Tempered vacuum glass and manufacturing method thereof

A vacuum glass and tempered glass technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of the support point not reaching the sintering temperature, the high sintering temperature of the support point, affecting the vacuum degree, etc., and shorten the heating time. effect of time, reduced sealing temperature, reduced risk of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments.

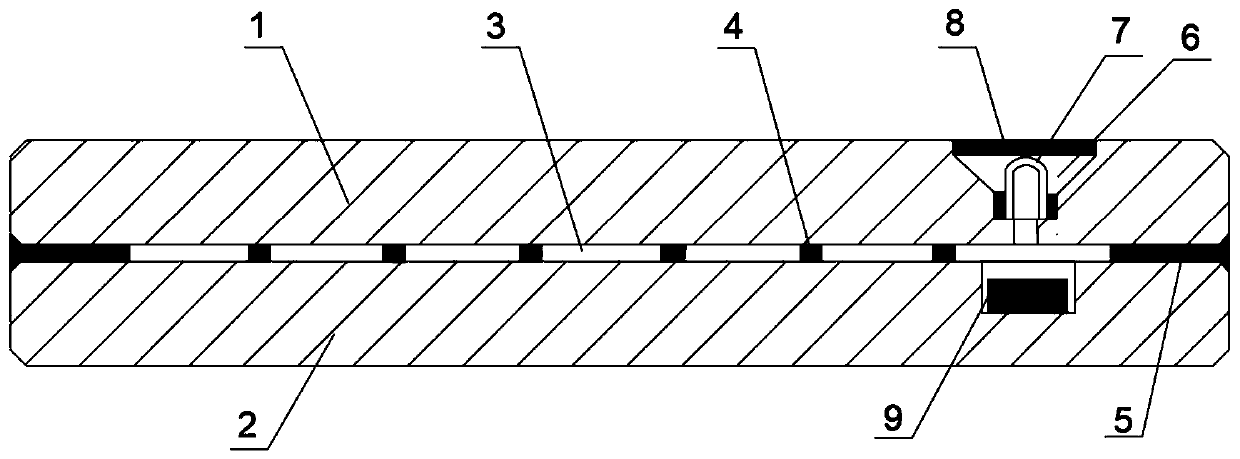

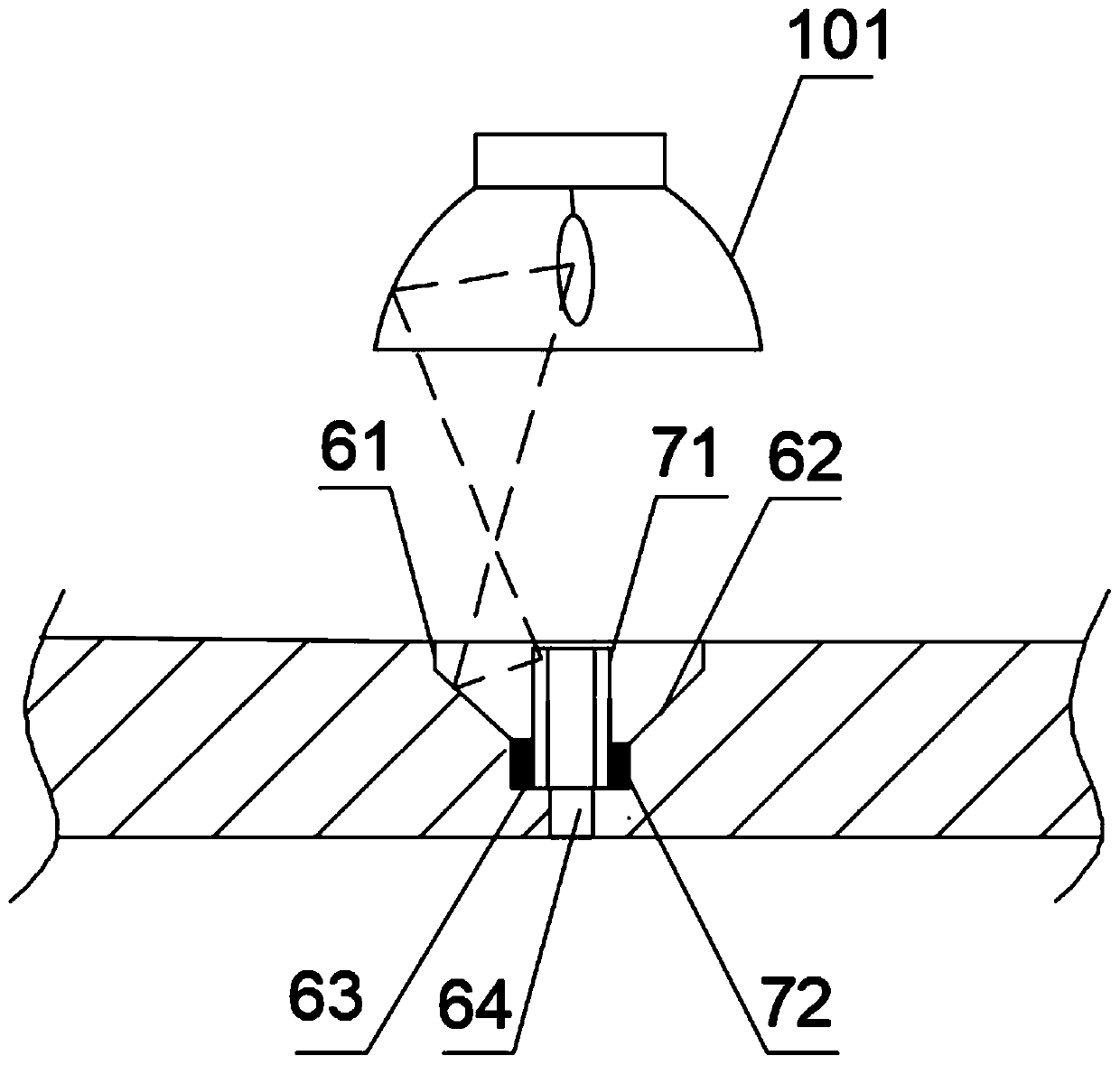

[0038] The present invention proposes a tempered vacuum glass, which comprises two tempered glass substrates 1-2, and a vacuum area 3 between the two glass substrates. The lower glass 2 is provided with ceramic glaze supports 