Patents

Literature

43results about How to "Move down smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

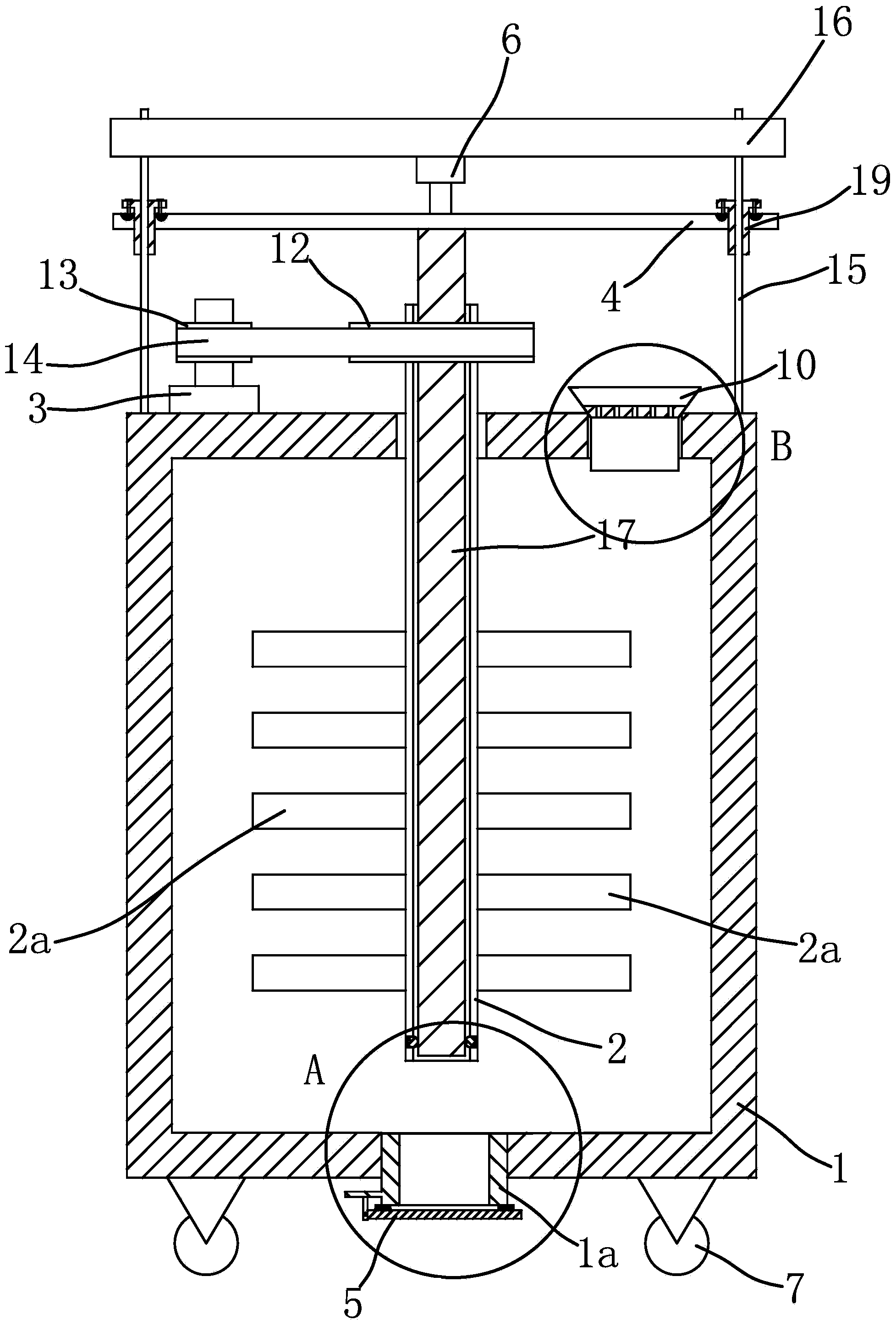

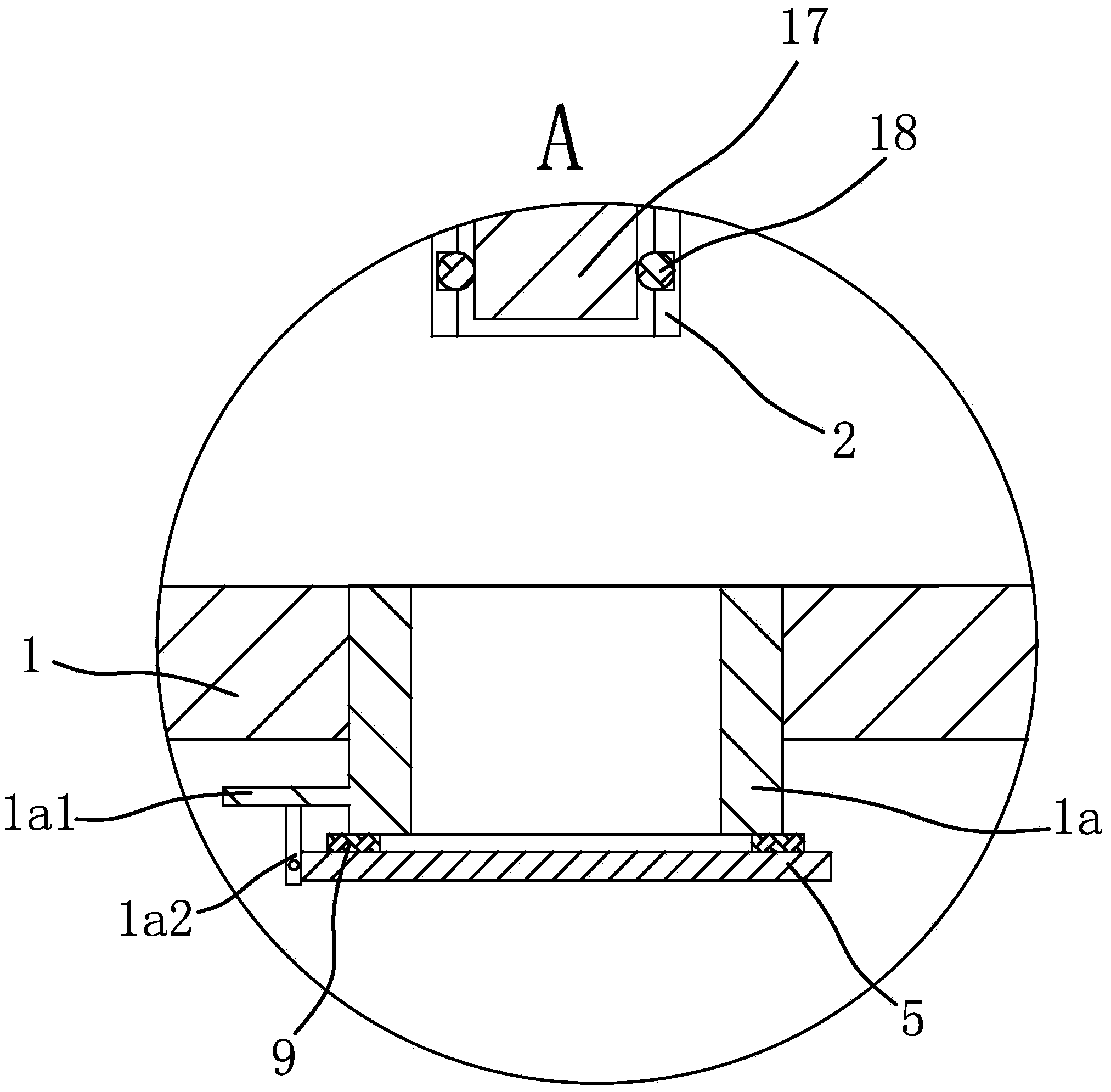

