Patents

Literature

129results about How to "Do not change the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

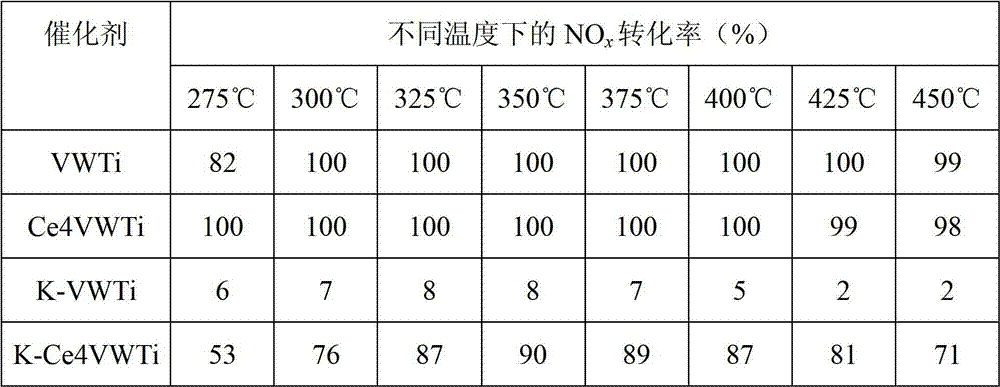

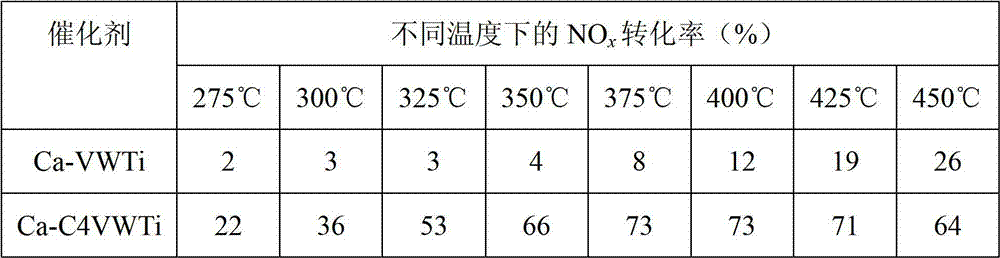

Vanadium-titanium oxide catalyst, and preparation method and application thereof

InactiveCN102764643ANo effect on activityDo not change the production processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMetal poisoningAlkaline earth metal

The invention relates to a vanadium-titanium oxide catalyst which can resist alkaline metal and alkaline earth metal poisoning. The catalyst is characterized in that the vanadium-titanium oxide catalyst is doped with an element Ce. The catalyst has fine resistance to alkaline metal poisoning, and above all, the doped cerium component has no influence on the activity of the SCR (selective catalytic reduction) catalyst while improving the resistance of the V2O5 / (MoO3)x(WO3)1-x-TiO2 catalyst to alkaline metal poisoning. The preparation method of the catalyst is simple and easy to implement and has very excellent N2 generation selectivity; and meanwhile, the Ce is a non-poisonous component and can not do harm to human health and ecological environment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Cured tobacco perfume formulation

The invention provides a formula of a cured tobacco flavor, and pertains to the technical field of flavors. The formula of the cured tobacco flavor takes vanillin, isoamyl isovaleriate, aglaia odorate flower concrete extract, rhodinol and Maillard reactant as the main raw materials. The formula is applied to the tobacco to cause the cigarette to have a novel and nice fragrance, in particular to cause the cigarette to have a pure and mellow fragrance, thus obviously improving the impure fragrance and the smoke taste and causing the characteristic of the cigarette fragrance to be obvious. The formula has available flavor raw materials, and does not need to increase devices and change the production process. The addition amount is 1.2-2.5 per mill of the tobacco usually.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

Liquid cement grinding aid

InactiveCN101318792AEasy to measureChange the production processSodium phosphatesTriterpenoid saponin

The invention relates to a liquid cement grinding aid which can obviously reduce the dosage of trolamine and does not contain urea. The grinding aid comprises the following compositions in weight percentage: 1 to 10 percent of trolamine, 5 to 10 percent of diglycol, 1 to 10 percent of trimeric sodium phosphate, 10 to 30 percent of molasses, 0 to 20 percent of sodium thiosulfate, 0 to 10 percent of air entraining component and the balance being water, wherein the air entraining compositions are triterpenoid saponin air entraining agent, sodium lignin sulfonate or a mixture of the triterpenoid saponin air entraining agent and the sodium lignin sulfonate at any proportion. The invention obviously reduces the dosage of the trolamine, does not contain the urea, lowers product cost and simultaneously facilitates the environmental protection. The sodium thiosulfate has the function of exciting mixed materials of cement and can improve the initial strength and the later strength of the cement, thereby effectively improving the service performance of the cement grinding aid. The triterpenoid saponin air entraining agent and the sodium lignin sulfonate have the action of the auxiliary aided grinding and simultaneously properly entrain air to reduce the water consumption of the cement standard consistence.

Owner:NANJING YONGNENG MATERIALS

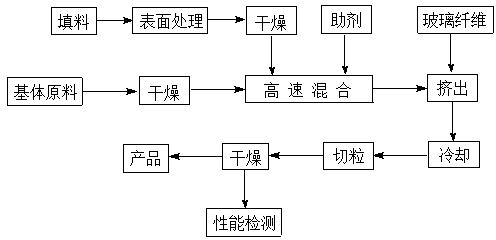

Multi-component compound modified nylon 6 composite material for carrier roller and preparation method thereof

The invention belongs to the field of high-molecular composite materials, and provides a high-performance multi-component compound modified nylon 6 composite material for a conventional carrier roller. The composite material consists of 100 parts of mixed nylon 6, 10-40 parts of alkali-free glass fiber, 5-30 parts of talcum powder, 0.01-1 part of nano silicon dioxide, 1-5 parts of solid lubricant, 0.01-3 parts of wear-resistant agent, 0.05-1 part of anti-aging agent, 0.2-1 part of dispersing agent and 0.01-0.5 part of silane coupling agent. After being uniformly mixed, the material system is extruded by a twin-screw extruder and granulated to obtain a high-performance composite material. By adopting the composite material provided by the invention, the prepared carrier roller has the characteristics of high strength, abrasion resistance, high-temperature resistance, light weight, low noise, long service life, appropriate price, convenience in maintenance and the like, and can be widely applied to the places such as mines except coal mines, wharfs, grain depots, cement plants, power plants, chemical plants, salt fields and the like.

Owner:HUNAN UNIV OF TECH

Cured tobacco essence

InactiveCN1590522AConvenient sourcePure smokeTobacco preparationEssential-oils/perfumesNicotiana tabacumRhodinol

An essence for the flue-cured tobacco to improve its fragrance is prepared from vanillin, isopentyl isovalerate, tree orchid extract, rhodinol and furanone. The productive technique is simple.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

Composite binder for iron ore pellets and preparation method thereof

The invention in particular relates to a composite binder for iron ore pellets and a preparation method thereof. The technical scheme is that the method comprises the following steps of: mixing 40 to 70 weight percent of sodium bentonite and 30 to 60 weight percent of rectorite; adding 0.1 to 1 weight percent of additive; uniformly mixing; and grinding until the particle size is less than 200 meshes to obtain the composite binder for the iron ore pellets, wherein the additive is prepared by mixing an adhesion promoter and a reinforcing agent in the mass ratio of 1:(1.5-9) and grinding the mixture until the particle size is less than 200 meshes; the adhesion promoter is more than two of polyacrylamide, modified starch and polyethylene oxide; and the reinforcing agent is one of carboxymethyl cellulose and humic acid salt. By the method, the equipment investment is not increased, the original production process is not changed and the quality of the pellets can be improved; and the composite binder prepared by the method has the characteristics of improving compression strength and dropping strength of green pellets, compressive strength and cracking temperature of dry pellets, compressive strength of and total iron grade of finished pellets.

