Patents

Literature

186results about How to "Change the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid cement grinding aid

InactiveCN101318792AEasy to measureChange the production processSodium phosphatesTriterpenoid saponin

The invention relates to a liquid cement grinding aid which can obviously reduce the dosage of trolamine and does not contain urea. The grinding aid comprises the following compositions in weight percentage: 1 to 10 percent of trolamine, 5 to 10 percent of diglycol, 1 to 10 percent of trimeric sodium phosphate, 10 to 30 percent of molasses, 0 to 20 percent of sodium thiosulfate, 0 to 10 percent of air entraining component and the balance being water, wherein the air entraining compositions are triterpenoid saponin air entraining agent, sodium lignin sulfonate or a mixture of the triterpenoid saponin air entraining agent and the sodium lignin sulfonate at any proportion. The invention obviously reduces the dosage of the trolamine, does not contain the urea, lowers product cost and simultaneously facilitates the environmental protection. The sodium thiosulfate has the function of exciting mixed materials of cement and can improve the initial strength and the later strength of the cement, thereby effectively improving the service performance of the cement grinding aid. The triterpenoid saponin air entraining agent and the sodium lignin sulfonate have the action of the auxiliary aided grinding and simultaneously properly entrain air to reduce the water consumption of the cement standard consistence.

Owner:NANJING YONGNENG MATERIALS

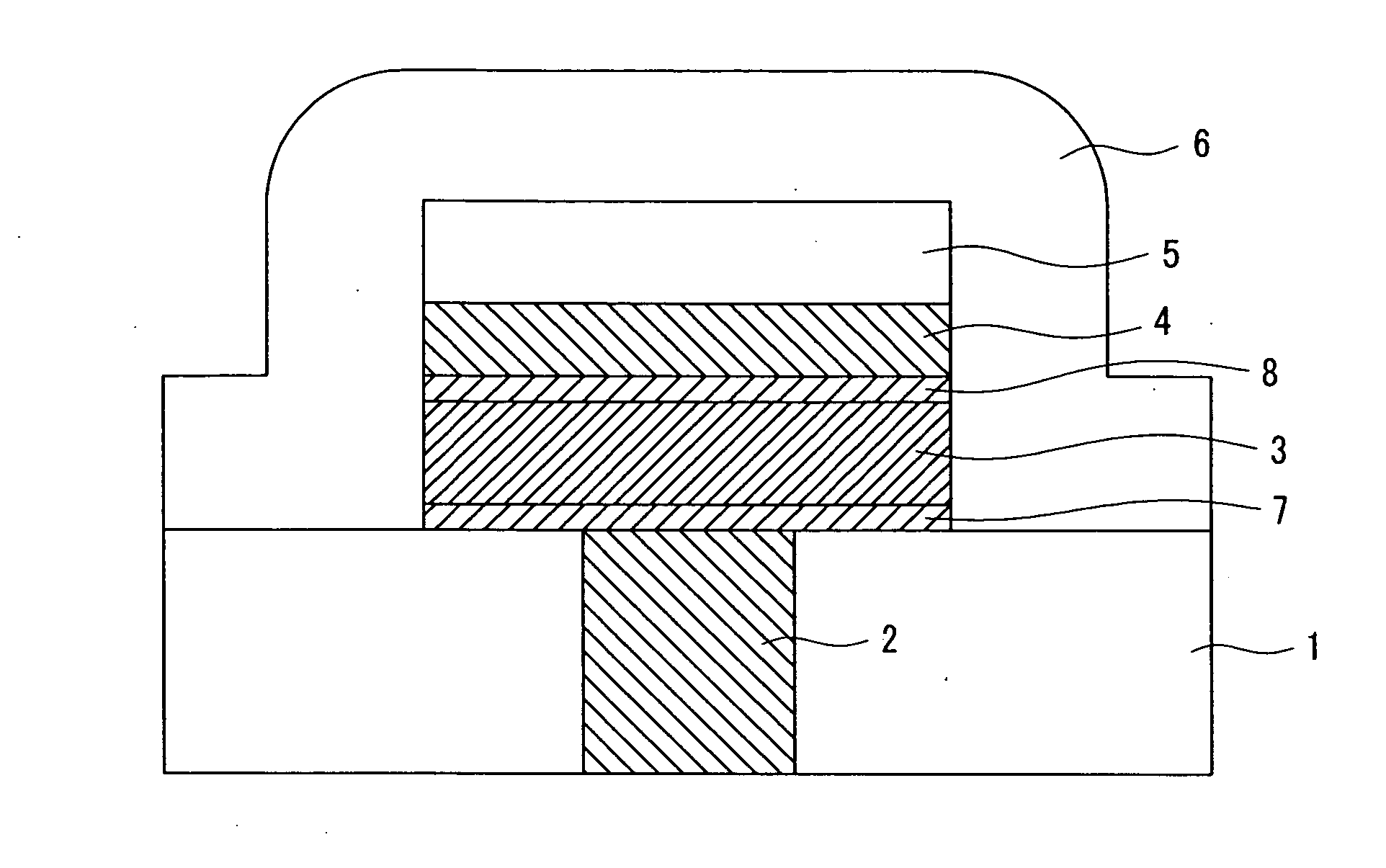

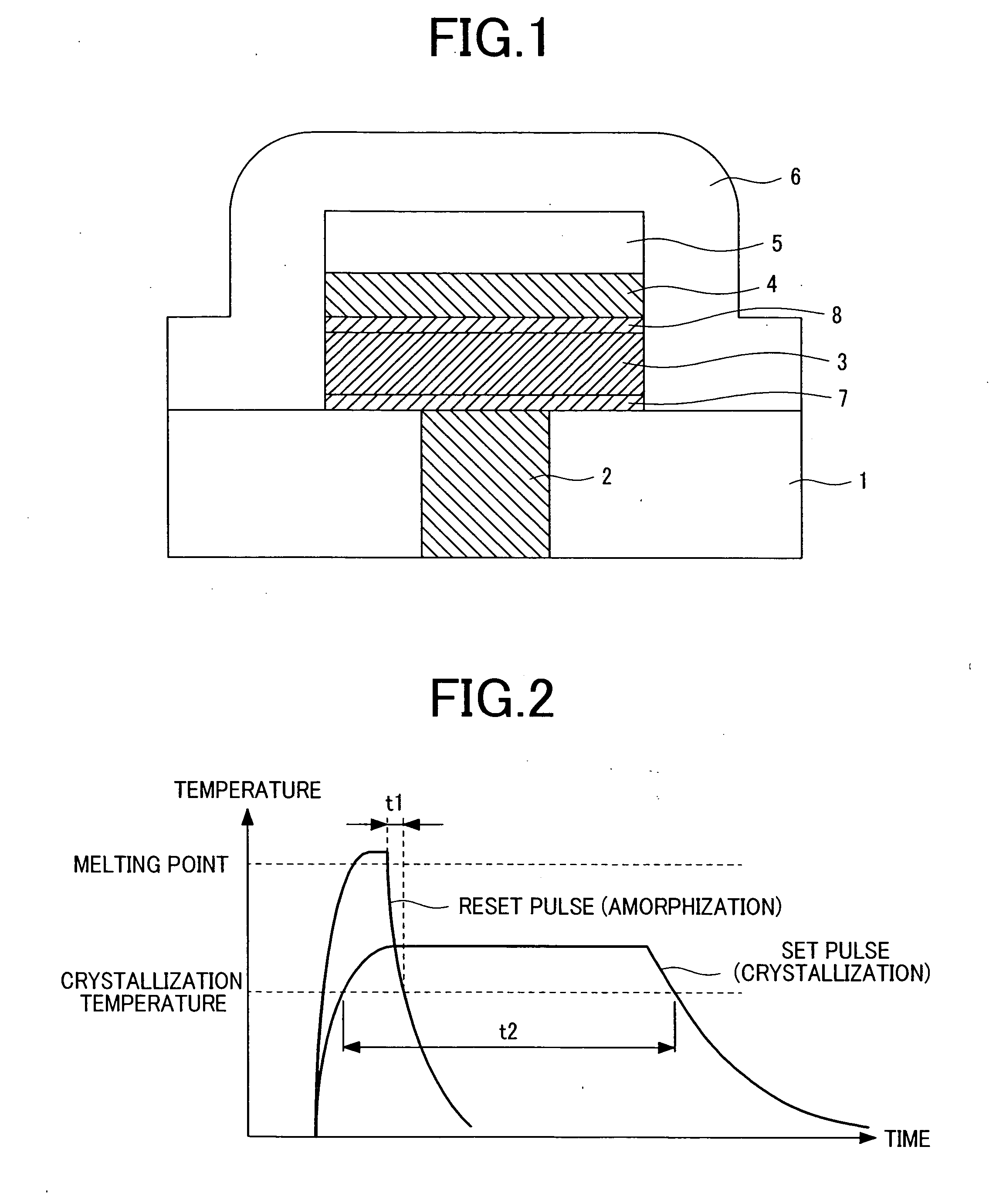

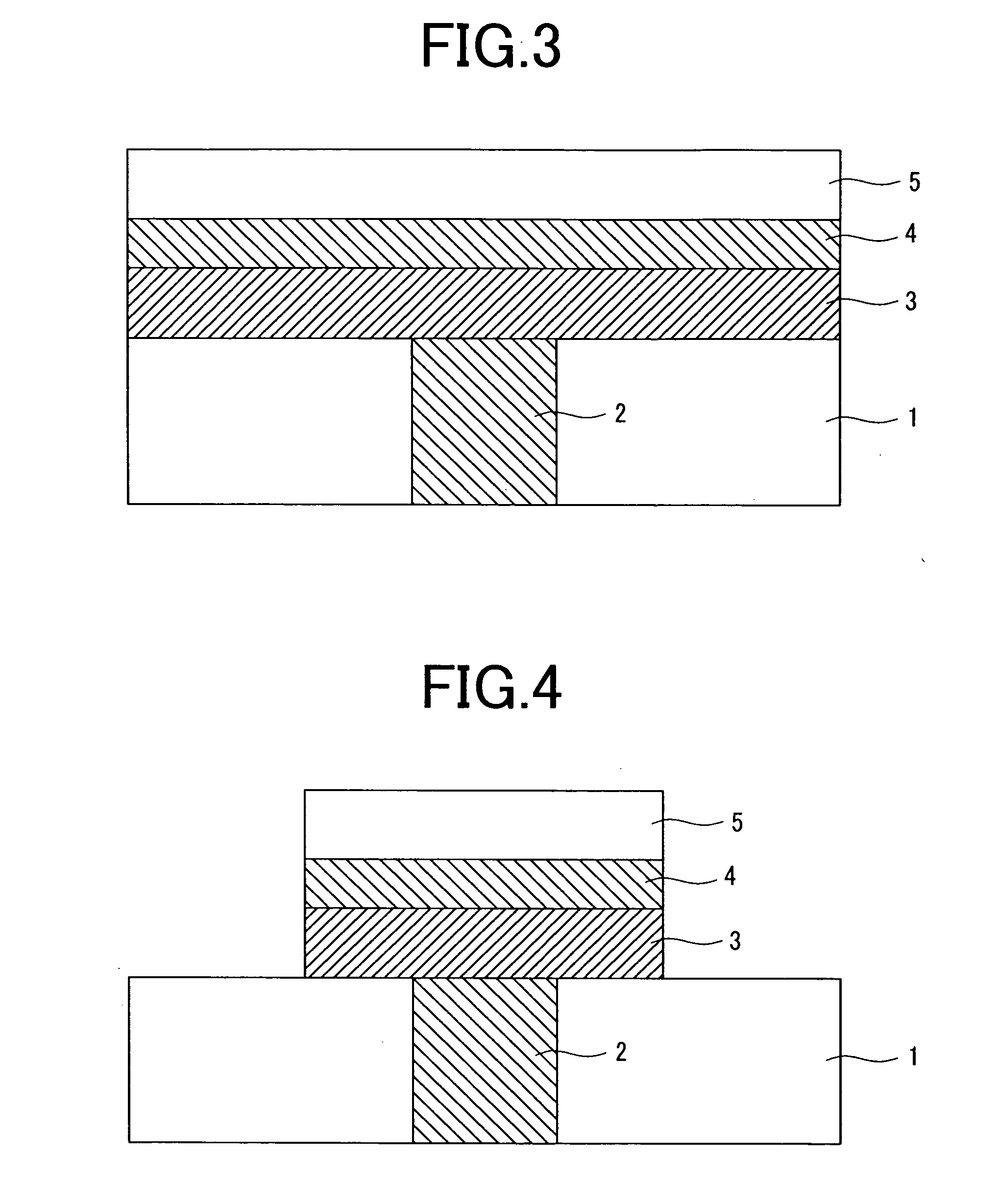

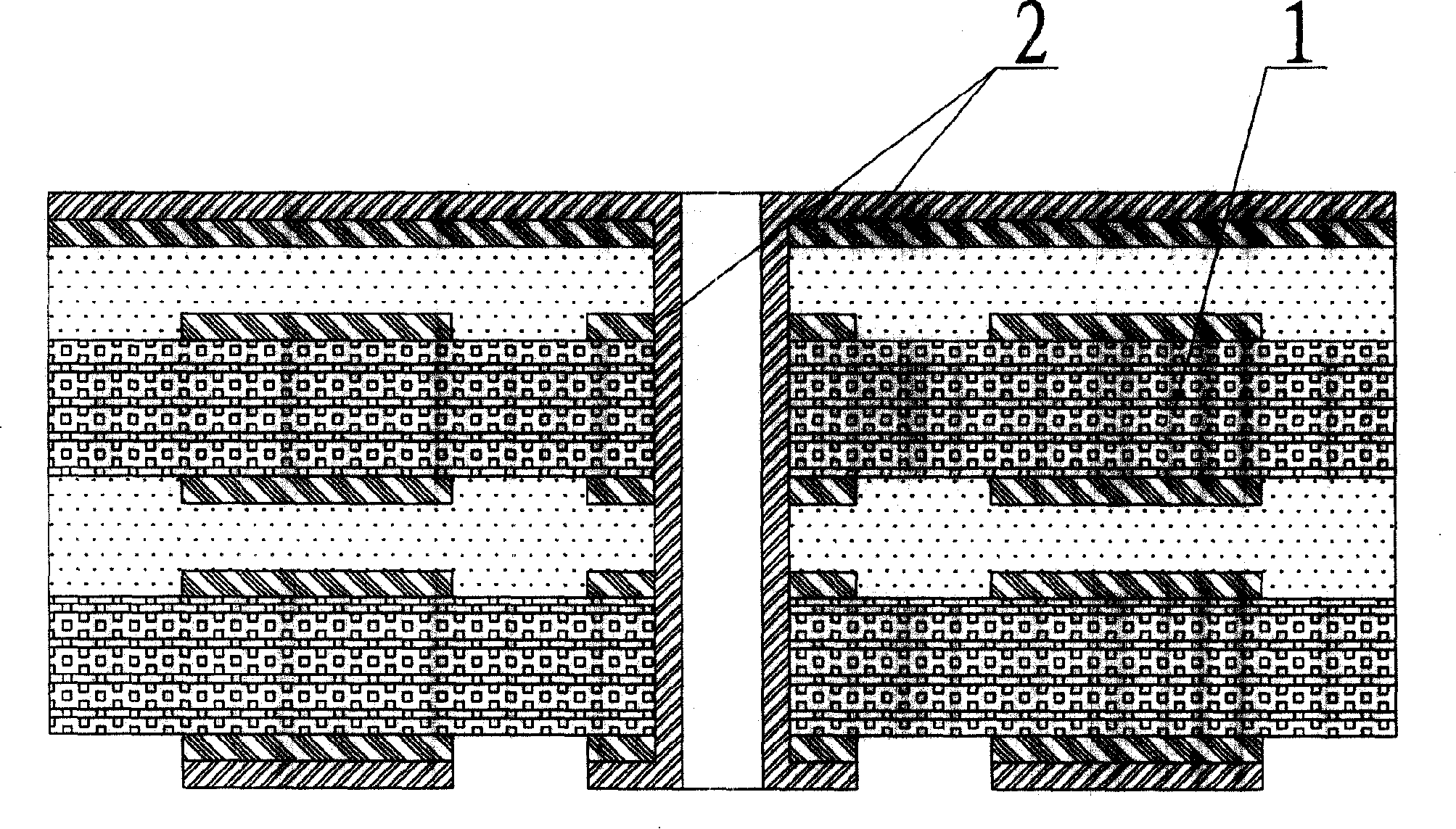

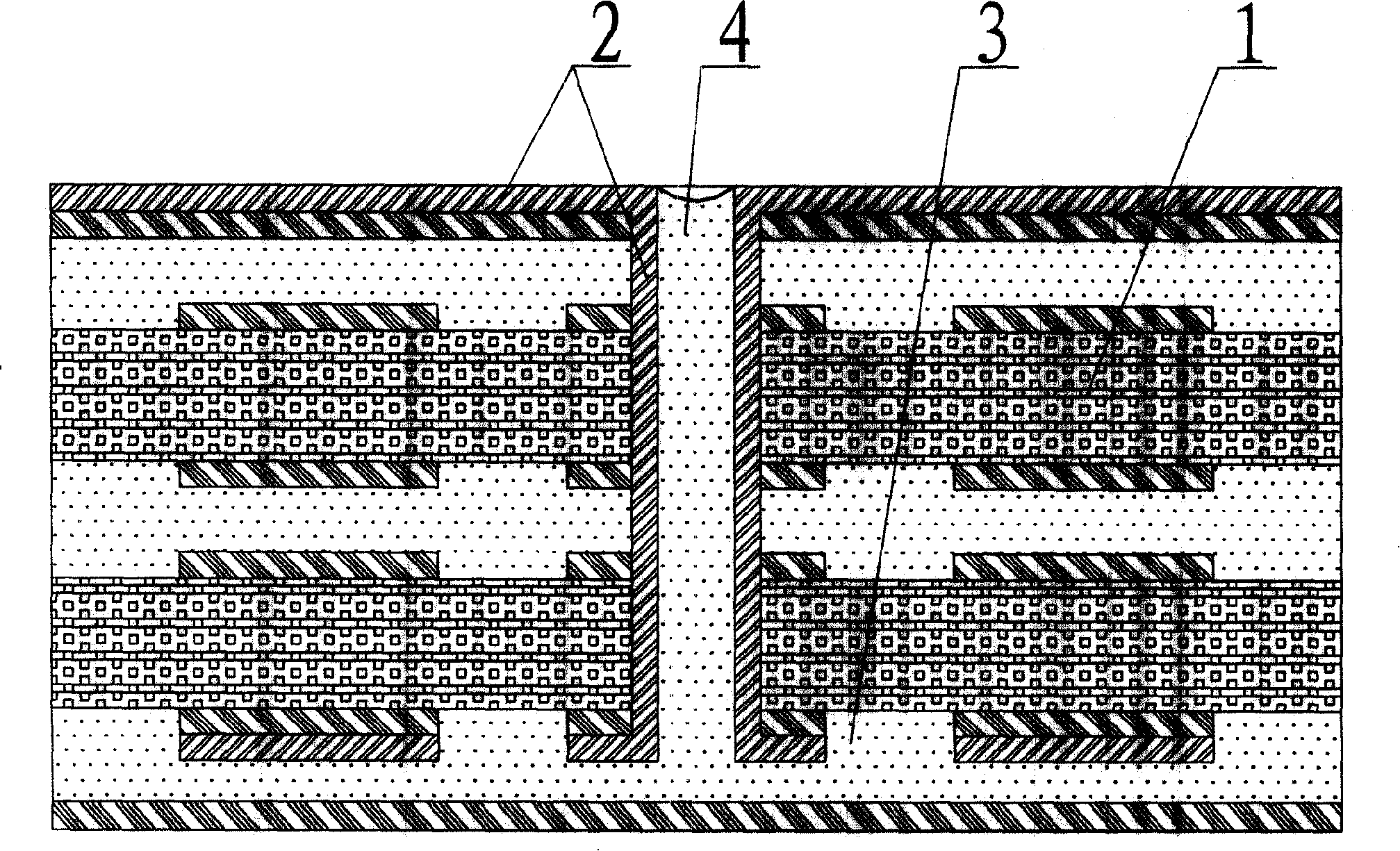

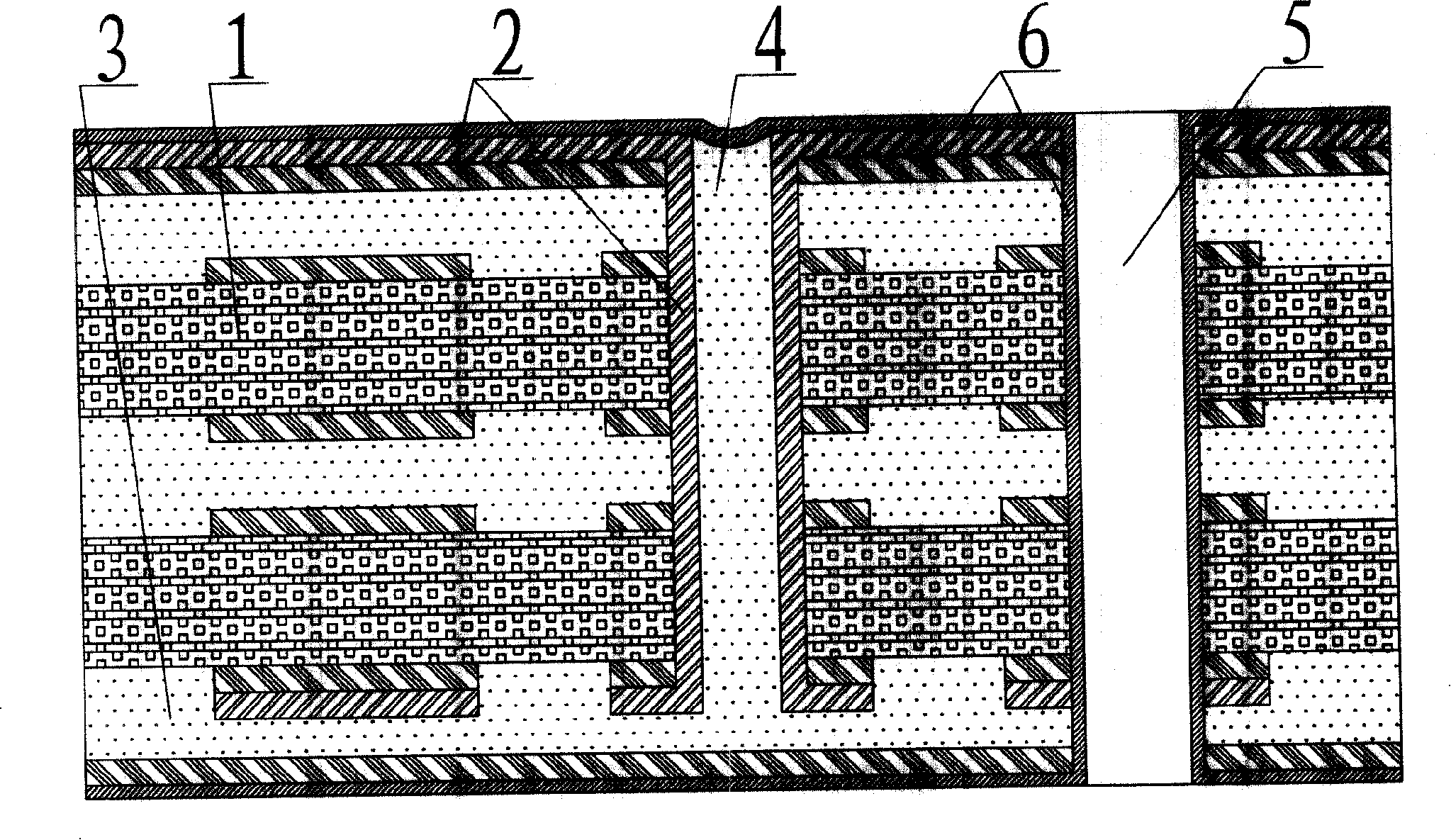

Semiconductor memory

InactiveUS20070170413A1Avoid layeringAvoid sublimationSolid-state devicesBulk negative resistance effect devicesPhase-change memoryManufacturing technology

Manufacturing processes for phase change memory have suffered from the problem of chalcogenide material being susceptible to delamination, since this material exhibits low adhesion to high melting point metals and silicon oxide films. Furthermore, chalcogenide material has low thermal stability and hence tends to sublime during the manufacturing process of phase change memory. According to the present invention, conductive or insulative adhesive layers are formed over and under the chalcogenide material layer to enhance its delamination strength. Further, a protective film made up of a nitride film is formed on the sidewalls of the chalcogenide material layer to prevent sublimation of the chalcogenide material layer.

