Patents

Literature

63results about How to "Increase acid value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

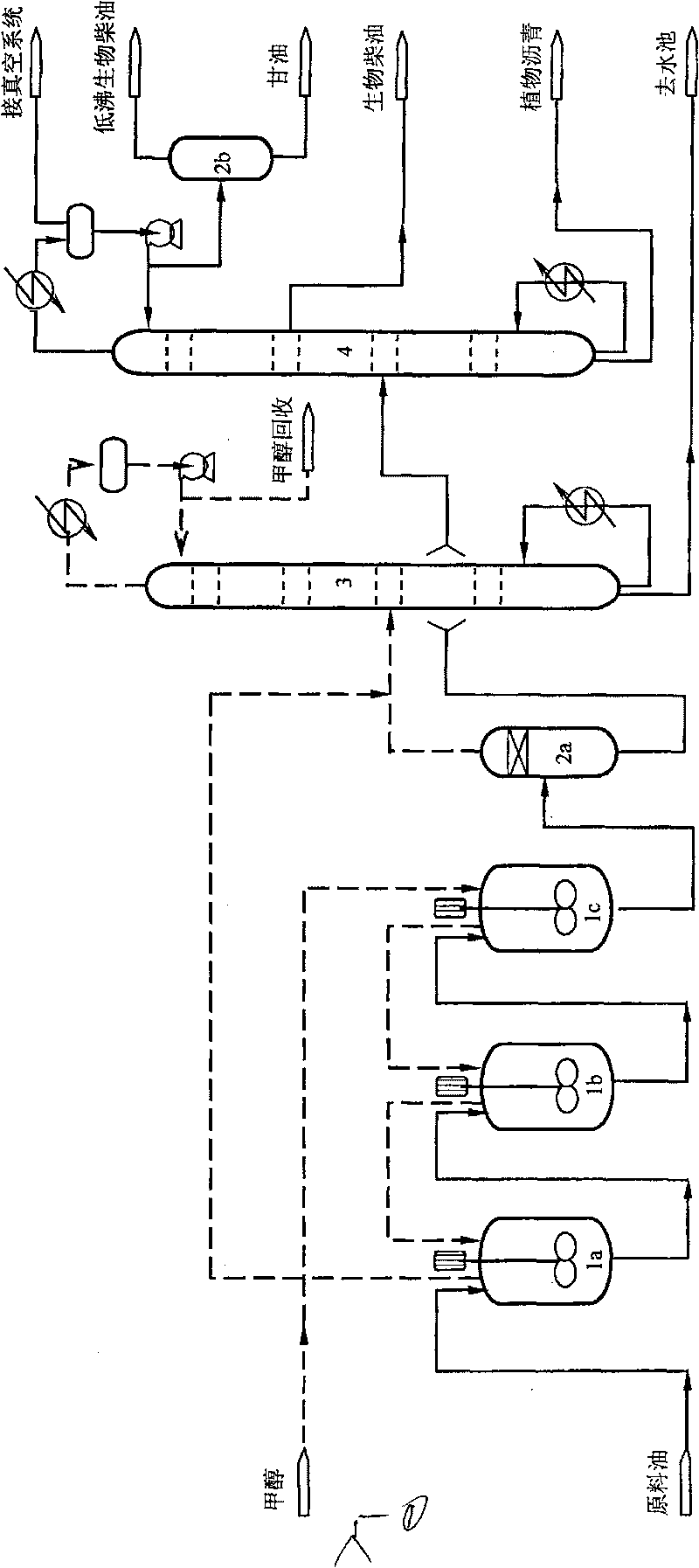

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

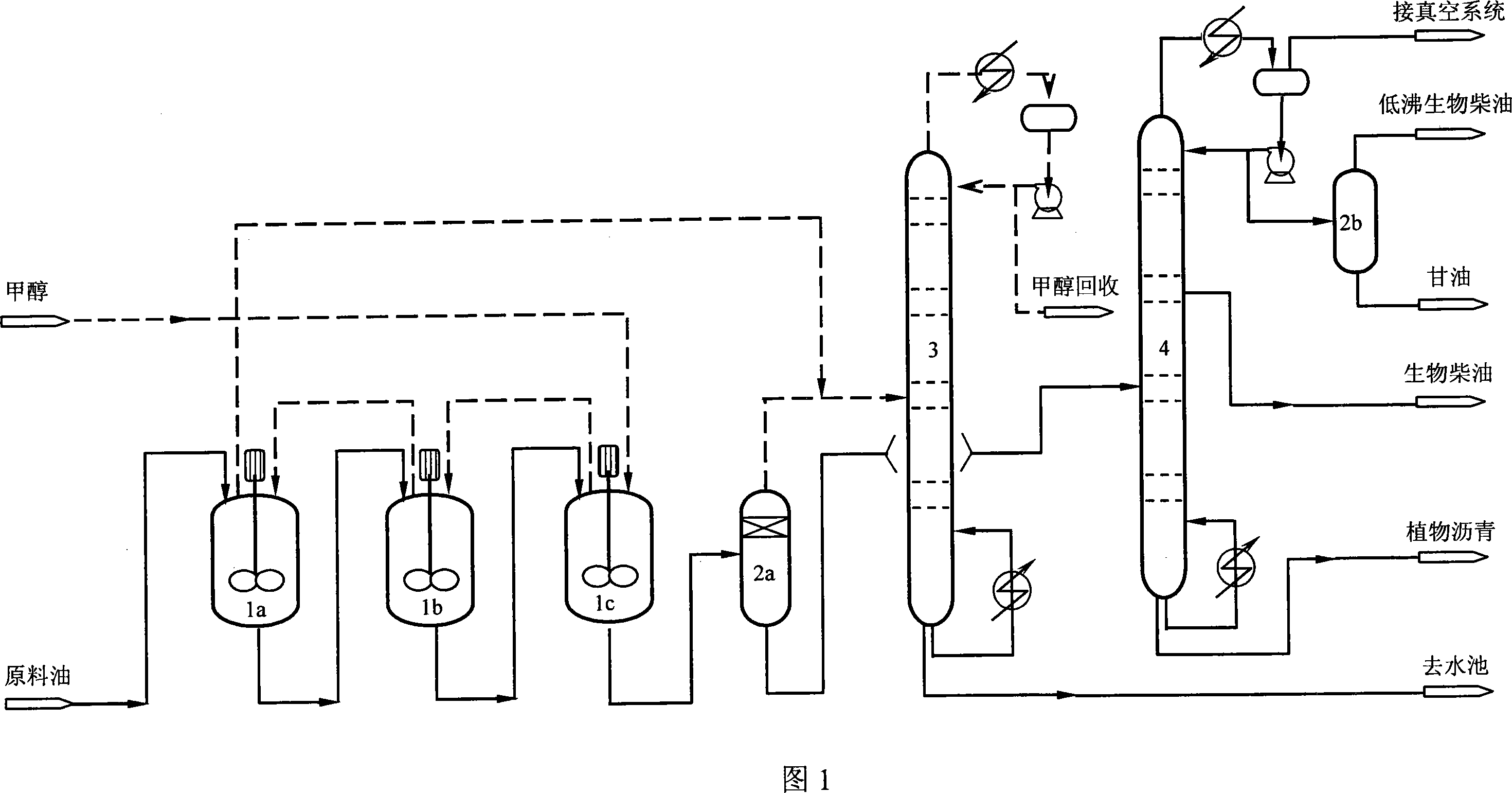

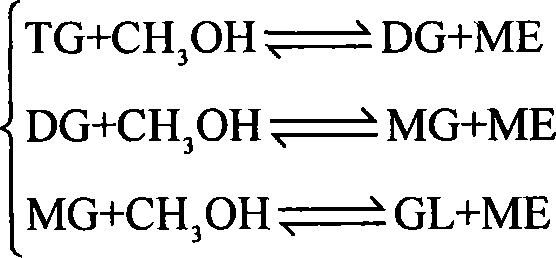

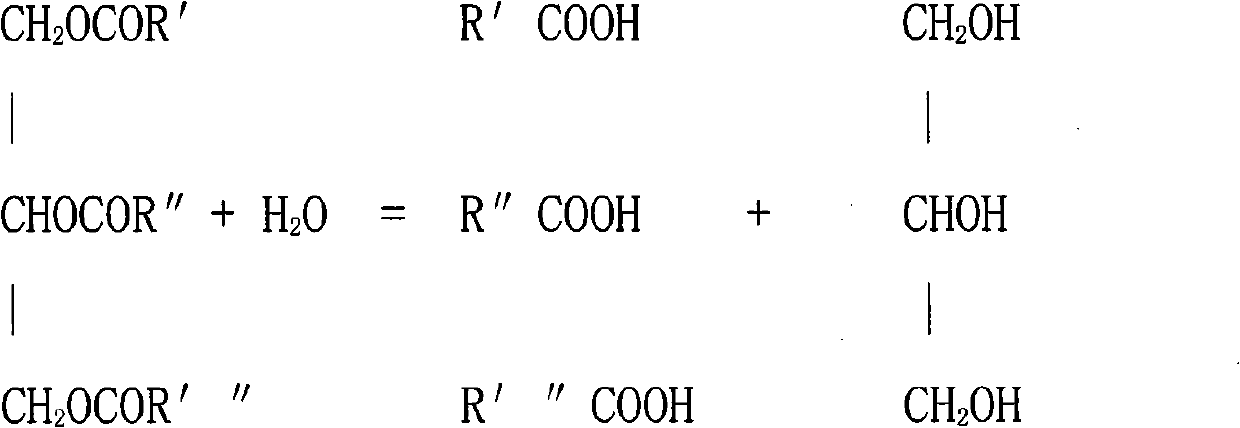

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

Method for preparing fire-retardant polyether by cyanuramide

A fire resisting polyether is prepared from cyanamine trimers by: mixing and stirring cyanamine solids and formaldehyde, heating to 80-100deg.C,reacting for 5-30 minutes, adding alcohol amine and agitating, reacting 30-180 minutes to produce cyanamine trimer solution, making the solution mol ratio of cyanamine trimer :formaldehyde :alcohol amine being = 1:3:2;then, mixing cyanamine trimer solution gotten said above with polyether polyol, Stirring for 1-15 minutes, adding isocyanate ester, stirring 10-60 for minutes, cooling to 5-35deg.C, evacuating to vacuum at -0.2--0.1 MPa and at 90-120deg.C conditions, and removing residual monomers to get fire-resisting polyether. The products have high oxygen index, without containing halogen, phosphorus, antimony, etc, good fluidity, low acid value, less water content, little smoking, good uniformity and mechanics intensity, improved fire resisting effect.

Owner:SOUTH CHINA UNIV OF TECH

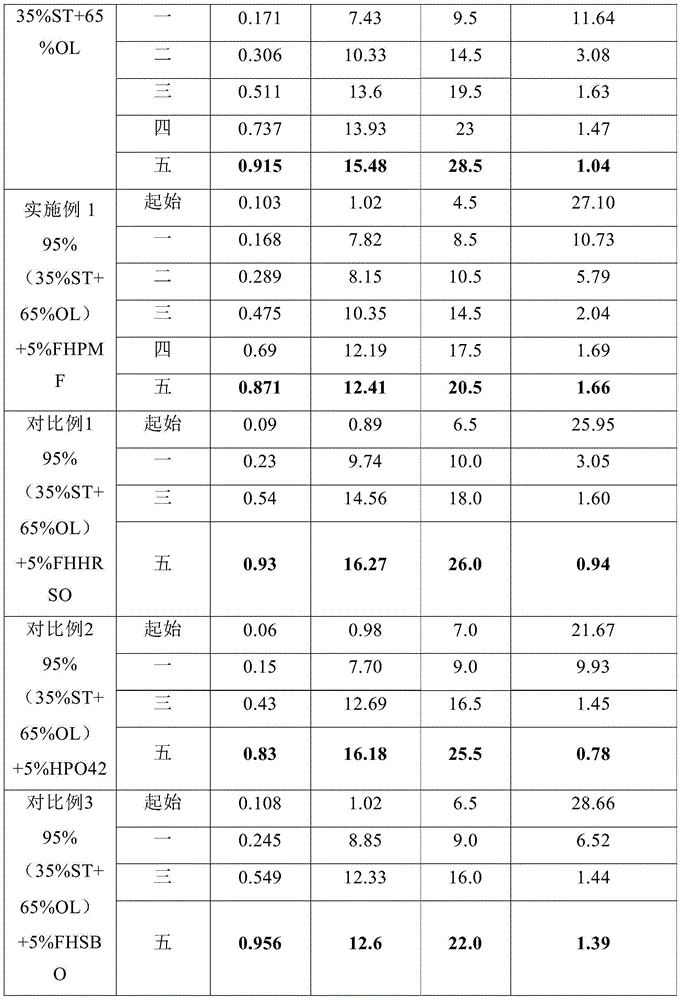

Grease composition for frying

The invention provides a grease composition for frying; the grease composition contains a fully hydrogenated palm oil intermediate fraction. The invention also relates to a preparation method of the grease composition for frying and a method of improving the frying performance of frying oil; the methods include the step of mixing the fully hydrogenated palm oil intermediate fraction and the frying oil. The invention also includes a use of the fully hydrogenated palm oil intermediate fraction in preparation of the grease composition for frying or improvement of the frying performance of the frying oil. The grease composition for frying does not have a health problem of trans-fatty acids, the frying stability is markedly improved, the oil absorption rate of fried products is significantly reduced, and color, luster, brittleness, flavor and greasy feeling are all improved.

