Blister packaging film for gamma ray disinfection and preparing method thereof

A blister packaging and gamma ray technology, which is applied in the field of gamma ray sterilized blister packaging film and its preparation, can solve the problem that the performance cannot meet the requirements of gamma ray sterilization, the materials of each layer cannot be well compounded, and the physical and mechanical properties are reduced. performance and other issues, to achieve significant economic and social benefits, good heat sealing effect, and high physical and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

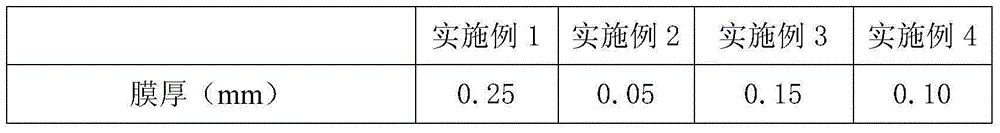

[0049] The preparation method of the blister packaging film used for γ-ray disinfection comprises the following steps: 1) sending each layer of raw materials to seven extruders of a seven-layer co-extrusion film blowing unit for heating and melting to form a polymer melt, Then pass through each flow channel of the spiral center die and each layer of components is stacked layer by layer on the top of the die to form a composite film; It is obtained by expanding, stretching and pulling into a film, and the pulling speed is 10-60m / min. The thickness of the film is different, and different pulling speeds are used; 3) the above-mentioned film is water-cooled and shaped; 4) the surface of the above-mentioned cooled and shaped film is Corona treatment, then rolled into a film roll, cut and packaged to obtain a blister packaging film for γ-ray disinfection with a total thickness of 0.05-0.25 mm;

[0050] Among them, the seven-layer co-extrusion film blowing unit uses a single-screw ex...

Embodiment 1

[0054] Prepare a blister packaging film suitable for gamma ray disinfection with a total thickness of 0.25mm, which includes 7 layers, followed by A layer, B layer, C layer, D layer, E layer, F layer and G layer, the thickness of each layer Determined by the screw speed and traction speed, the raw materials of each layer are:

[0055] Layer A: Polyamide 6;

[0056] B layer: adhesive resin PX3060;

[0057] Layer C: linear low-density polyethylene and low-density polyethylene, linear low-density polyethylene accounts for 60% of the total weight of raw materials for layer C, and low-density polyethylene accounts for 40% of the total weight of raw materials for layer C;

[0058]D layer: adhesive resin PX3060;

[0059] E layer: polyamide resin (homopolyamide 6);

[0060] F layer: adhesive resin PX3060;

[0061] G layer: linear low density polyethylene and metallocene polyethylene, linear low density polyethylene accounts for 60% of the total weight of G layer raw materials, met...

Embodiment 2

[0079] Prepare a blister packaging film suitable for gamma ray disinfection with a total thickness of 0.05mm, which includes 7 layers, followed by A layer, B layer, C layer, D layer, E layer, F layer and G layer, the thickness of each layer Determined by the screw speed and traction speed, the raw materials of each layer are:

[0080] Layer A: Polyamide 6;

[0081] B layer: adhesive resin PX3060;

[0082] C layer: linear low-density polyethylene and low-density polyethylene, linear low-density polyethylene accounts for 80% of the total weight of C layer raw materials, and low-density polyethylene accounts for 20% of the total weight of C layer raw materials;

[0083] D layer: adhesive resin PX3060;

[0084] E layer: polyamide resin (copolymer of polyamide 6 and polyamide 66);

[0085] F layer: adhesive resin PX3060;

[0086] G layer: linear low density polyethylene and metallocene polyethylene, linear low density polyethylene accounts for 80% of the total weight of G layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com