Preparation method of ester diesel anti-wear agent

A technology of antiwear agent and diesel oil, which is applied in the field of ester type antiwear agent, which can solve problems such as decreased matching accuracy, unstable idling speed, and insufficient engine power, and achieves good low-temperature storage performance, good anti-wear effect, and strong demulsibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

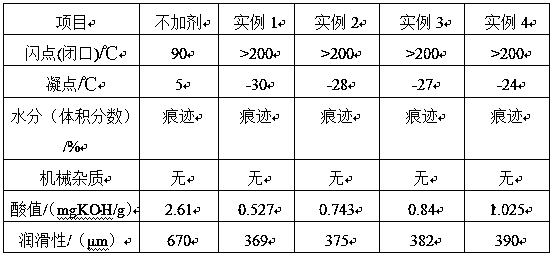

Examples

Embodiment 1

[0015] Preparation of anti-wear agent: Add 56 grams of oleic acid and 49 grams of ethylene glycol into the reaction kettle, then add 1.6 grams of ferric hydroxide catalyst and 1.05 grams of toluene, stir and raise the temperature to 80°C-130°C, under nitrogen protection , the reaction time is 4-6 hours, then lower the temperature to 30°C-60°C and add 1.05 grams of small molecule alcohol solvent, raise the temperature to 90°C-120°C for 2 hours, vacuumize and dehydrate for 30-60 minutes, and discharge the catalyst to filter and Recycle.

Embodiment 2

[0017] Preparation of anti-wear agent: Add 56 grams of oleic acid and 49 grams of ethylene glycol into the reaction kettle, then add 1.05 grams of ferric hydroxide catalyst and 2.2 grams of toluene, stir and raise the temperature to 130 ° C, under the protection of nitrogen, the reaction time 4-6 hours, then lower the temperature to 60°C and add 2.1 grams of small molecule alcohol solvent, raise the temperature to 120°C to react for 2 hours, vacuumize and dehydrate for 30 minutes, and discharge the catalyst to filter and recover.

Embodiment 3

[0019] Preparation of anti-wear agent: Add 46 grams of oleic acid and 41 grams of ethylene glycol into the reaction kettle, then add 1.3 grams of ferric hydroxide catalyst and 0.87 grams of toluene, stir and raise the temperature to 110 ° C, under the protection of nitrogen, the reaction time 4-6 hours, then lower the temperature to 40°C and add 0.87 g of small molecule alcohol solvent, raise the temperature to 90°C to react for 2 hours, vacuumize and dehydrate for 50 minutes, discharge the catalyst, filter and recover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com