Owner:嘉里特种油脂(上海)有限公司

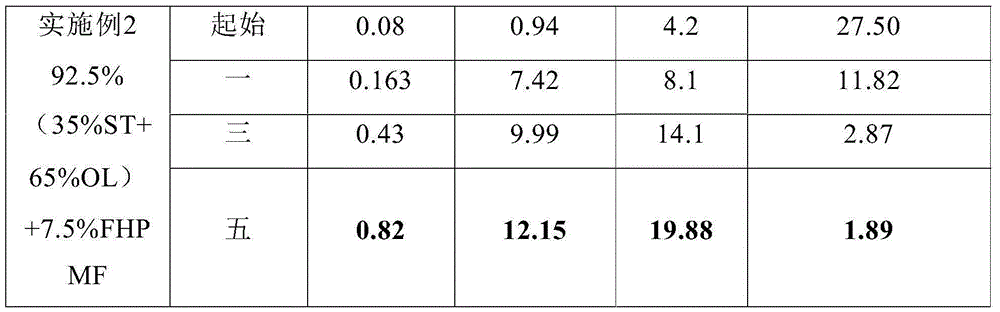

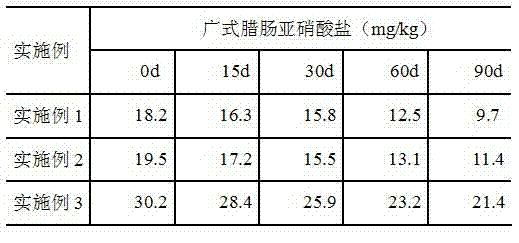

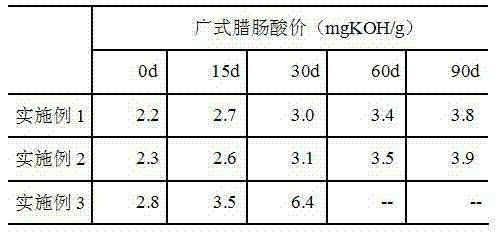

Preparation method of myrtle essential oil and application of myrtle essential oil in Guangdong sausage

InactiveCN102226131AIncrease acid valueSolve the technical problem of acid value exceeding the standardEssential-oils/perfumesMeat/fish preservation using chemicalsBiotechnologyEngineering

The invention relates to a preparation method of myrtle essential oil and application of the myrtle essential oil in Guangdong sausage. The preparation method of the myrtle essential oil comprises the following step: extracting at 30-50 DEG C for 1-2 hours while adding 1-2ml / g ethanol as an entrainer. The myrtle essential oil and TBHQ (tert-butylhydroquinone) are mixed and dissolved in ethanol, and the mixture can be added into Guangdong sausage, thereby obviously inhibiting the increase of the acid number of the Guangdong sausage in the storage process and reducing the residual quantity of nitrites in the Guangdong sausage.

Owner:SOUTH CHINA UNIV OF TECH

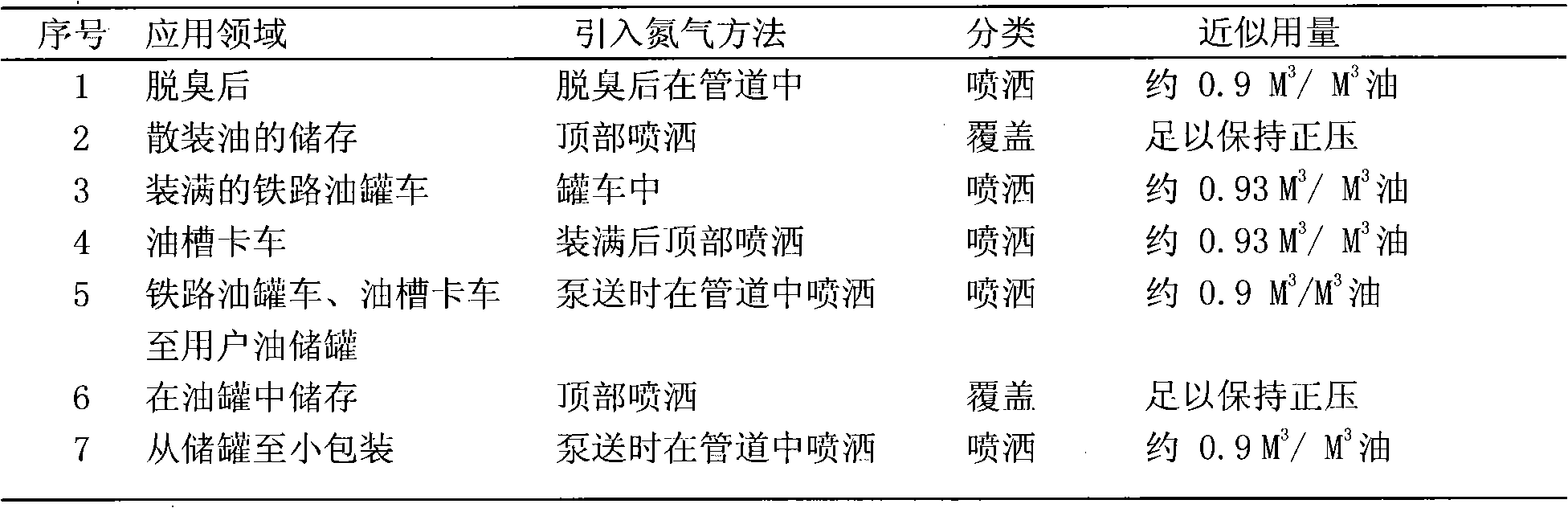

Low-temperature spread jet nitrogen charge refreshing method for maize germ oil

ActiveCN102080019AIncrease acid valueFatty substance preservation using additivesInjectorOil and grease

The invention discloses a low-temperature spread jet nitrogen charge refreshing method for maize germ oil. The method specifically comprises the following steps of: before oil is canned and stored, extending a nitrogen outlet of the conventional nitrogen charge pipeline and inserting the nitrogen outlet into oil liquid, and arranging a nitrogen spread injector made of a cellular material at the outlet of the nitrogen pipeline to ensure that the nitrogen passes through the spread injector to form tiny airflow to be mixed with the oil liquid to form turbulent mixing, so that oxygen mixed with and dissolved in the oil is removed and the aim of preventing the maize oil from being oxidized and deteriorated is fulfilled. The oxygen content of the maize germ oil processed by the nitrogen charge refreshing method is less than 0.008 percent; and the oxygen content of the maize germ oil processed by the conventional nitrogen charge covering method is 0.3 percent.

Owner:SHANDONG XIWANG FOOD

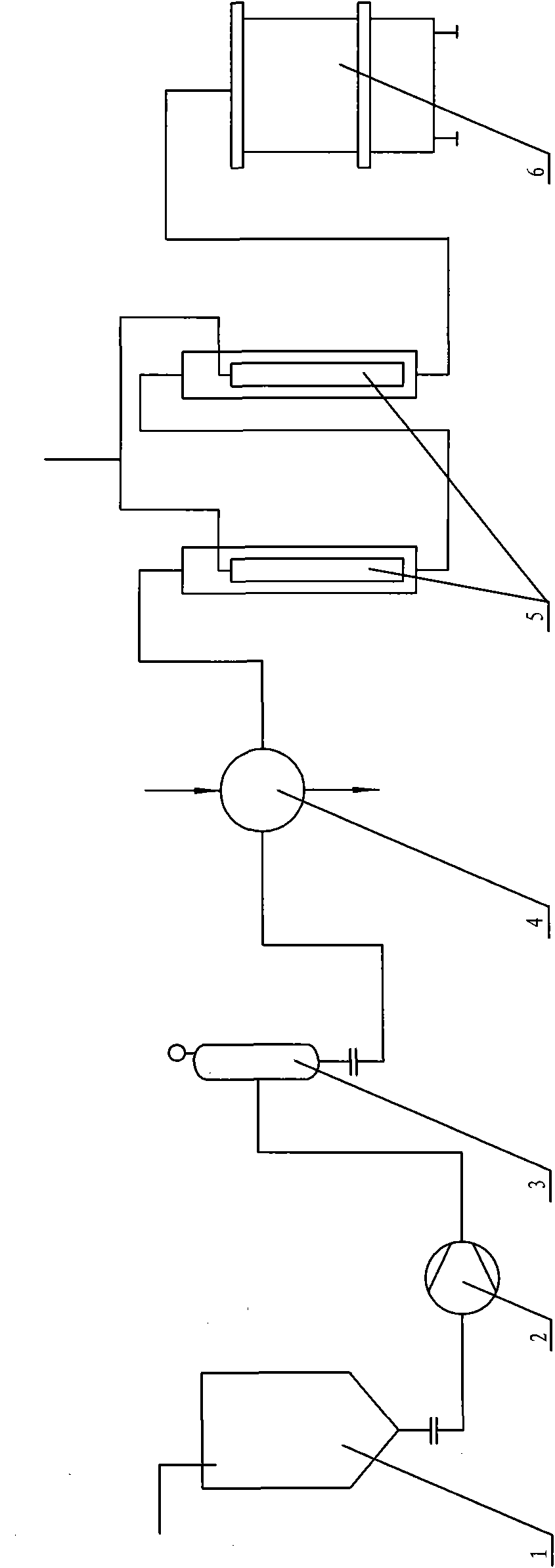

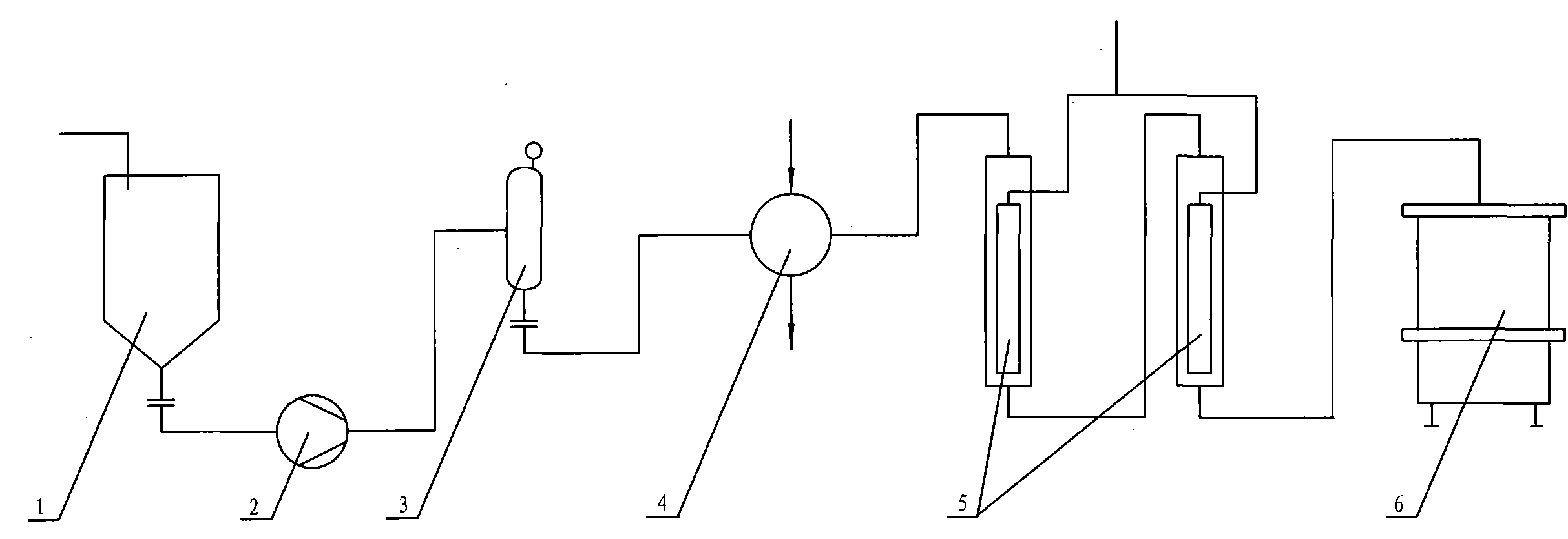

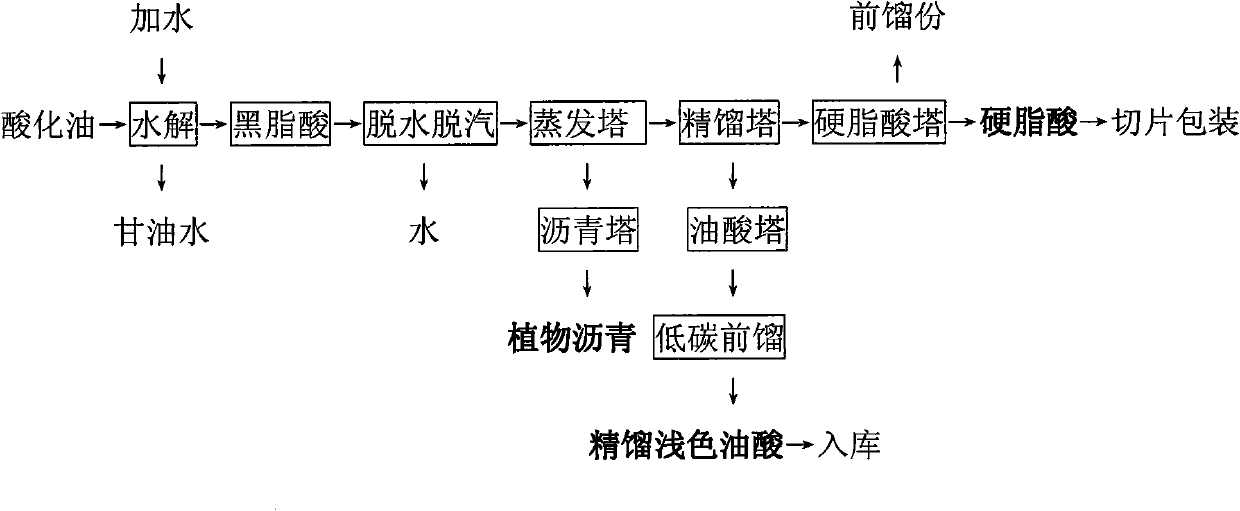

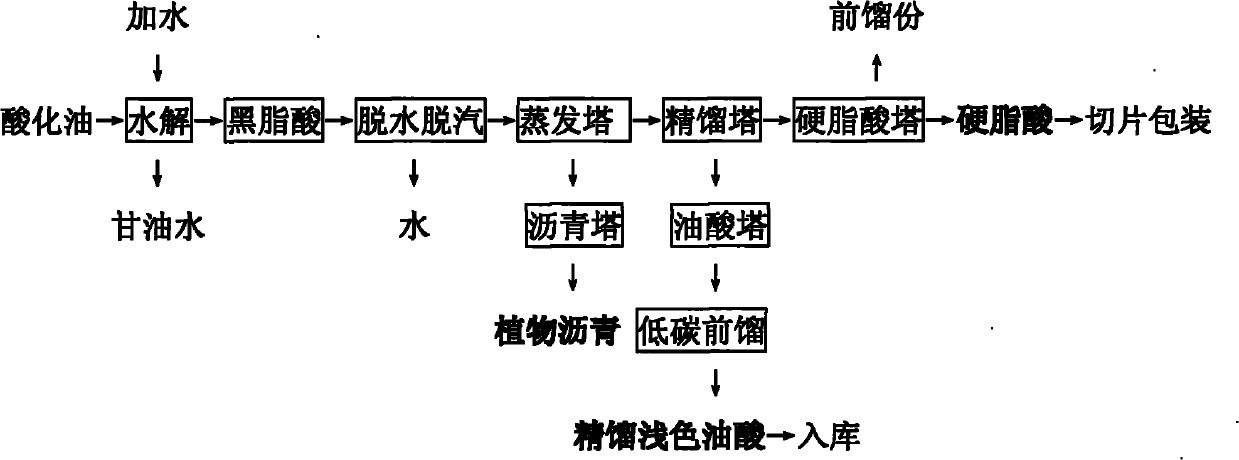

Production process of rectified light-colored oleic acid

InactiveCN101838590ASolve darker problemsHigh yieldOrganic chemistryFatty acids production/refiningMixed fatty acidDistillation

