High-temperature wear resistant nonstick coating layer material and preparation method thereof

A high-temperature wear-resistant and non-stick coating technology, which is applied in coatings and other directions, can solve the problems of not being too high in use temperature, resource waste environment, poor wear resistance, etc., and achieve easy operation, not easy to fall off, and excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a high-temperature wear-resistant non-stick coating material, which includes: 85% Teflon (polytetrafluoroethylene (PTFE)); 15% zirconium dioxide in weight percentage.

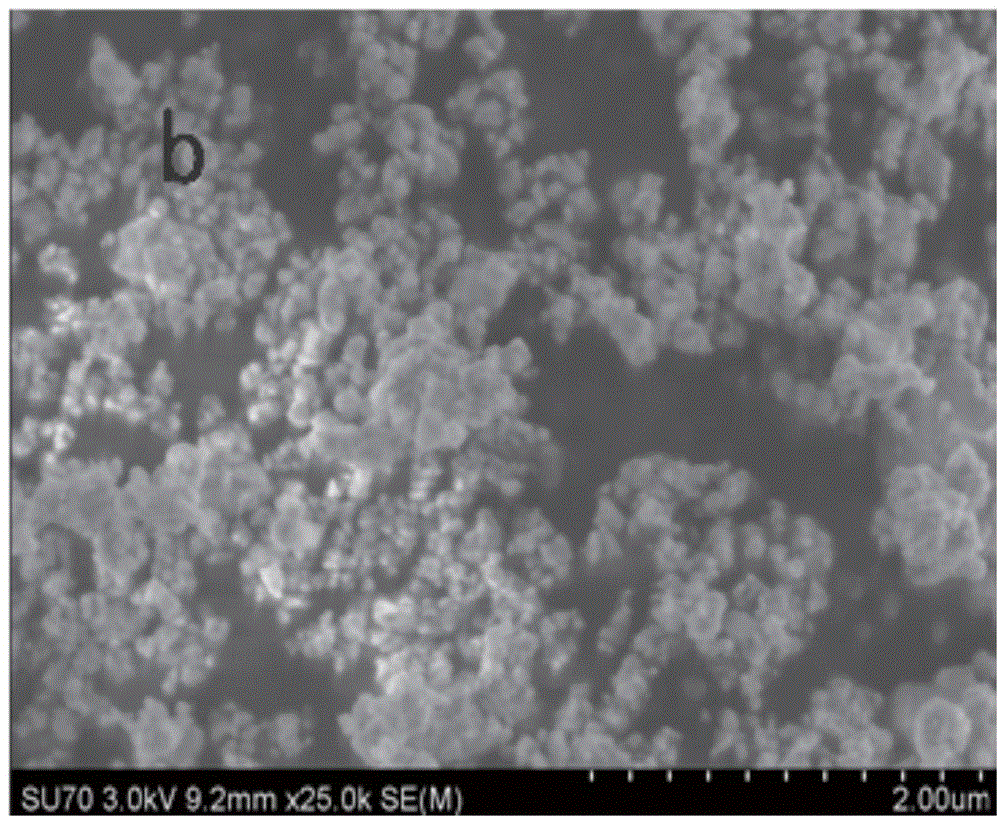

[0042] Among them, the particle size of Teflon is 10 μm, and the particle size of zirconium dioxide is 0.2-50 μm.

[0043] The preparation method of the high-temperature wear-resistant coating material of this embodiment is as follows:

[0044] (1) Insulate the commercially available zirconia powder material at 600° C. for 30 minutes, and then perform ball milling dispersion treatment for 20 minutes;

[0045] (2) Add the zirconia powder material after dispersion treatment to the Teflon coating material in a weight percentage of 1% to 20%, and stir evenly to prepare a zirconia / Teflon composite wear-resistant non-stick coating layer material.