Owner:WUHAN UNIV OF SCI & TECH

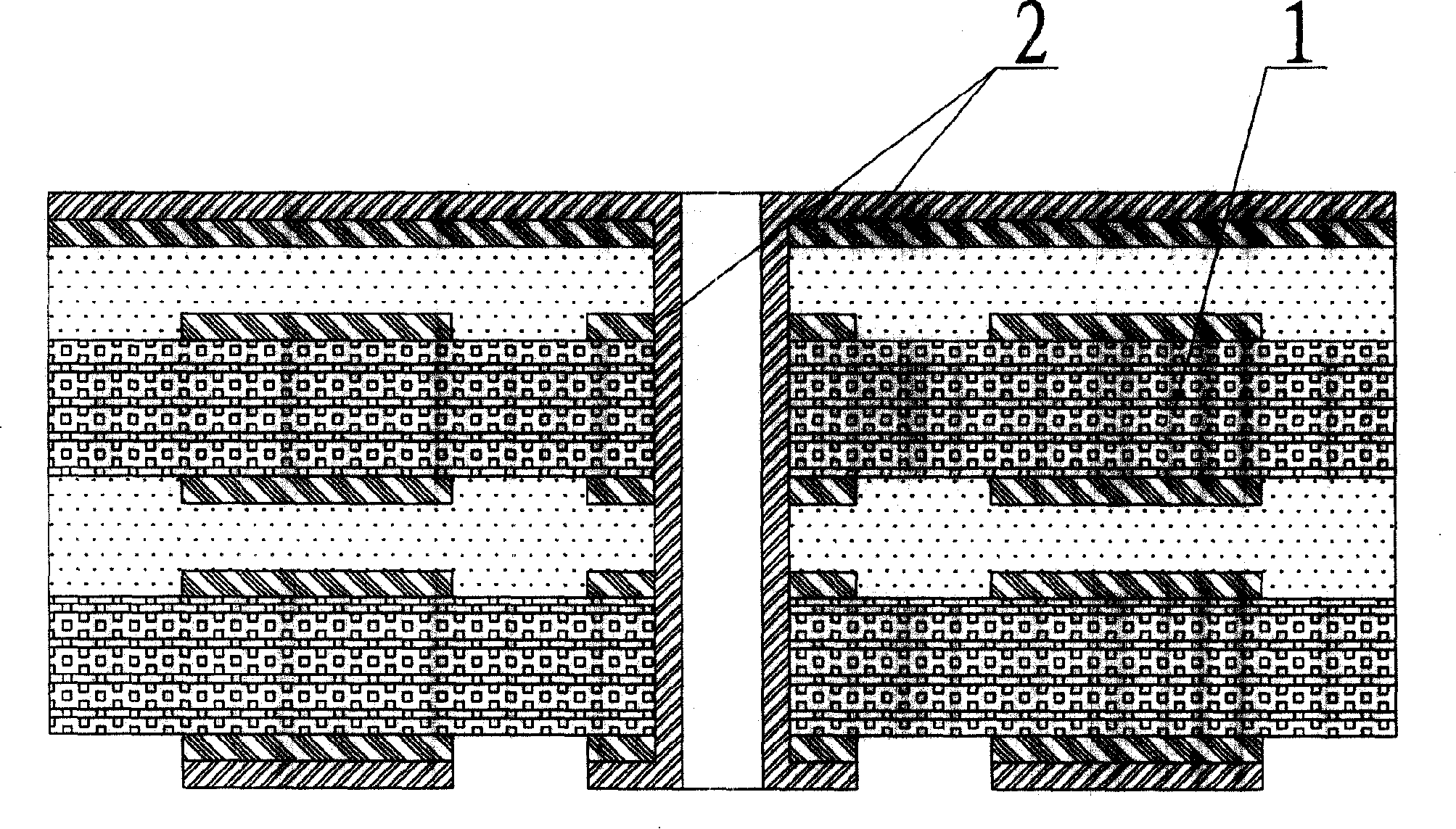

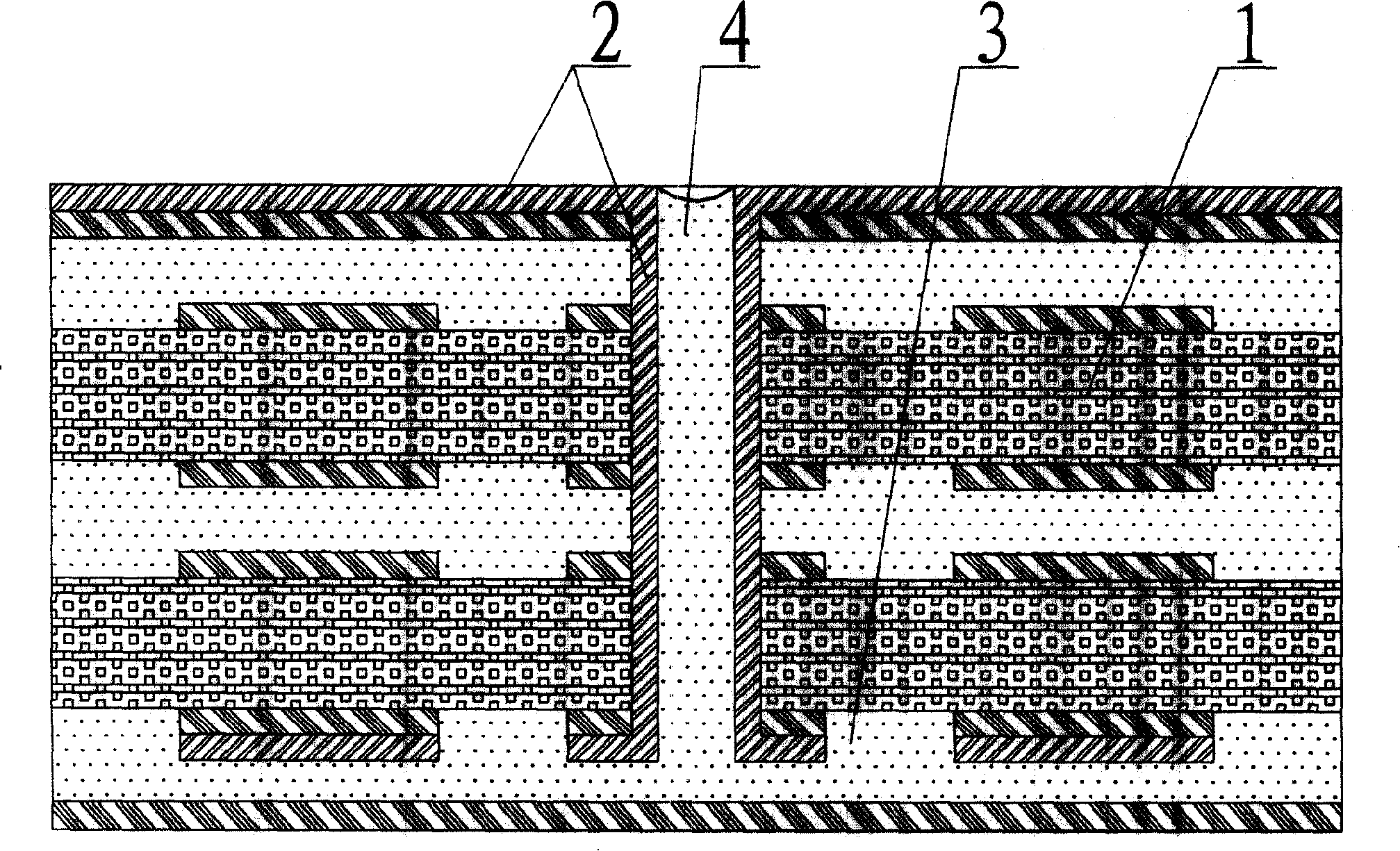

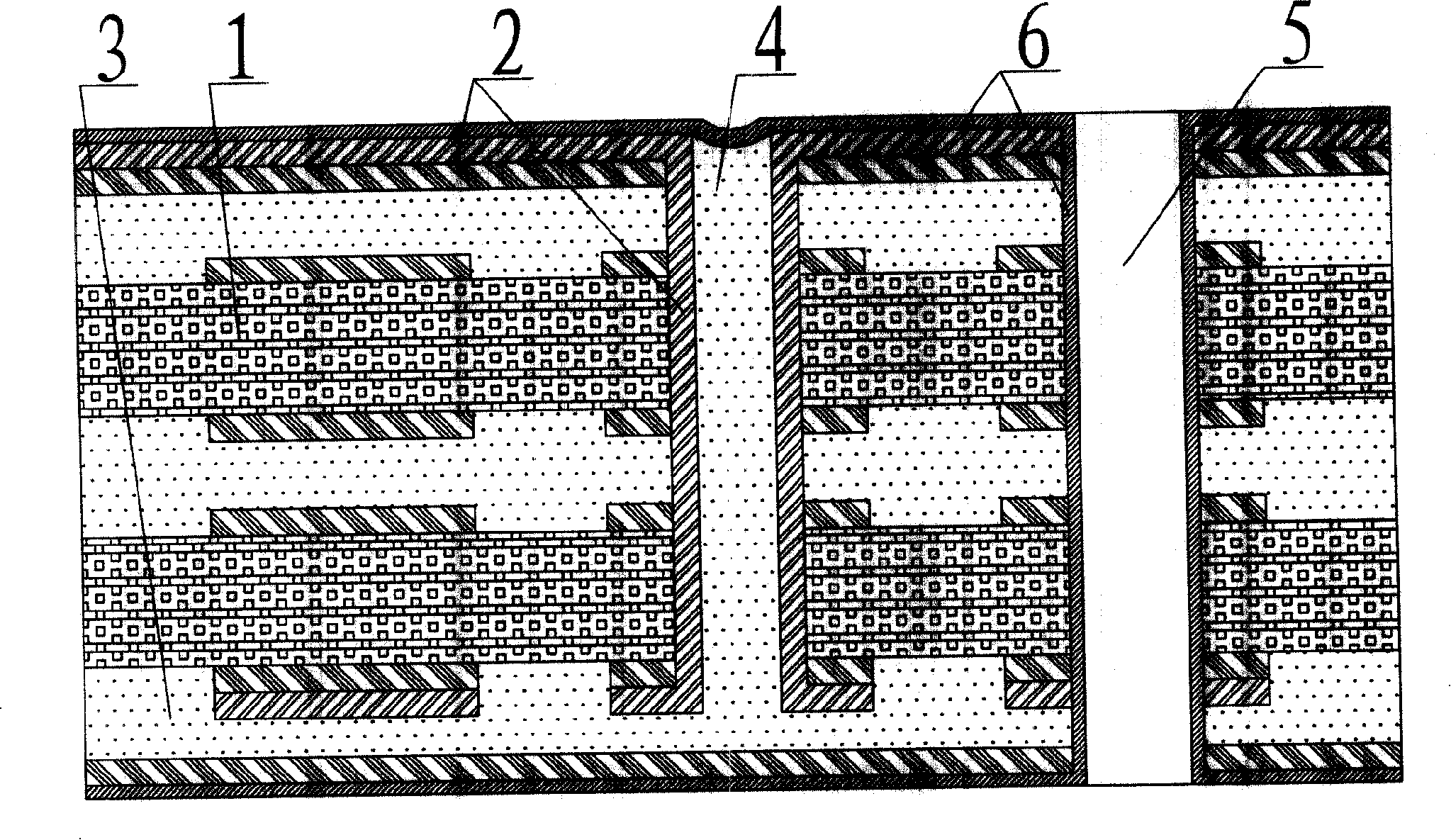

Blind hole plate and its processing method

InactiveCN101222817AReduce processReduce processing costsElectrical connection printed elementsMultilayer circuit manufactureGraphicsVena contracta diameter

The invention provides a blind orifice plate, wherein a welding disk on the top of a blind hole is provided with a through hole for relieving stress. The main method for processing the blind orifice plate is that: on the basis of the prior technology, only a part on a graphics film corresponding to the blind hole is made into a phonic zone which is smaller than the blind hole in diameter during the course of making graphics film. In the invention, the working procedure of 'processing-jacking hole with resin -curing-lapping' is deleted, the manufacturing circle is shortened and the processing cost is decreased correspondingly because the working procedure is reduced; after the process is reduced, the overall qualified product rate is improved. The invention is a modification on related design during the pre-production of film, which does not change the prior production technology; the operator can conduct normal operation according to the prior procedures, which avoids unnecessary accidents. The product of the invention can meet the requirements of consumers in terms of overall appearance and performance and the user is not affected to use the product.

Owner:DALIAN PACIFIC ELECTRONICS

Nano material modified polythene ground covering film

The present invention relates to a nano material modified polyethylene mulch film. It is made up by using (by weight portion) 1-98 portions of polyethylene resin, 1-50 portions of nano-grade calcium carbonate modification material and 0.03-5 portions of working adjuvant.

Owner:XINJIANG TIANYE GRP

Compound type binder used for pellet

The invention discloses a compound type binder used for pellet, which comprises the following raw materials in percentage by weight: 70-80% of clay powder, 10-20% of sodium humate, 3-6% of sodium carboxymethyl cellulose and 2-4% of sodium carbonate. The compound type binder used for the pellet of the invention is a pellet binder prepared by combining inorganic substance and organic substance, hasgood hydrophily and high viscosity, can be dissolved into water, replaces bentonite completely, has extremely low carry-in amount of detrimental impurity of the inorganic substance and does not influence the iron grade of the pellet; and when added into iron finemeal pellet for production, the invention does not change the original process and is an ideal and synergistic pellet binder.

Owner:王建忠

Antirust pigment for improving antirust property of antirust paint

InactiveCN1504516AReasonable priceImprove rust resistancePigmenting treatmentAnti-corrosive paintsNano siliconVanadium oxide

The invention discloses a composite ferrum-titanium powder, a rust-preventive pigment for improving the tarnish proofness for anti-corrosive paint, characterized in that, the composite ferrum-titanium powder uses natural or artificially synthesized ferriferrous oxide having a fineness of 200-1200 sieve number as carrying agent, to be added by nano silicon oxide, titanium oxide, vanadium oxide, yttrium oxide, zinc oxide, ferric oxide and calcium carbonate.

Owner:万达科技(无锡)有限公司

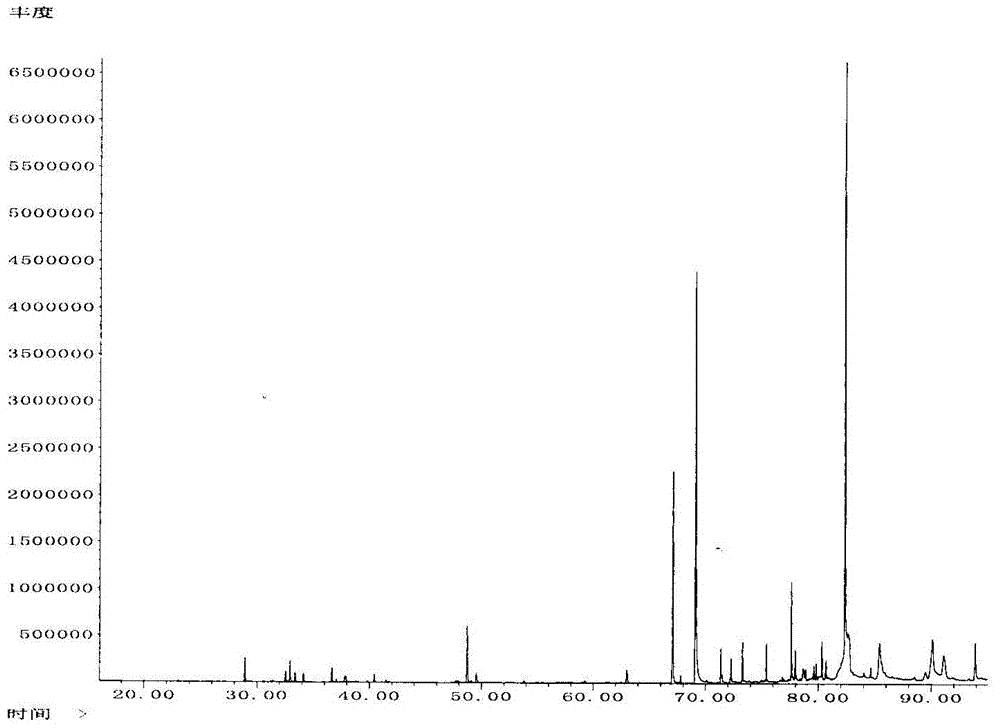

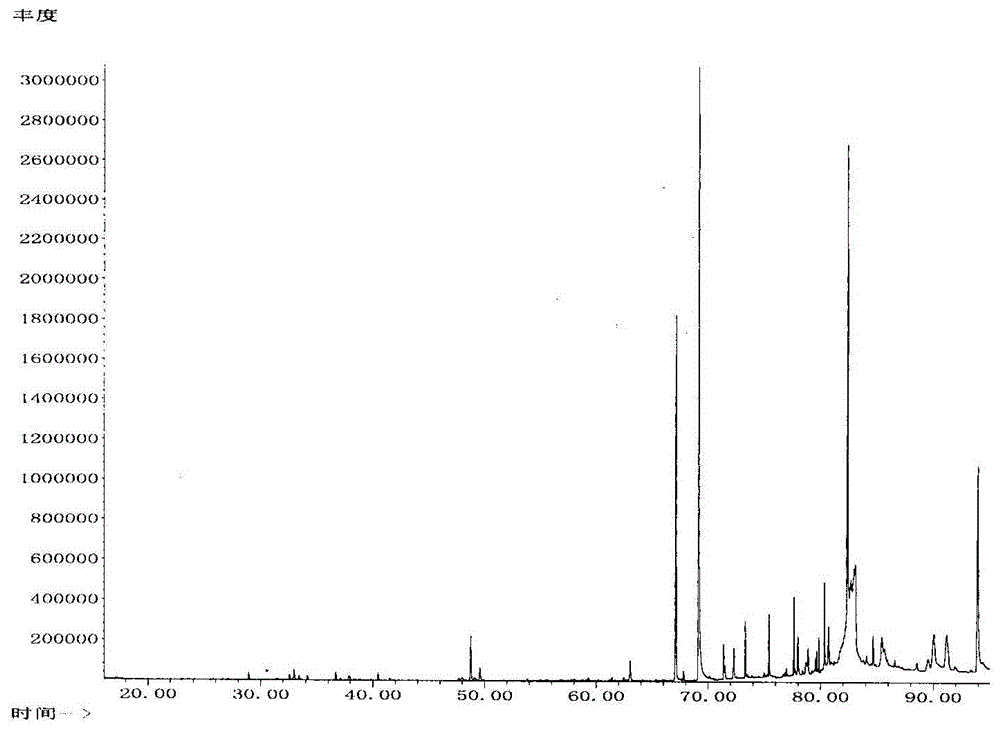

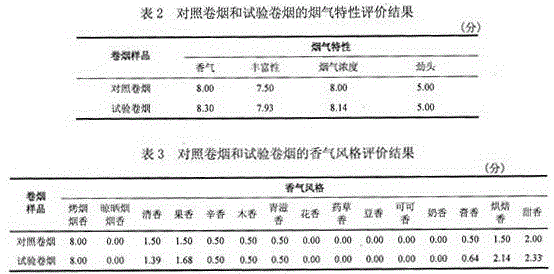

Malt caramel-like aroma spice suitable for cigarette products and application of malt caramel-like aroma spice to tobacco products

ActiveCN106165906AChange the production processStrengthen the style characteristics of Chinese cigarettesTobacco preparationTobacco treatmentWaxCyclopentenone

The invention belongs to the technical field of cigarette spices, and particularly relates to a malt caramel-like aroma spice and an application of the malt caramel-like aroma spice to tobacco products. The spice is prepared from caramel malt serving as a raw material, and a preparing method of the spice includes the following steps of a, raw material pretreating; b, ethyl alcohol extracting; c, freezing dewaxing; d, membrane separating. A pyrazine compound, a furan compound, a furanone compound, a pyrone compound, a cyclopentenone compound and the like are rich in the malt caramel-like aroma spice, the joyful caramel-like aroma smell can be given to cigarettes, and the Chinese-style cigarette style characteristic is intensified. According to the spice, the caramel-like aroma ingredients in caramel malt are purposefully extracted, separated and enriched, and ingredients such as vegetable wax, protein and starch which are contained in malt extract and have the side effects on sense organs of tobacco products are effectively removed. The preparing technology is simple and easy to operate, the cost of the raw material is low, the production process is economic and environmentally friendly, and the malt caramel-like aroma spice is suitable for large-scale industrial production application. The application of the spice to cigarettes cannot change the original processing technology of cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

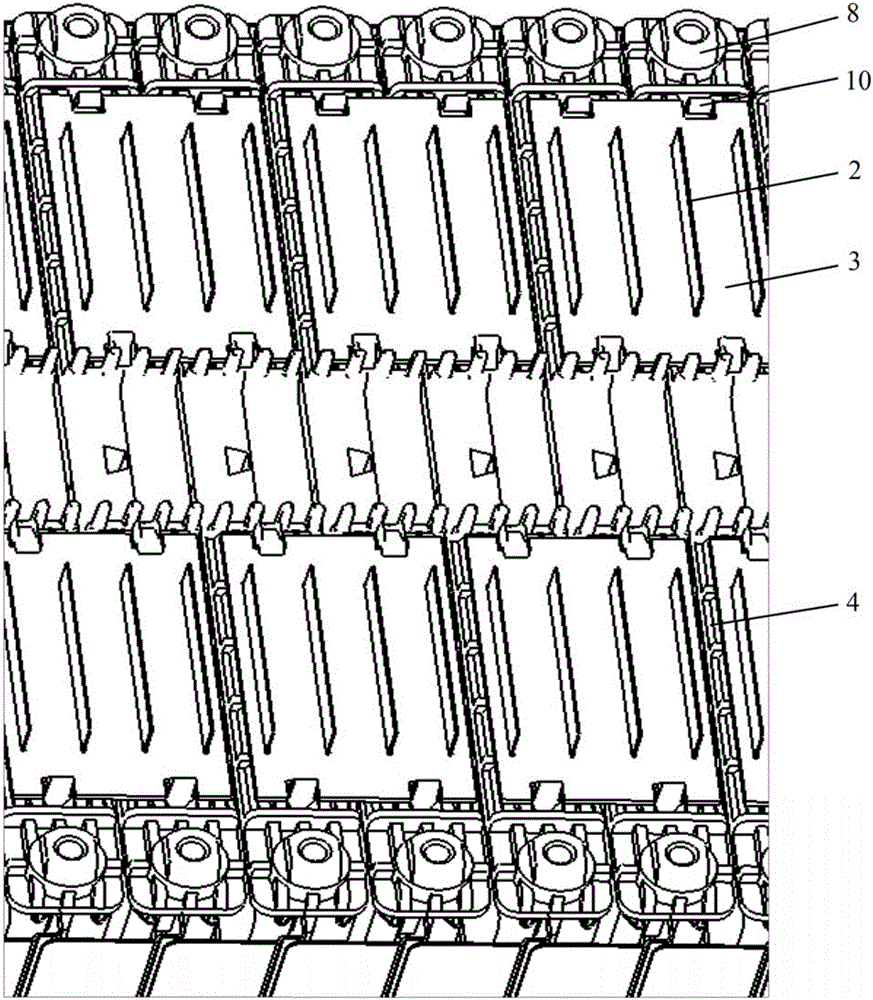

Module connecting structure for soft-package battery

ActiveCN106025162AReduce connection reliability riskLow costCell component detailsElectrical batteryConductive materials

The invention relates to a module connecting structure for a soft-package battery. The module connecting structure comprises multiple stacked battery cores, bus bars connected with tabs of the battery cores and bus bar supporting components for limiting positions between the tabs of the batter cores and the bus bars, wherein the positive and negative tabs of the battery cores are prepared from a copper-aluminum composite material; the positive and negative bus bars corresponding to the positive and negative tabs are prepared from the same single conductive material. Compared with the prior art, the connecting structure with improved tabs and bus bars has the advantages that the laser welding quality of the tabs and the bus bars is greatly improved, and the connection reliability is improved.

