Environmental thermoplastic PVC table tennis material and its preparation method of table tennis

A table tennis and thermoplastic technology, which is applied in the field of making table tennis balls with environmentally friendly thermoplastic PVC table tennis materials, can solve the problems of unsuitable use in winter games, complicated production processes, long production cycles, etc., and achieves excellent bounce ability and simple production process. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

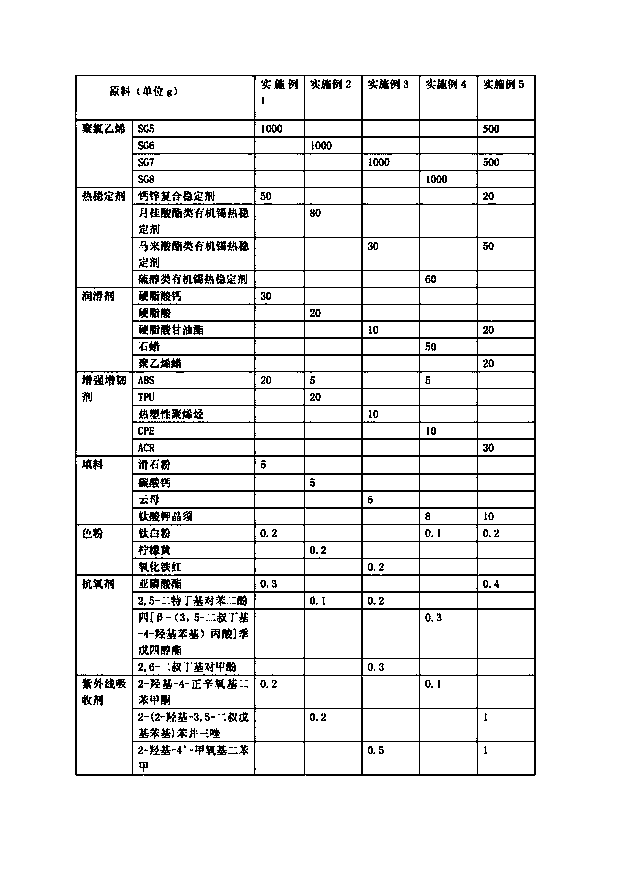

[0041] The raw material ratio of embodiment 1-5 sees the following table:

[0042]

[0043] The material of above-mentioned embodiment 1-5 is made into table tennis, and its method is: first injection molding is made into two hemispheres, and these two hemispheres can be spliced into a complete ball by adhesive agent, after polishing, in mold cavity It is expanded into a uniform table tennis ball, and then processed into a finished ball; the thickness of the hemisphere is divided into five different stages from the top to the bottom.

[0044] The injection point of the hemisphere is located on the circumference of the waist. There are 3 injection molding points in each hemisphere, and the injection molding points are evenly distributed on the circumference of the waist.

[0045] The wall thicknesses of the hemispheres from the apex to the bottom are: 0.53mm, 0.50mm, 0.49mm, 0.47mm, 0.53mm respectively, and the thickness of the glued part where the two hemispheres overlap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com