Patents

Literature

153results about How to "Improve qualified product rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

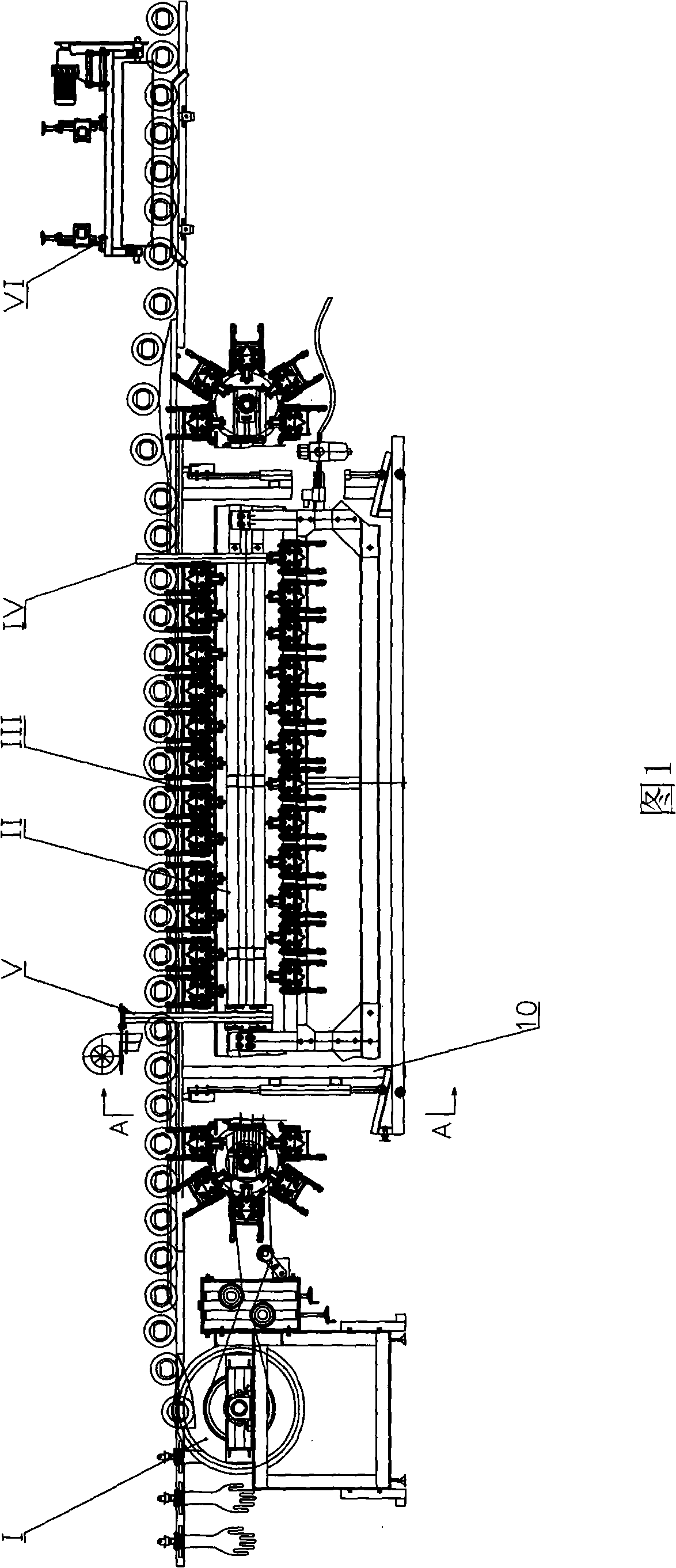

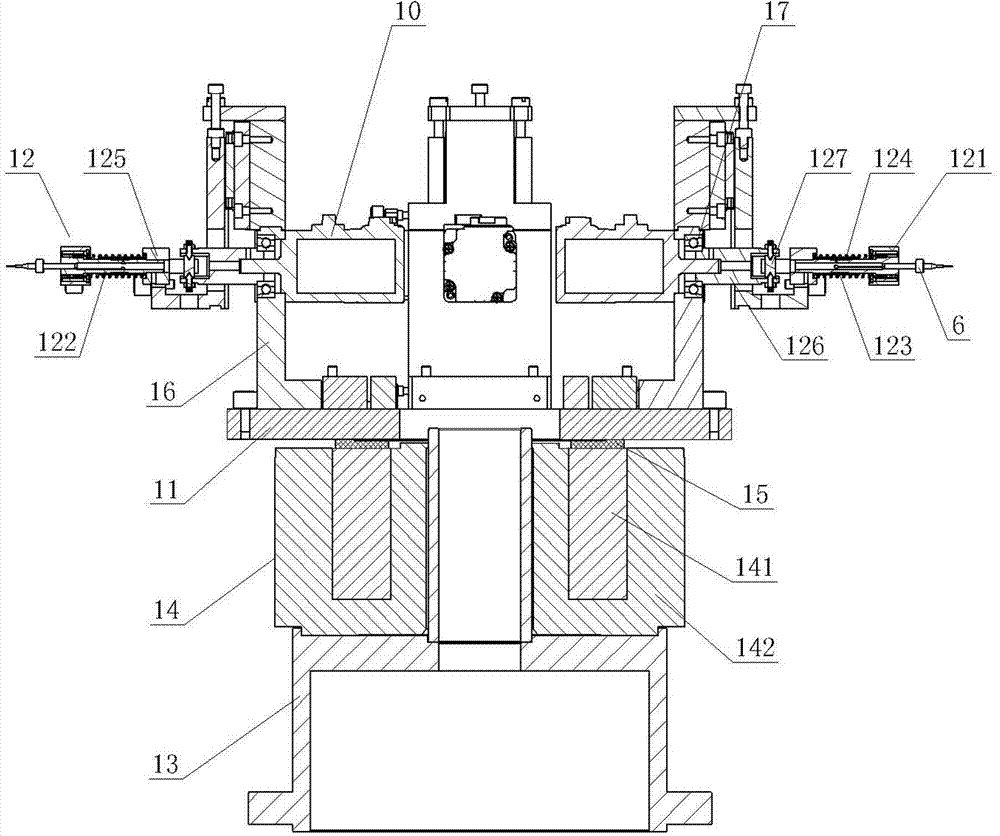

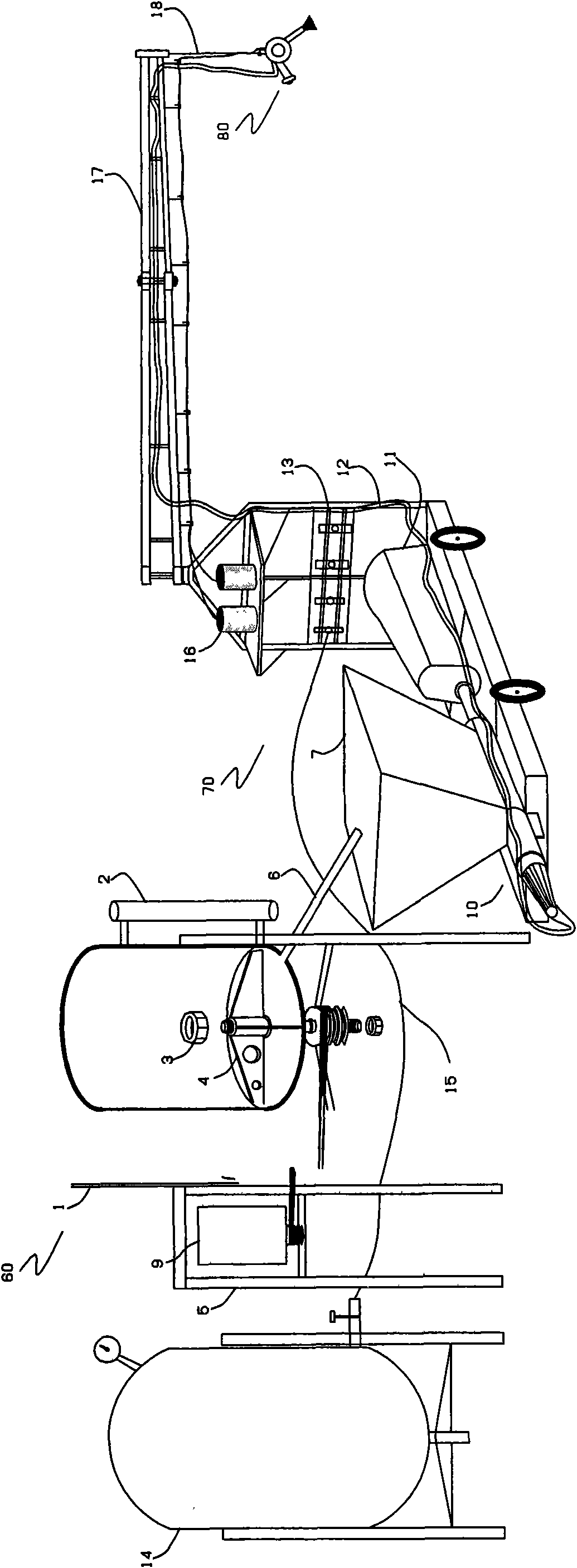

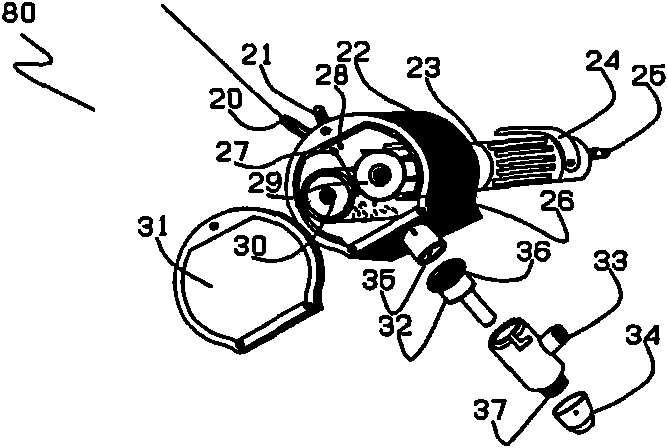

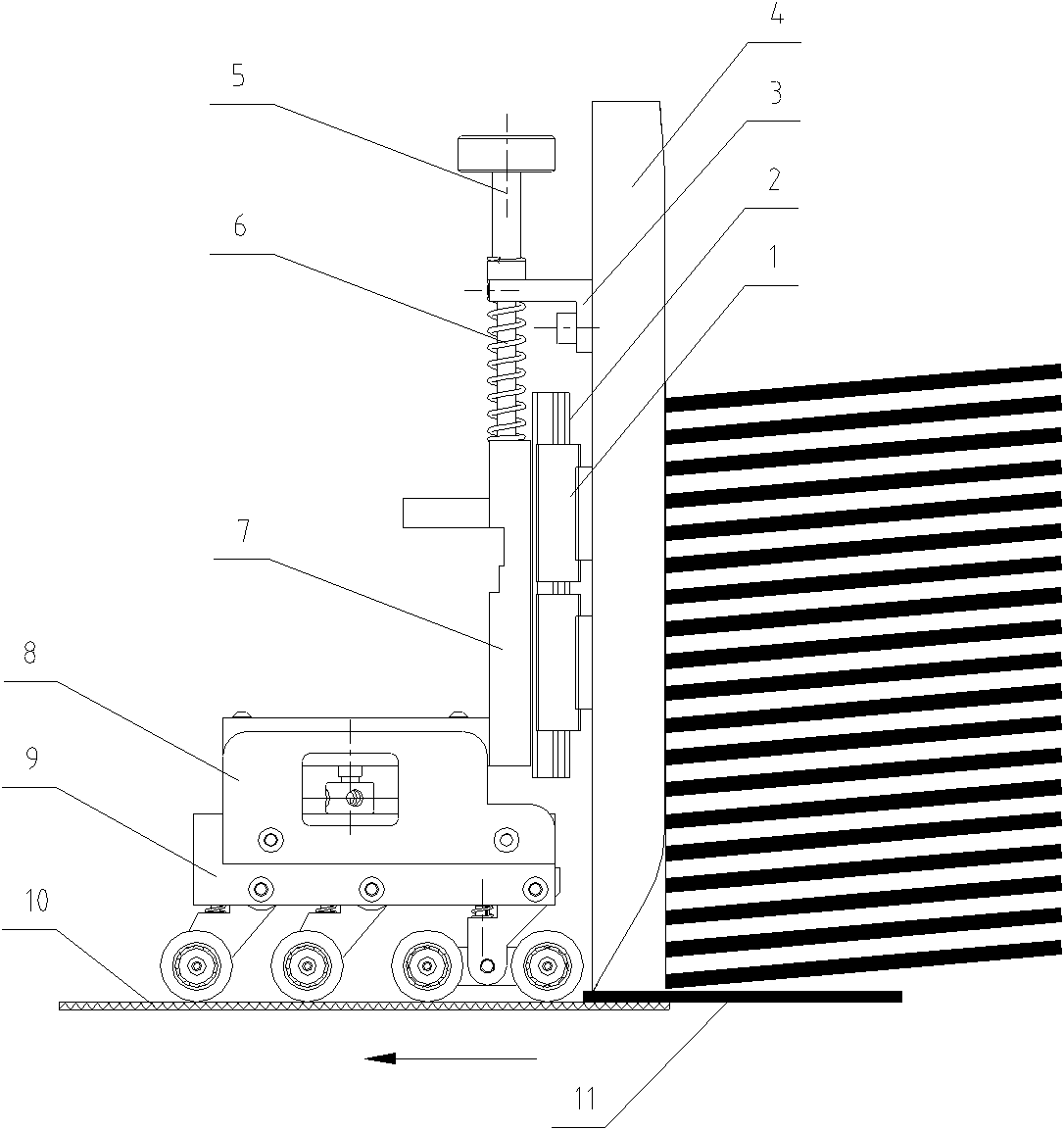

On-line automatic ingot stripper for glue gloves

The invention relates to a rubber glove online automatic demoulding machine, comprising a synchronous force grasping mechanism, a guide rail control mechanism, glove demoulding mechanisms, a glove blowing-aside mechanism and a glove blowing-down mechanism, wherein, a drive sprocket of the synchronous force grasping mechanism is engaged with a main drive chain for transmitting hand molds on a glove production line so as to transmit the power to the guide rail control mechanism; the glove demoulding mechanisms corresponding to the hand molds one by one are arranged on the guide rail control mechanism and can carry out circular movements of lengthwise synchronous moving, transverse separate moving and mechanical claw opening and closing, so as to complete the whole set of operations for glove demoulding; the glove blowing-aside mechanism and the glove blowing-down mechanism are respectively corresponding to the positions of initially grasping the hand mold and finally demoulding a glove by the mechanical claw, so that the glove can be blown to sleeve on the mechanical claw or blown down from the mechanical claw, thereby realizing full automation of glove demoulding. The rubber glove online automatic demoulding machine has quick demoulding speed, less operators, low cost, good product quality and high yield, and can completely replace manual operation.

Owner:杨志勇

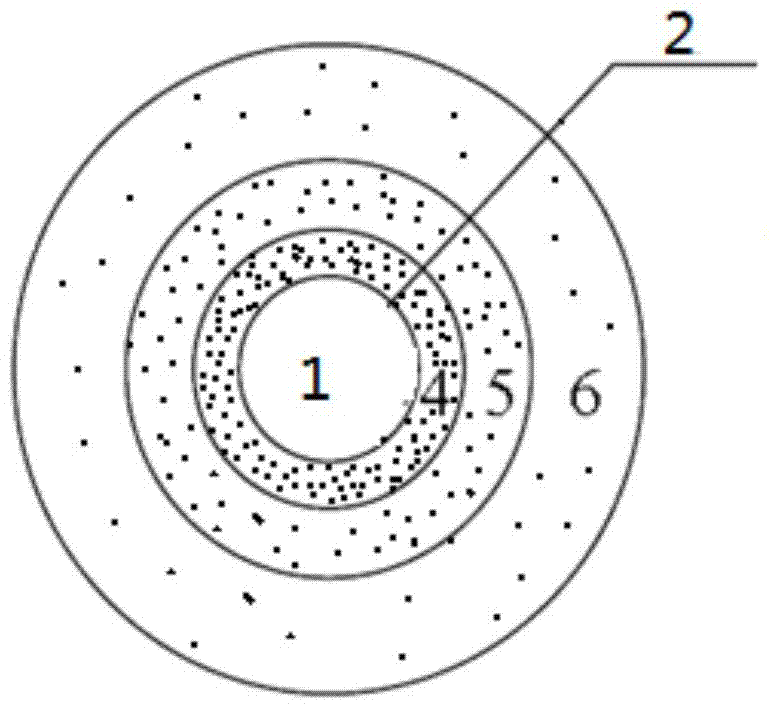

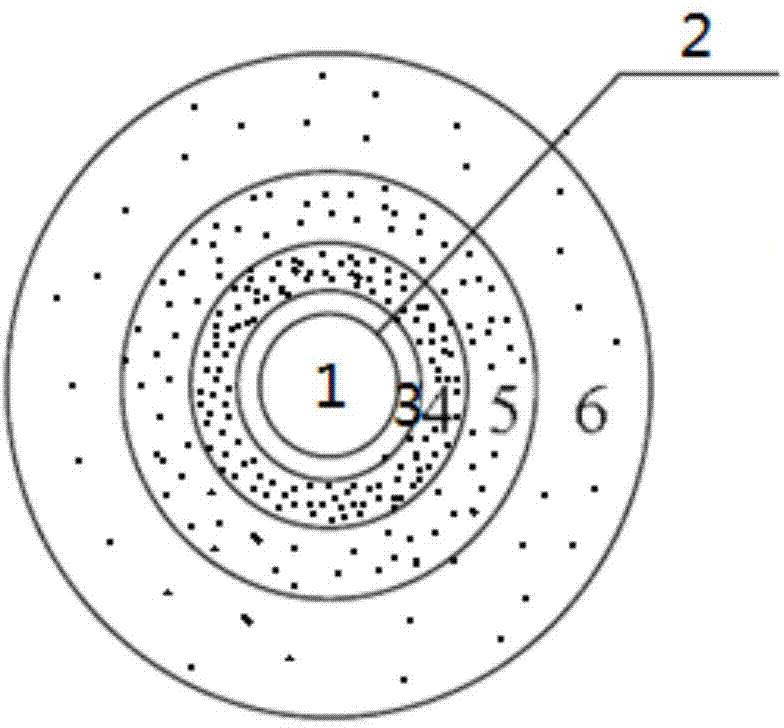

Balloon catheter

InactiveCN104511084AReduce drug lossGood compatibilityBalloon catheterMedical devicesDrugDrug eluting balloon

The invention provides a medicine eluting balloon catheter. The medicine eluting balloon catheter has the characteristics of simple structure, simple production process, less loss of medicines in a conveying process, and less medicine residue amount on a balloon after interventional operation. The medicine eluting balloon catheter has a simple structure and is also suitable for large-scale production.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

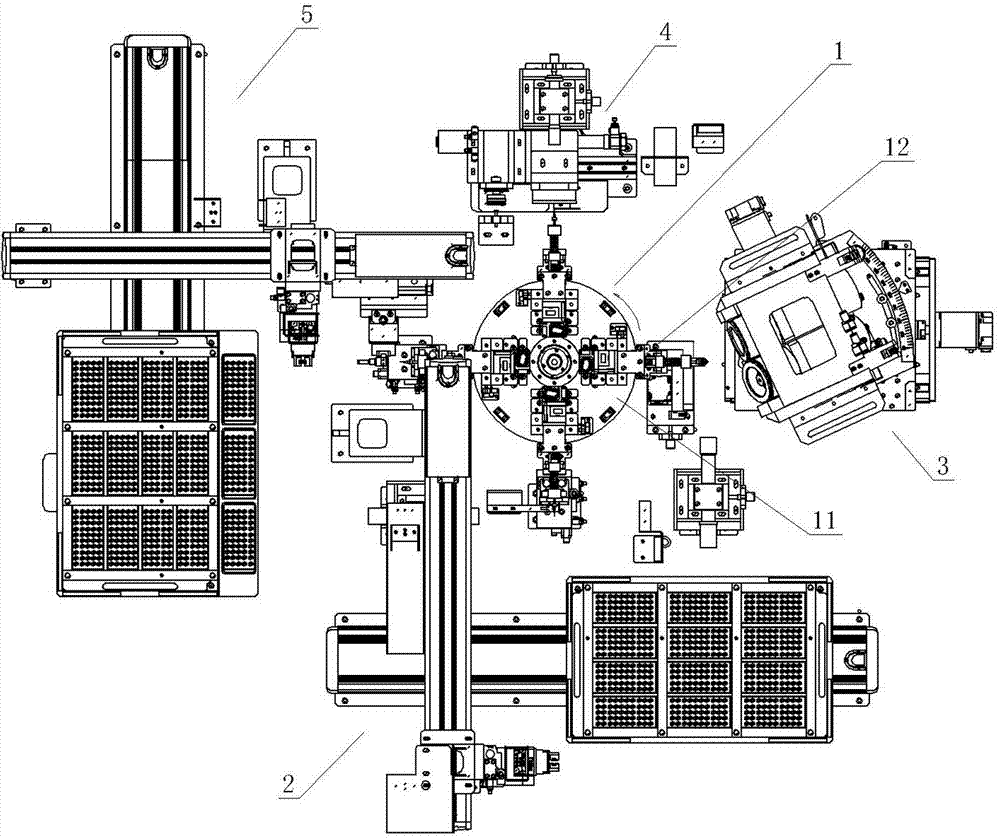

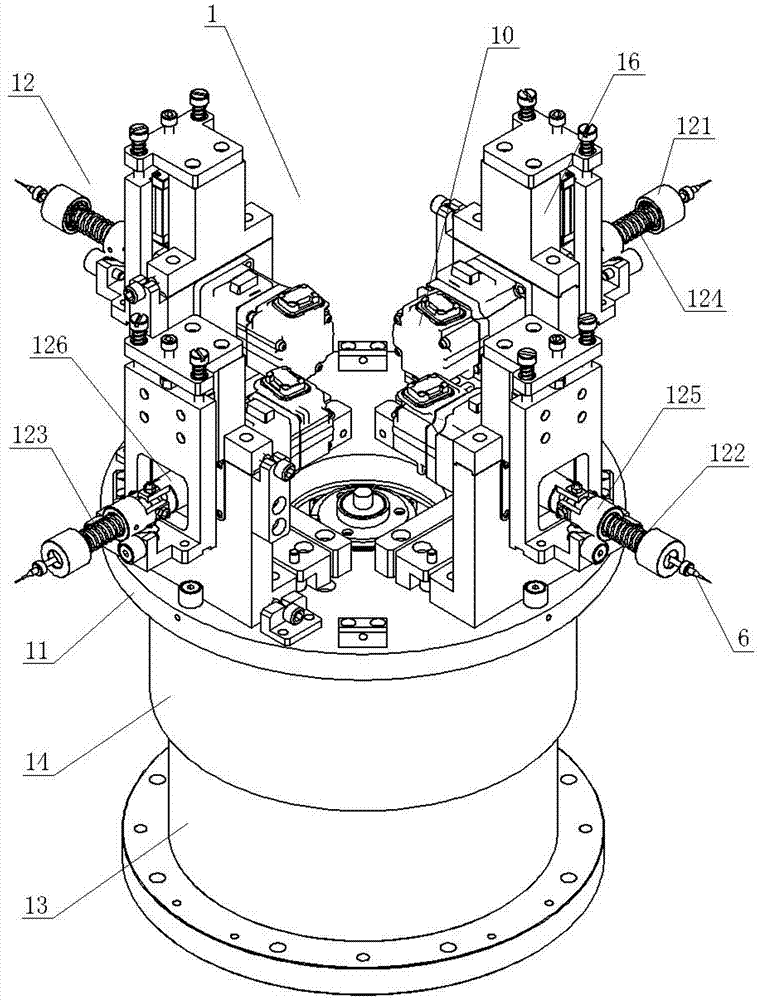

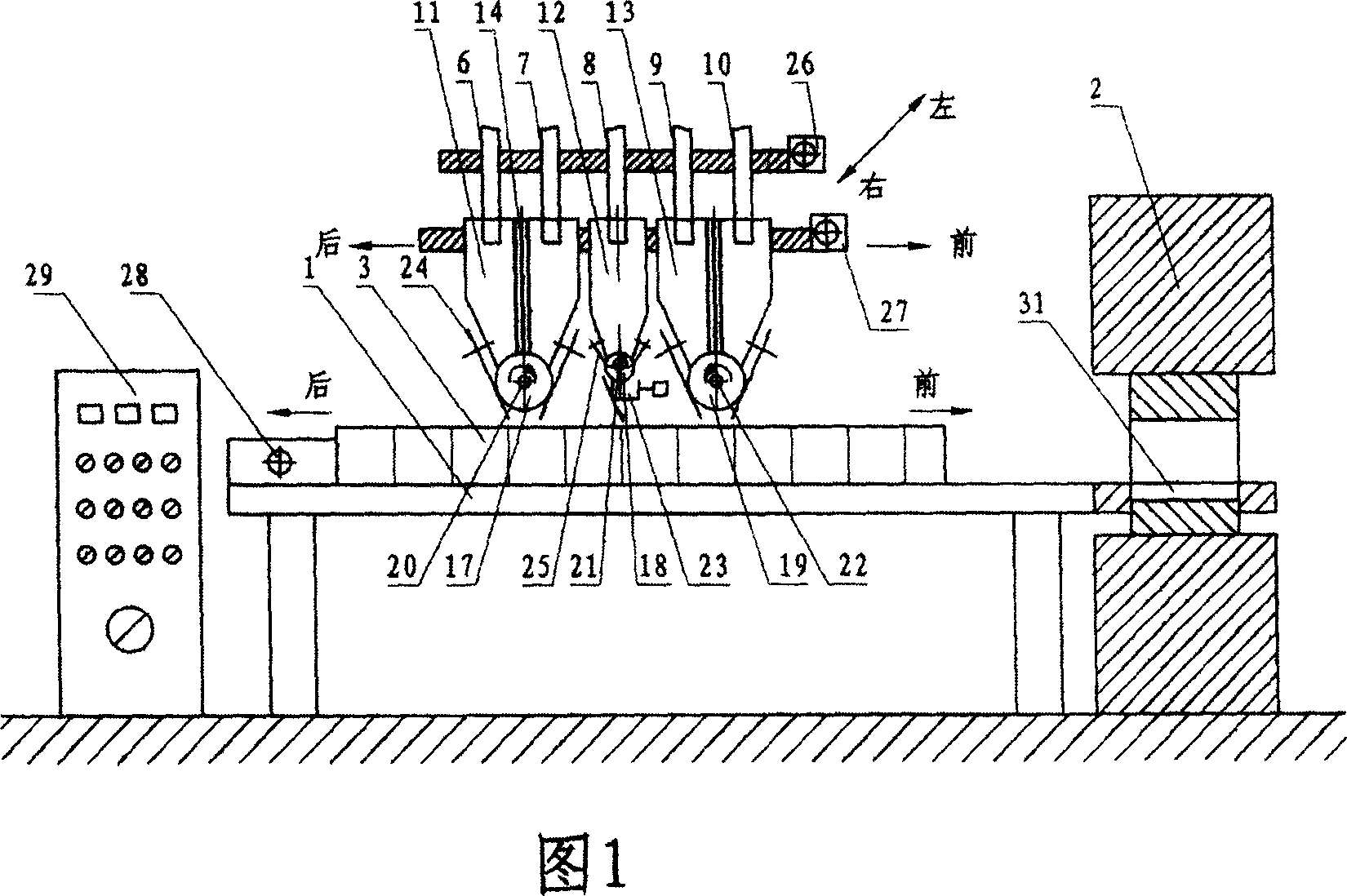

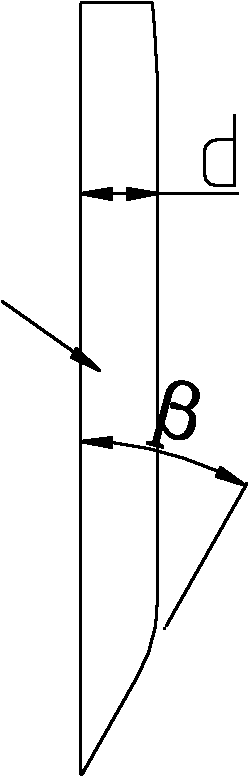

Full-automatic drill grinder

InactiveCN103567821AReduce the number of disassemblyImprove grinding pass rateGrinding feed controlDrilling toolsEngineeringMachining

The invention provides a full-automatic drill grinder. The full-automatic drill grinder comprises a transposition device as well as a feeding device, a grinding device, a detection device and a discharge device which are located around the transposition device, wherein the transposition device comprises a transposition disk and clamping heads arranged on the transposition disk, drills are mounted on the clamping heads through the feeding device, and then the transposition disk is rotated, so that the drills sequentially passes through the grinding device, the detection device and the discharge device for corresponding processing, a whole grinding process can be finished after one-time clamping, both the dismounting time of the drills and errors can be reduced, and the auxiliary time is shortened; servo motors are mounted behind the clamping heads and used for driving the drills on the clamping heads to rotate, so that grinding angles of the drills are adjusted correctly; and the drill grinder is controlled by a program and high in accuracy, the pass percent of the drills is increased, the labor condition is improved, the problems that workers are prone to fatigue and sight losing due to work under microscopes for a long time are solved, and the full-automatic drill grinder is widely applicable to grinding machining of various fine drills.

