Method for producing ultrafine-grain special mirabilite

A technology of ultra-fine particles and manufacturing methods, applied in chemical instruments and methods, alkali metal sulfites/sulfites, alkali metal compounds, etc., can solve the problem of uneven particles, no open patents have been found, and no ultra-fine particles have been reported. Special Glauber's salt and other problems of granules, to achieve the effect of good granule fluidity and change the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

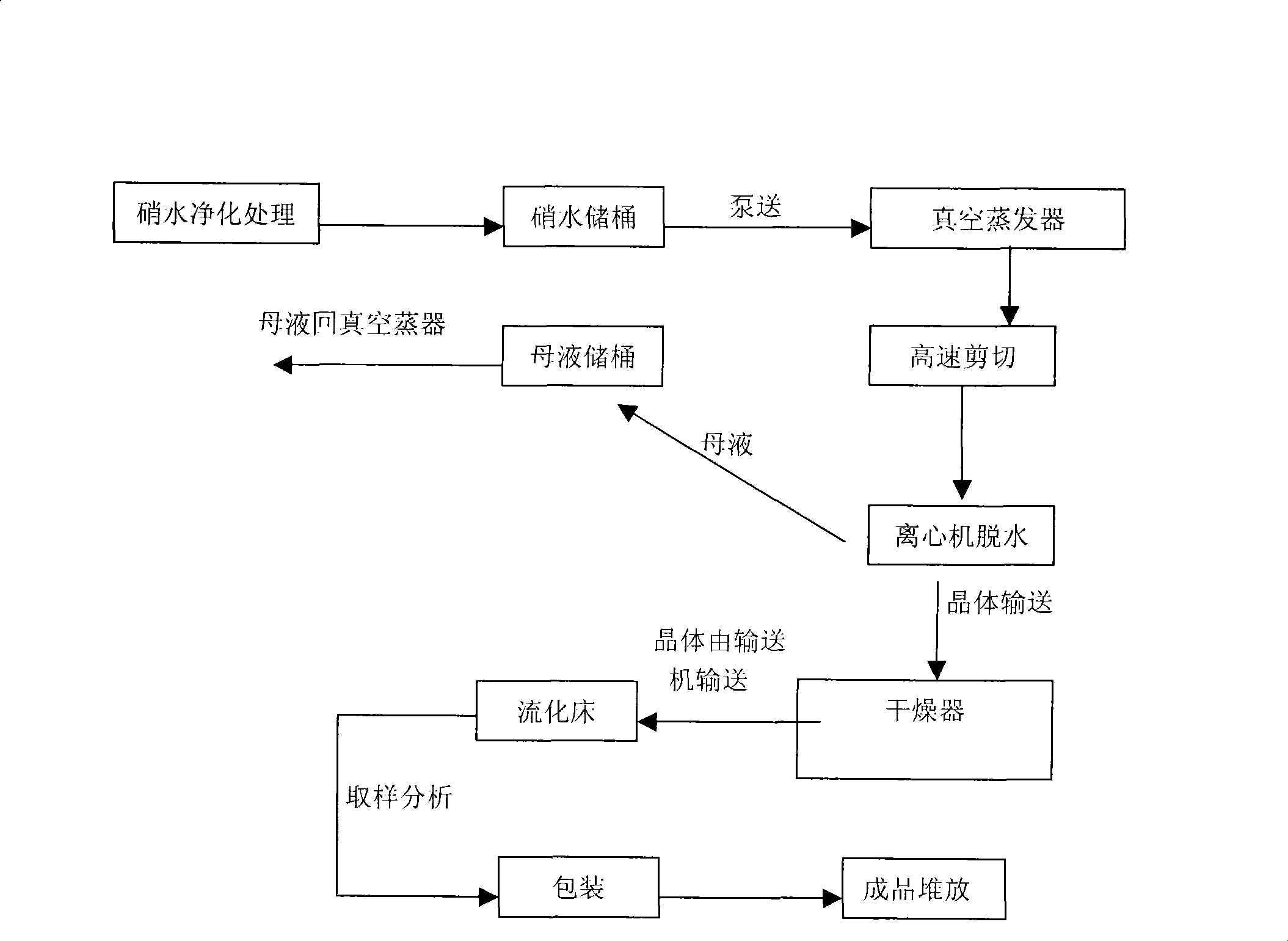

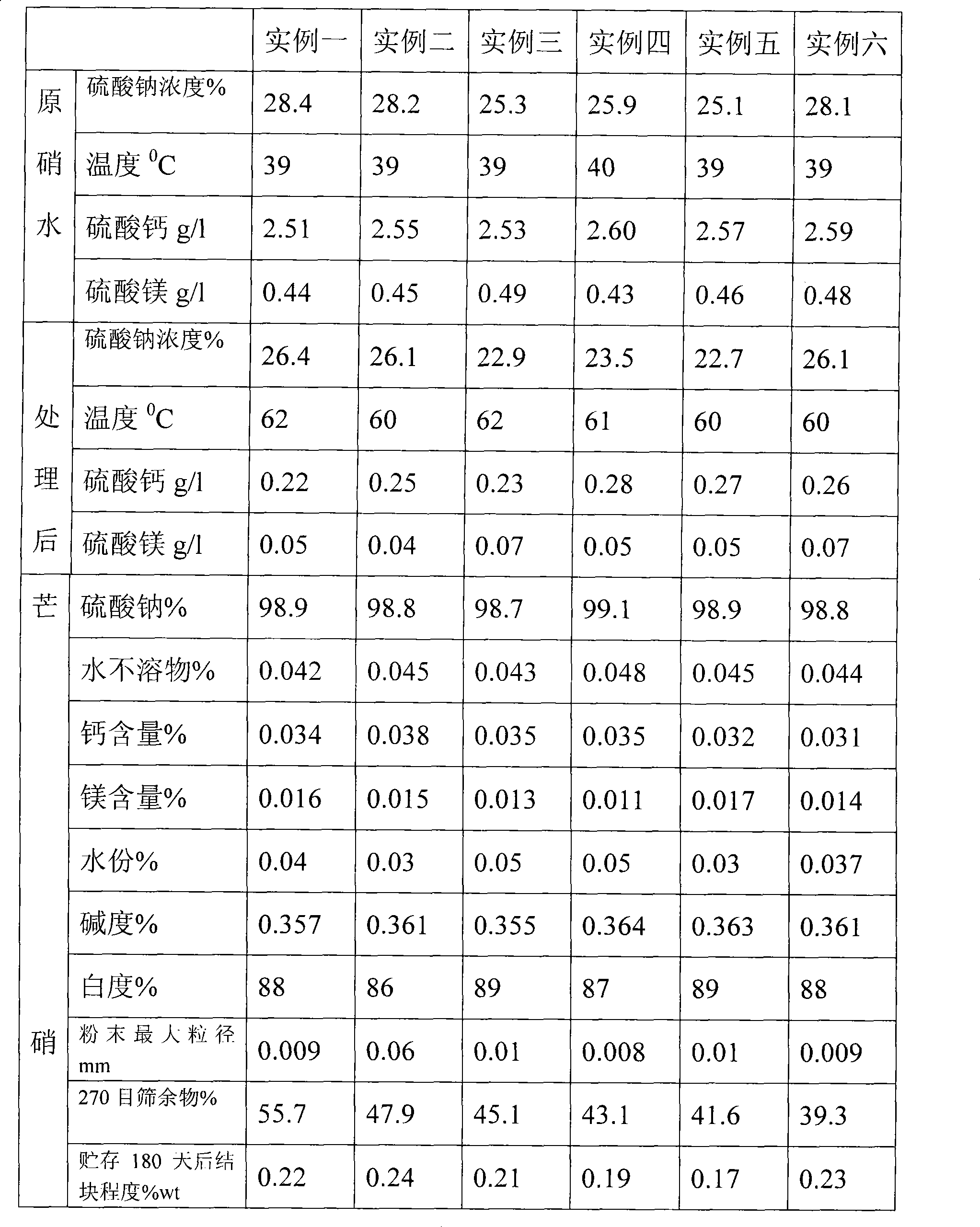

[0028] Use a pump to pump hot water at 40-70°C to dissolve the Glauber's salt (sodium sulfate) in the ore to form a Glauber's salt (sodium sulfate) solution (abbreviation: salt water) containing various impurities and a sodium sulfate concentration of 28.4%. After refining to remove impurities, five-effect vacuum evaporation and concentration, crystallization, the nitric acid slurry is subjected to high-speed shearing at 2000rpm, and after centrifugation, wet nitric acid with a water content of 3% is obtained, and the wet nitric acid is transported to a drying device for drying, and the product is sent to LLC-I Special fluidized bed treatment, separation of coarse particles of Glauber's salt, raw salt water and various data of the purity of Glauber's salt obtained from production figure 2 manifested in.

Embodiment 2

[0030] Use a pump to pump hot water at 40-70°C to dissolve sodium sulfate in the ore to form nitric water containing various impurities and a concentration of sodium sulfate of 28.1%. After refining to remove impurities, five-effect vacuum evaporation concentrates and crystallizes. After the nitric slurry is sheared at a high speed of 2200rpm, wet nitric acid with a water content of 6% is obtained. The wet nitric acid is transported to the drying device for drying, and the product is sent to the special fluidized bed of LLC-I for treatment, and the coarse granular mirabilite, raw nitric water and Various data on the purity of Glauber's salt are obtained in the figure 2 manifested in.

Embodiment 3

[0032] Use a pump to pump hot water at 40-70°C to dissolve sodium sulfate in the ore to form nitric water containing various impurities and a sodium sulfate concentration of 25.6%. After refining to remove impurities, five-effect vacuum evaporation concentrates and crystallizes. The nitrate slurry is sheared at a high speed of 2400rpm and centrifuged to obtain wet nitrate with a water content of 6%. The wet nitrate is transported to the drying device for drying, and the product is sent to the LLC-I special fluidized bed for treatment to separate the coarse particle of Glauber's salt. Various data on the purity of raw saltwater and thenardite obtained from production are in figure 2 manifested in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com