Owner:RENESAS ELECTRONICS CORP

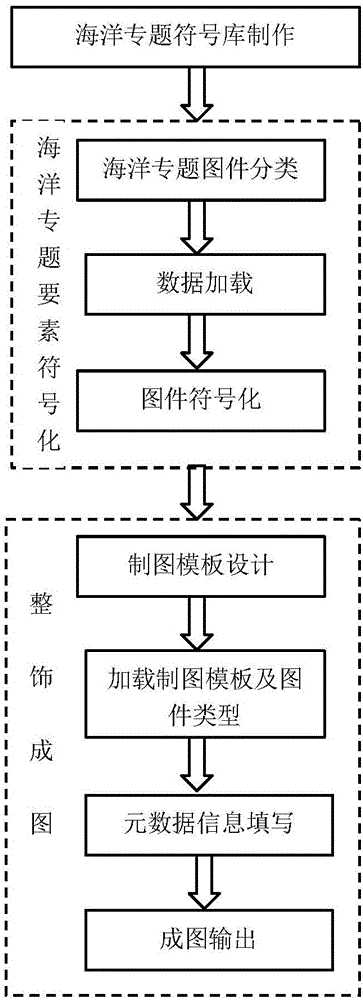

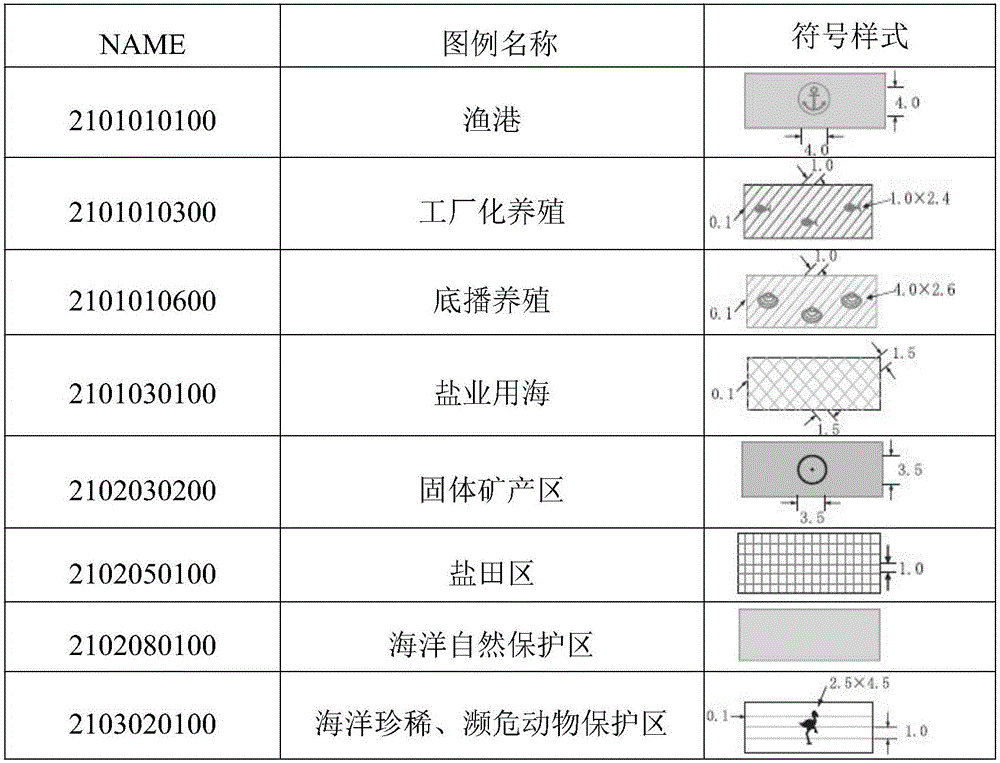

Ocean thematic drawing automatic compilation method based on task flow

InactiveCN106204684AChange the production processSimple stepsDrawing from basic elementsNatural language data processingTemplate designComputer science

The invention relates to an ocean thematic drawing automatic compilation method based on a task flow. The method comprises steps of (1) ocean thematic symbol database preparation which divides ocean thematic symbols into 14 classes; (2) ocean thematic element symbolization which comprises ocean thematic drawing classification, data loading and classification drawing symbolization; and (3) diagram finishing which comprises drawing template design, drawing template and drawing type loading, metadata information filling and diagram outputting. The invention firstly unifies standard preparation of ocean drawings, integrates complex ocean elements which cannot be achieved on the GIS platform on a general GIS platform, changes the present situations that lots of drawing software are simultaneously used and drawing data formats are not uniform, and fills gaps of standard, normal and rapid preparation in the domestic ocean thematic drawing field.

Owner:NAT MARINE DATA & INFORMATION SERVICE

Clostridium butyricum

InactiveCN101942405AHigh yieldImprove the quality rateBacteriaMicroorganism based processesHigh concentrationAlcohol

The invention aims to provide a Clostridium butyricum GK13 bacterial strain CCTCCNO. M2010175. The bacterial strain has the characteristics of high caproic acid yield and good growth stability, can be applied in preparing high-concentration compound Clostridium butyricum liquid after strengthening functional bacteria, can be applied in cultivating artificial pit mud, obtains the effect of shortening the newly-built cellar pool aging period and rejuvenating the degrade cellar pool function in the practical production, improves the alcohol yield and the superior product rate, and solves the problems of rejuvenating a degrade old cellar pool, and shortening the newly-built cellar pool aging time and the like.

Owner:HUBEI UNIV OF TECH

Blind hole plate and its processing method

InactiveCN101222817AReduce processReduce processing costsElectrical connection printed elementsMultilayer circuit manufactureGraphicsVena contracta diameter

The invention provides a blind orifice plate, wherein a welding disk on the top of a blind hole is provided with a through hole for relieving stress. The main method for processing the blind orifice plate is that: on the basis of the prior technology, only a part on a graphics film corresponding to the blind hole is made into a phonic zone which is smaller than the blind hole in diameter during the course of making graphics film. In the invention, the working procedure of 'processing-jacking hole with resin -curing-lapping' is deleted, the manufacturing circle is shortened and the processing cost is decreased correspondingly because the working procedure is reduced; after the process is reduced, the overall qualified product rate is improved. The invention is a modification on related design during the pre-production of film, which does not change the prior production technology; the operator can conduct normal operation according to the prior procedures, which avoids unnecessary accidents. The product of the invention can meet the requirements of consumers in terms of overall appearance and performance and the user is not affected to use the product.

Owner:DALIAN PACIFIC ELECTRONICS

Method for extracting solanesol and chlorogenic acid from discard tobacco leaves

ActiveCN103204765AAvoid dependenceReduce manufacturing costCarboxylic acid esters separation/purificationHydroxy compound separation/purificationChromatographic separationChlorogenic acid

The invention provides a method for extracting solanesol and chlorogenic acid from discard tobacco leaves. The method comprises the following steps: (1) subjecting the discard tobacco leaves to reflux extraction with an aqueous ethanol solution with a concentration of 90 to 97% at a temperature of 35 to 40 DEG C and then filtering an extract with a ceramic membrane; (2) subjecting the extract to reduced pressure condensation at a temperature of 38 to 42 DEG C so as to obtain a dried substance; (3) dissolving the dried substance with water, carrying out filtration with the ceramic membrane, subjecting a filtrate to reduced pressure condensation so as to obtain a concentrate and standing a filter residue for subsequent usage; (4) dissolving the filter residue with ethyl acetate, carrying out filtration with the ceramic membrane, carrying out chromatographic separation by using a silica gel column, carrying out elution with absolute ethyl alcohol and subjecting an eluate to condensation and then to crystallization so as to obtain solanesol; and (5) carrying out chromatographic separation on the concentrate obtained in step (3) by using a macro-porous resin, carrying out elution with an aqueous ethanol solution with a concentration of 55 to 65%, condensing an eluate, adjusting a pH value to 3 to 3.5 and carrying out crystallization so as to obtain chlorogenic acid. The method provided by the invention has a simple process, is convenient to operate, effectively improves the utilization rate of the discard tobacco leaves, reduces production cost for chlorogenic acid and solanesol, has high yield and can effectively guarantee large scale production.

Owner:CHINA TOBACCO HUNAN INDAL CORP

High-looseness tobacco sheet applied to low-temperature cigarette and production process

The invention provides a high-looseness tobacco sheet applied to a low-temperature cigarette and a production process. The tobacco sheet comprises, by mass, 50-80% of tobacco raw material powder, 10-30% of atomizing agent, 0.5-10% of adhesive, 0.01-1% of leavening agent, 5-15% of tobacco essence perfume and 0-30% of water and is manufactured by means of a roll pressing production process. During manufacturing of the sheet, the production process is not changed, only the leavening agent is added to a raw material formula to loosen the sheet, and absorption of a large quantity of the atomizing agent and the external perfume is facilitated. When a consumer smokes the low-temperature cigarette prepared from the sheet, the obtained smoke amount is larger, and the obtained physiological satisfaction feeling is stronger. At the same time, the production process of the sheet is mature, simple and high in controllability, and the quality is stable.

Owner:HUBEI CHINA TOBACCO IND

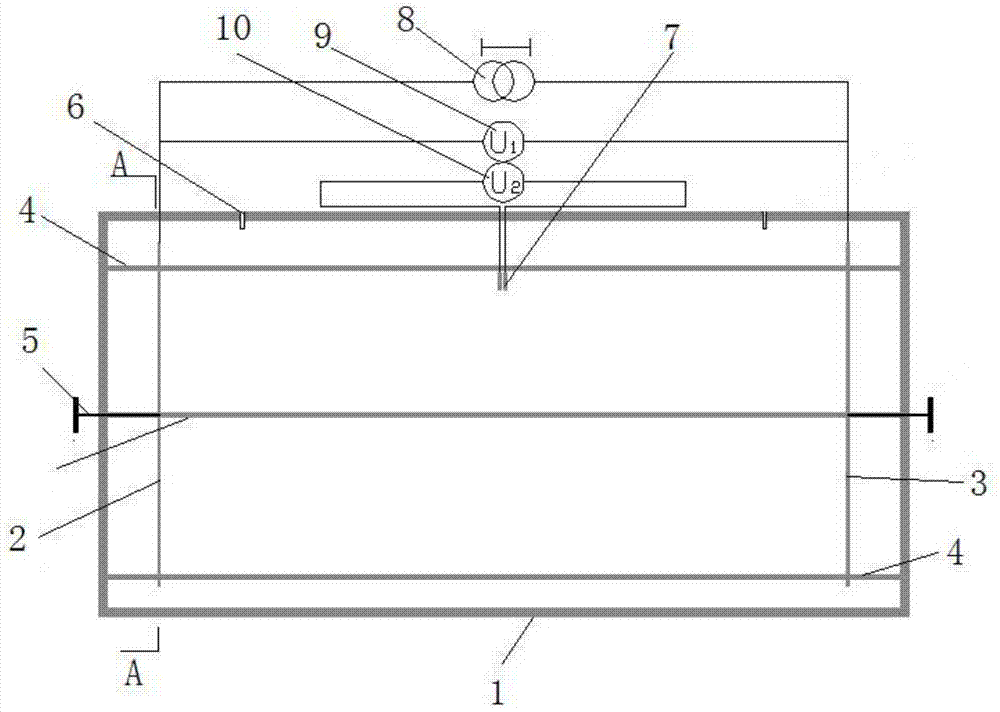

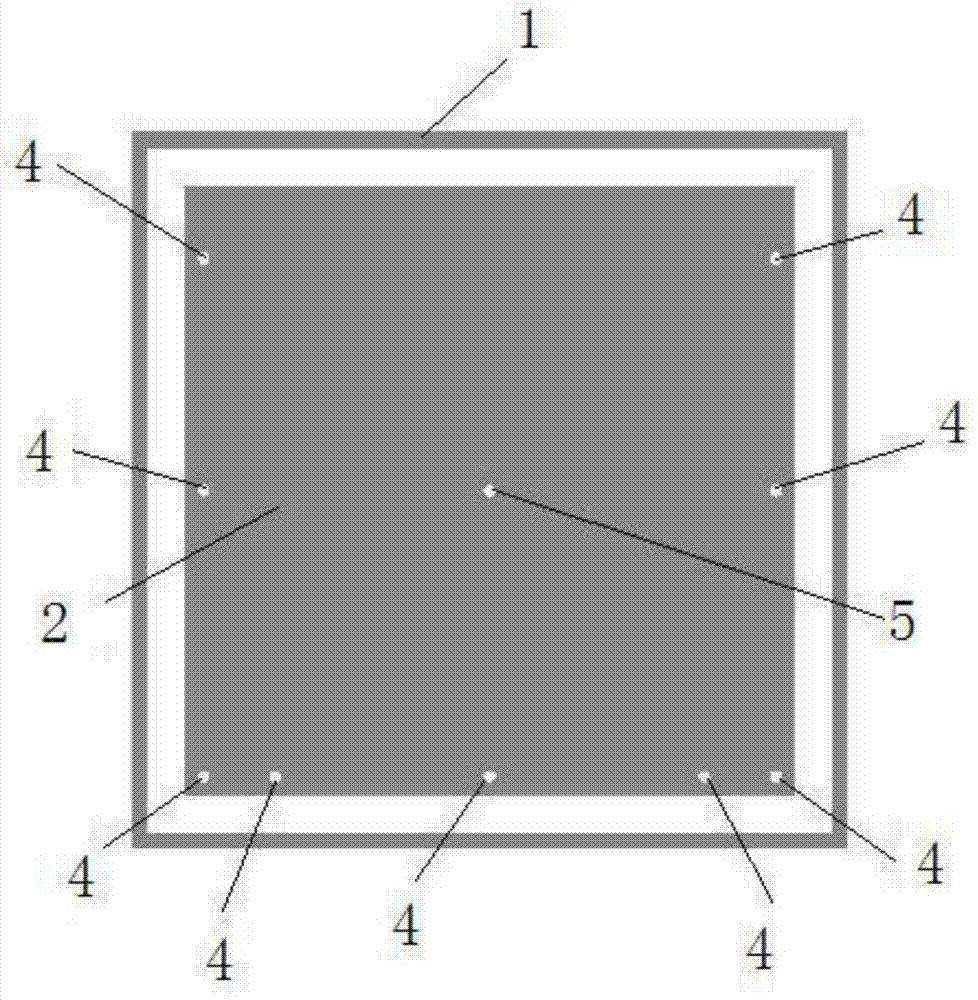

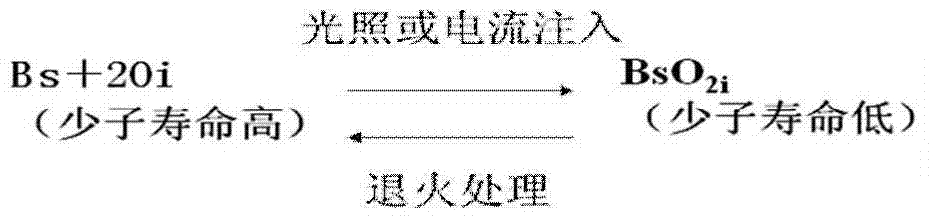

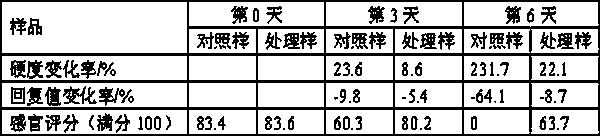

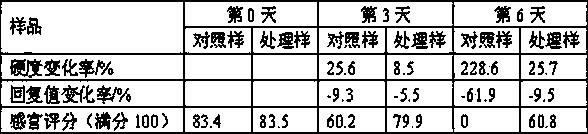

Device reducing light degradation of solar cell and method thereof

ActiveCN104505424AReduce light-induced attenuationNo change in electrical propertiesFinal product manufacturePhotovoltaic energy generationElectricityProduction line

The invention discloses a device reducing light degradation of a solar cell and a method thereof. The device is simple in structure and is easy to product in volume. The device comprises a thermostat, a left conducting plate, a right conducting plate, and a plurality of insulating support rods. The insulating support rods are installed in the thermostat. Two ends of the insulating support rod are respectively disposed on the left side surface and the right side surface of the thermostat. The left conducting plate and the right conducting plate are disposed in the thermostat and are installed on the insulating support rods. A constant current DC power supply is connected between the left conducting plate and the right conducting plate. A first voltmeter is connected with the left conducting plate and the right conducting plate. The middle of the internal of the thermostat is also provided with two pieces of sheet metal. A second voltmeter is connected between the two pieces of sheet metal. Beneficial effects of the device are that production technology of a production line is not changed, devices and equipment which are very expensive and occupy large land are not needed, original electrical performance and efficiency of a cell piece are not changed, the device is simple in structure, easy in mass production, obvious in effect, little in power consumption, high in yield, and high in reliability.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

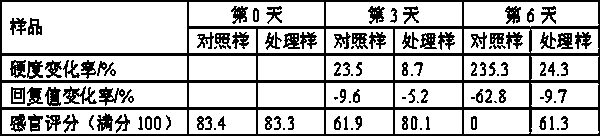

Method for preparing anti-aging steamed bread

InactiveCN103932038APrevent agingExtended shelf lifeFood ingredient as gelling agentFood ingredient for microbe protectionBiotechnologyImmunity

The invention relates to a method for preparing anti-aging steamed bread. The method concretely comprises the following operation steps: (1) preparing an activated yeast solution; (2) modulating paste, namely, mixing and stirring special flour for steamed bread with beta-glucan, and adding the yeast solution to obtain smooth and intact paste; (3) fermenting and molding for the second time; (4) steaming by steam to obtain the steamed bread; (5) packaging and storing, cooling and bagging at room temperature, and storing at room temperature. The method provided by the invention not only is simple and feasible, but also the aging of the steamed bread is inhibited and the shelf life of the steamed bread is prolonged to be over 6 days at the room temperature by the water-retaining property, the gelling property and the antibacterial activity of the beta-glucan. On the other hand, the beta-glucan is a biological response modifier, and has a plurality of physiological active functions of enhancing the immunity of the organism and the like, and the health quality of the anti-aging steamed bread is enhanced.