4 at a certain interval, and the upper A piece of glass 1 is located on the support 4, and a low-temperature solder 5 is provided in the gap between the two pieces of glass, and the low-temperature solder 5 is heated by rapid heating and cooling technology to seal the surroundings of the two pieces of glass. The air extraction pipe 7 and the air extraction part 6 of the reflection surface 63 are provided with a getter 9 at a position where the bottom glass 2 faces the air extraction part 6 .

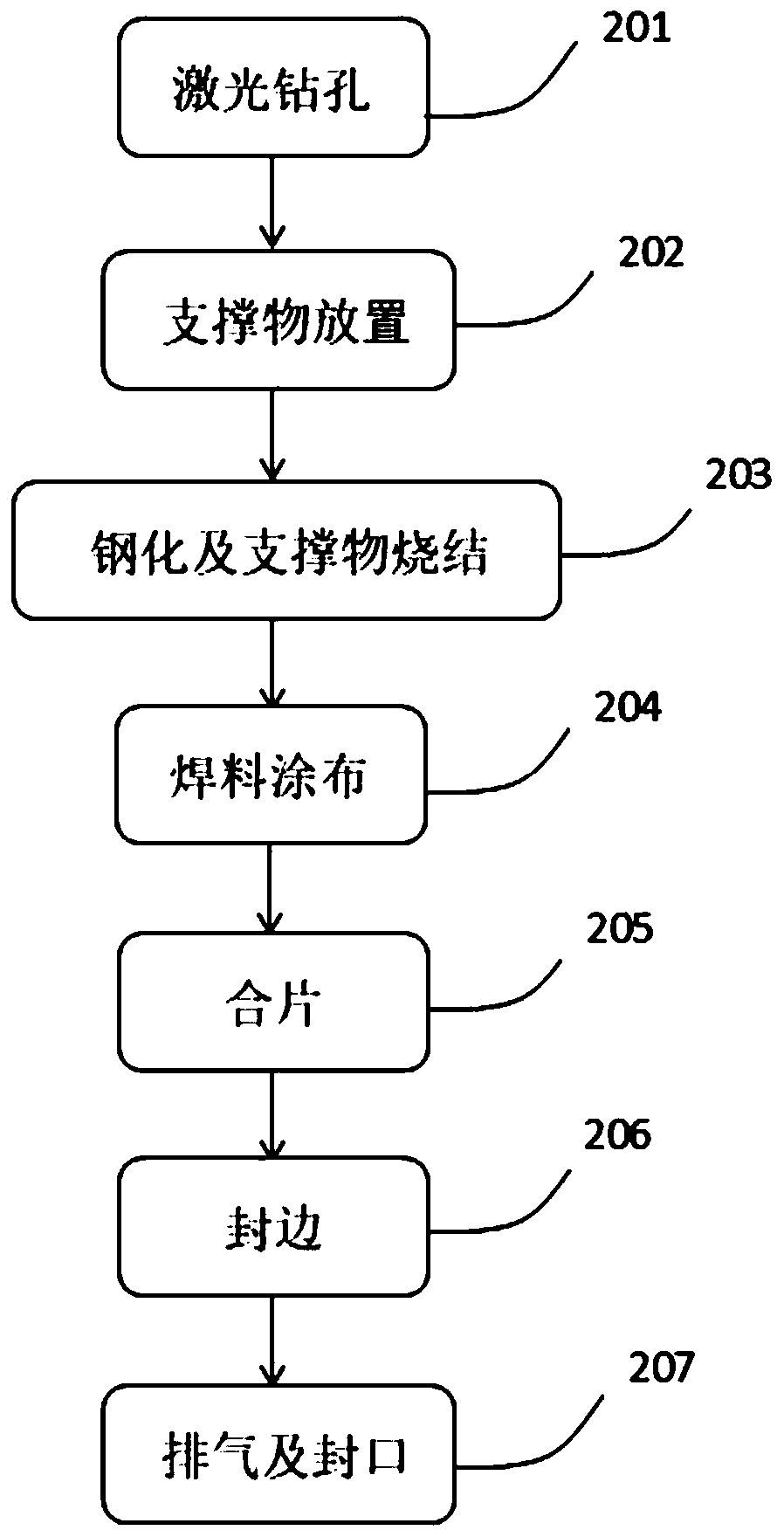

[0039] The present invention proposes a kind of preparation method of toughened vacuum glass, comprises the following steps:

[0040](1) Laser drilling 201: Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com