Owner:上海捷新动力电池系统有限公司

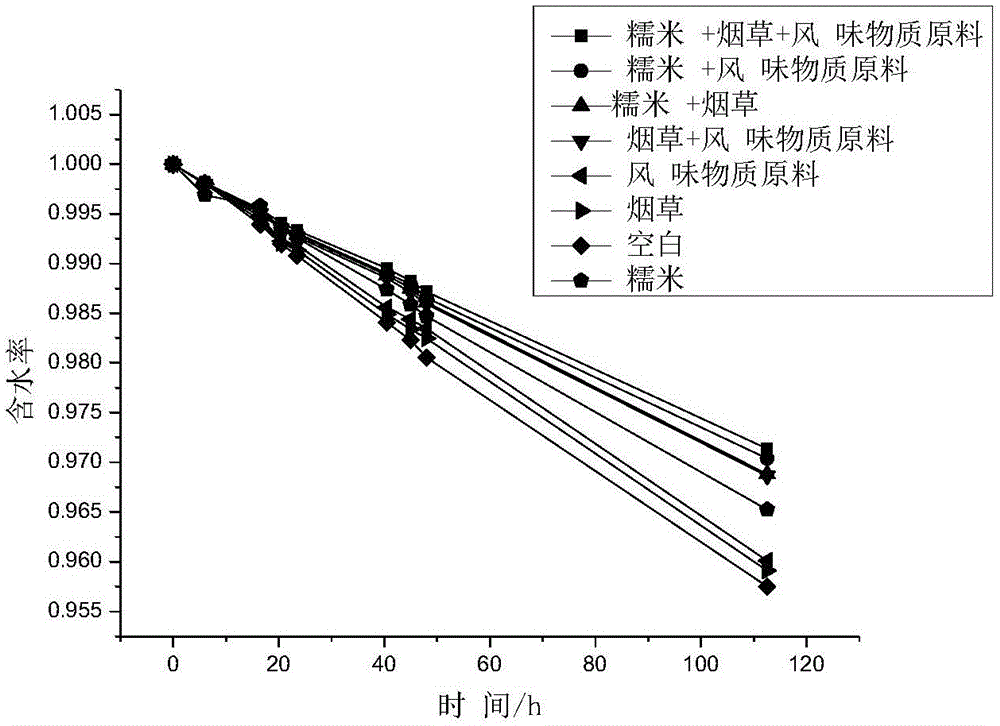

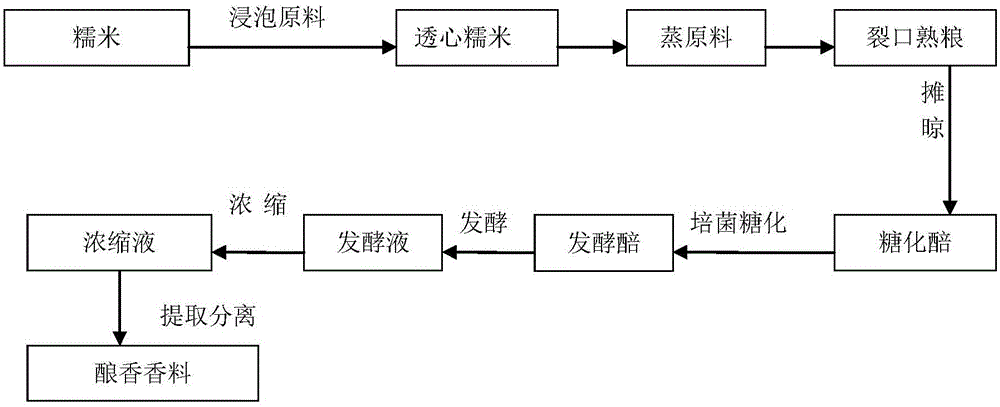

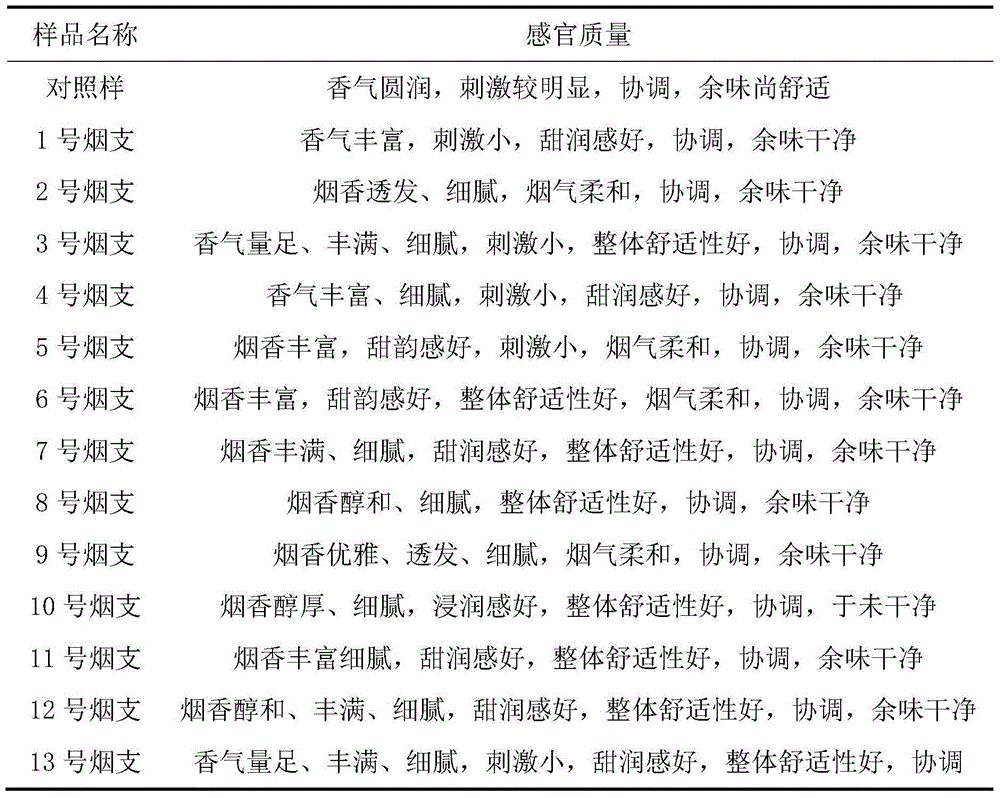

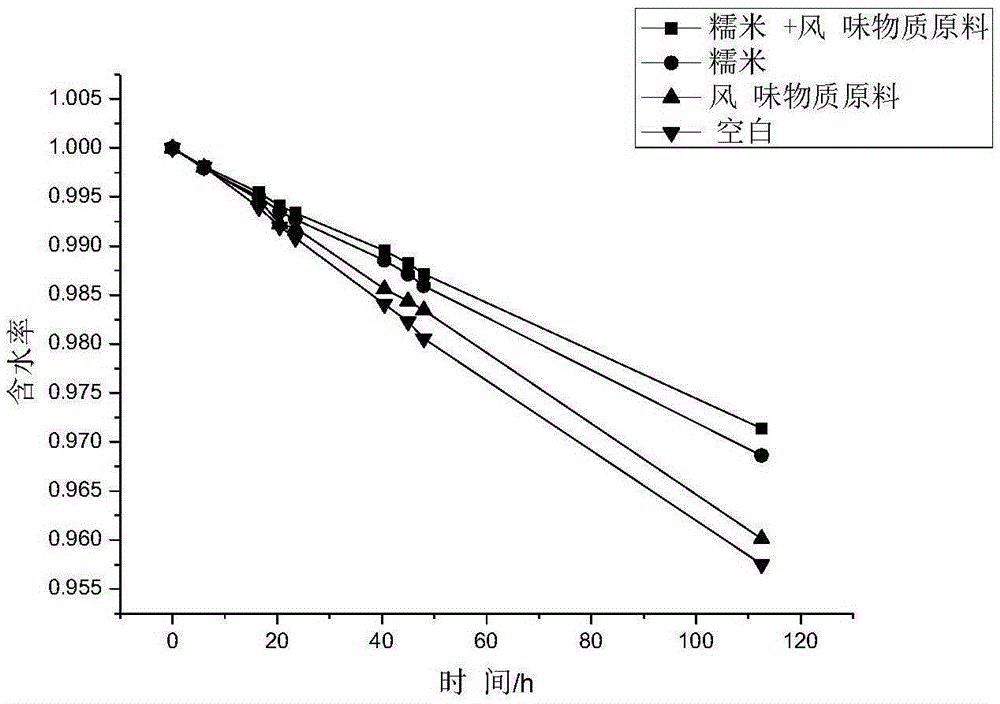

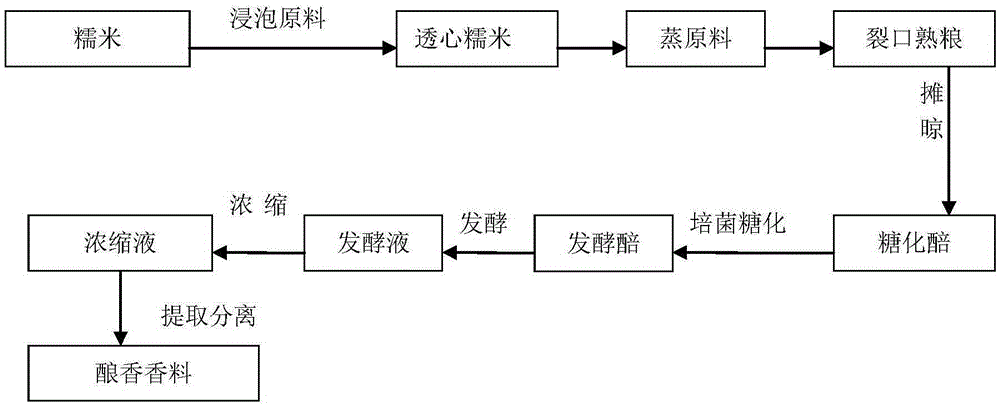

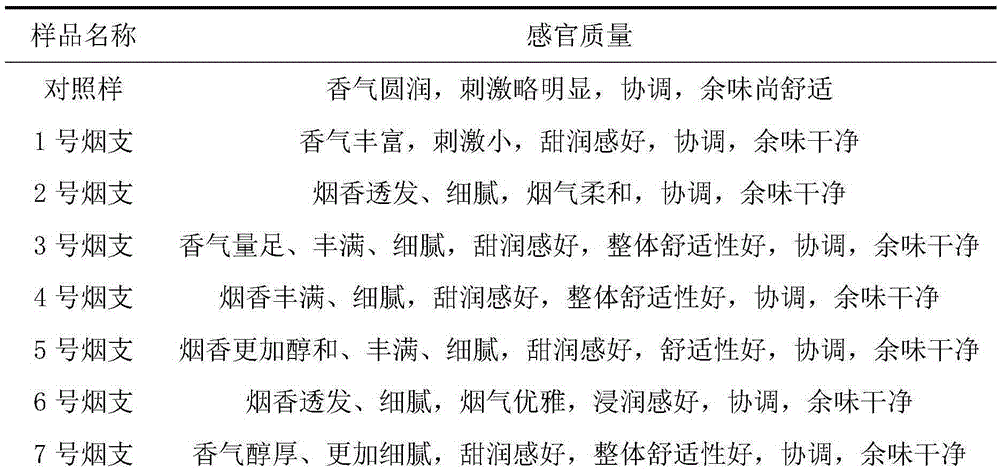

Aroma brewing flavor for cigarettes and application thereof in improving smoking quality of cigarettes

The invention relates to an aroma brewing flavor. The aroma brewing flavor is obtained by conducting solid compound fermentation on the raw materials of sticky rice, tobacco and flavor substances through microorganisms. The invention further relates to a preparation method of the aroma brewing flavor. The method comprises the steps that 1, the sticky rice is washed and soaked in distilled water for 15-20 h, water on the soaked sticky rice is drained, and direct steam is adopted to steam the sticky rice, the tobacco and the flavor substances till the rice is well done; 2, the steamed sticky rice, tobacco and flavor substances are spread out and aired, when the temperature is decreased to 30-35 DEG C, the sticky rice, the tobacco and the flavor substances are put into a fermentation tank, wine cube, yeast and tobacco strains are inoculated, even stirring is conducted, and saccharification is conducted; 3, the distilled water is added to saccharified materials according to the water addition ratio ranging from 1:1 to 1:5, and compound fermentation liquid is obtained after fermentation is conducted; 4, the liquid compound fermentation aroma brewing flavor of the sticky rice, the tobacco and the flavor substances is obtained after the compound fermentation liquid is processed. The aroma brewing flavor has the applications of improving the moistening feeling of cigarette smoke, reducing irritation of the cigarette smoke, increasing the comfort degree of the throat of a user, increasing the concentration of aroma of the cigarettes and / or keeping moisture of tobacco slices.