Owner:HEFEI UNIV OF TECH +1

Method for preparing high-purity carnosic acid by continuous medium pressure column chromatography

InactiveCN101851158AFacilitate industrial continuous productionChange the production processCarboxylic compound separation/purificationSilica gelEthyl acetate

The invention discloses a method for preparing high-purity carnosic acid by continuous medium pressure column chromatography. The method prepares the carnosic acid with the purity of over 98 percent by using a carnosic acid raw material with the content of not lower than 15 percent. The method comprises the following steps of: dissolving a coarse carnosic acid product into ethyl acetate, filtering the insoluble substances to obtain a column filling sample, and filling a column by using silica gel, namely dispersing the silica gel by using the ethyl acetate and then wetly filling the silica gel into the column; after filling, feeding liquid into the column through a plunger solvent pump by using the ethyl acetate as eluent, collecting the eluted fractions section by section, concentrating the fractions under reduced pressure till the eluent is dryly reclaimed to obtain a chromatographic product, reusing the reclaimed eluent, re-crystallizing the chromatographic product by using a hydrocarbon solvent, and drying a crystallized product under reduced pressure to obtain a pure carnosic acid product with the purity of over 98 percent, wherein after the ethyl acetate is reclaimed under reduced pressure, the mother solution serving as a column chromatography raw material can be re-purified, the used chromatographic column is regenerated by using a mixed solvent containing ethyl acetate and ethanol, the ethyl acetate is balanced by a balancing agent, and the balanced chromatographic column can be reused for over 30 times. The method has the main characteristics that the purification process has no pollution, all solvents can be recycled and the method is convenient for industrial continuous production.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

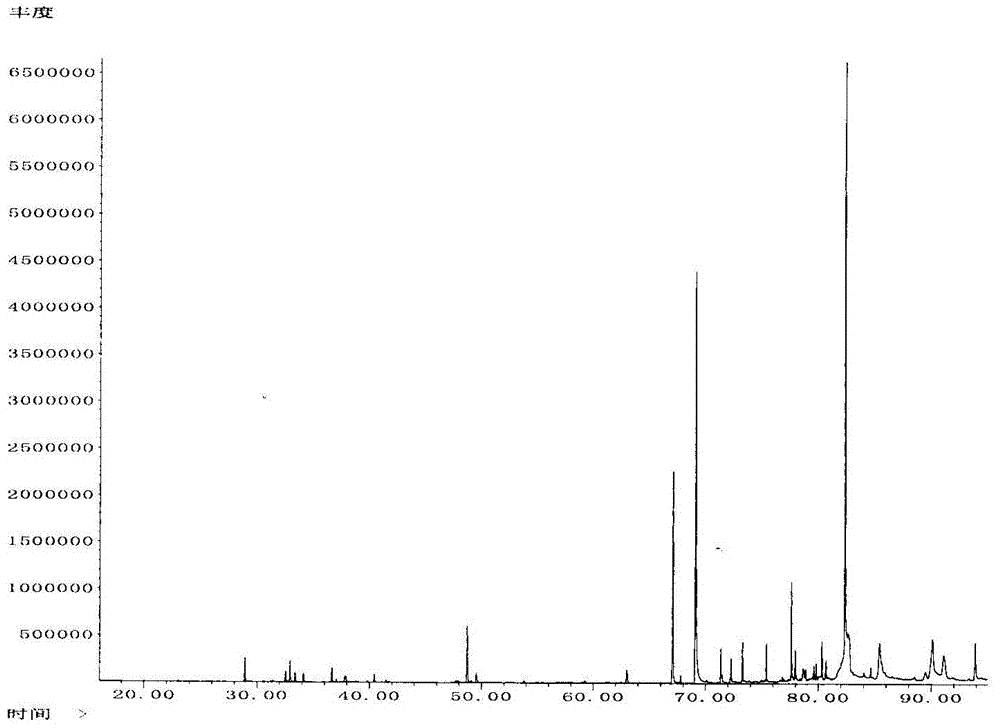

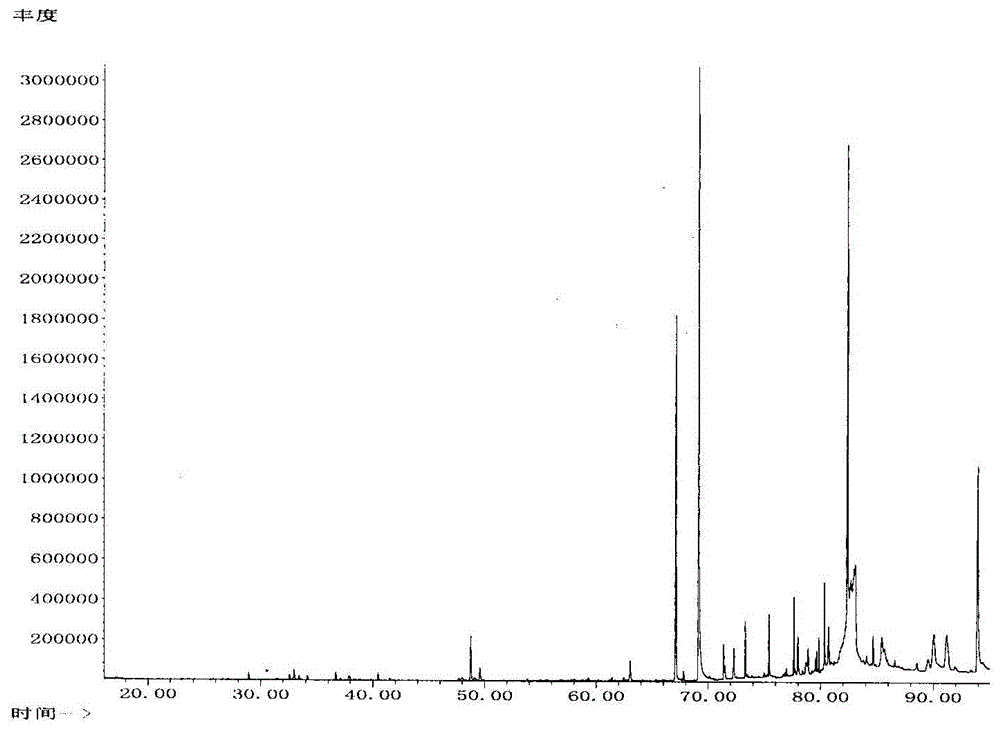

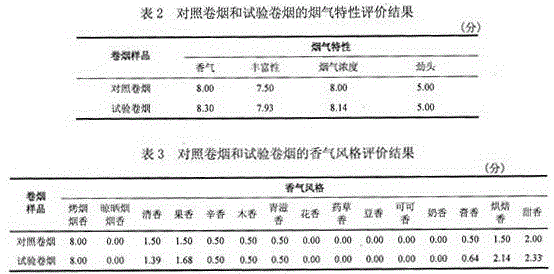

Malt caramel-like aroma spice suitable for cigarette products and application of malt caramel-like aroma spice to tobacco products

ActiveCN106165906AChange the production processStrengthen the style characteristics of Chinese cigarettesTobacco preparationTobacco treatmentWaxCyclopentenone

The invention belongs to the technical field of cigarette spices, and particularly relates to a malt caramel-like aroma spice and an application of the malt caramel-like aroma spice to tobacco products. The spice is prepared from caramel malt serving as a raw material, and a preparing method of the spice includes the following steps of a, raw material pretreating; b, ethyl alcohol extracting; c, freezing dewaxing; d, membrane separating. A pyrazine compound, a furan compound, a furanone compound, a pyrone compound, a cyclopentenone compound and the like are rich in the malt caramel-like aroma spice, the joyful caramel-like aroma smell can be given to cigarettes, and the Chinese-style cigarette style characteristic is intensified. According to the spice, the caramel-like aroma ingredients in caramel malt are purposefully extracted, separated and enriched, and ingredients such as vegetable wax, protein and starch which are contained in malt extract and have the side effects on sense organs of tobacco products are effectively removed. The preparing technology is simple and easy to operate, the cost of the raw material is low, the production process is economic and environmentally friendly, and the malt caramel-like aroma spice is suitable for large-scale industrial production application. The application of the spice to cigarettes cannot change the original processing technology of cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

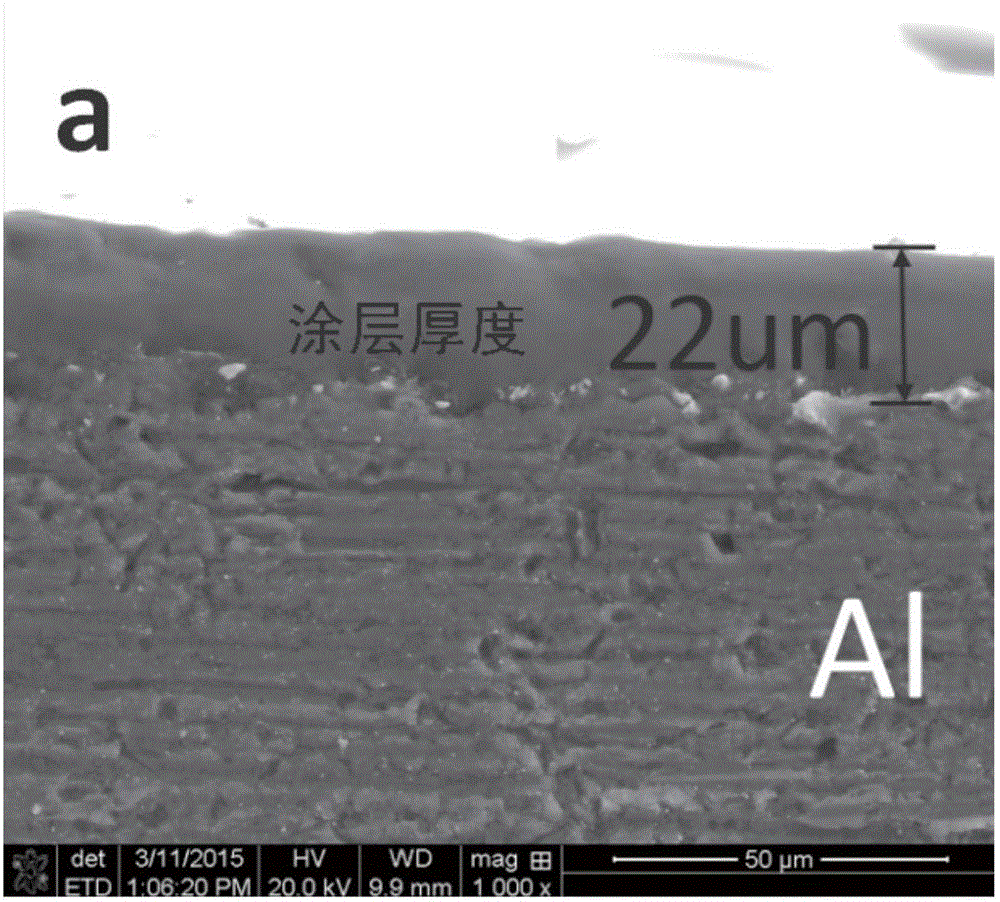

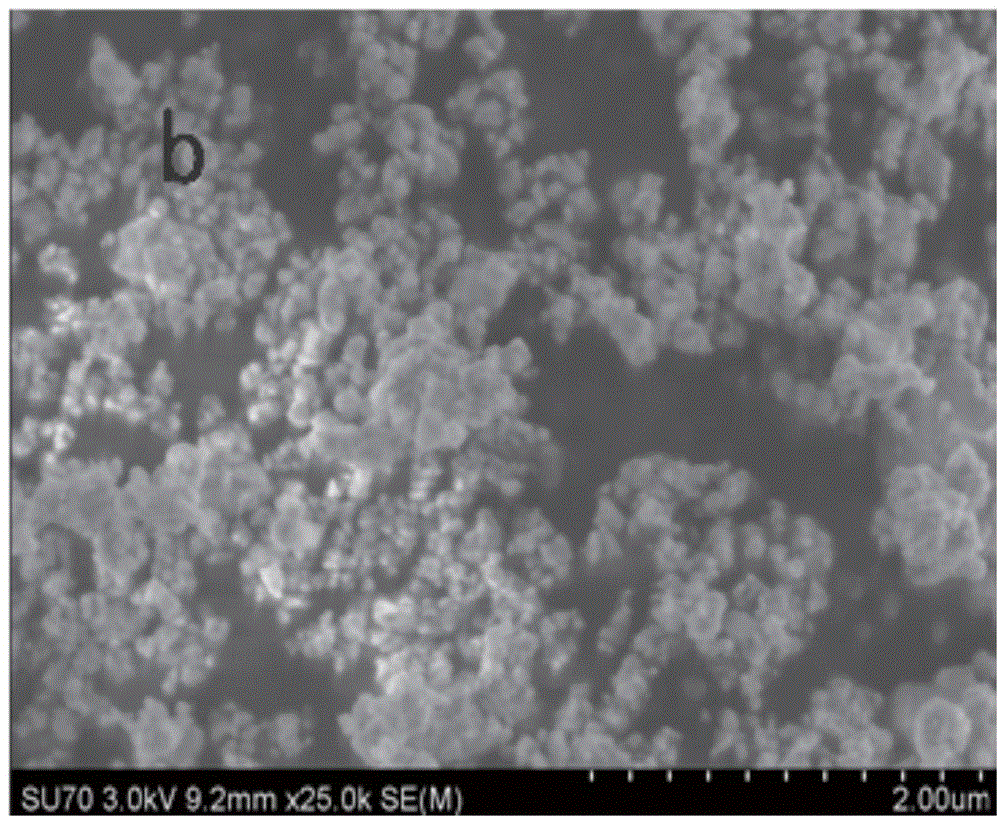

High-temperature wear resistant nonstick coating layer material and preparation method thereof

ActiveCN104962144AImprove wear resistanceImprove high temperature resistanceCoatingsWear resistantWear resistance

The invention discloses a high-temperature wear resistant nonstick coating layer material and a preparation method thereof. The high-temperature wear resistant nonstick coating layer material comprises 80-99wt% of Teflon and 1-20wt% of metal oxide. A nonstick coating layer is produced from the high-temperature wear resistant nonstick coating layer material through a present nonstick coating layer coating technology, and a result of the wear resistance test of the nonstick coating layer shows that the bearable friction frequency can reach 90000 (test standard: CMA2005 Kitchenware Association Standard, and the qualified friction frequency is 30000).

Owner:李吉学 +1

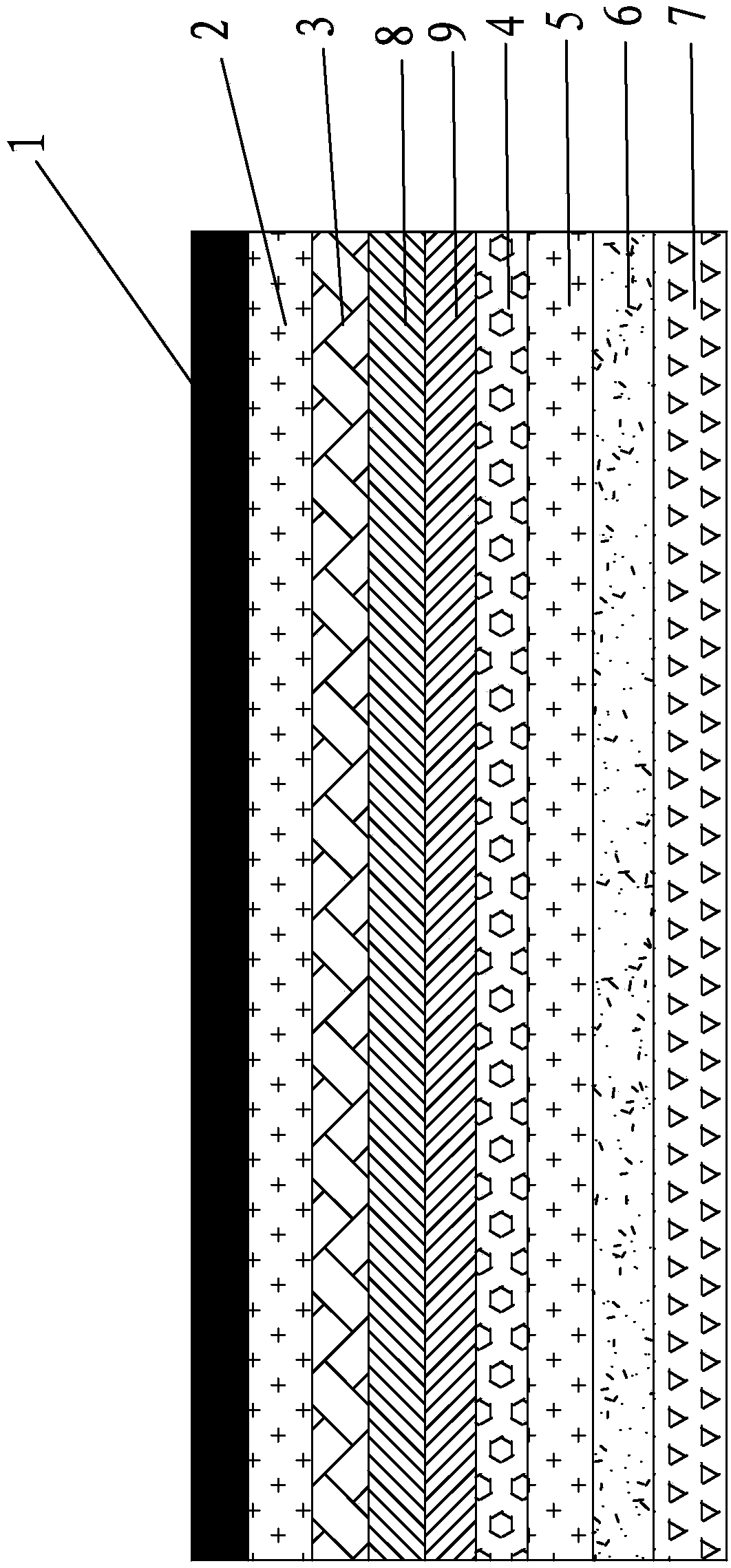

Spraying gradual-change composite-plate mobile-phone back shell

ActiveCN109413234AChange the production processSolve technical issues that cannot be made into gradient texturesSpraying apparatusPretreated surfacesChange colorEngineering

The invention discloses a spraying gradual-change composite-plate mobile-phone back shell. The back shell includes a surface wear resistance ink layer, a PMMA film layer, a PC film layer, an LOGO pattern layer, a UV transfer-printing texture pattern layer, an optical film layer and a base color ink layer which are disposed from a top to a bottom in sequence. A first color ink layer and a second color ink layer laminated from a top to a bottom are also disposed between the LOGO pattern layer and the above UV transfer-printing texture pattern layer. Thickness of the first color ink layer descends from a left to a right in sequence. Thickness of the second color ink layer descends from a right to a left in sequence. Thickness of all parts of the gradual-change color ink layers in a length direction of the mobile-phone back shell is the same. Compared with the prior art, the mobile-phone back shell which can be made through research and development of numerous experiments and tens of yearsof work experience of the inventor shows a natural gradual-change effect, an outer surface of the entire mobile-phone back shell cannot have a color separation line, and is natural and beautiful, andthe technical problem that existing plastic back shells cannot be made with gradual-change texture is solved.