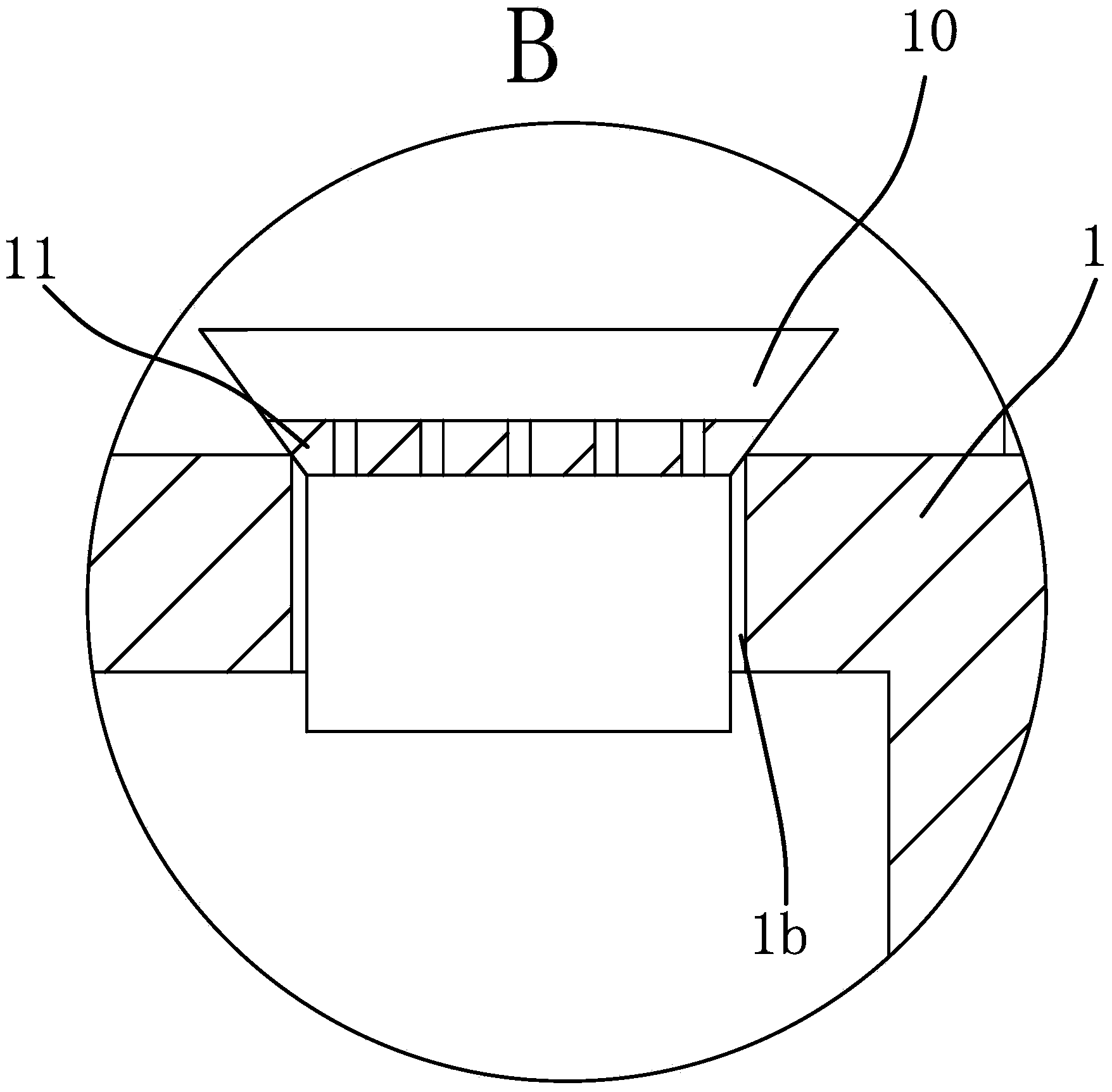

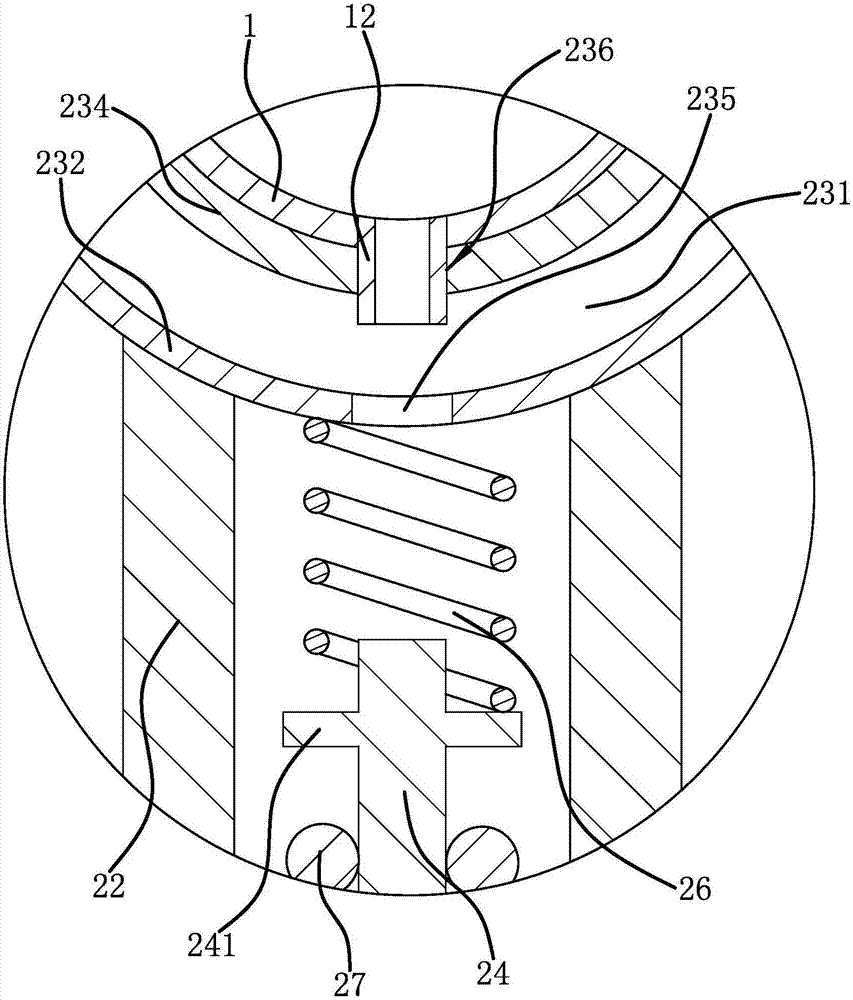

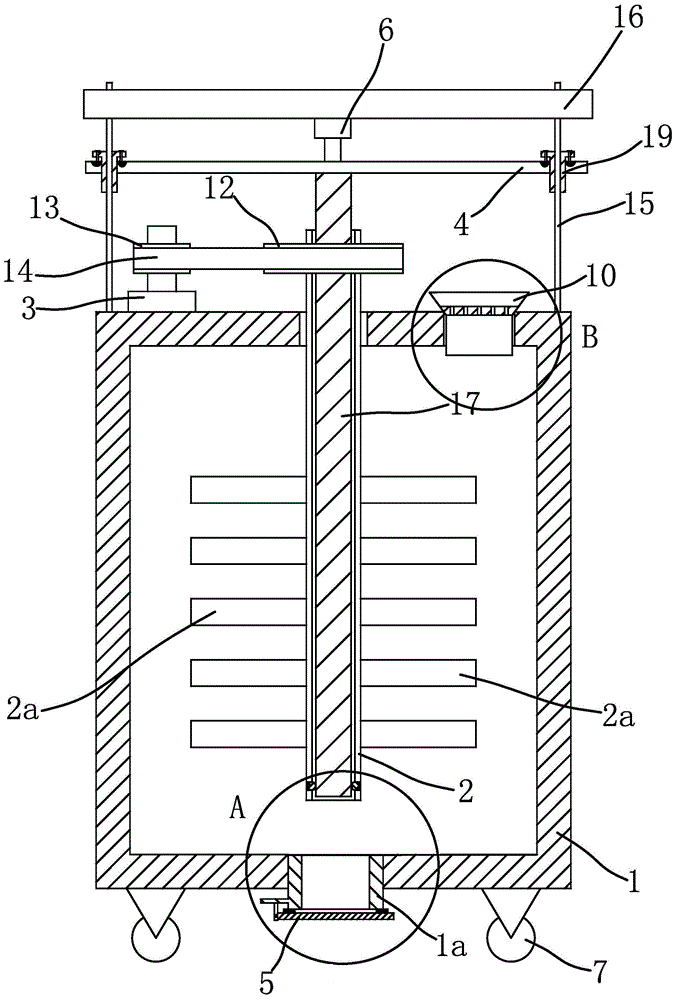

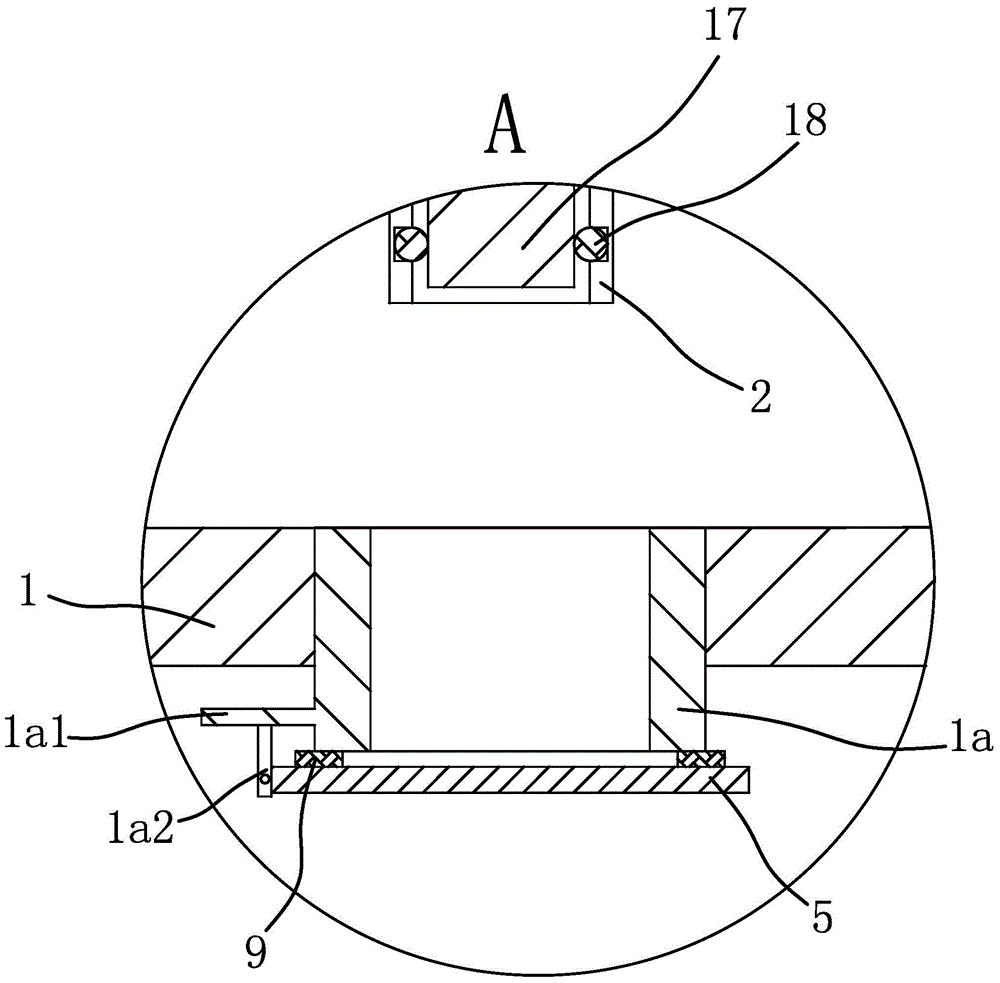

