Display panel, display device, and method for manufacturing display panel

A display panel and display device technology, applied in organic semiconductor devices, photovoltaic power generation, electrical components, etc., can solve problems such as reduced bending performance, black spots, bright spots, colorful spots, and display abnormalities in the display area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

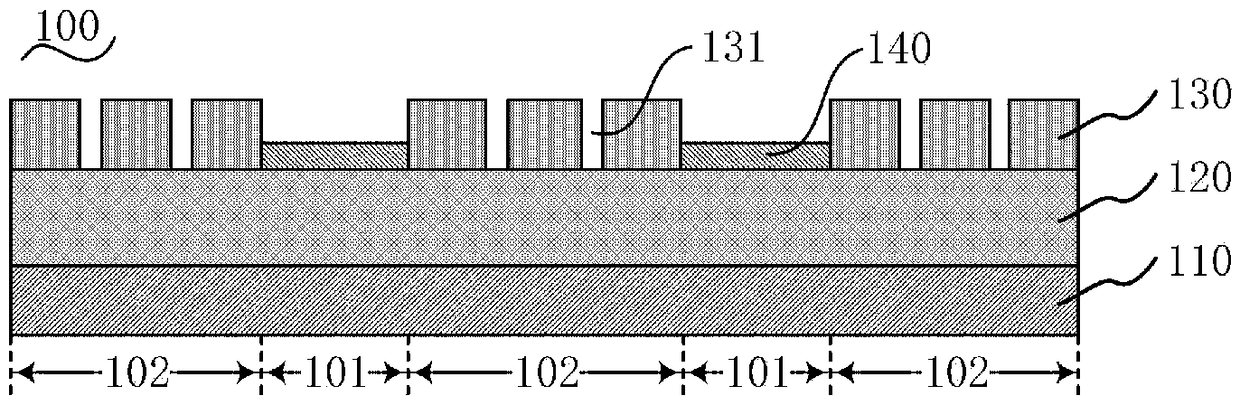

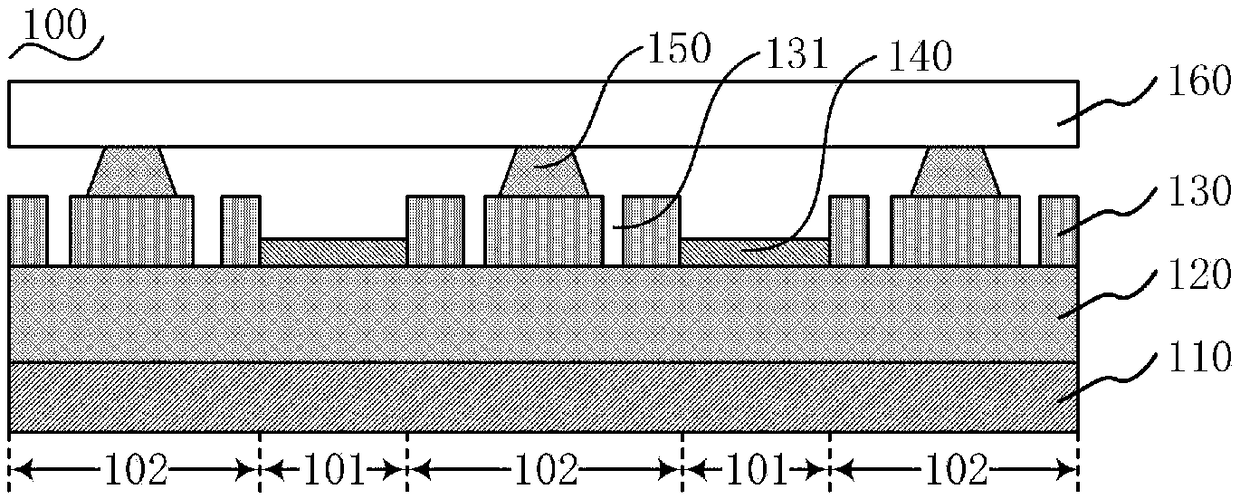

[0032] Display defects such as black spots, bright spots, and colored spots will appear in the existing display device after the ball drop test, and cannot be recovered, which affects the display performance of electronic equipment. Through the research on the existing technology, it is found that when the display panel is subjected to an instantaneous impact, the impacted part of the display panel will experience a surge in stress. If the display panel cannot disperse and absorb the stress in time, it will cause the hit part In some cases, there are problems with damaged components or peeling between film layers. In the prior art, an extra buffer material is usually used to improve the display abnormality, but this will increase the thickness of the display panel and reduce the bending ability.

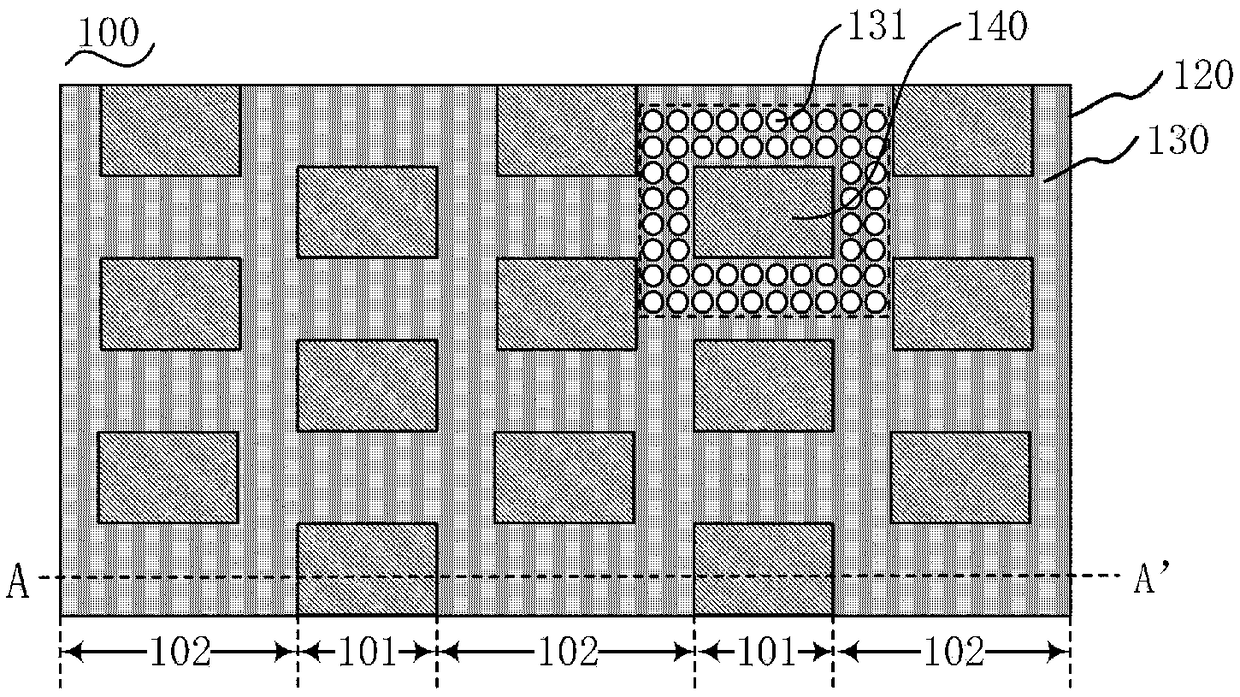

[0033] Based on this, the present application proposes a display panel, which includes an array substrate (including a substrate and TFTs disposed on the substrate) and a pixel defin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com