Owner:FUJIAN SHISHI TONGDA ELECTRICAL APPLIANCE

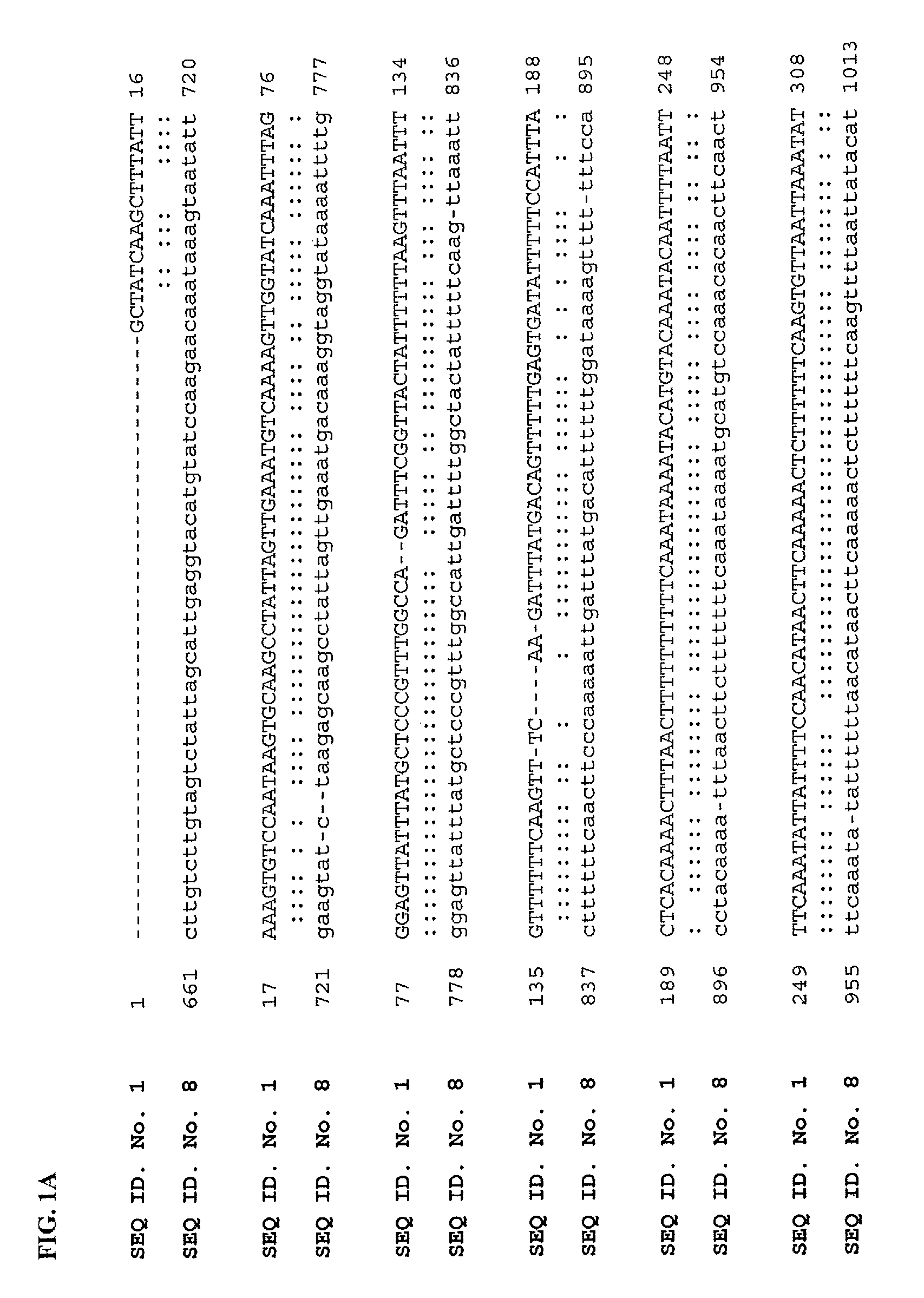

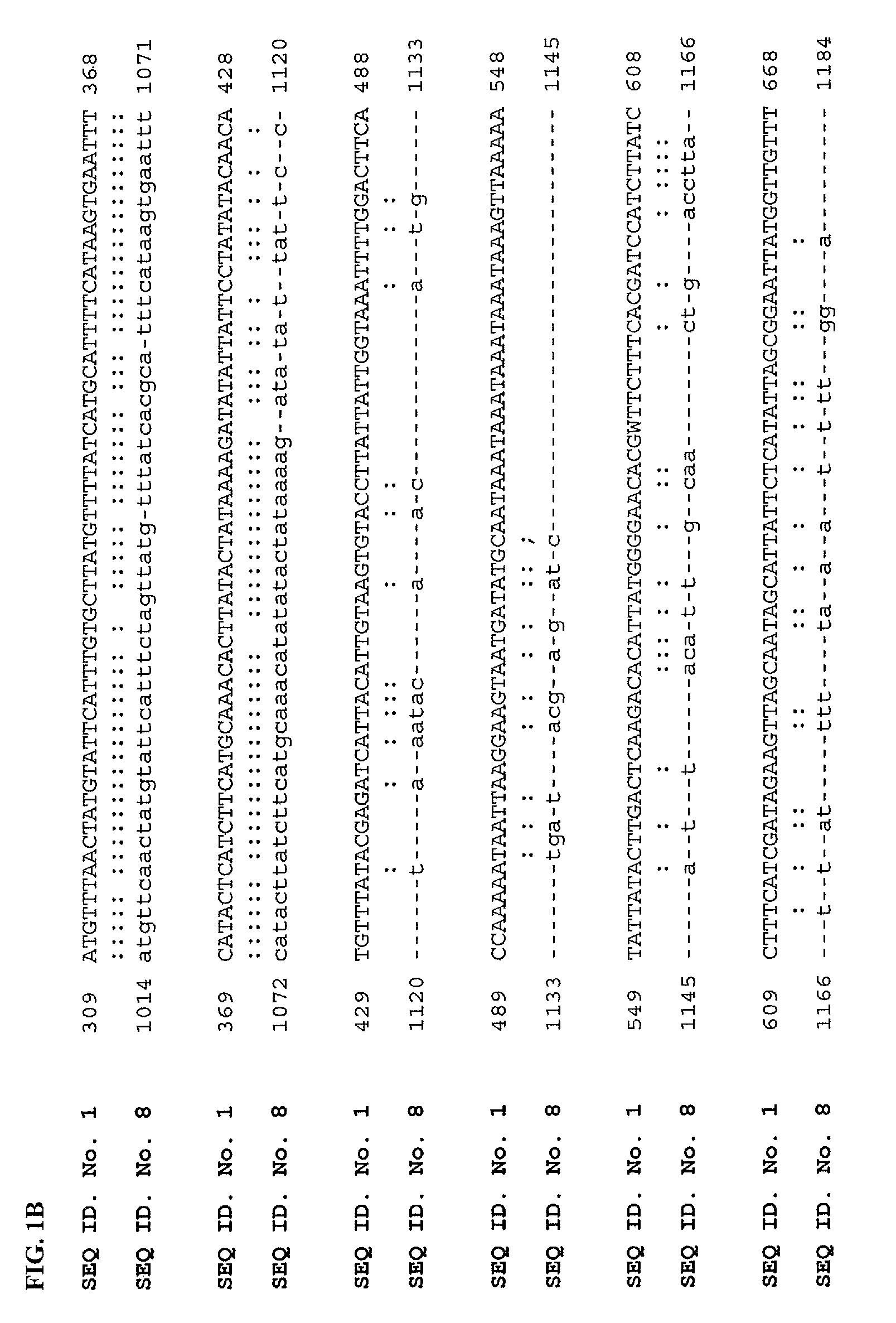

Modification of plant development and morphology

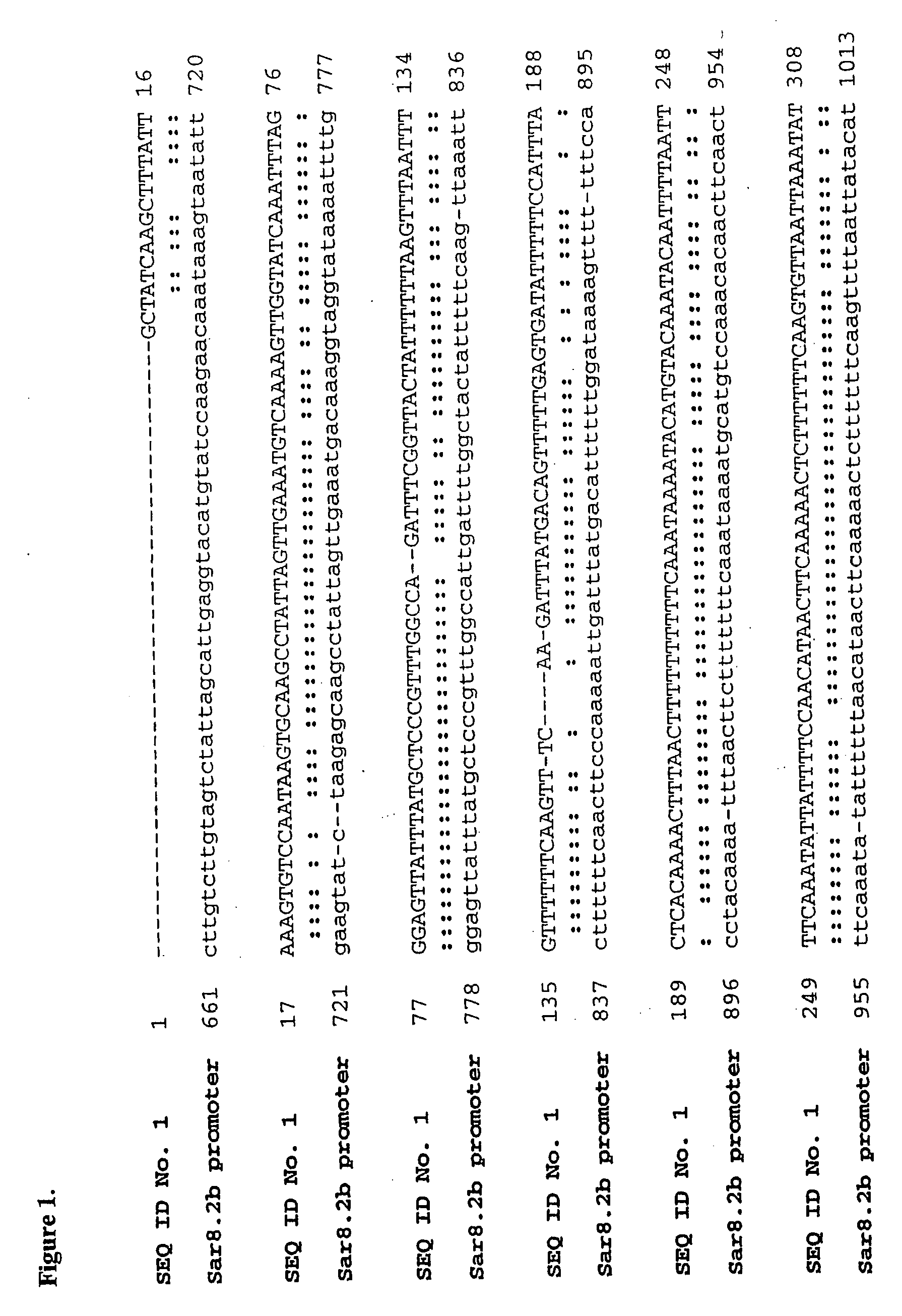

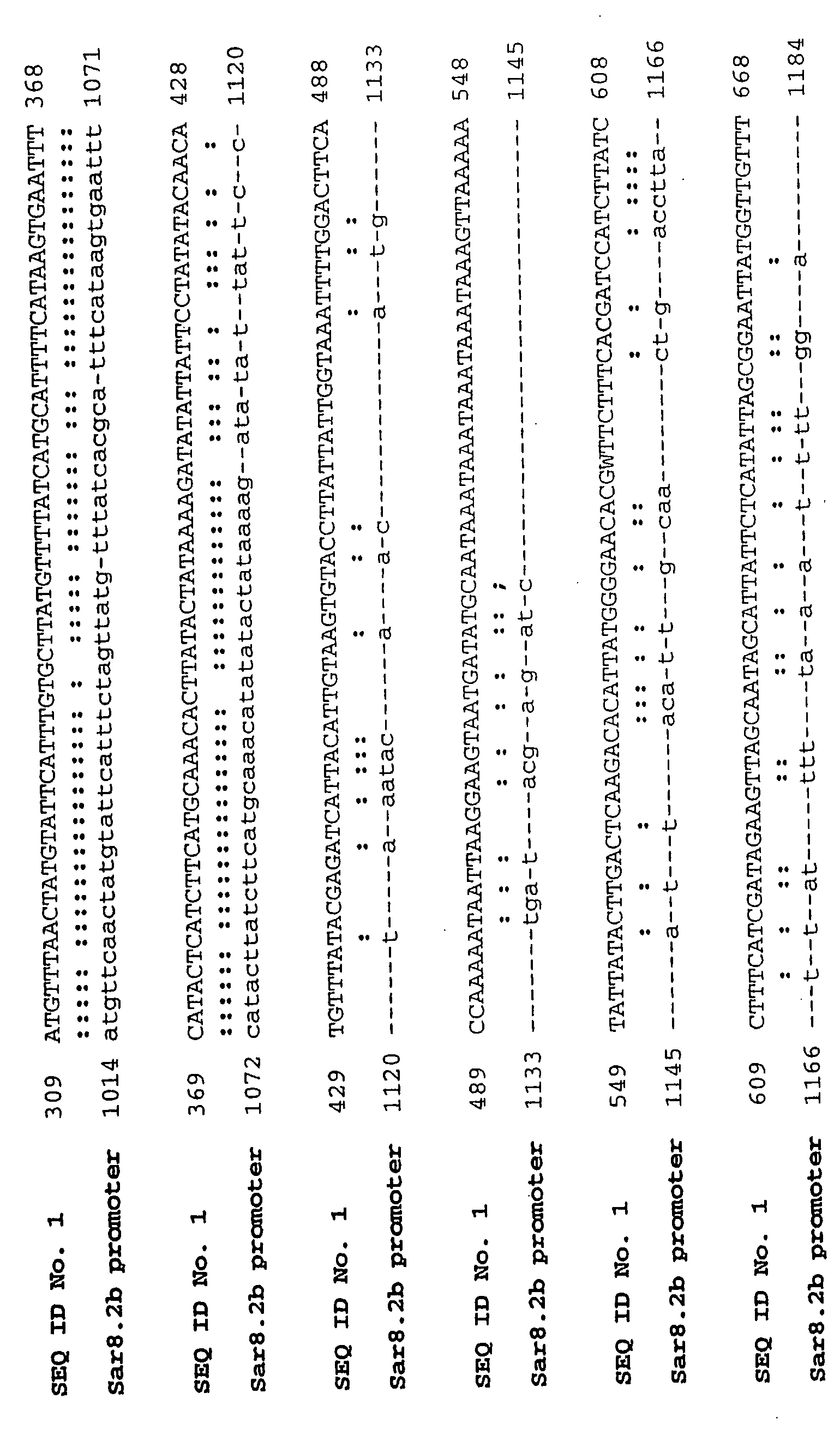

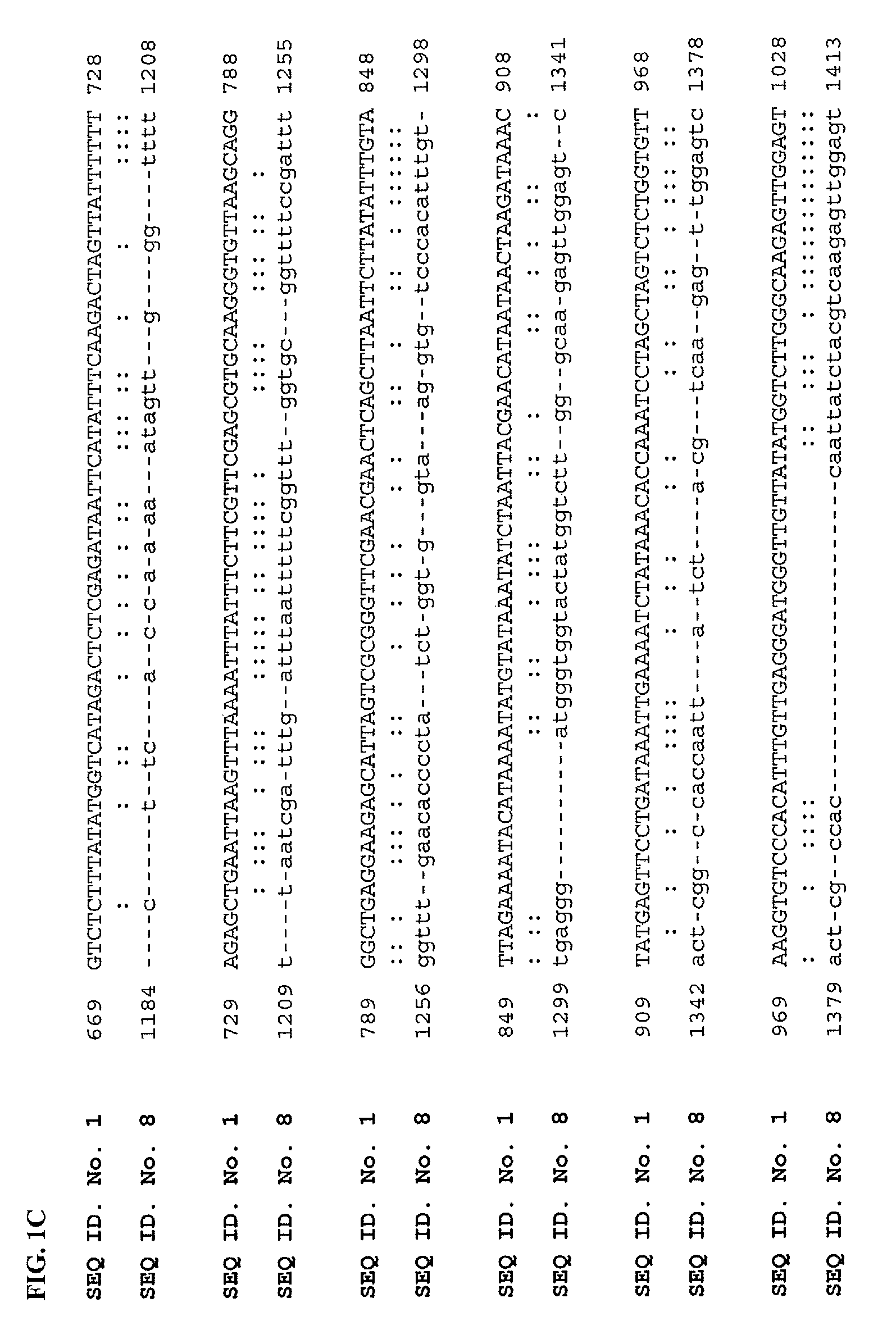

ActiveUS20090249518A1Outgrowth of lateral shoots may be enhancedPrevent and reduce delaySugar derivativesClimate change adaptationBiotechnologyGene product

A method of modifying morphology in a plant by introducing into a plant at least one chimaeric gene having a promoter sequence operably associated with a nucleic acid sequence, the promoter sequence being operable to direct expression in specific cells of the plant and the nucleic acid sequence encoding at least one gene product capable of altering the metabolism of or causing death of the specific cells and / or nearby cells. In particular, the promoter sequence is operable to direct expression in lateral bud or lateral shoot and the nucleic acid encoding at least one gene product capable of disrupting the metabolism of or causing the death of the lateral bud or lateral shoot or nearby cells. Preferably the promoter sequence has the sequence shown as SEQ ID No. 1 or SEQ ID No. 7 or SEQ ID No. 4, or a part thereof capable of regulating expression of a gene, or a sequence having at least 60%, preferably at least 75%, homology to SEQ ID No. 1 or SEQ ID No. 7 and being capable of regulating expression of a gene.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

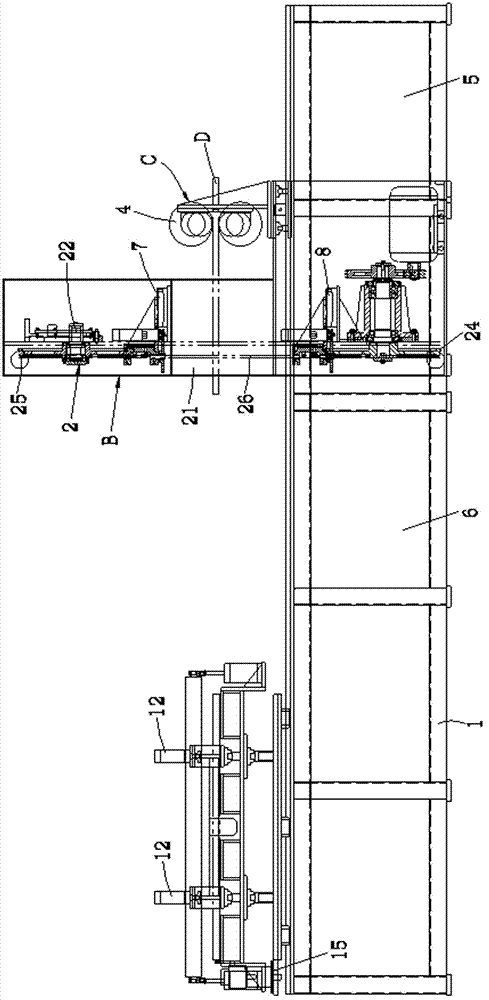

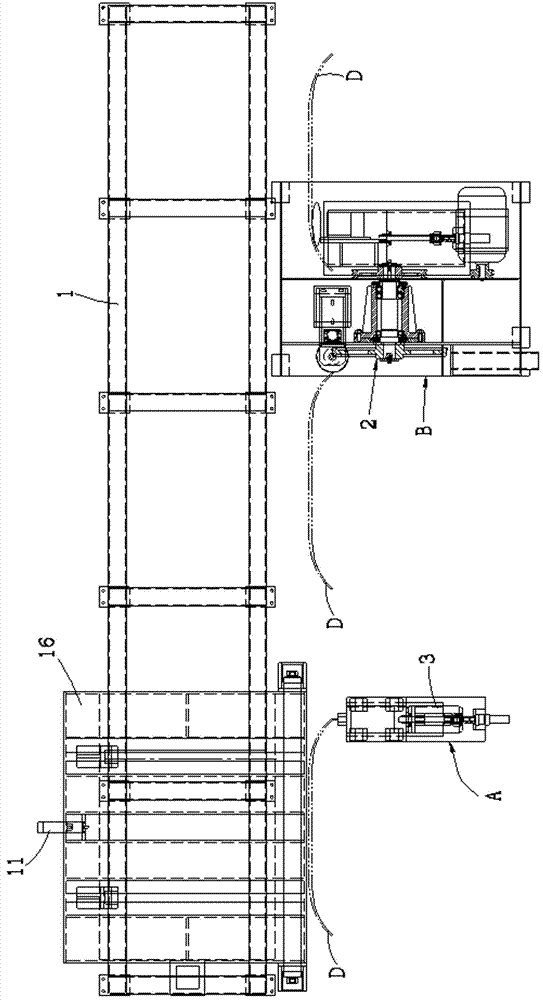

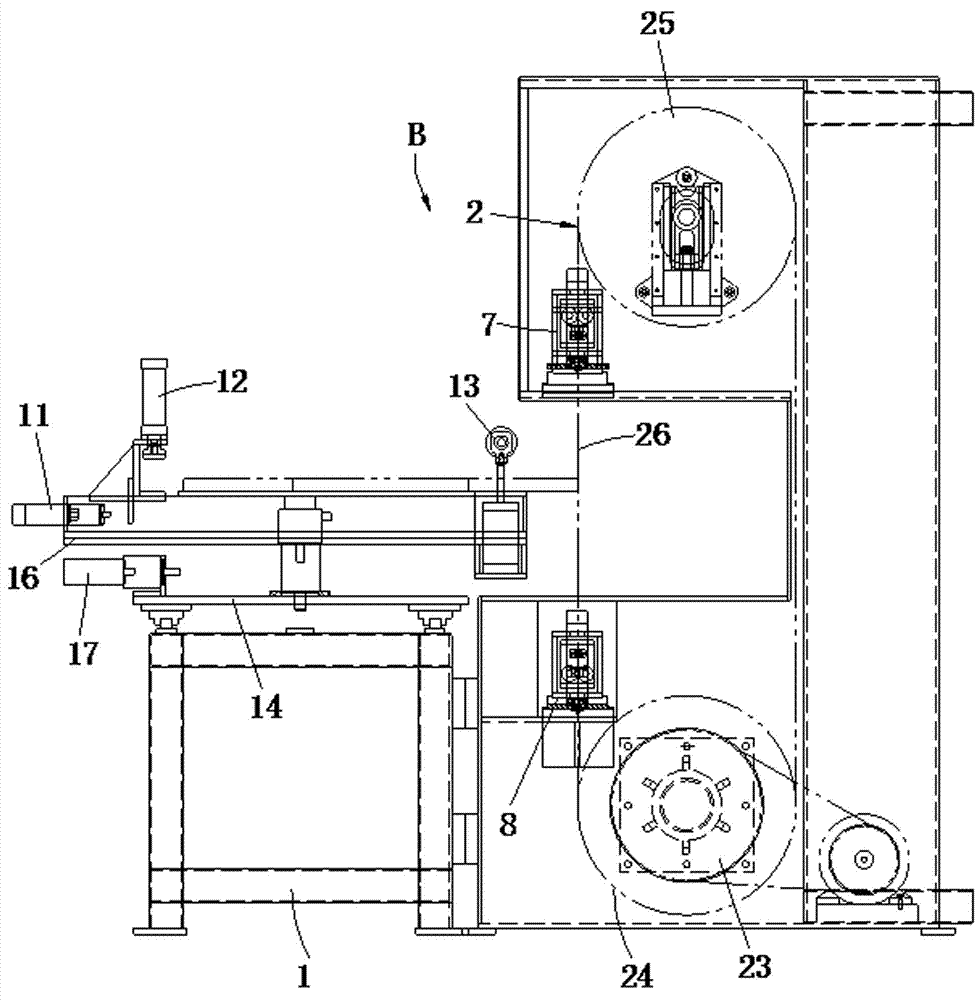

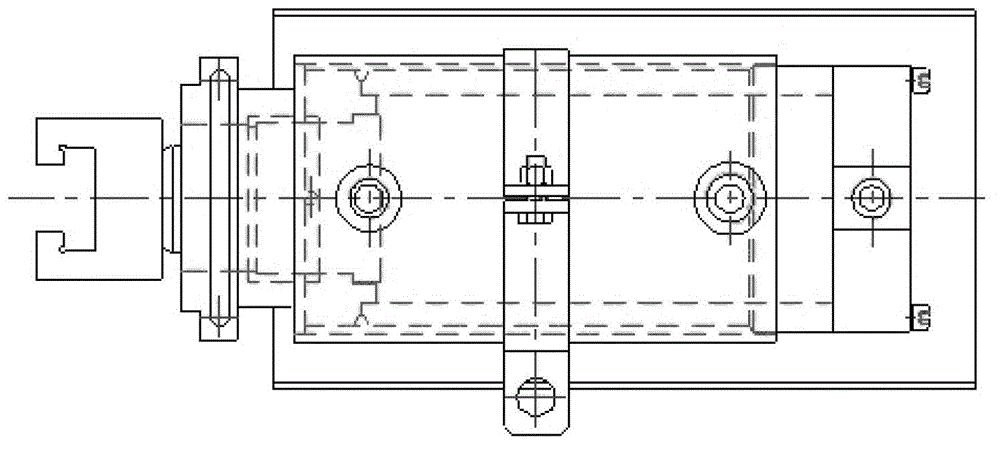

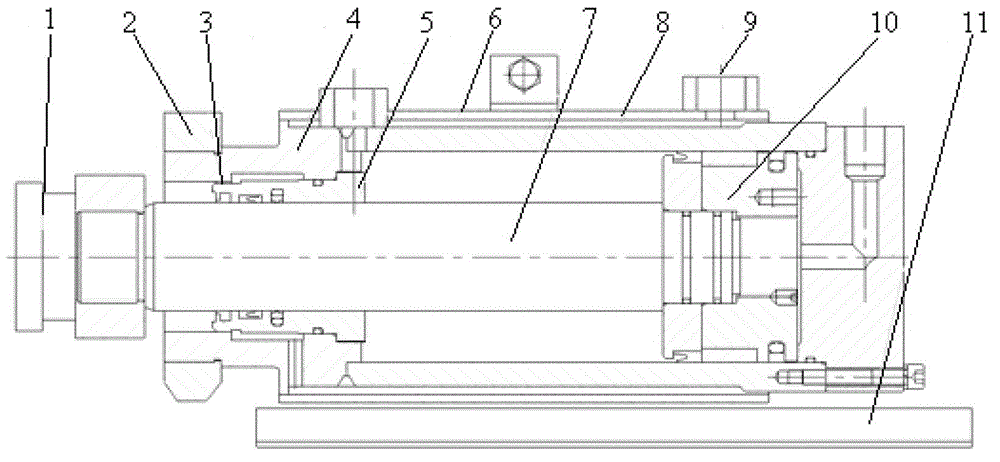

Automatic machining equipment and machining method for pantograph carbon slide plate of high-speed rail