The invention relates to a production process of rectified light-colored oleic acid, which comprises acidification, washing hydrolysis and distillation, wherein the distillation is multi-tower continuous vacuum rectification and comprises a rectification tower and an oleic acid tower; the rectification tower is used for performing rectification separation on a fatty acid mixture, the upper part of the rectification tower is provided with C16:0 palmitic acid, and the lower part of the rectification tower is provided with a C18 oleic acid mixture; and the oleic acid tower is used for re-distillation on the C18 mixture in the lower part of the rectification tower, the upper part of the oleic acid tower is provided with an outlet for producing low-carbon front-end volatiles, the middle part of the oleic acid tower produces the rectified light-colored oleic acid, and the lower part of the oleic acid tower produce nigrotic acid which is returned for re-production. So, the production process solves the problems that an oleic acid product has a light color and a low yield; and the production process has the characteristics of high product yield, low color and luster and low energy consumption.

Owner:九江力山环保科技有限公司

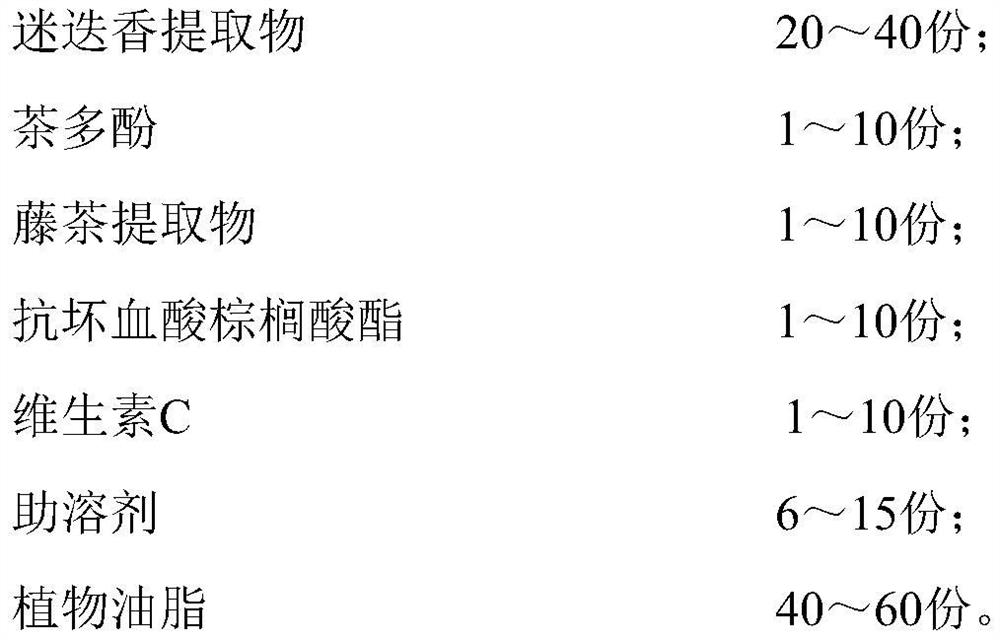

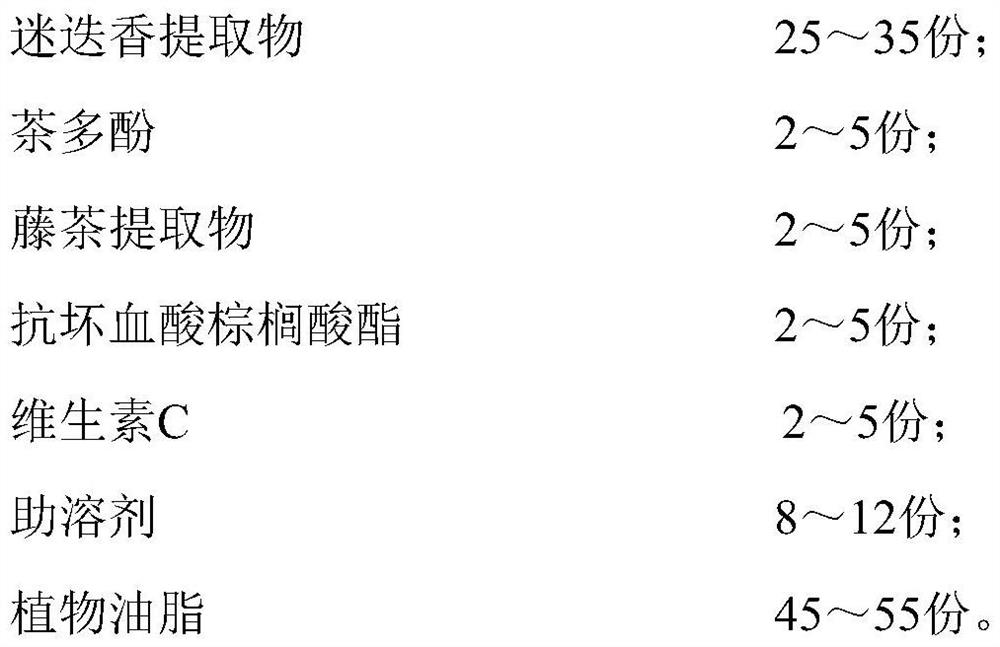

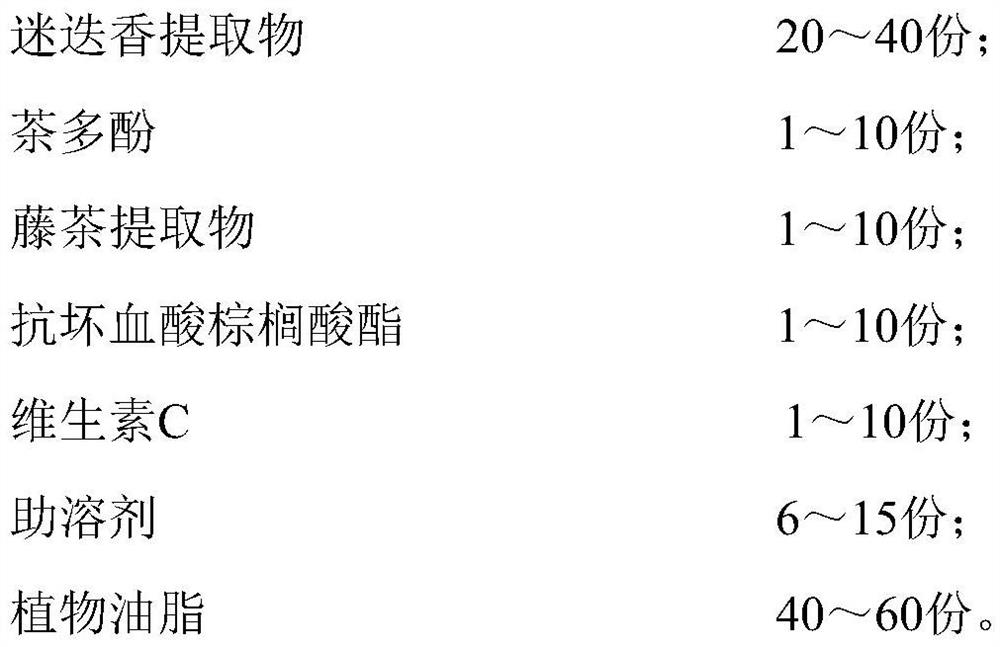

Compound antioxidant for improving stability of frying oil and fried food and preparation method thereof

PendingCN112841257AStable frying systemProlong the effective timeFood ingredient as antioxidantEdible seed preservationCarbonyl groupAnti oxidative

The invention discloses a compound antioxidant for improving the stability of frying oil and fried food and a preparation method thereof. Through the synergistic effect of all substances of a main antioxidant and the synergistic effect of an auxiliary antioxidant, the increase of acid value, polar components and carbonyl value caused by thermal oxidation reaction in the frying oil can be inhibited, and the growth of the polar component caused by the polymerization reaction is also inhibited; and the peroxide value and the malondialdehyde content increase rate during the storage process of the fried food are reduced, the generation of the peculiar smell such as rancidity is inhibited, the oxidation stability of the frying oil can be effectively improved, and the antioxidant effect can be continuously performed in the fried food along with the carrying of the oil so as to prolong the shelf life of the fried food.

Owner:湖南先伟阳光生物科技有限公司

Hot pot seasoning containing antibacterial peptide and preparation method thereof

ActiveCN107625108AImprove antioxidant capacityImprove oxidation capacityFood scienceFlavorFood safety

The invention discloses a hot pot seasoning containing an antibacterial peptide; no preservatives are added, spicy fragrance is strong, spicy flavor is soft, no raw spicy flavor exists, especially with scientific compounding of a composite antibacterial peptide, conventional food preservatives are completely replaced, the composite antibacterial peptide not only contains bacteria antibacterial peptides and capsicum antimicrobial peptides, but also has a natural chili pepper fragrance and soft spicy flavor, and is quite suitable for addition of the hot pot seasoning; with scientific compoundingof a seasoning sauce, the taste and flavor of the hot pot are enhanced; the functional properties such as the antioxidant, antibacterial and pharmacological properties of the hot pot seasoning are enhanced, and comprehensive flavor substances of food materials in a roast-smoking state are collected, so the hot pot seasoning has a strong and attractive characteristic roast-smoked flavor, and a leading card of organic integration of the roast-smoked flavor and the hot pot seasoning are created; a hot pot soup prepared by the hot pot seasoning has the advantages of delicious taste, outstanding beef flavor, strong roast-smoked flavor, low cholesterol content and strong food safety, and a new shortcut is explored for preparation of the hot pot seasoning with functional characteristic flavor.

Owner:宁夏红山河食品股份有限公司

Hotpot condiment capable of effectively preventing grease oxidation and preparation method thereof

ActiveCN107495275AIncrease acid valueLow acid valueFood ingredient as antioxidantLactobacillusFlavorPeroxide value

The invention discloses a hotpot condiment capable of effectively preventing grease oxidation. The hotpot condiment capable of effectively preventing grease oxidation is not added with any spice essence, antioxidant and preservative, and is heavy in barbecue flavor, obvious in beef flavor, strong in oxidation resistance, and low in peroxide value and acid value, and the quality guarantee period is as along as 15-18 months. Especially, due to the scientific compounding of the bechamel, not only can the taste and flavor of hotpot be improved, and can the oxidation resistance, bacterial inhibition and pharmaclogical property of the hotpot condiment be enhanced, but also comprehensive flavor substances of food materials in a barbecue state are collected, so that the hotpot condiment has heavy and attractive distinctive barbecue flavor, and organic fusion of barbecue flavor and the hotpot condiment is initiated; meanwhile, by virtue of scientific compounding of a base sauce and compound enzyme, while special flavor of beef is obtained, the cholesterol content of the hotpot condiment is reduced, and a new functional substance cholest-4olefine-3ketone is generated, so that the possibility that cholesterol generates carcinogens at a high temperature is completely eradicated, and therefore, a new shortcut for preparing a hotpot condiment with functional distinctive flavor is explored.