Owner:CHINA TOBACCO YUNNAN IND

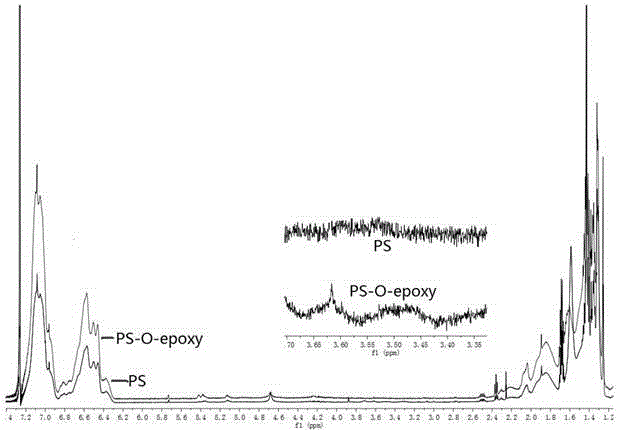

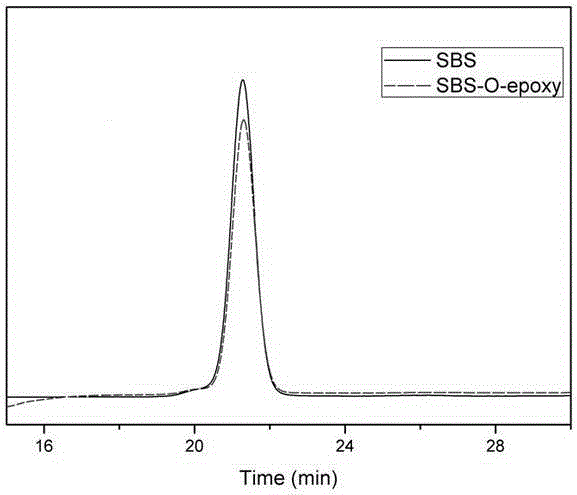

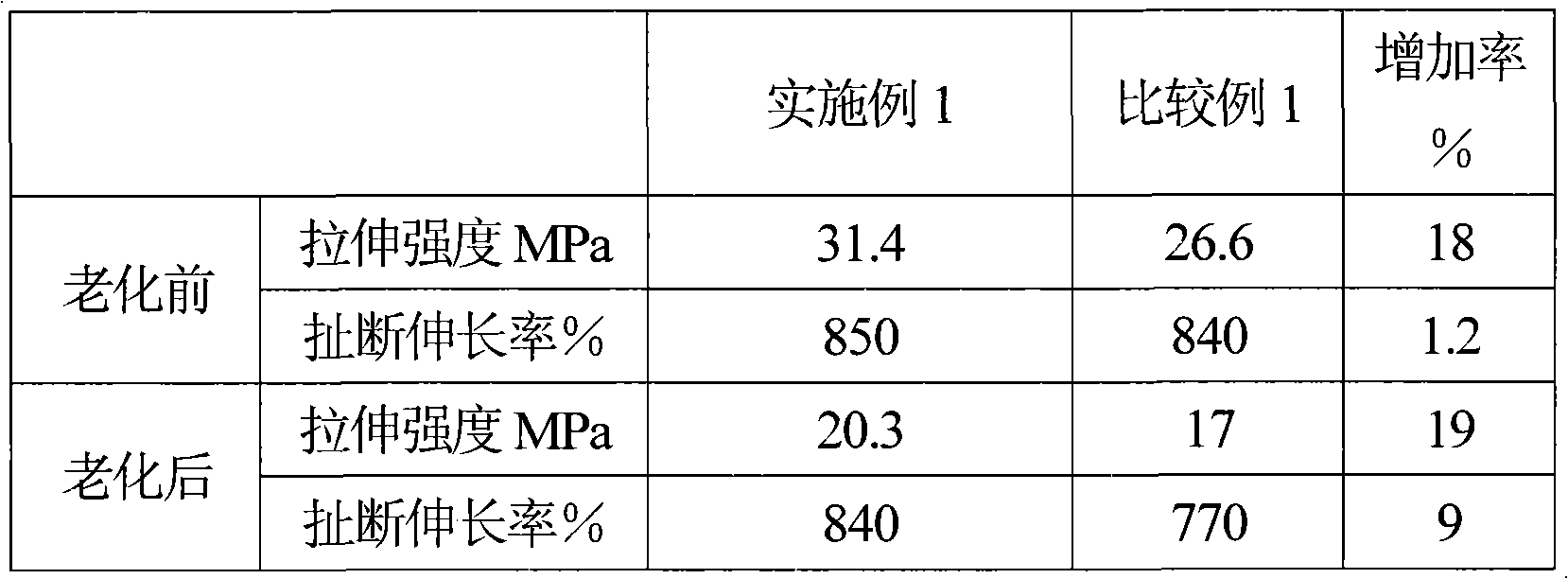

Preparation method of epoxy group-terminated styrene-butadiene-styrene (SBS) ternary block copolymer

The invention discloses a preparation method of an epoxy group-terminated styrene-butadiene-styrene (SBS) ternary block copolymer. A SBS ternary block copolymer is synthesized by a lithium initiator anion solution polymerization technology and a three-step feeding method, after the third-stage reaction, an alkylene oxide compound is used so that carbanion activity is reduced, then epoxy alkylogen is added into a reaction system, the mixed reaction system undergoes a reaction, after the reaction, an antiager is added into the reaction product, and a solvent in the reaction system is removed so that the epoxy group-terminated SBS ternary block copolymer is obtained. The preparation method does not change the existing SBS production technology, has a high ending ratio, has simple processes and a low cost and can be industrialized easily.

Owner:CHINA PETROLEUM & CHEM CORP

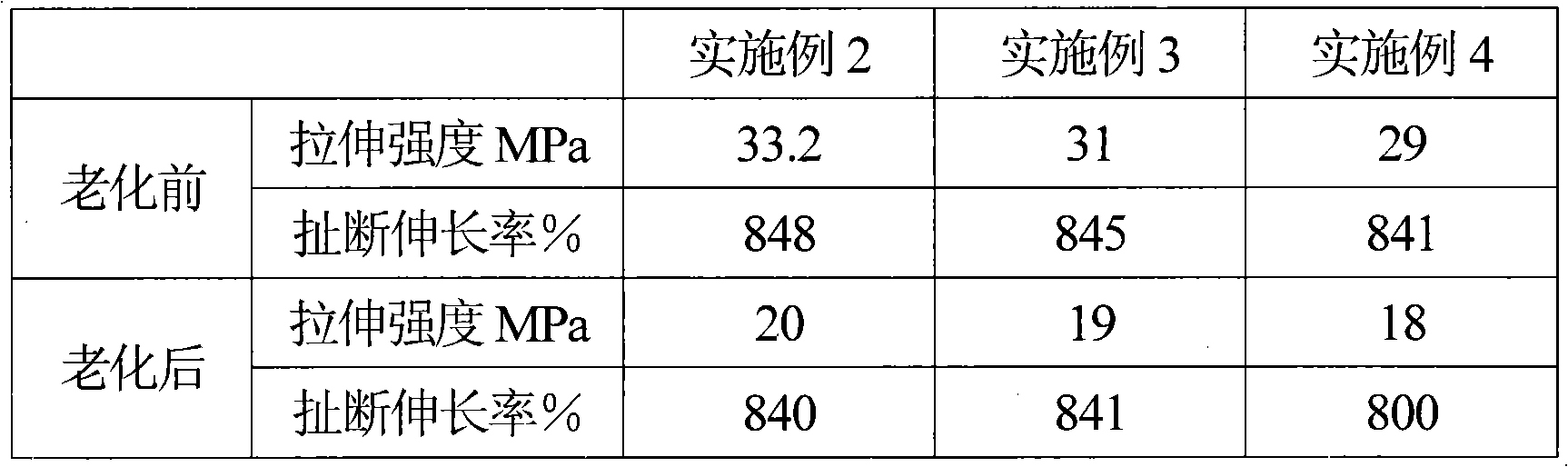

Nano-composite emulsion product and preparation method thereof

InactiveCN101293976AHigh mechanical strengthImprove antibacterial propertiesEmulsionAging resistance

The invention relates to a novel nano composite material, a nano composite latex product, and a preparation method thereof, and belongs to the field of rubber industry. The nano composite latex product is made from (a) natural latex, (b) an auxiliary agent, (c) nano zinc oxide concentrated slurry and (d) water. The auxiliary agent comprises an anti-aging agent, a stabilizer, a promoter, etc. According to the invention, the nano concentrated slurry of a certain concentration is prepared firstly, then the nano concentrated slurry, together with other conventional ingredients, is added and uniformly dispersed in the natural latex at a certain proportion during the conventional presulfurization or compounding operation procedure of the raw materials of the latex product, and finally the latex product containing nano materials is yielded through the conventional immersion molding process. The invention is characterized in that: the nano zinc oxide concentrated slurry is uniformly dispersed in the latex product, so as to avoid aggregate formation caused by direct addition of nano powders and thereby improve the product performance. The latex product has good mechanical properties, such as aging resistance, anti-tear strength, etc., and has antibacterial effect.

Owner:中科纳米涂料技术(苏州)有限公司

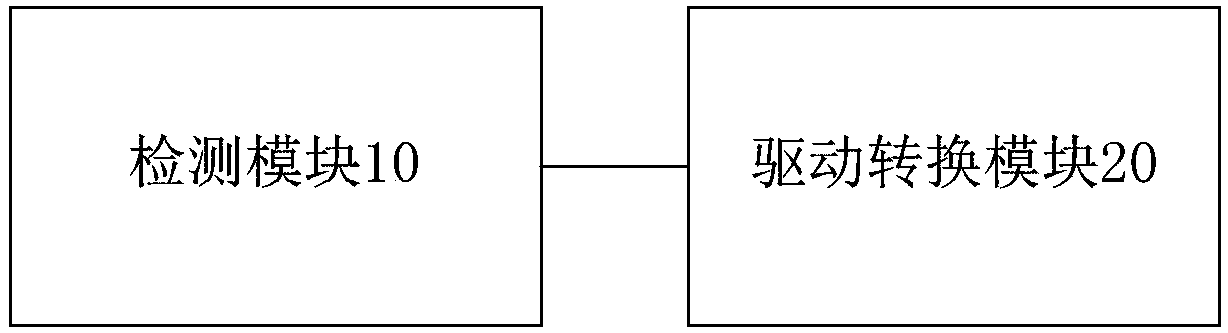

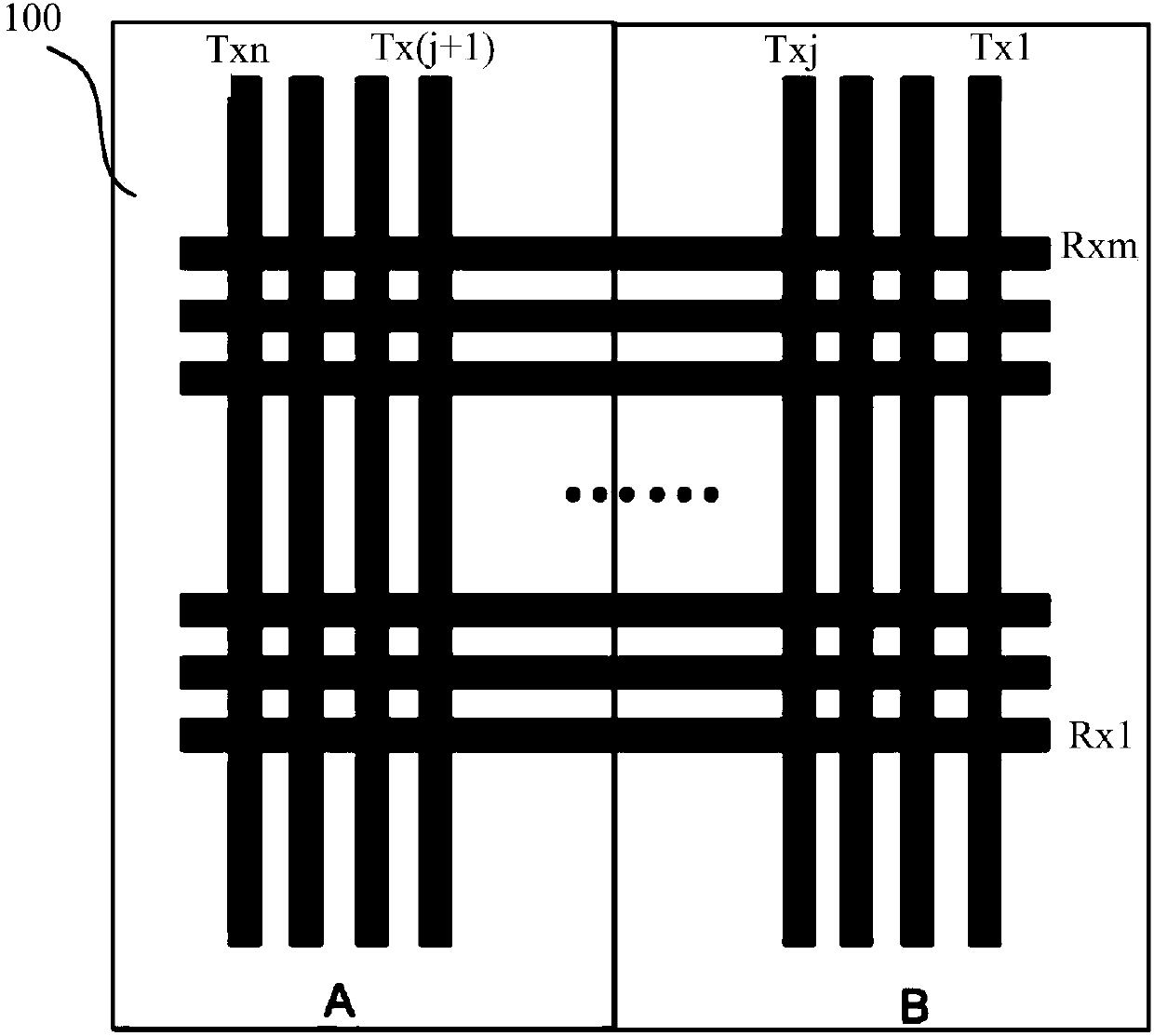

Electronic device, flexible screen and false touch prevention apparatus and method for flexible screen

ActiveCN107807752ADo not change the production processAvoid false touchesInput/output processes for data processingEmbedded systemElectronic equipment

