Method for keeping preserved meat sliced products fresh based on synergy of pulse glare and ultraviolet

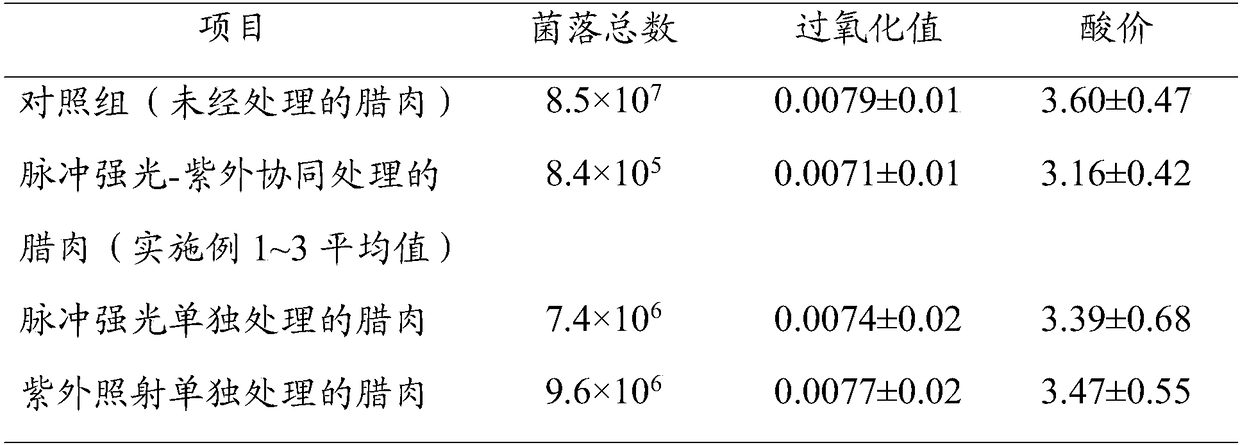

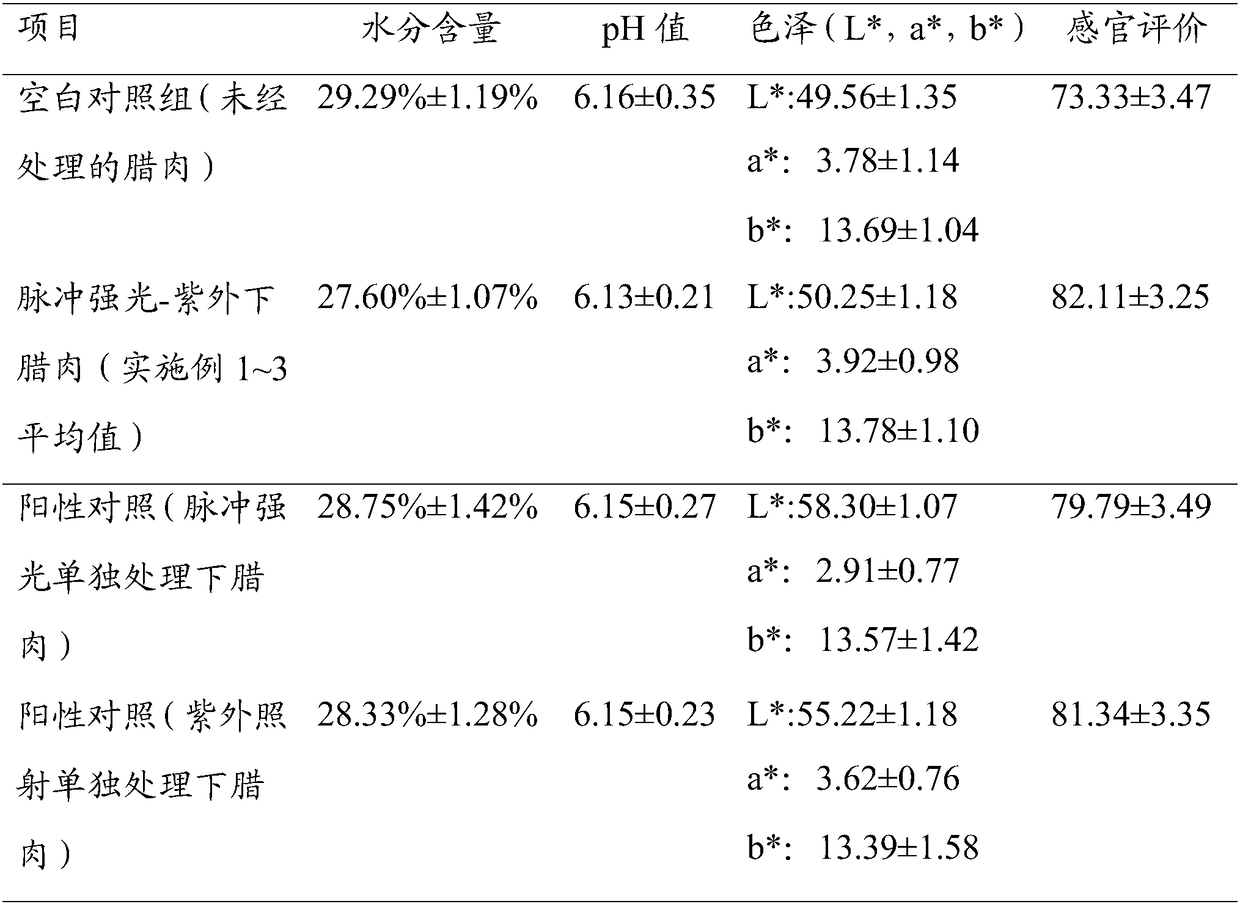

A technology of pulsed strong light and fresh-keeping method, which is applied to the preservation of meat/fish through radiation/electrical treatment, etc., which can solve the problems of long ultraviolet irradiation time, radiation damage of bacon products, taste and taste of bacon that cannot be compared with bacon, and achieve sensory Evaluate the effect of improvement of relevant physical and chemical indicators, high safety and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

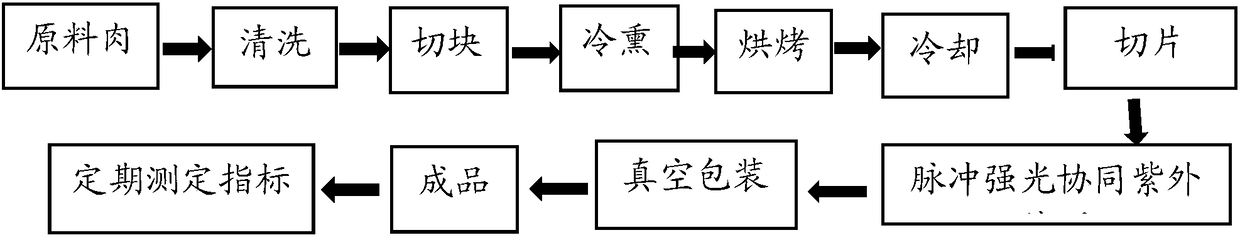

[0039] 1) Production of cured meat: After the raw meat is cleaned, cut into pieces, cured, cold-smoked, baked, and cooled, the required cured cured meat product is obtained.

[0040] 2) Slicing the bacon: Slicing the prepared bacon raw materials with a thickness of 2 mm.

[0041]3) Ultraviolet treatment assisted by pulsed strong light: put the sliced bacon processed in steps 1 and 2 into a pulsed strong light instrument for pulsed strong light-ultraviolet light irradiation treatment. The method is to use a quartz glass tube-type pulsed xenon lamp as the pulse light source and The ultraviolet xenon lamp is an ultraviolet light source. The specifications of the pulse lamp are: length 100mm, diameter 5mm, the distance between the sliced bacon and the pulse light source is 15cm, the pulse flash frequency is 3 times / s, the single pulse energy is 10J, and the pulse flash energy Strength is 10J / cm 2 . The distance between the sliced bacon and the ultraviolet light source is: ...

Embodiment 2

[0045] 1) Production of cured meat: After the raw meat is cleaned, cut into pieces, cured, cold-smoked, baked, and cooled, the required cured cured meat product is obtained.

