Multi-component stink exhaust gas biological purifying method

A biological purification, multi-component technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of not being able to purify exhaust gas at the same time, the impact of biological purification is large, and it is difficult to ensure the purification rate, etc. Degradation efficiency and operation flexibility, reduction of processing load, and the effect of large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

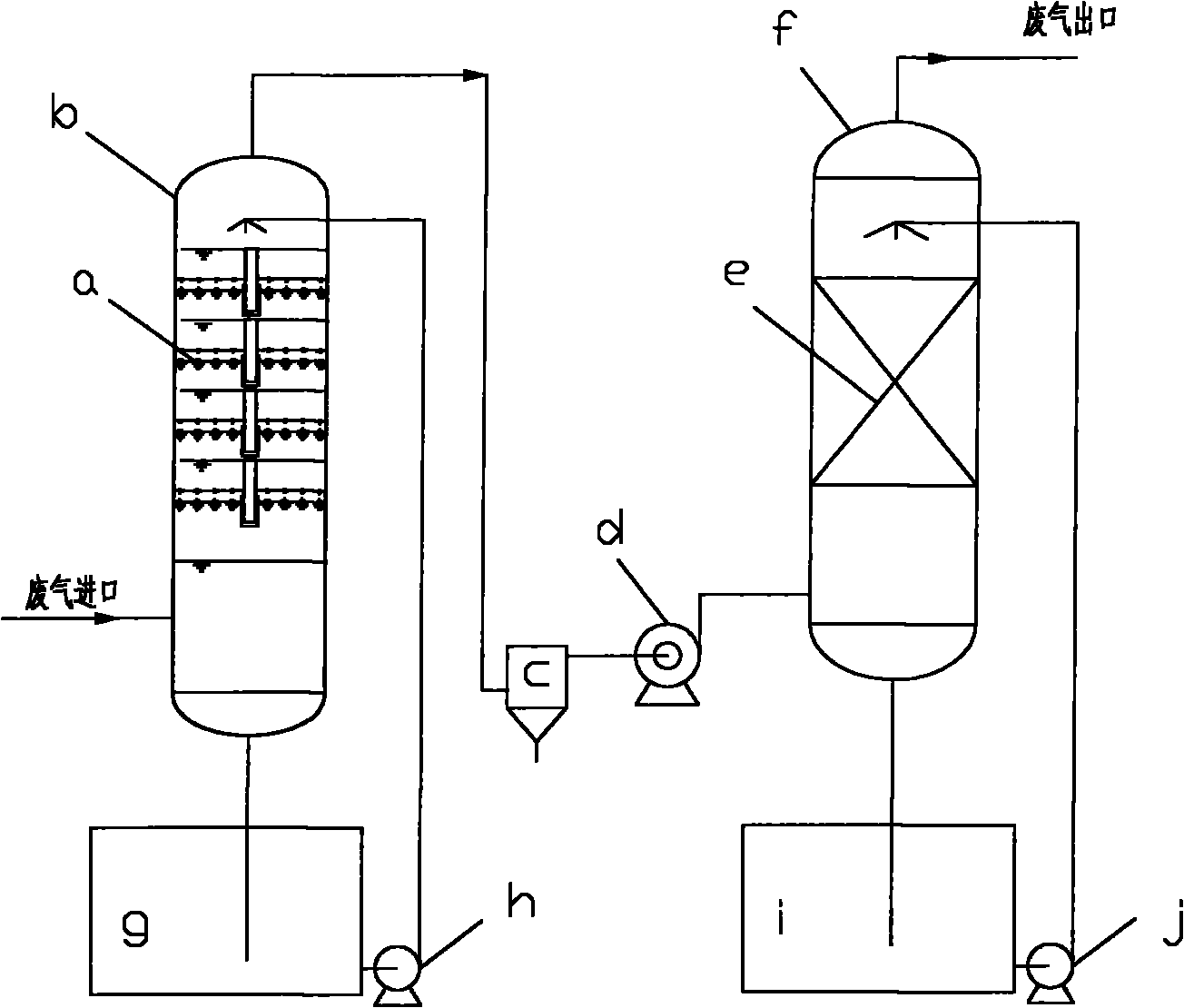

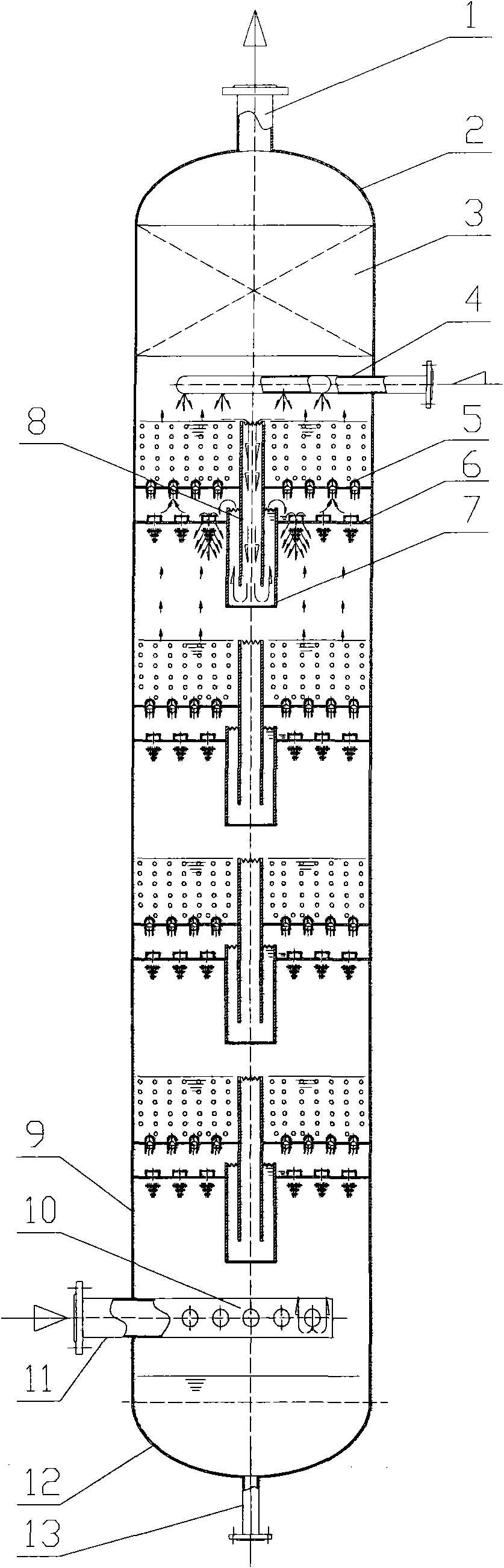

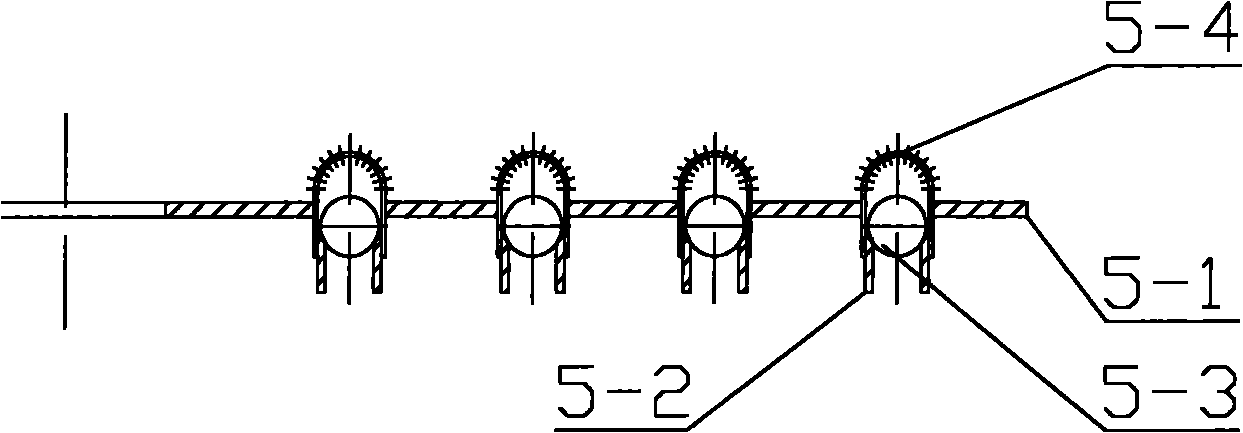

Method used

Image

Examples

Embodiment 1

[0037] The fugitive exhaust gas from the biochemical aeration tank of a sewage treatment plant contains 50-100 mg / m of hydrogen sulfide 3 , dimethyl disulfide 10mg / m 3 , toluene 40mg / m 3 , Xylene 60mg / m 3 , the flow rate is 5000Nm 3 / h or so. A three-stage biological bubbling purification tower is adopted, including three bubbling reaction zones and three spraying reaction zones. The internal components of the bubbling purification tower are determined according to the preferred data in the specific embodiment, and the liquid-gas ratio is 10L / Nm 3 , The residence time of the biological bubbling purification tower bacteria liquid in the liquid storage tank is 30 seconds. The thickness of the liquid phase layer in the bubbling reaction zone is 100mm, and the height of the spray section is 250mm. The temperature of the bacterial liquid in the bubbling purification tower is 25°C, mainly acidophilic thiobacillus, and the pH value of the microbial liquid is maintained at about ...

Embodiment 2

[0040] In the fugitive exhaust gas of the sewage treatment plant of an oil refinery. Hydrogen sulfide 10mg / m 3 , VOCs 300mg / m 3 , the flow rate is 2000Nm 3 / h or so. A two-stage pulse bubbling purification tower is adopted, including two bubbling reaction zones and two spraying reaction zones, and the internal components of the bubbling tower are determined according to the preferred data in the specific embodiment. The thickness of the liquid phase layer in the bubbling reaction zone is 100mm, and the height of the spray section is 200mm. The temperature of the bacterial solution was 10°C. The filter tower adopts trickling filter tower, and the packing adopts plastic polyhedral ball packing. Other operating conditions are identical with embodiment 1.

[0041] After being purified by the biological bubble tower and the biological trickling filter tower, the hydrogen sulfide purification rate is 100%, the VOCs purification rate is 99%, and the tail gas emission rate is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com