Owner:宁夏红山河食品股份有限公司

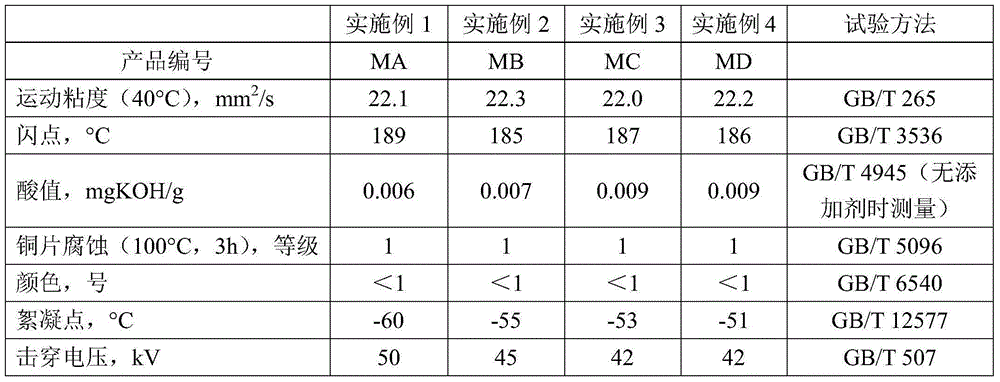

Refrigerator oil and refrigeration compressor and system

InactiveCN105001940ALow viscosityHigh flash pointBase-materialsRefrigeration compressorRefrigerator car

The invention discloses refrigerator oil, a refrigeration compressor and a refrigeration compressor system. Refrigerants adopted by the refrigeration compressor are selected from components of the HCs group. The refrigerator oil comprises alkyl benzene, wherein the distillation range of the alkyl benzene comprises an initial distillation point ranging from 250 DEG C to 310 DEG C and a final distillation point ranging from 470 DEG C to 540 DEG C. The refrigerator oil has the good advantages that the viscosity is low, the flash point is high, the intersolubility with the refrigerants is good, the acid value is low, and the chroma is excellent, so that when the refrigerator oil is used for the refrigeration compressor and the system thereof, good heat stability and chemical stability are achieved, and the energy consumption is low.

Owner:SHANGHAI MINGSHUO CHEM TECH CO LTD

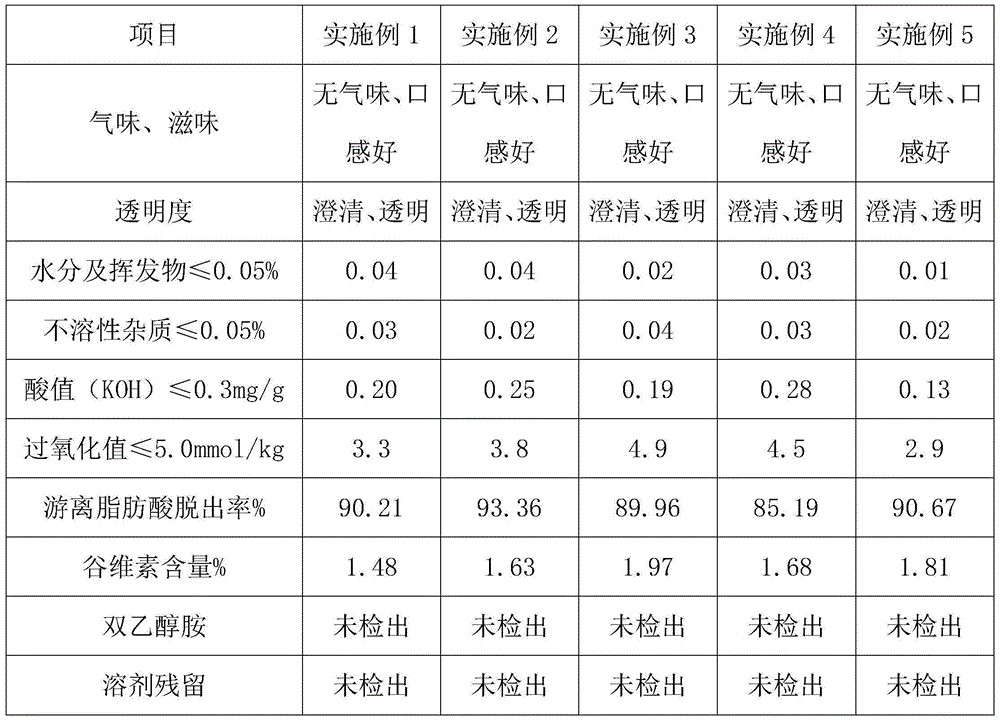

Deep-processing method of camellia oil

InactiveCN107653056AGuaranteed Natural NutrientsImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionBiotechnologyFood additive

The invention provides a deep-processing method of camellia oil. The deep-processing method includes following steps: (1), cleaning; (2), drying; (3), stabbing embryos of camellia seeds; (4), steam-frying; (5), pressing; (6), refining crude oil: preliminary filtering, vacuum decoloring, secondary filtering and low-temperature refined filtering. Embryo stabbing is performed before steaming-frying of camellia seeds, and embryo stabbing and steam-frying are combined, so that oil yield during pressing is increased, and the oil yield of the camellia seeds reaches 33-45%, an increase of at least 3%when compared with that of the prior art; by controlling pressing temperature, increase of acid value and peroxidation value caused by high-temperature pressing is avoided, and benzopyrene is ensurednot to exceed standards. Multiple times of filtering are combined with a vacuum decoloring box for refining of crude oil, dephosphorizing, degumming and refining processes in the prior art are not needed, and no food additive is added, so that natural nutritional ingredients of the camellia oil are ensured. The whole process is environment-friendly, and indexes of obtained finished product oil areall higher than national standards on class-A pressed oil.

Owner:竹山县荣华油茶专业合作社

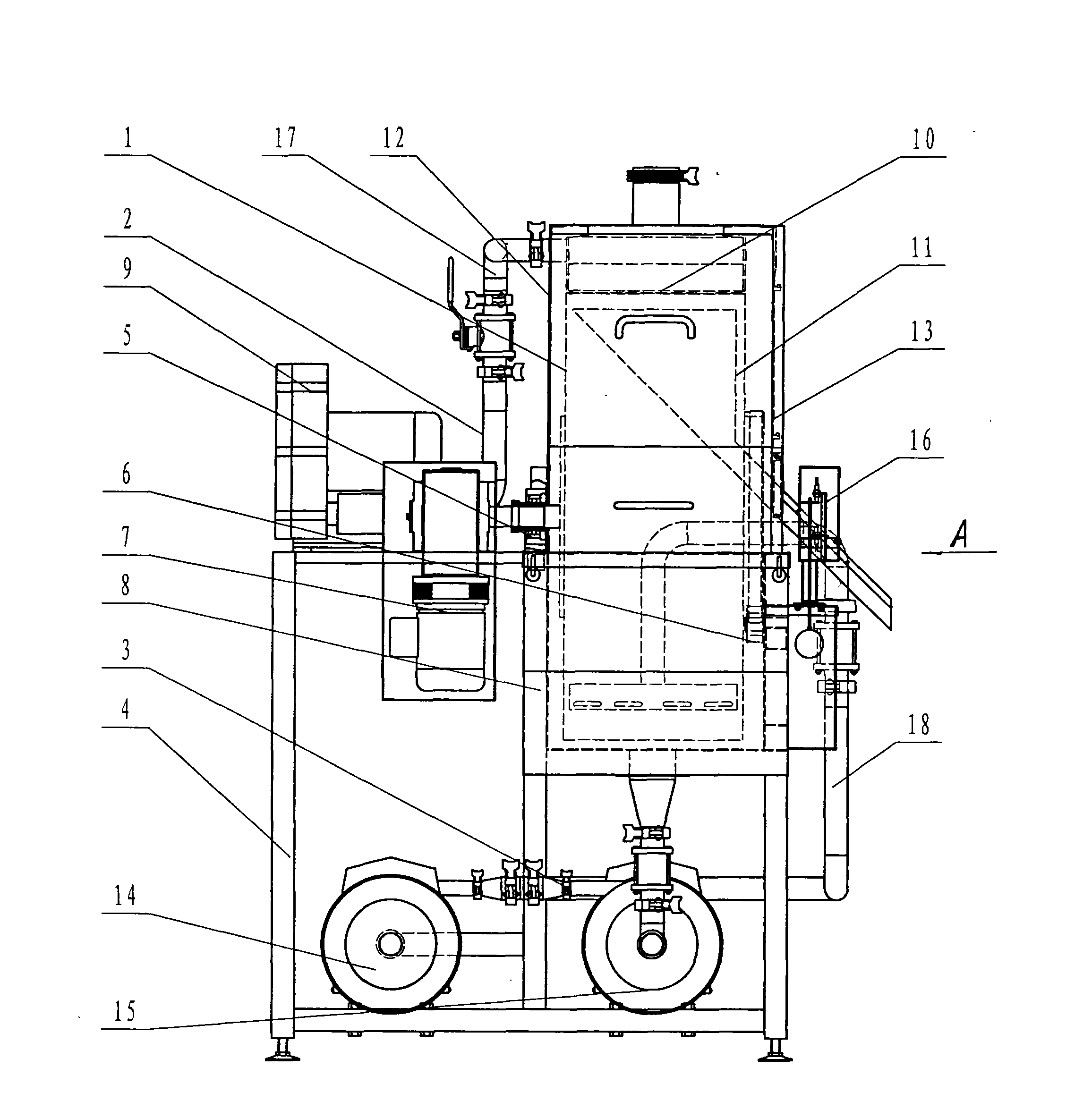

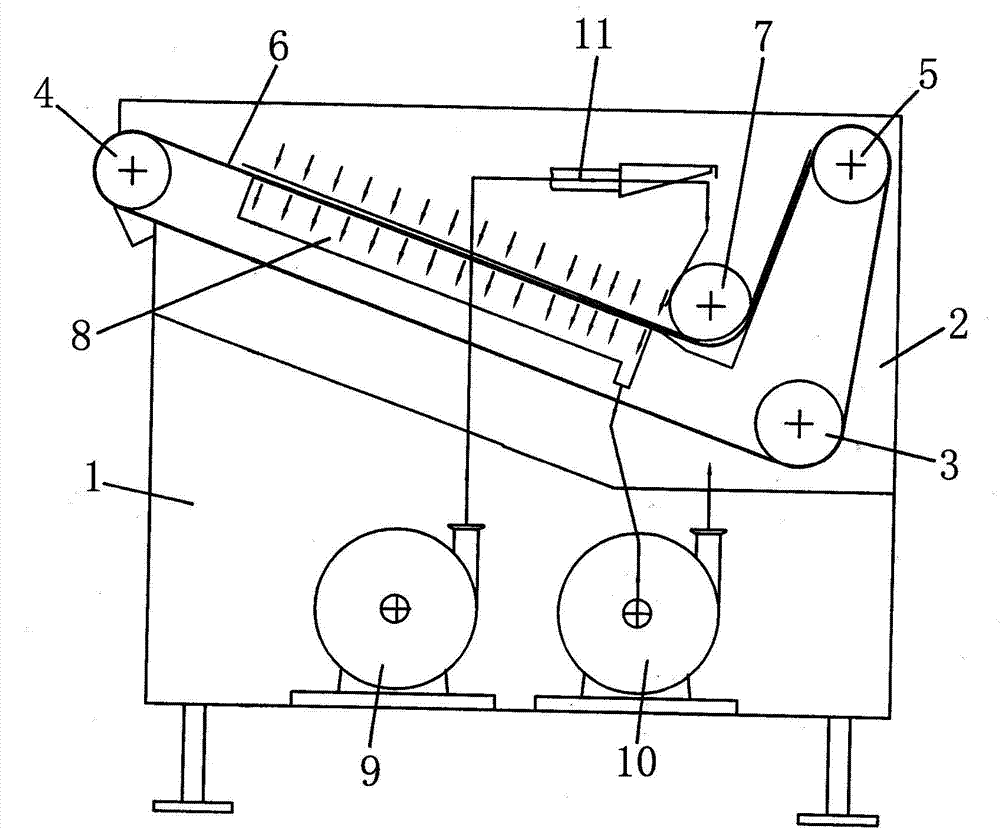

Rotary oil filtering equipment

InactiveCN101632883AImprove the frying environmentIncrease profitEdible oils/fatsFood preparationSlagAquatic product

The invention discloses a rotary oil filtering equipment, which is mainly used for filtering oil for frying food such as meat, aquatic products, vegetables and fruits in food processing factories. The equipment comprises a filter drum, a slag removing device, a circulating system and a machine body, wherein the filter drum is arranged on the filter drum; the slag removing device is arranged on the machine body and on one side of the filter drum; an air knife on the slag removing device is arranged on the filter drum; the circulating system is arranged on the end of the filter drum; and a suction circulating pump is connected with the filter drum through an oil inlet pipe. The equipment of the invention can completely discharge the oil slag filtered out to radically separate the oil slag and food frying oil and has the advantages of continuous operation, low operation cost, simple operation, convenient cleaning, low fault rate, safe and reliable use and the lie.

Owner:JILIN SSK MASCH&ELECTRON CO LTD

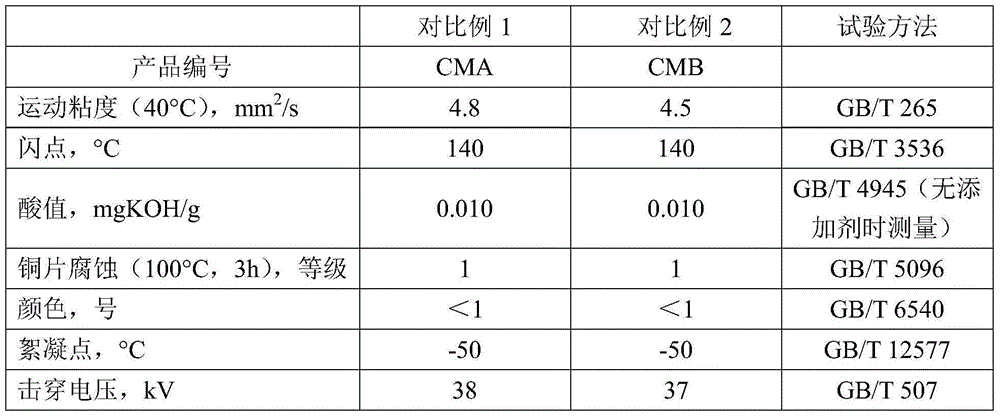

Method for measuring insulation oleic acid value of plant

InactiveCN106226459AIncrease acid valueThe acid value method is simpleChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorAcid valueOleic Acid Triglyceride

The invention discloses a method for measuring the insulation oleic acid value of a plant. The mass range of an oil sample to be tested is reduced to be 8-12 g; the titration end point is strictly controlled by observing the color of the oil sample and using a pH meter in the test process. The method is directly used for testing the insulation oleic acid value of the plant and the accuracy is 0.01 mgKOH / g; the method has simple steps and does not need the step of dividing different sampling masses according to the acid value range.