Owner:BOE TECH GRP CO LTD +1

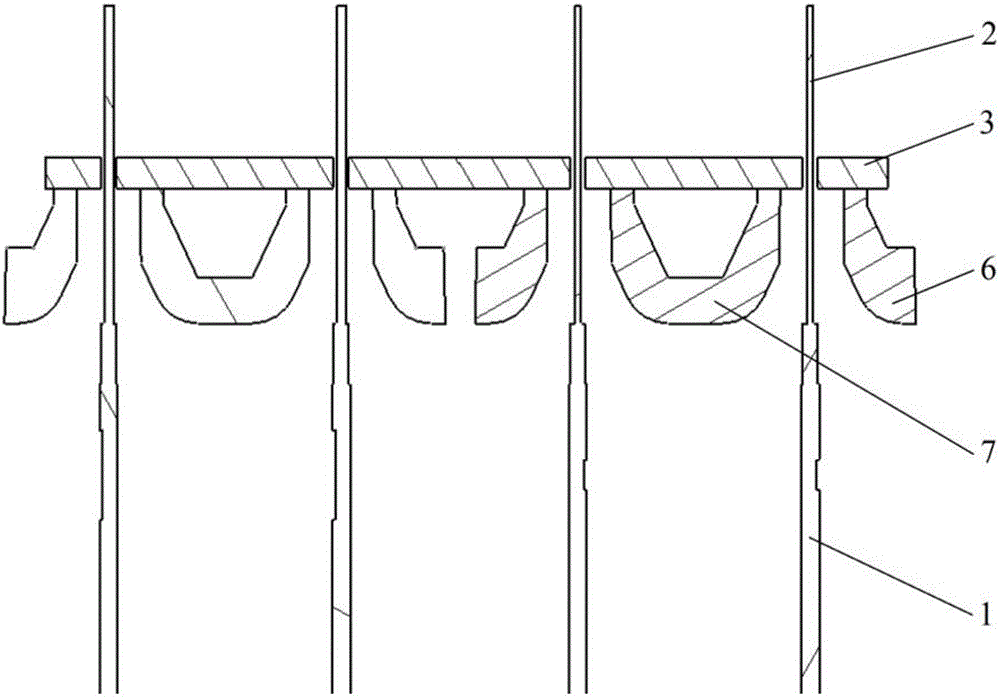

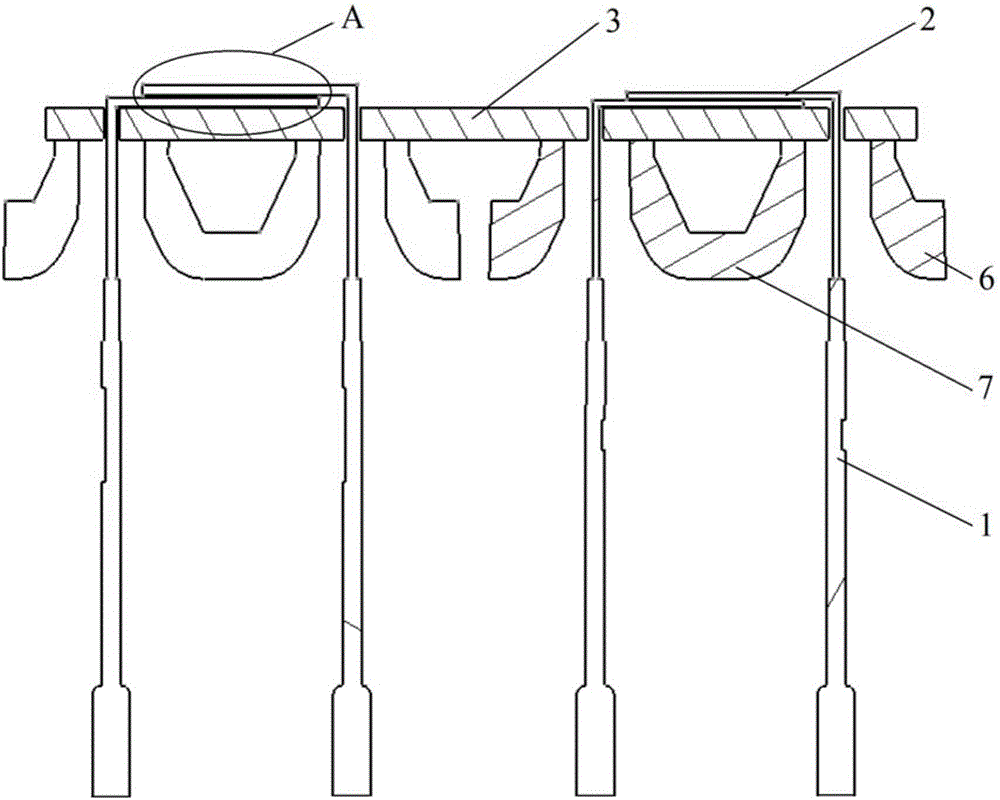

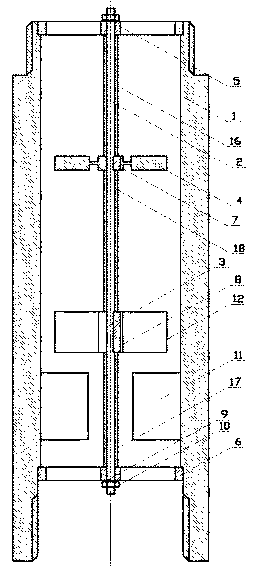

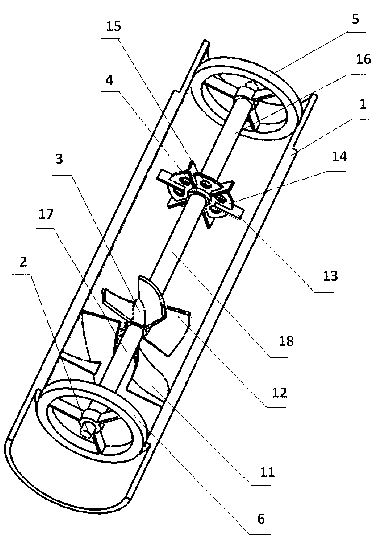

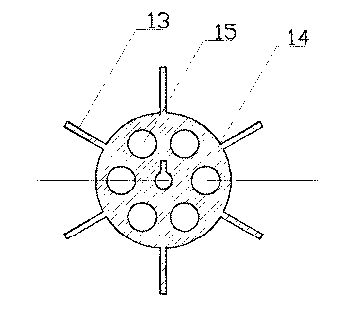

Active rotary dynamic mixer applicable to thick oil mixed with thin oil mining

InactiveCN103306647ARealize serial useDo not change the production processFluid removalImpellerPetroleum engineering

The invention relates to an active rotary dynamic mixer applicable to thick oil mixed with thin oil mining, and belongs to underground mixed stirring equipment of thick oil mining in an oil field. The active rotary dynamic mixer mainly comprises a barrel, a central shaft, a power impeller, a stirring impeller, an upper bearing, a lower bearing, flat keys, a limiting sleeve, guide blades, power blades, stirring blades, a disk and overflowing holes, wherein the upper end of the barrel is connected with the upper bearing by inner threads; the lower end of the barrel is connected with the lower bearing by inner threads; the power impeller and the stirring impeller are arranged on the central shaft; mixed oil flows into the mixer, and vertically impacts the power impeller to rotate after passing through the guide blades; the power impeller is connected with one flat key, and transmits torque to the central shaft; the central shaft is connected with the other flat key to transmit the torque to the stirring impeller; the limiting sleeve is arranged between the power impeller and the stirring impeller; and the guide blades are welded on an inner wall of the barrel, and located below the power impeller. The active rotary dynamic mixer is simple in structure, and convenient to assemble and dismount.

Owner:SOUTHWEST PETROLEUM UNIV

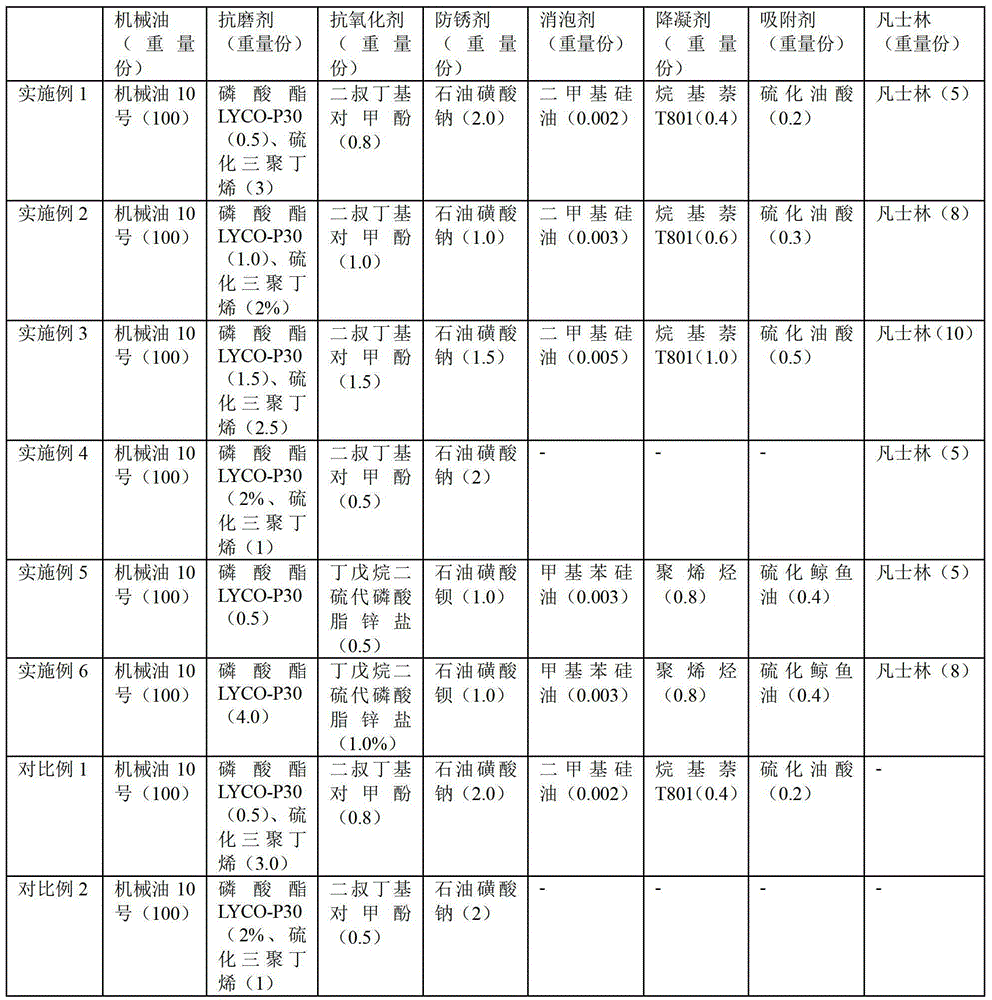

Welding anti-spattering agent for galvanized steel plate and galvanized oil-coated steel plate

ActiveCN104057215ADo not change the production processMeet the requirements of welding process qualityLayered productsWelding/cutting media/materialsSheet steelAntioxidant

The invention provides a welding anti-spattering agent for a galvanized steel plate and a galvanized oil-coated steel plate formed by coating of the welding anti-spattering agent on the galvanized steel plate. The welding anti-spattering agent contains 100 parts of machine oil, 0.2-5 parts of an anti-wear agent, 0.2-2 parts of an antioxidant, 0.5-2 parts of an antirust agent and 3-15 parts of Vaseline in parts by weight. The welding anti-spattering agent can form an antirust oil layer on the galvanized steel plate, so that the galvanized oil-coated steel plate has an anti-corrosion effect and an anti-welding-spattering effect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

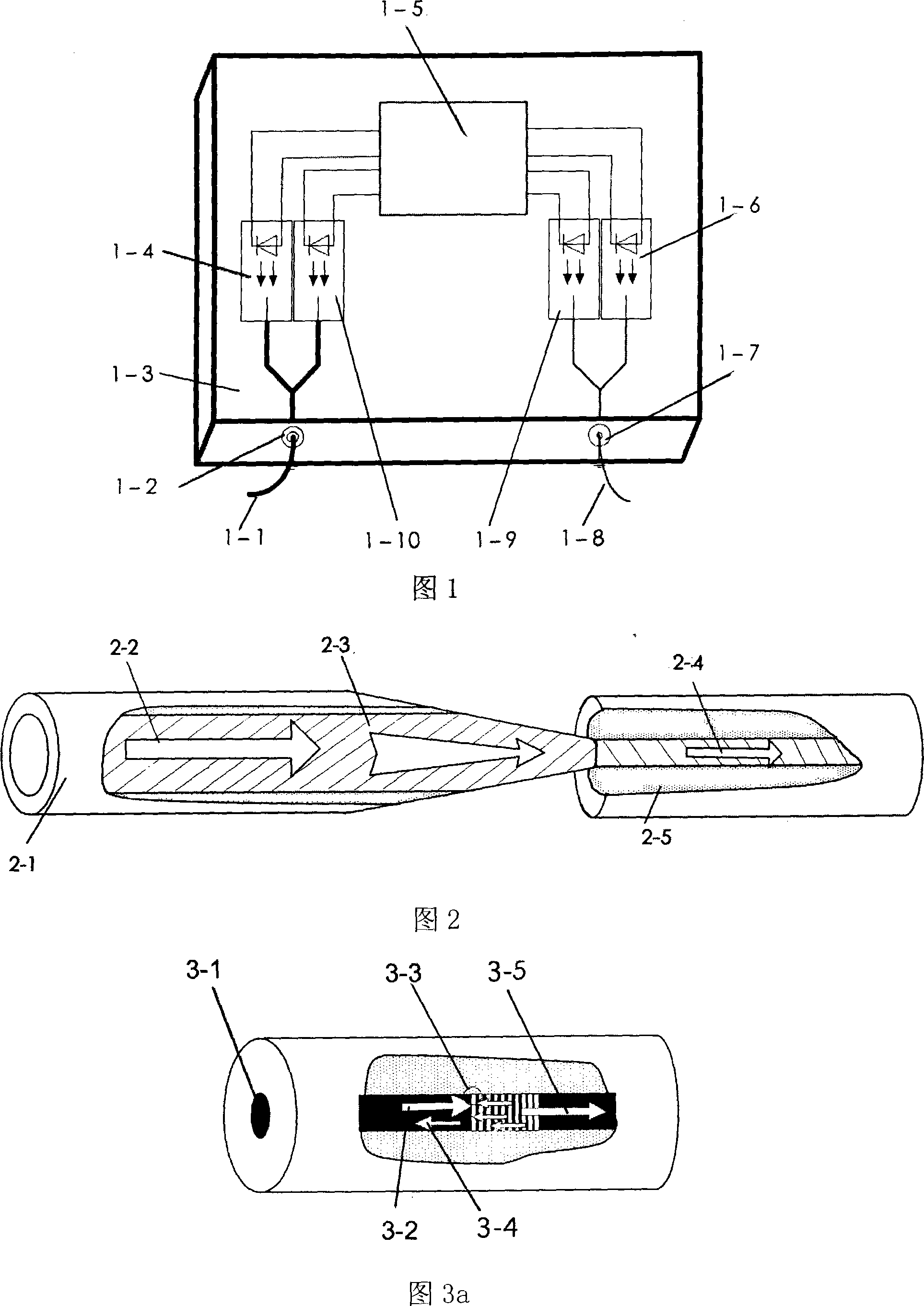

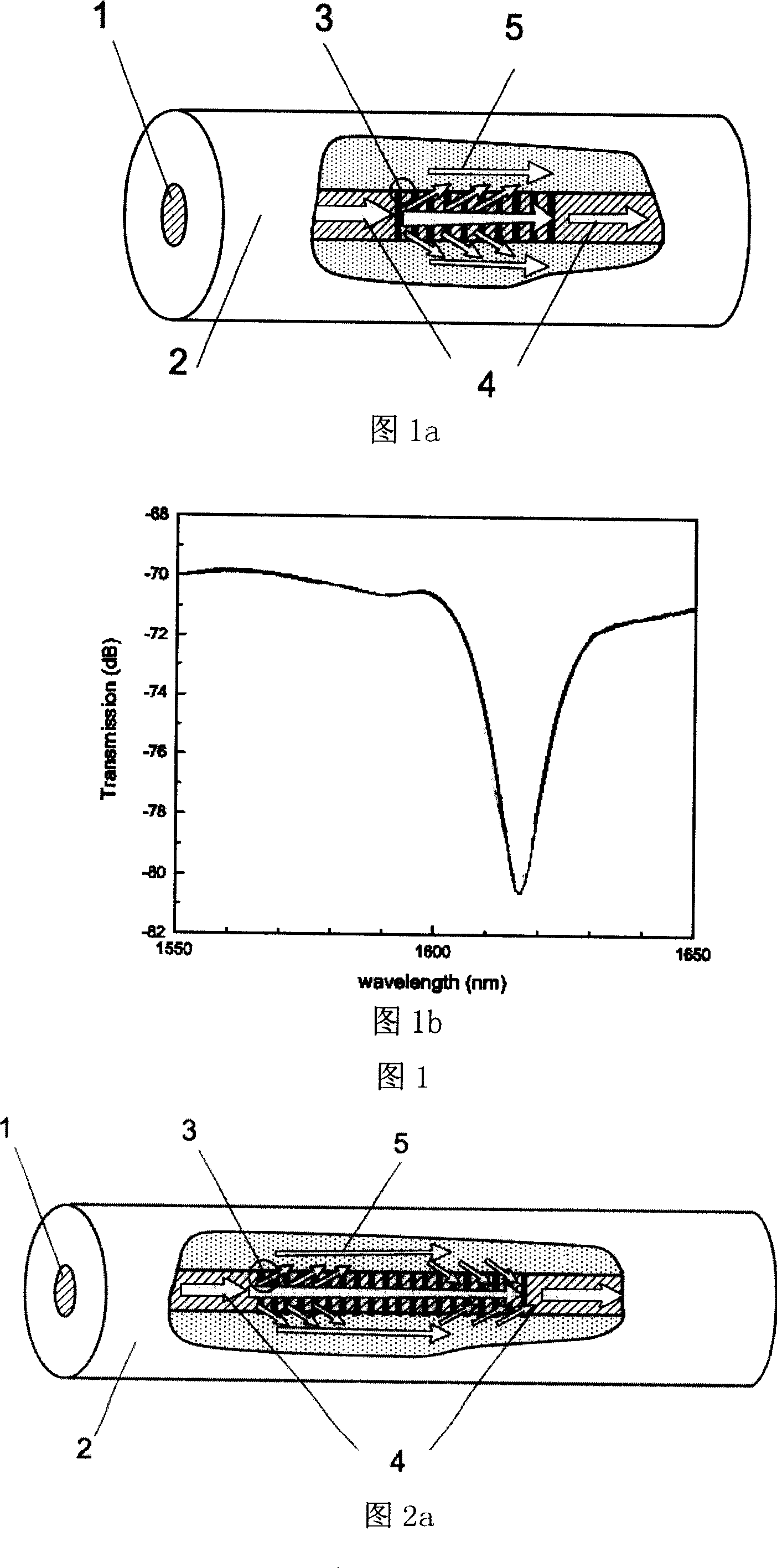

Multi-mode-single mode optical network full optical fiber interconnecting method and interconnector for realizing the same method

InactiveCN101022311AImplementing Bandpass FilteringLow Loss InterconnectMultimode transmissionLong-period fiber gratingGrating

A method for interconnecting all-optical fiber of multimode-singlemode optical network includes connecting normal multimode optical fiber with LPFG, preparing a core mould absorber with the same diameter as fiber core on LPFG long end surface fiber core at connector position for using it to block light transmission in multimode optical fiber to single-mode optical fiber core but not influencing light transmission in multimode optical fiber to single-mode optical fiber covering to from a band pass filter.

