Mesh-belt continuous edible oil filtering machine

An oil purifier, mesh belt technology, applied in filtration and separation, oil/fat refining, moving filter element filters, etc. The effect of improving the utilization rate, improving the frying environment, and reducing the cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

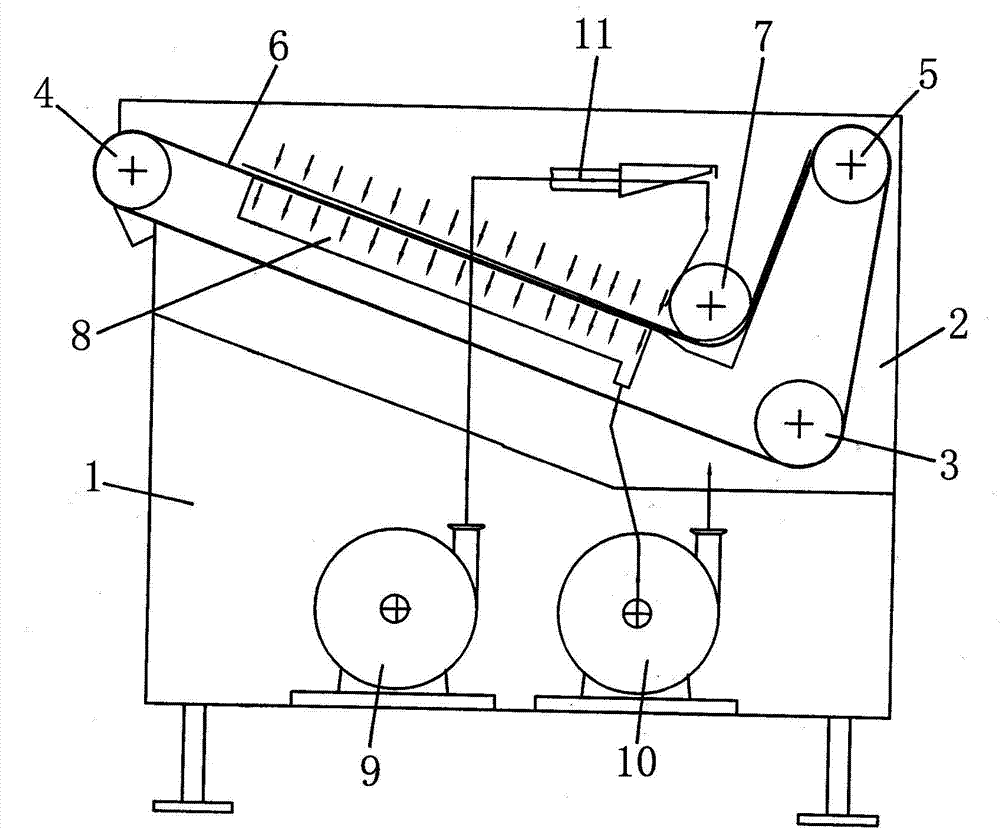

[0009] like figure 1 As shown, the present invention is provided with the box body 2 that bottom is inclined on the top of frame 1, is provided with tension roller 3 at the bottom side of box body 1, and driving roll 4 is located at the outer side of box body 1, and transition roller 5 It is arranged at the upper end of the other side inside the box body 1, and an annular filter mesh belt 6 is wound on the tension roller 3, the driving roller 4 and the transition roller 5, and the guide roller 7 is arranged on the upper surface side of the annular filter mesh belt 6, The annular filter belt 6 is compressed, and an oil receiving box 8 is arranged under the upper annular filter belt 6 , and the suction pump 9 and the suction pump 10 are arranged at the bottom of the frame 1 .

[0010] Through the above settings, the suction pump 9 of the present invention sucks the dirty oil in the fryer on the food production line into the oil sprinkling pipe 11, and the oil sprinkling pipe 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com