Owner:刘锦波

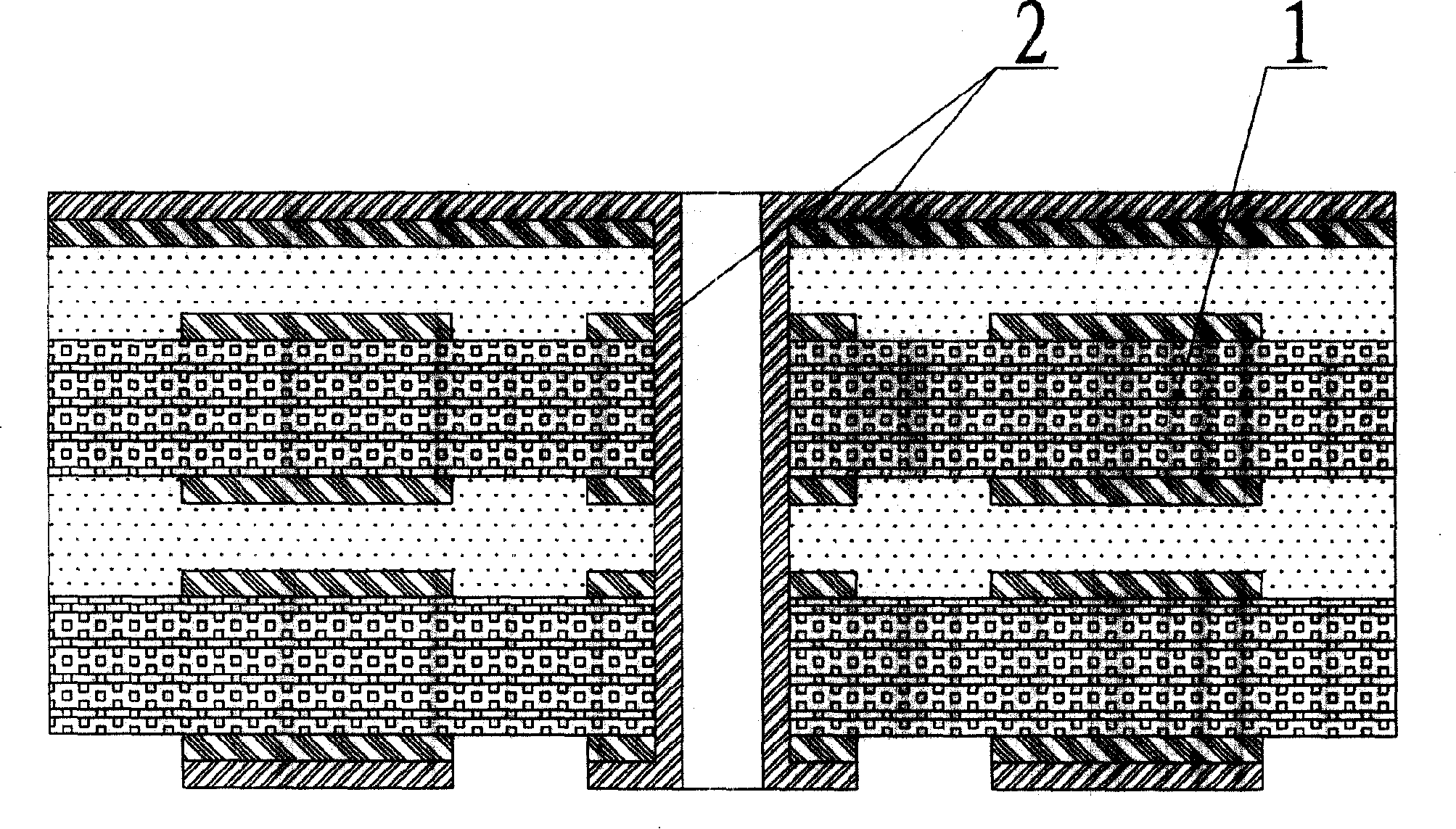

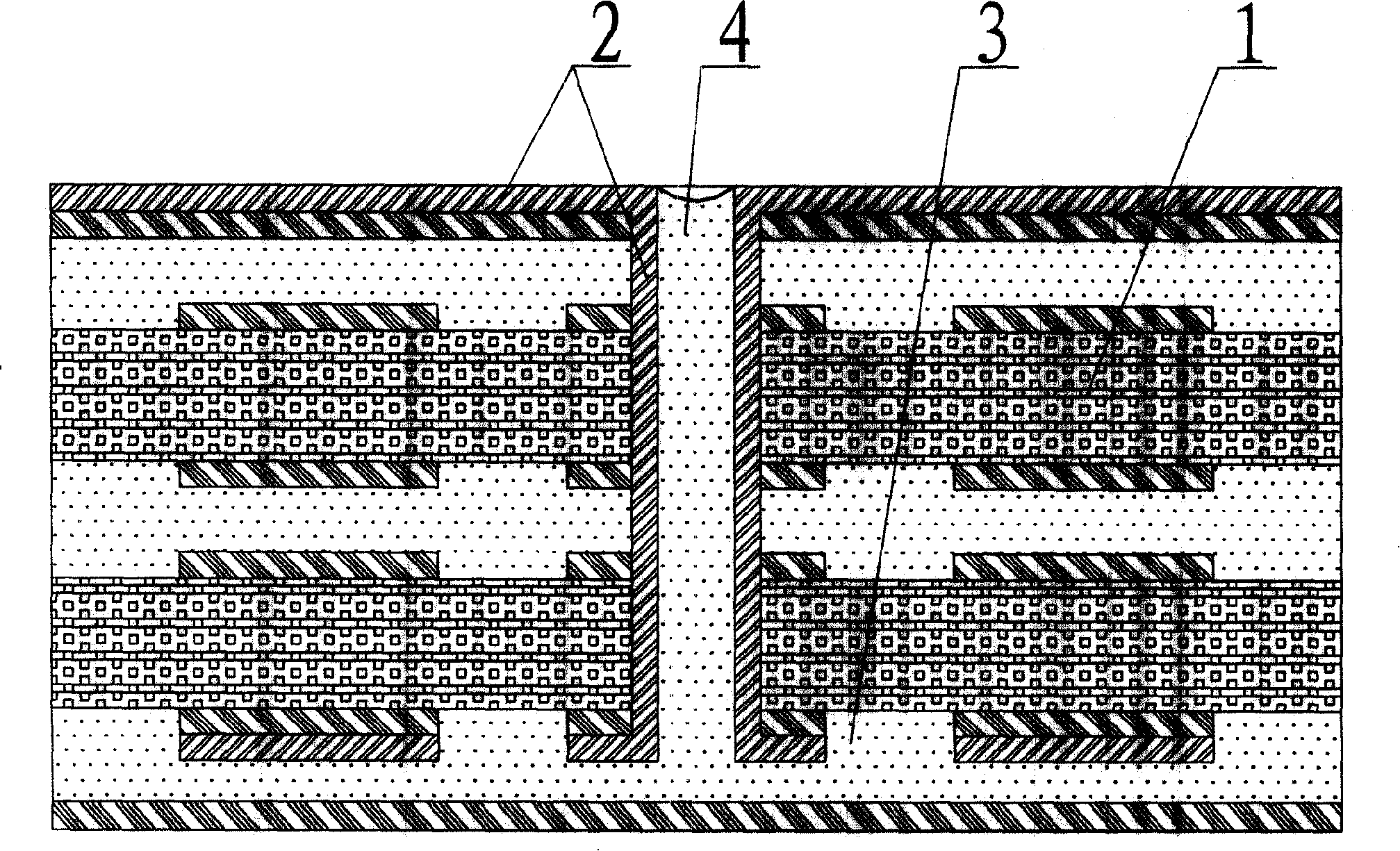

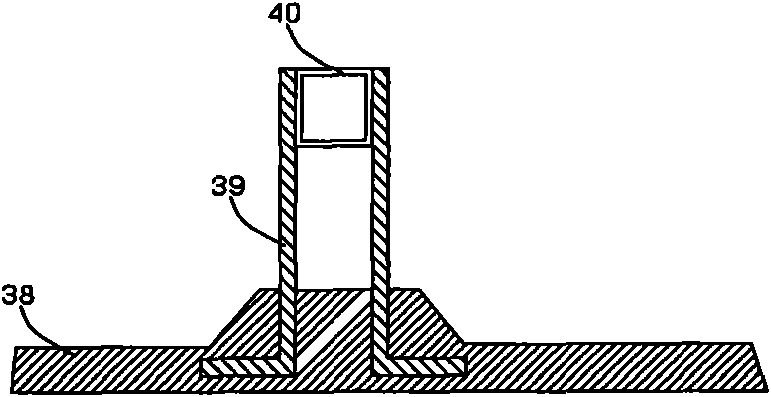

Blind hole plate and its processing method

InactiveCN101222817AReduce processReduce processing costsElectrical connection printed elementsMultilayer circuit manufactureGraphicsVena contracta diameter

The invention provides a blind orifice plate, wherein a welding disk on the top of a blind hole is provided with a through hole for relieving stress. The main method for processing the blind orifice plate is that: on the basis of the prior technology, only a part on a graphics film corresponding to the blind hole is made into a phonic zone which is smaller than the blind hole in diameter during the course of making graphics film. In the invention, the working procedure of 'processing-jacking hole with resin -curing-lapping' is deleted, the manufacturing circle is shortened and the processing cost is decreased correspondingly because the working procedure is reduced; after the process is reduced, the overall qualified product rate is improved. The invention is a modification on related design during the pre-production of film, which does not change the prior production technology; the operator can conduct normal operation according to the prior procedures, which avoids unnecessary accidents. The product of the invention can meet the requirements of consumers in terms of overall appearance and performance and the user is not affected to use the product.

Owner:DALIAN PACIFIC ELECTRONICS

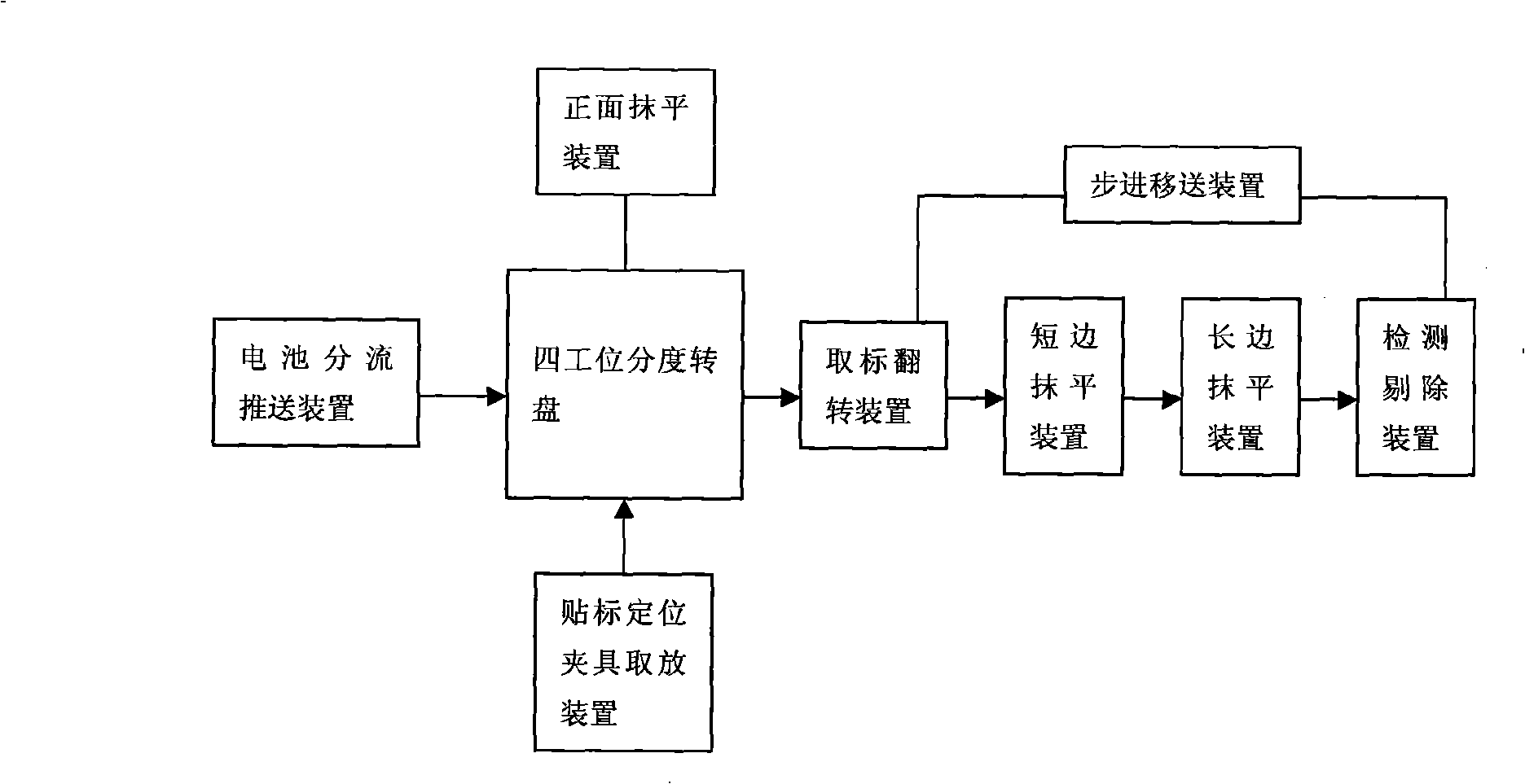

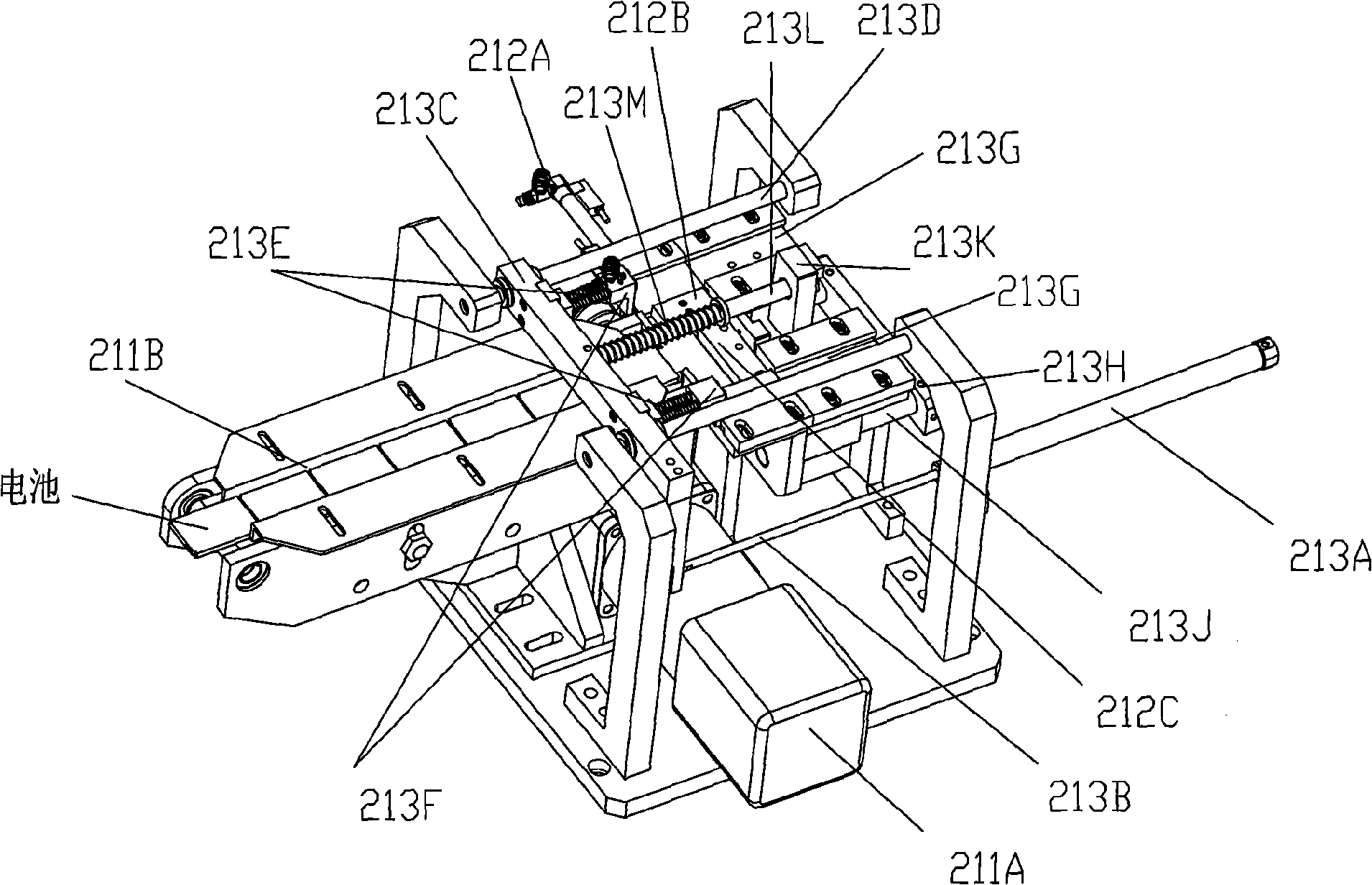

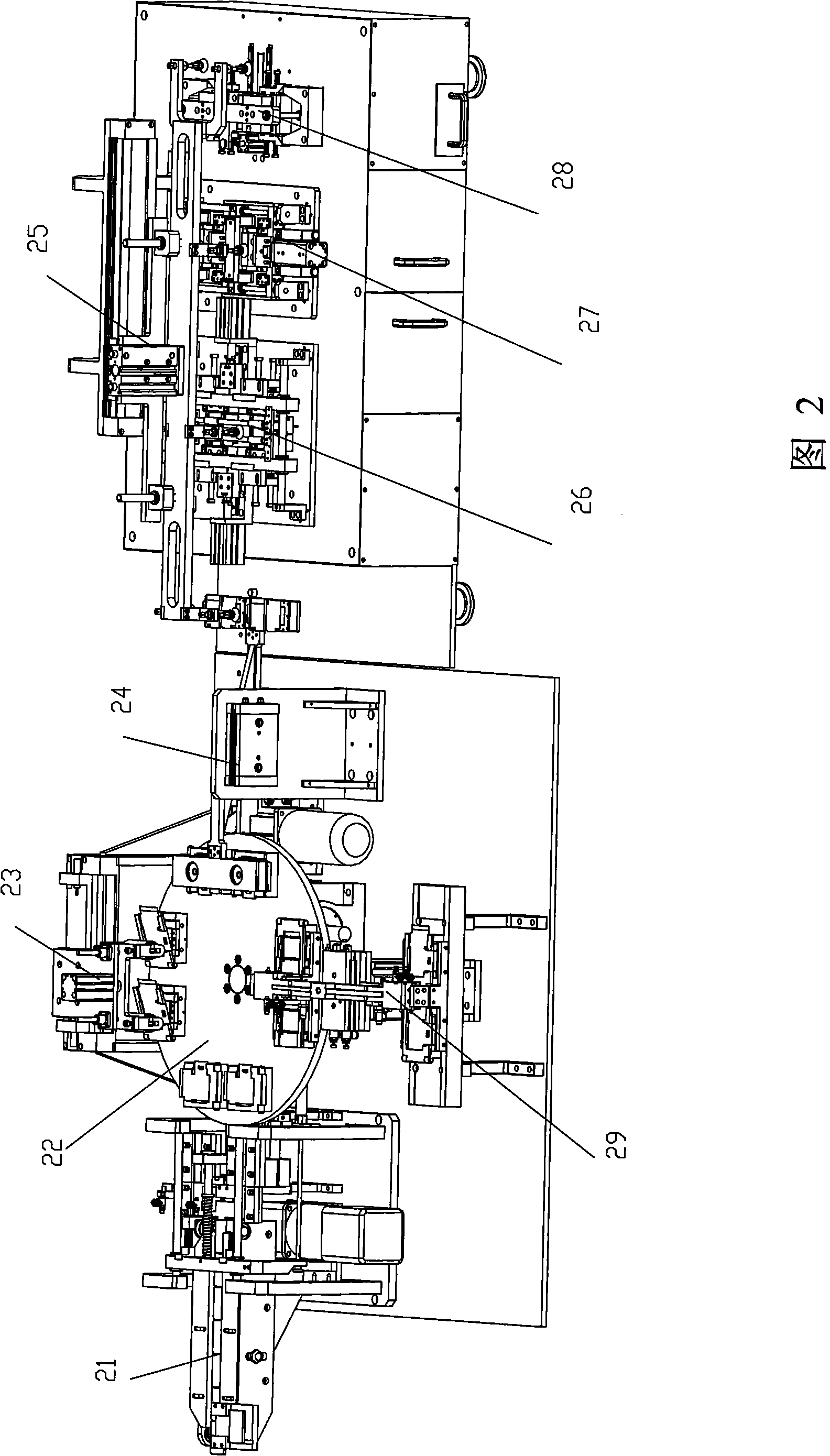

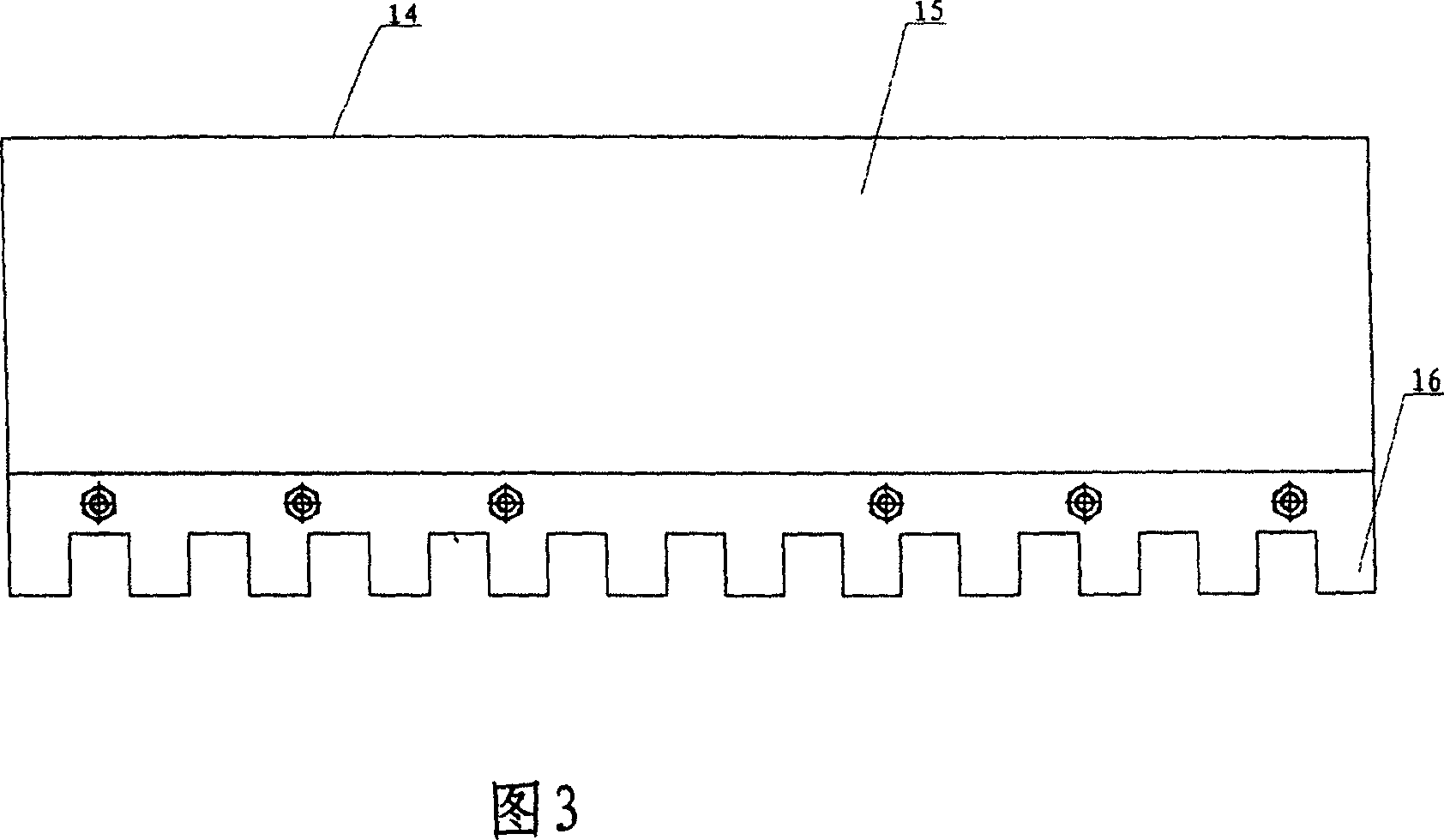

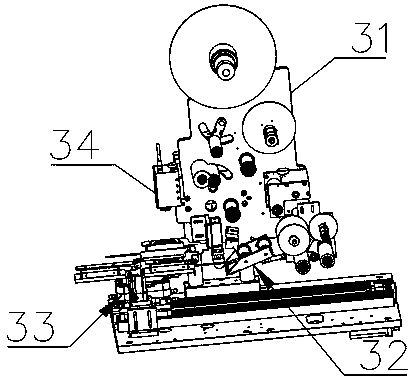

Label holder and mobile phone cell automatic labeler therewith

InactiveCN101279653AIncrease productivityImprove qualified product rateLabelling flat rigid surfacesLabelling machinesMobile phoneBiomedical engineering

The invention discloses a label clamp, comprising a clamp base and a clamp frame cover; the clamp frame cover is rotationally matched with the clamp base; the clamp frame cover is provided with a hollow part used for fixing the label; the clamp base is provided with a battery jar used for containing the battery; the clamp frame cover and the clamp base are mutually attracted magnetically. The invention also discloses a mobile phone battery automatic labeling machine using the label clamp.

