Oil-stain-resistant ceramic sheet and preparation method thereof

A ceramic thin plate and oil-resistant technology, which is applied in the field of ceramic thin plates, can solve the problems of poor oil resistance of thin plates and affect the use efficiency, and achieve the effect of strong structural system stability, good strength, and excellent strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

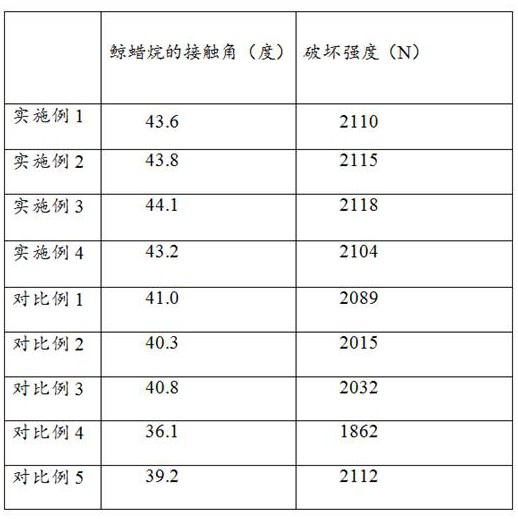

Examples

Embodiment 1

[0037] A kind of anti-oil stain ceramic thin plate of the present embodiment comprises following raw materials in parts by weight:

[0038] Mullite 20 parts, cordierite 10 parts, talc powder 5 parts, fiber reinforced graphene 4 parts, wollastonite hybrid modified a-alumina 2 parts, silicon nitride composite nanopowder 1 part, barium carbonate 1 part of sintering aid.

[0039] The preparation method of the fiber reinforced graphene body of the present embodiment is:

[0040] S1: Put the graphene into a hydrochloric acid solution with a mass fraction of 2% and soak for 15 minutes at a temperature of 65°C. After soaking, wash with water and dry;

[0041] S2: Then mix the graphene and silicon carbide fibers of S1 at a weight ratio of 3:1, add acetone 10 times the total amount of silicon carbide fibers, and perform ultrasonic reaction and mixing. The ultrasonic power is 500W, and the ultrasonic time is 20 minutes. After the ultrasonic wave is completed, wash with water , to obtai...

Embodiment 2

[0060] A kind of anti-oil stain ceramic thin plate of the present embodiment comprises following raw materials in parts by weight:

[0061] 30 parts of mullite, 20 parts of cordierite, 10 parts of talc powder, 6 parts of fiber-reinforced graphene, 6 parts of wollastonite hybrid modified a-alumina, 3 parts of silicon nitride composite nanopowder, barium carbonate 5 parts of sintering aid.

[0062] The preparation method of the fiber reinforced graphene body of the present embodiment is:

[0063] S1: Put the graphene into a hydrochloric acid solution with a mass fraction of 6% and soak for 25 minutes at a temperature of 75°C. After soaking, wash with water and dry;

[0064] S2: Then mix the graphene and silicon carbide fibers of S1 at a weight ratio of 3:1, add acetone 10 times the total amount of silicon carbide fibers, and perform ultrasonic reaction and mixing. The ultrasonic power is 1000W, and the ultrasonic time is 30min. After the ultrasonic wave is completed, wash with ...

Embodiment 3

[0083] A kind of anti-oil stain ceramic thin plate of the present embodiment comprises following raw materials in parts by weight:

[0084] 25 parts of mullite, 15 parts of cordierite, 7.5 parts of talc, 5 parts of fiber-reinforced graphene, 4 parts of wollastonite hybrid modified a-alumina, 2 parts of silicon nitride composite nanopowder, barium carbonate 3 parts of sintering aid.

[0085] The preparation method of the fiber reinforced graphene body of the present embodiment is:

[0086] S1: Put the graphene into a hydrochloric acid solution with a mass fraction of 4% and soak for 20 minutes at a temperature of 70°C. After soaking, wash with water and dry;

[0087] S2: Then mix the graphene and silicon carbide fibers of S1 at a weight ratio of 3:1, add acetone 10 times the total amount of silicon carbide fibers, and perform ultrasonic reaction mixing. The ultrasonic power is 750W, and the ultrasonic time is 25min. After the ultrasonic wave is completed, wash with water , to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com