ActiveCN104772827AChange the production processGuaranteed machining accuracyMetal sawing devicesRailway vehiclesNumerical controlEngineering

The invention relates to automatic machining equipment and a machining method for a pantograph carbon slide plate of a high-speed rail. The automatic machining equipment is sequentially provided with a milling station, a sawing station and a chamfering station and comprises a machine stand, a band sawing machine, a workpiece milling device, a workpiece chamfering device, a CNC (Computer Numerical Control) system and a pneumatic system; a carbon slide plate workpiece to be machined is arranged on the machine stand and is sequentially subjected to milling, sawing and chamfering machining; a saw frame of the band sawing machine is also provided with a saw band upper guide servo rotating device and a saw band lower guide servo rotating device which are capable of freely, synchronously and correspondingly rotating a band saw blade within a certain range. According to the automatic machining equipment and the machining method disclosed by the invention, the carbon slide plate can be machined in a sawing manner, and the working procedures, namely sawing, milling and chamfering are integrated on one equipment and can be automatically finished after once clamping, so that materials are saved and the working efficiency is improved.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

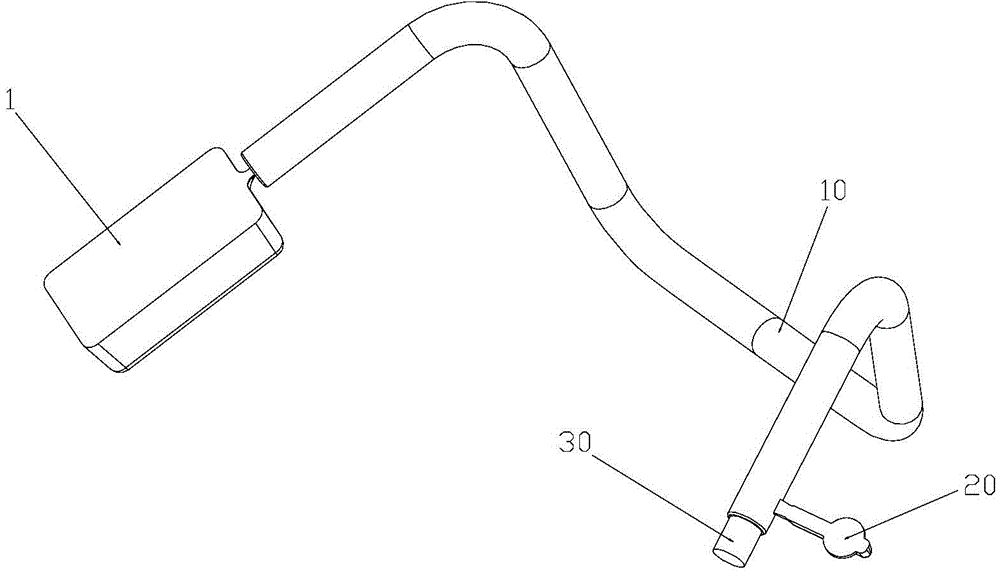

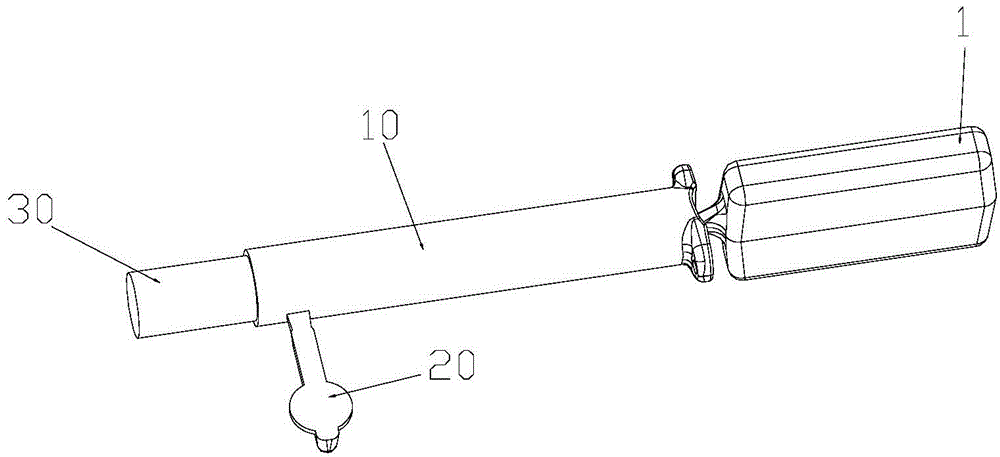

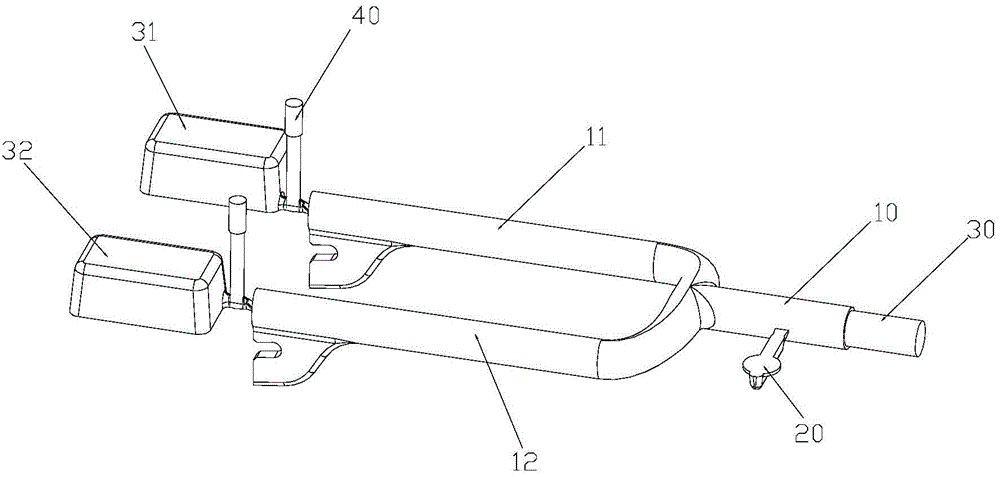

Processing mechanism and processing method of main body component of bicycle

InactiveCN103552220AUniform wall thicknessHigh shape precisionDomestic articlesCycle framesHigh pressure waterHigh pressure

The invention provides a processing mechanism and a processing method of a main body component of a bicycle. The processing mechanism is characterized in that a water needle for injecting water into a cavity is arranged at a main cavity channel of the cavity of a mold, wherein the front part of the water needle is inserted into the cavity, and a material overflowing cavity for containing overflowed materials is communicated with the other end, opposite to the direction of the water needle, of the main cavity channel through an overflowing pipe; a closeable glue feeding member for injecting glue materials is further arranged at the side wall of the main cavity channel. According to the processing mechanism and the processing method, a water-assisted molding process is introduced into an injection molding process, the two processes are organically combined, and high pressure water is utilized for driving the redundant glue materials in a product out of the cavity, so that the component product is very rapid to cool, and pressure maintaining and cooling processes in the normal injection molding process can be omitted; furthermore, the product can be molded at a time, so that the efficiency is greatly improved, meanwhile, the strength is guaranteed, the wall thickness of the component is very uniform, the shape precision is greatly improved as well, the shapes of bicycle components such as bicycle frames having more braches are diversely designed, and the weights of the bicycle components are light.

Owner:TIANJIN SILVER BASSIS TECH CO LTD

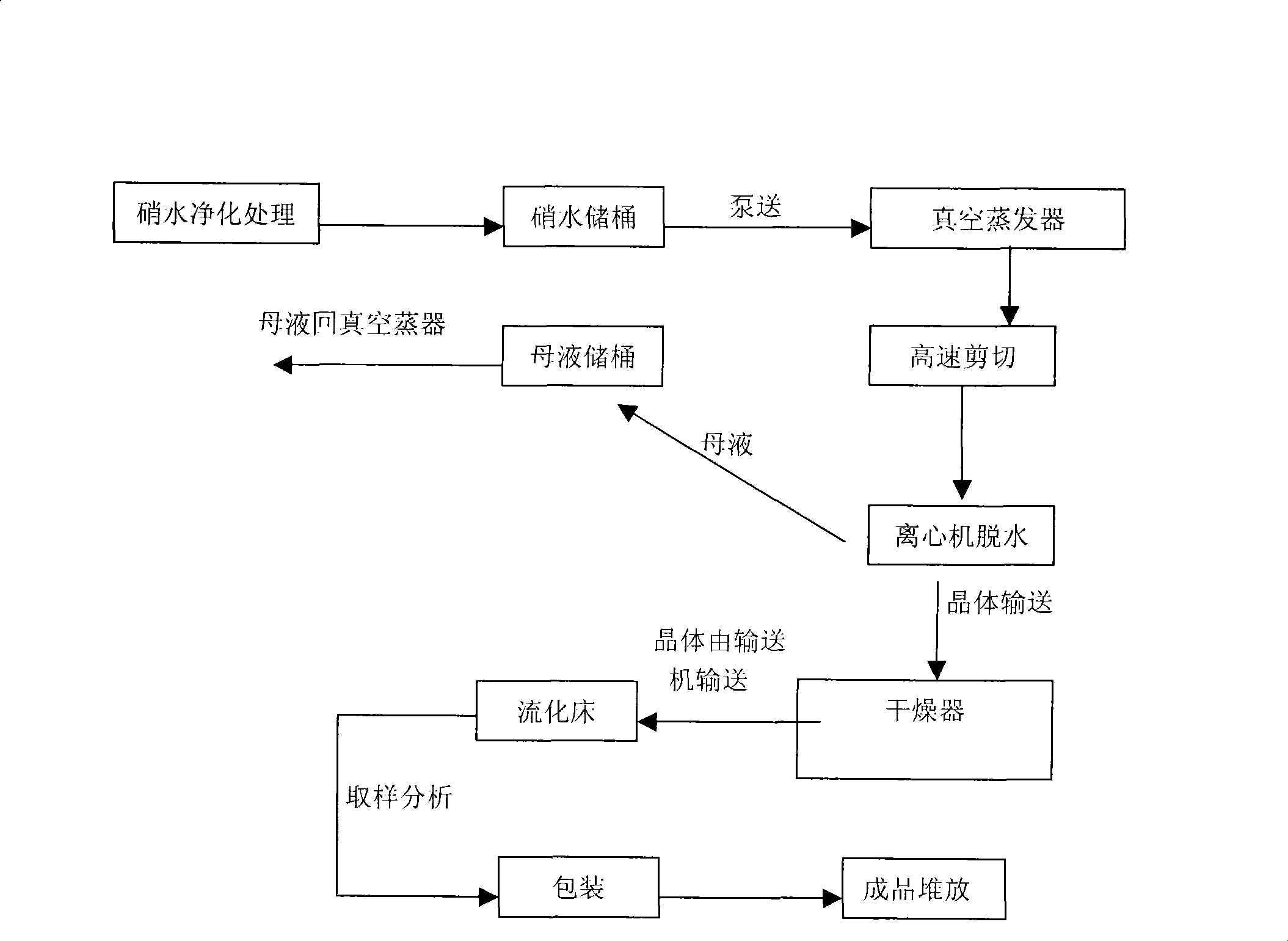

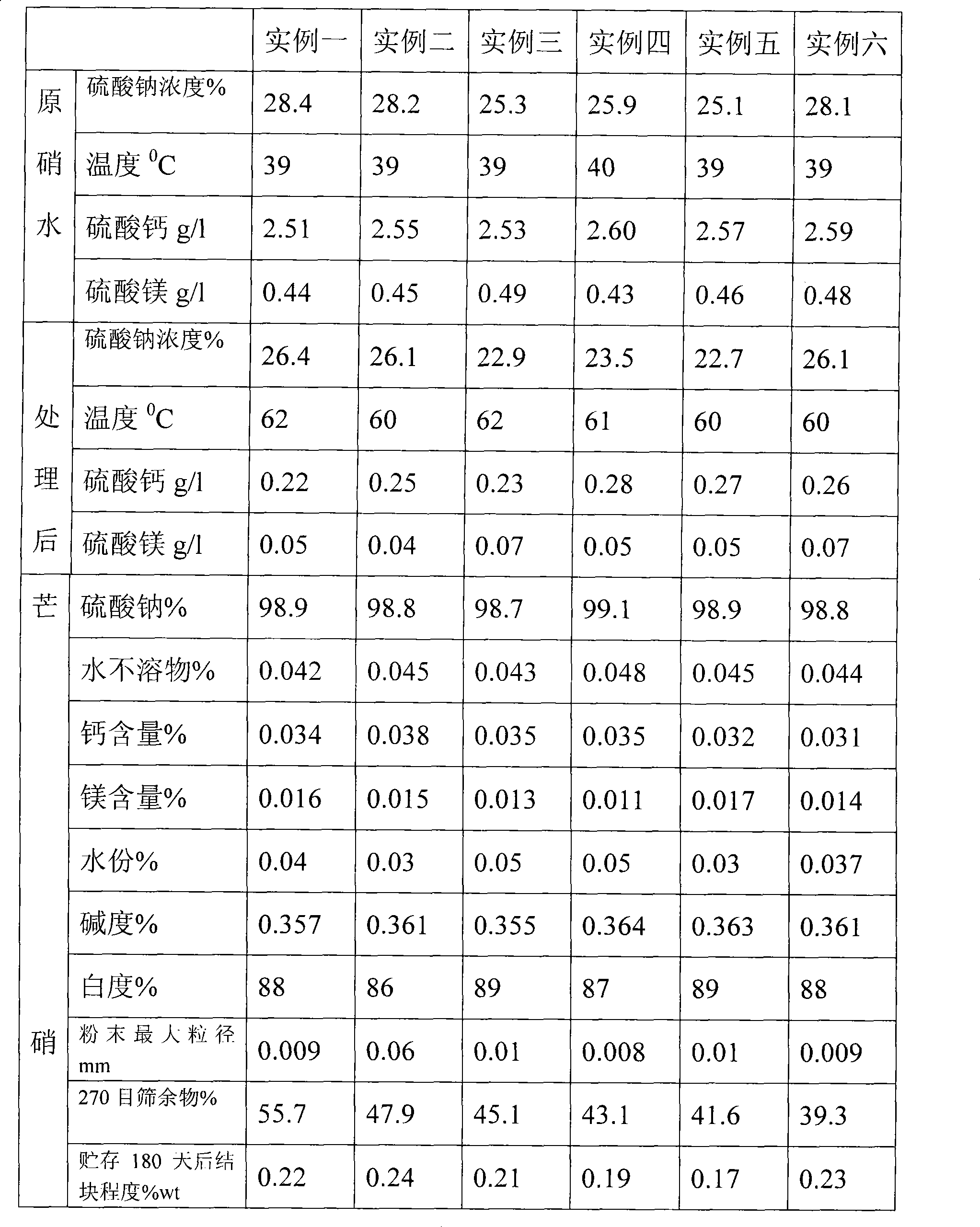

Method for producing ultrafine-grain special mirabilite

InactiveCN101428827AParticles have good fluidityNo cakingAlkali metal sulfite/sulfate purificationFluidized bedMirabilite

The invention discloses a method for preparing superfine granule special type saltcake, which includes the following technical steps: pumping hot water at 40-70 DEG C, and forming a saltcake solution containing a plurality of impurities; concentrating for crystallization by vacuum evaporation after refining impurities; cutting the saltcake solution at a high rotating speed; drying after centrifugal separation, processing by a fluidized bed, separating coarse granule saltcake and obtaining a superfine granule special type saltcake product. The anhydrous superfine granule special type saltcake product obtained by the process method of the invention after high rotating speed cutting and fluidized bed processing has the advantages of good granule fluidness and low possibility of agglomeration. The product can be widely used for preparing sodium sulfide, sodium silicate and the like, and is also used in industries of paper making, glass, printing and dyeing, synthetic fiber, hide manufacture, food, medicine and the like.

Owner:四川省川眉芒硝有限责任公司

Industrial producing method for powder, particle and sheet bromine-chlorine-dimethyl hydantoin disinfectant

ActiveCN101103723ANo emissionsChange the production processBiocideDisinfectantsDisinfectantFiltration

The invention discloses an industrial production method of fine powder, granular and tablet bromo-chloro-dimethyl hydantoin disinfectants, which includes the 5,5-dimethylhydantoin and the flake caustic soda put in a reaction vessel and dissolved in water. The brine is frozen for cooling. With the use of bromine and the chlorine added, the reaction solution is obtained. The reaction solution is put into a filtration tank. After the vacuum filtrating, the ionic water leaching and purification and the centrifuge dripping, the wet products enter a dryer for drying. Thus the powder bromo-chloro-dimethyl hydantoin is obtained after the crushing. A granulator is used for the powder granulation so that the granular bromo-chloro-dimethyl hydantoin can be obtained. The particles poured into a blender are mixed with the adhesives and lubricants to blend evenly, which enter a preforming machine for tabletting, thus the tablet bromo-chloro-dimethyl hydantoin can be obtained. In the invention, the prior production method feeding order of powder bromo-chloro-dimethyl hydantoin is changed, and the processes such as leaching purification, roll dry granulation are added. The degree of purity of powder and granular products produced reach 99.1%, while that of the tablet product is 98%. With low production cost and simple equipment operation, the waste gas and trash discharge almost do not occur.

Owner:河北利仕化学科技有限公司

Scrape-removable water-based ink for flexographic printing and preparation method thereof

The invention provides scrape-removable water-based ink for flexographic printing, which comprises raw materials of color paste, base ink and an admixture, wherein the base ink comprises water-based silver ink, shading black, peeling oil and protective water-based oil. The invention further provides a preparation method of the scrape-removable water-based ink for flexographic printing. The preparation method comprises the steps as follows: step 1, the water-based silver ink is prepared for reserve; step 2, the shading block is prepared for reserve; step 3, the peeling oil is prepared for reserve; step 4, the protective water-based oil is prepared for reserve; step 5, the base ink is prepared for reserve; step 6, the color paste is prepared in an agitator for reserve; step 7, the color paste prepared in the step 6 is added to water and dispersed and ground in a dispersion machine for reserve; and step 8, the color paste, the base ink and the admixture are taken by weight percentage andevenly agitated and mixed, and then the product is prepared. The invention provides the one-step water-based ink and the manufacturing method thereof, which have the advantages that the production process flow of special water-based ink is changed, the manufacturing time is shortened, production procedures are reduced and complete grinding is not needed.

Owner:HENAN UNIV OF SCI & TECH

Modification of plant development and morphology

ActiveUS8093459B2Outgrowth of lateral shoots may be enhancedPrevent and reduce delaySugar derivativesClimate change adaptationBiotechnologyGene product

A method of modifying morphology in a plant by introducing into a plant at least one chimaeric gene having a promoter sequence operably associated with a nucleic acid sequence, the promoter sequence being operable to direct expression in specific cells of the plant and the nucleic acid sequence encoding at least one gene product capable of altering the metabolism of or causing death of the specific cells and / or nearby cells. In particular, the promoter sequence is operable to direct expression in lateral bud or lateral shoot and the nucleic acid encoding at least one gene product capable of disrupting the metabolism of or causing the death of the lateral bud or lateral shoot or nearby cells. Preferably the promoter sequence has the sequence shown as SEQ ID No. 1 or SEQ ID No. 7 or SEQ ID No. 4, or a part thereof capable of regulating expression of a gene, or a sequence having at least 60%, preferably at least 75%, homology to SEQ ID No. 1 or SEQ ID No. 7 and being capable of regulating expression of a gene.

