Production process of rectified light-colored oleic acid

A production process, oleic acid technology, applied in the production process field of rectified light-colored oleic acid, can solve problems such as poor color and luster, achieve the effects of increasing yield, shortening hydrolysis time, and high product yield

Inactive Publication Date: 2010-09-22

九江力山环保科技有限公司

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the middle of the 1990s, tower distillation was used for production, and the product yield and color have been greatly improved. At present, more than ten domestic manufacturers are producing, and the process adopted is simple tower distillation, that is, the upper part is separated. The low-boiling point stearic acid products, the lower part is high-boiling point oleic acid products, the defect is that the color is poor, generally 4~5# color, still can not meet the needs of some customers with high requirements (such as high-grade paint, high-grade dimer acid)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

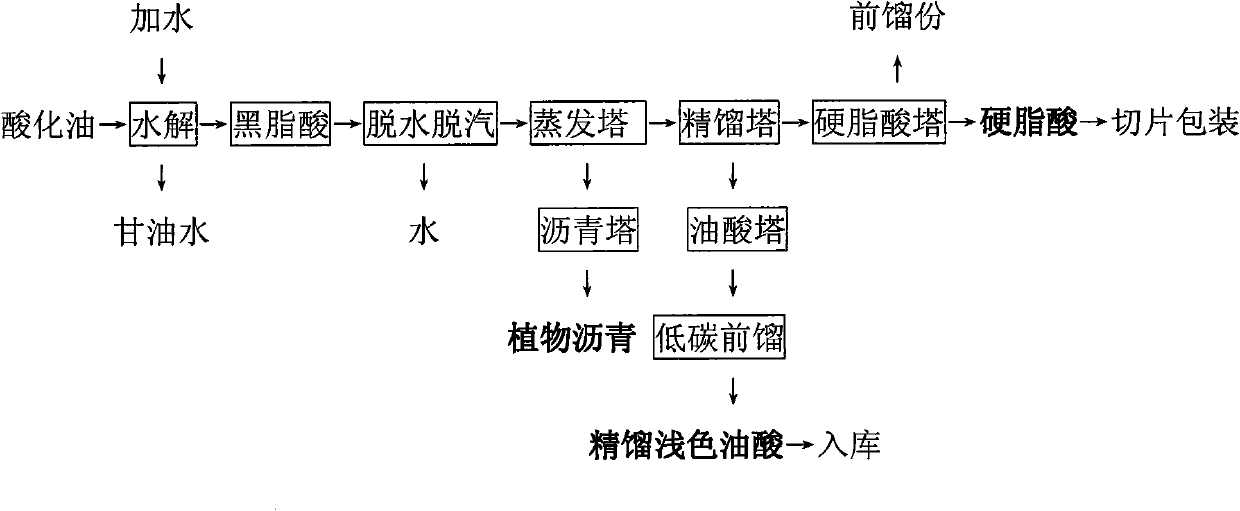

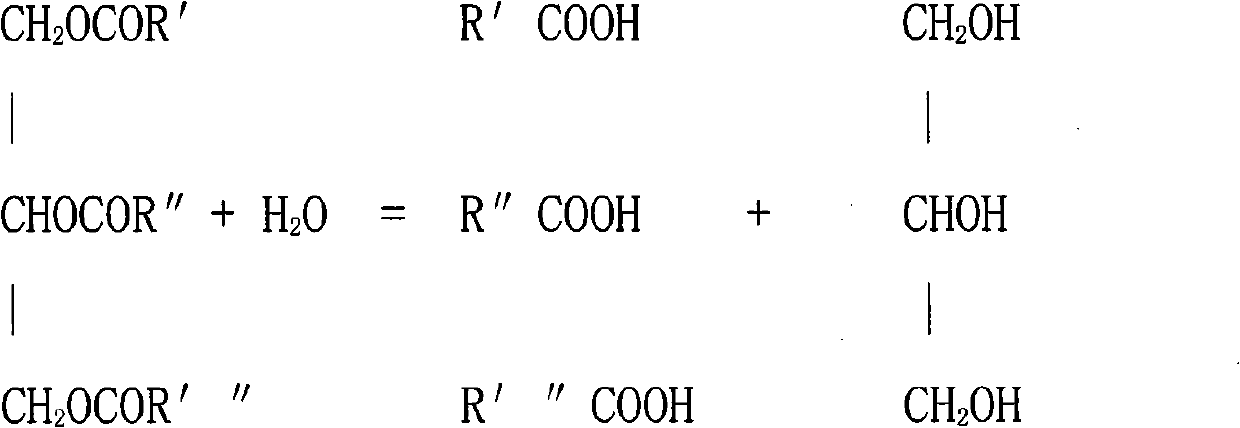

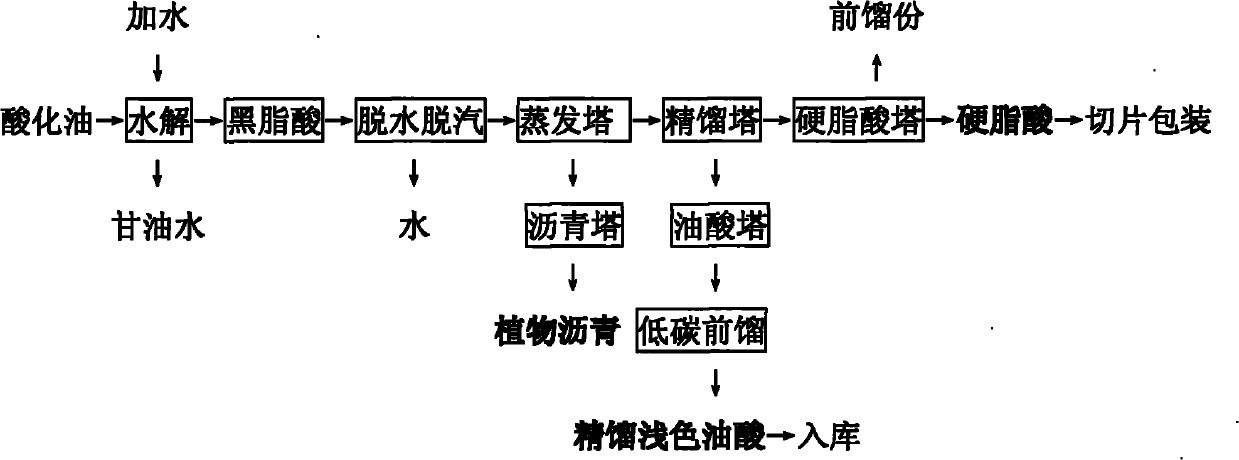

The invention relates to a production process of rectified light-colored oleic acid, which comprises acidification, washing hydrolysis and distillation, wherein the distillation is multi-tower continuous vacuum rectification and comprises a rectification tower and an oleic acid tower; the rectification tower is used for performing rectification separation on a fatty acid mixture, the upper part of the rectification tower is provided with C16:0 palmitic acid, and the lower part of the rectification tower is provided with a C18 oleic acid mixture; and the oleic acid tower is used for re-distillation on the C18 mixture in the lower part of the rectification tower, the upper part of the oleic acid tower is provided with an outlet for producing low-carbon front-end volatiles, the middle part of the oleic acid tower produces the rectified light-colored oleic acid, and the lower part of the oleic acid tower produce nigrotic acid which is returned for re-production. So, the production process solves the problems that an oleic acid product has a light color and a low yield; and the production process has the characteristics of high product yield, low color and luster and low energy consumption.

Description

technical field The invention relates to a production process of oleic acid, in particular to a production process of rectifying light-colored oleic acid. Background technique In the field of oleochemical industry, fatty acid is the most basic, largest output and most widely used chemical raw material. Although my country is a country with a long history of oleochemical industry, it lags behind other developed countries in terms of its technology development. In recent years, with the development of oleochemical production technology, humans can use vegetable oil to produce tens of thousands of products required by the chemical industry, such as: paints, inks, rubber, various additives, lubricants, curing agents, hot melt Glue, food additives, pharmaceutical intermediates, etc. my country has also intensified research and development efforts in oleochemicals, and has developed many new products, new technologies, new materials and new processes. The supply of fatty acid pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11C1/10C07C57/12

Inventor 吴中将

Owner 九江力山环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com