Owner:CHINA ELECTRIC POWER RES INST +3

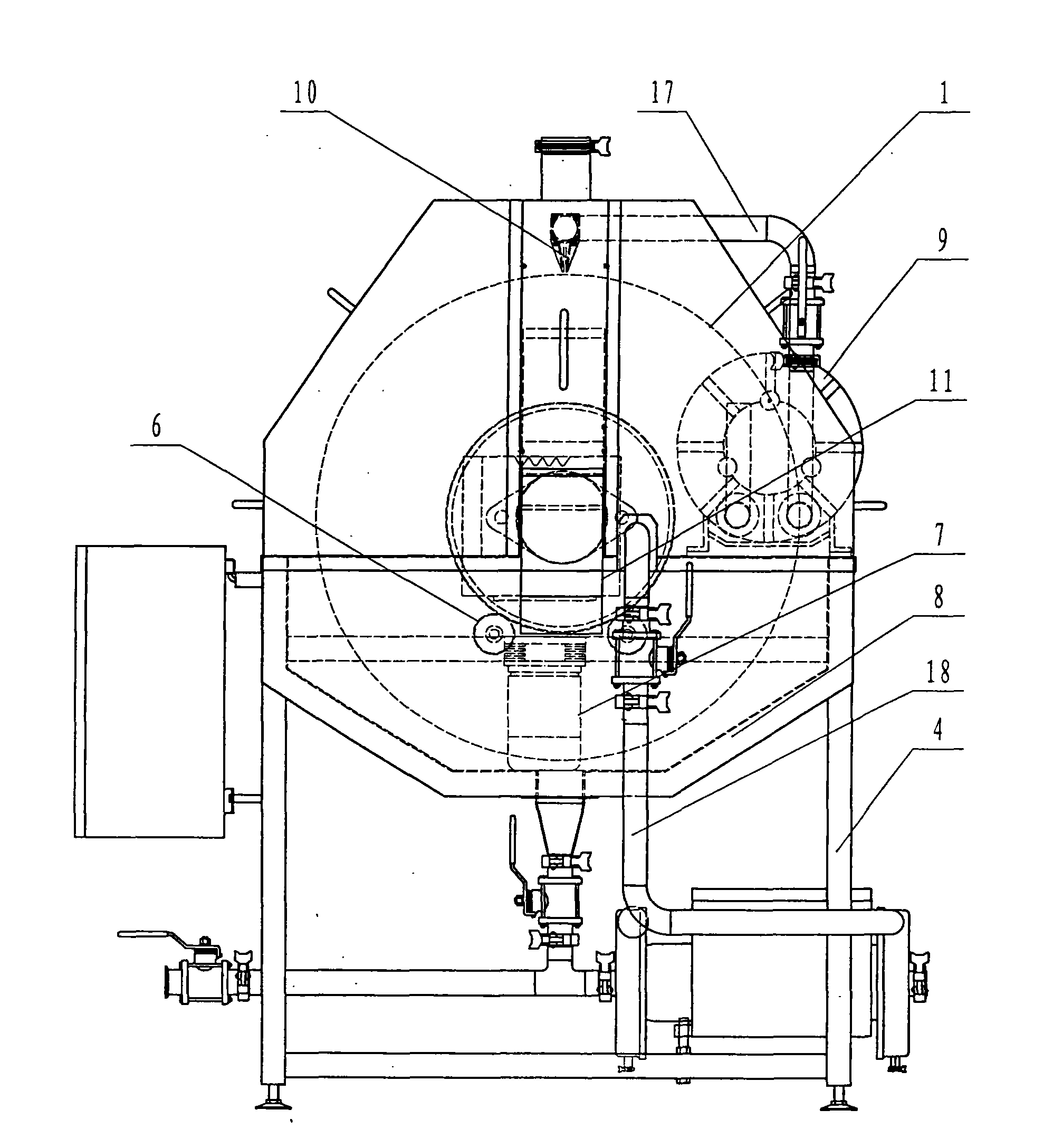

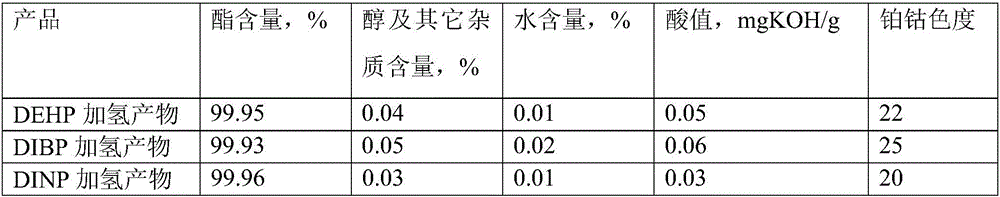

Refining method of cyclohexane dicarboxylates plasticizer

ActiveCN106748774AHigh purityIncrease acid valueOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholPlasticizer

The invention discloses a refining method of a cyclohexane dicarboxylates plasticizer. The refining method comprises the following steps: (1) introducing a phthalates plasticizer hydrogenated mixed product into a dealcoholization tower to remove little alcohols and other light-component impurities; (2) introducing a dealcoholized product into a dehydrating tower to remove little water; and (3) enabling a dehydrated material to enter a refining reactor to perform deacidification and discoloration, wherein the refining reactor is divided into two bed layers, an upper bed layer is filled with modified carclazyte, the lower bed layer is filled with active carbon, and operation conditions of the refining reactor are as follows: the reaction temperature is 70 to 120 DEG C, the normal pressure is adopted, the volume air velocity is 0.5 to 2.0 h<-1>, the purity of the refined cyclohexane dicarboxylates plasticizer is greater than 99.9 percent, the acid value is less than 0.07 mg KOH / g, the water content is less than 0.02 percent, and the chromaticity of platinum-cobalt is less than 30. The method is used for purifying phthalates hydrogenated products and has the characteristics of high product purity, short process flow and no emission of alkaline washing waste water.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091BHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

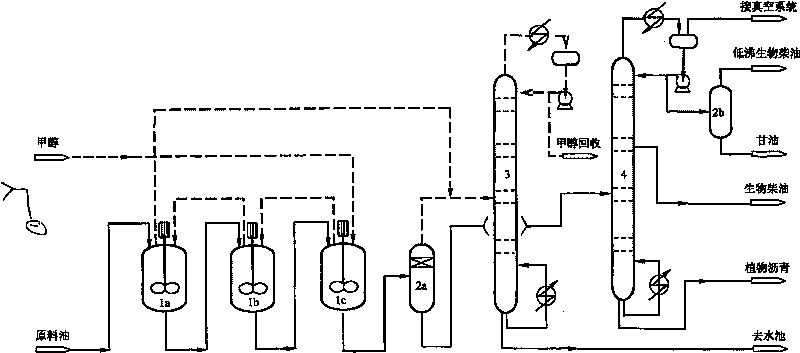

Preparation method for high-quality rice bran oil

InactiveCN105087136AImprove antioxidant capacityHigh oil extraction rateFatty-oils/fats refiningFatty-oils/fats productionWater bathsRoom temperature

The invention discloses a preparation method for high-quality rice bran oil. The method comprises the following steps: S1, rice bran preservation: a step of placing rice bran in an extrusion-expansion machine, carrying out heating to 100 to 120 DEG C, wherein a diameter of an extrusion film hole is 14 to 16 mm, then carrying out extrusion and expansion with a speed of 110 to 130 r / min, carrying out cooling to room temperature, spraying 0.03 to 0.05 wt% of vitamin E with rice bran weight as datum, and carrying out uniform mixing so as to obtain preserved rice bran; S2, crude rice bran oil extraction: a step of adding the preserved rice bran obtained in the S1 into a solvent, carrying out water bath heating to 50 to 60 DEG C, carrying out ultrasonic treatment under an ultrasonic power of 600 to 700 W for 30 to 50 min, then carrying out filtering and rotary evaporation so as to obtain crude rice bran oil; and S3, refining: a step of subjecting the crude rice bran oil obtained in the S2 to degumming, deacidifying, dewaxing, decolorizing and deodorizing so as to obtain the high-quality rice bran oil. The preparation method for the high-quality rice bran oil provided by the invention has the advantages of high oil quality, high oil extraction rate, high free fatty acid removal efficiency and simple operation.

Owner:BENGBU QIONGHUAI GRAIN & OIL

Camellia oil for pregnant women skin care and preparation method thereof

InactiveCN108685806AImprove water storage capacityRestore elasticityCosmetic preparationsToilet preparationsWrinkle skinPolygonum cuspidatum root extract

The invention discloses camellia oil for pregnant women skin care, wherein the camellia oil comprises camellia seed oil, glyceryl caprylate / caprate, tocopherol acetate, limnanthes alba seed oil, jojoba seed oil, hoplostethus atlanticus oil, squalane, butyrospermum parkii kotschy fruit oil, a chamomilla recutita leaf extract, a glycyrrhiza glabra root extract, a herba centellae extract, tocopherol,a scutellaria root extract, a tea leaf extract and a polygonum cuspidatum root extract. The camellia oil has the beneficial effects that edible raw materials are adopted, natural wild organic safflower camellia seed oil is extracted, and the camellia oil nourishes skin, improves the smoothness of pregnant skin, is affinity and easy to absorb, strengthens the water storage capacity of the skin, solves the problems of dry itching and redness of the pregnant skin, restores skin elasticity, effectively improves the relaxation of the pregnant skin and prevents the production of fine wrinkles.

Owner:她芙医美(厦门)科技有限公司

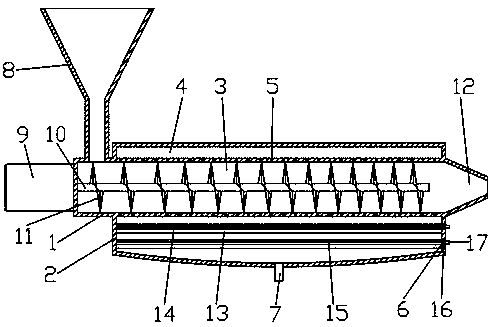

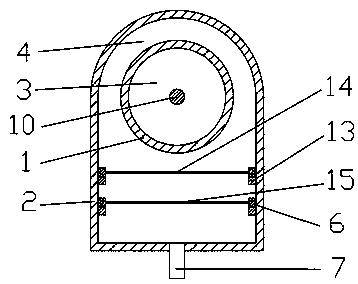

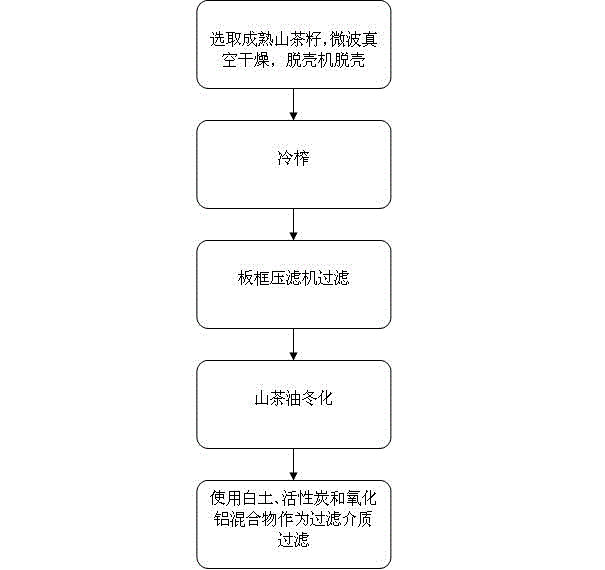

Cold pressing and physical refining process of camellia oil

ActiveCN102504938BPromote dissolutionIncrease delayFatty-oils/fats refiningFatty-oils/fats productionOil and greaseDistillation

The invention relates to a cold pressing and physical refining process of camellia oil. The cold pressing and physical refining process of the camellia oil is characterized by comprising the following steps of: (1) selecting ripe camellia seeds and drying the ripe camellia seeds by microwave vacuum until the water content is 3-6%; and conveying the dried camellia seeds into a huller to be hulled;(2) carrying out cold pressing on the hulled camellia seeds to squeeze the camellia oil, wherein the temperature of a barrel is in a range of 100-150 DEG C and an oil output temperature is in a rangeof 80-120 DEG C; (3) removing solid impurities in the squeezed camellia oil through a plate and frame filter press; (4) winterizing the camellia oil filtered by the plate and frame filter press at a temperature in a range from below 5 DEG C to 5 DEG C; (5) carrying out molecular distillation on the winterized camellia oil to remove free fatty acid, oil peroxide products, moisture and other low-boiling-point substances from the camellia oil; and (6) taking a mixture of carclazyte, active carbon and aluminum oxide as a filtering medium to filter; and removing impurities and pigments of the camellia oil treated by the molecular distillation to obtain the finished product. The cold pressing and physical refining process of the camellia oil has the advantages of environmental friendliness, high oil yield, and high retention ratio of micronutrients in finished oil.