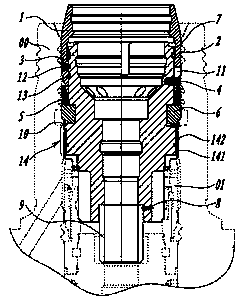

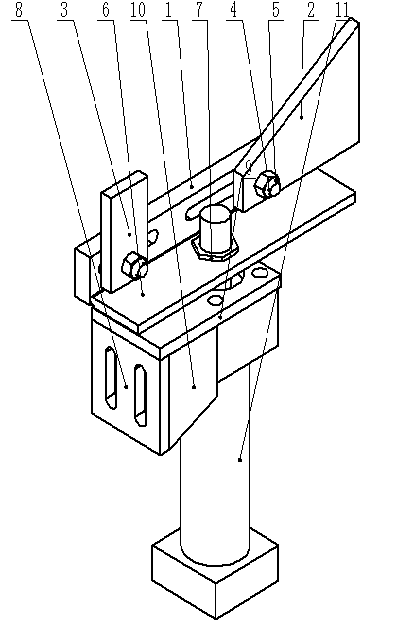

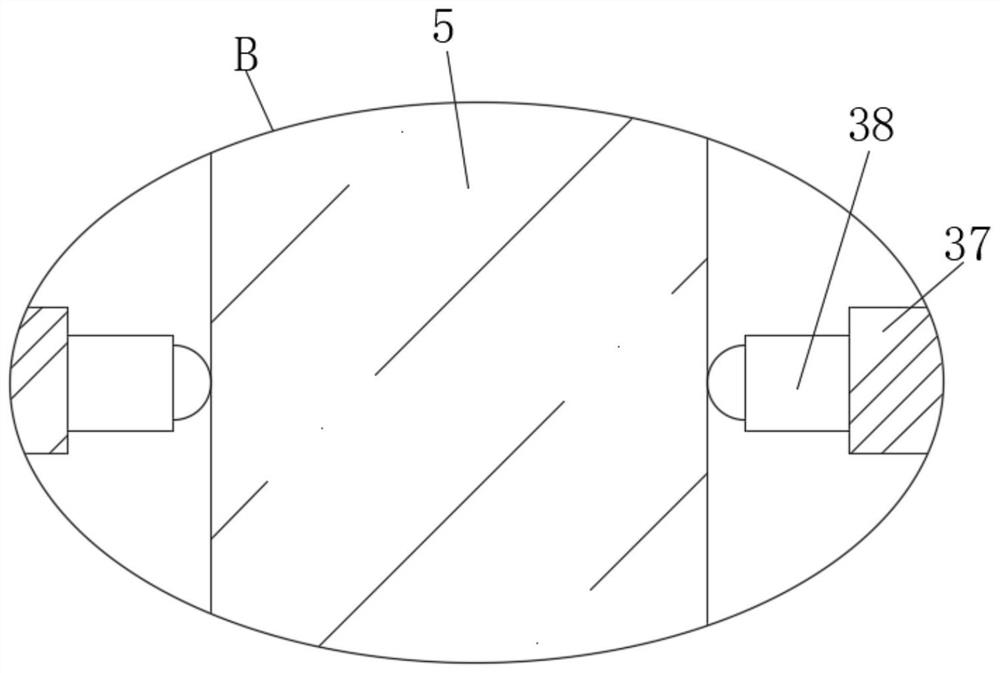

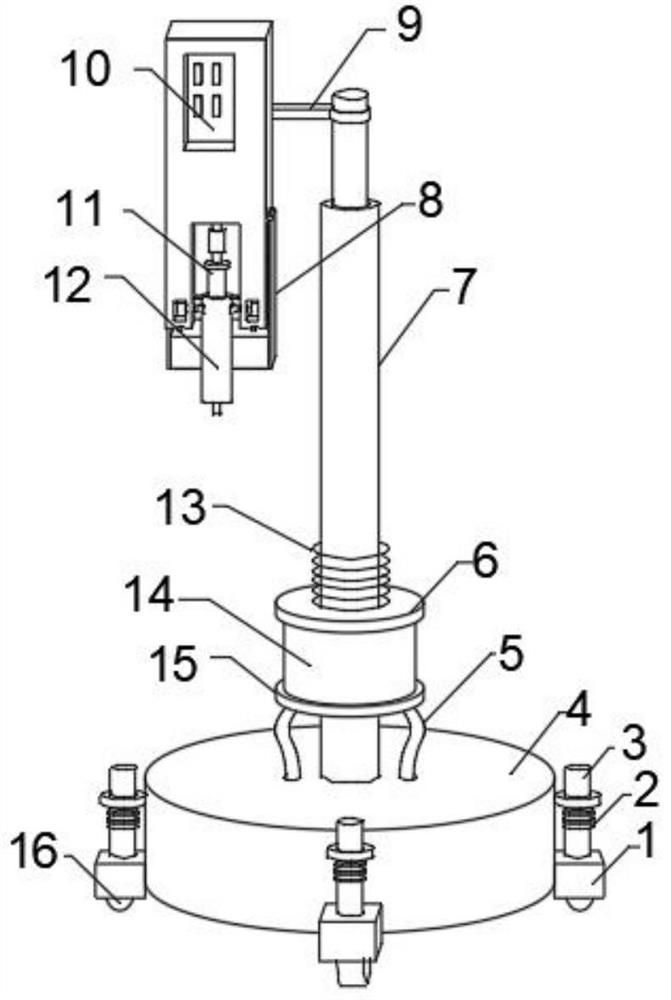

