Metal-bonded light emitting diode and method for forming metal-bonded light emitting diode

A technology of light-emitting diodes and metal bonds, which is applied to metal-bonded light-emitting diodes to form metal-bonded light-emitting diodes, can solve the problems of not considering the cost of various material characteristics, and achieve easy control, low cost, and low boiling point. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

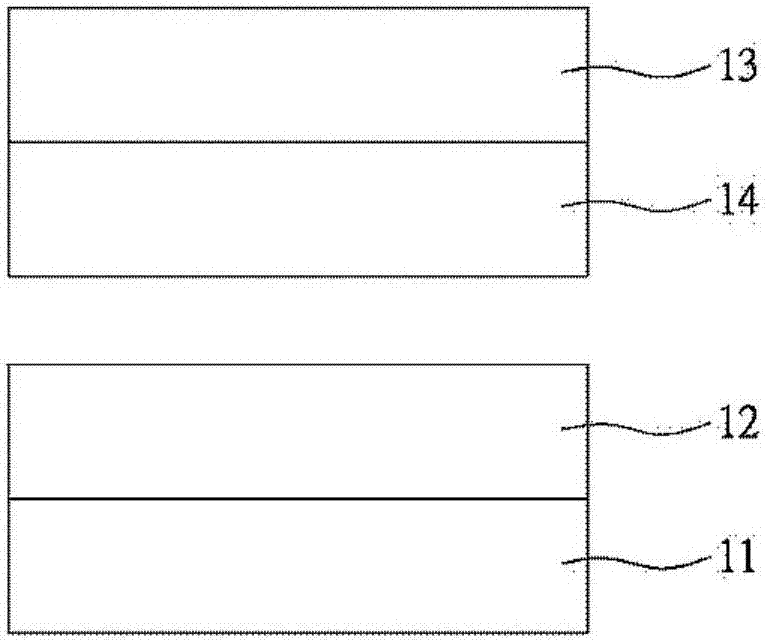

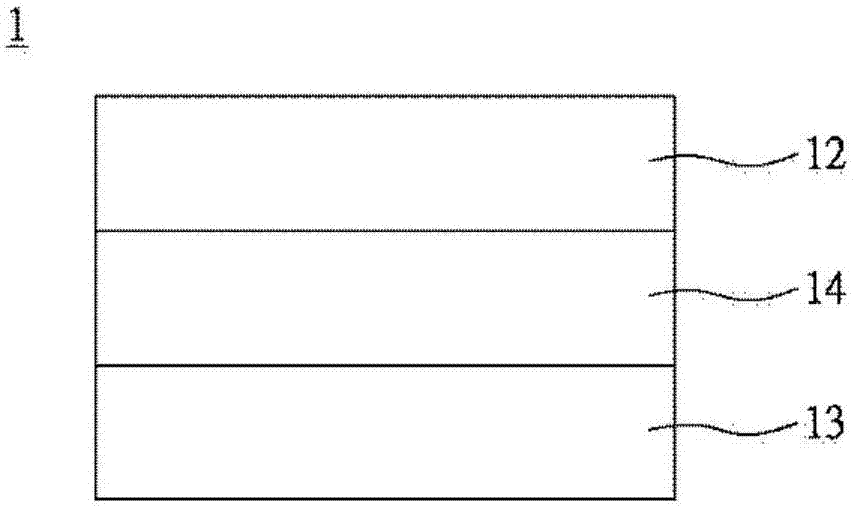

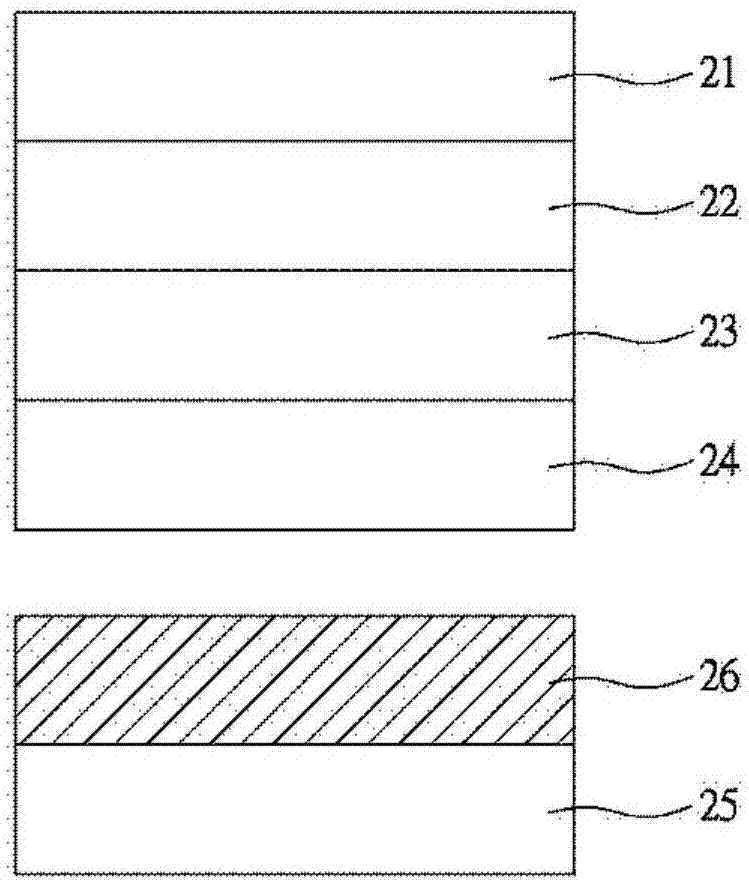

[0047] see Figure 2A and Figure 2B , which is a structural diagram completed by the method for forming a metal-bonded light-emitting diode according to the present invention. The method for forming a metal-bonded light-emitting diode of the present invention includes the following steps: setting a first substrate 25; forming a first bonding metal layer 26 on the first substrate 25; setting a second substrate 21; forming an epitaxial layer 22 on the second substrate 21 ; forming a conductive oxide layer 23 on the epitaxial layer 22 ; forming a second bonding metal layer 24 on the conductive oxide layer 23 ; bonding the first bonding metal layer 26 and the second bonding metal layer 24 ; removing the second substrate 21 .

[0048] see Figure 2C , which is a structural diagram of adding a covering layer according to the method for forming a metal bonded light-emitting diode of the present invention. The above method also includes forming a cover layer 27 between the epitaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com