Owner:GRAND TECH SHENZHEN

Glass fiber reinforced gypsum product, and preparation method and equipment thereof

The invention relates to a glass fiber reinforced gypsum product, which comprises the ingredients including gypsum powder, glass fiber, water reducing agents, retarding agents and water, wherein the glass fiber is short glass fiber with the length ranged form 1 to 3cm, and is uniformly distributed in the gypsum product. Because the glass fiber reinforced gypsum product of the invention adopts 1 to 3 cm of glass fiber uniformly and disorderly distributed in the gypsum product, the intensity and the toughness of each part of the gypsum product are enhanced, and the delamination structure is avoided. The invention also provides a method for preparing the glass fiber reinforced gypsum product, and special equipment for implementing the method.

Owner:秦永超

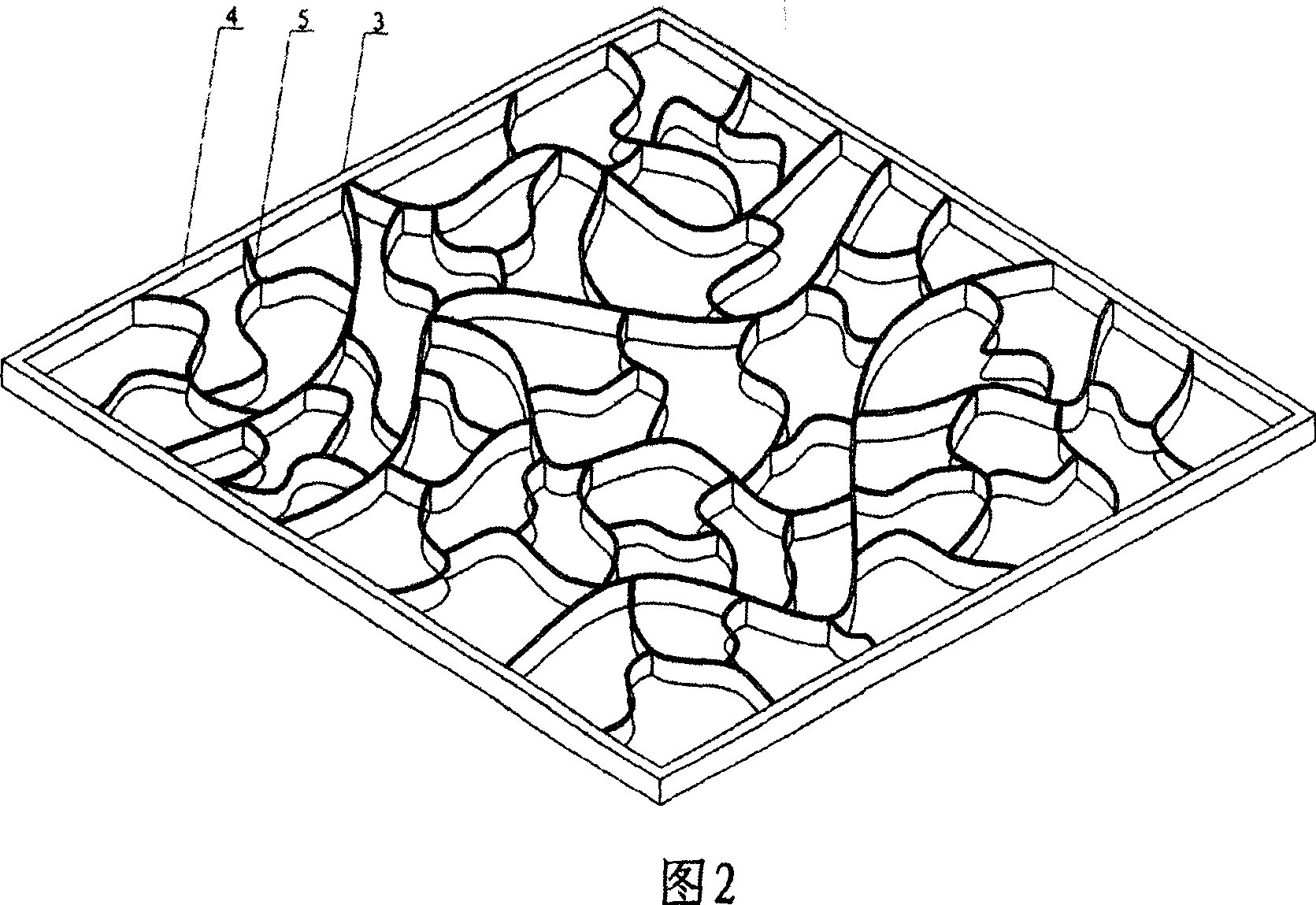

Emulating natural porcelain brick machine-shaping material-distributing equipment and method

InactiveCN101077591AAccurately control accessSolve unforeseen and uncontrollable technical problemsFeeding arrangmentsBrickGrating

The present invention is material distributing apparatus and process for producing ceramic tile with natural grains. The material distributing apparatus includes a feeding bottom plate connected to an external electric control device, a grating on the bottom plate and a hydraulic forming machine. The grating is provided with movable material bins, material distributing drums with baffles on two sides and notches corresponding to the material distributing area in the grating, a material mixing partition board, and driving devices connected separately to the grating and the material distributing drum. The material distributing process includes the following steps: 1. providing different powdered materials to the material bins; 2. rotating the drums for mixing the powdered materials inhomogeneously; 3. making the notches in the drum correspond to the material distributing area; 4. moving the grating for distributing material; and 5. feeding the material to the mold for forming.

Owner:GUANGDONG WINTO CERAMICS

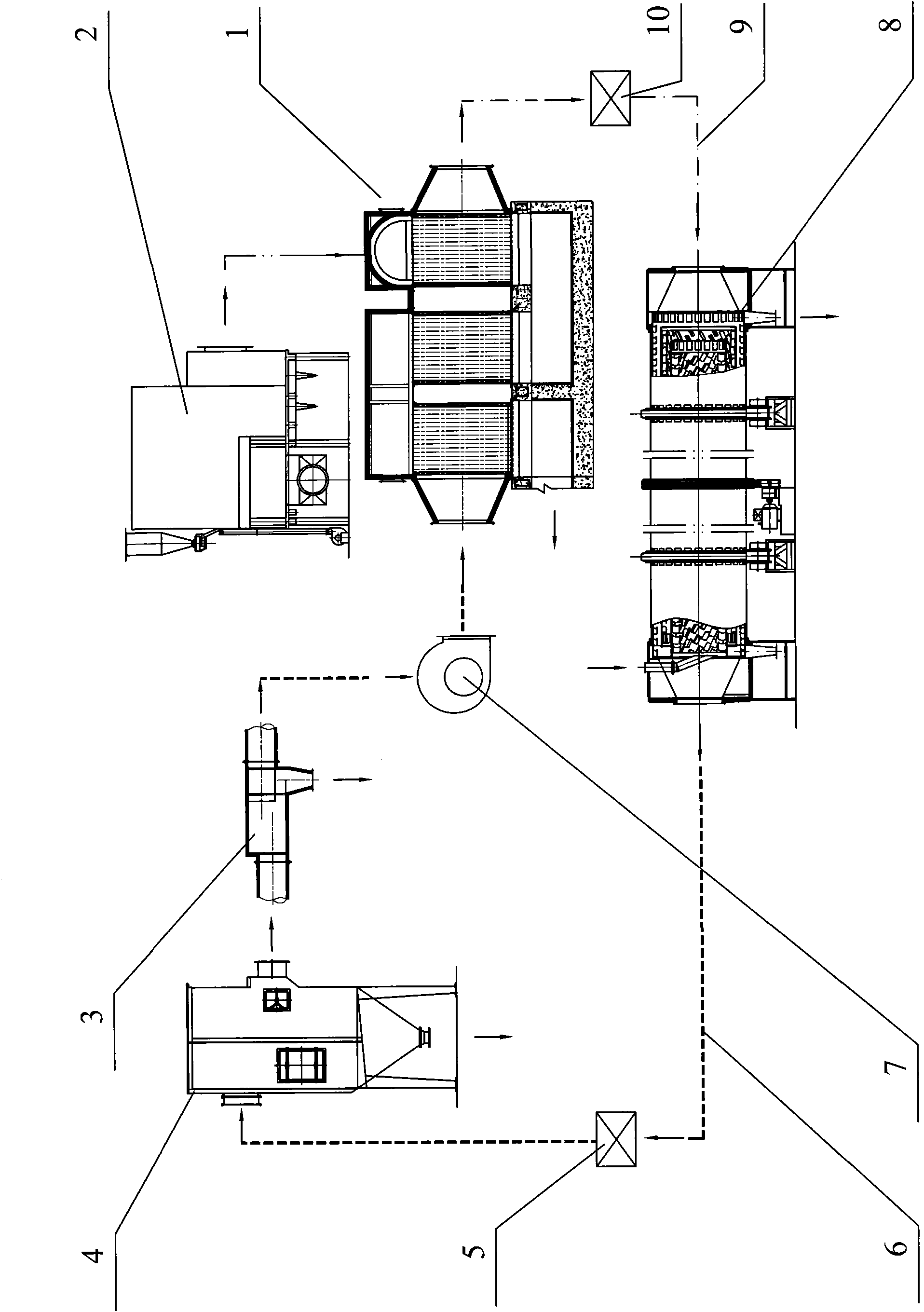

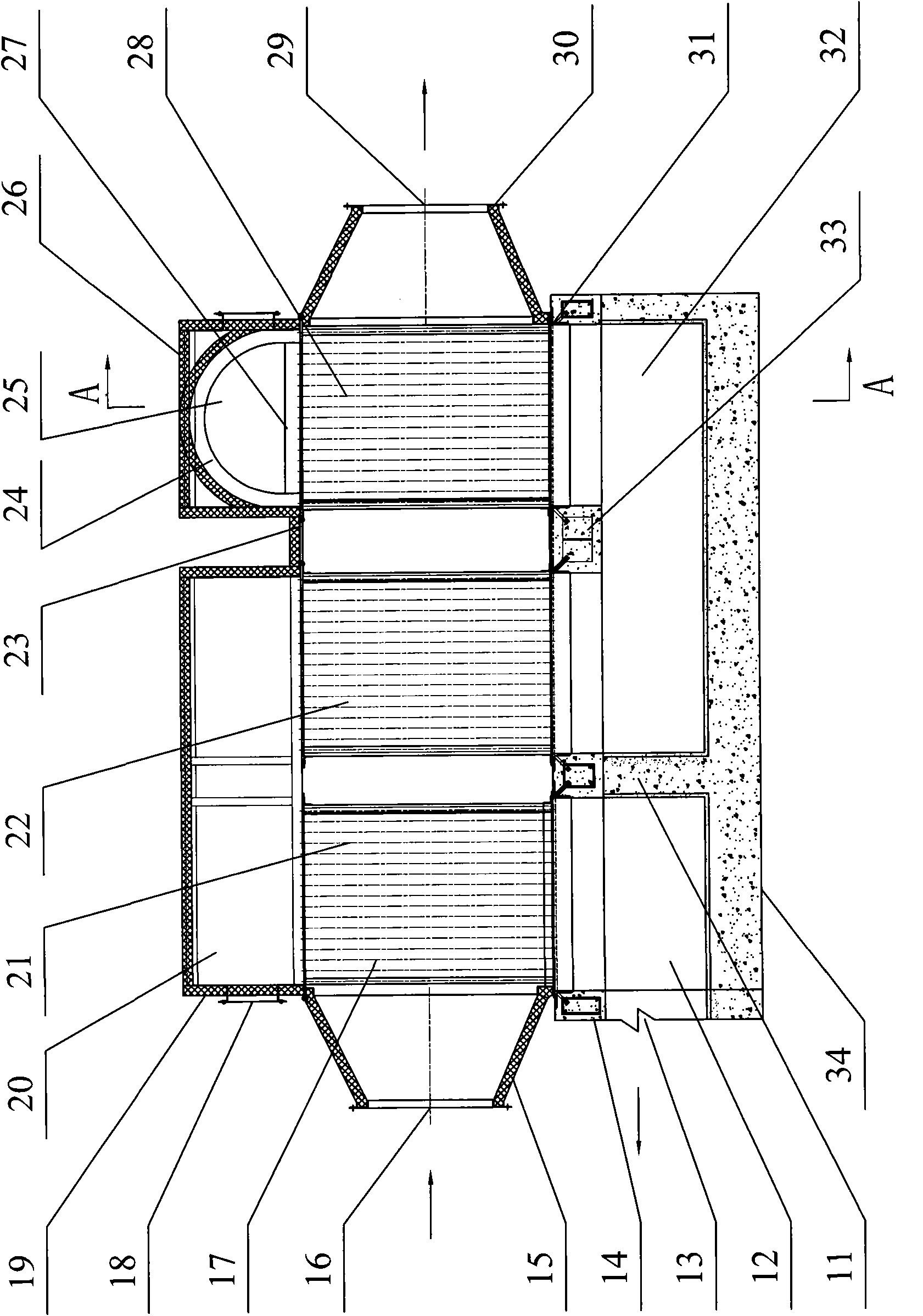

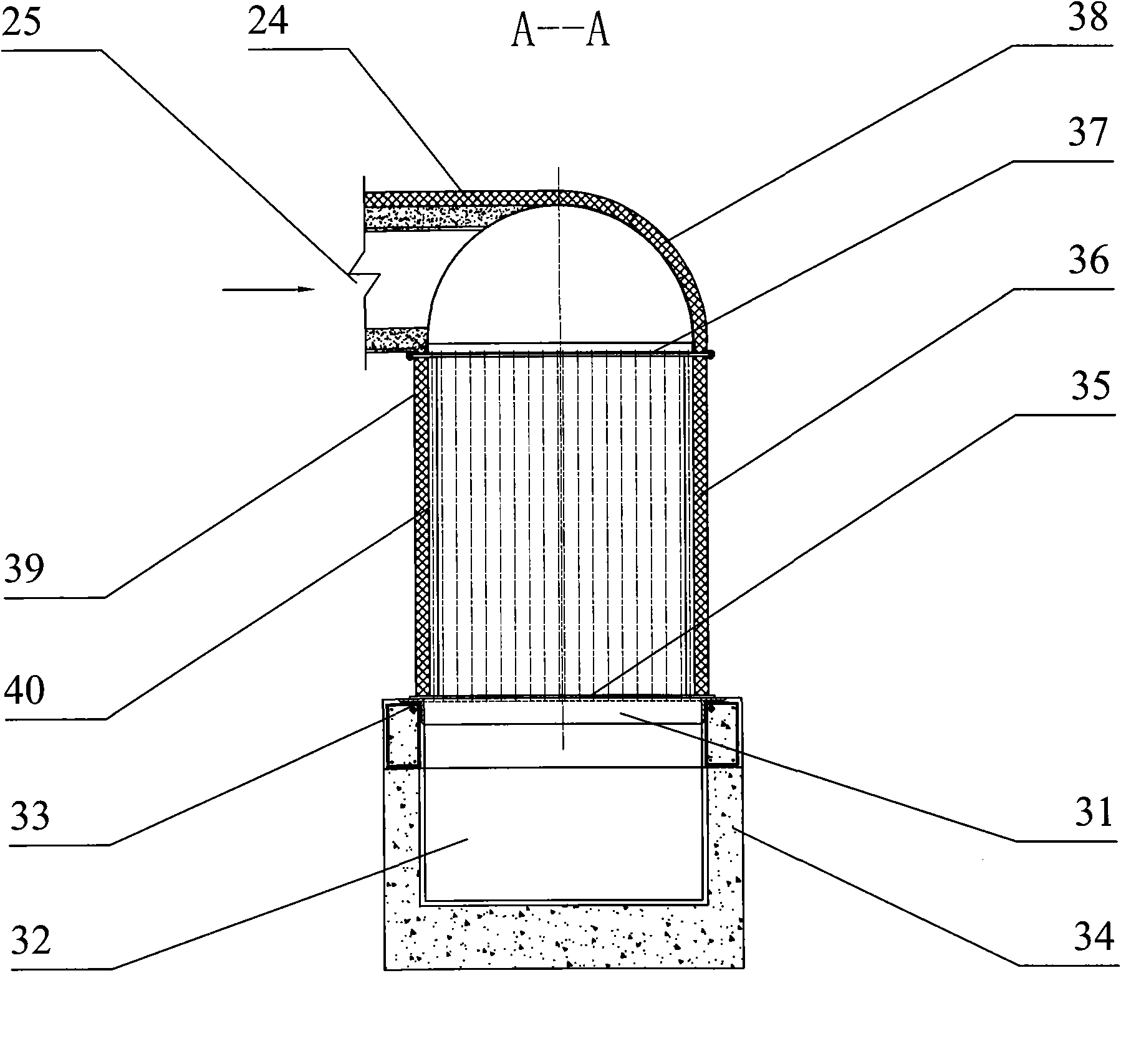

Lignite-drying and quality-improving process for preparing superheated steam from waste heat steam

InactiveCN101915497AReasonable process designEasy routeDrying solid materials with heatDrying gas arrangementsHot blastProcess engineering

The invention relates to a lignite-drying and quality-improving process for preparing superheated steam from waste heat steam. The process comprises the following operation steps of: firstly, providing a heat source for a heat energy device for preparing the superheated steam from the waste heat steam by using high-temperature flue gas produced by a hot-blast stove; secondly, recycling, purifying and refining waste heat steam produced by a normally-running energy-saving cylindrical lignite-drying and quality-improving device; thirdly, preparing high-temperature superheated steam by using the heat energy device for preparing the superheated steam from the waste heat steam; fourthly, drying wet-based lignite and improving quality by using the energy-saving cylindrical lignite-drying and quality-improving device; and finally, recycling the waste heat steam produced in a drying process by the recycling, purifying and refining steps. The process uses the waste heat steam to dry the lignite and has the characteristics of reasonable design and simple, convenient and smooth route. The device has the characteristics of optimized design, compact structure, small floor area, a small amount of investment, low running cost, high yield, large dehydrating range, safe running, energy conservation, capability of saving power, lowering consumption and reducing emission, wide application range of quality-improved lignite and the like.

Owner:沈阳清井环保机械工程有限公司

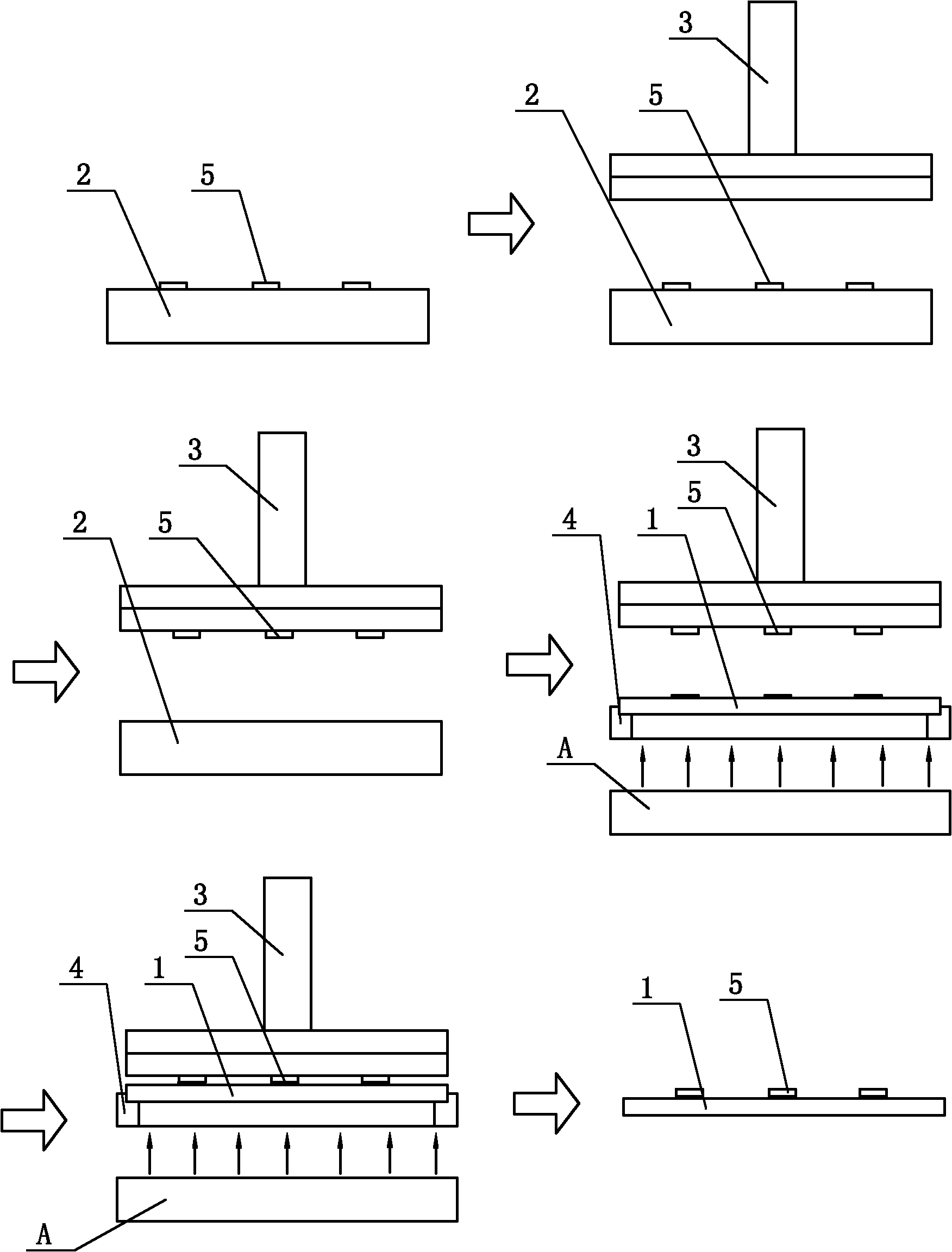

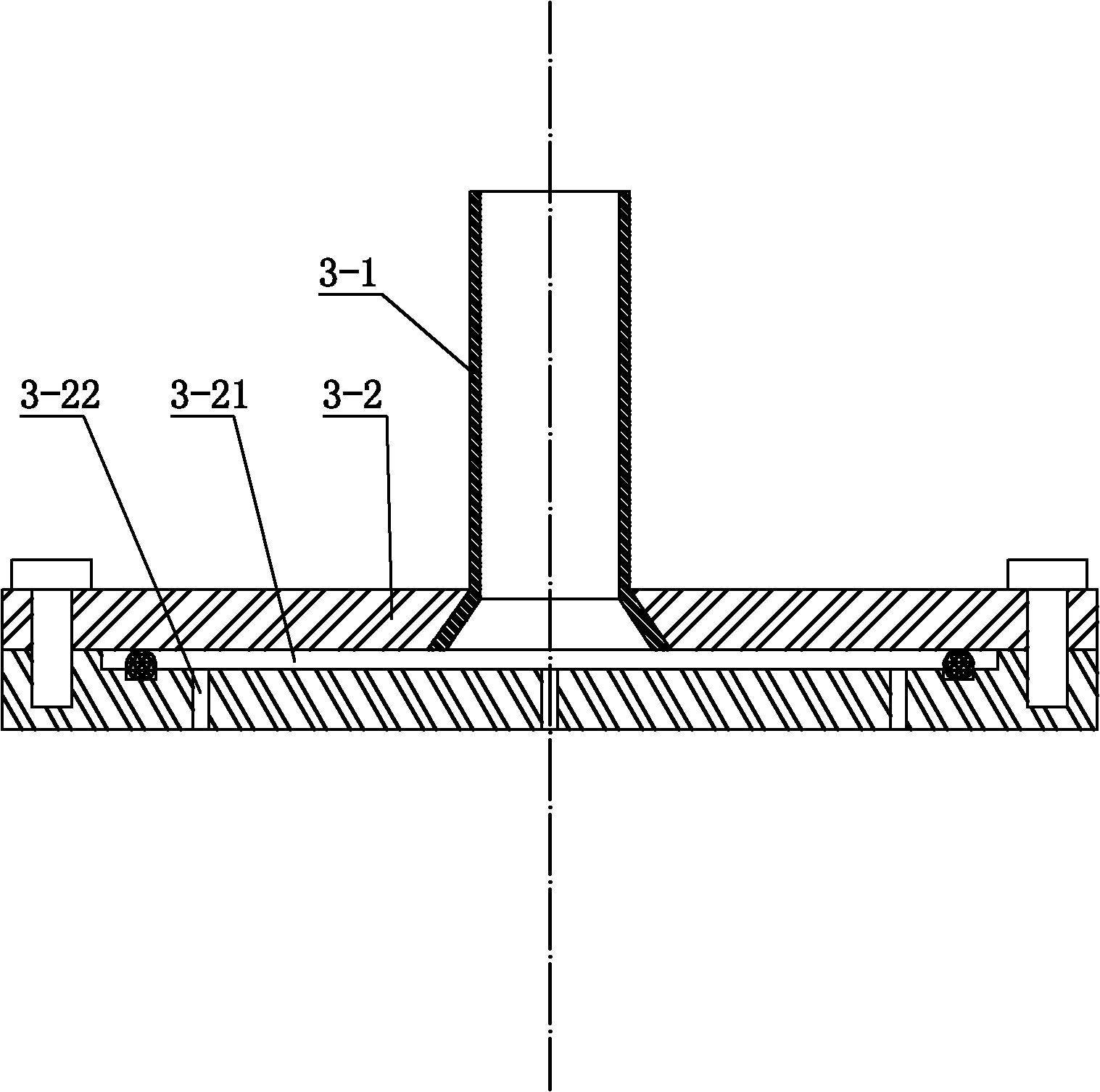

Single-substrate multi-chipset high-power LED (Light-Emitting Diode) encapsulation one-step bonding method

InactiveCN102157630ASolve driftReduce failure rateSolid-state devicesSemiconductor devicesScreen printingFree cooling

The invention relates to a single-substrate multi-chipset high-power LED (Light-Emitting Diode) encapsulation one-step bonding method, belonging to the technical field of multi-chipset high-power LED encapsulation. The invention solves the problem that the whole bonding time is too long as multiple chipsets are sequentially spliced in the traditional multi-chipset high-power LED encapsulation technology. The method comprises the following steps of: cleaning a substrate, a chip carrying platform, a multi-chip suction nozzle and a supporting platform; placing the substrate on the supporting platform; determining positions of chips to be bonded on the front of the substrate, and placing multiple chips to be bonded on the chip carrying platform corresponding to the positions of the chips to be bonded; uniformly coating soldering paste on the positions of the chips to be bonded by adopting screen printing, and then simultaneously picking up multiple chips to be bonded with the multi-chip suction nozzle; heating the back of the substrate, enabling multiple chips to align with the positions to be bonded and then attached to the soldering paste, continuously heating for 5-10s, naturally cooling to room temperature, and removing the multi-chip suction nozzle, thus the bonding process is completed. The invention provides an encapsulation bonding method.