Owner:BRITISH AMERICAN TOBACCO (INVESMENTS) LTD

A method of preparing a high-fastness elastic jean adhered fabric

ActiveCN107283996AImprove crispnessIncrease the amount of glueLamination ancillary operationsSynthetic resin layered productsShrinkage rateEvaporation

A method of preparing a high-fastness elastic jean adhered fabric is provided. The method includes surface fabric treating steps including beaming, dyeing, weaving, singeing, long-vehicle desizing, mercerizing and finishing; base fabric treating steps including preparing a grey fabric, desizing, dyeing and sizing with clear water; a surface fabric preshrinking step adopting a loose dryer, with water treating and drying being performed under a condition of no weft tension to reduce a weft shrinkage rate; a step of tightly pressing and adhering the surface fabric and a TPE film; a step of subjecting the adhered surface fabric and the TPE film to evaporation curing; a step of adhering the adhered surface fabric and the base fabric; a step of subjecting the surface fabric and the TPE film which are adhered to evaporation curing; and a water pouring step, namely a step of performing water pouring surface fabric treatment by adopting a waterproofing agent the liquid rate of which is 30-50%, and performing first-stage drying and second-stage drying. The method improves fabric fitting fastness, and increases water pressure resisting and water pouring resisting functions, and the like.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

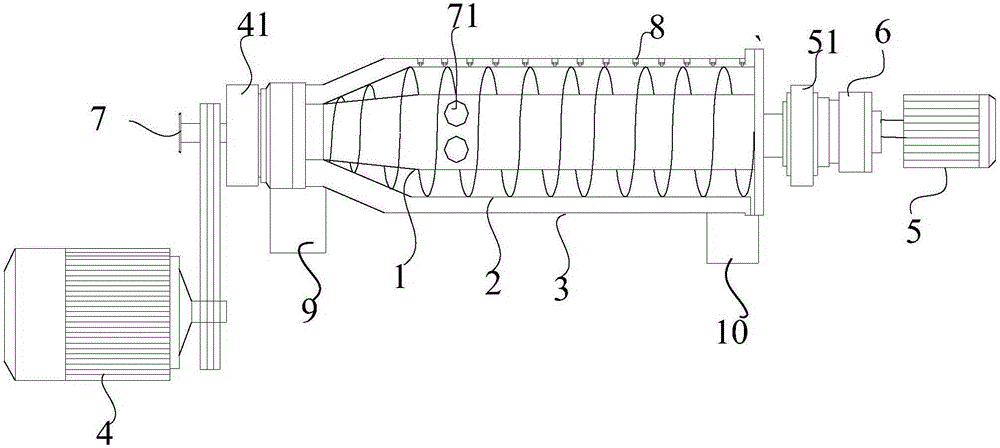

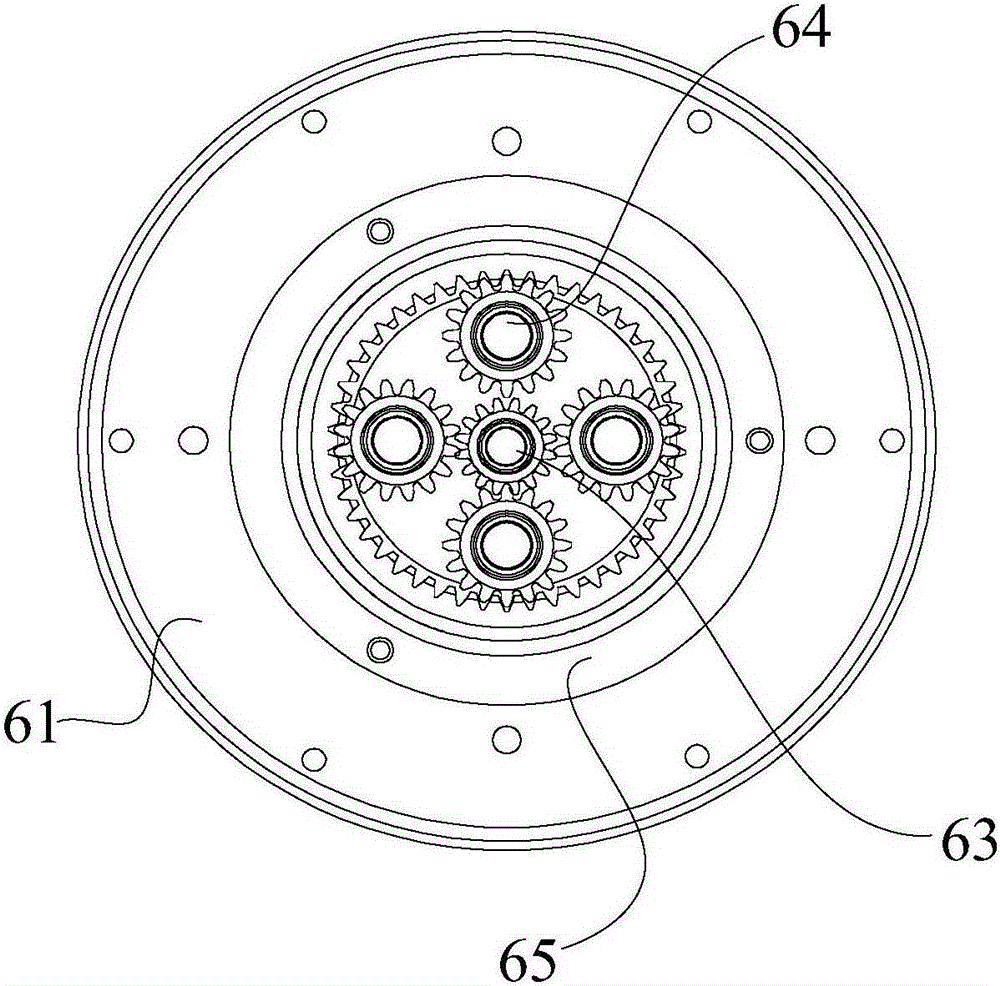

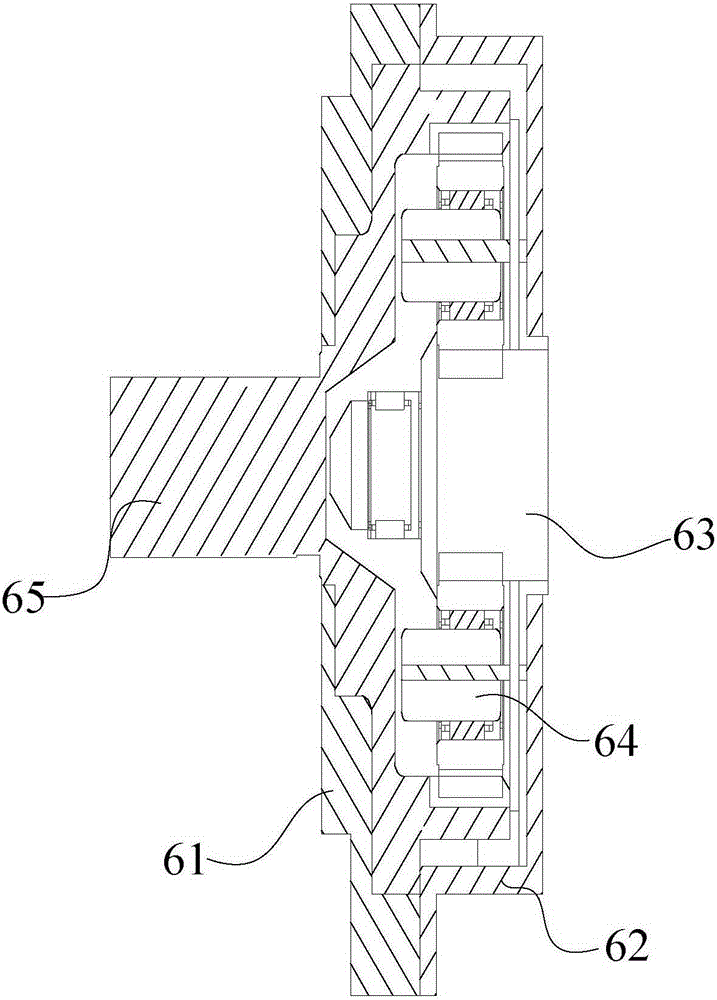

Improved horizontal screw centrifuge for corn protein dehydration and corn protein production technology

The present invention belongs to the field of food processing, in particular to an improved horizontal screw centrifuge for corn protein dehydration and a corn protein production technology. The corn protein production technology comprises the following steps: a, purifying; b, soaking; c, breaking; d, screening by a curved screen; e, separating; f, concentrating; g, dehydrating; h, drying; and i, packaging. Compared with the prior art, the advantages and positive effects of the corn protein production technology are as follows: the present invention provides an improved horizontal screw centrifuge for corn protein dehydration, which is applied to the production technology of corn protein, completely changes the traditional corn protein production technology, thereby increasing the protein yield and yield coefficient, and at the same time also ensuring the quality of the protein.

Owner:SHANDONG XIANGRUI PHARMA +1

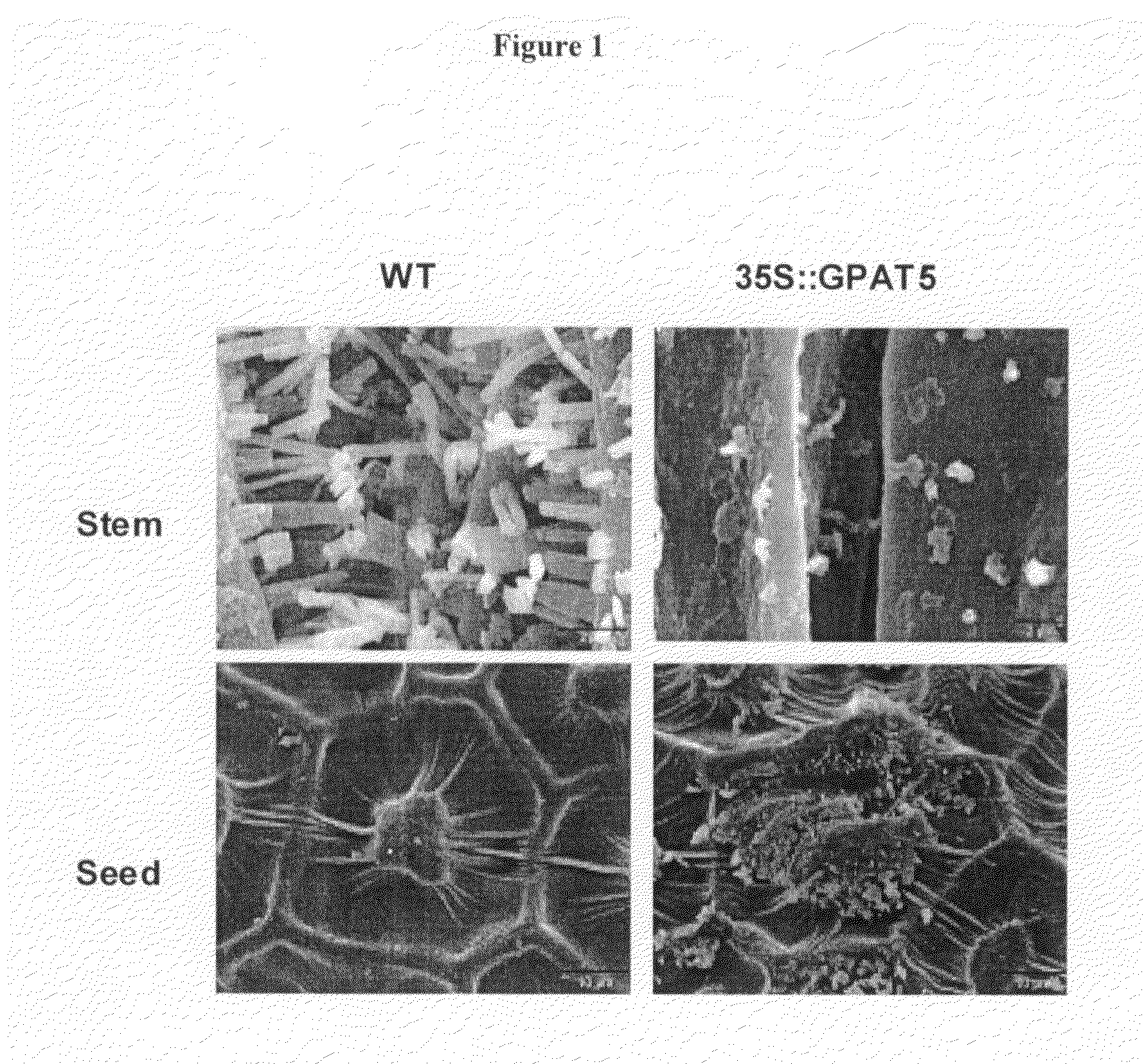

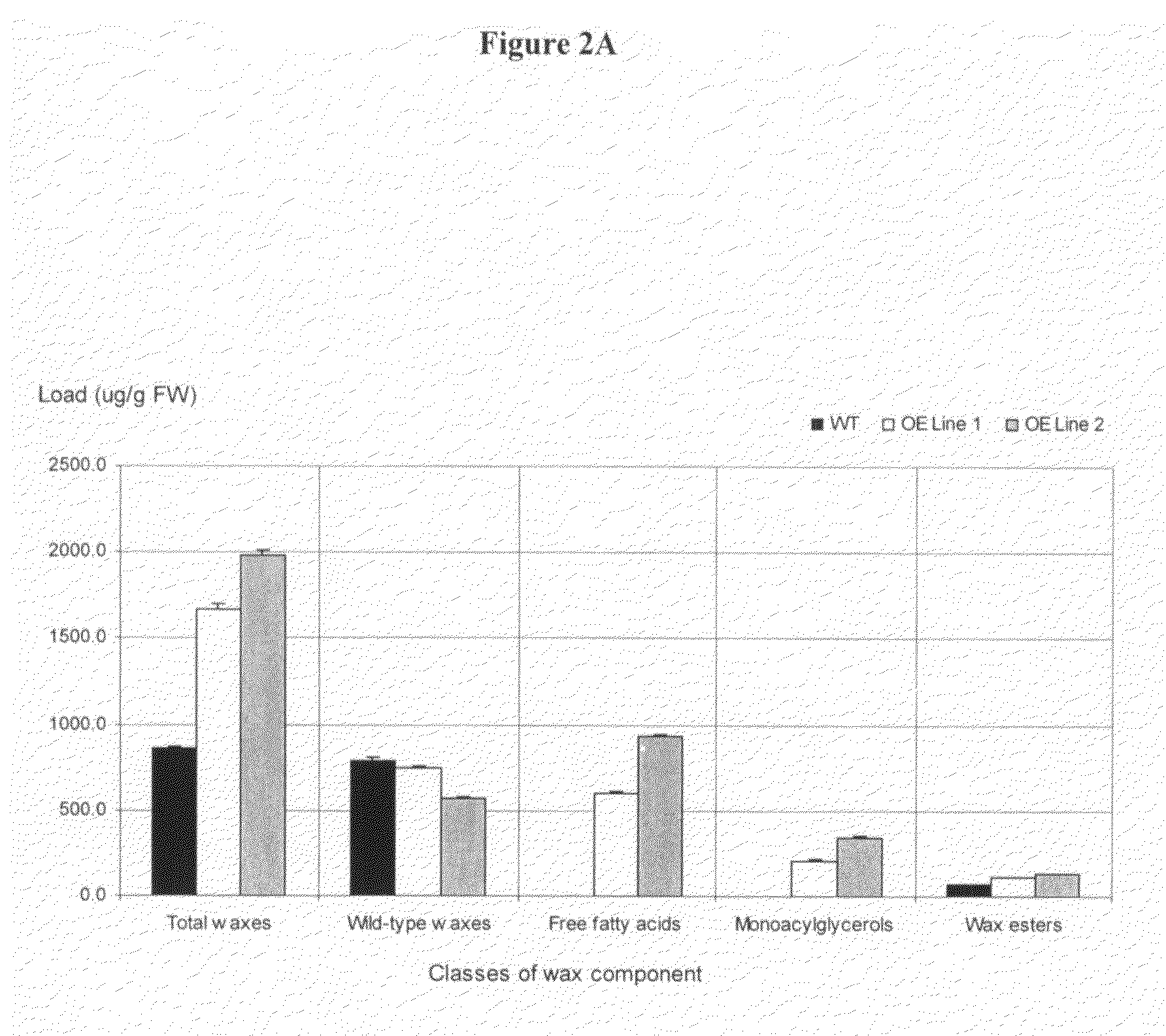

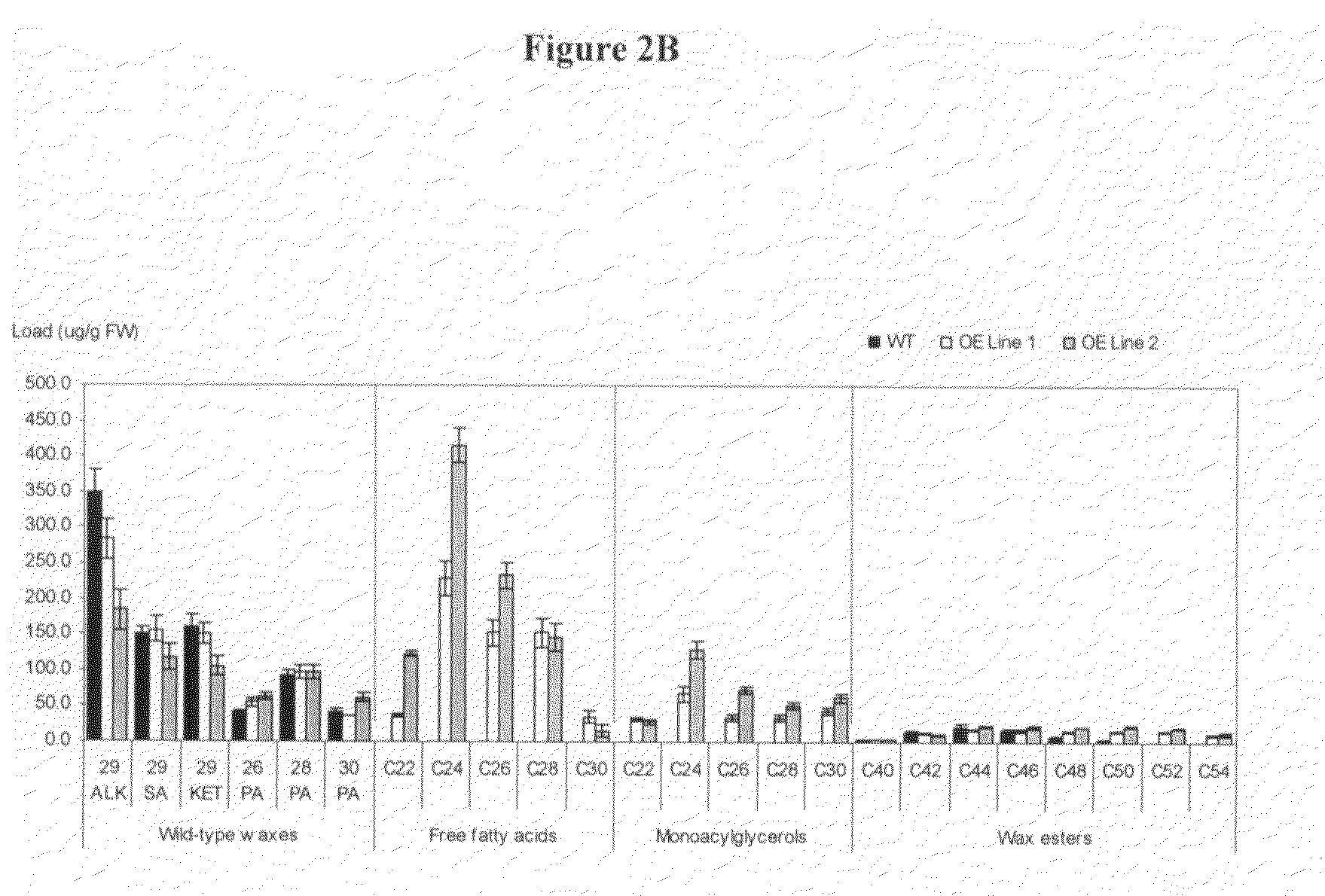

Compositions and methods for using acyltransferases for altering lipid production on the surface of plants

InactiveUS20090163729A1Increase volumeEnhancing environmental stress toleranceBryophytesOrganic chemistryLipid formationFatty acid

The present invention relates to compositions comprising acyltransferase nucleic acid molecules for altering lipids on the surface of plants, and related methods. In particular, the present invention provides compositions and methods for increasing the amount of free fatty acids, acylglycerols, and other lipids on the surface of a plant. In a preferred embodiment, the present invention relates to increasing activity of a GPAT acyltransferase for altering lipid on the plant surface, for increasing surface lipids, for enhancing environmental stress tolerance, increasing resistance to biotic stress, and providing novel plant lipids for commercial products. In further embodiments, the present invention relates to using an Arabidopsis thaliana GPAT acyltransferase for altering lipid compounds on the surface of a plant.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