[0046] 2) Slicing the bacon: Slice the prepared bacon raw materials, and the thickness of the slices is 3 mm.

[0047] 3) Ultraviolet treatment assisted by pulsed strong light: put the sliced bacon processed in steps 1 and 2 into a pulsed strong light instrument for pulsed strong light-ultraviolet light irradiation treatment. The method is to use a quartz glass tube-type pulsed xenon lamp as the pulse light source and The ultraviolet xenon lamp is an ultraviolet light source. The specifications of the pulse lamp are: length 500mm, diameter 20mm, the distance between the sliced bacon and the pulse light source is 10cm, the pulse flash frequency is 8 times / s, the single pulse energy is 8J, and the pulse flash energy Strength is 8J / cm 2 . The distance between the sliced bacon and the ultraviolet lig...

Embodiment 3

[0051] 1) Production of cured meat: After the raw meat is cleaned, cut into pieces, cured, cold-smoked, baked, and cooled, the required cured cured meat product is obtained.

[0052] 2) Slicing the bacon: Slicing the prepared bacon raw materials, the thickness of the slices is 4mm.

[0053] 3) Ultraviolet treatment assisted by pulsed strong light: put the sliced bacon processed in steps 1 and 2 into a pulsed strong light instrument for pulsed strong light-ultraviolet light irradiation treatment. The method is to use a quartz glass tube-type pulsed xenon lamp as the pulse light source and The ultraviolet xenon lamp is an ultraviolet light source. The specifications of the pulse lamp tube are: 250mm in length and 15mm in diameter. The distance between the sliced bacon and the pulse light source is 15cm. Strength is 5J / cm 2 . The distance between the sliced bacon and the ultraviolet light source is: 10cm, the ultraviolet specification is 20w, the wavelength is 250nm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com