Owner:HARBIN INST OF TECH

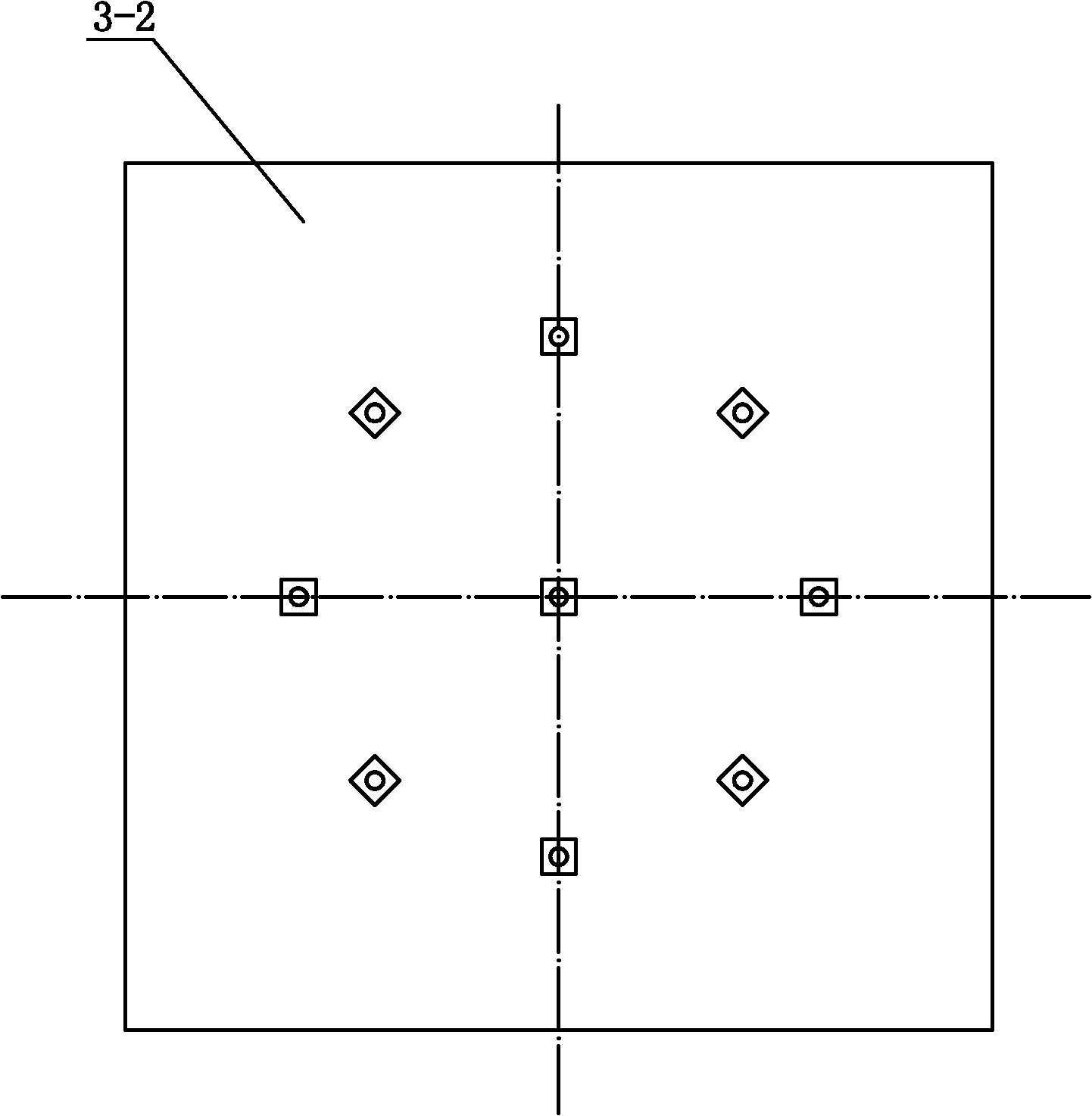

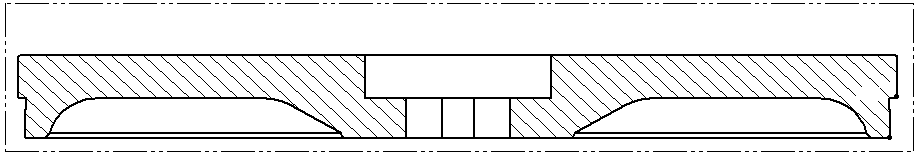

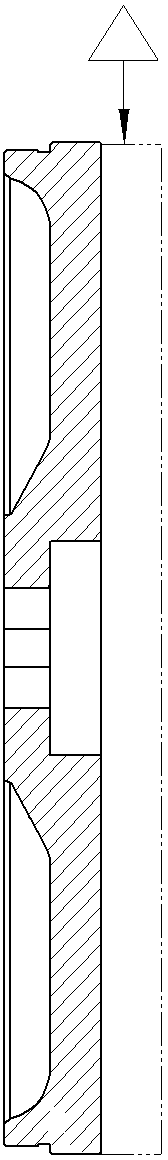

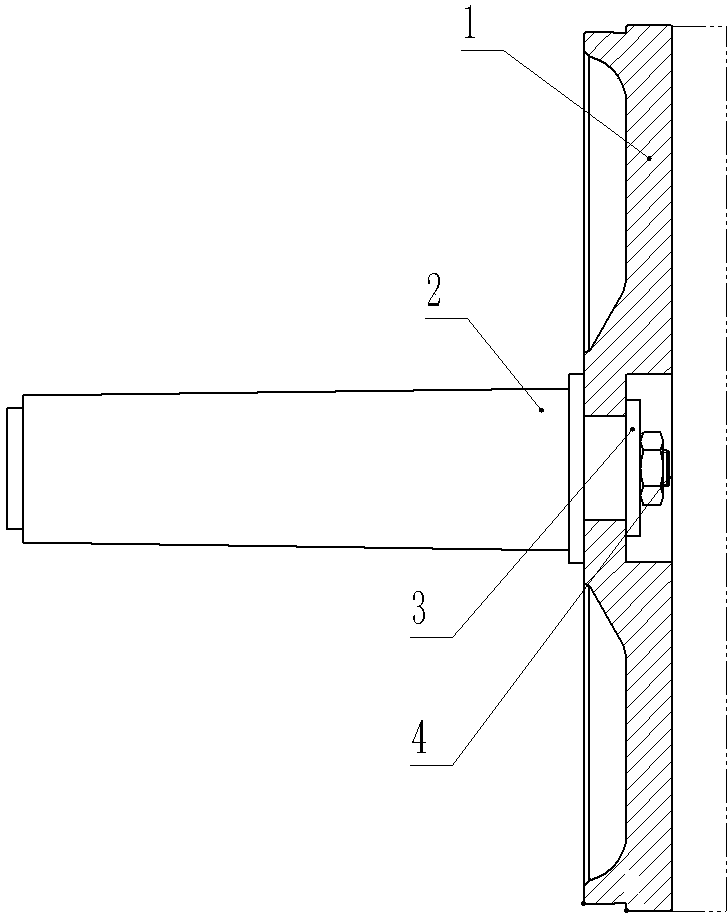

Aluminum alloy pattern block low-pressure casting equipment and low-pressure casting and gravity feeding compound process

The invention discloses aluminum alloy pattern block low-pressure casting equipment. A disk-type runner substrate is arranged on a crucible, and the lower end of a riser tube passes through the center hole of the runner substrate and then stretches into the crucible; a runner cover board is hermetically covered on the runner substrate, a plurality of casting moulds are distributed on the runner cover board, a feed head is arranged at the upper end of each casting mould, and an inner runner is arranged at the lower end of each casting mould; and a main runner is laid in a hollow cavity between the runner substrate and the runner cover board, a plurality of runner channels are distributed on the main runner, and the runner channels are respectively communicated with the inner runners of the casting moulds and the upper port of the riser tube. The invention can solve the secondary pollution problem of aluminum liquid in the partitioning and casting process of aluminum alloy pattern blocks and achieve simultaneously casting a plurality of aluminum alloy pattern block castings, and is beneficial to improving the casting production efficiency.

Owner:合肥大道模具有限责任公司

Method for producing dry type duplicating body paper

InactiveCN103103863AHigh opacityGood light transmissionNatural cellulose pulp/paperWater-repelling agents additionWet strengthSizing

The invention belongs to a papermaking technology, and relates to a method for producing dry type duplicating body paper. The method comprises the following steps of: making finished paper by crushing, grinding and mixing basic raw materials of bleached chemical broad-leaved wood pulp and bleached chemical softwood pulp, sizing, dehydrating, pre-drying, performing surface sizing, post-drying, glossing and coiling; during manufacturing, adding fillers, an inner sizing agent, a wet-strength agent and a surface sizing agent, wherein the two basic raw materials comprise 65-85 percent of bleached chemical broad-leaved wood pulp and 15-35 percent of bleached chemical softwood pulp, and the fillers comprise titanium dioxide and calcium carbonate; adding the titanium dioxide during pulp crushing, wherein the adding amount is 20-60 kilograms for per ton of paper; and adding the calcium carbonate during pulp mixing, wherein the adding amount is 120-280 kilograms for per ton of paper. With the method, the production cost can be reduced, the yield is improved, and the non transparency of a product is improved.

Owner:ZHENJIANG DADONG PULP & PAPER

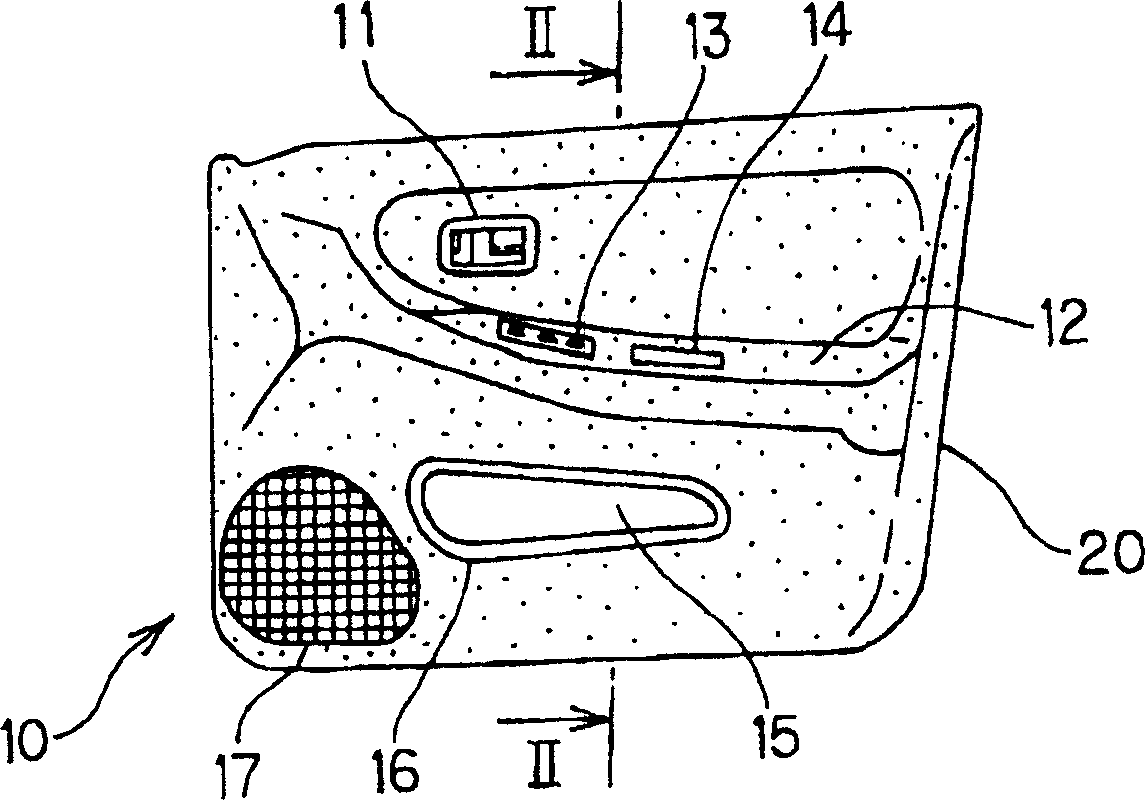

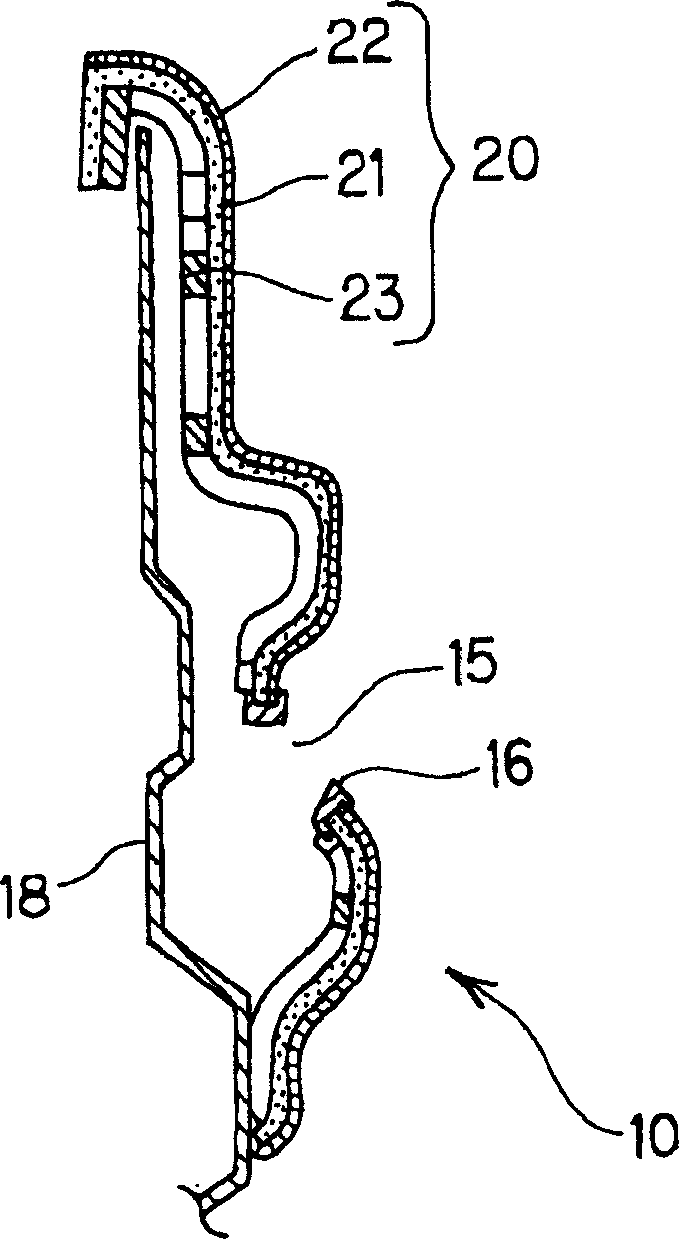

Interior decoration part for automobile and method for manufacturing the same

Owner:KASAI KOGYO CO LTD

Thin wall processing technology and its special-purpose knife tool

InactiveCN1876295AImprove processing efficiencyImprove qualified product rateWorkpiecesTurning toolsMachining processBiomedical engineering

The invention relates to a mechanical preparing technology, especially to a thin wall preparing process and private knife device. The process comprises following steps: (1) grasping work piece blank; (2) fixing private knife for thin wall preparation on feed knife carrier, and the two cutting points of outer and internal diameter cutter head is vertical to feeding direction; (3) cutting; (4) cutting blank. Said knife device comprises knife handle, left front fork and right front fork, the left and right front fork extends forwardly to form U shape and they are equipped with outer diameter processing cutter head and internal diameter processing cutter head, the distance between two knife head cutting point is corresponding to the thickness required by thin wall element. The invention is characterized by high thin-walled processing efficiency and stable quality of thin-walled element.

Owner:CRRC QISHUYAN CO LTD

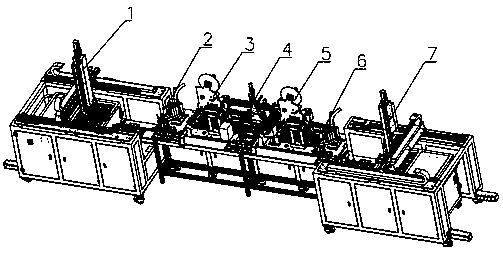

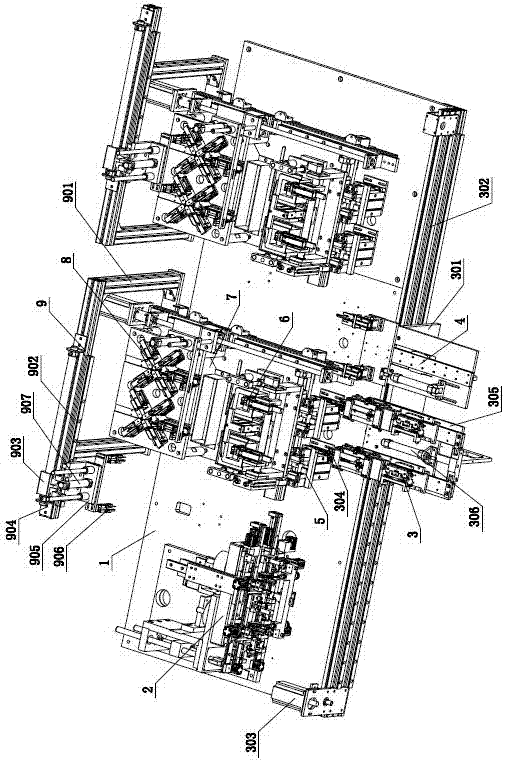

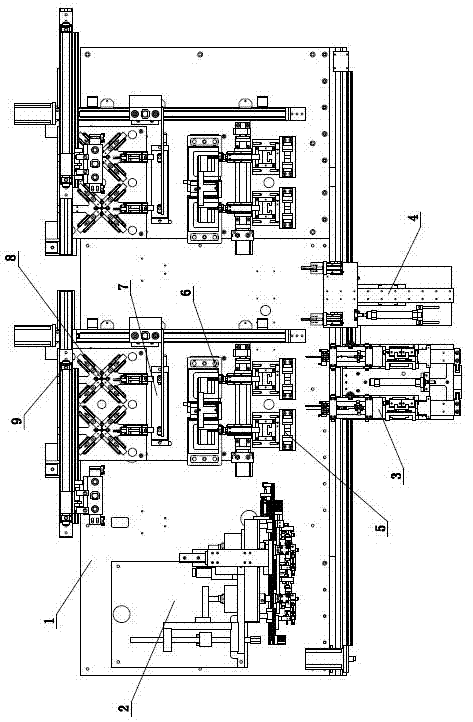

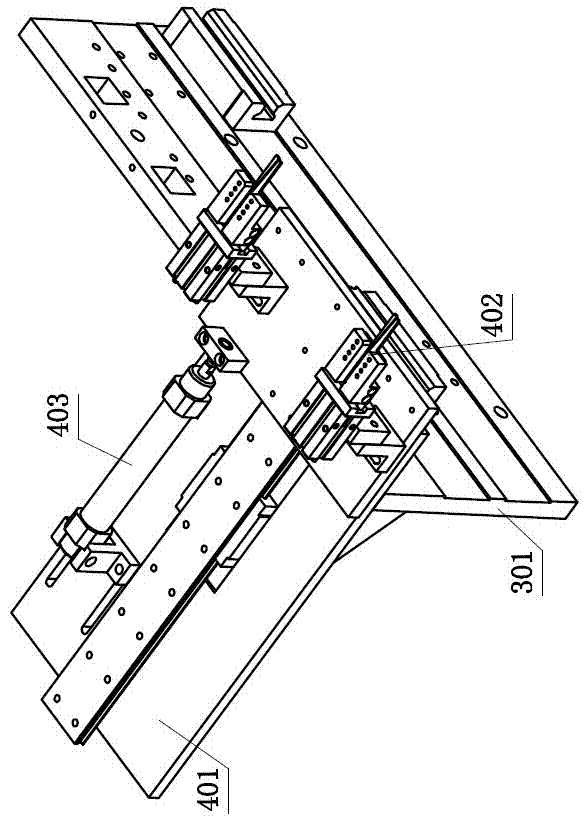

Full-automatic double-side film sticking production line for electronic product

The invention discloses a full-automatic double-side film sticking production line for an electronic product. The full-automatic double-side film sticking production line is characterized by comprising a feeding part, an upper transfer part, a front side film sticking part, a transfer turnover part, a back side film sticking part, a lower transfer part, a discharging part and a conveying belt; theconveying belt sequentially communicates with the feeding part, the upper transfer part, the front side film sticking part, the transfer turnover part, a rear surface film sticking part, the lower transfer part and the discharging part; the back side film sticking part and the front side film sticking part are of the same structure; the lower transfer part and the upper transfer part are of the same structure; the discharging part and the feeding part are of the same structure; the back side film sticking part is arranged at the next station of the transfer turnover part; the lower transfer part is arranged at the next station of the back side film sticking part; and the discharging part is arranged at the next station of the lower transfer part. The full-automatic double-side film sticking production line disclosed by the invention is high in automation degree, saves labor, lowers the production cost, improves the production efficiency, increases the percent of qualified products andachieves a good market application value.