Owner:CHONGQING UNIV

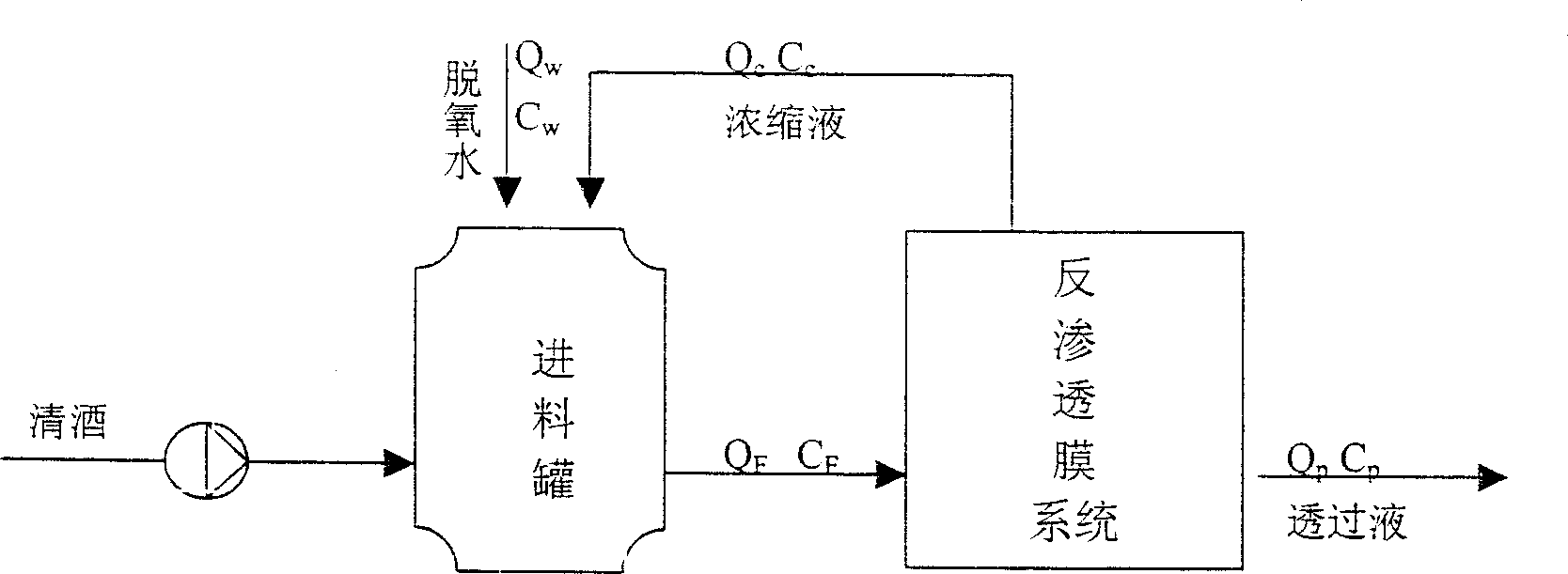

Method for reverse osmosis preparation of alcohol-free beer

ActiveCN1721520AStability is not affectedChange the production processAlcoholic beverage preparationFlavorAlcohol content

The present invention is reverse permeation process of producing alcohol-less beer, and relates to the application of reverse permeation technology in beer producing industry. Beer is pumped into reverse permeating unit, permeated liquid flow rate is controlled to equal to that of replenished deoxidized water, and concentrated liquid is returned into the feeding tank for circulated dealcoholization until alcohol content in beer lower than 0.5 vol%. The reverse permeation is controlled to have the reverse permeated liquid is 4-5 times the volume of the material liquid, the operation pressure of 1.8-2.5 MPa and the temperature of 4-12 deg.c. The reverse permeation process of producing alcohol-less beer can lower alcohol content by over 85 % and has no need of altering the available beer producing process, and the alcohol-less beer has the original flavor of beer maintained and delicious taste.