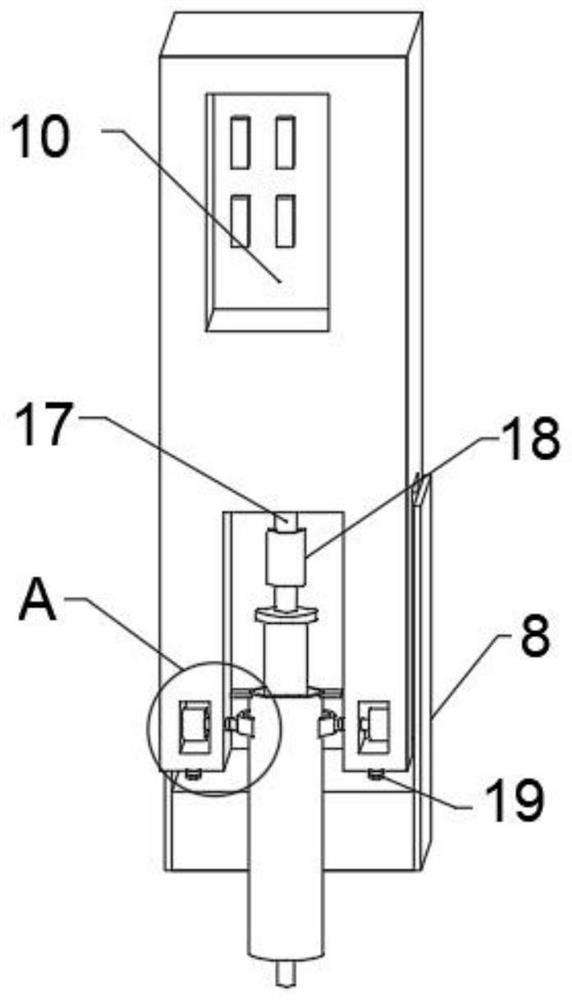

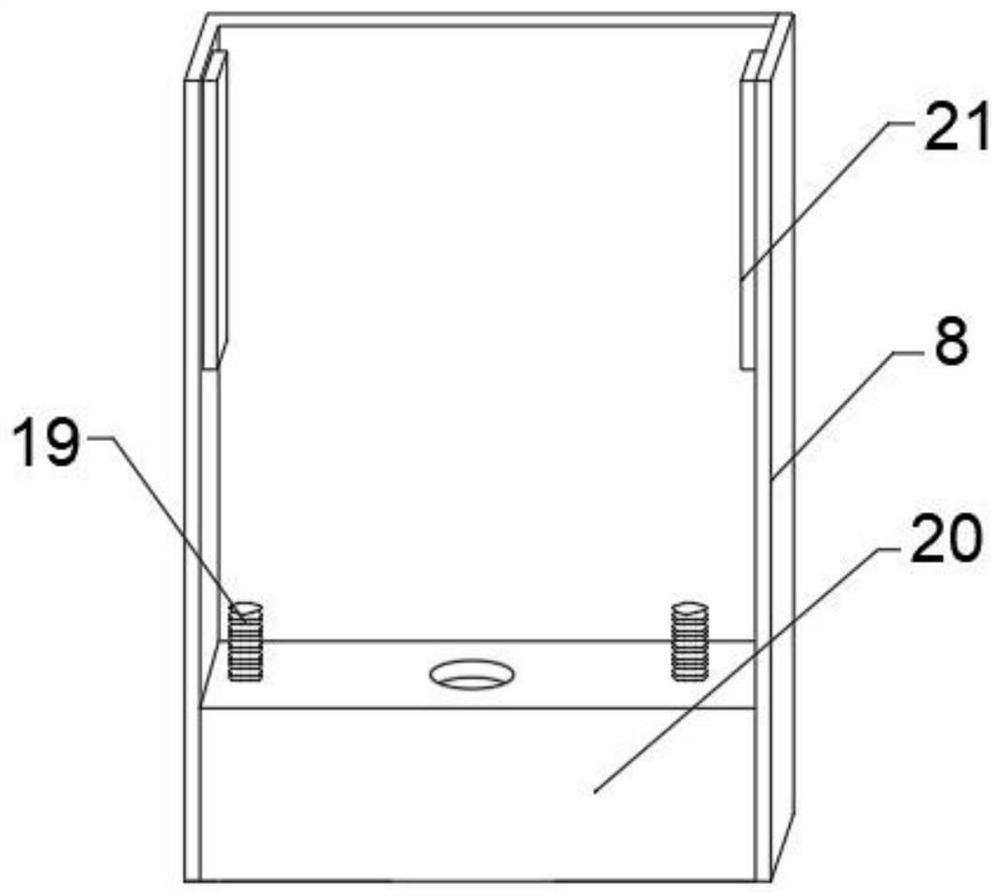

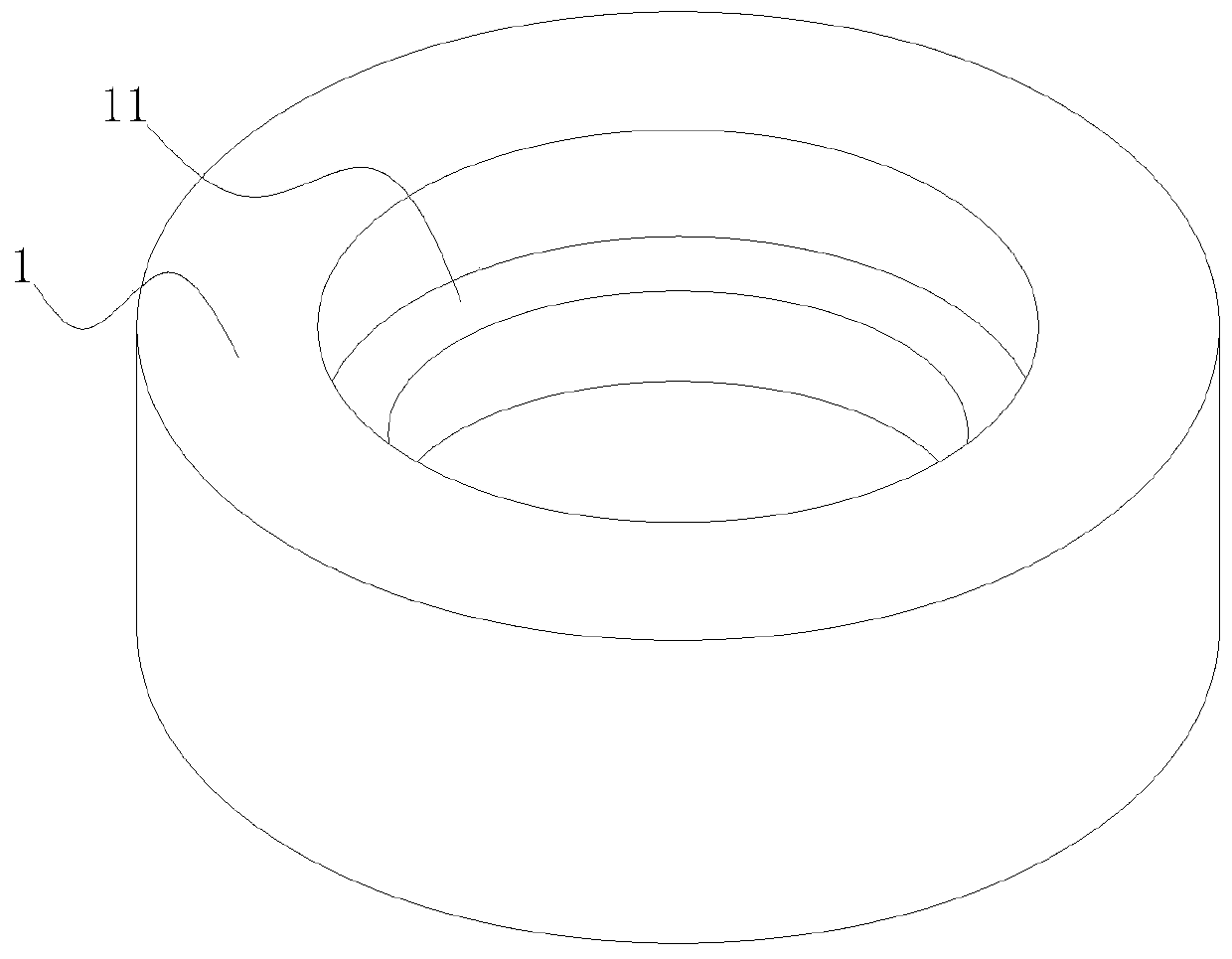

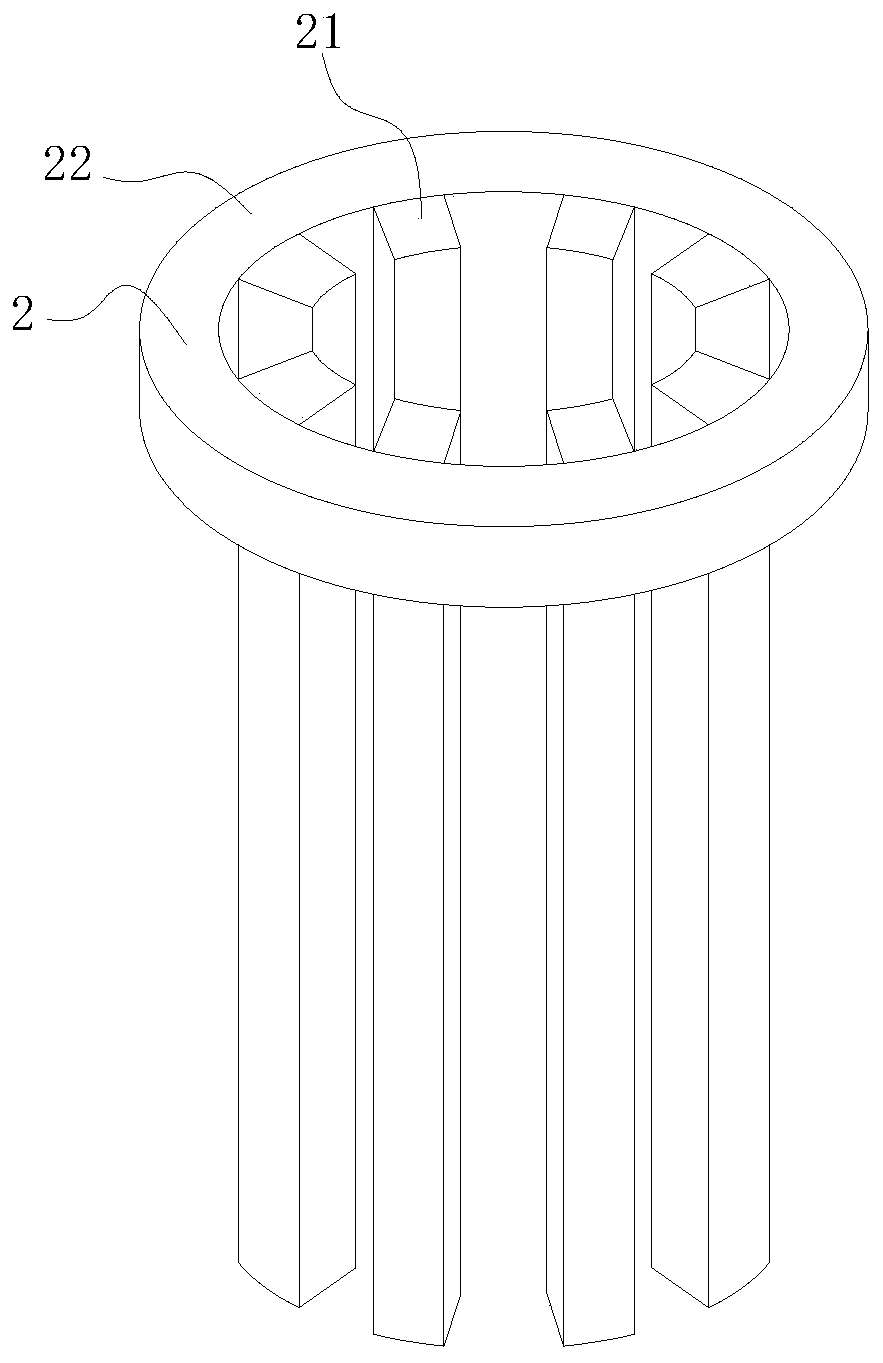