Owner:温州瑞雪农业开发有限公司

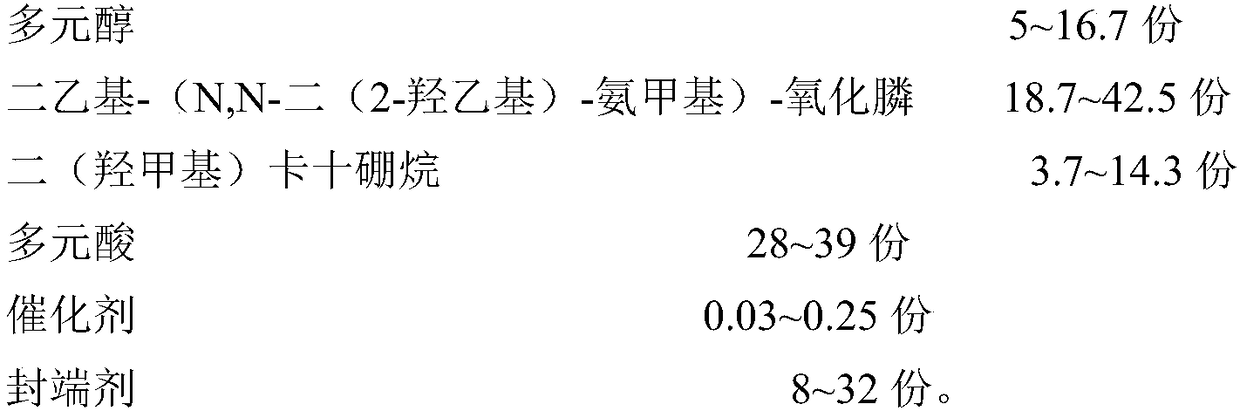

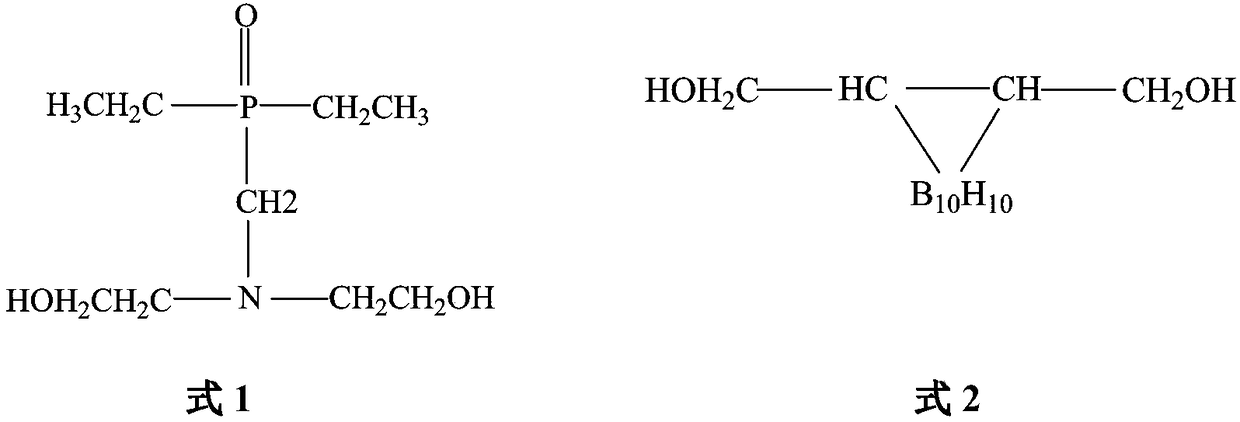

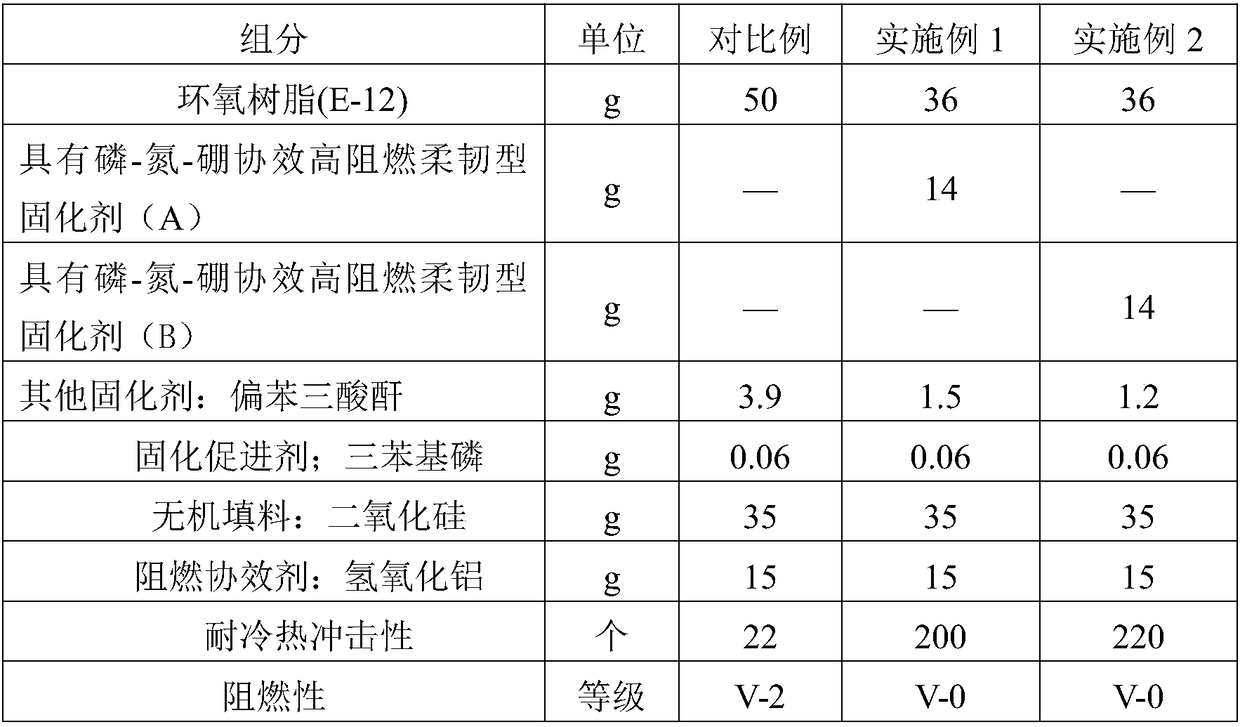

Phosphorus-nitrogen-boron synergistic efficient flame retardant flexible curing agent and synthesis method thereof

The invention relates to a phosphorus-nitrogen-boron synergistic efficient flame retardant flexible curing agent and a synthesis method thereof. The curing agent comprises the following components: 5to 16.7 parts of polyhydric alcohol, 18.7 to 42.5 parts of a phosphorus-nitrogen reactive flame retardant, 3.7 to 14.3 parts of a boron reactive flame retardant, 28 to 39 parts of polyatomic acid, 0.03 to 0.25 part of a catalyst, and 8 to 32 parts of an end-capping reagent; the acid value of the curing agent is 50 to 200 mgKOH / g; the melt viscosity is 800 to 7000 mPa.s / 180 DEG C; the softening point is 60 to 125 DEG C; the P content is 2.7 to 6.4 wt%%; the N content is 1.2 to 2.9 wt%; the B content is 2 to 8 wt%. The existence of phosphorus, nitrogen and boron flame retardant elements and flexible chain ensures that the curing agent has excellent flame retardant efficiency, flame retardant durability and flexibility.

Owner:法拉新材料连云港有限公司

Processing method of sesame oil

InactiveCN107760438ASolves bitter tasteImprove qualityFatty-oils/fats refiningFatty-oils/fats productionOrganic acidMicrowave

The invention discloses a processing method of sesame oil. The processing method comprises the following steps: adding sesame into an aqueous solution of sodium hydroxide for soaking, washing, peeling, drying and carrying out microwave processing to obtain pretreated sesame; adding the pretreated sesame into a hydraulic oil press, and carrying out first-time squeezing to obtain first-time squeezedsesame oil and squeezed sesame-seed cakes; adding the sesame-seed cakes into the hydraulic oil press, and carrying out second-time squeezing to obtain second-time squeezed sesame oil; mixing the first-time squeezed sesame oil with the second-time squeezed sesame oil to obtain crude oil; carrying out air drying on radix glycyrrhizae, fructus momordicae, cortex eucommiae and garlic stems and leaves, crushing, and carrying out microwave processing and CO2 supercritical extraction in sequence to obtain a plant extract; adding the plant extract, resveratrol and organic acid into the crude oil, decoloring, standing and filtering to obtain discolored sesame oil; cooling the discolored sesame oil and then adding diatomite, standing and filtering. The processing method of the sesame oil, providedby the invention, is simple in process and high in oil yield, facilitates industrialization, and retains protein in the sesame-seed cakes; the obtained sesame oil has the advantages of light color, high transparency and good quality.

Owner:BENGBU QIONGHUAI GRAIN & OIL

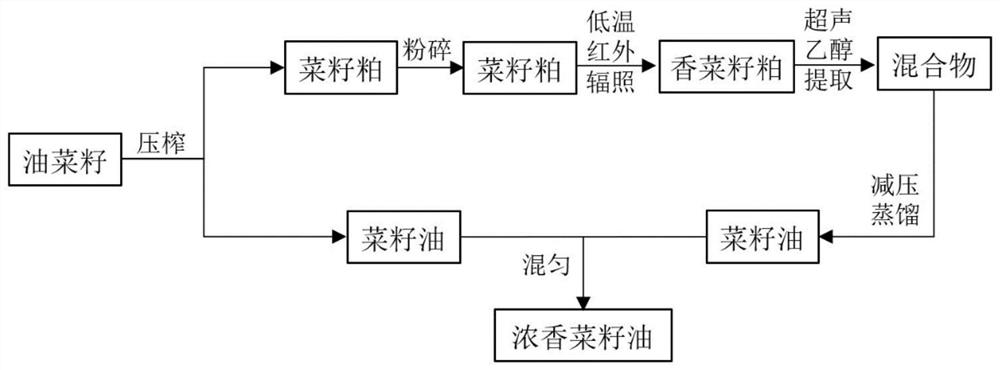

Method for preparing aromatic rapeseed oil by low-temperature infrared irradiation aroma-producing method

InactiveCN112522025AReduce negative impactReduce the temperatureFatty-oils/fats refiningFatty-oils/fats productionOil processingRapeseed

The invention discloses a method for preparing aromatic rapeseed oil by a low-temperature infrared irradiation aroma-producing method, and belongs to the field of grain and oil processing. The methodcomprises the following steps: primarily squeezing rapeseeds, performing irradiation aroma production on rapeseed meal by adopting low-temperature infrared irradiation, extracting residual rapeseed oil and aroma substances in the rapeseed meal by adopting an ultrasonic-assisted solvent, separating the solvent, and mixing the oil with rapeseed oil obtained by primary squeezing, thereby obtaining the strong-aroma rapeseed oil. The method has the advantages of high grease extraction efficiency, simple and safe operation process, greenness, environmental protection, solvent saving, light rapeseedoil color, strong fragrance and no burnt smell, and accords with the flavor characteristics of the traditional fragrant rapeseed oil, wherein the fragrance generation temperature of the fried seeds is40-60 DEG C lower than that of the traditional seed frying process.

Owner:JIANGNAN UNIV

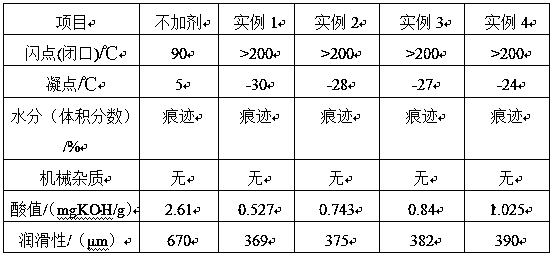

Preparation method of ester diesel anti-wear agent

InactiveCN108277051ALow costImprove wear resistanceLiquid carbonaceous fuelsFuel additivesAlcoholPolyol

The invention relates to a diesel anti-wear agent with low cost and excellent anti-wear effect. The diesel anti-wear agent has the characteristics of low acid value, good low-temperature storage performance, lubricating property and the like. The ester diesel anti-wear agent provided by the invention consists of higher fatty acid, polyol, a catalyst, a water carrying agent and a small-molecular alcohol solvent. The preparation method comprises the following steps: under the protection of nitrogen, adding the higher fatty acid and the polyol into a reaction kettle according to a certain proportion, adding the catalyst and the water carrying agent, carrying out heating to 80-130 DEG C under mechanical stirring, carrying out a reaction for 4-6 hours, then adding the small-molecular alcohol solvent when the temperature is reduced to 30-60 DEG C, then carrying out heating to 90-120 DEG C, carrying out a reaction for 2 hours, carrying out vacuum dehydration on the reaction system for 30-60 minutes after the reaction is finished, and filtering and recycling the catalyst for reuse. The diesel anti-wear agent related to by the invention has a simple and efficient synthetic method, is environmentally friendly, and has strong controllability of process parameters.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

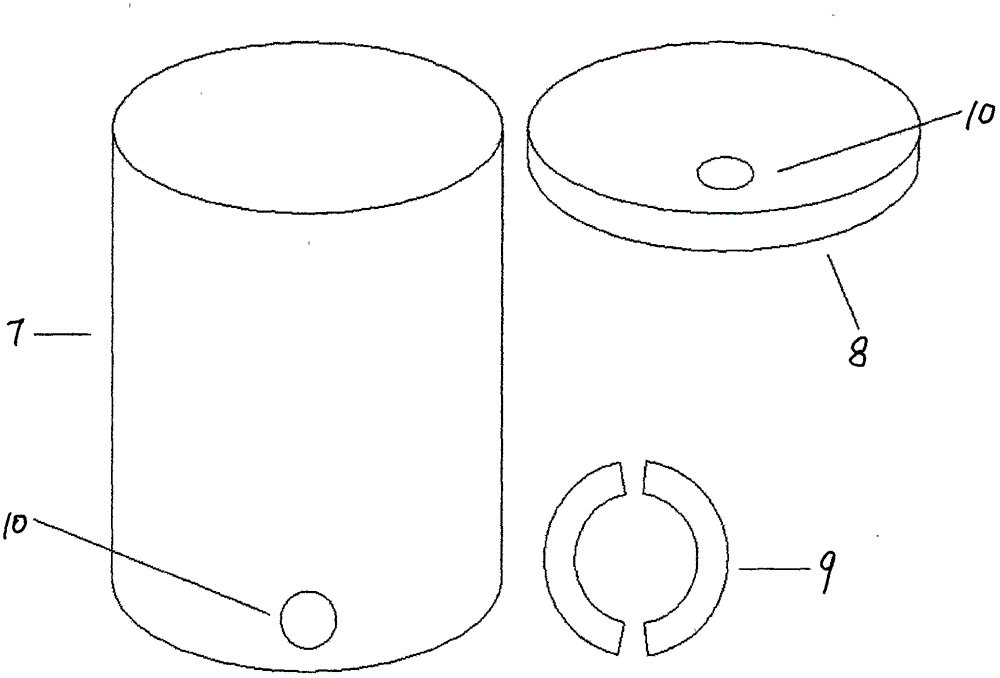

Potting wax for capacitor and preparation method thereof

InactiveCN107936584AImprove uniformityEnhanced cold shrinkage properties and high temperature stabilityThin/thick film capacitorStacked capacitorsParaffin waxSodium carboxymethylcellulose

The invention discloses a potting wax for a capacitor, belonging to the technical field of capacitors. The potting wax is prepared from the following substances: paraffin wax, a composite filling material, coumarone resin, C-5 petroleum resin, terpene resin, olive oil, peanut oil, polyisoprene, sodium octadecyl sulfonate, beeswax, sodium carboxymethylcellulose, sodium alginate, pentaerythritol, calcium stearate and barium stearate. The potting wax eventually prepared in the invention has excellent electrical properties, outstanding resistance to oxidation and low-temperature cracking, and goodmoisture resistance, fluidity and temperature resistance, ensures the stability and service life of the capacitor, and is high in use value.