Owner:JIANGNAN UNIV

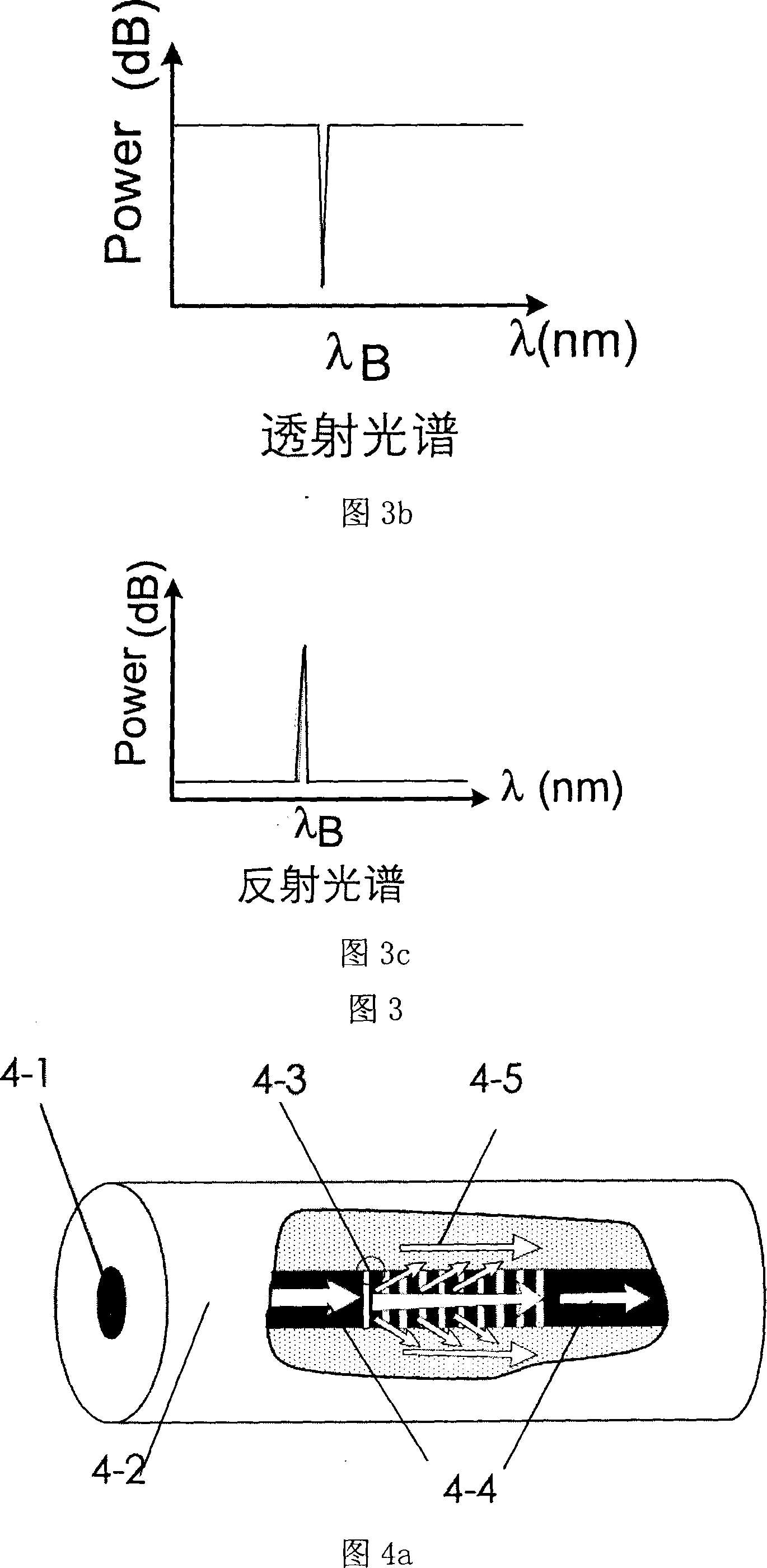

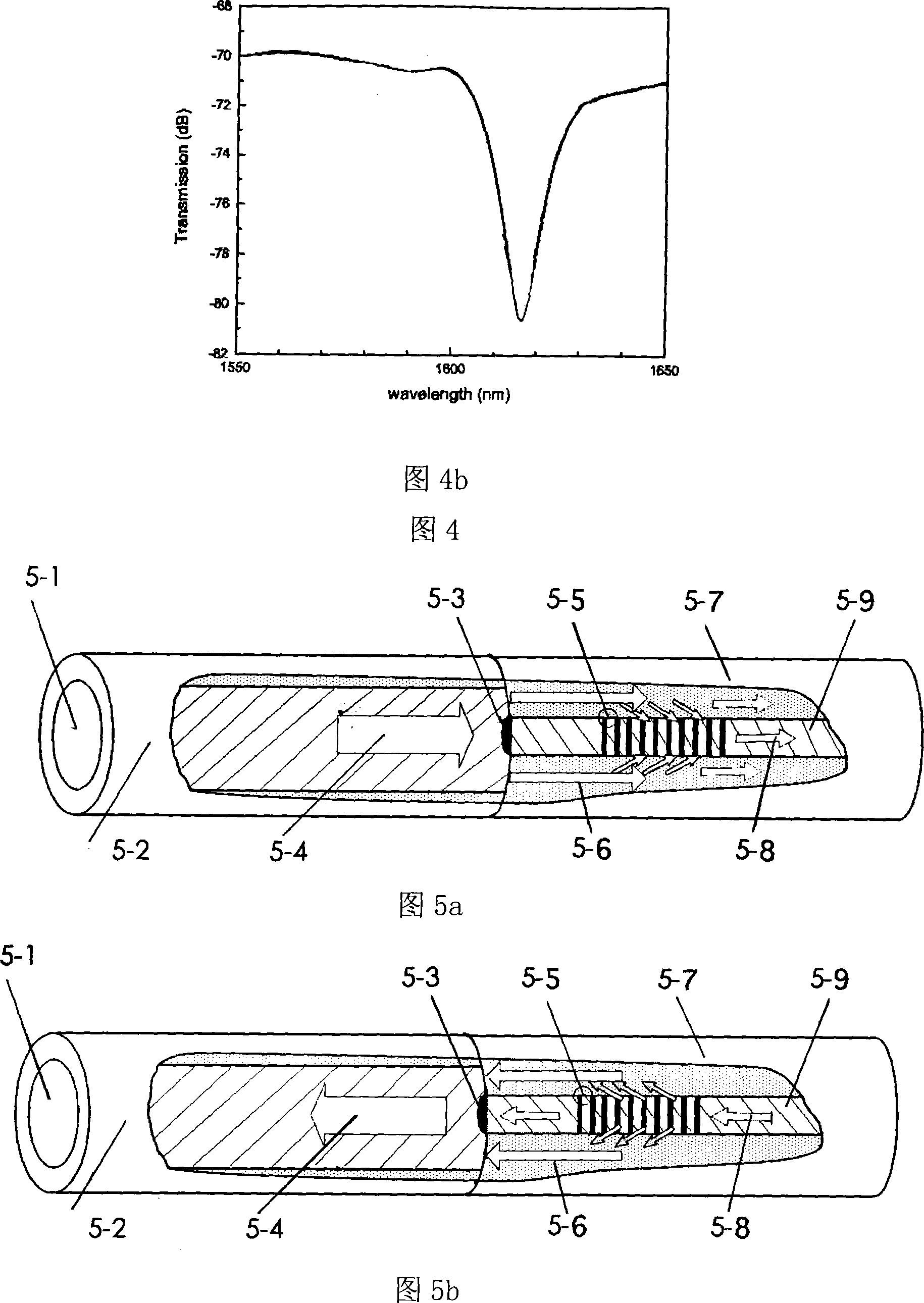

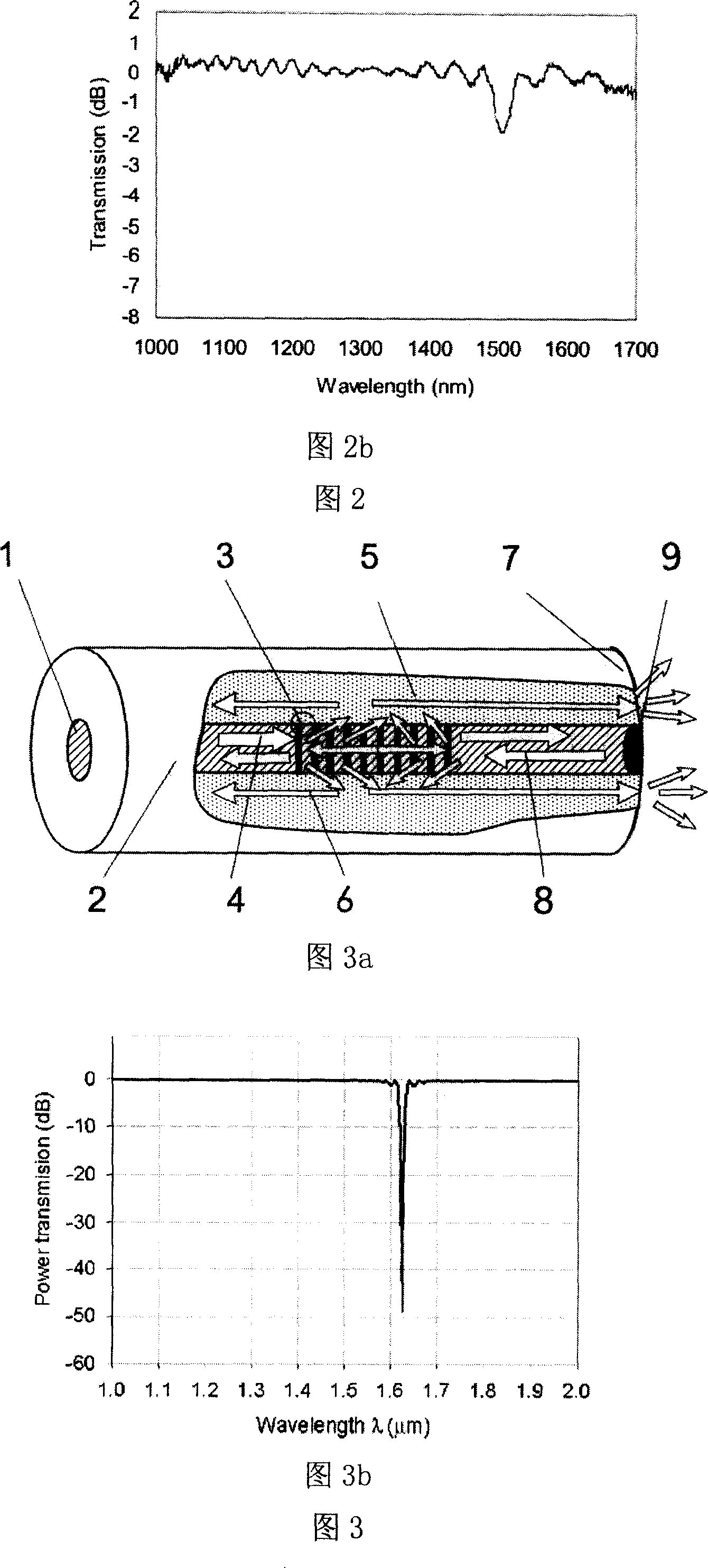

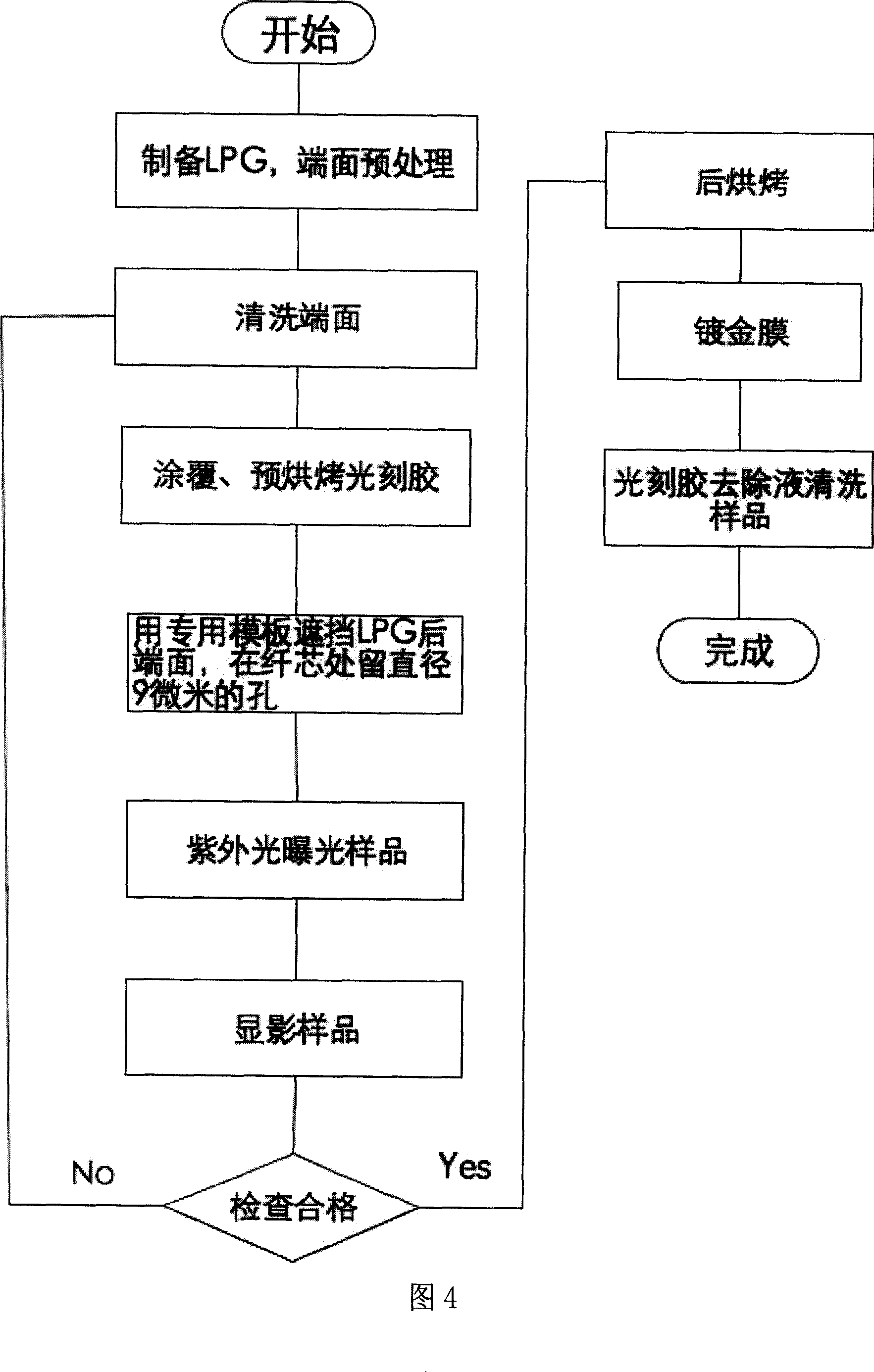

Method for raising intensity of long periodic optical-fibre grating and reducing tape width and optical-fibre grating

InactiveCN101000394ASave bandwidthHigh strengthCladded optical fibreCoupling light guidesPhase matchingFiber

A method for increasing LPFG intensity and decreasing bandwidth includes setting a core mode reflector at back end of LPFG, only reflecting fiber core fundamental mode but not reflecting the cladding mode by said reflector, reflecting fiber core fundamental mode light passed grating region back to let it pass the same grating region twice and to let light satisfied with phase matching condition be coupled to cladding layer twice for realizing purpose of increasing couple intensity by square means and making grating length be doubled i.e. decreasing bandwidth.

Owner:CHONGQING UNIV

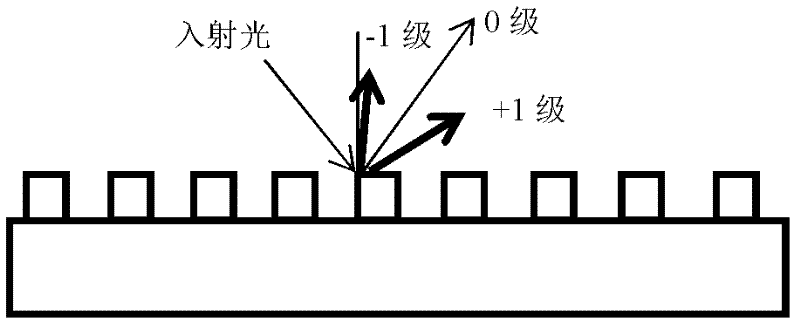

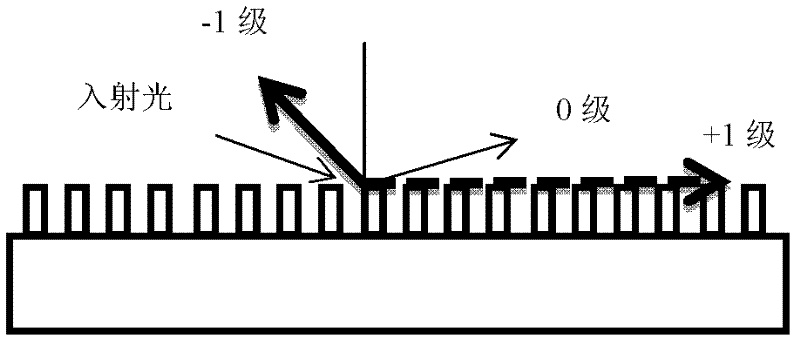

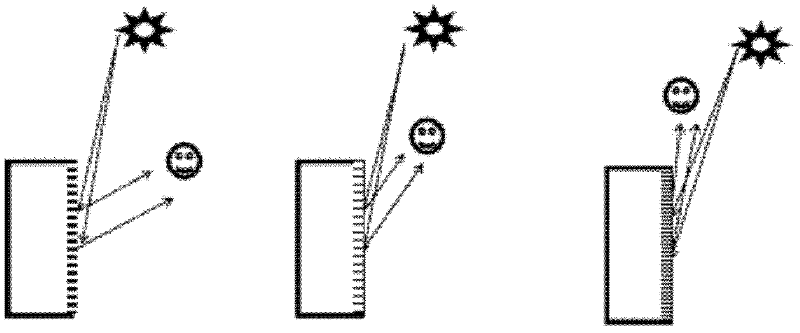

Safety paper with optical invisible watermarks

ActiveCN102418302AInvisibility effect is goodChange the production processNon-fibrous pulp additionGratingWavelength

The invention relates to safety paper with optical invisible watermarks. According to the safety paper, sub-wavelength gratings are adopted as pixels of a watermark image. Therefore, the image can only be observed in a special glancing angle when glancing lights incidence exists. According to the invention, reflective optical watermarks are realized, the production requirements of optical watermarks are improved, the difficulty of watermark image imitation is greatly increased, and the observability of the watermarks is simplified. The watermark can be observed under a common light source without an additional special tool. Therefore, the safety paper with the optical invisible watermark has a wide application field.

Owner:SUZHOU UNIV +1

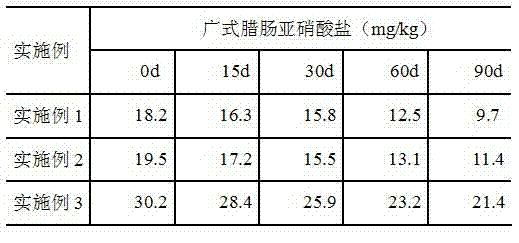

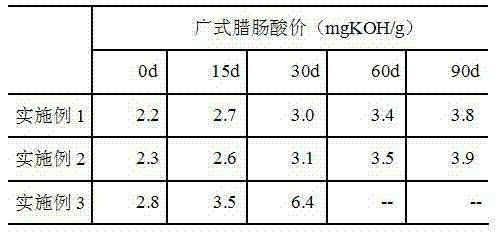

Preparation method of myrtle essential oil and application of myrtle essential oil in Guangdong sausage

InactiveCN102226131AIncrease acid valueSolve the technical problem of acid value exceeding the standardEssential-oils/perfumesMeat/fish preservation using chemicalsBiotechnologyEngineering

The invention relates to a preparation method of myrtle essential oil and application of the myrtle essential oil in Guangdong sausage. The preparation method of the myrtle essential oil comprises the following step: extracting at 30-50 DEG C for 1-2 hours while adding 1-2ml / g ethanol as an entrainer. The myrtle essential oil and TBHQ (tert-butylhydroquinone) are mixed and dissolved in ethanol, and the mixture can be added into Guangdong sausage, thereby obviously inhibiting the increase of the acid number of the Guangdong sausage in the storage process and reducing the residual quantity of nitrites in the Guangdong sausage.

Owner:SOUTH CHINA UNIV OF TECH

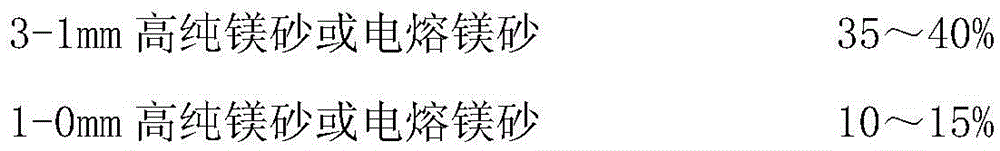

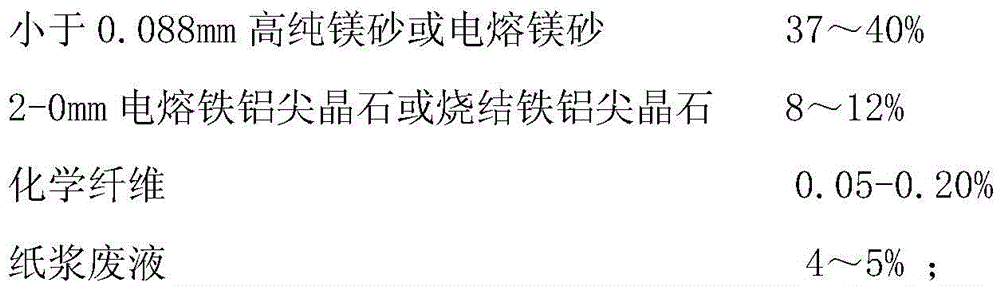

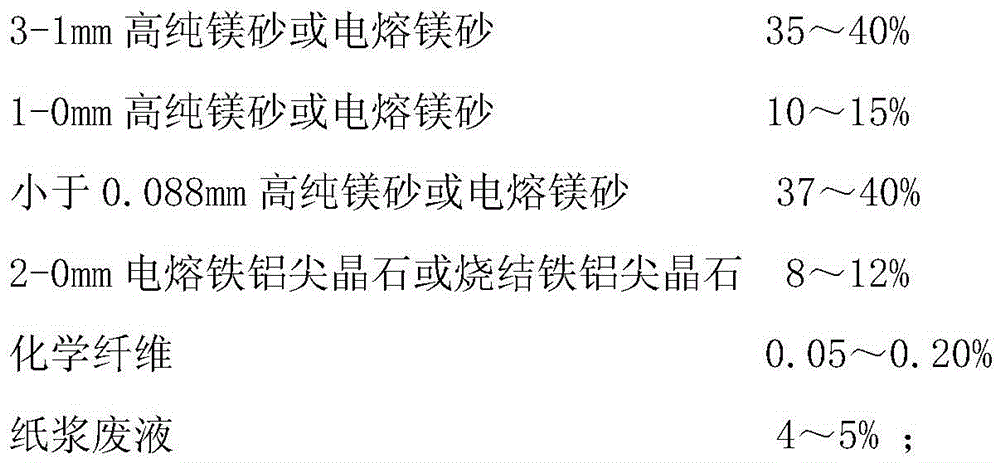

Low-heat-conductivity magnesia-hercynite brick used for cement rotary kiln and production method thereof

The invention discloses a low-heat-conductivity magnesia-hercynite brick used for a cement rotary kiln and a production method thereof. According to the invention, external temperature of a kiln body is reduced, and the effects of energy conservation and emission reduction are achieved. The magnesia-hercynite brick comprises the following components: high-purity magnesia or fused magnesia with a size of 3 to 1 mm, high-purity magnesia or fused magnesia with a size of 1 to 0 mm, high-purity magnesia or fused magnesia with a size of less than 0.088 mm, fused hercynite or sintered hercynite with a size of 2 to 0 mm, chemical fiber, and paper-pulp waste liquor with a concentration of 4 to 5%. The method comprises the following steps: material preparation, mixing and grinding, press molding into a green body, drying, and high-temperature sintering. According to the invention, uniform fiber micropores can be remained at a relative position in an internal structure of the magnesia-hercynite brick, so a gas-solid interface in the structure of a brick is increased; phonon dispersion of heat conduction of a solid phase is enlarged; heat conductivity of the brick is effectively reduced; and heat loss in a kiln is decreased.

Owner:UNIV OF SCI & TECH LIAONING

Brewed spice for cigarettes and application of spice to cigarette smoking quality improvement

InactiveCN105255591AHigh fullnessImprove finenessTobacco preparationEssential-oils/perfumesMicroorganismFlavor

The invention relates to brewed spice which is obtained by carrying out solid composite fermentation on sticky rice and a flavor substance raw material serving as raw materials by the utilization of microorganisms. The invention further relates to a preparing method for the brewed spice. The preparing method comprises the following steps that 1, the sticky rice is washed cleanly, and soaked in distilled water for 15-25 h, after being soaked, the sticky rice is drained off, and direct steam is adopted for stewing the sticky rice and the flavor substance raw material until the rice is well done; 2, after being stewed, the sticky rice and the flavor substance raw material are spread and aired, and when temperature falls to 30 DEG C-35 DEG C, the sticky rice and the flavor substance raw material are placed into a fermentation tank, inoculated with starter and yeast, stirred uniformly and saccharified; 3, distilled water is added into the saccharified material according to the volume ratio of 1:1-1:5, and the mixture is fermented to obtain composite fermentation liquor; 4, the composite fermentation liquor is treated to obtain the liquid stick rice and flavor substance raw material composite fermentation brewed spice. The brewed spice has functions of enhancing moistening sense of cigarette smoke, reducing irritation of the cigarette smoke, improving throat comfort of a user, increasing fragrance amount of the cigarettes and / or preserving moisture of cigarette shreds.

