Nano-composite emulsion product and preparation method thereof

A latex product and nano-composite technology, applied in the rubber field, can solve problems affecting product performance, etc., and achieve the effects of simple composition, enhanced tear strength and anti-aging ability, and strong antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

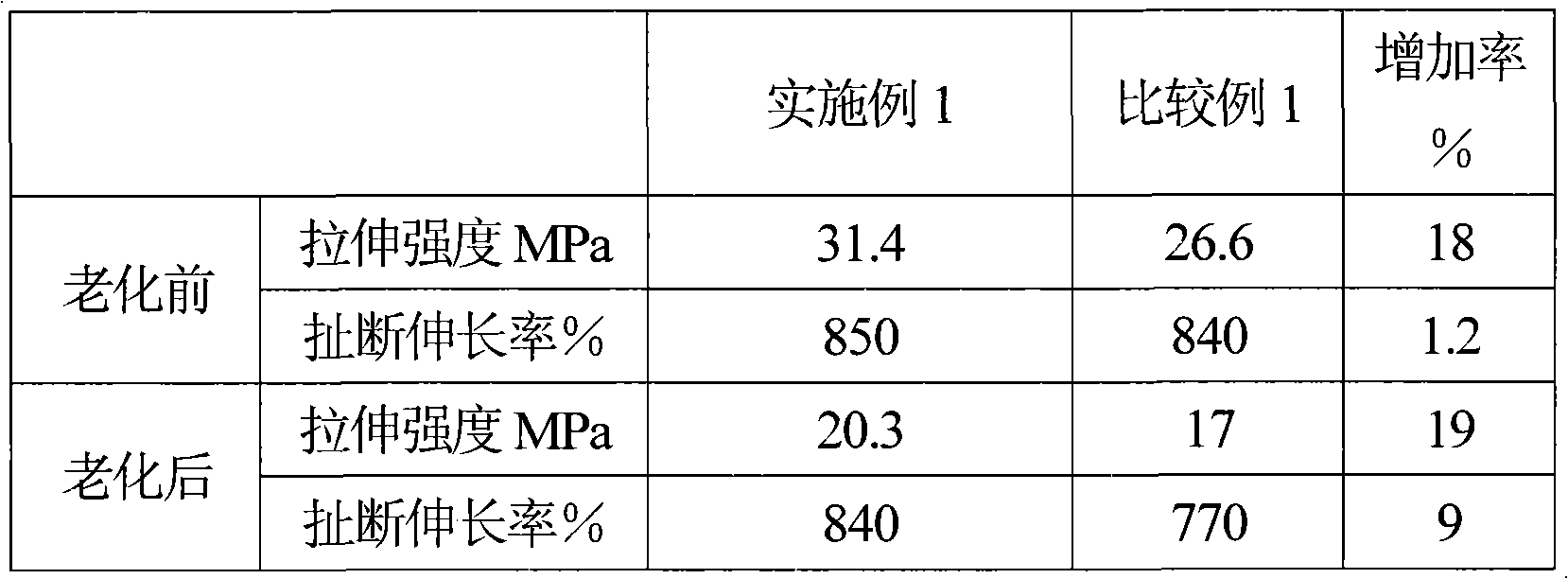

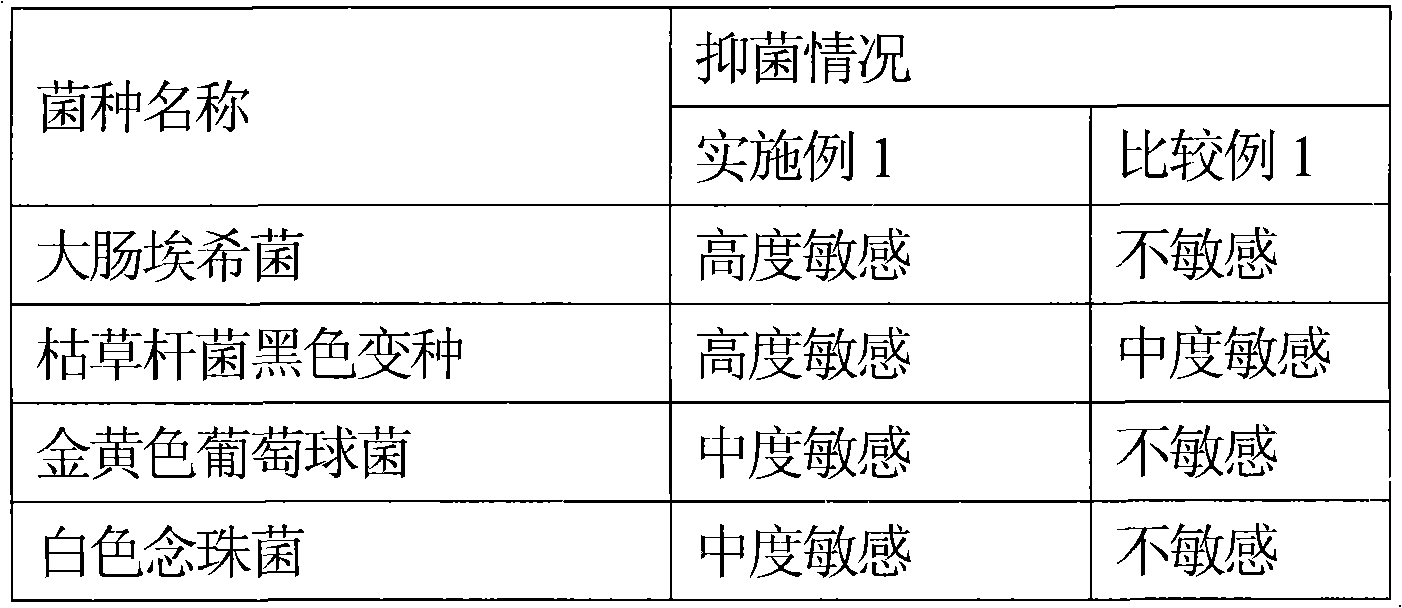

Embodiment 1

[0039] Replace all the zinc oxide in comparative example 1 with the concentrated nano-zinc oxide slurry, that is, the concentrated nano-zinc oxide slurry (effective content is 65%) accounts for 0.77% of the total formula. Its specific composition and preparation process are as follows:

[0040] Nano-composite latex products are calculated as a percentage based on the total weight of the following materials, including:

[0041] (a) Natural latex 40%

[0042] (b) Additives 3.3% (Methylcellulose 0.3%, PX 1.0%, MB 2.0%)

[0043] (c) Nano zinc oxide concentrated slurry 0.77%

[0044] (d) Water 55.93%

[0045] The auxiliary agent (b) mentioned therein includes a mixture of several or more stabilizers, accelerators, anti-aging agents and the like. The used stabilizers, accelerators, anti-aging agents, etc. are conventional auxiliary agents for preparing latex products; in this embodiment, the stabilizer is methyl cellulose, the accelerator is PX, and the anti-aging agent is MB. ...

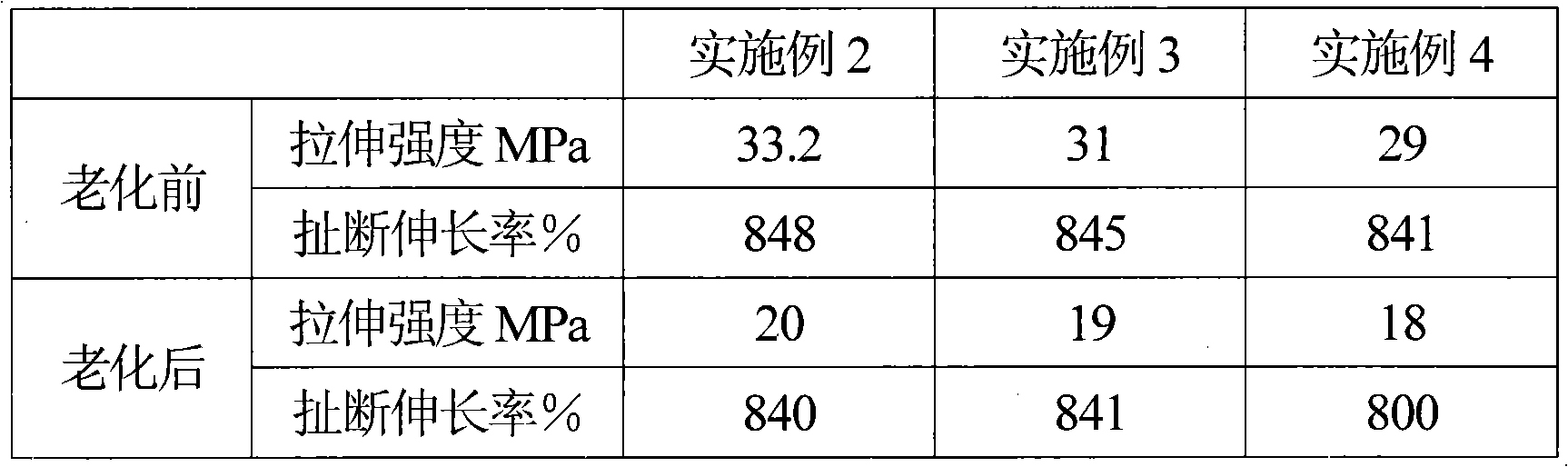

Embodiment 2

[0058] The specific composition and preparation process of nanocomposite latex products are as follows:

[0059] Nano-composite latex products are calculated as a percentage based on the total weight of the following materials, including:

[0060] (a) Natural latex 35.5%

[0061] (b) Auxiliary ingredients 3.3%

[0062] (c) Nano zinc oxide concentrated slurry 1%

[0063] (d) Water 60.2%

[0064] The auxiliary agent (b) mentioned therein includes a mixture of several or more stabilizers, accelerators, anti-aging agents and the like. The used stabilizer, accelerator, anti-aging agent, etc. are conventional auxiliary agents for preparing latex products; in the present embodiment, the stabilizer is gum arabic, and the addition is 0.2%; the accelerator is zinc dimethyl dithiocarbamate (PZ), the addition amount is 1.5%; the anti-aging agent is 2,2'-methylene-bis(4-methyl-6-tert-butylphenol), the addition amount is 1.6%.

[0065] Wherein, the formula of described nano concentrate...

Embodiment 3

[0070] The specific composition and preparation process of nanocomposite latex products are as follows:

[0071] Nano-composite latex products are calculated as a percentage based on the total weight of the following materials, including:

[0072] (a) Natural latex 35.5%

[0073] (b) Auxiliary ingredients 3.3%

[0074] (c) Nano zinc oxide concentrated slurry 0.2%

[0075] (d) Water 61%

[0076] The auxiliary agent (b) mentioned therein includes a mixture of several or more stabilizers, accelerators, anti-aging agents and the like. The used stabilizer, accelerator, anti-aging agent, etc. are conventional auxiliary agents for preparing latex products; in this embodiment, the stabilizing agent, accelerator, and anti-aging agent are the same as in Example 2.

[0077] Wherein, the formula of described nano concentrated slurry is identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com