Owner:陈馨雅

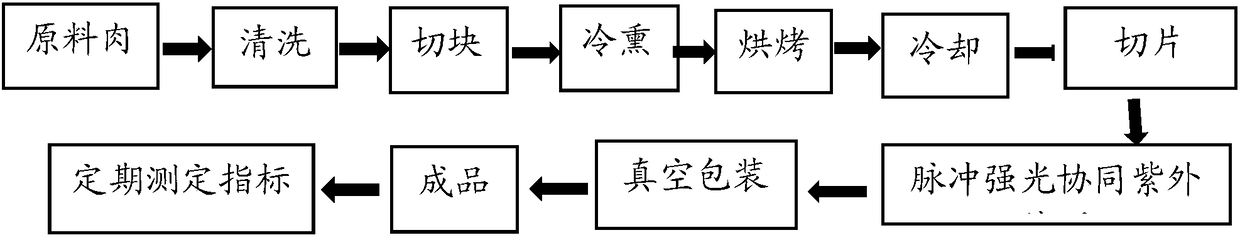

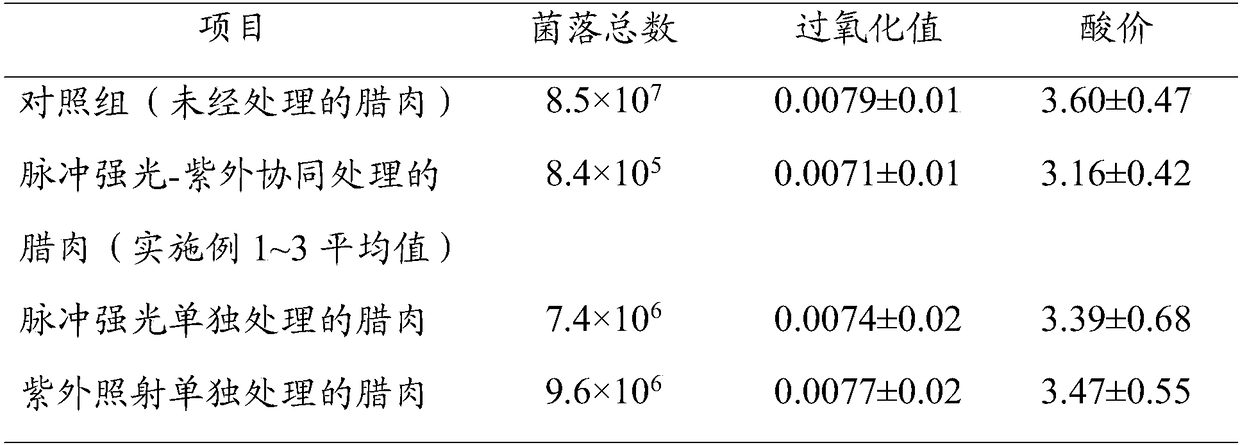

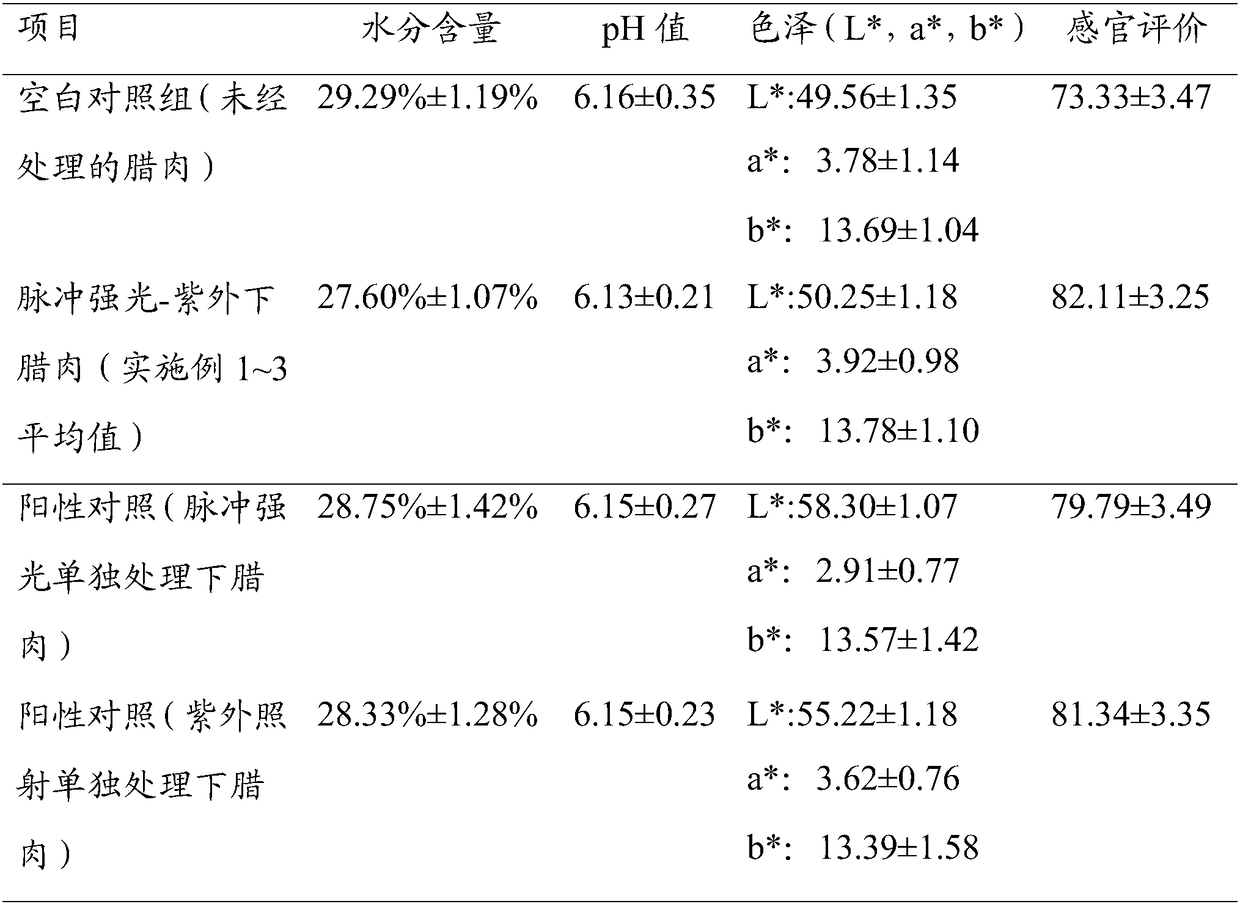

Method for keeping preserved meat sliced products fresh based on synergy of pulse glare and ultraviolet

PendingCN108391716AComposition has little effectImprove qualityMeat/fish preservation by irradiation/electric treatmentUltravioletProduct base

The invention provides a fresh keeping method for preserved meat sliced products based on synergy of pulse glare and ultraviolet irradiation. The fresh keeping method comprises the following steps ofplacing the preserved meat sliced products under pulse glare and ultraviolet rays for irradiation at the same time, and performing vacuum packing on the irradiated preserved meat sliced products, wherein the irradiation time of front sides and rear sides of the preserved meat sliced products is 1-30min, the flash irradiation frequency of pulse is 1-10 times / s, the single-time energy of the pulse is 5-20J, the intensity of the flash irradiation energy of the pulse is 5-20J / cm<2>, the energy of the ultraviolet rays is 15-25w, the wave length of the ultraviolet rays is 240-260nm, and the intensity of the ultraviolet rays is 80-120uw / cm<2>. The sterilizing rate of the fresh keeping method through pulse glare and ultraviolet synergy treatment is increased to 96.6% than that of a fresh keeping method through single use of ultraviolet sterilization, and the sterilizing rate of the fresh keeping method through pulse glare and ultraviolet synergy treatment is increased to 95.7% than that of fresh keeping method through single use of pulse glare treatment, so that the ultraviolet irradiation and the pulse glare are jointly used for sterilization to achieve strengthened effects.

Owner:GUIZHOU UNIV

Method for preparing alkyl naphthalene from mixed olefins and application of alkyl naphthalene

The invention belongs to the technical field of high-quality lubricant base oil, and particularly discloses a method for preparing alkyl naphthalene from mixed olefins and application of the alkyl naphthalene. The preparation method comprises the following specific steps: mixing reaction raw materials, namely mixed alpha-olefins and naphthalene, adding a solid acid catalyst and a solvent, and performing a high-temperature reaction to obtain a product. According to the invention, a plurality of mixed alpha-olefins are used for replacing an olefin with a single carbon number in a traditional process, and the alkyl naphthalene product is prepared through synergism of the catalyst and reaction conditions; and the alkyl naphthalene product is improved in the aspects of viscosity, pour point, flash point, chromaticity, acid value, water content and the like, and overcomes the technical bias that the performance of alkyl naphthalene prepared from mixed olefins in the prior art is difficult to reach the performance index of alkyl naphthalene prepared from an olefin with a single carbon number.

Owner:SICHUAN LUTIANHUA +1

Mesh-belt continuous edible oil filtering machine

InactiveCN103920326AImprove the frying environmentIncrease profitFatty-oils/fats refiningMoving filtering element filtersProduction lineCarbide

The invention discloses a mesh-belt continuous edible oil filtering machine which is characterized in that an upper portion of a rack is provided with a case having an inclined bottom; an annular filter mesh belt is wound around a tension roller, a drive roller and a transitional roller; a guide roller is arranged at one side of the upper surface of the annular filter mesh belt to press the annular filter mesh belt; an oil catch box is disposed below the upside of the annular filter mesh belt; and a suction pump and a draft pump are arranged on the bottom of the rack. Through the above arrangement, the machine provided by the invention is important auxiliary equipment for a fried food production line. According to the invention, other harmful substances such as particle impurities, carbide and the like which are generated during food frying process by the use of high-temperature frying oil are effectively filtered out by a physical method; frying environment of food is improved; rising of acid value and peroxidation value is inhibited; utilization rate of edible oil is raised; enterprise costs are reduced; and enterprise efficiency and product quality are enhanced.

Owner:ZHUCHENG XINXUDONG MACHINERY

Rapeseed gel oil with liver detoxifying function and production method thereof

InactiveCN106172878AImprove nutritional efficacyFull of nutritionEdible oils/fats ingredientsEdible oils/fats production/working-upMicro nanoMANNITOL/SORBITOL

The invention discloses rapeseed gel oil with liver detoxifying function, made with the following components, by weight: 105-110 parts of rapeseed oil, 8-9 parts of high-purity free glycyrrhizic acid, 2-3 parts of proantho cyanidins oligomer, 9-10 parts of micro-nano graded porous diatomaceous powder, 9-10 parts of mannitol, 10-11 parts of rice bran wax, and suitable deionized water. The rapeseed gel oil is prepared through the constructed functional dispersion, rapeseed oil and the gel factor rapeseed bran wax, has good nutrition and certain liver detoxifying effect, and also has good antioxidant property and richer nutrition.

