Special polybutylene alloy pipe material for cold/hot water pipe and preparation method of special polybutylene alloy pipe material

A polybutene alloy, cold and hot water pipe technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems not involved in the formulation and processing of special materials for pipes, and achieve excellent resistance to environmental stress cracking and thermal creep resistance The effect of improving the resistance and flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Components and formulations provided by Table 1 (according to weight percent, the following examples are all the same) weigh the material, after mixing in a high-speed mixer for 5 minutes, in a twin-screw extruder with an aspect ratio of 45 and a diameter of 50 Extrusion granulation to obtain the special material for polybutene alloy resin pipes. The mass content of iPB in the polybutene alloy resin used is 66%, and its melt flow rate (190° C., load 2.16 kg) is 0.5 g / 10 min. The temperature of each section of the extruder is: 150°C in zone 1, 165°C in zone 2, 180°C in zone 3, 190°C in zone 4, 210°C in zone 5, 230°C at the head, 20 rpm of extruder, and melt pressure 15MPa.

[0033] The performance test results are shown in Table 2.

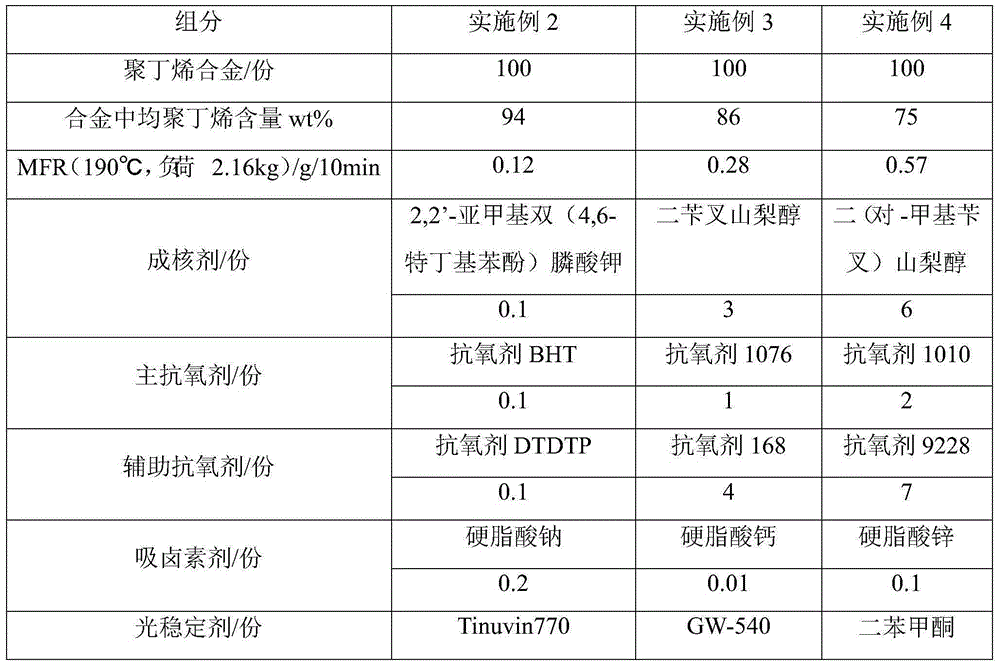

Embodiment 2~4

[0043] Components and formulations provided by Table 3 (according to weight percent, the following examples are the same) weigh the material, after mixing in a high-speed mixer for 5 minutes, in a twin-screw extruder with an aspect ratio of 45 and a diameter of 50 Extrusion granulation to obtain the special material for polybutene alloy pipe material. The temperature of each section of the extruder is: 140-160°C for the first zone, 160-170°C for the second zone, 175-185°C for the third zone, 180-200°C for the fourth zone, 190-230°C for the fifth zone, 190-230°C for the head, The speed is 10~30r / min, and the melt pressure is 12~20MPa.

[0044] The performance test results are shown in Table 4.

[0045] From the test results in Table 4, it can be seen that through proper proportioning and optimized processing conditions, special polybutene alloy pipe materials that meet the requirements for the use of pipe materials for cold and hot water pipes can be prepared.