Owner:郑州众益德网络科技有限公司

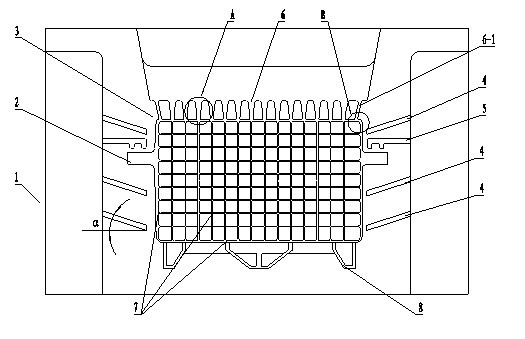

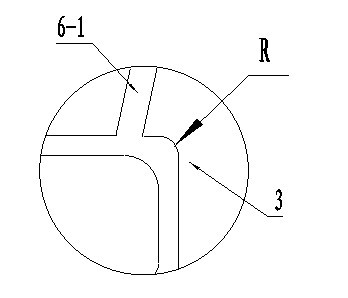

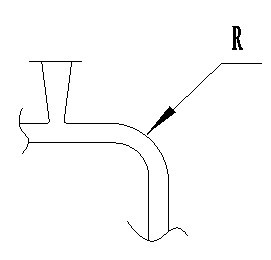

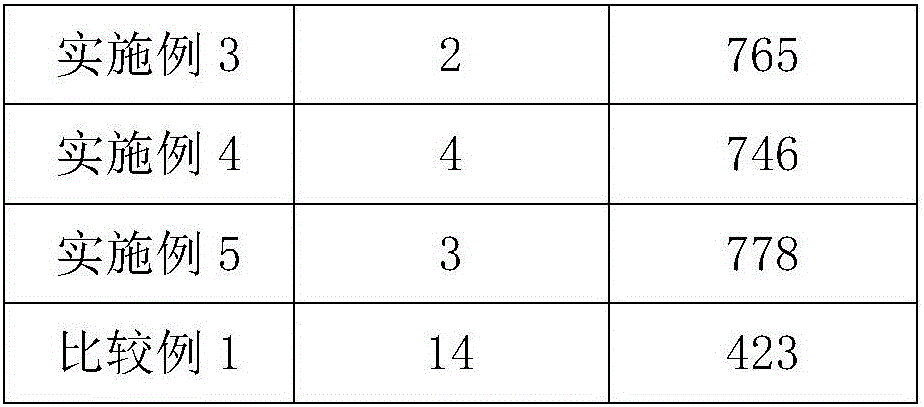

Method for inhibiting generation of pores of plate grid of valve-controlled accumulator, and plate grid mould

The invention relates to a method for inhibiting the generation of pores of a plate grid of a valve-controlled accumulator, and a plate grid mould, solving the problems of pore generation of the plate grid of the valve-controlled accumulator. The method comprises the following steps of: a, fusing raw materials, i.e. lead-calcium-stannum-aluminum alloys, of the plate grid at the temperature of 480-510 DEG C; b, heating the plate grid mould at the temperature of 180-230 DEG C; c, preparing a mould release agent from 30-35 parts by weight of cork powder, 10-18 parts by weight of sodium silicate,5 parts by weight of bentonite and 1000 parts by weight of water, and spraying the plate grid mould; and d, pouring the lead-calcium-stannum-aluminum alloys. With the method, the structure of the plate grid mould is improved, an air passage is additionally arranged, a sprue gate is enlarged, the radius R of a circular arc positioned on the transition round corner part of the plate grid is reduced, and the like; and in addition, quality tracking shows that the method can be used for effectively inhibiting the generation of the pores of the plate grid of the valve-controlled accumulator on the basis of no increase of the production cost and the manufacturing difficulty of the plate grid mould, enhancing the qualification rate of products by 1-2 percentage points and reducing the percentage point of the products and the waste of resources, thereby saving the fund cost for enterprises.

Owner:FENGFAN

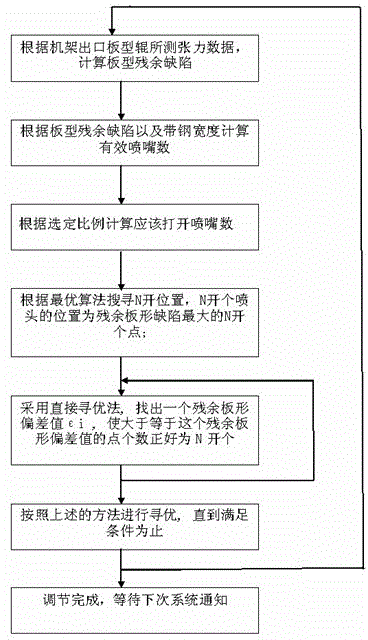

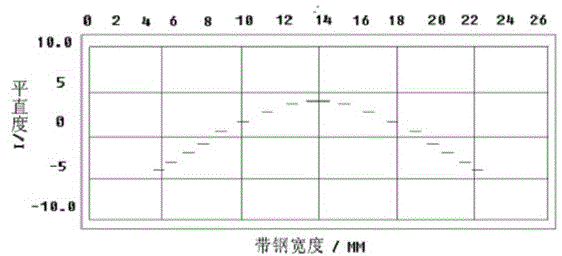

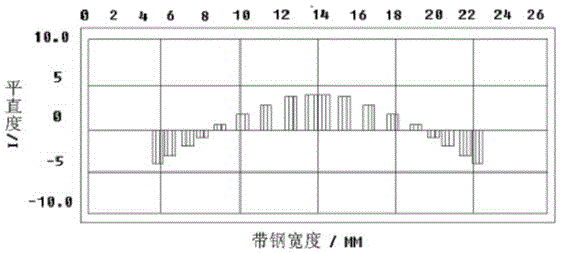

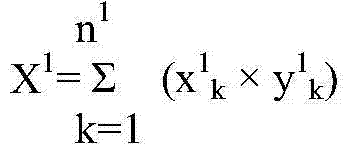

Emulsion fine cooling system control method and control device

ActiveCN104874614AReduce resistanceAvoid damageTemperature control deviceWork cooling devicesEmulsionShape deviation

The invention relates to an emulsion fine cooling system control method. The emulsion fine cooling system control method is characterized by comprising the following steps that the plate-shaped residual defect is calculated in dependence on steel strip contact tension data detected by a frame outlet plate-shaped roller; 2) the valid nozzle number is calculated in dependence on the plate-shaped residual defect and the steel strip width, N (valid)=B / 52, wherein B is the steel strip width (mm), and the distance between any two adjacent nozzles is 52mm; 3) the number N (open) of nozzles which need to be opened is calculated in dependence on a selected proportion, N (open) = N (valid)*K1, K1 is the selected open proportion, and is generally selected to be 50%, and the K1 can be reset as needed; 4) the positions of the N (open) nozzles are searched in dependence on the optimal algorithm, the positions of the N (open) nozzles are N (open) points where the plate-shaped residual defect is maximal; 5) through a direct optimum seeking method, a residual plate-shaped deviation value [epsilon]I is found out, and the number of points which are smaller than or equal to the residual plate-shaped deviation value is just equal to N (open); and 6) the optimum seeking is carried out through the above way until the condition is satisfied.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

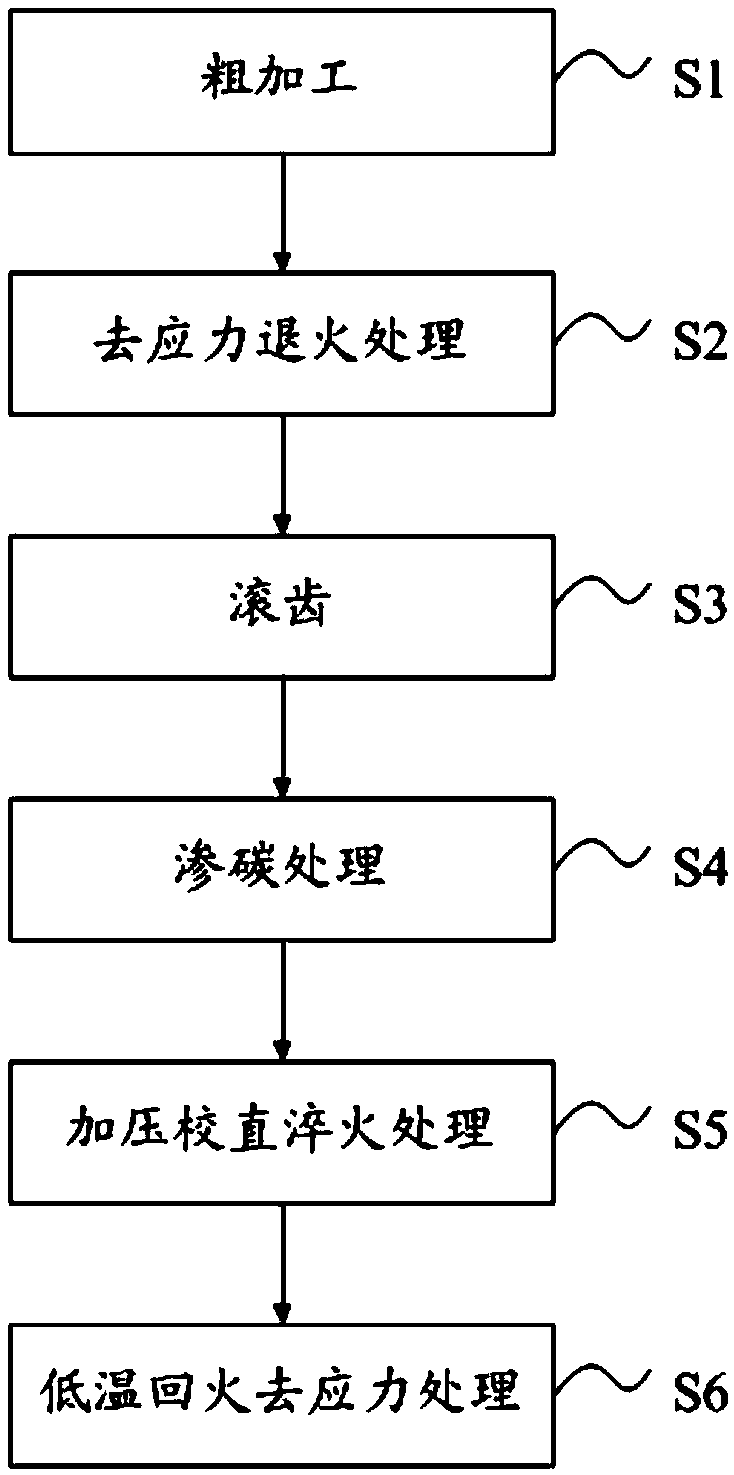

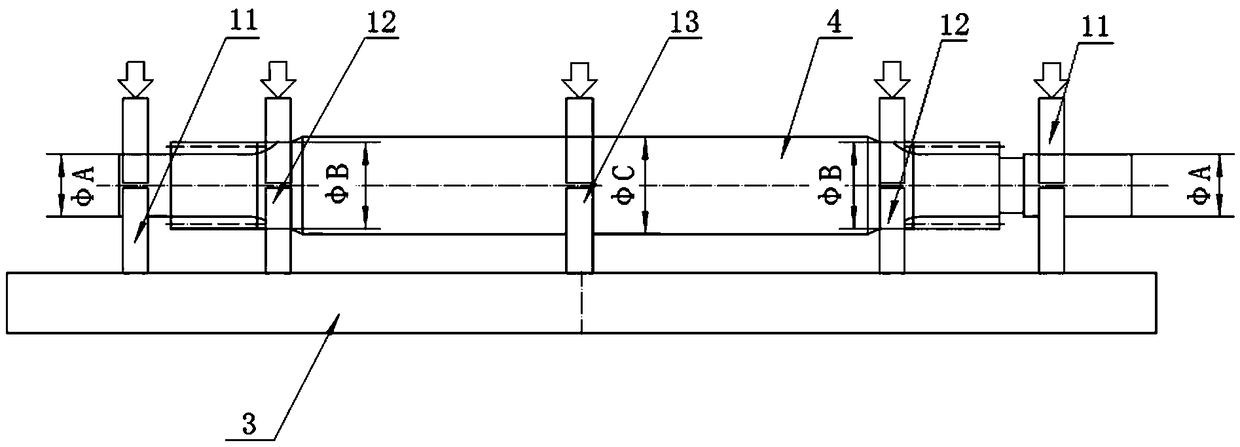

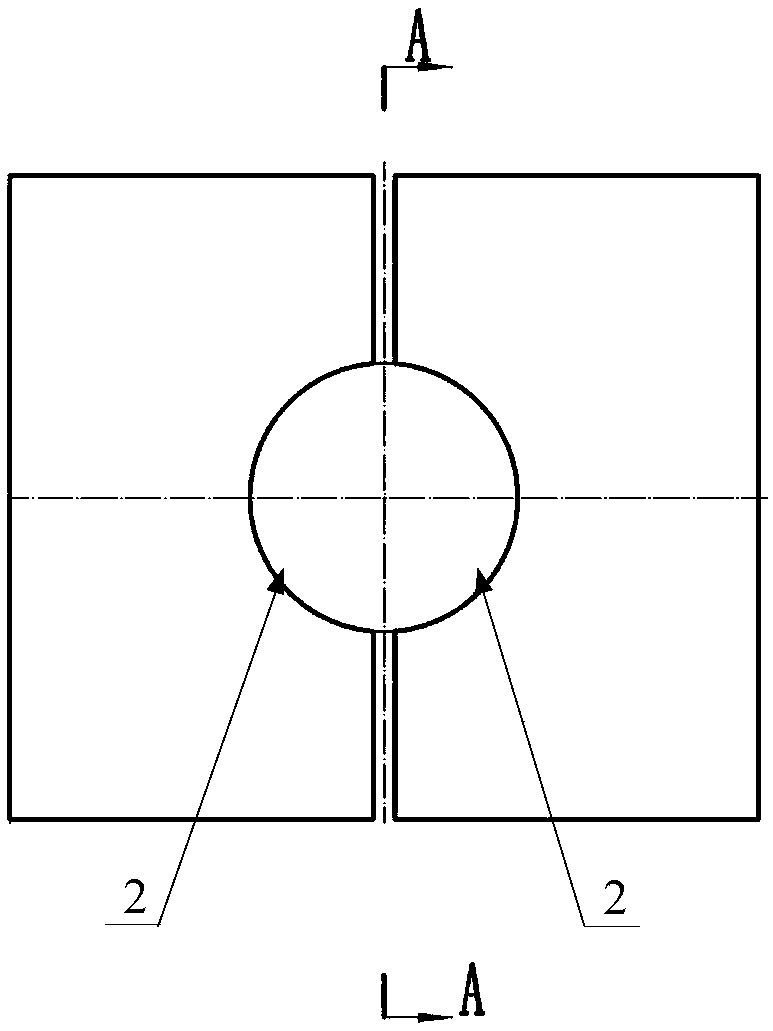

Elongated gear shaft heat treatment deformation control process method

ActiveCN109097551ASolving deformation control problemsSmall quenching deformationSolid state diffusion coatingFurnace typesHobbingStress relieving

The invention discloses an elongated gear shaft heat treatment deformation control process method. The method comprises the following steps that rough machining is carried out; stress-relieving and annealing treatment are carried out on a part after the rough machining; hobbing is carried out, the hobbing are carried out at the two ends of the part, and grinding allowance of the tooth surface is reserved; carburizing treatment is carried out, deformation direction and deformation quantity of the part are detected after carburization; pressurization, straightening and quenching treatments are carried out, according to the deformation direction and the deformation quantity of the part, a pressurizing position is selected, and a supporting part is correspondingly arranged; a pressurizing heavy object is placed at the upper end of the part corresponding to the pressurizing position; the part, the supporting part and the pressurizing heavy object are integrally hoisted into a quenching furnace for heat preservation, and then the quenching oil is wholly hoisted; and after quenching, low-temperature tempering and stress-relieving treatment are carried out. According to the technological process, a supporting point is arranged in the quenching process, pressurizing and quenching are carried out at the supporting point, so that deformation caused by quenching can be effectively reduced,the qualified rate is greatly improved, the rejection rate is remarkably reduced, and the problem that deformation control of the large-span herringbone-tooth long gear shaft is solved.