Owner:JINCAIDI FOOD CO LTD

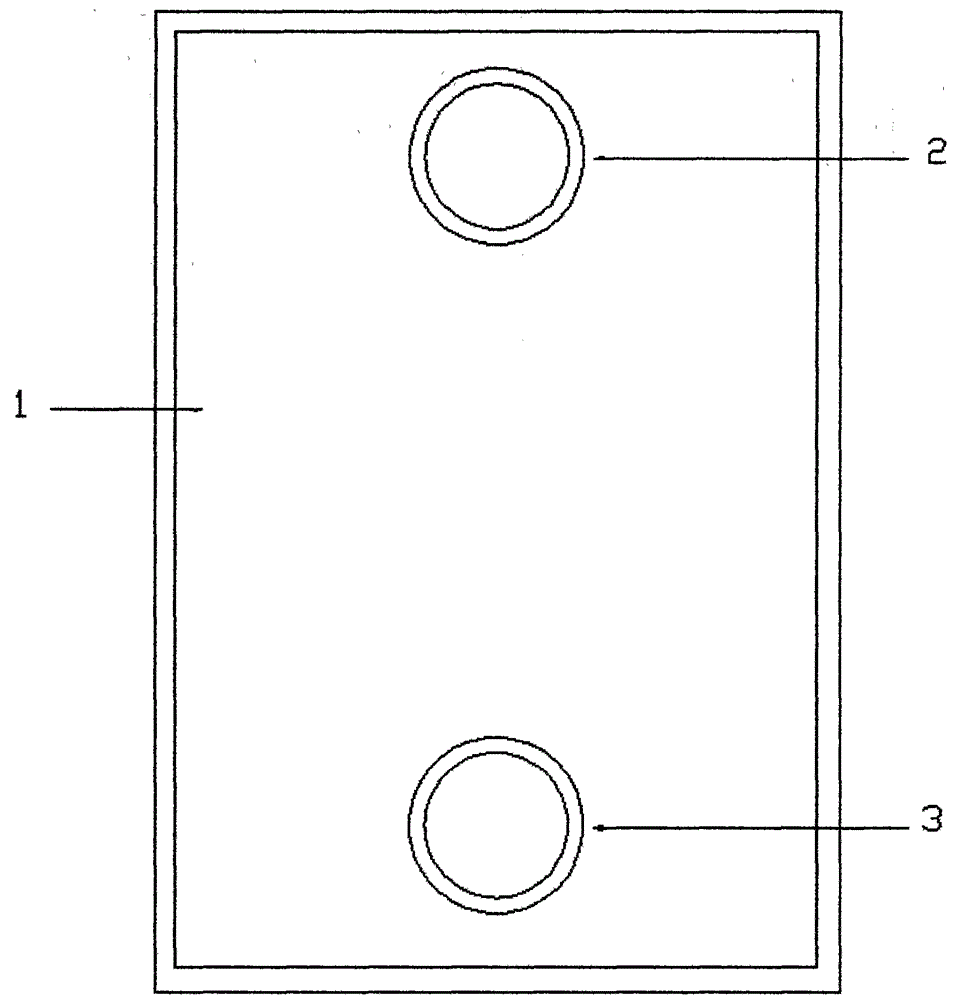

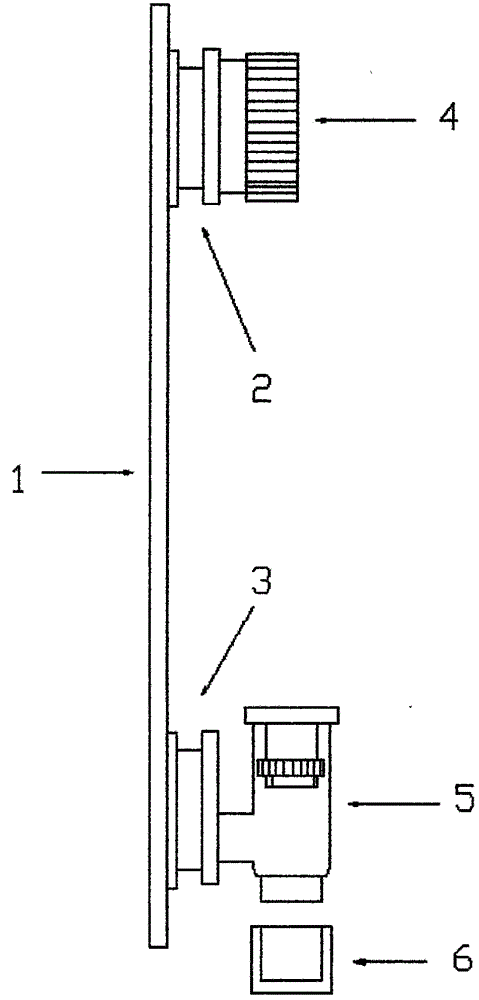

Edible oil vacuum preservation in-barrel bag

InactiveCN105883226AReduce the cost of preservationSolve the problems of accelerating the oxidation and deterioration of edible oilPackaging under vacuum/special atmosphereKitchen equipmentMicroorganismComposite film

The invention discloses an edible oil vacuum preservation in-barrel bag and belongs to the technical field of edible oil preservation. The edible oil vacuum preservation in-barrel bag is composed of a double-opening type composite film bag body, a sealing cover, a piston switch, a light avoiding barrel and double-buckle rings. The double-opening type composite film bag body is provided with an oil inlet and an oil outlet. The oil inlet is provided with the sealing cover. The oil outlet is provided with the piston switch. The position of an outlet of the piston switch is sleeved with a dustproof cover. The double-opening type composite film bag body is installed in the light avoiding barrel. The sealing cover and the piston switch stretch out of the light avoiding barrel and are fixed through the double-buckle rings correspondingly. By means of the edible oil vacuum preservation in-barrel bag, the preservation cost of edible oil after the edible oil is unsealed is reduced to the minimum for families, and the problem that after bottled edible oil bought by the families is unsealed, oxidative deterioration of the edible oil is accelerated due to influences of factors of air, light, moisture, microorganisms and the like is solved.

Owner:纪彤欣

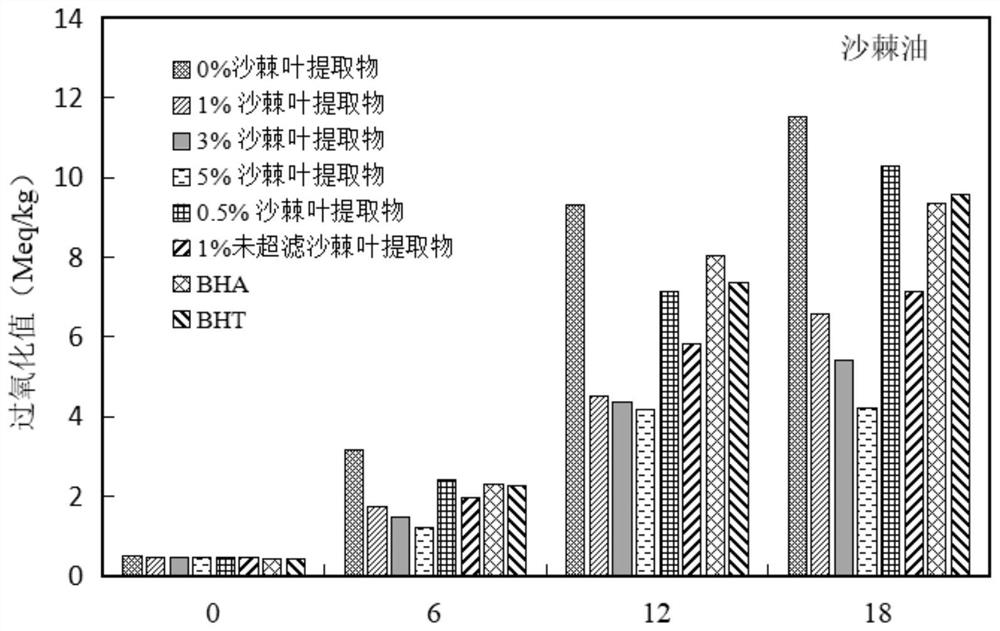

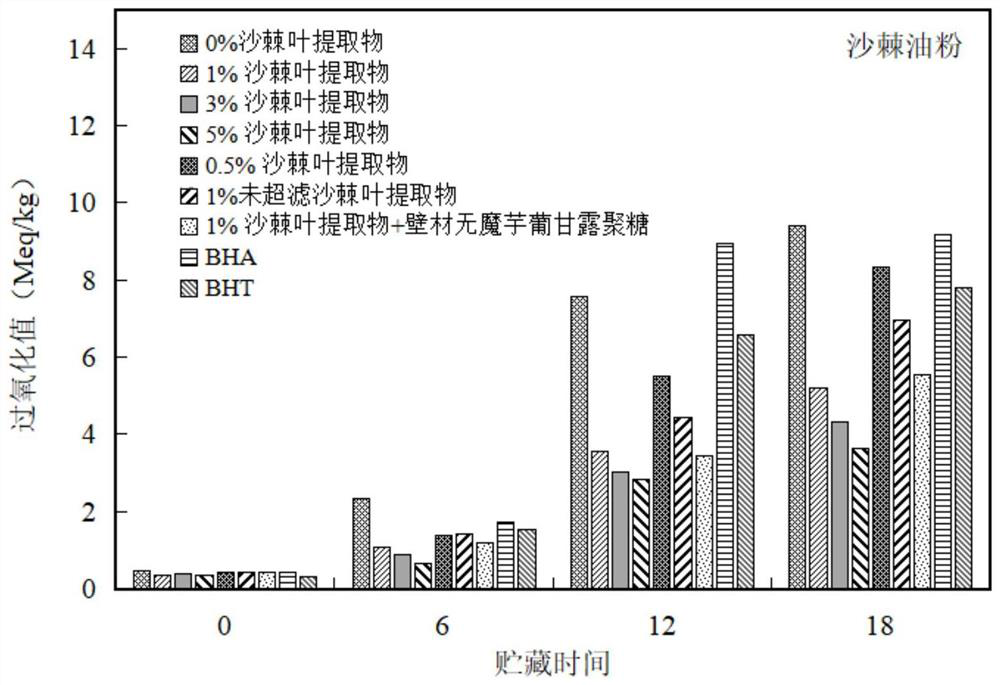

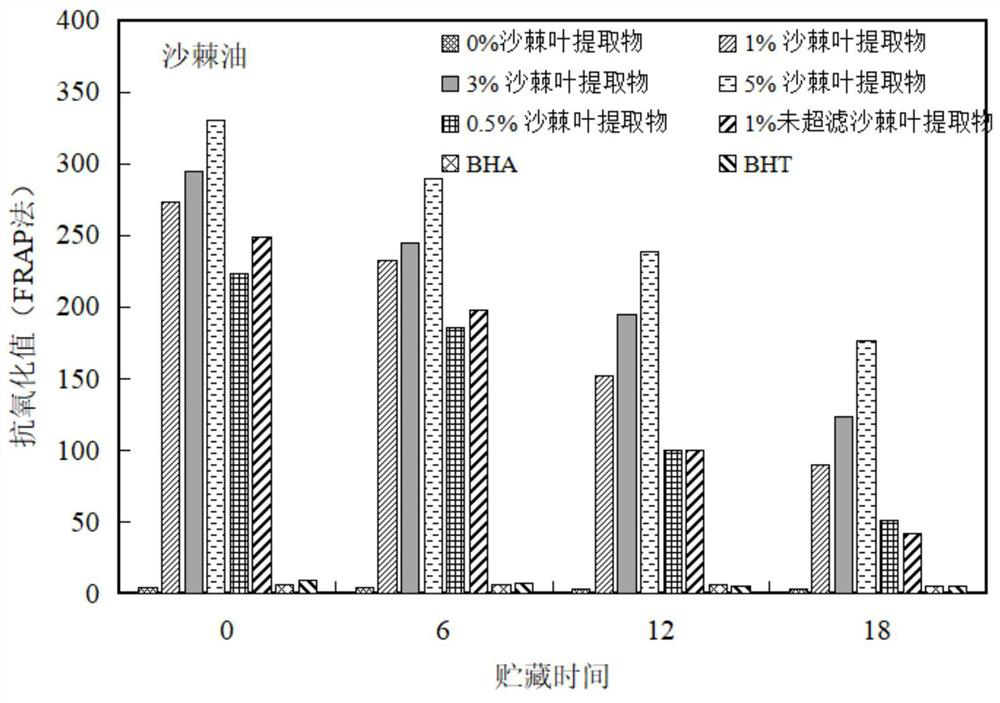

Sea buckthorn oil with high oxidation resistance and high stability, sea buckthorn oil powder and preparation method thereof

PendingCN113142584AHigh in polyphenolsHigh in flavonoidsFatty substance preservation using additivesLipidic food ingredientsUltrafiltrationSpray dried

The invention discloses sea buckthorn oil with high oxidation resistance and high stability, sea buckthorn oil powder and a preparation method thereof, and belongs to the technical field of food processing. The preparation method of the sea buckthorn oil powder comprises the following steps that sea buckthorn leaves are crushed; extracting is carried out; ultrafiltration is carried out; concentrating is carried out; drying is carried out; and the sea buckthorn leaves are added into sea buckthorn oil, are mixed with protein and polysaccharide, are homogenized to obtain sea buckthorn oil, and are subjected to spray drying to obtain the sea buckthorn oil powder. The sea buckthorn oil and sea buckthorn oil powder prepared by the method have high oxidation resistance and high stability, the increase of peroxide value and the like in the oil storage process is remarkably inhibited, the ingredients are simple and natural, and the market acceptability is high.

Owner:NORTHWEST UNIV(CN)

A method for extracting microbial oil

ActiveCN103525537BReduce adverse reactionsPrevent oxidationFatty-oils/fats productionOil and greaseMicrobial oil

The invention relates to a method of extracting microbial oil. The method comprises the following steps of: carrying out inoculated fermentation on oleaginous microbes; processing fermentation broth obtained after fermentation in a separation system to prepare wet thalli with the water content of 30-80wt percent; uniformly mixing the wet thalli and an organic solvent for extraction, and carrying out circulation crushing until the volume average particle diameter of emulsion particles is less than 800 microns; carrying out solid-liquid separation on the thallus mixed solution after the circulation crushing to obtain mixed oil and thallus meal; and carrying out desolvation on the mixed oil to obtain the microbial oil. With the adoption of the method, a high-temperature drying procedure is not needed, so that numerous deterioration reactions of oil under a high temperature can be greatly lowered, and the energy consumption is also lowered; in addition, as crushing and extraction are carried out synchronously, the oil can be prevented from coming into contact with air to the greatest extent, oxidation of the oil under the state of small particle sizes is avoided, and the purpose of extracting the high-quality microbial oil with low acid value, light color and low peroxide value by virtue of the method is reached.

Owner:CABIO BIOTECH WUHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com