are symmetrically connected to the support column via hinges; the left explosion door leaf and the right explosion door leaf are symmetrically opened in reverse directions; self-locking devices are symmetrically mounted on the left explosion door leaf and the right explosion door leaf; symmetrical guide brackets are mounted on the outer side of a shaft opening cavity; a pulley block is fixed on each guide bracket; a counterweight device heavy hammer is arranged at the tail end of each guide bracket. The self-restoring type explosion door has the advantages that the ventilation safety can be automatically restored after mine shafts are exposed, and the safety of workers in the mine shafts can be guaranteed.

Owner:枣庄和顺达机电科技股份有限公司

Solar concentrated optical disc

The invention discloses a solar concentrated optical disc. The solar concentrated optical disc comprises a back plate, a reflective curved plate and a rear cover plate, wherein the surfaces of the reflective curved plate and the back plate are adhered, the back surface of the back plate is fixedly connected with radial ribs, the periphery of the back surface of the back plate is also fixedly connected with circumferential ribs, the rear cover plate is fixedly connected with the radial ribs and the circumferential ribs, fillers are arranged between the back plate and the rear cover plate, the fillers are filled in an area formed by the radial ribs and the circumferential ribs of the back plate and the rear cover plate, and sealing edges are arranged between the peripheral edges of the reflective curved plate and the circumferential ribs of the back plate. According to the solar concentrated optical disc disclosed by the invention, the weight is light, the production cost is low, and the mass production can be easily realized.

Owner:司宗宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com