Single-component waterborne finishing coat and preparation method thereof

A single-component, water-based technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor flexibility and insufficient elasticity, and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

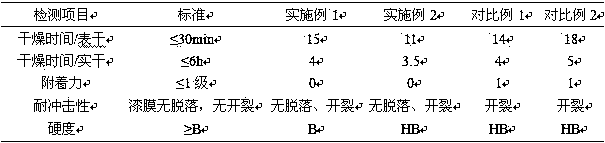

Examples

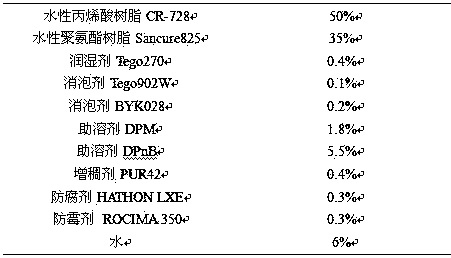

Embodiment 1

[0028] .

[0029] The preparation steps of described a kind of one-component waterborne elastic finish paint are as follows:

[0030] (1) Add 50 kg of water-based acrylic resin and 35 kg of water-based polyurethane resin in sequence into container A that meets the requirements.

[0031] (2) Start stirring, disperse at a low speed of 400~600 r / min, add 0.4 kg of wetting agent Tego270, 0.1 kg of defoamer Tego902W, 0.2 kg of BYK028, and disperse at a high speed of 1000~1400 r / min for 10~15 min.

[0032] (3) Add 1.8 kg of co-solvent DPM, 5.5 kg of DPnB and 5 kg of water into a clean container B that meets the requirements, and disperse at a low speed for 5 minutes to form a uniformly dispersed mixed solution. Stop stirring and add the mixed solution to container A .

[0033] (4) Add thickener PUR42 0.4 kg, water 1 kg to adjust the viscosity to 65-70ku / 25 o C, stirring at high speed for 5 min.

[0034] (5) Add 0.3 kg of preservative and 0.3 kg of antifungal agent in turn, an...

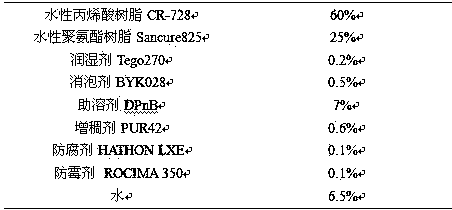

Embodiment 2

[0037] .

[0038] The preparation steps of described a kind of one-component waterborne elastic finish paint are as follows:

[0039] (1) Add 60 kg of water-based acrylic resin and 25 kg of water-based polyurethane resin in sequence into container A that meets the requirements.

[0040] (2) Start stirring, disperse at a low speed of 400~600 r / min, add 0.2 kg of wetting agent Tego270, and 0.5 kg of defoamer BYK028 in sequence, and disperse at a high speed of 1000~1400 r / min for 10~15 min.

[0041] (3) Add 7 kg of co-solvent DPnB and 5.5 kg of water into a clean container B that meets the requirements, and disperse at a low speed for 5 minutes to form a uniformly dispersed mixed solution. Stop stirring, and add the mixed solution to container A.

[0042] (4) Add thickener PUR42 0.6 kg, water 1 kg to adjust the viscosity to 65-70ku / 25 o C, stirring at high speed for 5 min.

[0043] (5) Add 0.1 kg of preservative and 0.1 kg of antifungal agent in sequence, and disperse evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com