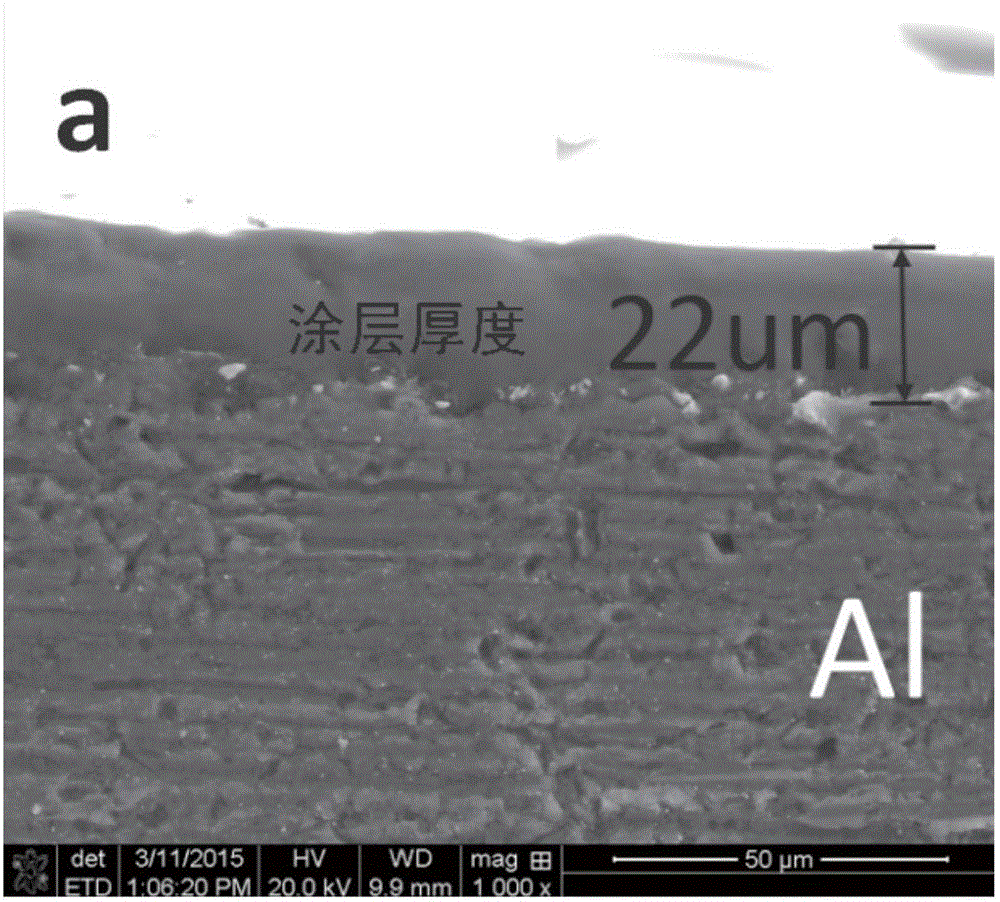

[0046] The high-temperature wear-resistant non-stick coating material of this embodiment is made into a non-stick coating through the coa...

Embodiment 2

[0049] This embodiment provides a high-temperature wear-resistant non-stick coating material, which includes: Teflon 85% (polytetrafluoroethylene (PTFE)); titanium dioxide 15% in weight percentage.

[0050] Among them, the particle size of Teflon is 10 μm, and that of titanium dioxide is 0.2-5 μm.

[0051] The preparation method of the high-temperature wear-resistant coating material of this embodiment is as follows:

[0052] (1) Insulate the commercially available titanium dioxide powder material at 600°C for 30 minutes, and then perform ball milling dispersion treatment for 20 minutes;

[0053] (2) Add the dispersed titanium dioxide powder material into the Teflon coating material at a weight percentage of 1% to 20%, and stir evenly to prepare a titanium dioxide / Teflon composite wear-resistant non-stick coating material.

[0054] The high-temperature wear-resistant non-stick coating material of this embodiment is made into a non-stick coating through the coating process of th...

Embodiment 3

[0056] This embodiment provides a high-temperature wear-resistant non-stick coating material, which includes: 85% Teflon (polytetrafluoroethylene (PTFE)); 15% aluminum oxide.

[0057] Among them, the particle size of Teflon is 10 μm, and the particle size of aluminum oxide is 0.2-20 μm.

[0058] The preparation method of the high-temperature wear-resistant coating material of this embodiment is as follows:

[0059] (1) heat-preserve the commercially available aluminum oxide powder material at 600°C for 30 minutes, and then carry out ball milling dispersion treatment for 20 minutes;

[0060] (2) Add the Al2O3 powder material after the dispersion treatment to the Teflon coating material in a weight percentage of 1% to 20%, and stir evenly to prepare Al2O3 / Teflon composite wear-resistant Adhesive coating material.

[0061] The high-temperature wear-resistant non-stick coating material of this embodiment is made into a non-stick coating through the coating process of the existin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com