Cast-in-situ type polyurethane micro-foaming runway surface layer and construction technology thereof

A construction technology, polyurethane technology, applied in coatings, roads, pavements, etc., can solve the problems of impact absorption performance to be improved, high cost of ETPU particles, poor waterproof effect, etc., to improve anti-oxidation ability and ensure impact resistance effect , Improve the effect of skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

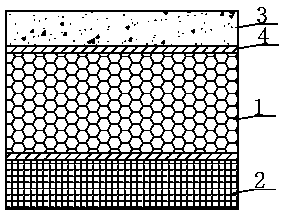

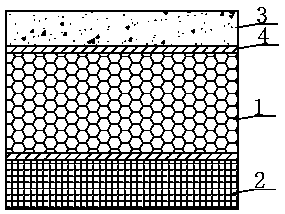

[0030] according to figure 1 Shown is a cast-in-place polyurethane micro-foaming runway surface layer, including an elastic layer 1, the elastic layer 1 is made by reacting component A and component B, wherein the main materials used in component A are by weight Including: 10 parts of polyether polyol, 10 parts of diluent and 60 parts of HDI trimer, the main ingredients used in the B component include by weight: 20 parts of polycarbonate diol (PCDL), chain extender 5 parts of dimethylolpropionic acid (DMPA), 20 parts of MDI, 2 parts of triethylamine (TEA), 10 parts of deionized water, 5 parts of pigment, 20 parts of filler and 0.1 part of auxiliary agent, the preparation of the elastic layer 1 The adjuvant used in comprises 0.1 part of foaming agent, 0.2 part of foam stabilizer and 0.1 part of thickener by weight percentage;

[0031] The bottom of the elastic layer 1 is provided with a primer layer 2, and the primer layer 2 is specifically an epoxy adhesive, and fillers are e...

Embodiment 2

[0044] according to figure 1 Shown is a cast-in-place polyurethane micro-foaming runway surface layer, including an elastic layer 1, the elastic layer 1 is made by reacting component A and component B, wherein the main materials used in component A are by weight Including: 15 parts of polyether polyol, 15 parts of diluent and 65 parts of HDI trimer, the main ingredients used in the B component include by weight: 25 parts of polycarbonate diol (PCDL), chain extender 7.5 parts of dimethylolpropionic acid (DMPA), 25 parts of MDI, 6 parts of triethylamine (TEA), 15 parts of deionized water, 7.5 parts of pigments, 20.25 parts of fillers and 0.15 parts of additives, the preparation of the elastic layer 1 The adjuvant used in comprises 0.2 parts of foaming agent, 0.3 part of foam stabilizer and 1.75 parts of thickening agent by weight percentage;

[0045] The bottom of the elastic layer 1 is provided with a primer layer 2, and the primer layer 2 is specifically an epoxy adhesive, an...

Embodiment 3

[0058] according to figure 1 Shown is a cast-in-place polyurethane micro-foaming runway surface layer, including an elastic layer 1, the elastic layer 1 is made by reacting component A and component B, wherein the main materials used in component A are by weight Including: 20 parts of polyether polyol, 20 parts of diluent and 70 parts of HDI trimer, the main ingredients used in the B component include by weight: 30 parts of polycarbonate diol (PCDL), chain extender 10 parts of dimethylolpropionic acid (DMPA), 30 parts of MDI, 10 parts of triethylamine (TEA), 30 parts of deionized water, 10 parts of pigments, 25 parts of fillers and 0.2 parts of additives, the preparation of the elastic layer 1 The adjuvant used in comprises 0.3 part of foaming agent, 0.4 part of foam stabilizer and 0.25 part of thickener by weight percentage;

[0059] The bottom of the elastic layer 1 is provided with a primer layer 2, and the primer layer 2 is specifically an epoxy adhesive, and fillers are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com