Method for reverse osmosis preparation of alcohol-free beer

A non-alcoholic beer and reverse osmosis technology, which is used in the preparation of alcoholic beverages, can solve the problems of traffic accidents endangering life and safety, and achieve the effects of full-bodied wine, convenient operation, potential economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

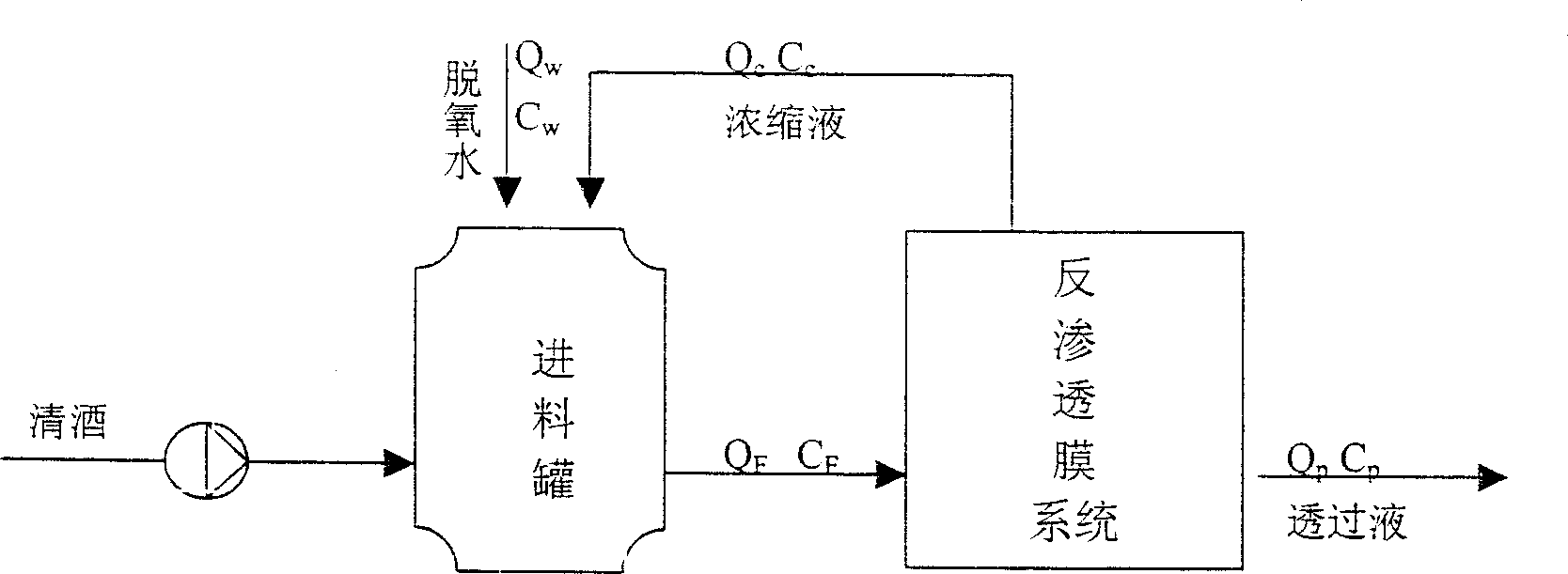

[0038]The pilot test of producing alcohol-free beer by reverse osmosis was carried out according to the process shown in the accompanying drawing. Put 100L sake in the feed tank, pump it into the reverse osmosis membrane system for dealcoholization by a high-pressure pump, control the flow rate of additional deoxygenated water to be equal to the flow rate of the permeate, and the concentrated liquid still flows back to the feed tank for circular dealcoholization , until the alcohol content is lower than 0.5% (v / v). The operating pressure is 1.8-2.5Mpa, the operating temperature is 4-12°C, and the reverse osmosis is permeated for 16 minutes first (both the permeate and the concentrate flow back into the feed tank) to stabilize the permeability of the membrane. The indexes of original wine and non-alcoholic beer obtained after dealcoholization were analyzed and compared.

[0039] 1. Analysis of physical and chemical indicators and sensory evaluation of wine before and after dea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com