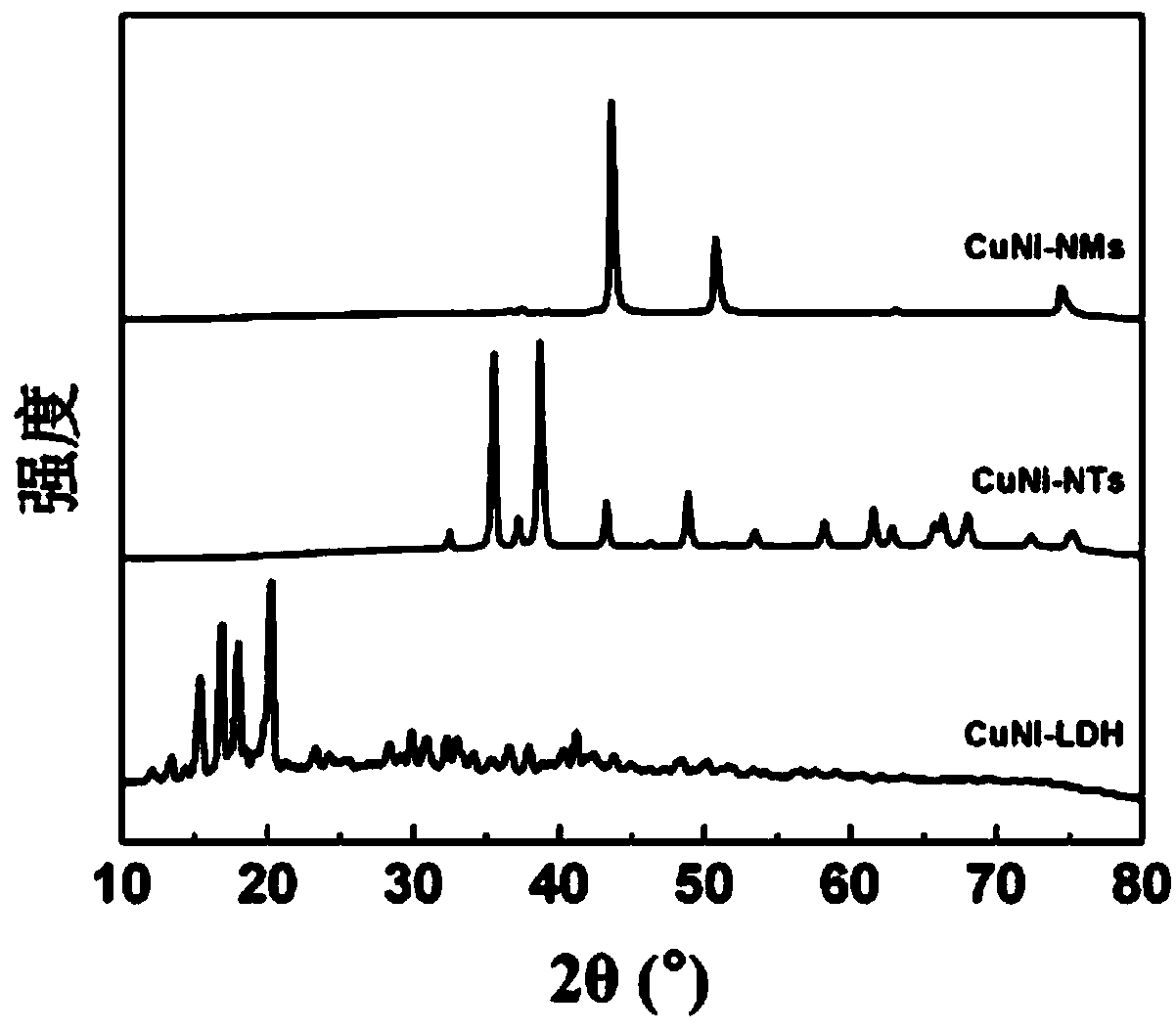

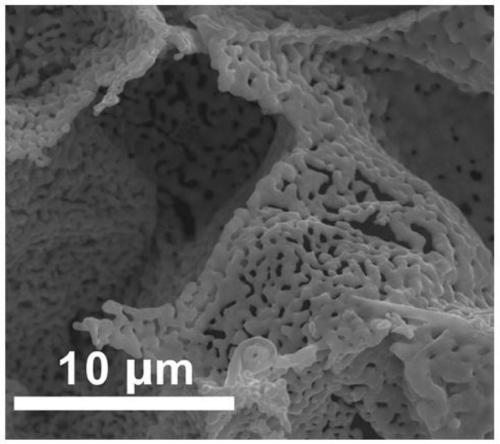

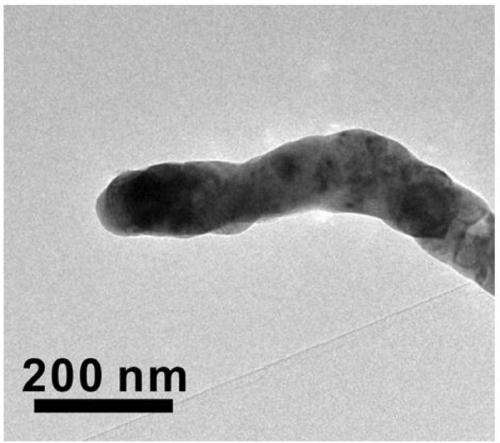

Preparation and application methods of Cu-Ni-based catalyst for reversed water gas reaction

ActiveCN109499577AAvoid structureReduce manufacturing costCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsNickel saltMixed gas

The invention relates to preparation and application of catalysts and aims at providing preparation and application methods of a Cu-Ni-based catalyst for reversed water gas reaction. The preparation method comprises the following steps: dissolving soluble copper salt and soluble nickel salt into a mixed solution of water and ethanol; adding a complexing agent and reacting under heating and stirring conditions to obtain CuNi hydrotalcite; drying and roasting to prepare CuNi mixed oxide with a nanotube structure; after carrying out reduction reaction in a mixed gas atmosphere of flowing H2 and Ar, naturally cooling to room temperature, so as to obtain the Cu-Ni-based catalyst. The complexing preparation method provided by the invention is simple and feasible; influences, caused by uncertainfactors in a preparation process, on the structure and performance of the catalyst are avoided. Active components of the catalyst comprise copper and nickel and any noble metal is not used so that thepreparation cost of the catalyst is relatively low, and industrial large-scale production of the catalyst is easy to realize. The catalyst can be used for a CO synthesis technology and is further connected with a CO hydrogenation catalyst in series to produce alcohols and hydrocarbons with high additional value, so that the catalyst has an application prospect.

Owner:ZHEJIANG UNIV

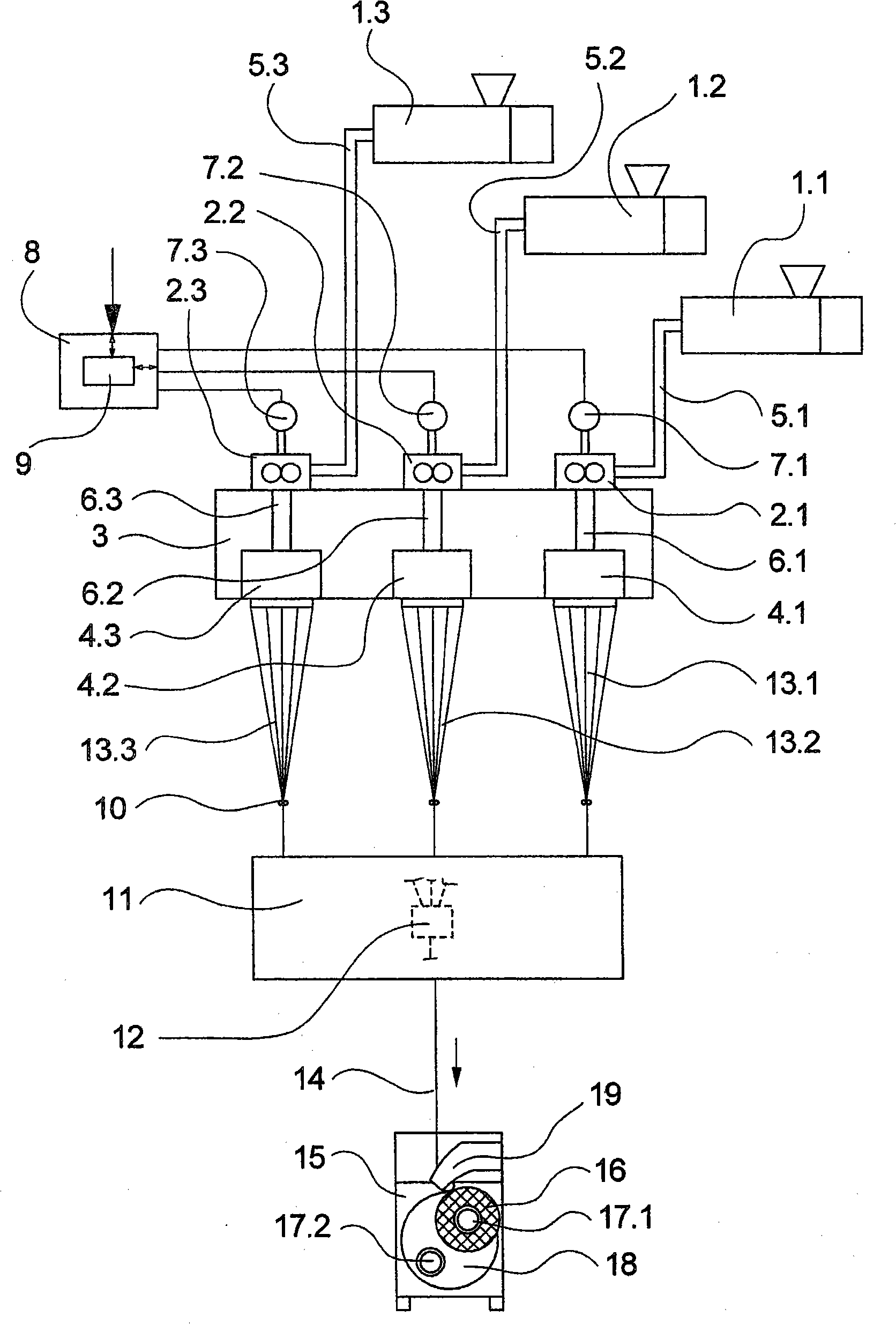

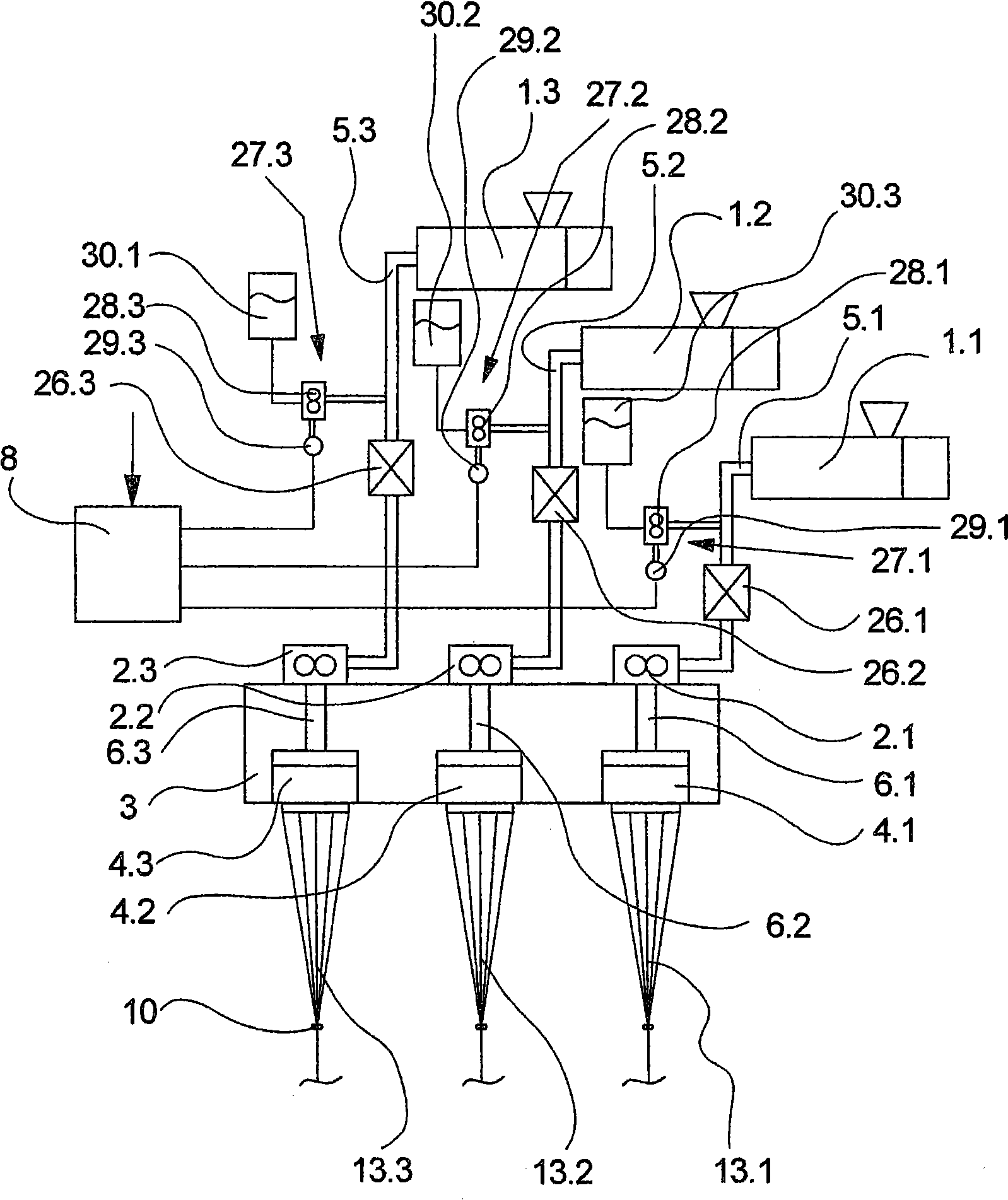

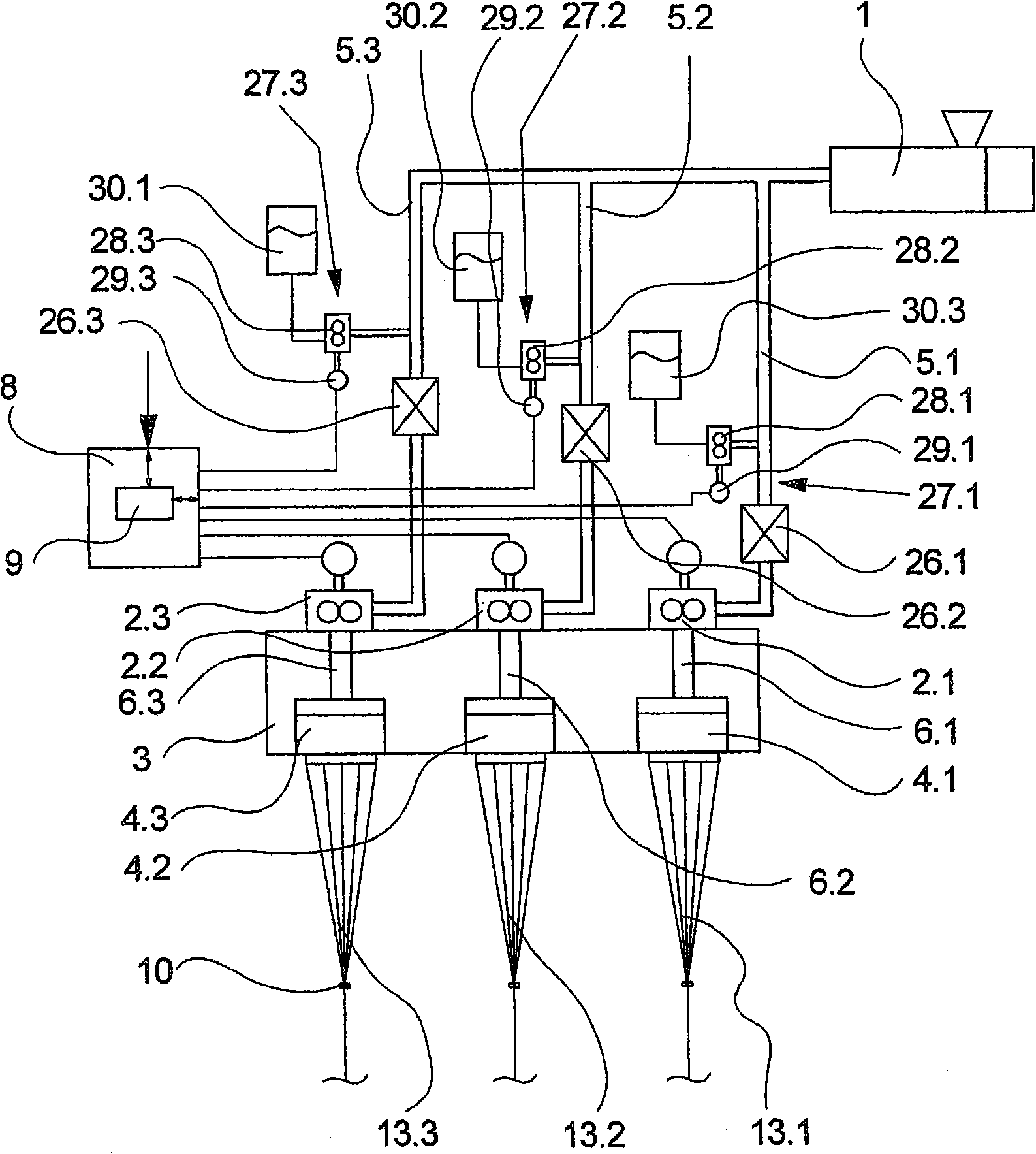

Method and device for producing a multi-colored composite thread

InactiveCN101835928ADrive speed reductionBlend color changeSpinning head liquid feederMelt spinning methodsEngineeringPolymer melt

The invention relates to a method and a device for producing a multi-colored composite thread made of a plurality of extruded colored filament bundles. To this end, a plurality of different dyed polymer melts are generated and extruded in parallel through a plurality of spinnerets to form the colored filament bundles. The colored filament bundles are brought together as a mixed color to form the composite thread. In order to generate a color pattern or to correct the mixed color of the composite thread, according to the invention, the generation of the dyed polymer melts is modified during the extrusion of the filament bundle in order to modify the mixed color of the composite thread.

