Preparation method of myrtle essential oil and application of myrtle essential oil in Guangdong sausage

A Cantonese-style sausage and myrtle technology, which is applied in the directions of essential oils/spice, preservation of meat/fish with chemicals, and fat production, can solve the problems of unfavorable Cantonese-style sausages, deteriorating flavor, and high residues, reducing the Residual amount of nitrite, inhibiting the rise of acid value, and solving the effect of excessive acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Pretreatment of myrtle: sun-dried myrtle and crushed to 40 mesh;

[0020] (2) Supercritical extraction of myrtle: 10 MPa, extraction temperature of 45°C, extraction time of 1 h, volume-to-weight ratio of entrainer absolute ethanol to myrtle fruit of 0.5 L / kg to obtain myrtle essential oil . The extraction rate of myrtle essential oil is 2.54%.

[0021] (3) After mixing 70g of myrtle essential oil, 10g of TBHQ and 4kg of koji wine evenly, add 70kg of lean meat, 30kg of fat meat, 12kg of sugar, 3.5kg of salt, 20g of nitrite, and 20kg of water. After mixing evenly, enema, hot air Dry it to get Cantonese-style sausage. Extraction rate of myrtle essential oil = (weight of essential oil - weight of ethanol) / weight of myrtle fruit * 100% (the same below).

Embodiment 2

[0023] (1) Pretreatment of myrtle: fresh myrtle is dried and crushed to 70 mesh;

[0024] (2) Supercritical extraction of myrtle: 20 MPa, extraction temperature of 55°C, extraction time of 2 hours, volume-to-weight ratio of entrainer absolute ethanol to myrtle fruit of 2 L / kg, myrtle essential oil was obtained . The extraction rate of myrtle essential oil is 2.25%.

[0025] (3) After mixing 140g of myrtle essential oil, 10g of TBHQ (tert-butyl hydroquinone) and 4kg of koji wine evenly, add 70kg of lean meat, 30kg of fat meat, 12kg of white sugar, 3.5kg of table salt, 20g of nitrite, water 20kg, mixed evenly, enema, hot air drying, to get Cantonese-style sausage.

Embodiment 3

[0027] After mixing 10g of TBHQ and 4kg of koji wine evenly, add 70kg of lean meat, 30kg of fat meat, 12kg of white sugar, 3.5kg of salt, 20g of nitrite, and 20kg of water.

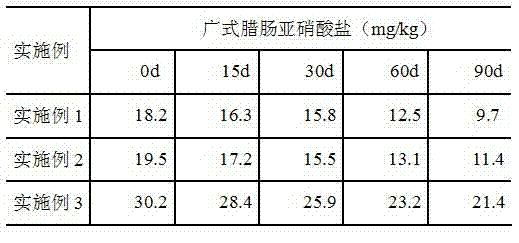

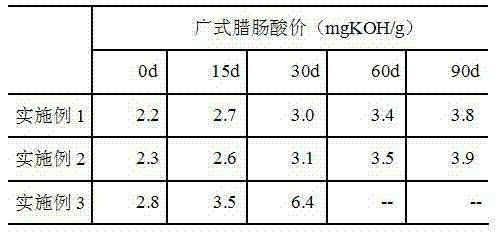

[0028] Table 1 shows the changes in acid value of Cantonese-style sausages prepared in different ways during storage at 25°C. Table 2 shows the changes of nitrite during the storage of Cantonese-style sausages prepared in different ways at 25 degrees.

[0029] It can be seen from Table 1 that the myrtle essential oil was added in Example 1 and Example 2, and the acid value of Cantonese-style sausage rose slowly during storage. After 90 days of storage, the acid value of Cantonese-style sausage was 3.8 and 3.9 mgKOH / g respectively . In Example 3, myrtle essential oil was not added, and after 30 days of storage, the acid value reached 6.4 mgKOH / g.

[0030] It can be seen from Table 2 that the residual amount of nitrite in Cantonese-style sausage during storage showed a downward trend with the prolongation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com