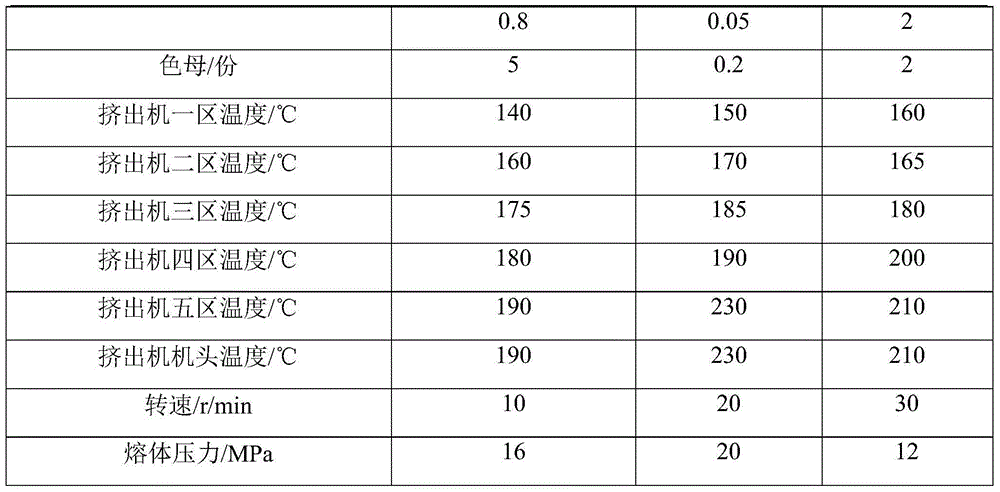

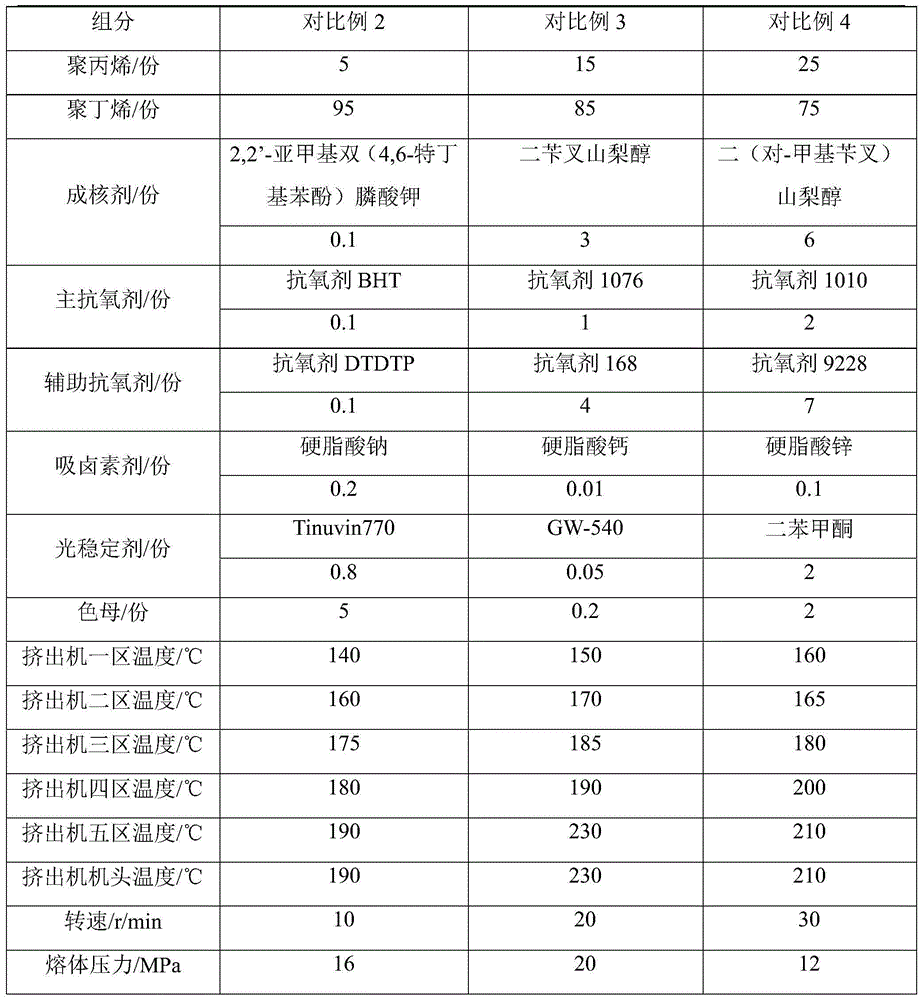

[0046] Compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com