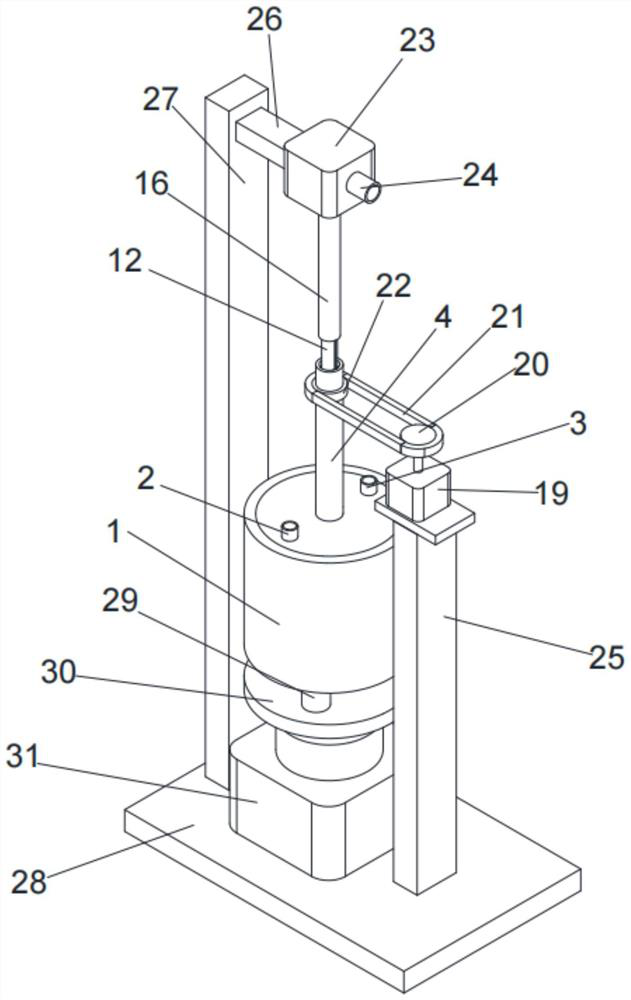

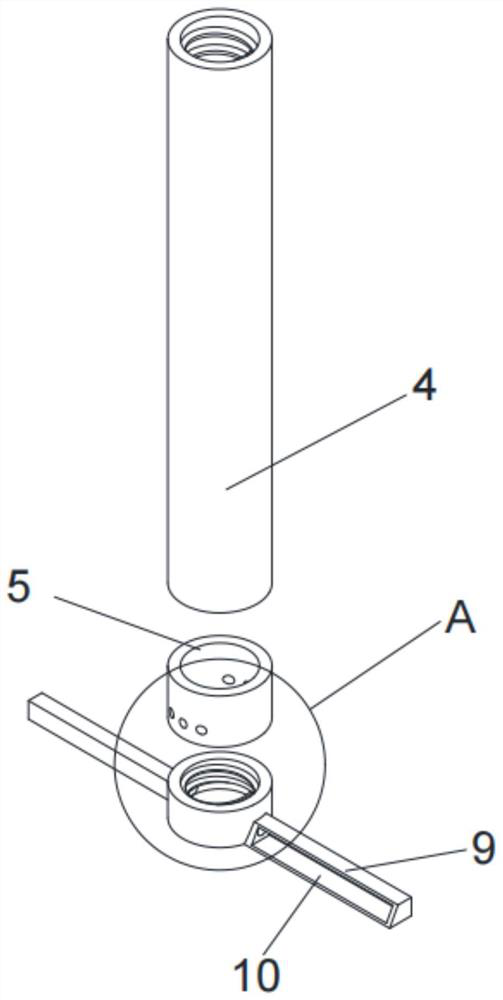

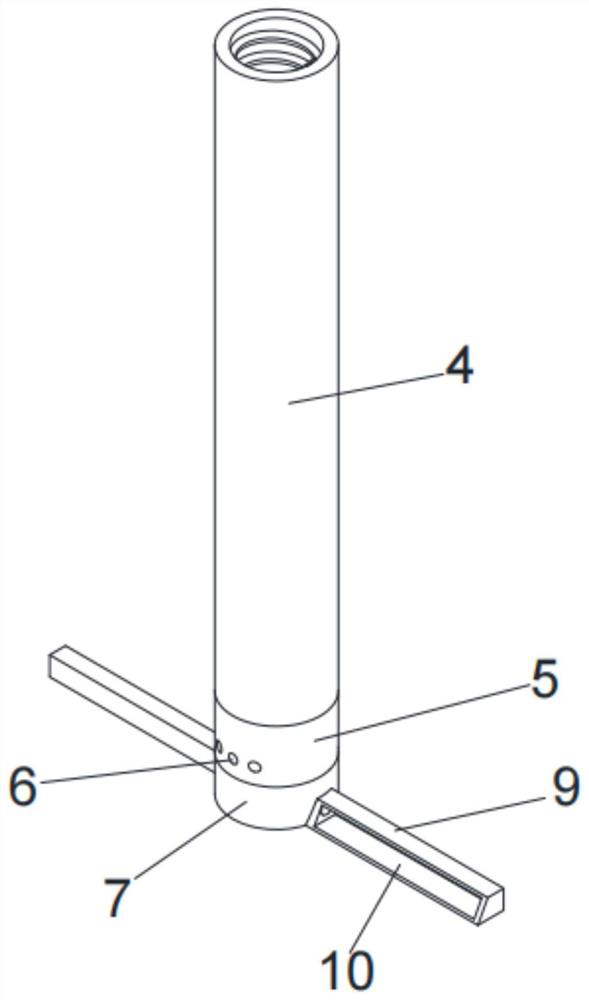

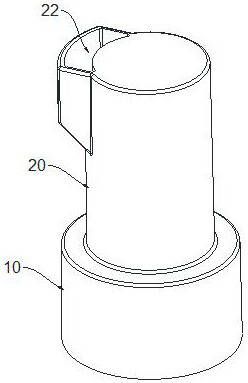

Stirring device applicable to liquid medicine and chemical feed liquid

ActiveCN104307405AEasy to operateOperation time savingRotary stirring mixersMixer accessoriesBiochemical engineeringPiston rod

