Cold pressing and physical refining process of camellia oil

A technology of physical refining and camellia oil, applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of difficulty in ensuring the quality of finished products, inability to remove free fatty acids and fatty acid peroxidation products, and high oil yield , to avoid the increase of acid value and peroxide value, reduce the increase of oil peroxidation products, and reduce the increase of free fatty acid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

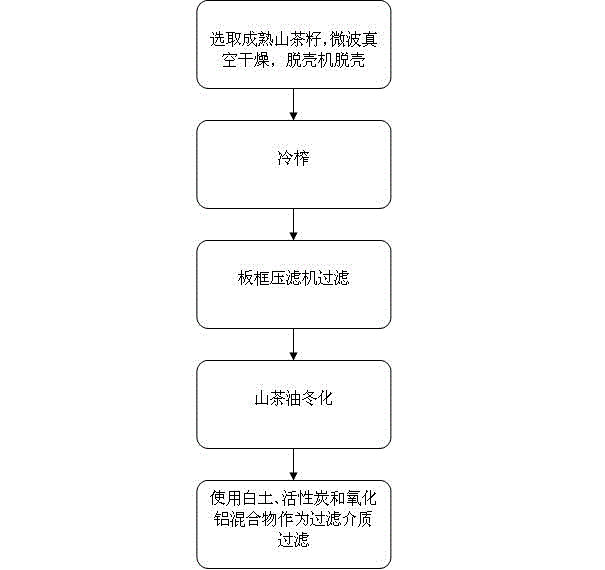

[0030] Embodiment 1: as figure 1 The cold pressing and physical refining process of camellia oil shown includes:

[0031] (1) Select the raw material of mature camellia seed, which is dried in a microwave vacuum at a frequency of 2450MHz to a moisture content of 3%, and the pressure is controlled at 12KPa, so that the drying temperature will be controlled at 50°C to avoid excessive temperature and air Oxygen causes the oil in the camellia seed kernel to oxidize and decompose. Since camellia oleifera shells contain benzo(a)pyrene, the shelling rate of raw materials after drying should be above 99%, so as not to mix too much shells and produce benzo(a)pyrene during the pressing process. The microwave vacuum drying in the present invention is usually between the mass content of 3-6%, for example, it can be 4%, 4.5% or 5%. The microwave vacuum drying pressure in the present invention is usually 7KPa~20KPa, for example, it can be 10 KPa, 12KPa, 14KPa, 16KPa or 18KPa.

[0032] (2...

Embodiment 2

[0041] Camellia oil cold pressing and physical refining process includes:

[0042] (1) Select 100 kg of mature camellia seeds, put them into a microwave vacuum drying oven, and dry them to a moisture content of 5% under microwaves with a frequency of 2450 MHz and a pressure of 20 KPa. Send the dried shelled camellia seeds to the sheller for shelling, the shelling rate is 99%;

[0043] (2) Send the husked camellia seeds to a cold press for pressing, control the temperature of the press chamber at 130°C, and control the oil outlet temperature below 100°C;

[0044] (3) the camellia oil squeezed out is filtered through plate and frame to remove solid impurities;

[0045] (4) The camellia oil obtained by filtering the plate frame was winterized at 3° C. for 24 hours to remove high melting point waxes, esters, etc.;

[0046] (5) Put the winterized camellia oil into the feed cup of molecular distillation, degas it under the vacuum of 200pa for 15min, and then degas it under the pre...

Embodiment 3

[0049] Camellia oil cold pressing and physical refining process can also be used to produce Torreya oil, the steps are as follows:

[0050] (1) Select 500 kg of ripe torreya seeds without arils, put them into a microwave vacuum drying oven, and dry them to a moisture content of 3% with microwaves at a frequency of 2450 MHz and a vacuum of 10 KPa. The dried raw materials are sent to the shelling machine for shelling, and the shelling rate is 99%;

[0051] (2) Send the shelled Chinese torreya seed kernel to the cold press for pressing, the temperature of the pressing chamber is controlled at 120°C, and the oil outlet temperature is controlled below 80°C;

[0052] (3) the torreya torreya oil that squeezes out, removes solid impurity by plate and frame press filtration;

[0053] (4) The torreya oil obtained by filtering the plate frame was winterized at 1° C. for 18 hours to remove high melting point waxes, esters, etc.;

[0054] (5) Put the winterized torreya oil into the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com