Composite car panel and preparation method thereof

A technology of composite materials and compartment panels, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of easy peeling, damaged panels, uneven surface of metal compartment panels, and achieve excellent compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

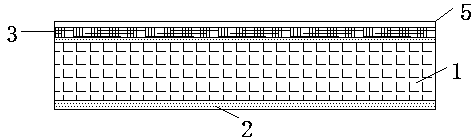

[0019] A method for preparing a composite material compartment panel, the steps are as follows: (1) lay surface layers 2 on the upper and lower surfaces of a core 1, and after the laying is completed, put the whole body into a hot press for hot pressing, so that the core 1 and the surface Layer 2 is connected as one, and the hot pressing temperature is 200°C~240°C, such as 200°C, 205°C, 210°C, 215°C, 220°C, 225°C, 230°C, 235°C or 240°C, etc., preferably 210°C~230°C ℃, the hot pressing pressure is 3bar~4bar, such as 3 bar, 3.5 bar, 3.6 bar, 3.8 bar, 4 bar, etc., and then cooled and shaped; (2) The adhesive medium layer 3 is wound on the continuous unwinding device, through the continuous The unwinding device continuously unwinds and the rolling device rolls, lays the adhesive medium layer on the surface of one layer 2, and heats the whole body at a heating temperature of 250 ° C ~ 300 ° C; (3) through the bonding roller Coat the PUR hot melt adhesive layer on the adhesive mediu...

Embodiment 1

[0023] The board core 1 is a PP honeycomb core board, and two layers of continuous glass fiber reinforced thermoplastic resin prepreg sheets are hot-compressed on the upper and lower surfaces of the PP honeycomb core respectively. The hot-pressing temperature is 220°C and the hot-pressing pressure is 4bar. , two layers of continuous glass fiber-reinforced thermoplastic resin prepreg sheets are laid according to 0° / 90°, and the continuous glass fiber-reinforced thermoplastic resin prepreg sheets are made of unidirectional continuous glass fibers after being melt-impregnated with polypropylene and then pressed into shape , the areal density of the continuous glass fiber reinforced thermoplastic resin prepreg sheet is 900 g / m 2 , with a thickness of 0.6mm, based on the total weight of the single-layer continuous glass fiber reinforced thermoplastic resin prepreg ply, the weight percentage of continuous glass fiber is 55wt%, the weight percentage of polypropylene is 45wt%, and the ...

Embodiment 2

[0029] On the basis of Example 1, the surface density of the spunlace PET nonwoven fabric is set to 25 g / m 2 , and the rest of the content is the same as in Embodiment 1.

[0030] According to GB / T13775-1992, the wear resistance of the surface of the composite material car plate is 5 grades; according to GB / T9279.1-2015, the scratch resistance of the surface of the composite material car plate is tested: the minimum load of surface penetration is > 20N; GB / T16422.3-2014 tests the anti-aging performance of composite material compartment panels: 3000h, no pulverization, △E<3.0, loss of light rate<10%; according to GB / T1462-2005 test the water absorption of load material compartment panels 0.5%. In addition, according to GB / T2790-1995, the 180° peel strength of the composite material compartment panel surface is 9N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com