Owner:CHONGQING GEARBOX

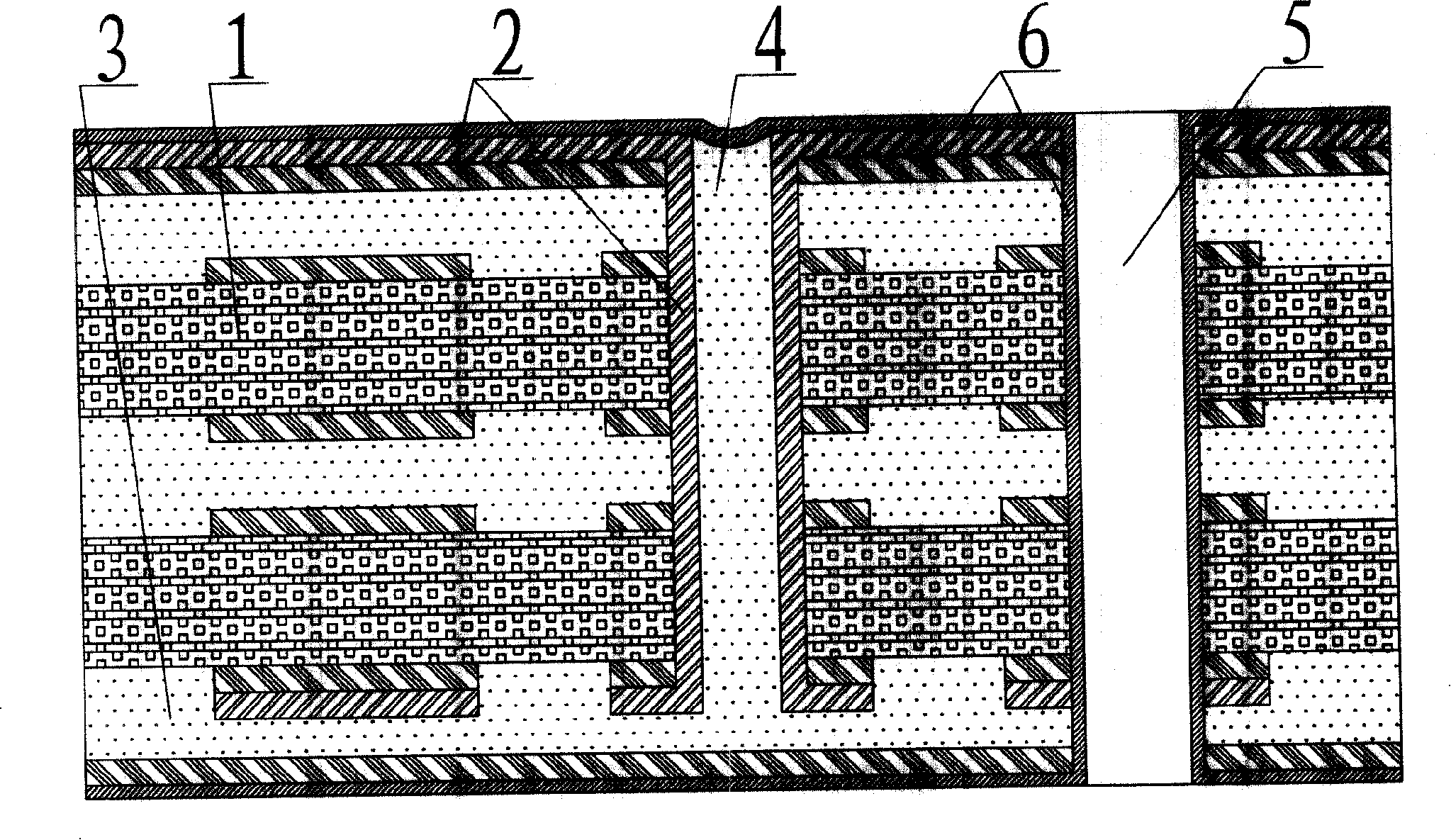

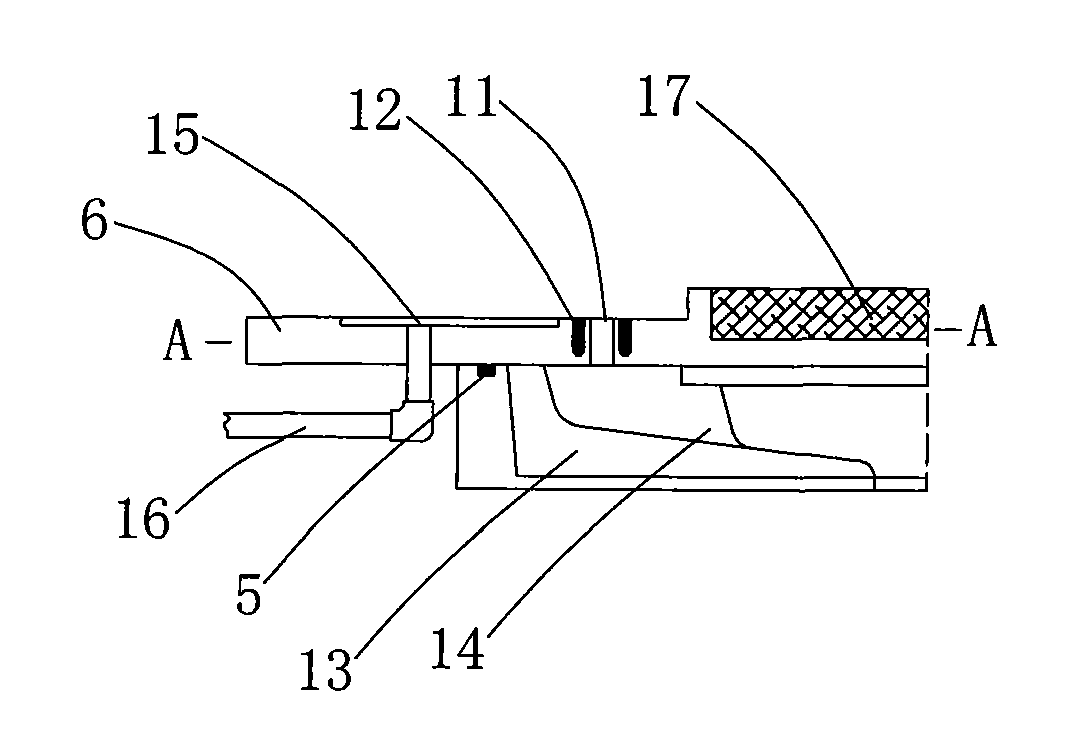

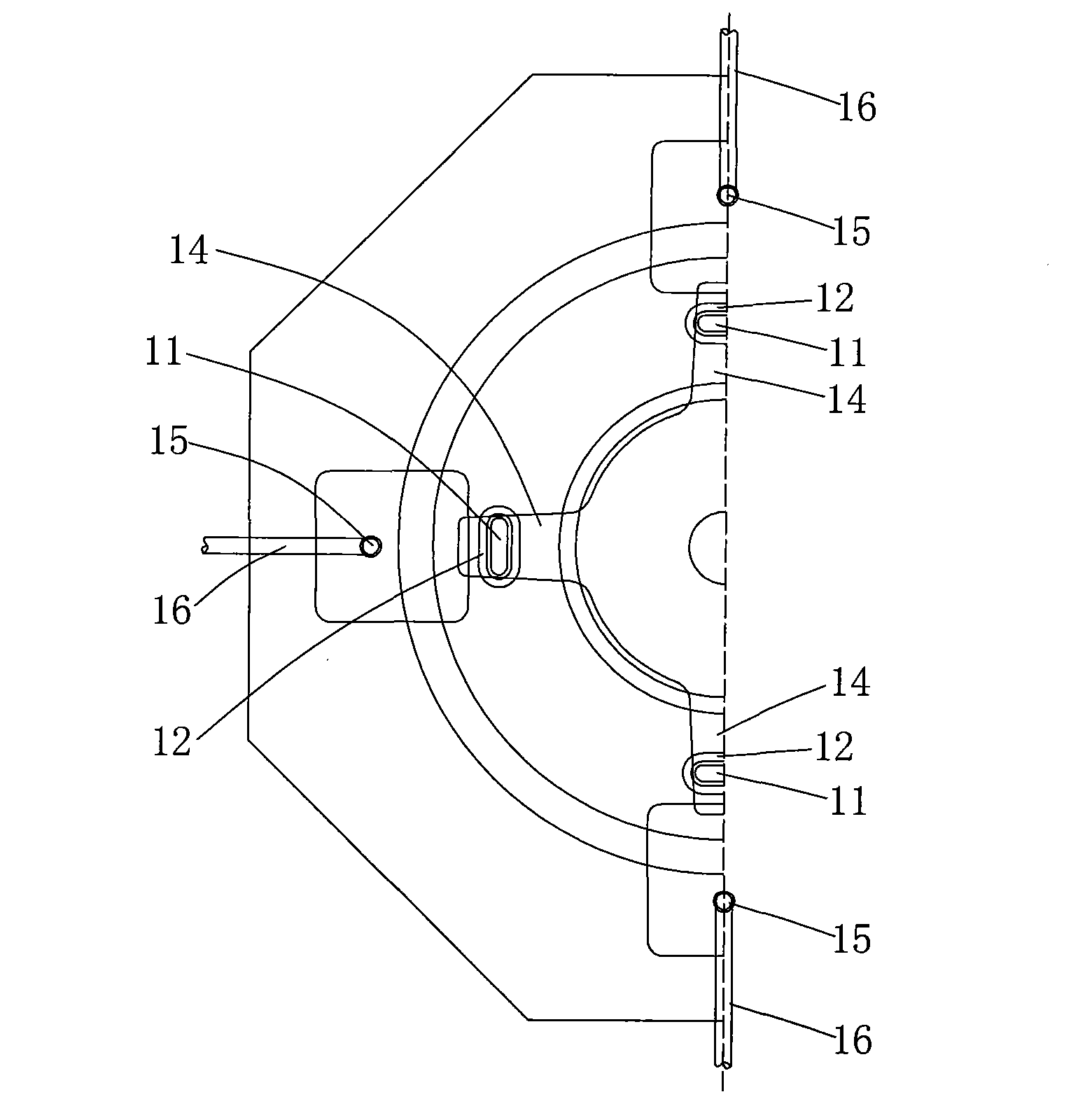

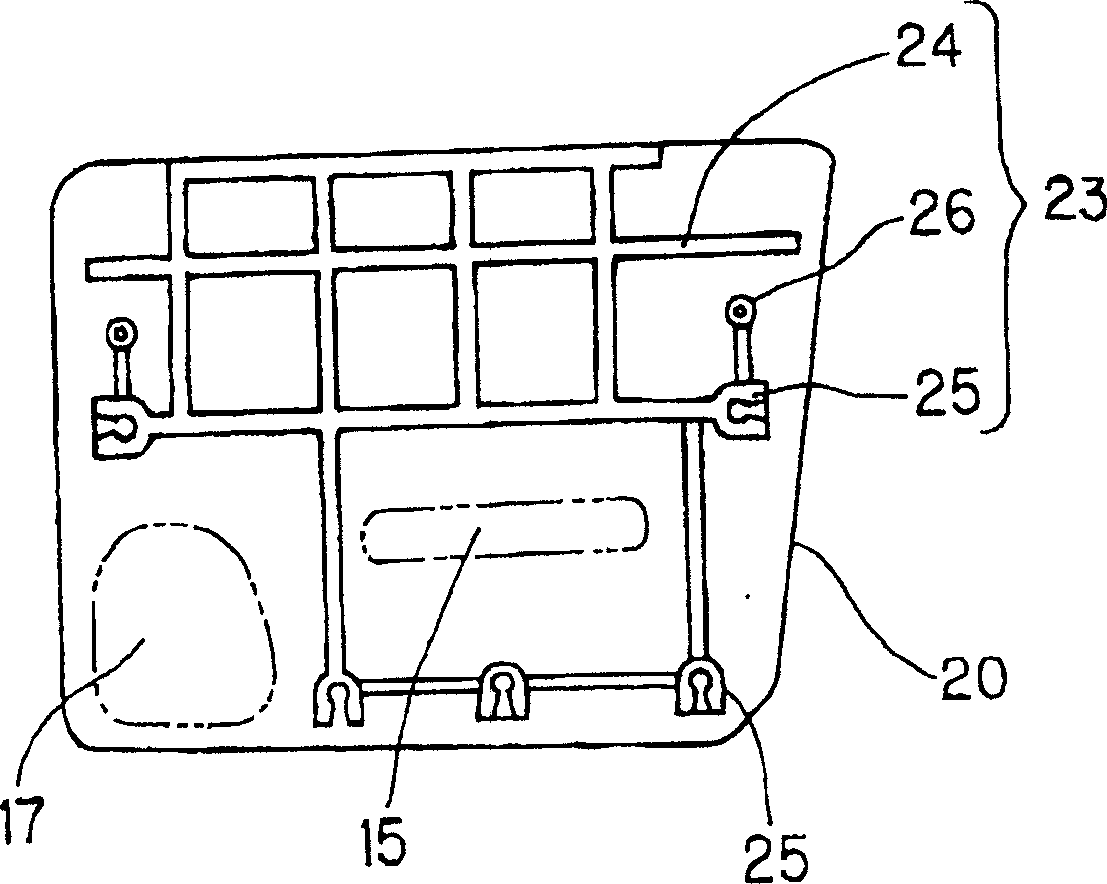

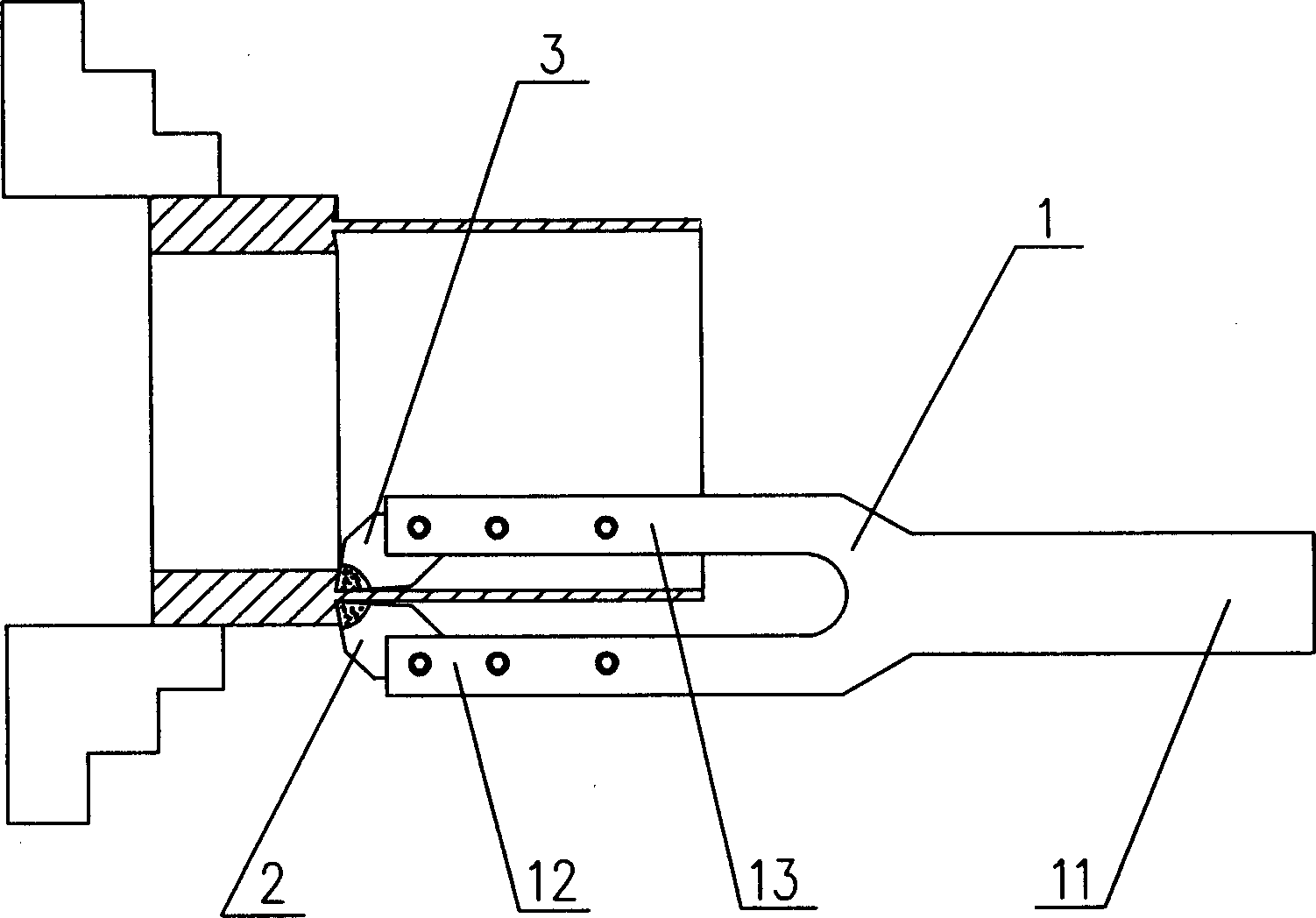

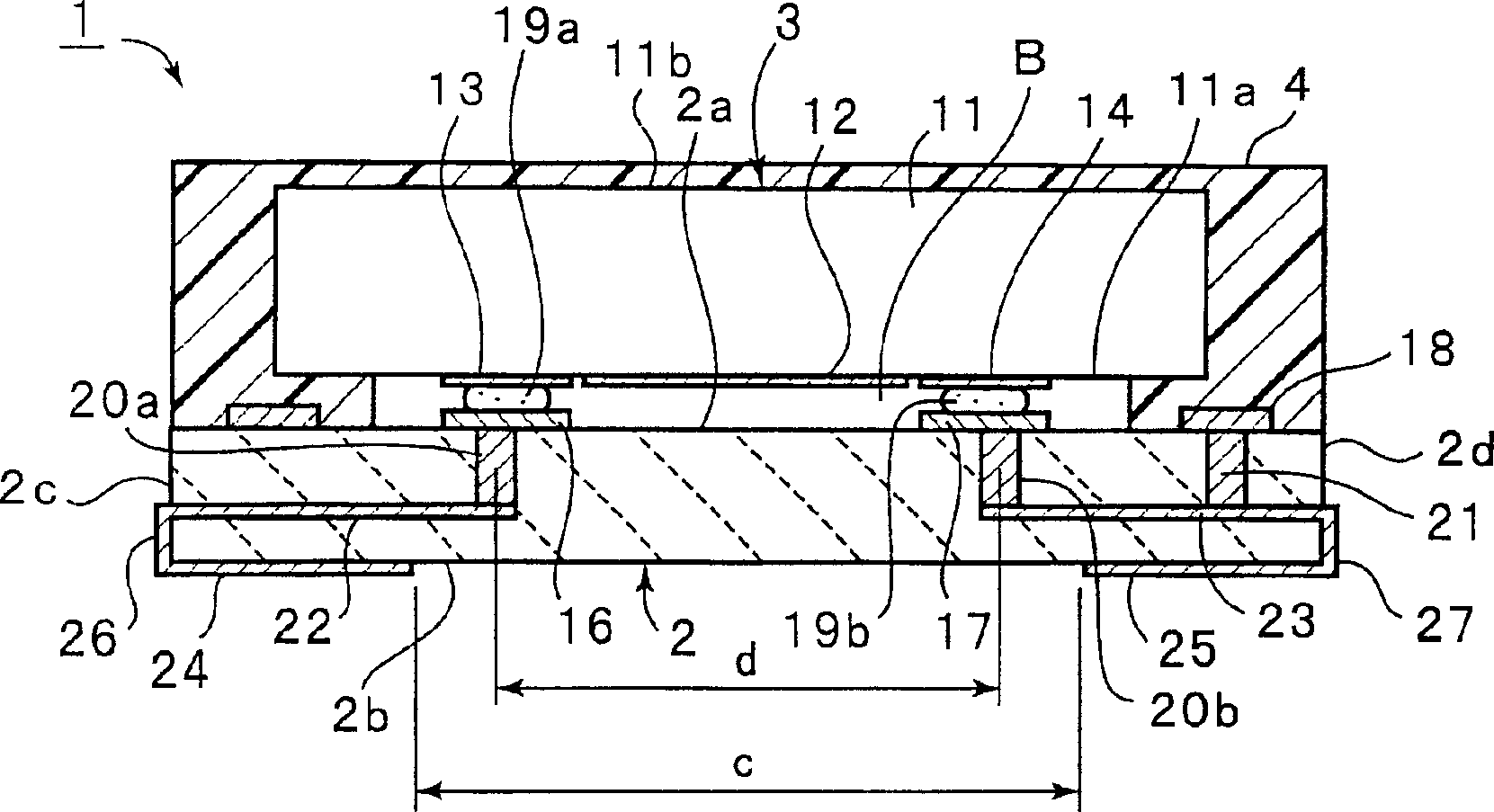

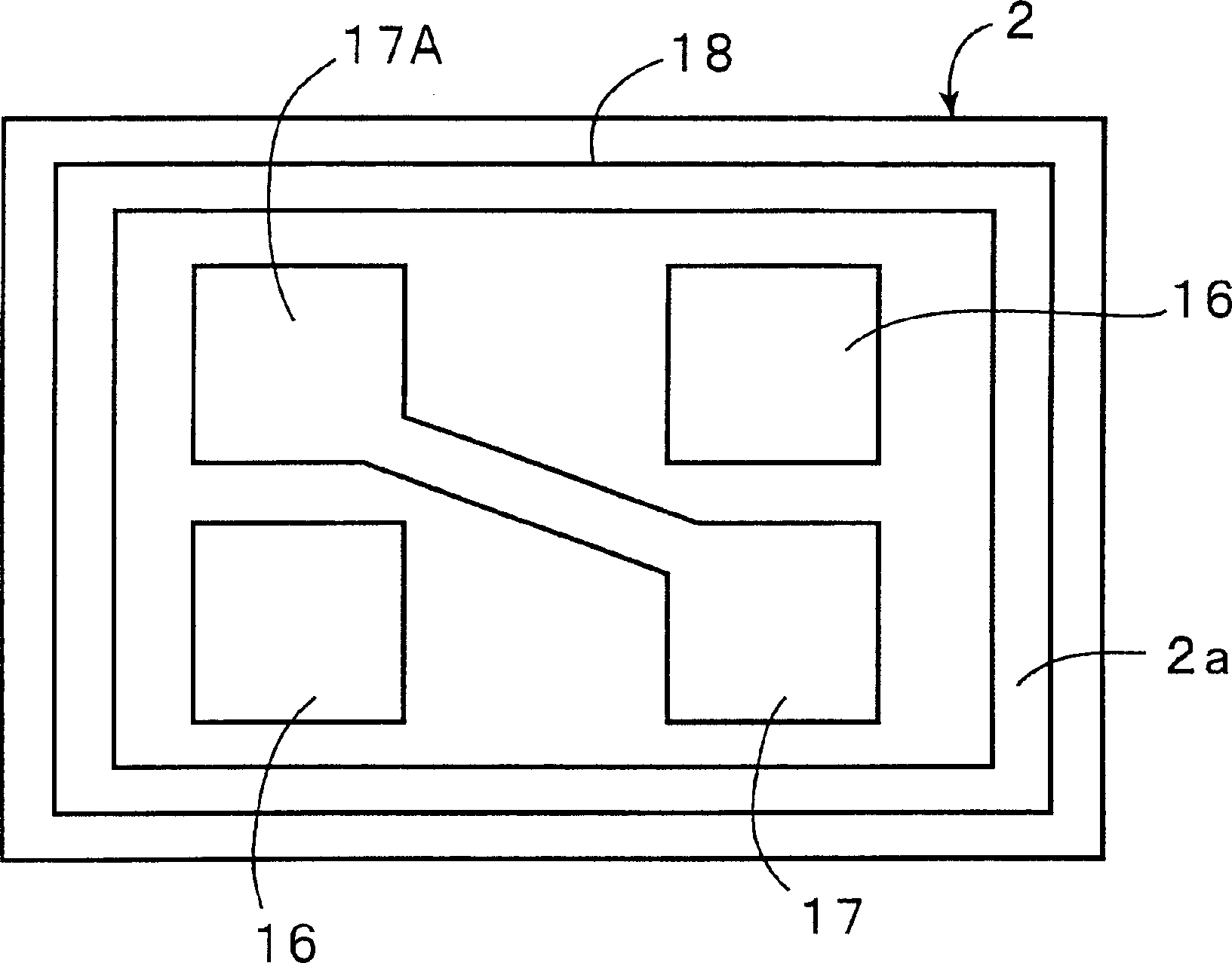

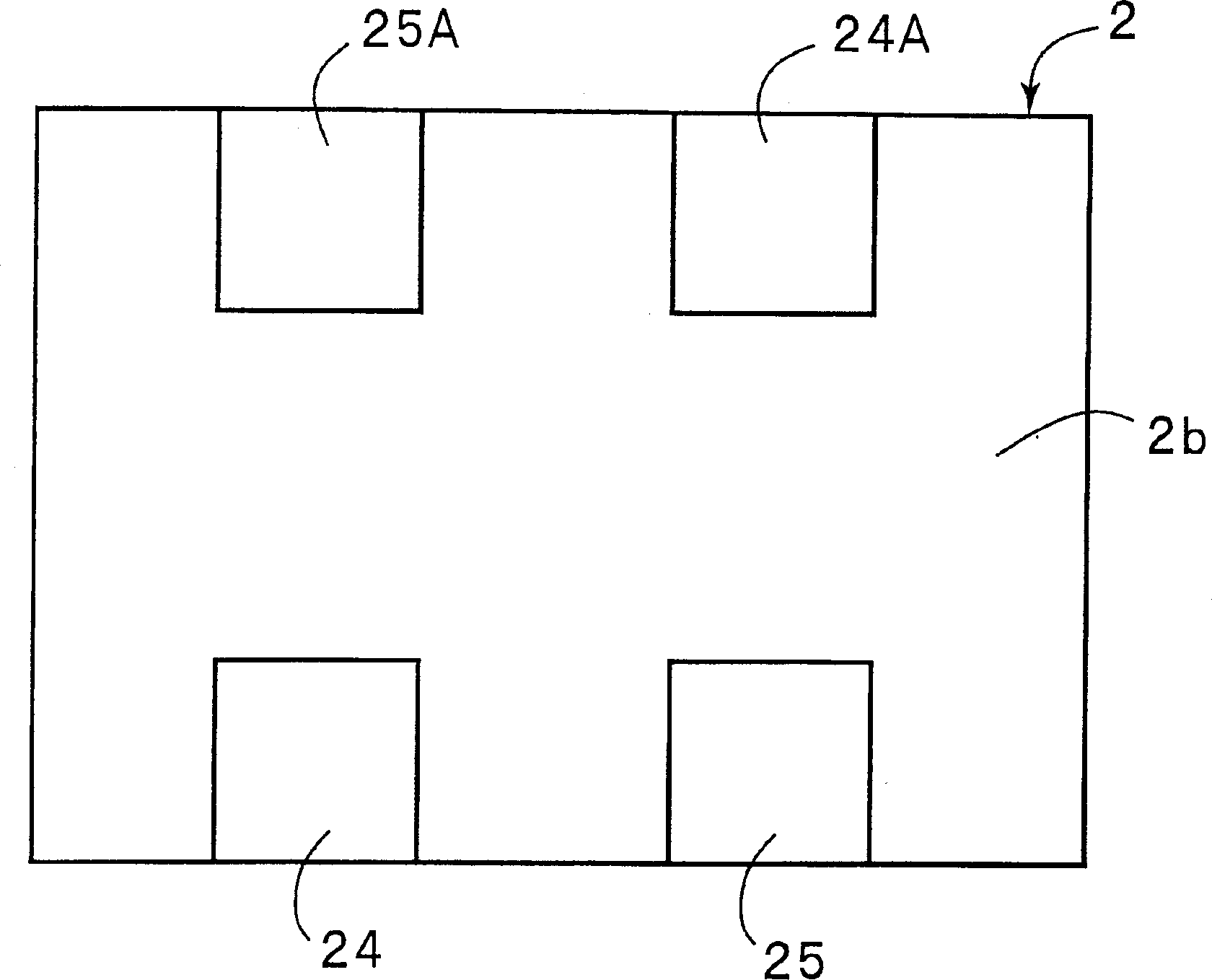

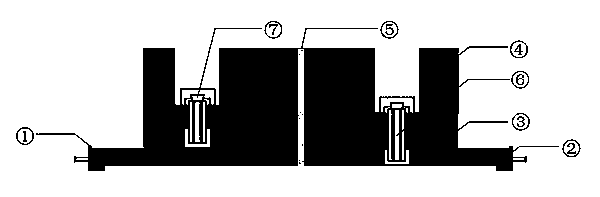

Acoustic surface wave device

InactiveCN1428930AAvoid short circuitForm confirmationImpedence networksSemiconductor/solid-state device detailsMiniaturizationEngineering

A surface acoustic wave device which hardly causes short- circuit between mounting electrodes in mounting of an elastic surface wave element, even devised to be miniaturized, and facilitates checking the formation of fillets of a conductive bond in mounting, thus reducing the cost, with the element being mounted on a board and sealed with a resin-sealing layer. The surface acoustic wave device 1 has a surface acoustic wave element 3, which is mounted on a multilayer board 2 by the face down method using bumps 19a, 19b and sealed with a resin-sealing layer 4. Electrode lands 16, 17 on the upper side 2a of the multilayer board 2 connected to the bumps 19a, 19b are connected to inner electrodes 22, 23 via electrodes 20a, 20b, and the inner electrodes 22, 23 are electrically connected to mounting electrodes 24, 25 on the lower side of the board 2 and to end-face wiring electrodes 26, 27.

Owner:MURATA MFG CO LTD

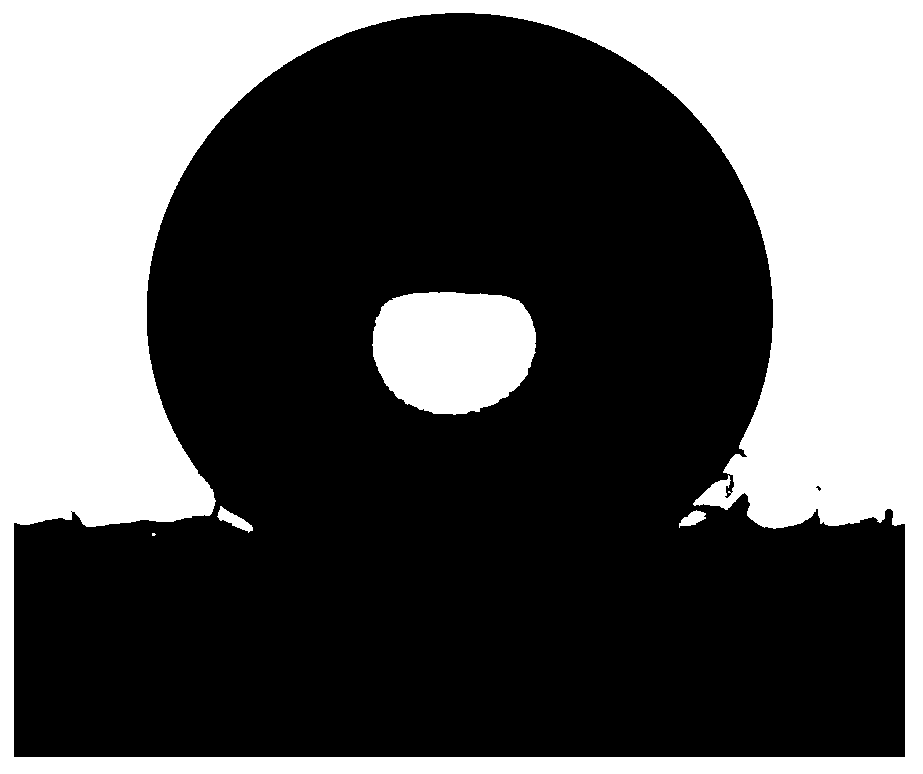

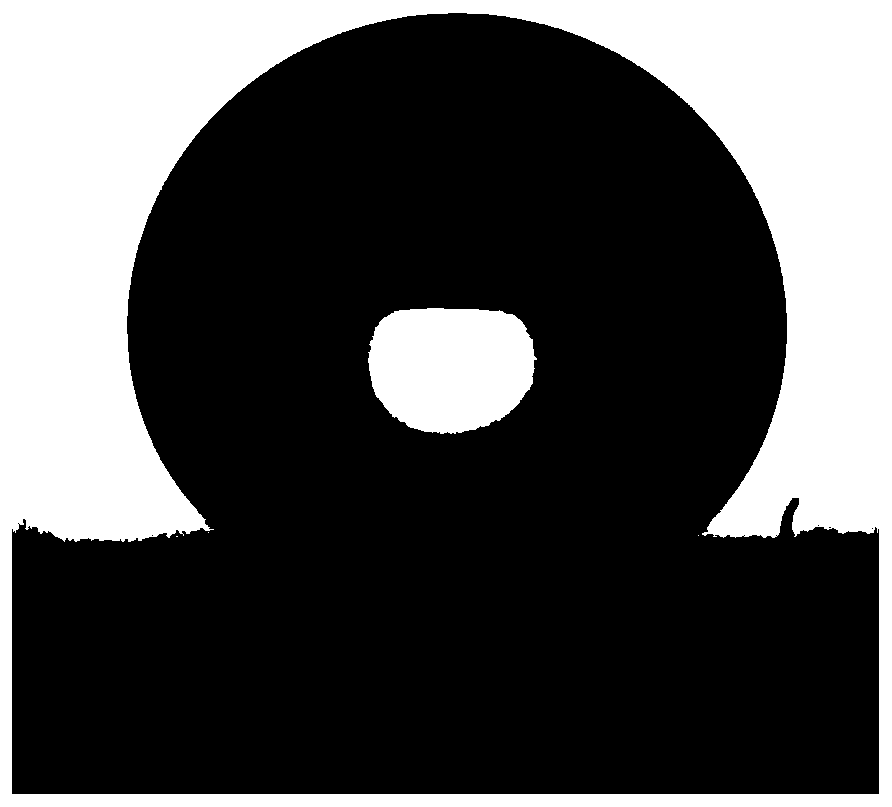

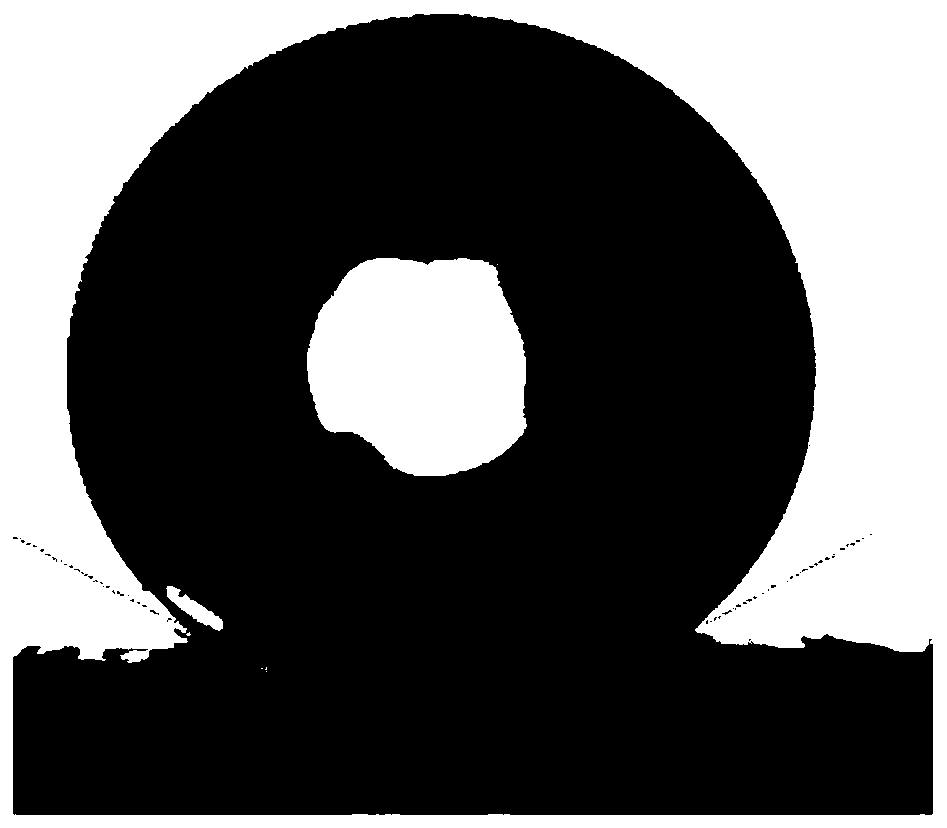

One-bath one-step processing method for dyeing and waterproof finishing of polyester fabric

ActiveCN110344262AEmission reductionShorten the dyeing and finishing processDyeing processPolyesterSocial benefits

The invention relates to a one-bath one-step processing method for dyeing and waterproof finishing of a polyester fabric. The method of the invention comprises starting dyeing at room temperature, soaking the polyester fabric to be dyed in a working fluid, heating gradually to a working temperature, holding the temperature, carrying out dyeing and waterproof finishing at the same time, cooling tocomplete the dyeing and waterproof finishing, subjecting the fabric to reductive cleaning, and carrying out acid neutralization, water washing and baking. The conventional dyeing and post-finishing stepwise processing method is broken through; the dyeing and finishing process is shortened; production cost is reduced; emission of wastewater is reduced; the method of the invention has high production efficiency and good environmental friendliness, as well as good economic and social benefits, and is important to the development of clean dyeing and finishing and ecological textiles.

