Composition for glass, aluminosilicate glass and method for preparing aluminosilicate glass

An aluminosilicate glass and aluminosilicate technology, applied in glass manufacturing equipment, glass tempering, glass forming, etc., can solve the problems of mismatched thermal expansion coefficient and high softening point, and achieve suitable expansion coefficient and softening point. Low and good energy transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

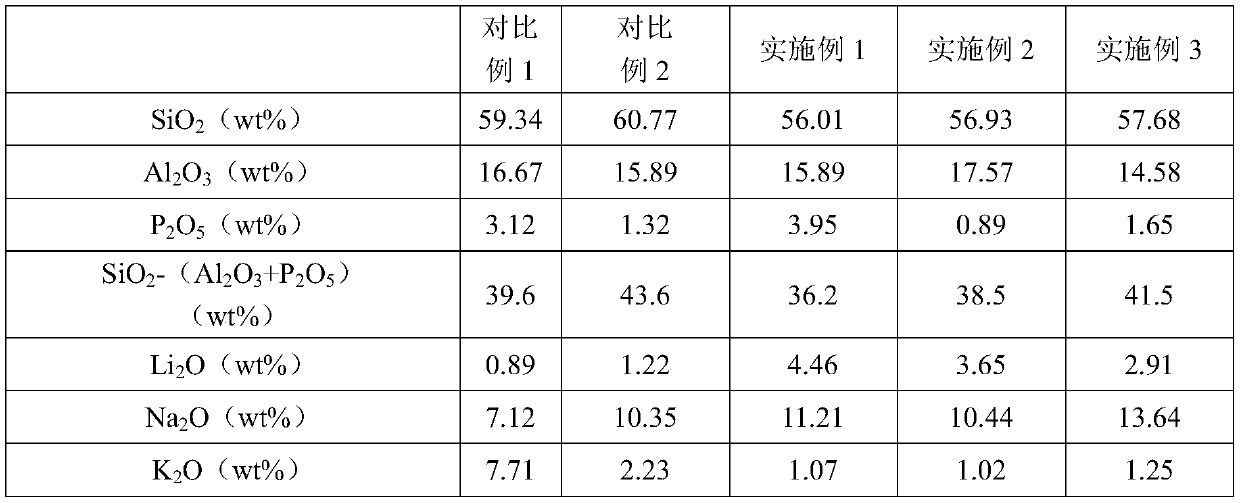

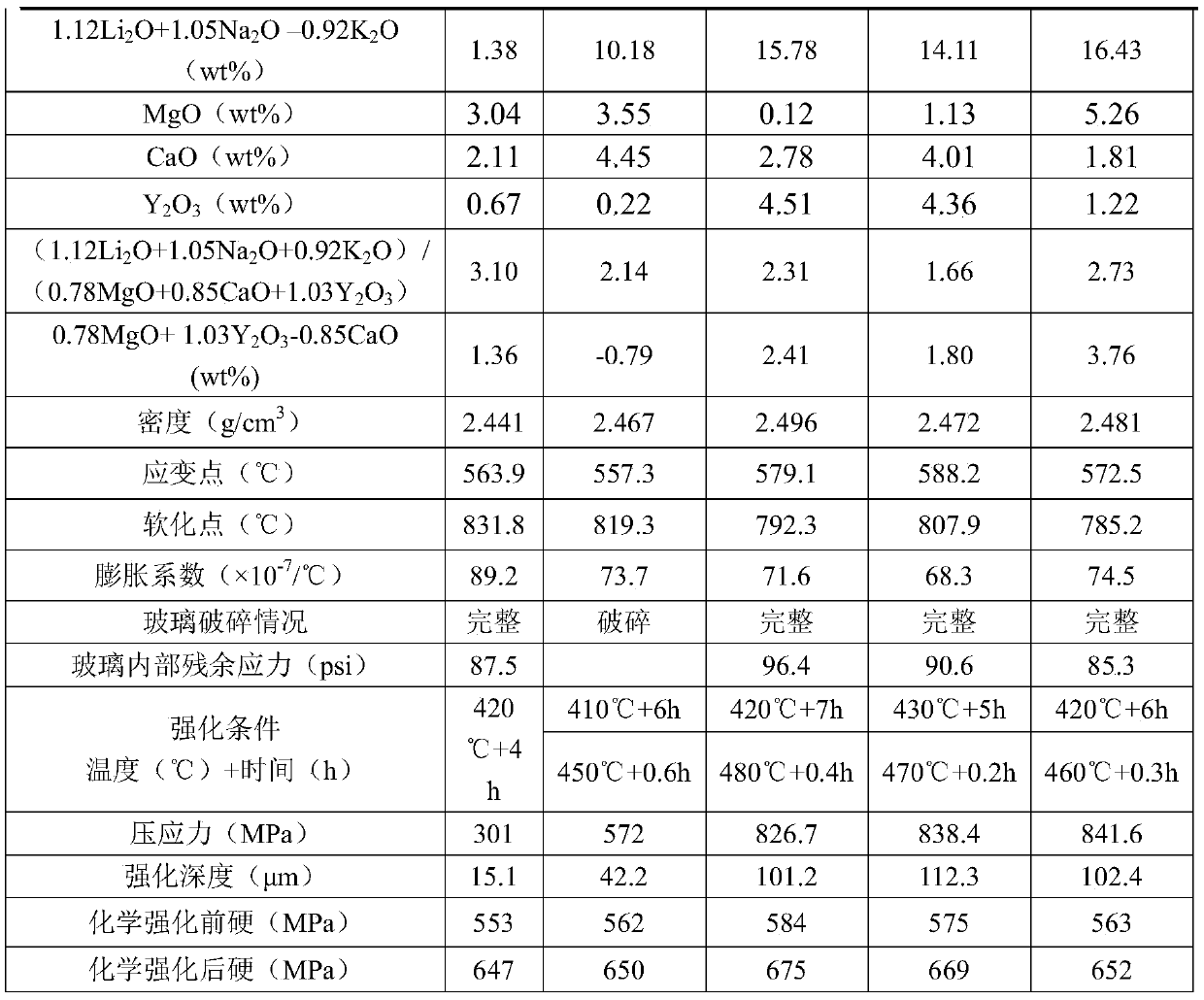

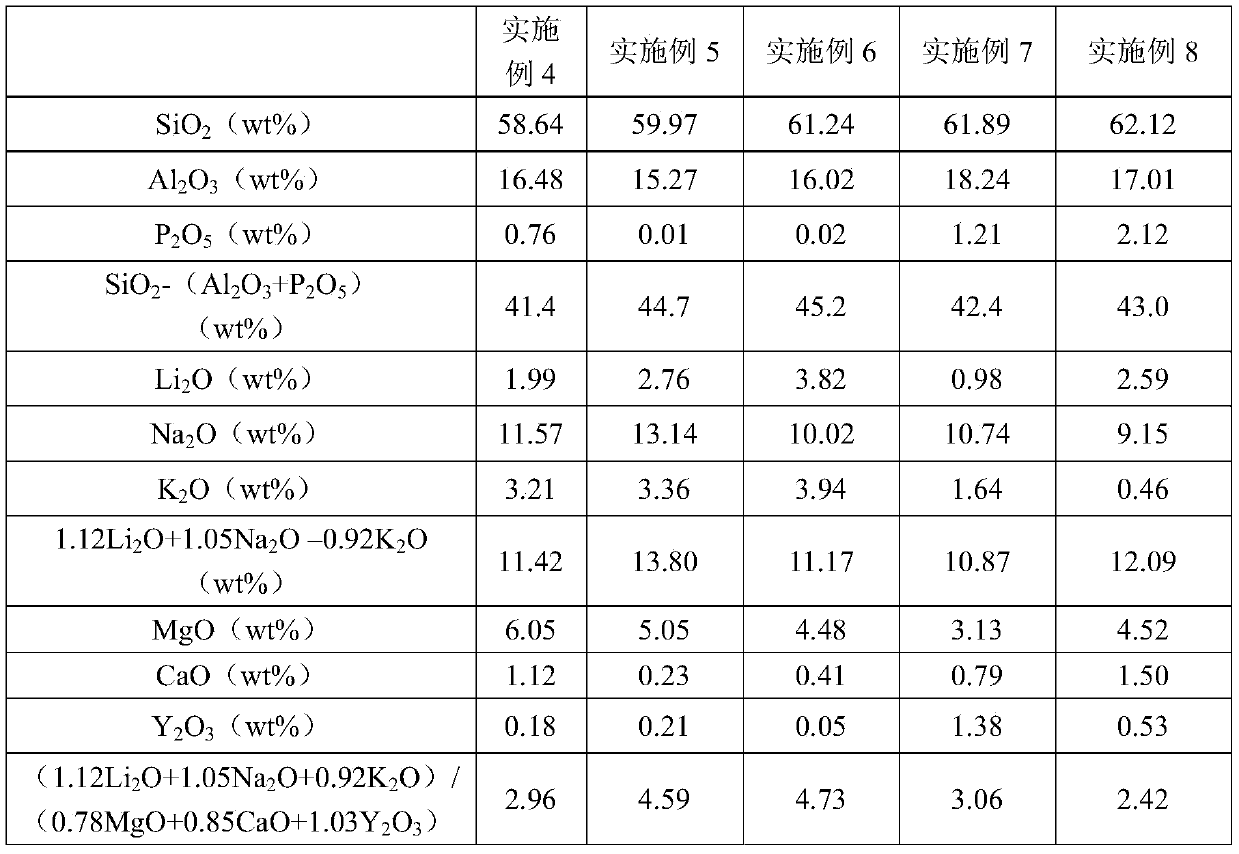

Examples

preparation example Construction

[0055] 3. Preparation method of aluminosilicate glass

[0056] The method for preparing aluminosilicate glass according to the embodiment of the present invention comprises: sequentially mixing, melting, homogenizing, molding and annealing the aforementioned composition for glass to obtain aluminosilicate glass.

[0057] In the present invention, the raw materials in the aluminosilicate glass composition may be known chemical raw materials or mineral raw materials for glass production.

[0058] Among them, the obtained glass composition can be molded into a glass plate by the float method, the down-draw method, or the overflow method.

[0059] Preferably, after the step of annealing, chemical strengthening is also included. In the present invention, primary chemical strengthening or secondary chemical strengthening can be used.

[0060] Primary chemical strengthening, preferably molten salt is LiNO 3 、NaNO 3 and KNO 3 mixed molten salt, the content of which is 0-5% LiNO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com