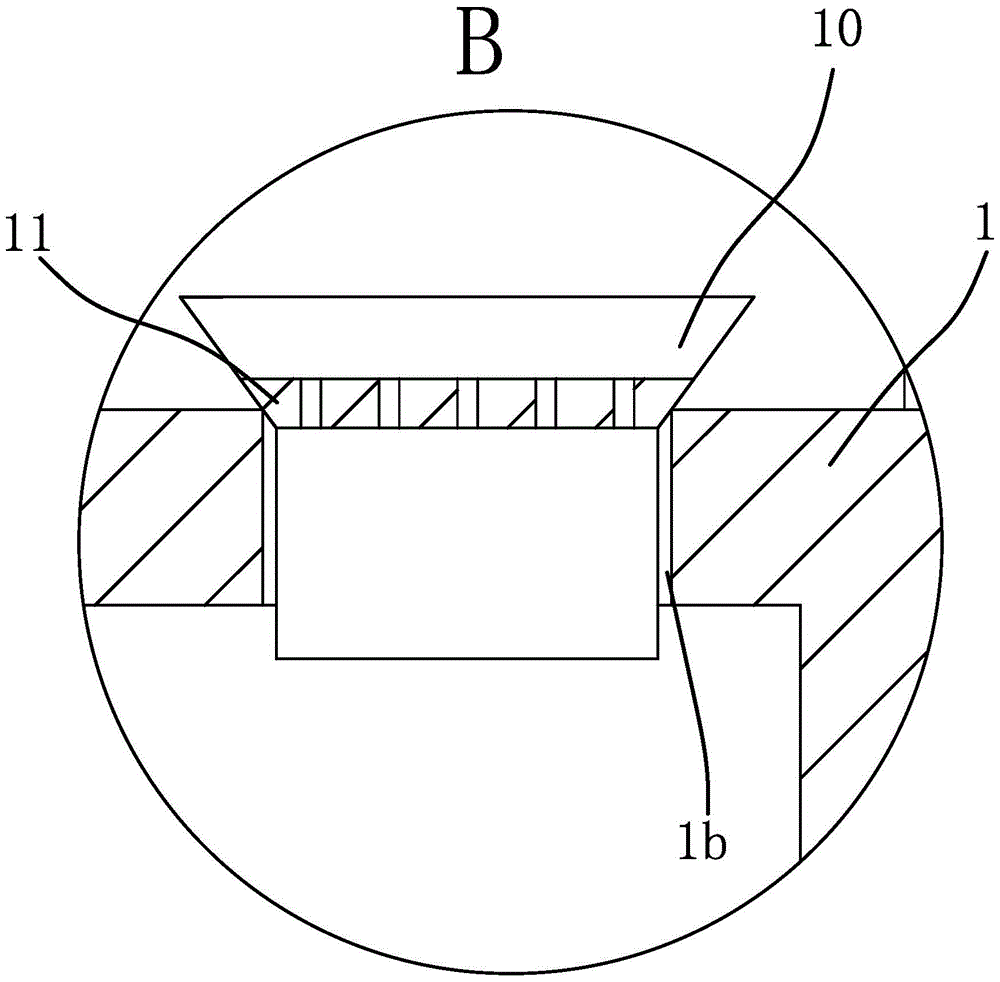

The invention provides a stirring device applicable to liquid medicines and chemical feed liquids and solves the problem of tedious operation of a conventional stirring device. The stirring device applicable to liquid medicine and chemical feed liquid comprises a stirring shaft and a tank body provided with a liquid inlet opening; the stirring shaft is vertically arranged in the tank body, and the upper end of the stirring shaft extends out of the tank body; a plurality of stirring paddles are arranged on the outer edge of the lower end of the stirring shaft; a liquid outlet pipe is arranged at the bottom of the tank body; a motor is arranged at the top of the tank body and drives the stirring shaft to rotate through a transmission mechanism; a joint pin is arranged on the outer edge of the liquid outlet pipe; a cover plate is hinged to the joint pin, and a torsional spring having the tendency of enable the cover plate to seal the liquid outlet pipe is arranged between the joint pin and the cover plate; the stirring shaft is hollow, and a mandril is inserted in the stirring shaft; an air cylinder which can enable the lower end of the mandril to be propped against the cover plate and enable the cover plate to overcome the torsion of the torsional spring and to rotate around the hinge point is arranged at the top of the tank body; the piston rod of the air cylinder is connected with the upper end of the mandril. The stirring device applicable to liquid medicine and chemical feed liquid has the advantages that the operation is simple and time is saved.

