Lead-containing sealing glass powder with spectrally selective absorption characteristics and its manufacturing method

A technology for sealing glass and absorbing characteristics, applied in the field of lead-containing sealing glass powder and its manufacturing, can solve the problems of slow heating speed, large heating area, and the overall temperature of the object to be sealed, etc. Appropriate expansion coefficient, easy to prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

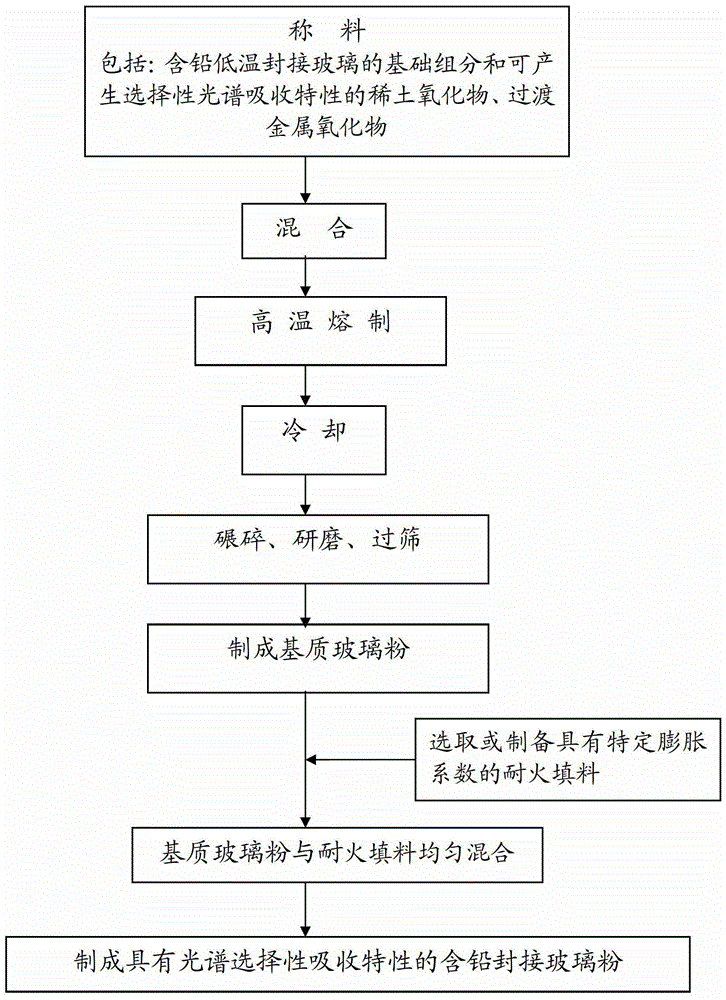

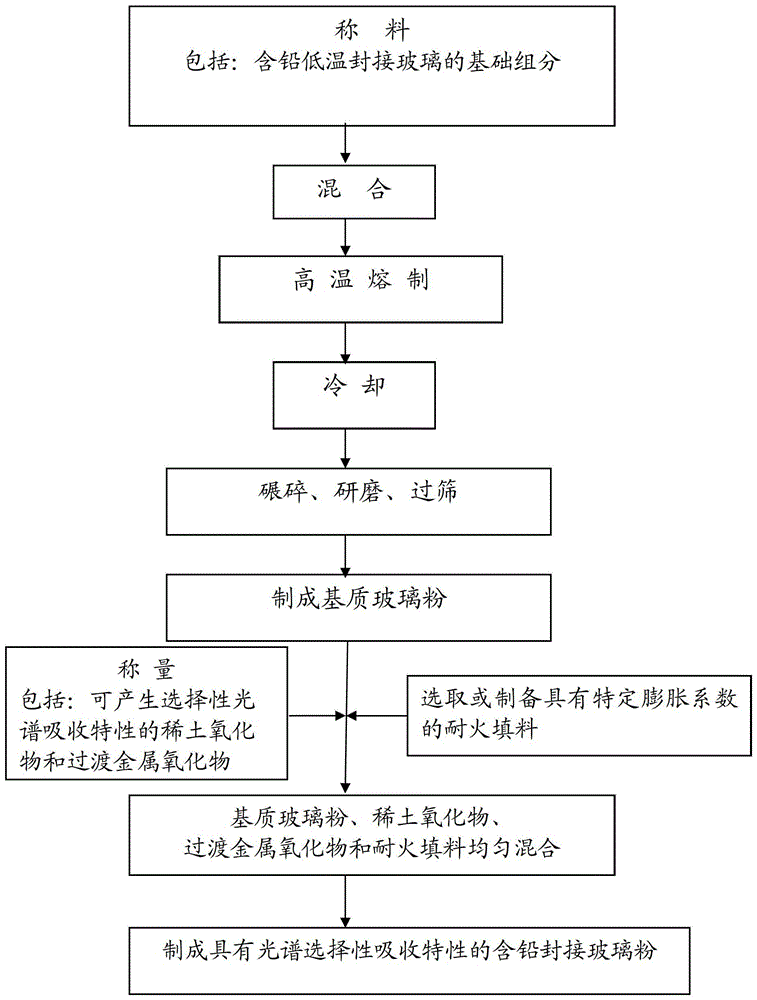

[0036] A method for manufacturing a lead-containing sealing glass frit with spectrally selective absorption properties:

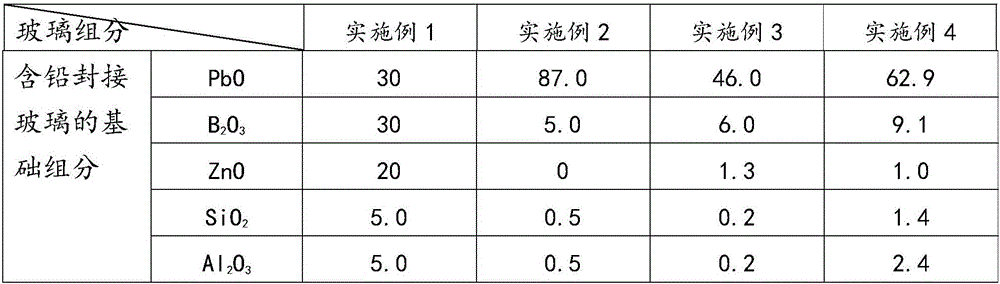

[0037] Step 101: According to the components corresponding to Example 1 in Table 1, that is, the basic components and the composition of rare earth oxides and transition metal oxides, weigh various oxide raw materials and / or compounds corresponding to the oxides, and mix them thoroughly, Make a mixture; Wherein, boron oxide, calcium oxide, strontium oxide and barium oxide select their corresponding compounds for use, and the parts by weight of the corresponding compounds are the corresponding parts by weight converted according to their oxide content;

[0038] Step 102: melting the mixture obtained in step 101 at 1200°C for 3 hours to obtain a molten liquid of the mixture;

[0039] Step 103: cooling the molten liquid of the mixture obtained in step 102 on an iron plate, crushing and grinding the cooled glass pieces, and passing through a 200-mesh sieve to o...

Embodiment 2

[0051] A method for manufacturing a lead-containing sealing glass frit with spectrally selective absorption properties:

