Blind hole plate and its processing method

A processing method and blind hole board technology, which are applied in the formation of electrical connection of printed components, manufacturing of multi-layer circuits, and electrical connection of printed components, etc., can solve the problems of lowering product qualification rate and large cost impact, and achieve the reduction of processing costs and the reduction of working procedures. The effect of reducing and preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

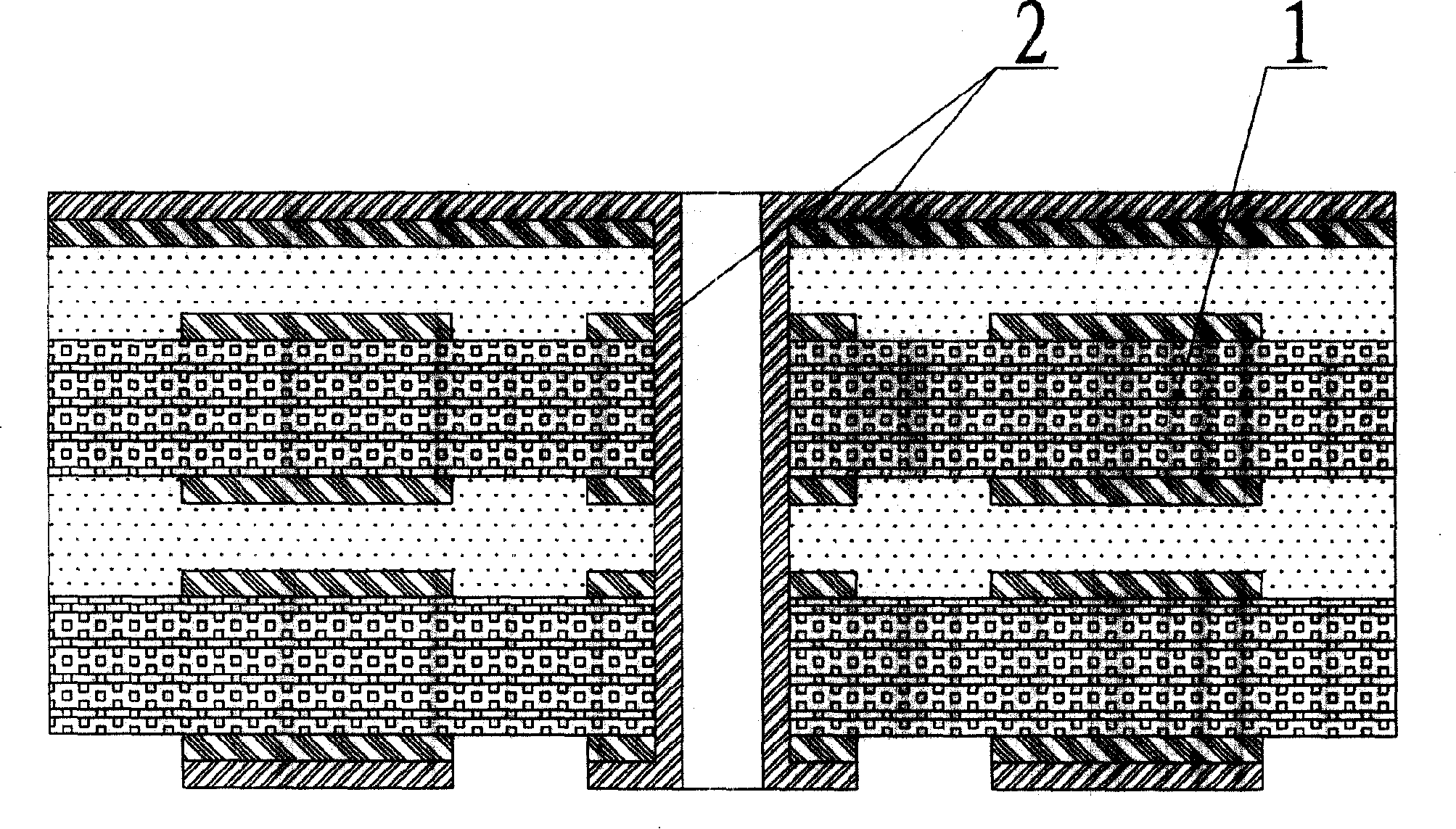

