Mechanical tape type oil filter

A technology of oil filter and mechanical belt, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., which can solve the problems of rancidity and blackening of oil quality, increase of enterprise cost, and failure to meet the requirements of food safety and sanitation conditions, etc. , to achieve the effects of preventing pollution, reducing enterprise costs and improving the frying environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

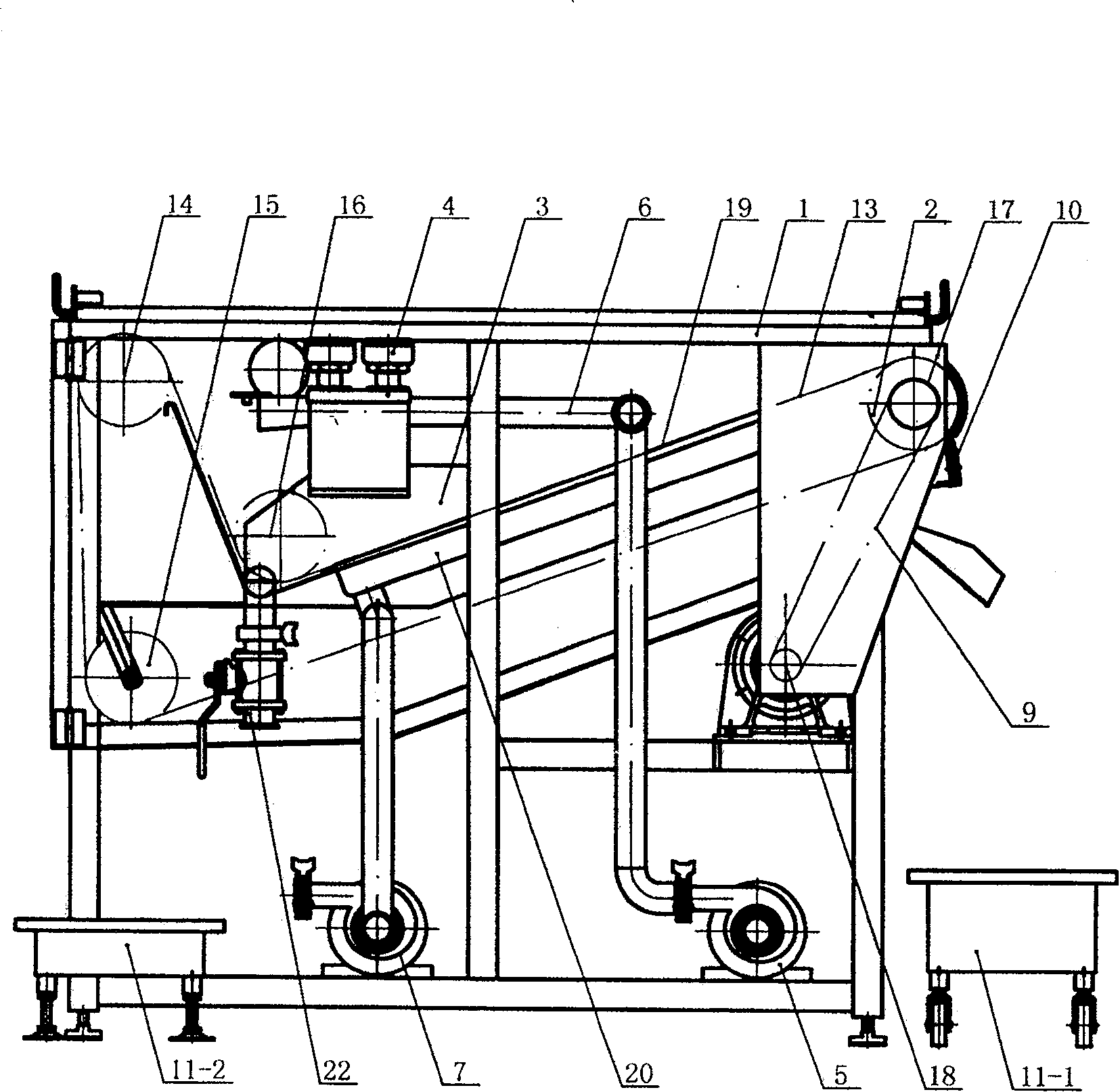

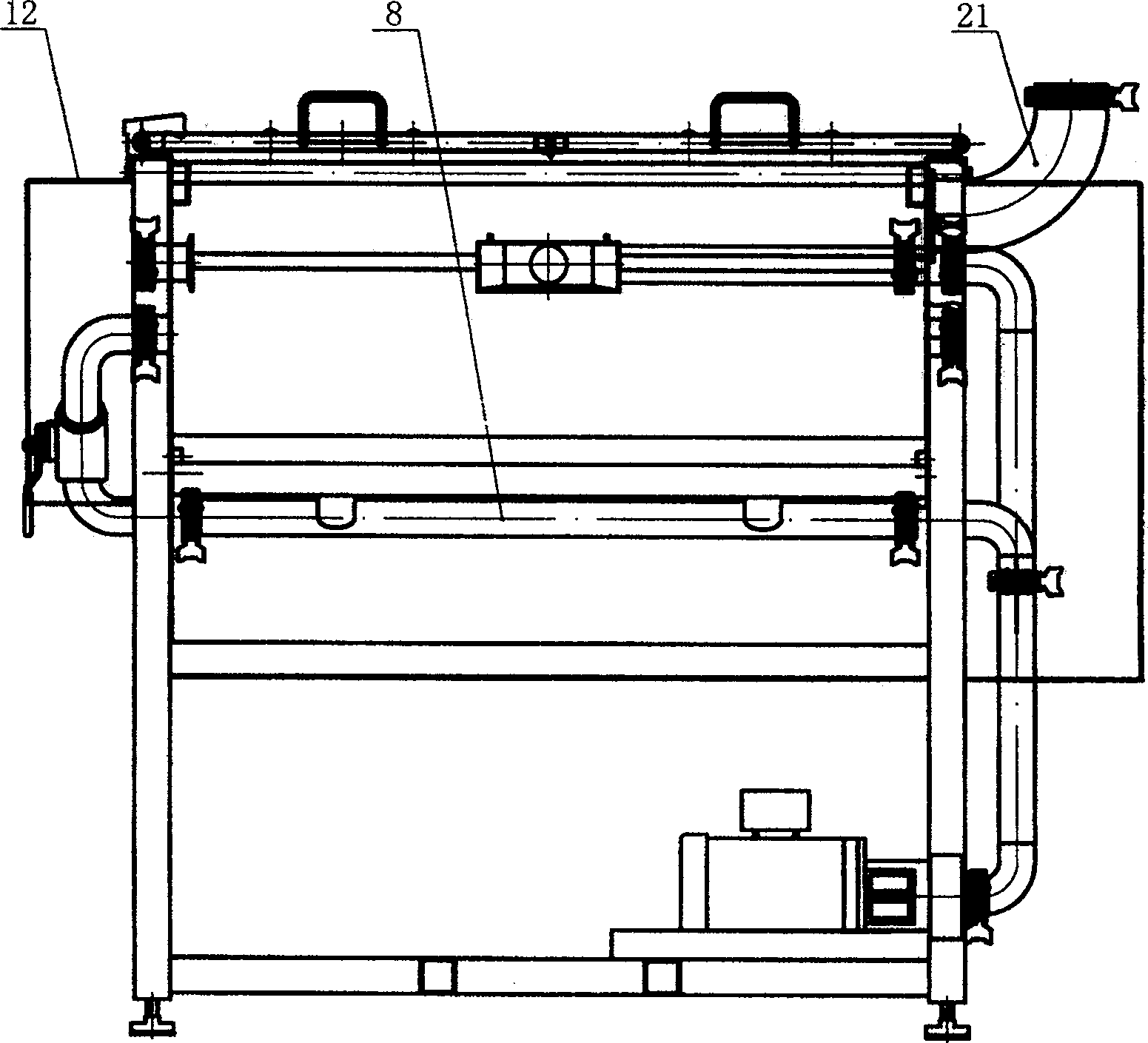

[0018] The mechanical belt oil filter includes a main frame 1, a mesh belt transmission device 2, an oil storage tank 3, an audio liquid level control device 4, an oil inlet pump 5, an oil inlet pipe 6, an oil outlet pump 7, an oil outlet pipe 8, and a drive motor 9 , slag removal mechanism 10, slag receiving box 11, electrical control device 12, its mesh belt conveying device 2 is arranged on the main frame 1, on the top of the main frame 1, a filter mesh belt 13 is provided with an oil storage box passing through its inner bottom surface 3. The tuning fork liquid level control device 4 is set on the main frame 1 and communicates with the oil storage tank 3 , and an oil inlet pump 5 and an oil outlet pump 7 are arranged under the main frame 1 .

[0019] The mesh belt conveyor 2 includes a passive roller 14, a tension roller 15, an intermediate roller 16, a drive roller 17, a drive motor 18, a filter mesh belt 13, and its filter mesh belt 13 is set on the passive roller 14, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com