[0052] Step 101: According to the components corresponding to Example 2 in Table 1, that is, the composition of the basic components and rare earth oxides and transition metal oxides, weigh various oxide raw materials and / or compounds corresponding to the oxides, and mix them thoroughly, Make a mixture; make a mixture; wherein, boron oxide, potassium oxide, sodium oxide, lithium oxide and silver oxide are selected from their corresponding compounds, and the weight of the corresponding compounds is the corresponding weight converted according to their oxide content number of copies;

[0053] Step 102: melting the mixture obtained in step 101 at 800°C for 0.5 hour to obtain a molten liquid of the mixture;

[0054] Step 103: cooling the molten liquid of the mixture obtained in step 102 on an iron plate, crushing and grinding the cooled glass pieces, and passi...

Embodiment 3

[0066] A method for manufacturing a lead-containing sealing glass frit with spectrally selective absorption properties:

[0067] Step 101: According to the components corresponding to Example 3 in Table 1, that is, the basic components and the composition of rare earth oxides and transition metal oxides, weigh various oxide raw materials and / or compounds corresponding to the oxides, and mix them thoroughly, Make a mixture; wherein, boron oxide, calcium oxide, strontium oxide, barium oxide and silver oxide select their corresponding compounds for use, and the parts by weight of the corresponding compounds are the corresponding parts by weight converted according to their oxide content;

[0068] Step 102: melting the mixture obtained in step 101 at 1100°C for 2 hours to obtain a molten liquid of the mixture;

[0069] Step 103: cooling the molten liquid of the mixture obtained in step 102 on an iron plate, crushing and grinding the cooled glass pieces, and passing through a 300-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com