Frit suitable for color development as well as colored vitreous enamel product and preparation method

A technology of color glaze and porcelain products, which is applied in the field of frit and color glaze porcelain products, preparation, and high-grade porcelain color glaze. It can solve problems such as difficult, complicated decoration of high-grade porcelain color glaze, and difficulty in serialized decoration, etc., and achieve expansion coefficient Appropriate, meet the diverse needs of the market, and the effect of rich and colorful social needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

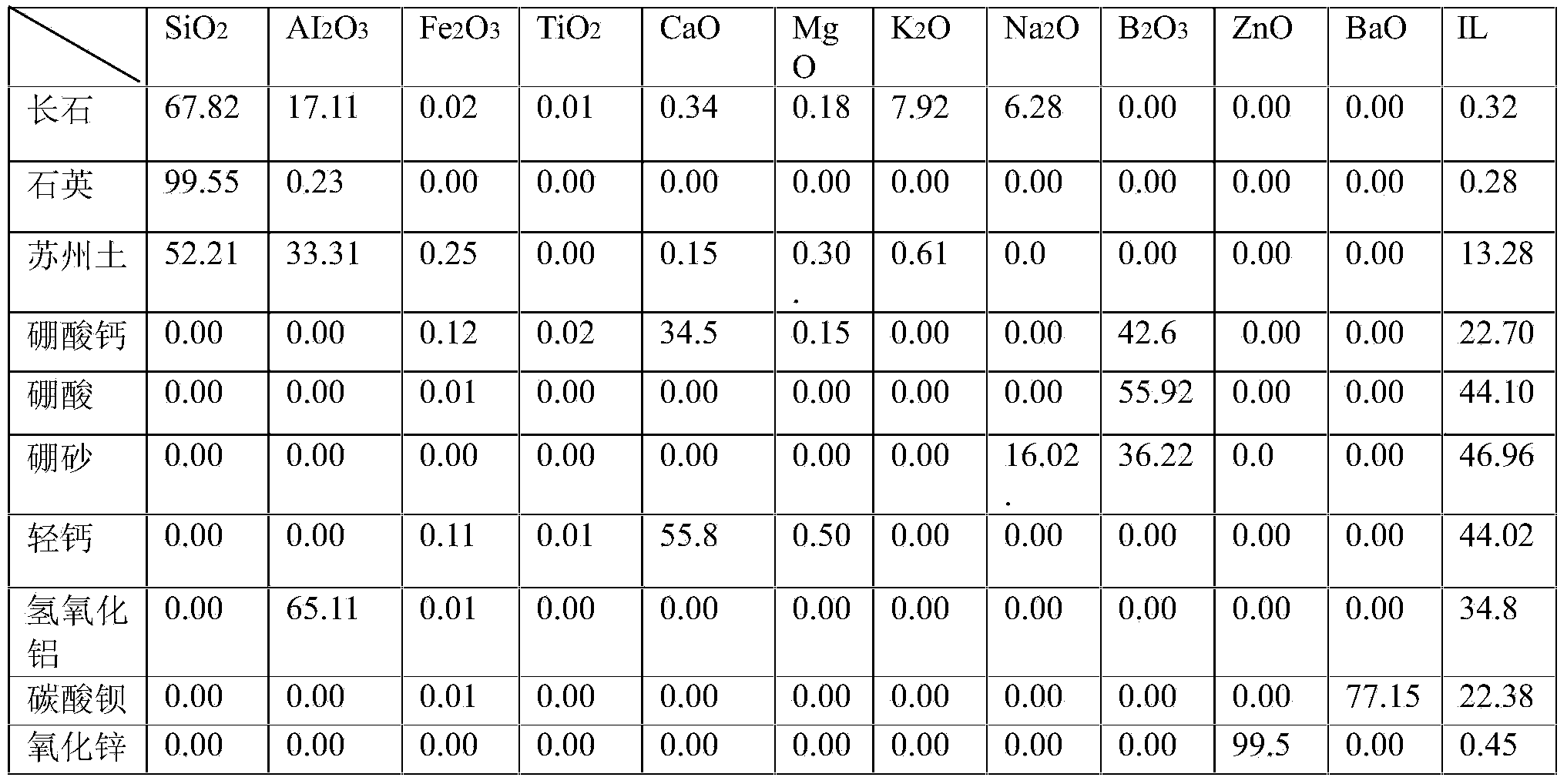

[0040] Preparation of frit suitable for color development:

[0041] Each component material is subjected to a moisture test; each component is weighed, by weight, 28 parts of feldspar, 35 parts of quartz, 5 parts of Suzhou soil, 3 parts of calcium borate, 1 part of aluminum hydroxide, 25 parts of light calcium carbonate, 1 part of barium carbonate and 1 part of borax are mixed in a mixer; the uniformly mixed mixture is sent to a relevant melting furnace for melting.

Embodiment 2

[0043] Preparation of frit suitable for color development:

[0044] Each component material is subjected to a moisture test; each component is weighed, by weight, 35 parts of feldspar, 10 parts of quartz, 5 parts of Suzhou soil, 5 parts of calcium borate, 7 parts of aluminum hydroxide, 12 parts of light calcium carbonate, 6 parts of barium carbonate, 4 parts of borax; 8 parts of boric acid and 6 parts of zinc oxide are mixed in a mixer; the uniformly mixed mixture is sent to a relevant melting furnace for melting.

Embodiment 3

[0046] Preparation of frit suitable for color development:

[0047] Each component material was tested for moisture; each component was weighed, by weight, 20 parts of feldspar, 35 parts of quartz, 0.5 part of Suzhou soil, 6 parts of calcium borate, 7 parts of aluminum hydroxide, 22 parts of light calcium carbonate, 5 parts of barium carbonate, 2 parts of borax, 1 part of boric acid, and 3 parts of zinc oxide are mixed in a blender; the uniformly mixed mixture is sent to a relevant melting furnace for melting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com