Owner:上海驰纺材料科技有限公司

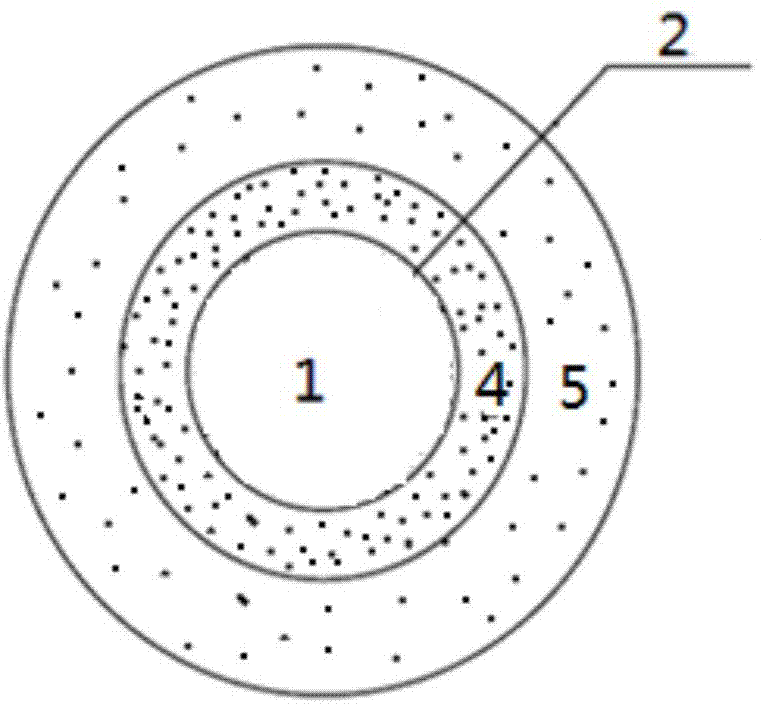

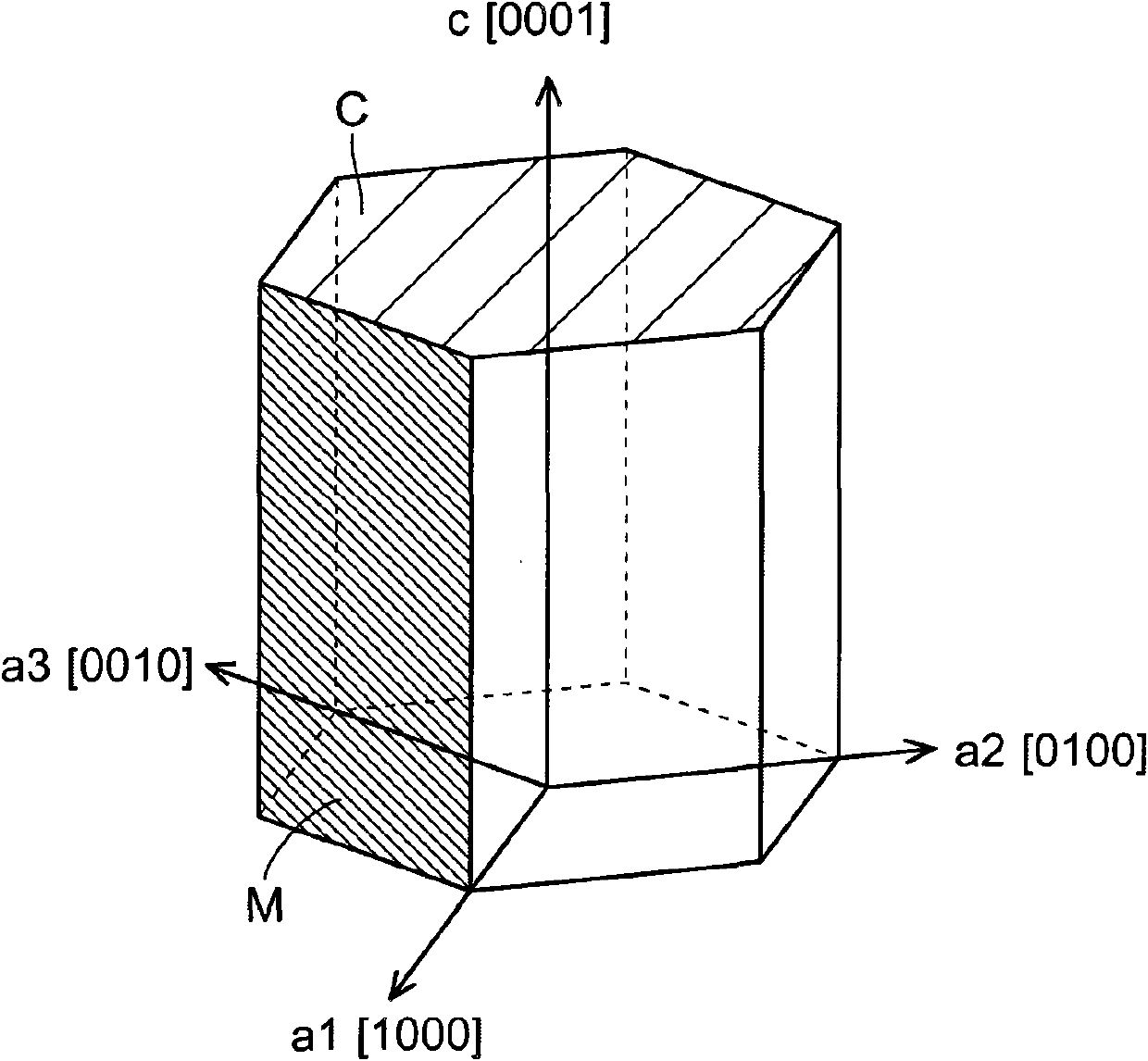

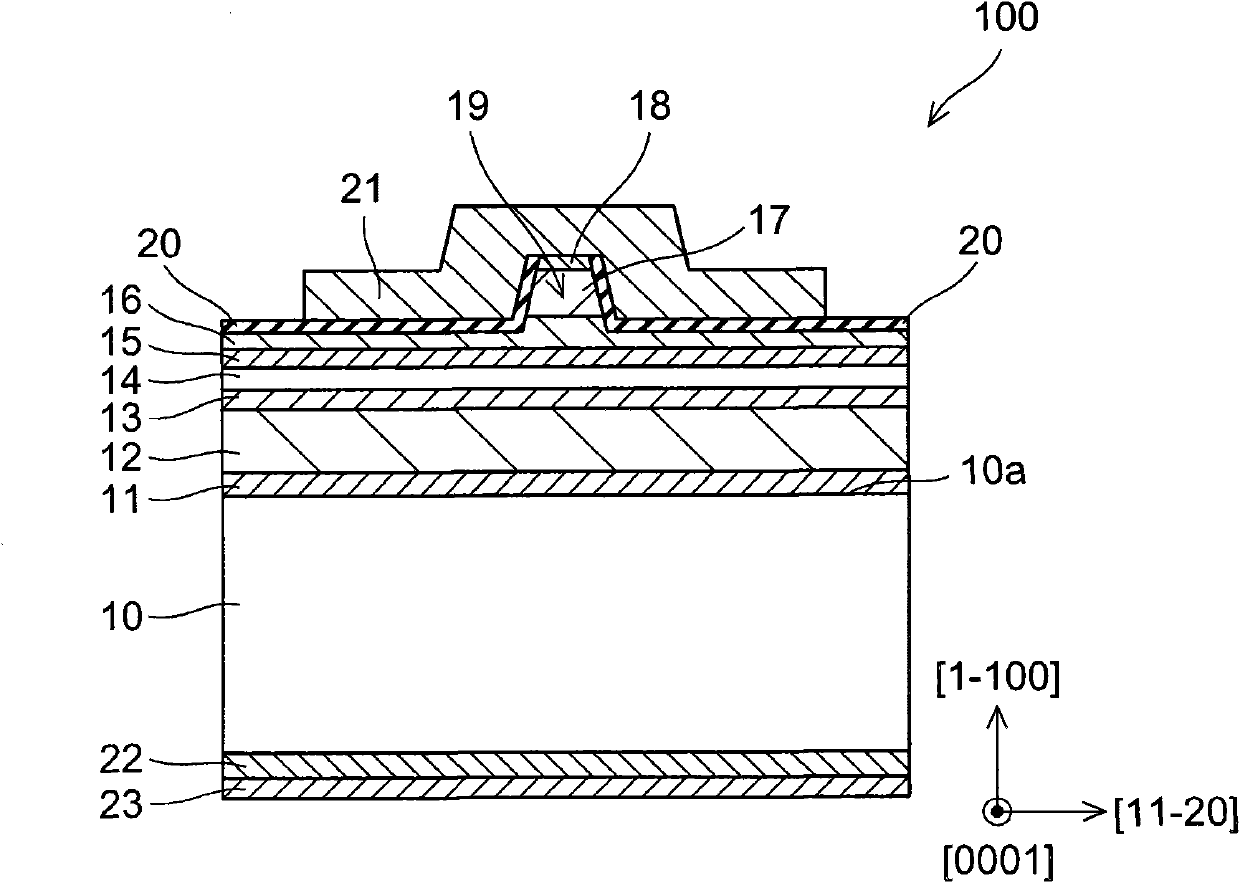

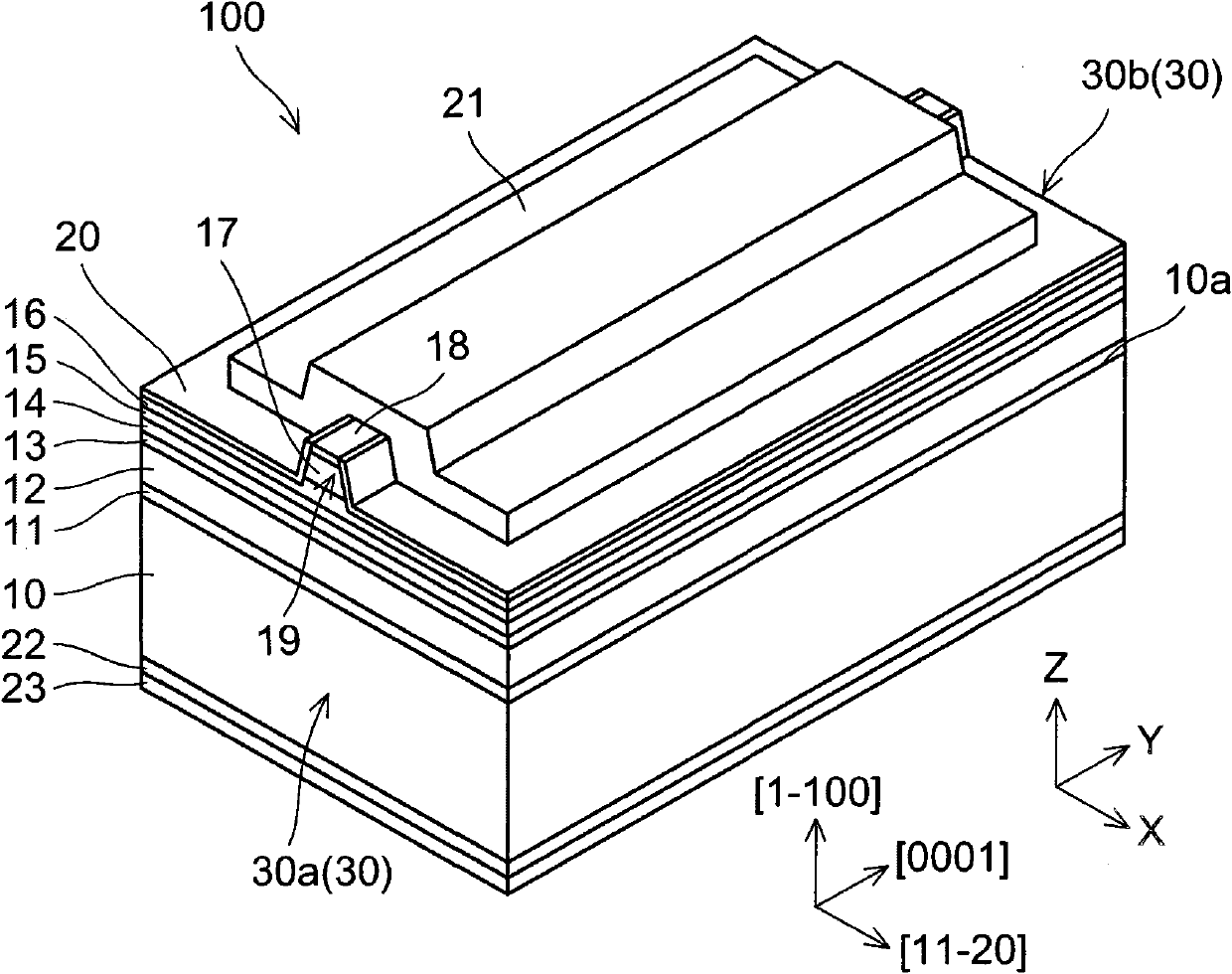

Nitride semiconductor wafer, nitride semiconductor chip, method of manufacture thereof, and semiconductor device

InactiveCN101997268AImprove luminous efficiencyImprove qualified product rateOptical wave guidanceLaser detailsWaferingDevice material

The invention relates to a Nitride semiconductor wafer,a nitride semiconductor chip, a method of manufacture thereof, and semiconductor device. The nitride semiconductor chip allows enhancement of luminous efficacy. The nitride semiconductor laser chip (nitride semiconductor chip) has a GaN substrate, which has a principal growth plane, and an active layer, which is formed on the principal growth plane of the GaN substrate and which has a quantum well structure including a well layer and a barrier layer. The principal growth plane is a plane having an off angle in the a-axis direction relative to the m plane. The barrier layer is formed of AlGaN, which is a nitride semiconductor containing Al.

Owner:SHARP KK

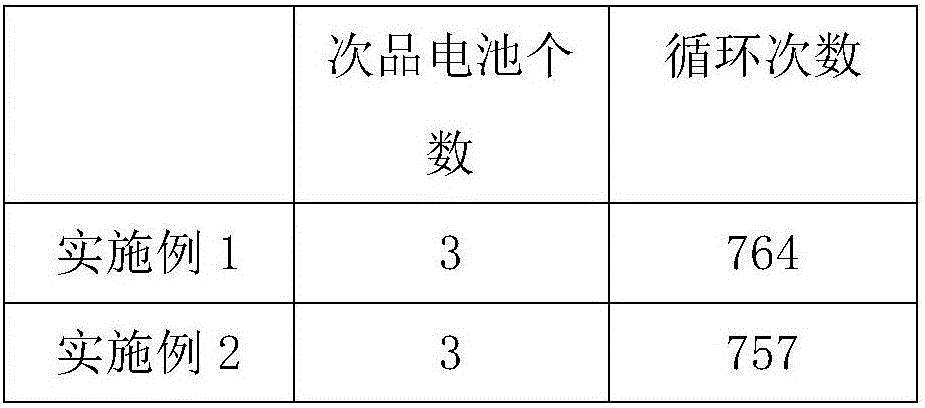

Intelligent formation method of lithium ion battery

InactiveCN107528091AImprove performanceImprove life performanceFinal product manufactureElectrolyte accumulators manufactureGeneration ratePower flow

The invention provides an intelligent formation method of a lithium ion battery. The parameters of the battery are detected in a formation process, relevant parameters of current and voltage in the formation process are formulated according to the condition of the battery, and a formation procedure is formulated according to internal conditions of each battery, so that the generation rate of poor products in the formation process is reduced, and the performance of the lithium ion battery is improved. According to the method provided by the invention, the rate of qualified lithium ion batteries is increased, the life performance of the lithium ion batteries is improved, and the production cost is lowered.

Owner:青岛恒金源电子科技有限公司

Processing method of thin aluminum piece

The invention discloses a processing method of a thin aluminum piece. The processing method comprises the steps as follows: A, a chuck position is retained, and a workpiece is dismounted; B, the thin aluminum piece is placed for 3-5 days; C, a large end excircle, a small end excircle and a small end surface are subjected to finish turning, and a central hole is drilled; D, a stepped hole in the side of the large end excrcle is subjected to turning; and E, a thin aluminum piece turning clamp is adopted to perform turning on the large end surface of the thin aluminum piece subjected to the stepped hole turning. Compared with the prior art, the processing method of the thin aluminum piece can solve the problems of poor turning stability and low qualified rate of a conventional piston cover plate.

Owner:WUZHOU WANGJIE MACHINERY MFR

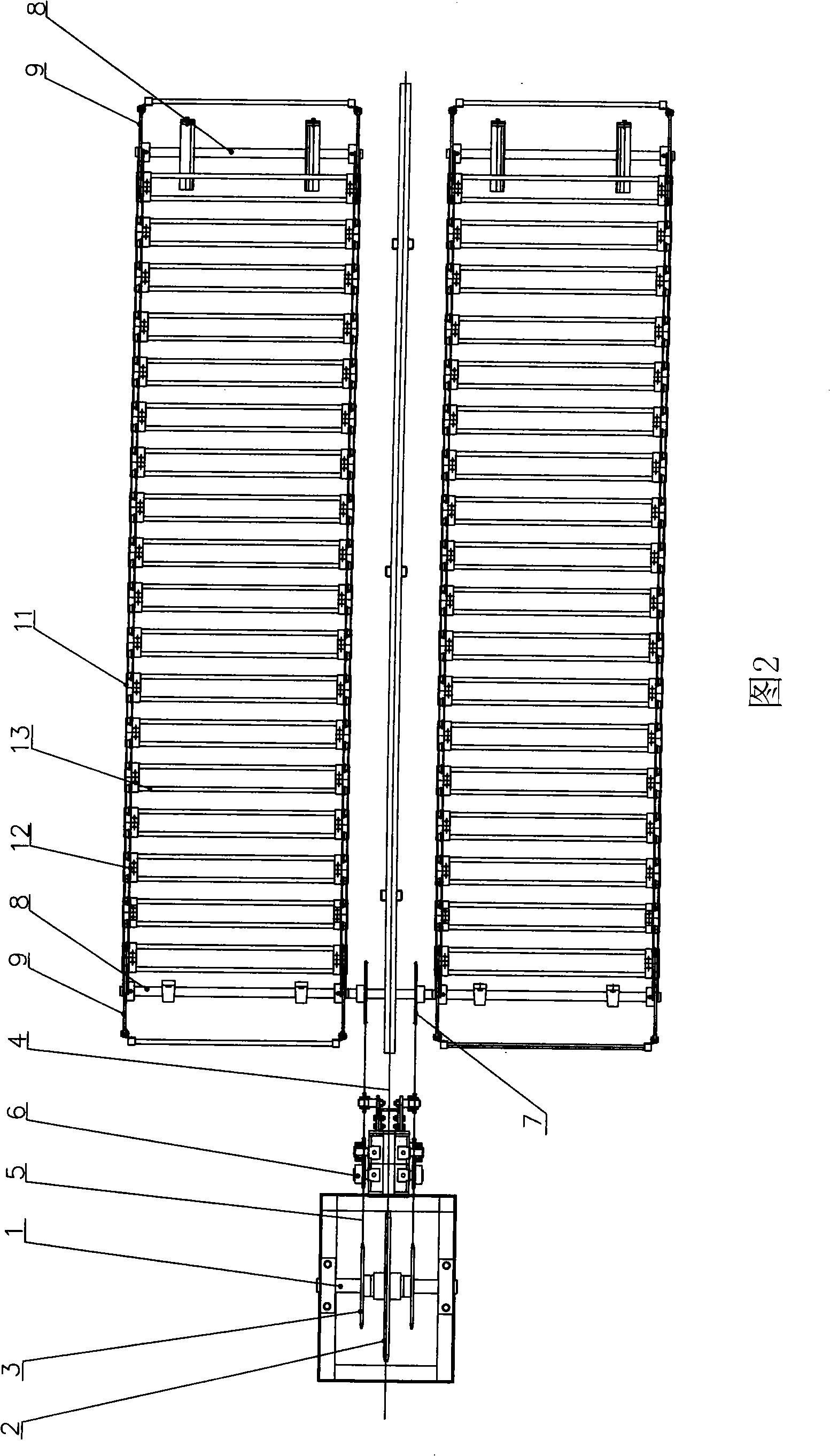

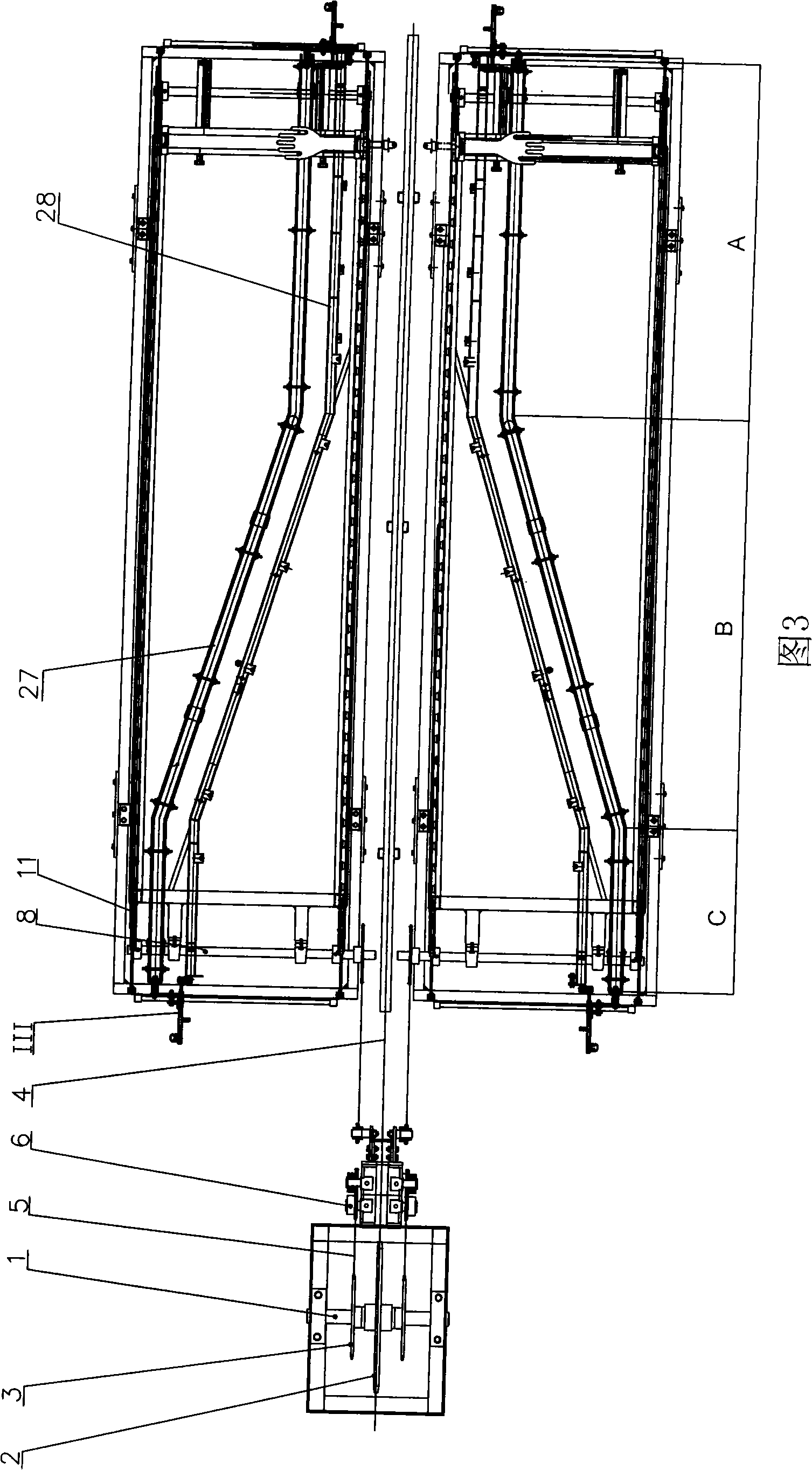

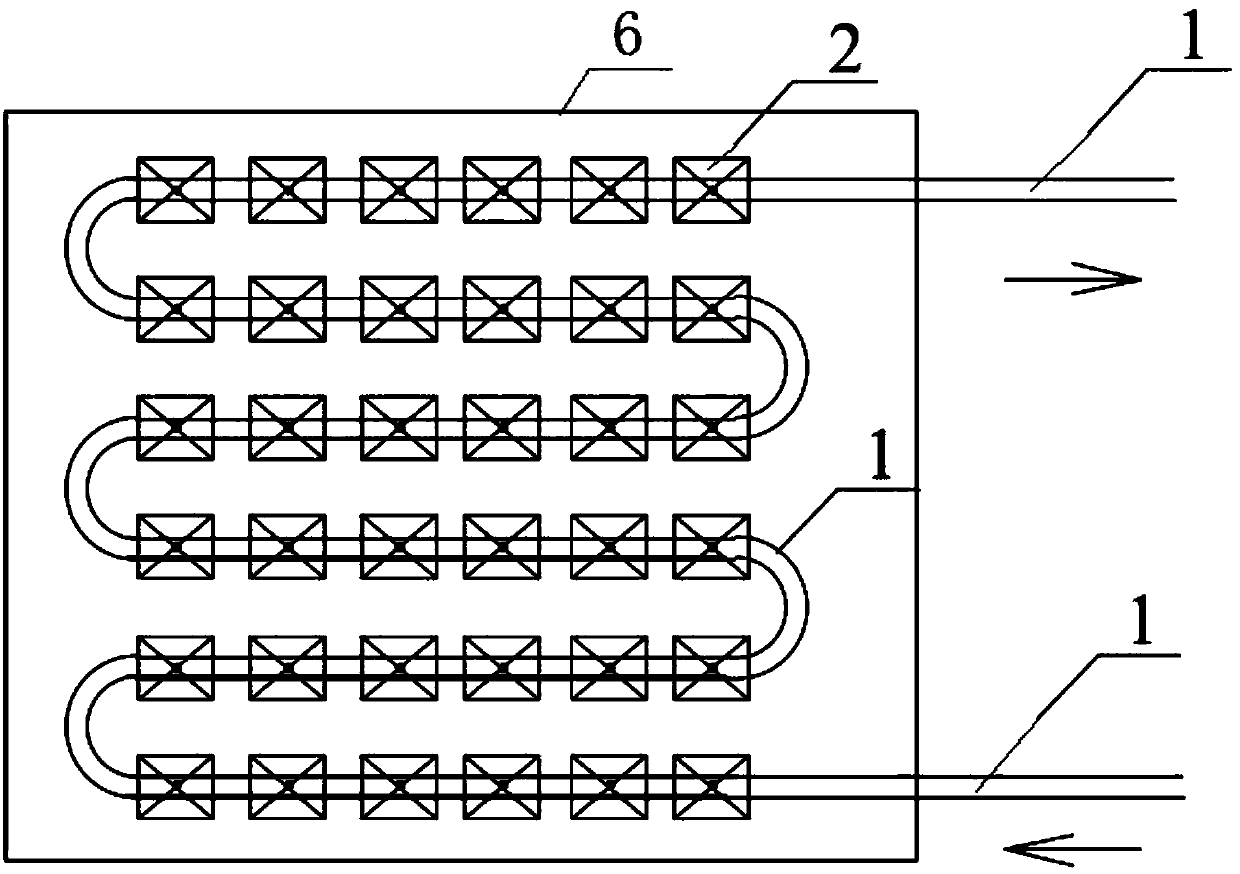

Alcohol solvus hollow cup armature coil production line system and production method thereof

InactiveCN102868262ABeautiful appearanceGood shape and size consistencyManufacturing dynamo-electric machinesWinding machineProduction line

The invention relates to the technical field of alcohol solvus hollow cup armature manufacturing, in particular to an electric control cabinet comprising an operating platform, a winding machine and a PLC (programmable logic controller) controller. The electric control cabinet is characterized in that the winding machine is fixed on an initial station of an operating platform surface; at least one production line mechanism is arranged on the initial station behind the winding machine, and the production line mechanism further comprises a hot embossing device, a tin immersion device, an alcohol immersion device, a bruting device and a mechanical hand pickup converyer positioned above the bruting device which are arranged on the operating platform surface in sequence; and a transmission line twisting device moving from left to right back and forth is arranged between the winding machine and the hot embossing device of the production line mechanism, and a trimming device is fixed at the top of a transmission sliding plate of the transmission line twisting device. Due to the above structure, the electric control cabinet has the advantages that working efficiency is increased, quality of products is improved and production cost is lowered.