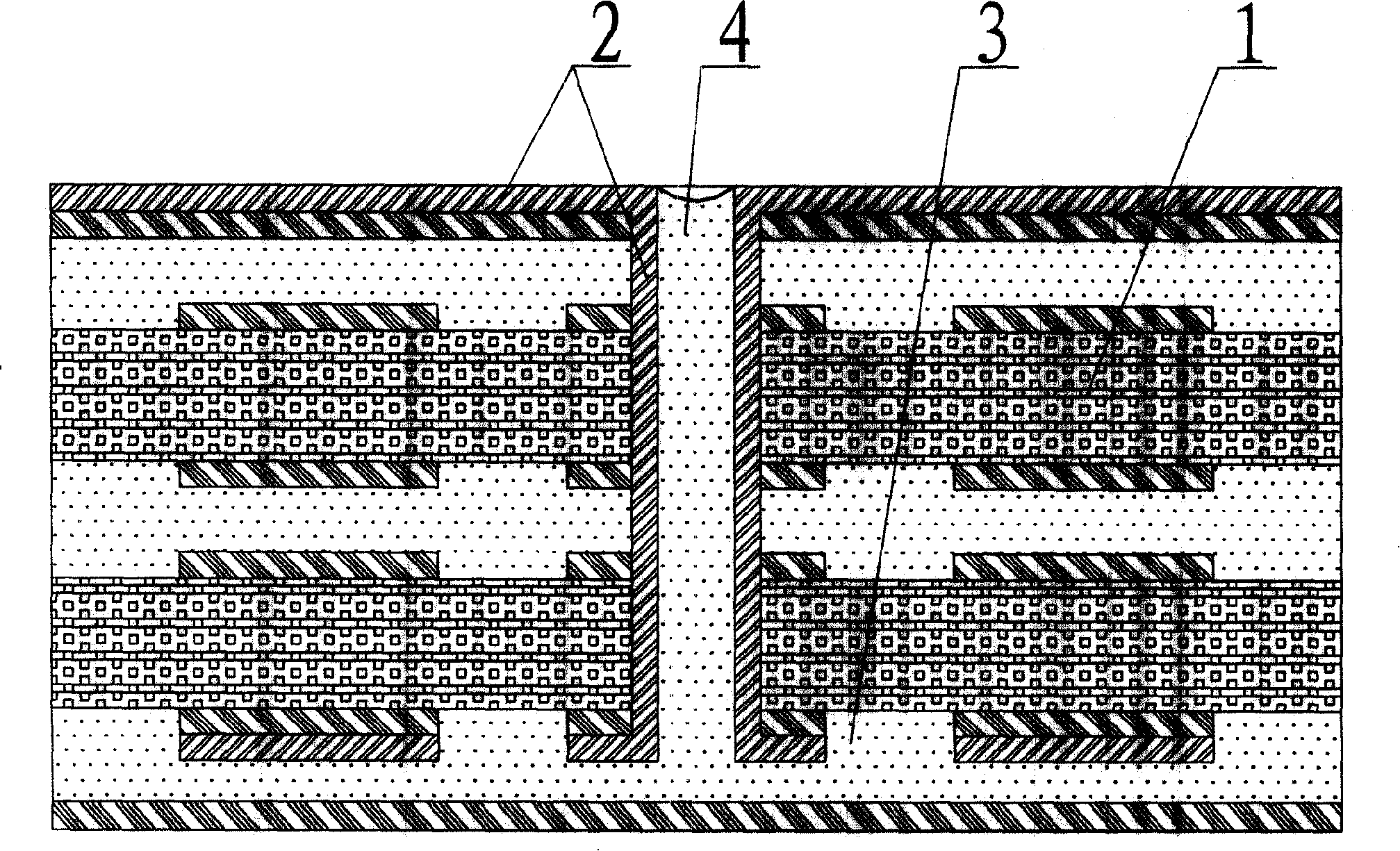

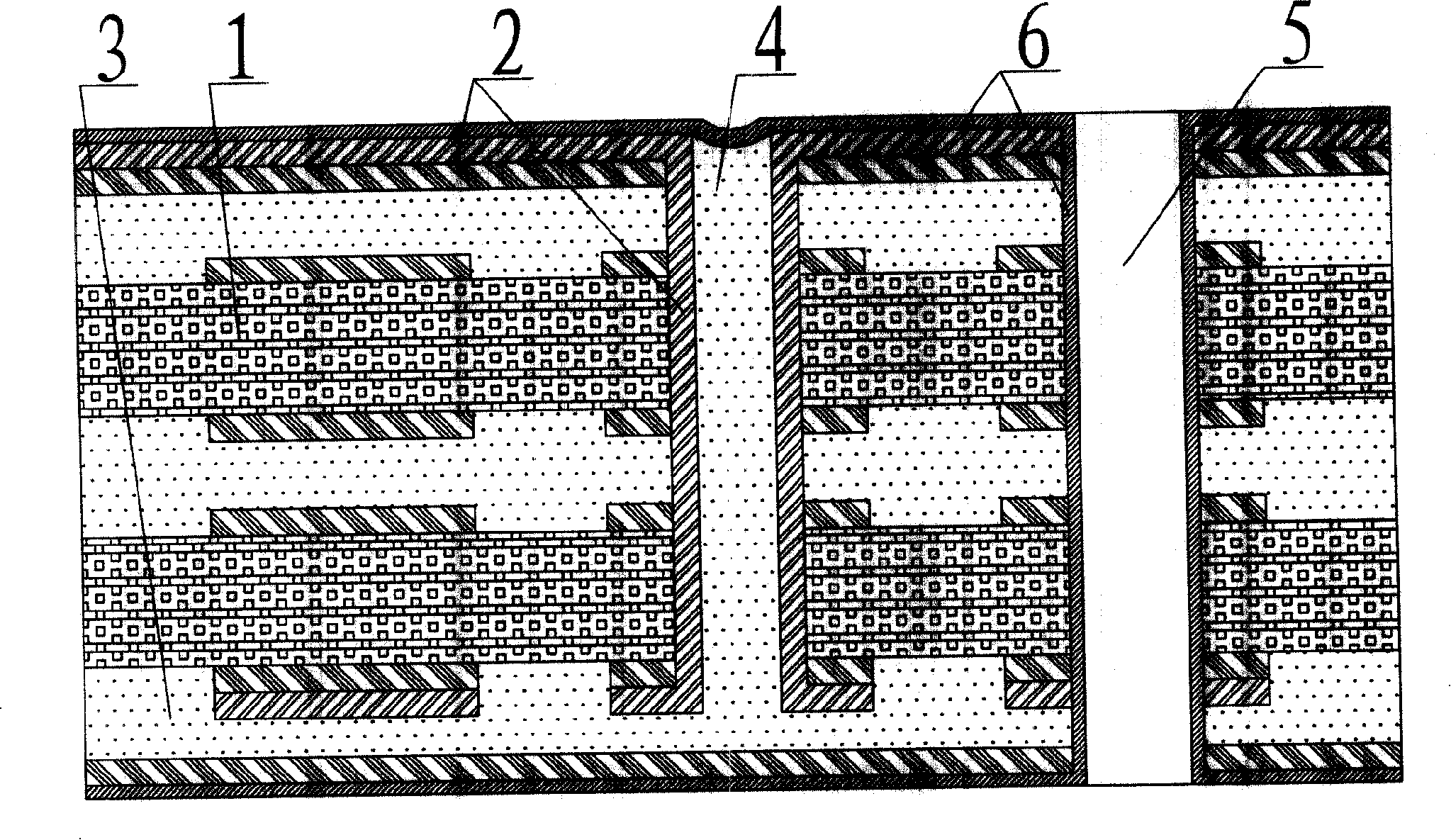

[0030] First, laminate the multi-layer board 1 corresponding to the number of layers of blind holes, then drill holes on the multi-layer board, and plate copper 2 on the hole wall, as in figure 1 shown. The above-mentioned multi-layer board is used as a sub-board and another layer of sub-board 3 is laminated twice, and the resin in the prepreg fills the hole after copper plating to form a blind hole 4, such as figure 2 shown. Drill through holes 5 and electroless copper plating on multilayer boards containing blind holes, so that a layer of copper 6 is attached to both sides of the drilled through holes and the circuit board, such as image 3 shown. Make a film for graphic transfer, make the part corresponding to the blind hole on the graphic film into a light-transmitting area smaller than the diameter of the blind hole, and paste a photosensitive dry film 7 on the surface of the blind hole multilayer board, which will be used for graphic transfer The film 8 is pasted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com