Protection mat and its fabrication process

A technology of protective pads and cushioning units, applied in chemical instruments and methods, protective clothing, layered products, etc., can solve the problems of poor air permeability, high difficulty in mold processing, and low strength, so as to improve air permeability and use comfort , the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

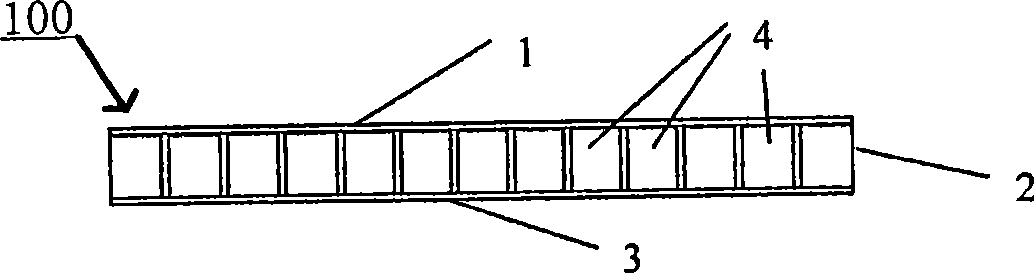

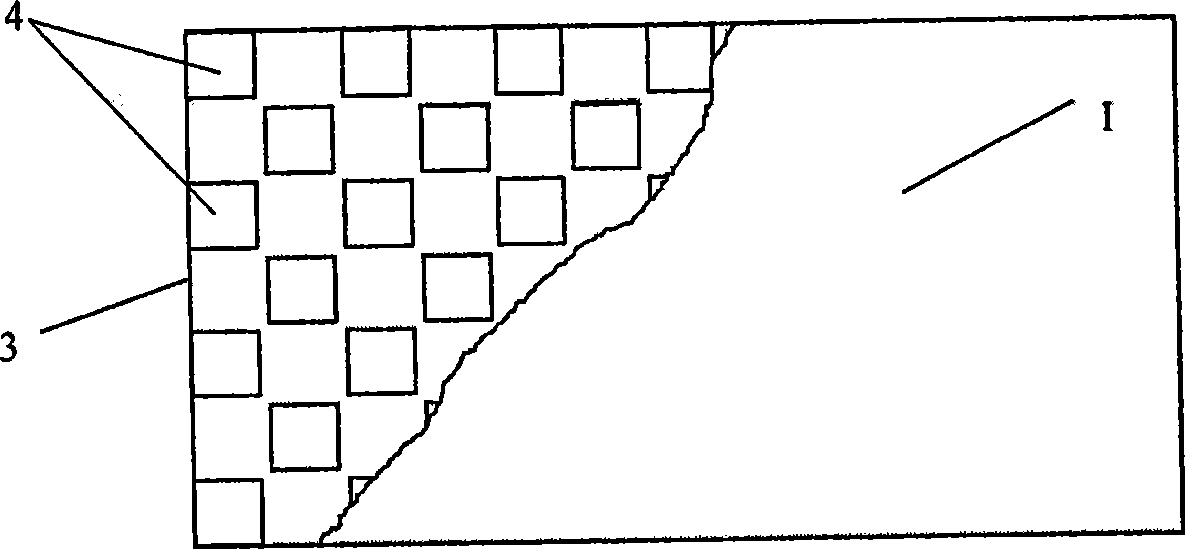

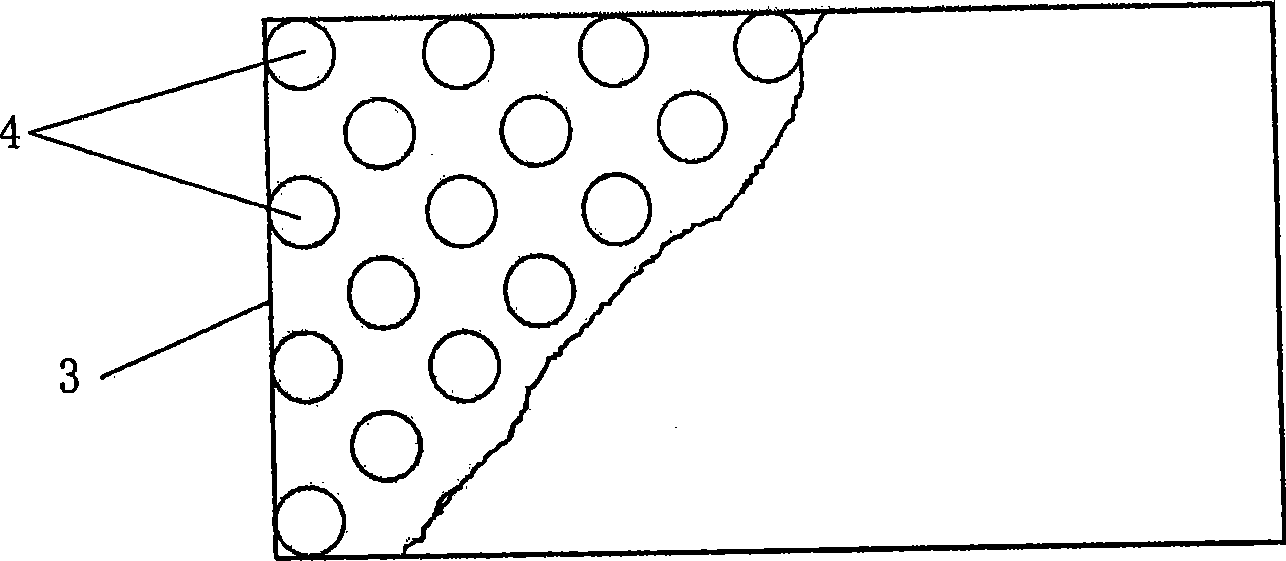

[0030] figure 1 A side view of the composite structure of the protective pad 100 according to the present invention is shown. Such as figure 1 As shown, the protective pad 100 has a three-layer structure: the outer layer 1 is a soft and stretchable elastic fiber or film material; the middle layer 2 is a buffer layer composed of a series of staggered independent buffer units 4; the base material 3 is a soft fiber or film material.

[0031] The material of the outer layer 1 is a very soft elastic material with good stretchability, such as polyurethane film, elastic fabric or elastic non-woven material. The outer layer 1 is bonded to one end of the buffer unit 4 in the middle, and the part of the outer layer 1 between the buffer units 4 can be bent and stretched freely. Therefore, when the protection pad 100 is subjected to bending, the portion of the outer layer 1 that is not bonded to the cushioning units 4 (that is, the portion between the cushioning units 4) can increase w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com