Separation equipment and separation process for ginsenoside extract plasticizer

A technology of ginsenosides and separation equipment, which is applied in the directions of biochemical equipment and methods, filtration separation, separation methods, etc., can solve the problems of excessive plasticizers and other problems, and achieve the effect of sensitive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

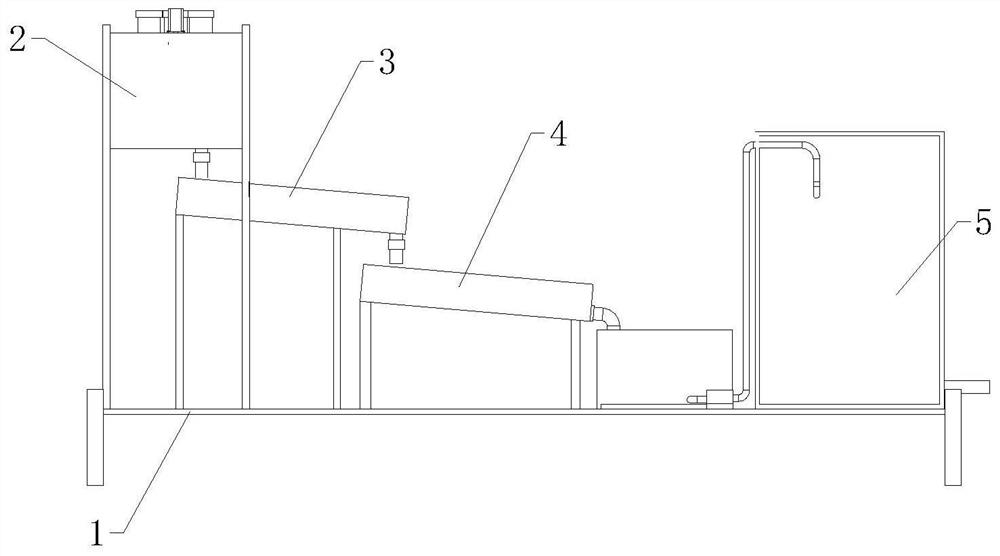

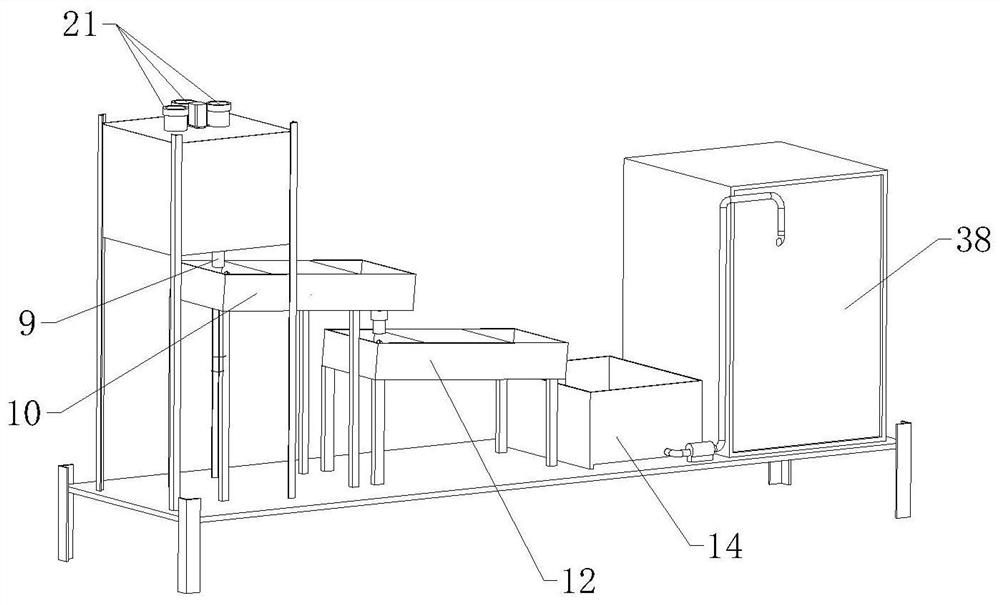

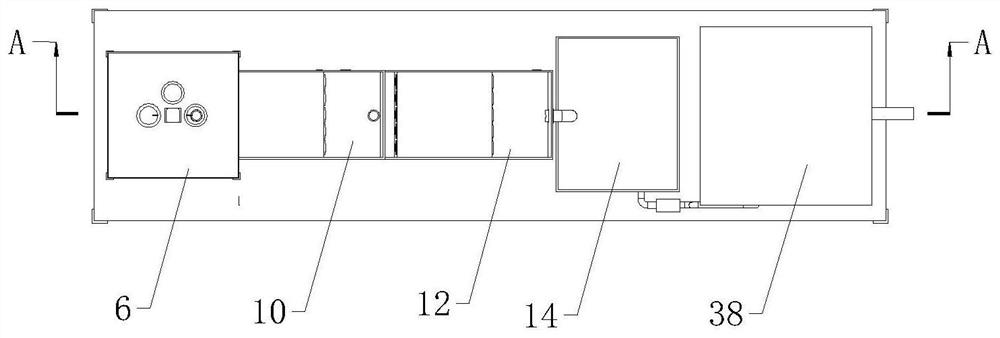

[0032] refer to Figure 1 to Figure 6 Shown, a kind of separation equipment that is used for ginsenoside extract plasticizer comprises base 1, stirring mechanism 2, clarification mechanism 3, adsorption mechanism 4 and drying mechanism 5, and described stirring mechanism 2 comprises heating box 6 and The stirring tank 7, the heating box 6 is vertically positioned above one end of the base 1, the heating box 6 is connected with the base 1 through the first support, the stirring tank 7 is vertically arranged inside the heating box 6, and the inside of the stirring tank 7 A reverse stirring assembly is provided, the top of the stirring tank 7 is provided with a filling pipe 8, and the bottom of the stirring ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com