Owner:CHINA TOBACCO YUNNAN IND

Method for preparing ruthenium-containing corrosion resistant titanium alloy

A method for preparing ruthenium-containing corrosion-resistant titanium alloy relates to a method for adding the element ruthenium to the titanium ingot smelting, and is applied to the procedure of preparing titanium and titanium alloy in the fields, such as nuclear power, metallurgy, petrochemical engineering and the like. The method, which adopts the materials of sponge titanium and master alloy to press electrodes and the preparation method of vacuum arc smelting, is characterized in that the alloy composition ruthenium is added in the form of powder when the electrodes are pressed. All you need to do for realizing the new smelting process for preparing the ruthenium-containing titanium alloy without changing the original process for preparing the titanium and the titanium alloy is to add the ruthenium powder in a certain amount to the procedure of pressing the electrodes, and the prepared element ruthenium is evenly distributed without metallurgical defects, such as inclusion and the like. The invention has the remarkable advantages of convenient operation, low cost, precise and stable composition control and the like, solves the problem with the addition of the element ruthenium in smelting the titanium ingot and improves the corrosion resistance of the titanium material on the premise that the conventional performance of the prepared ruthenium-containing titanium alloy is not affected, therefore, the method can meet the requirements of the titanium material in the industrial field.

Owner:BAOJI TITANIUM IND CO LTD

Biological blood globulin wood adhesive

InactiveCN101412900AEasy to makeBroaden applicationProtein adhesivesStarch adhesivesSolid woodHuman body

The invention discloses a biological corpuscle protein wood adhesive, relates to a wood adhesive, and solves the problems that the prior synthesized resin adhesive releases formaldehyde, pollutes environment and harms human body. The biological corpuscle protein wood adhesive is biological corpuscle protein powder. The biological corpuscle protein wood adhesive consists of the biological corpuscle protein powder and a reinforcing agent. The biological corpuscle protein wood adhesive has the advantages that the biological corpuscle protein wood adhesive does not pollute the environment and has no harm to the human body, does not change production processes and parameters of the prior artificial boards after the adhesive is applied to adhering core boards, three-layer base materials of solid wood composite floors and multilayer floor base materials, and is easy to coat. Adhesive layers are even, and release amount of the formaldehyde is 0 to 0.4 milligram per liter.

Owner:黑龙江省木材科学研究所

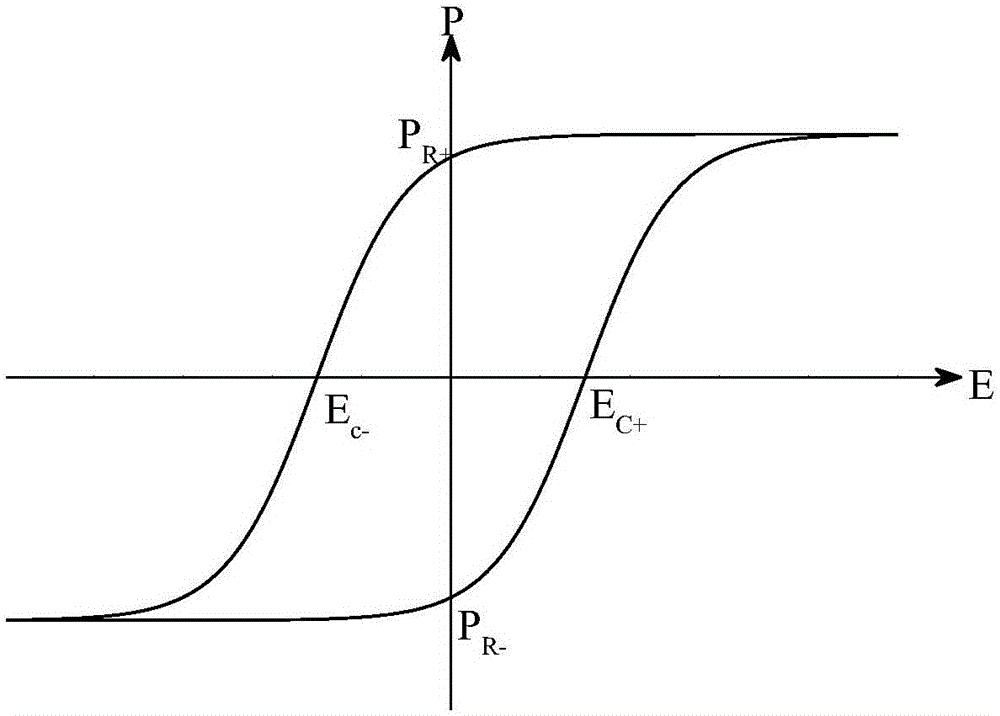

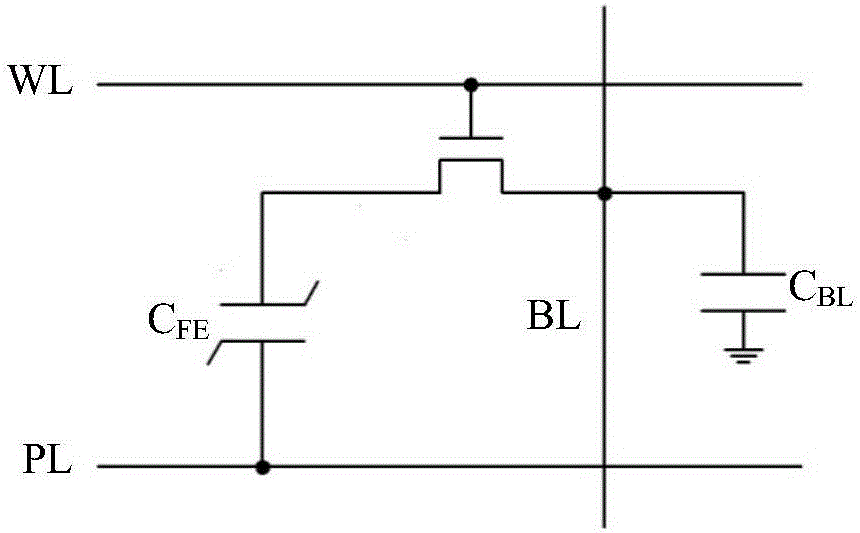

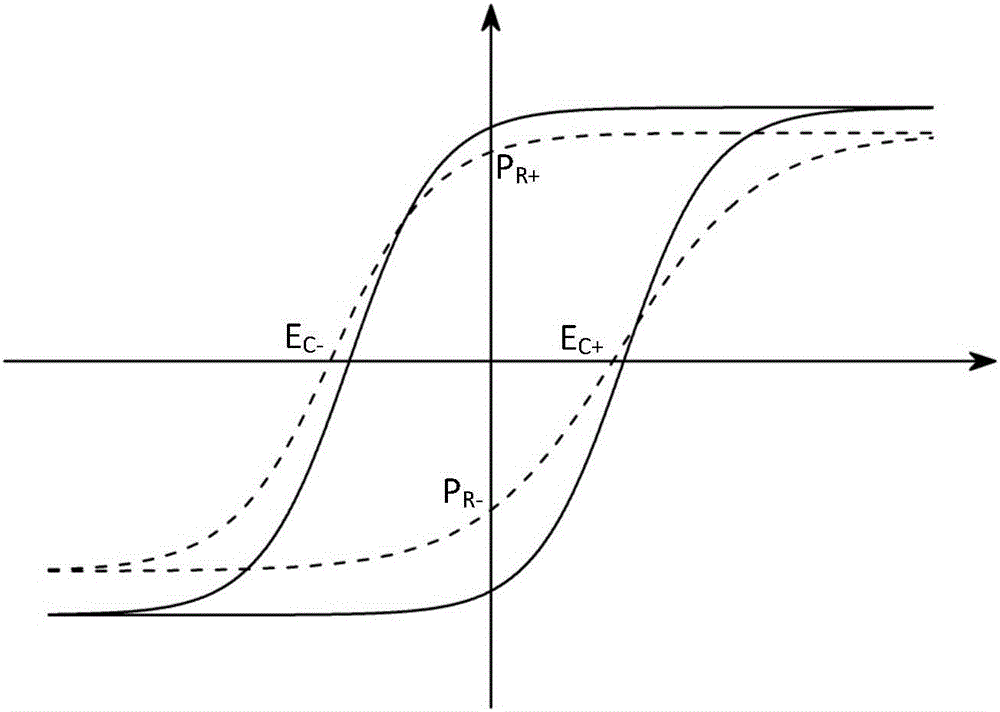

Strengthening method for resisting against single event upset of ferroelectric memory

ActiveCN106847330ADo not change the layoutChange the production processDigital storageRe engineeringSingle event upset

The invention provides a strengthening method for resisting against single event upset of ferroelectric memory. The method comprises the following steps: selecting sample chips and grouping according to irradiation dose; comparing a radiation sample with a non-radiated sample and removing the sample chips with seriously degraded performances; performing a single event upset test on the acquired sample chips with normal performances on a heavy ion accelerator; taking the non-radiated same-batch sample chips as control groups; testing under a same experimental environment; acquiring the single event upset sections of the sample chips under different accumulated dosages; analyzing section data in e, thereby acquiring an optimal accumulated dosage meeting the strengthening requirement; and taking the optimal accumulated dosage as a standard dosage for resisting against single event upset and reinforcing of the ferroelectric memory. The invention relates to an external reinforcing method; the layout and production process of the chips are not changed and the packaging size and the working sequence of the chips are not changed, so that the reinforced chips can be directly used for replacing the unreinforced chips; and the circuit does not need to be redesigned.

Owner:NORTHWEST INST OF NUCLEAR TECH

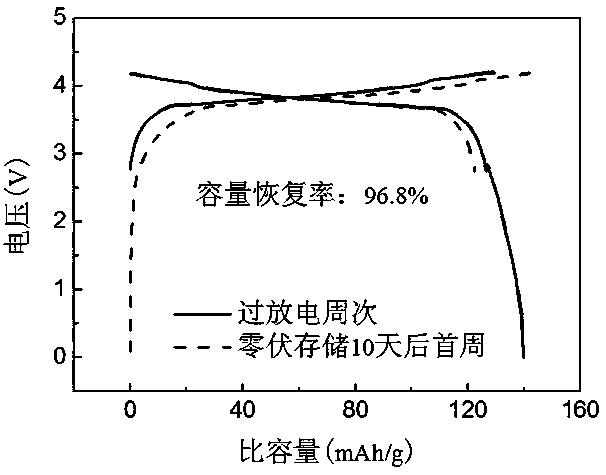

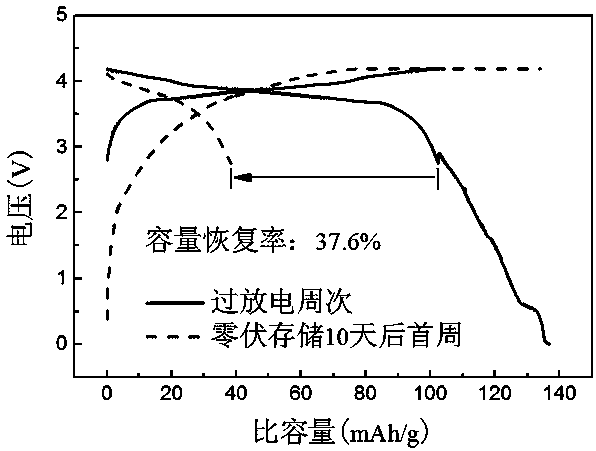

Lithium ion battery with excellent zero volt storage performance

ActiveCN108717977ANo reduction in specific energyChange the production processCell electrodesFinal product manufactureAdhesivePhysical chemistry

The invention discloses a lithium ion battery with excellent zero volt storage performance. The lithium ion battery comprises a shell and a positive pole, a negative pole, a diaphragm and electrolyteinside the shell, wherein the positive pole comprises a positive active material, a positive additive, a conductive agent, an adhesive and a positive current collector; the positive additive is LixMOyor a mixture thereof, wherein x is greater than or equal to 3, y is greater than or equal to 3, and M is any one of Fe, Co, Mo, Ir, Mn, Zn, Pt, Sb, Te, Ti, V, Nb, B, Si, Ge, Sn, Al, Ga and P; the electrolyte comprises an electrolyte lithium salt, an electrolyte solvent and an electrolyte additive; the electrolyte lithium salt is lithium difluoroborate (LiODFB) or a mixed lithium salt of the LiODFB and other lithium salts; and the electrolyte additive is a nitrile compound. The lithium ion battery disclosed by the invention follows a conventional production process for manufacturing, gives consideration to long-time stability of both a negative solid / electrolyte interfacial film and a negative copper current collector at a high level so as to have excellent zero volt storage performance.

Owner:HARBIN INST OF TECH

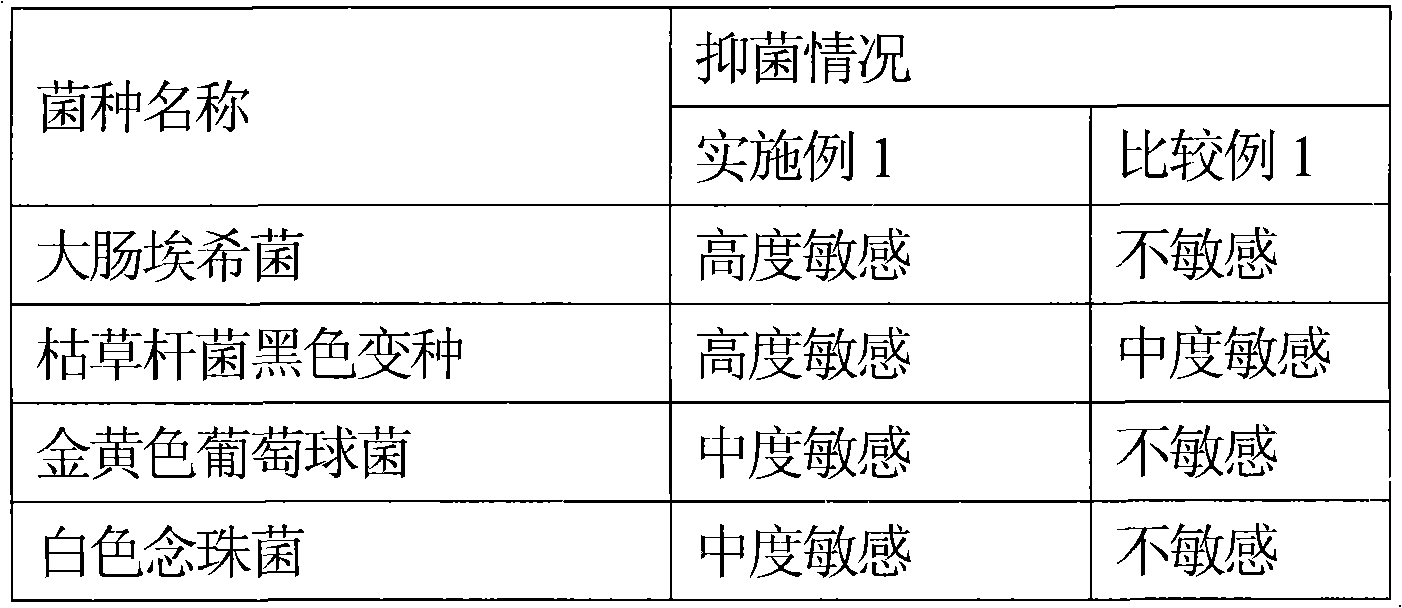

Biological antibiosis agent and biological antibiosis paper, prepn. method and application thereof

InactiveCN1692737AChange the production processNo stimulationBiocidePaper/cardboardMicroorganismAntibiosis

A biologic antibacterial agent for effectively suppresing bacteria, viruses and microbes is proportionally prepared from polyaminopolyose, cationic polyacrylamide, TiO2, zinc oxide, Cu ions, I ions and hinokitol. A biologic antibacterial paper is prepared from said biologic antibacterial agent and paper, and can be used as packing paper, antistaling paper, wall paper, etc.

Owner:华子昂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com