Owner:CHONGQING ZHONGZHIYU TECH

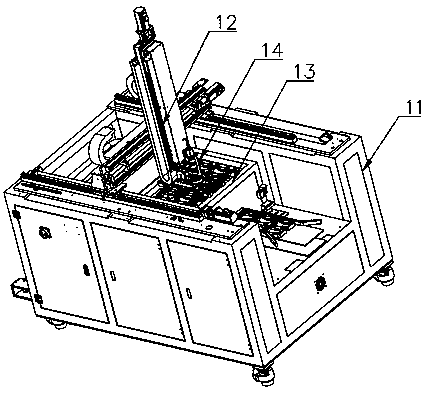

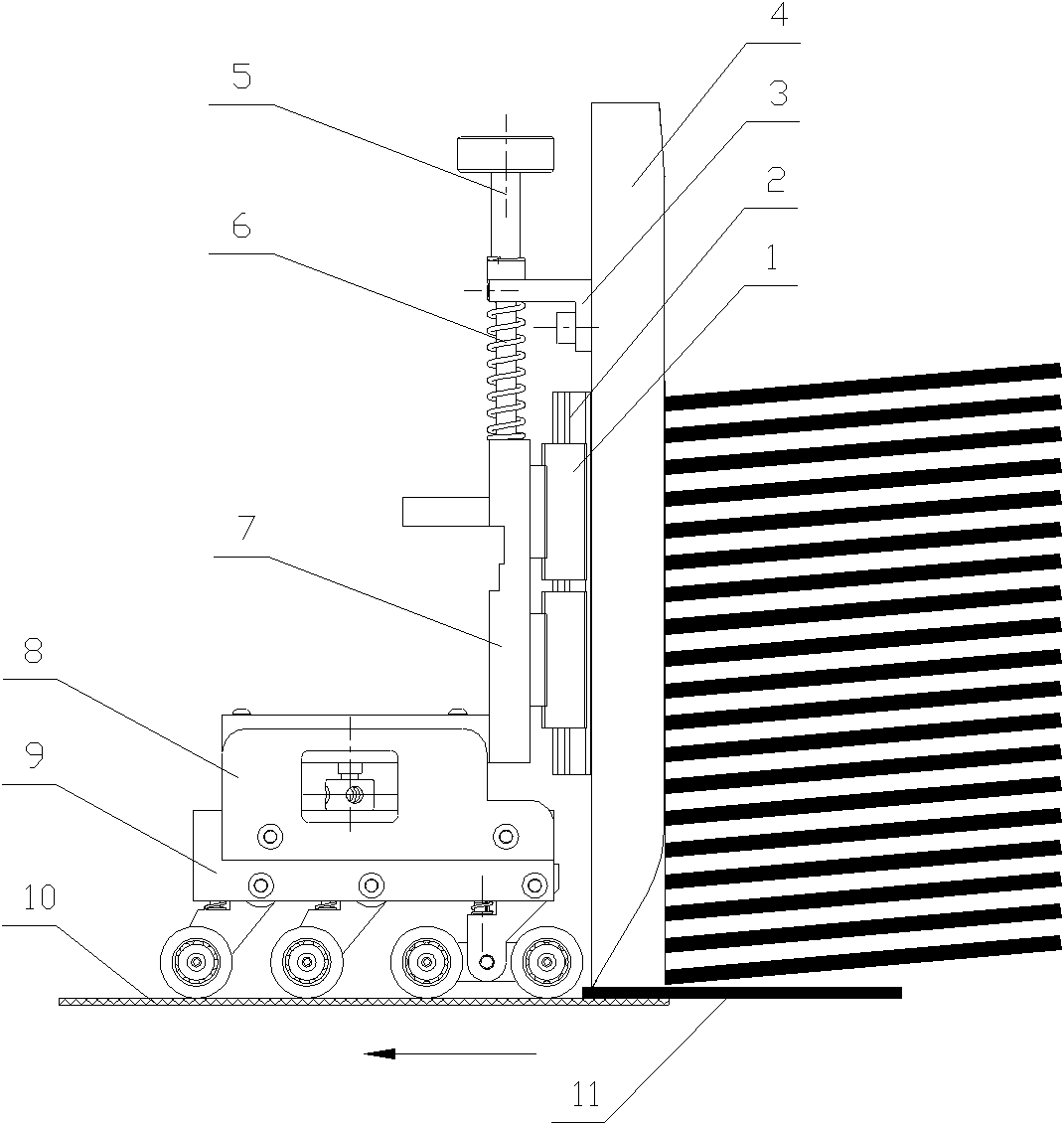

Paper feeding device and work method thereof

Owner:MASTERWORK GROUP CO LTD

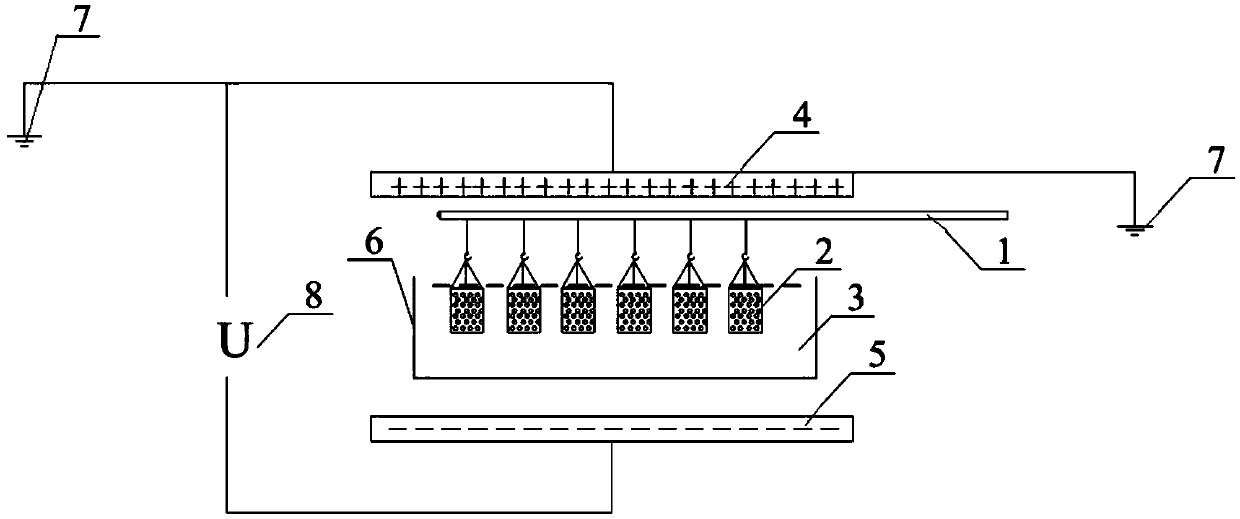

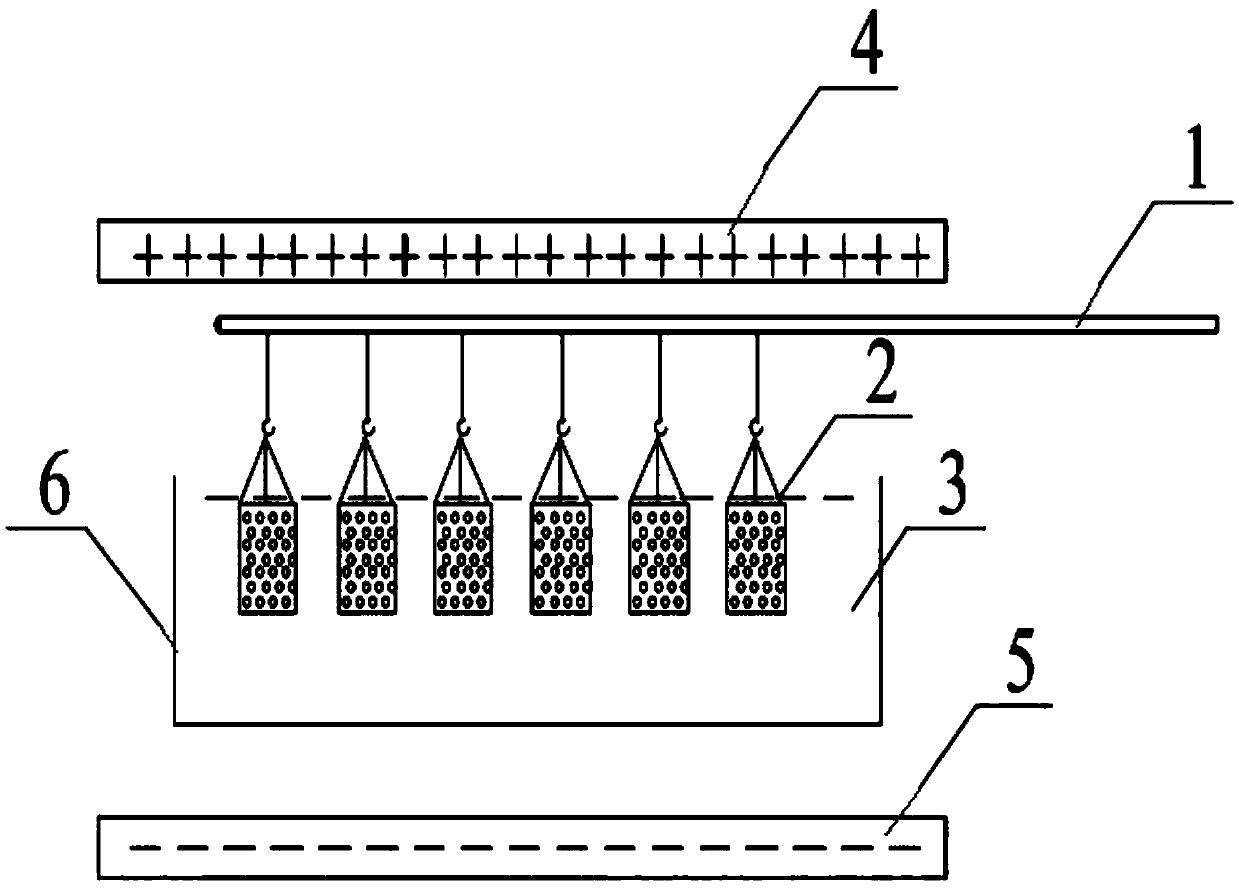

Rapid reformed egg manufacturing system and method using medium-high voltage electric field

The invention relates to a rapid reformed egg manufacturing system and method using a medium-high voltage electric field. The system comprises an overhead rail delivering system, a medium-high voltageelectric field pickling system, and a washing system. Eggs to be processed is introduced into the system from the input end of the overhead rail delivering system; the output end of the overhead raildelivering system is connected to the input end of the washing system; the medium-high voltage electric field pickling system is arranged between the overhead rail delivering system and the washing system; the overhead rail delivering system can drive the eggs to go through the medium-high voltage electric field pickling system; eggs are pickled in the medium-high voltage electric field picklingsystem after the eggs enter the medium-high voltage electric field pickling system; and the washing system can wash and dry pickled eggs. The structure is simple, the operation is convenient, automation is easy to realize; the system can be applied to production lines in a factory, the efficiency is high, energy is saved, environment is protected, industrial production is easy to realize, and thesystem can be applied to large scale production of reformed eggs.

Owner:TIANJIN UNIV OF SCI & TECH

Combined gold-stamping embossing pressure compensation plate-adjusting-free technology

InactiveCN103373052ASimplify the version adjustment processEasy to operateBronze printingRotary pressesEngineeringCopper

The invention relates to a combined gold-stamping embossing pressure compensation plate-adjusting-free technology applied to gold-stamping embossing pressure compensation. An aluminum bottom plate with a positioning pin is fixed on a rack plate frame, an iron plate is fixed on the aluminum bottom plate through a first screw, and a gold-stamping embossing copper plate is fixed on the iron plate through a second screw. According to the technology, when the pressure is changed, the iron plate combined with the gold-stamping embossing copper plate is directly taken down for backing, the gold-stamping embossing copper plate is not required to be moved again for gauge distance proofreading with patterns of printed matter, the operation is facilitated while the plate adjusting link is simplified, the quality rate of products is improved by above 20%, and the work efficiency is improved by above 30%.

Owner:襄阳金飞环彩色包装有限公司

Composite carbon tool steel/plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life

InactiveCN102154537AHigh hardnessImprove uniformityIncreasing energy efficiencyFurnace typesHigh resistanceWear resistant

The invention discloses a composite carbon tool steel / plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life. Aiming at characteristics of an explosive composite wear-resistant material and operating requirements of a metallurgical wear-resistant lining board, the surface induction heating principle and the metal phase transformation theory are used for controlling the depth of heat penetration, the hardness of an appropriate layer interface, and the depth and uniformity of a quench hardening layer so that the hardness of the composite layer is distributed in gradient, and the complete martensite phase change is avoided from occuring in the composite interface layer during quenching so to reduce the structure stress formed on the interface and keep the original combination state of the composite board to the greatest extend. The composite metallurgical lining board with high resistance, high uniformity and long service life has surface hardness of larger than 61HRC (rockwell hardness) and uniformity of hardness of less than 3 HRC (rockwell hardness); A 5mm place of the composite layer in the thickness direction has a hardness value of larger than 50HRC (rockwell hardness); and the three fifth to four fifth place of the composite layer thickness has the hardness value of less than 35HRC (rockwell hardness).

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

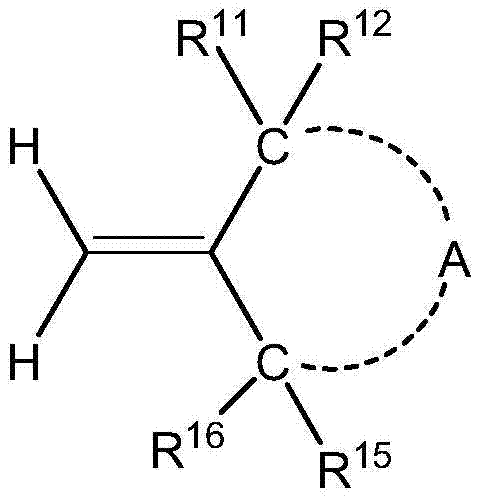

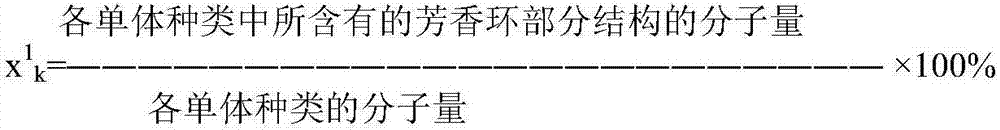

Semi-cured product, cured product, methods for producing same, optical component, and curable resin composition

InactiveCN104204006AImprove qualified product rateExcellent heat resistance and colorabilityOptical elementsMethacrylatePolymer science

A curable resin composition containing a (meth)acrylate monomer having an aromatic ring, a non-conjugated vinylidene group-containing compound represented by general formula (1), and / or a thermal radical polymerization initiator and / or photo-radical polymerization initiator (where the non-conjugated vinylidene group-containing compound does not include the (meth)acrylate monomer) (R11, R12, R15, and R16 each independently represent a substituent group, and A represents an atomic group needed in order to form a cyclic structure) makes it possible to produce a cured product having minimized occurrence of burring during molding, high favorable product yield rate after molding, favorable heat coloration resistance, and low Abbe number.

Owner:FUJIFILM CORP

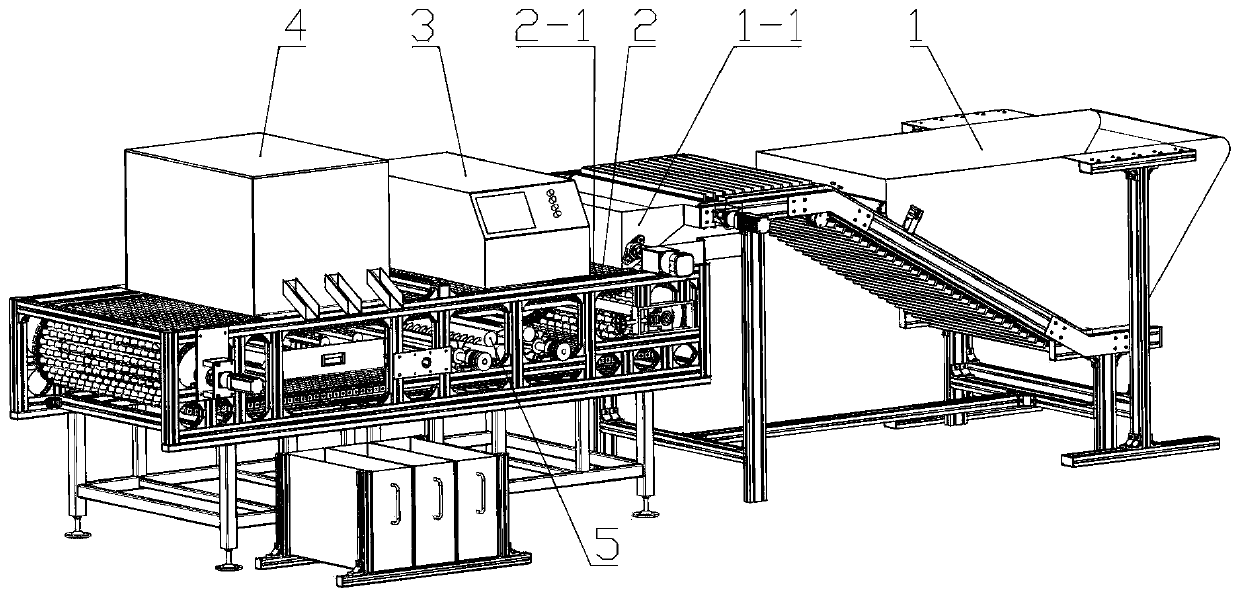

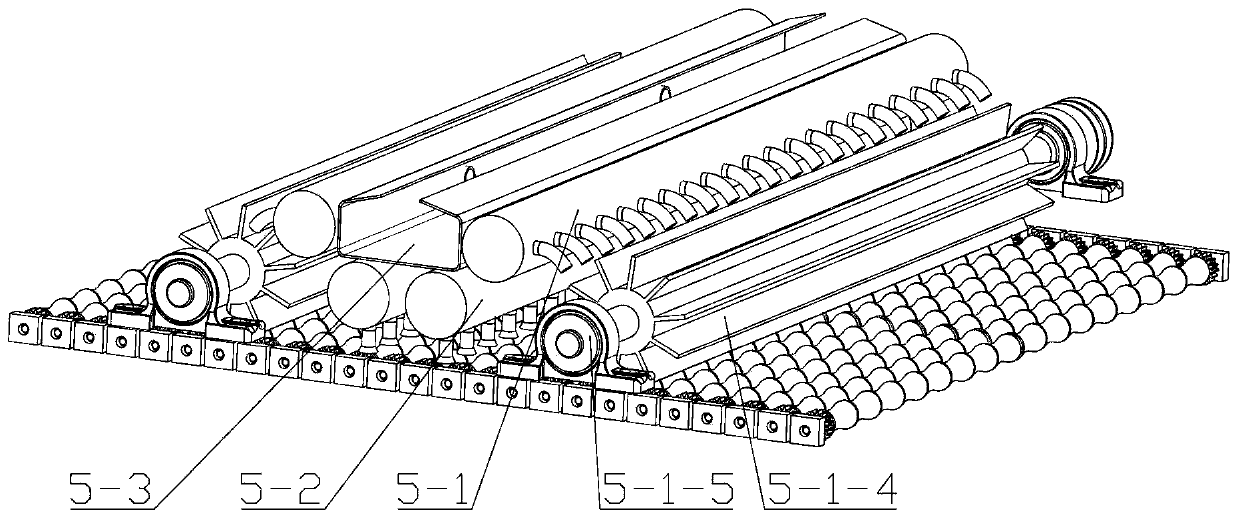

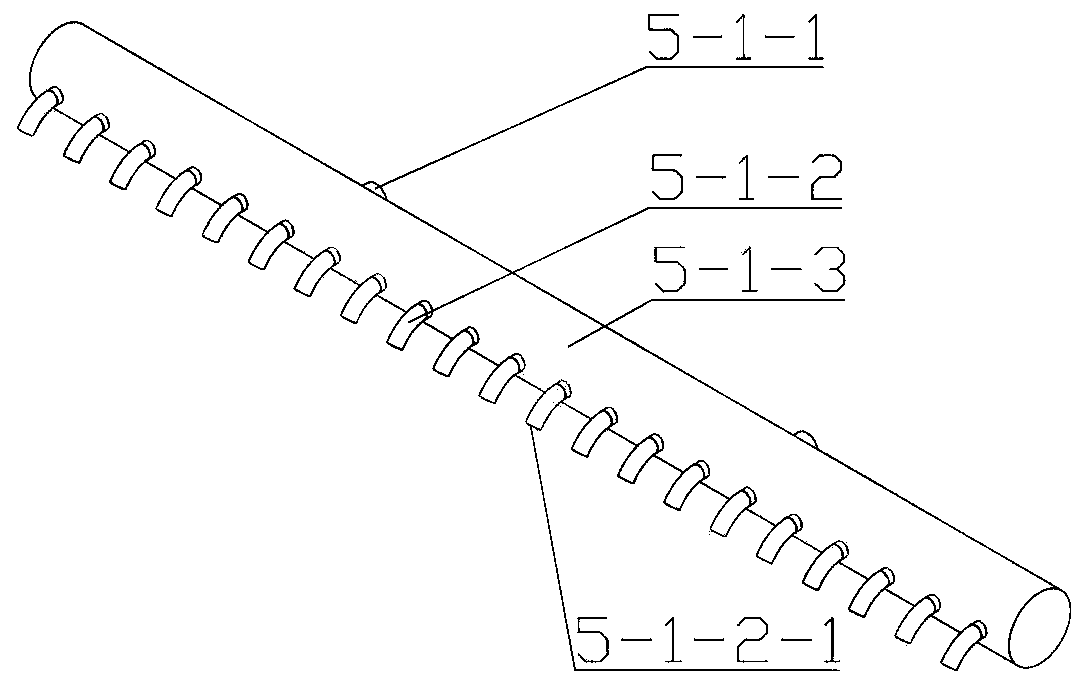

Fruit optimizing equipment with cleaning-airdrying function

PendingCN110813771AEnsure environmental qualityGuarantee fruit qualitySortingFood treatmentWater storageAgricultural engineering

The invention provides fruit optimizing equipment with a cleaning-airdrying functions. The fruit optimizing equipment mainly comprises a feeding device, a horizontal conveying device, a detecting device, screening and discharging devices and a cleaning-airdrying device. The overall structure of the feeding device is a transverse groove with certain height. The horizontal conveying device is composed of a horizontal conveying belt formed by rolls. The detecting device taking an industrial camera as a core and the screening and discharging devices are arranged above the horizontal conveying belt. The cleaning device is arranged in the middle of the horizontal conveying device, and mainly comprises a first-stage water inlet pipe, a second-stage water inlet pipe, a middle water storage pipe, arolling brush and a belt wheel. An airdrying device is arranged below the cleaning device, also adopts a two-stage structure, and mainly comprises a first-stage air inlet pipe, a second-stage air inlet pipe and a middle air storage pipe. According to the fruit optimizing equipment, a cleaning and airdrying structure adopting two-stage division is designed, an efficient and deep cleaning and airdrying effect is guaranteed, and the cleaning and airdrying cost of the fruit optimizing equipment is reduced.

Owner:ZHENGZHOU UNIV

High-cleanliness tinplate plate printing process

InactiveCN112172364AQuality improvementImprove qualified product rateDuplicating/marking methodsPattern printingThermodynamicsProcess engineering

The invention relates to the technical field of tinplate printing, in particular to a high-cleanliness tinplate plate printing process. The process comprises the following steps of (1) pretreatment, specifically, carrying out surface treatment on tinplate, and then carrying out internal coating and external coating; (2) plate making, specifically, carrying out color separation on an original manuscript to be printed, making a pattern subjected to color separation into a sample pattern on a PS plate, and exposing the PS plate through a continuous printing-down machine to form a printing plate;(3) printing, specifically, transferring ink to the outer coating surface of the tinplate by using an offset press and the printing plate; and (4) drying, specifically, putting the tinplate into a drying box to sequentially pass through a temperature rising area, a constant-temperature area and a cooling area for drying. According to the plate printing process, the steps of pretreatment, plate making, printing and drying are adopted, in the drying step, the tinplate is put in the drying box and sequentially passes through the temperature rising area, the constant-temperature area and the cooling area for drying, the quality of tinplate printing is high, and the qualified rate is high.

Owner:DONGGUAN TINSHINE TIN BOX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com