Owner:OERLIKON TEXTILE GMBH & CO KG

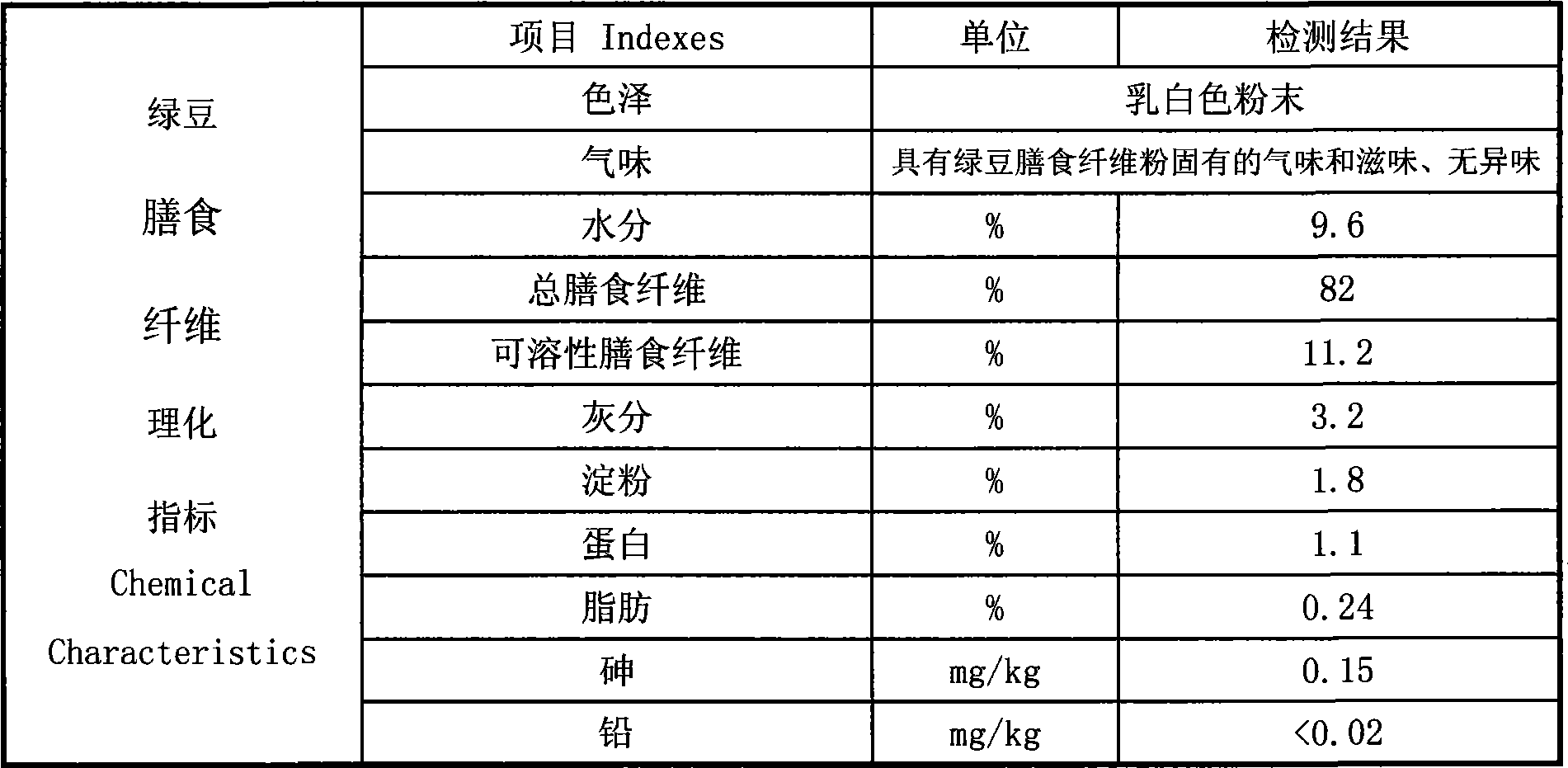

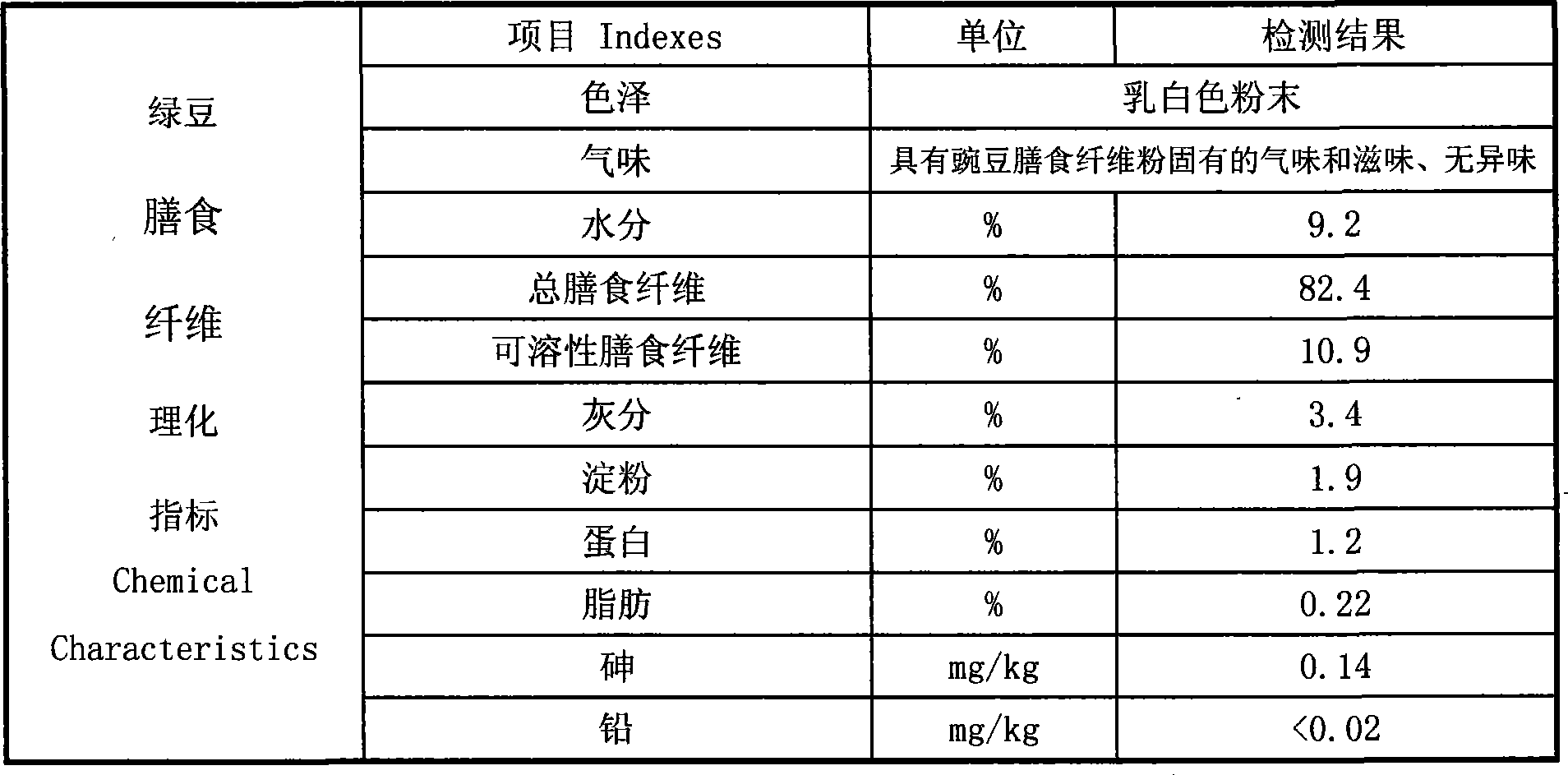

Mung bean or pea dietary fiber and method for producing the same

The invention relates to dietary fibers and a method for producing the same, and belongs to the technical field of dietary fibers and a method for producing the same. A method for producing mung bean or pea dietary fibers is characterized by comprising the following steps of: 1, bean dreg separation; 2, plate pressure filtration; 3, flash streaming drying; 4, microwave sterilization; 5, superfine crushing; and 6, screening and packing. The dietary fibers are made by the method for producing the bean or pea dietary fibers. The invention provides dietary fibers and a method for producing bean or pea dietary fibers. The method processes dietary fibers by using bean dregs from starch process as a raw material and adopting a superfine crushing and extraction technique to achieve a granularity of certain fineness, and improves the prior production process. The dietary fibers are used to be added into foods to bring a fine mouth feel for the foods, have a health-care effect, modify the water retention, oil retention, color and taste of the foods, and have an active effect on environmental protection.

Owner:王雪源

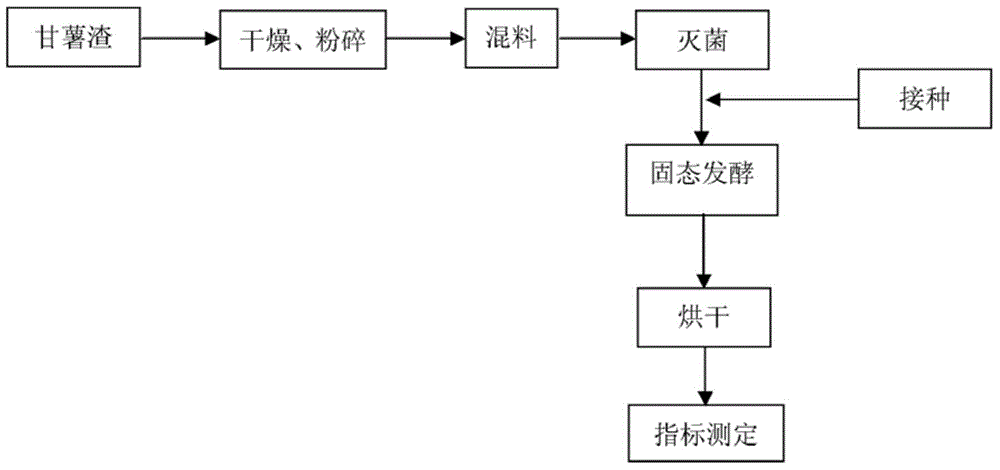

Sweet potato dreg type fermented feed and production method thereof

InactiveCN104431338AImprovement ingredientsClear parametersAnimal feeding stuffBiotechnologyFermentation

The invention provides sweet potato dreg type fermented feed which is prepared through the fermentation technology of candida utilis and the like by using the abundant sweet potato dreg resources in areas where sweet potatoes are planted densely. According to the sweet potato dreg type fermented feed, the existing technology of fermented sweet potato dregs is improved, production parameters are made clear, production links are reduced, and the fermented sweet potato dregs with the higher feeding value are acquired.

Owner:SHANDONG BIO SUNKEEN

High-temperature-resistant hydraulic cylinder manufacturing technology

InactiveCN104014985AIncrease profitImprove high temperature resistanceFluid-pressure actuatorsManufacturing technologyMaterials science

A high-temperature-resistant hydraulic cylinder manufacturing technology comprises the following steps of (1) material selection, (2) product machining and (3) technology design. A material of a hydraulic cylinder is selected according to the pressure of a working medium and the size of a working cylinder. 40 forged steel or 45 forged steel or carbon steel STKM13C can be selected as the material of the hydraulic cylinder and a piston rod can be made of S45C carbon steel. Seamless cold drawing is conducted on the surface of the hydraulic cylinder, high-accuracy inclination intersecting boring is conducted on the inner diameter portion, the tolerance of the inner diameter ranges from H7 to H9, the surface roughness ranges from 0.8 S to 2.0 S, and the tension strength is over 5.2 MPa. Grinding and hard chroming are conducted on the outer diameter portion of the piston rod, the tolerance of the appearance ranges from f7 to f8, the surface hardness is over HV700, the surface roughness ranges from 0.8 S to 1.6 S, and the chroming thickness is 20 micrometers. According to the high-temperature hydraulic cylinder manufacturing technology, the hydraulic cylinder is good in high-temperature-resistant performance, the service life of a sealing device of the hydraulic cylinder can be prolonged, the number of needed spare parts is small, the number of replacement periods can be reduced, and therefore the labor intensity of workers is relieved; the structure is simple and the hydraulic cylinder is safe and reliable.

Owner:LIUZHOU WEILISHI HYDRAULIC DEVICE

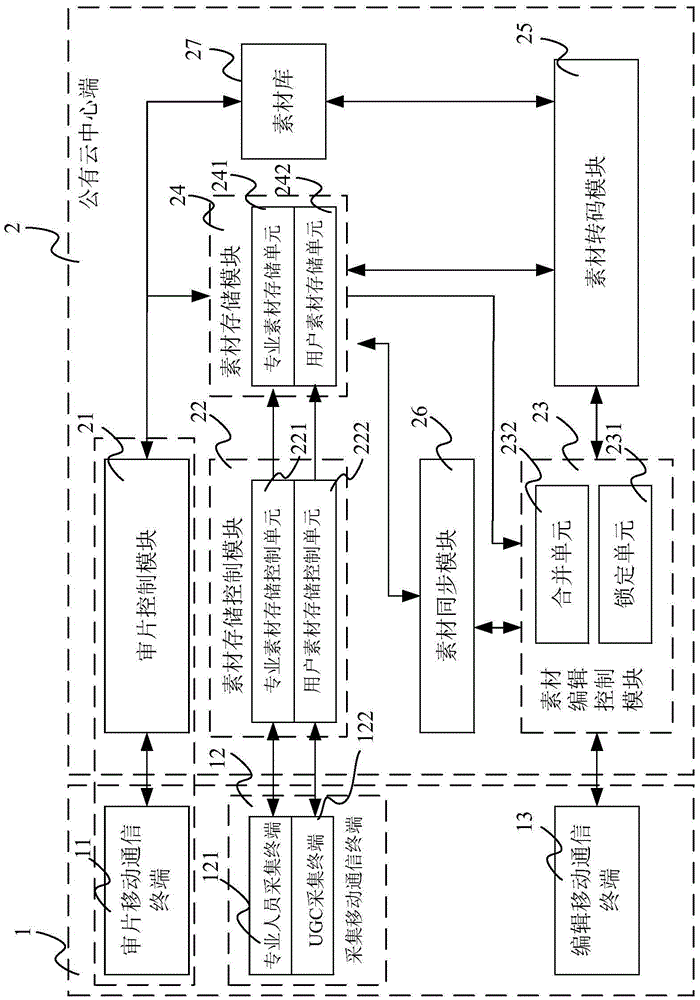

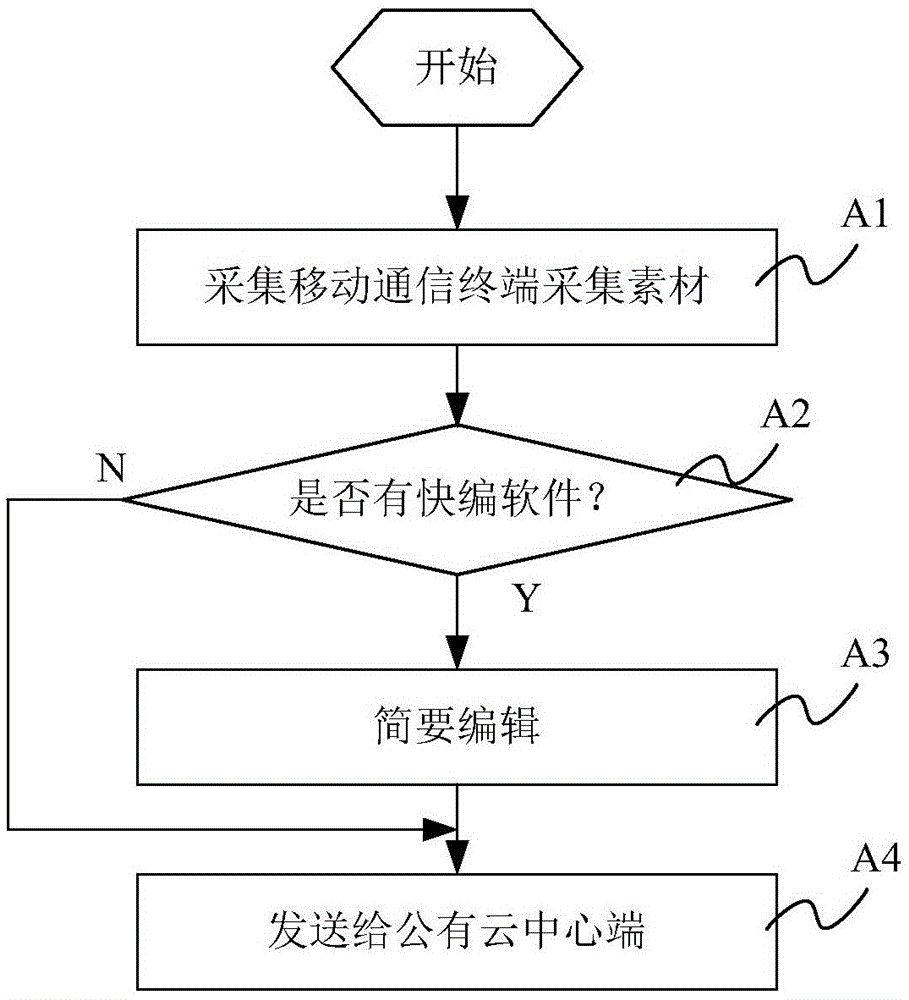

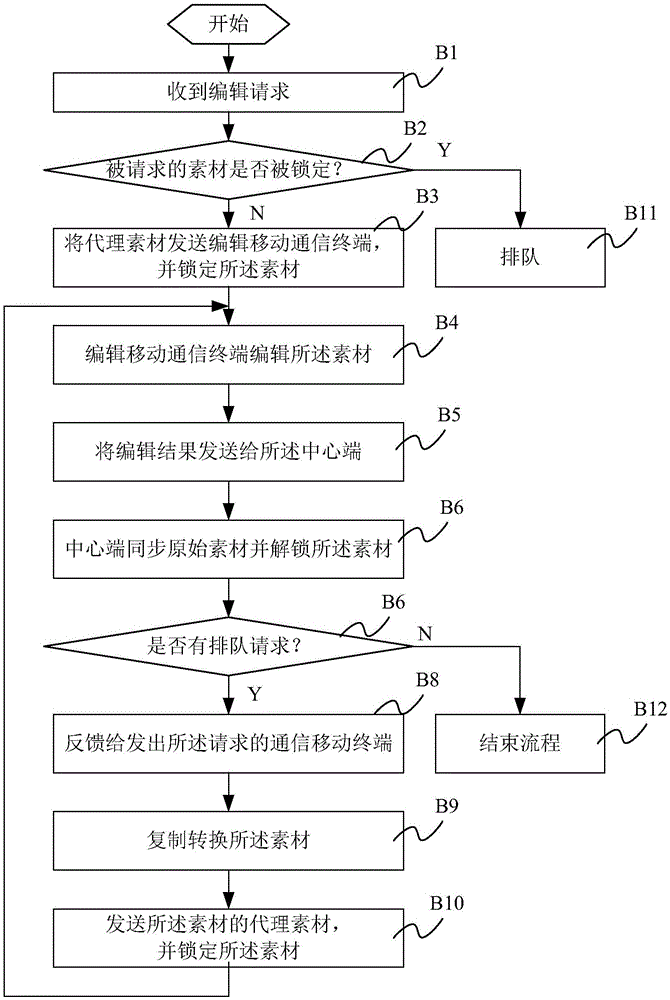

Video program collecting, editing and making method and system based on public cloud

ActiveCN105472421AReduce data volumeReduce delivery pressureSelective content distributionFile transmissionMaterial editing

The invention provides a video program collecting, editing and making method and system based on public cloud, and the method comprises the steps: obtaining a video material through a mobile communication terminal; transmitting the video material to a public cloud center end through the mobile communication terminal and a network; copying and converting the raw video material into a code stream through the public cloud center end, wherein the code stream is an agent material of an agent code stream suitable for network transmission; responding to a request from the mobile communication terminal, and transmitting the agent material to the mobile communication terminal; and enabling the mobile communication terminal and the public cloud center end to cooperatively edit and / or check the video material. The method employs the support of the public cloud, achieves the quick collecting and editing, lowers the request for a material editing site, and improves the file transmission and program making efficiency.

Owner:BEIJING ZHENGQI LIANXUN TECH

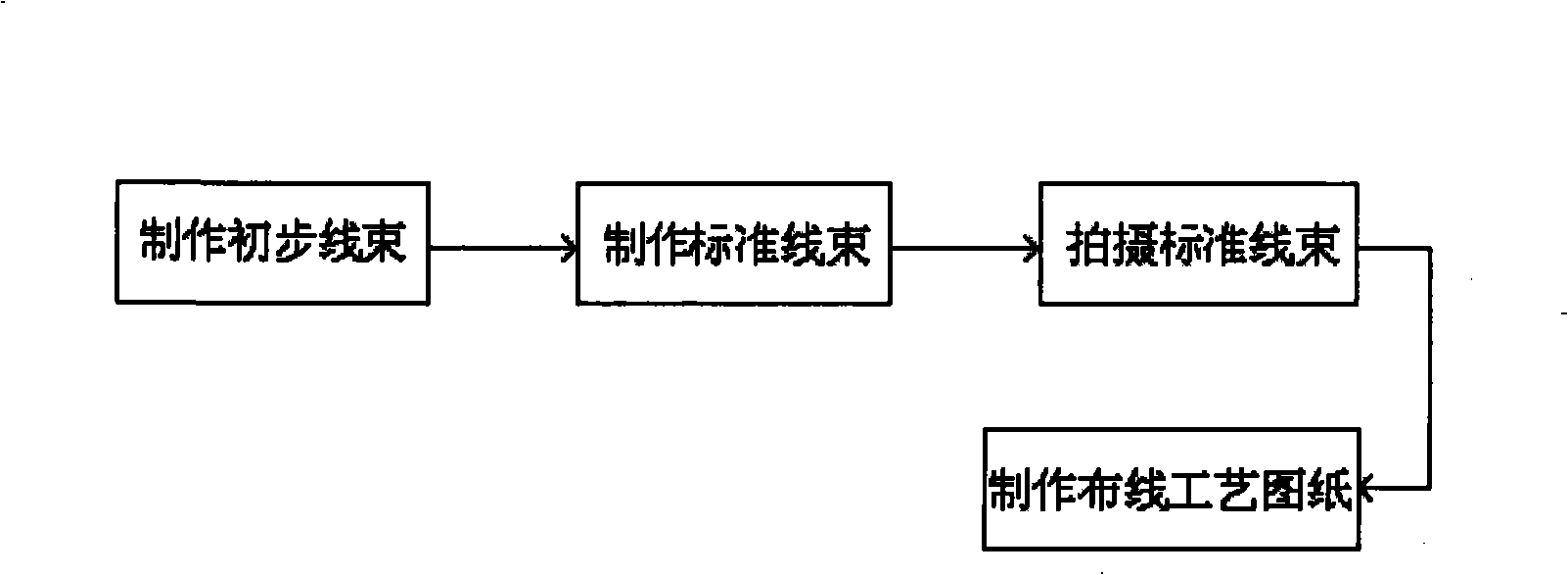

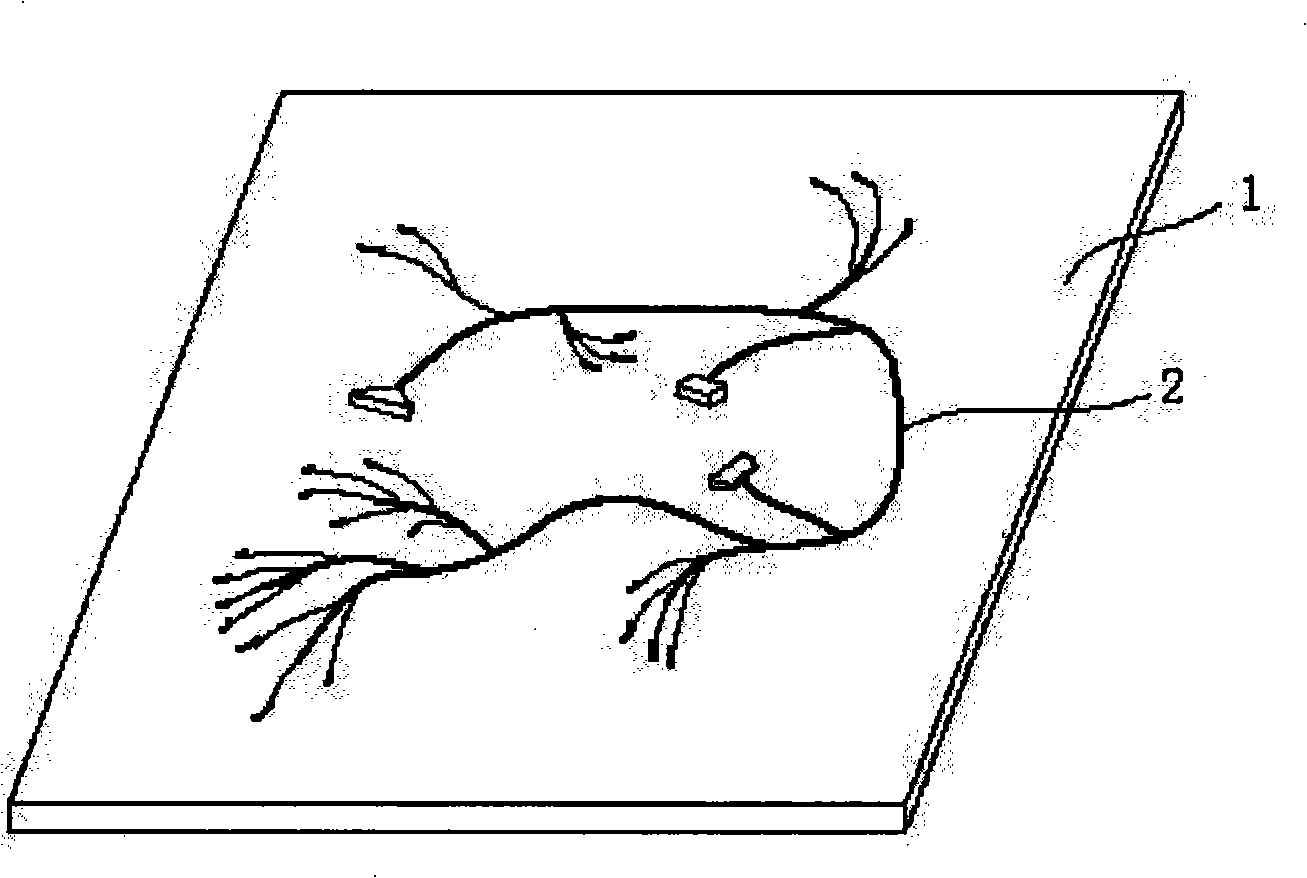

Production method and routing method of routing art work sheet

InactiveCN101272670AChange the production processGuarantee product qualityCircuit arrangements on support structuresManufacturing wire harnessesCable harnessProcess requirements

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com