Rotary oil filtering equipment

A rotary oil filtering technology, applied in food preparation, filtration and separation, edible oil/fat, etc., can solve the problems of impossible continuous operation, troublesome operation, high operating cost, improve the frying environment, use safe and reliable, The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

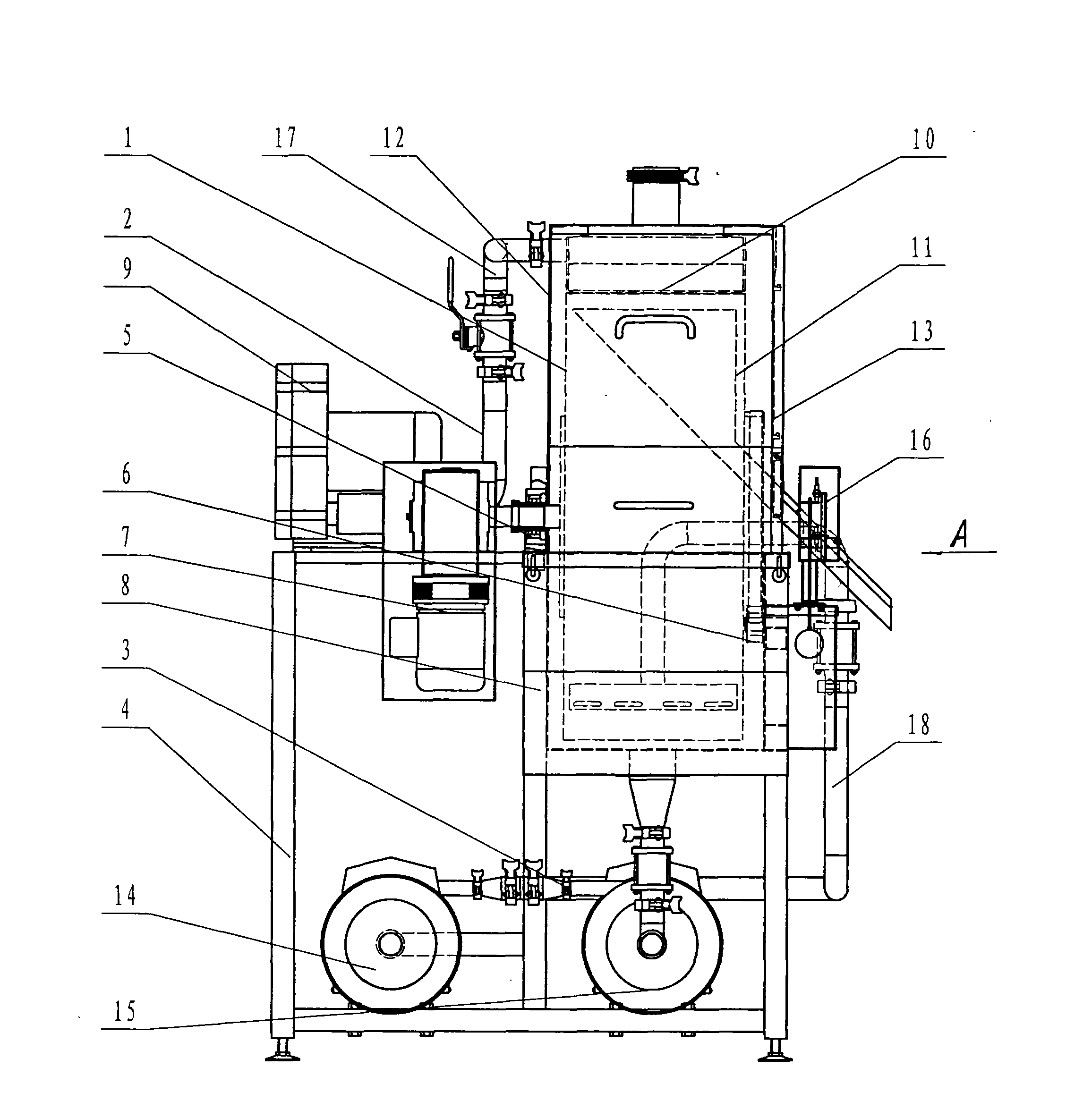

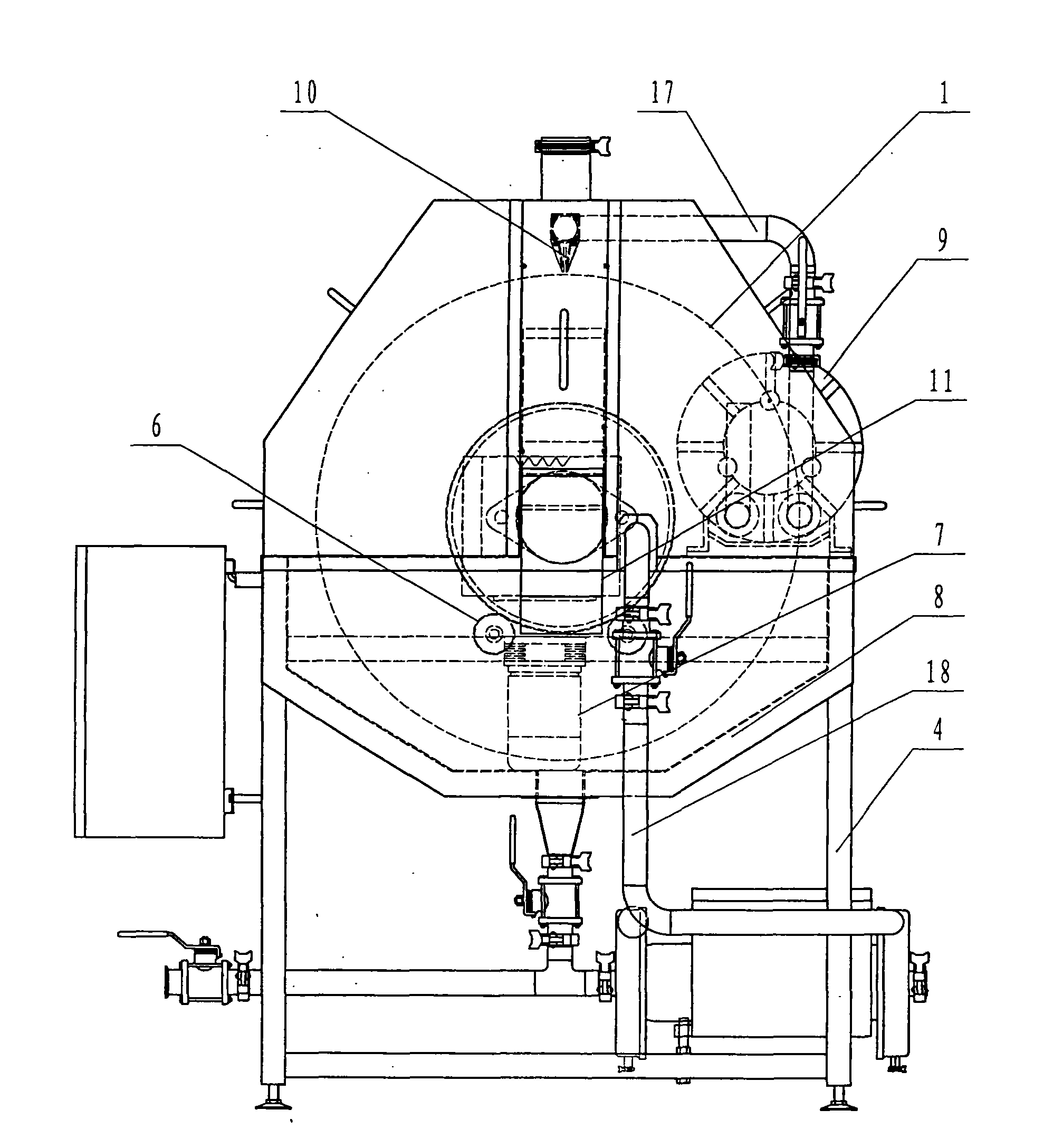

[0015] As shown in the accompanying drawings: the filter equipment includes a filter drum 1, a slag removal device 2, a circulation system 3, and a body 4. The filter drum 1 is arranged on the body 4, and the slag removal device 2 is arranged on the body 4. On one side of the filter drum 1, the circulation system 3 is arranged at the lower part of the body 4 and communicates with the filter drum 1 and the body 4 respectively.

[0016] The shape of the filter drum 1 is cylindrical, and the filter drum 1 is set on the body 4 through the bearing seat 5 and the support roller 6. The filter drum 1 can rotate at a constant speed under the drive of the reducer 7; the bearing seat 5 and the reducer Machine 7 is fixed on the body 4 top, and support roller 6 is fixed on the groove body 8 inside of body 4.

[0017] The slag removal device 2 uses the air volume generated by the fan 9 to blow the oil residue adsorbed on the filter drum 1 onto the discharge slide 11 through the air knife 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com