Owner:珠海君瑞恒医药科技有限公司

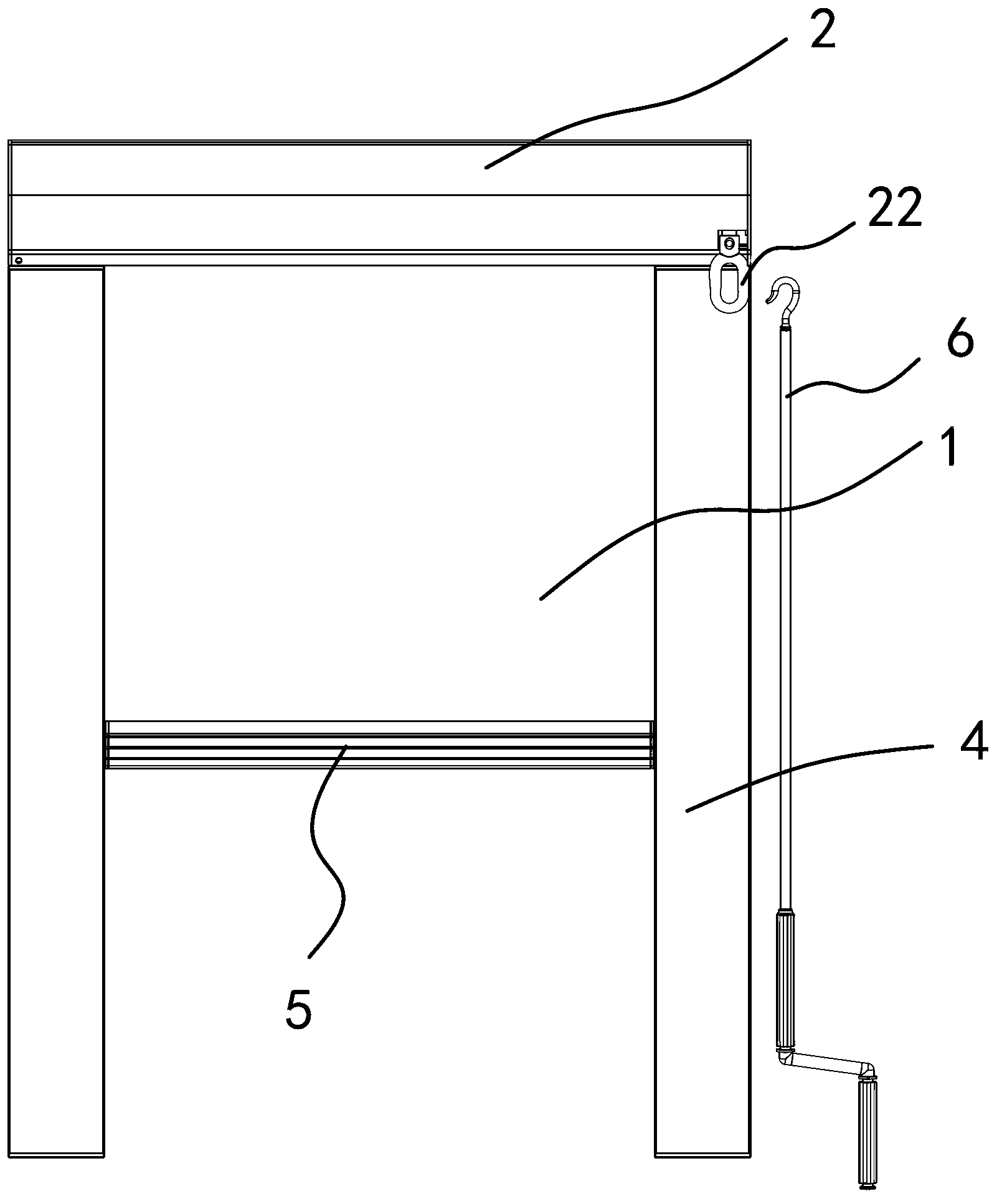

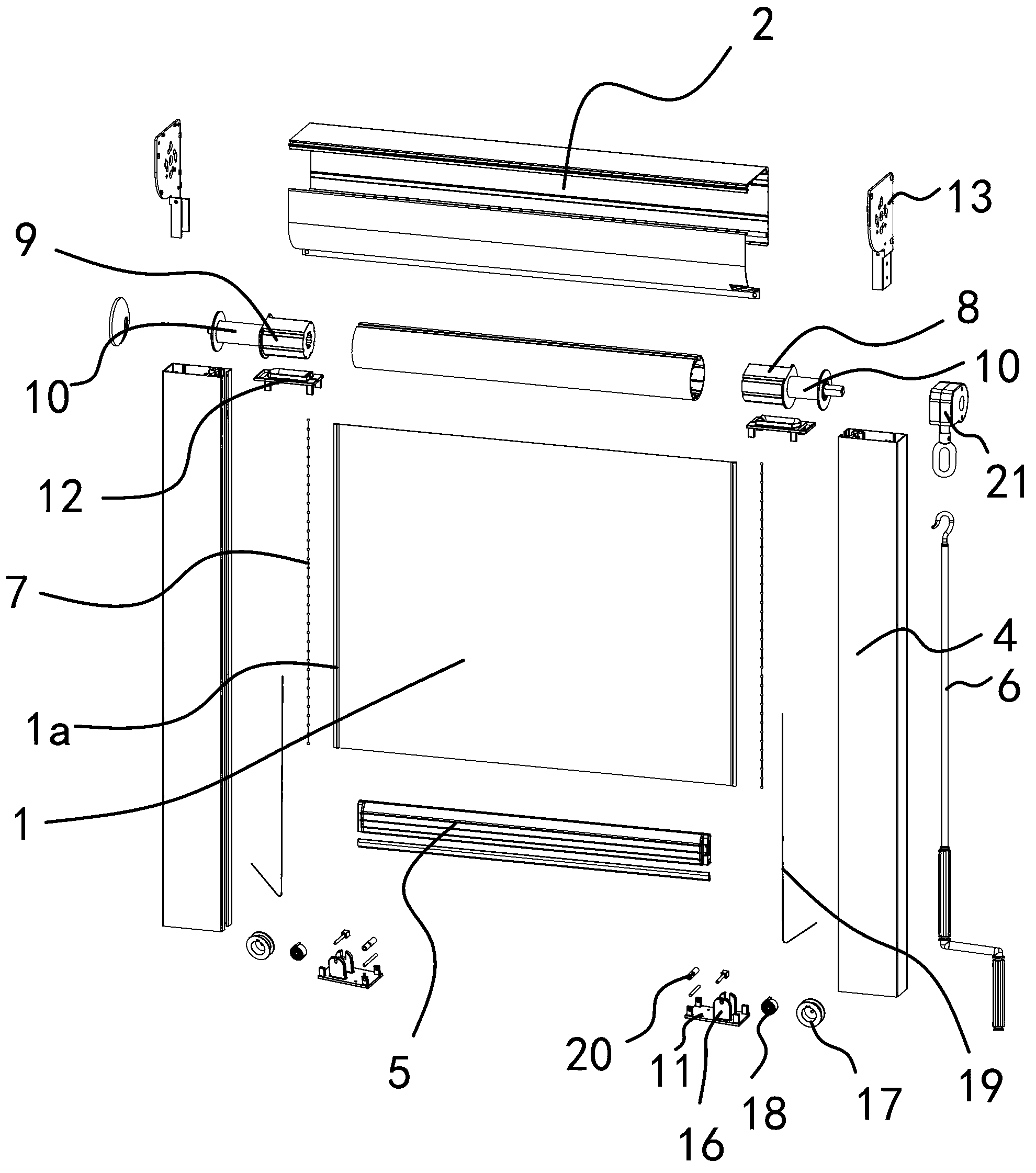

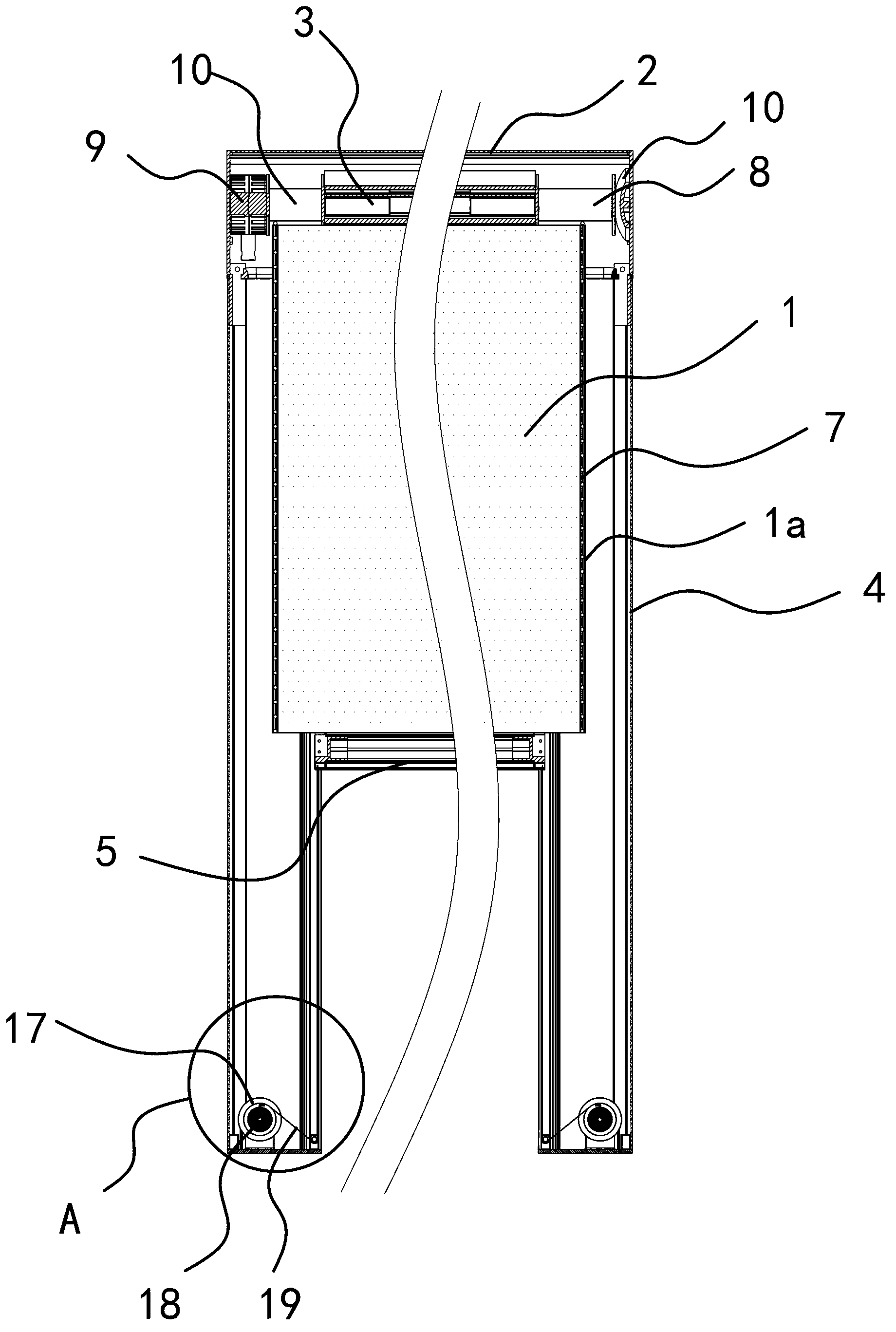

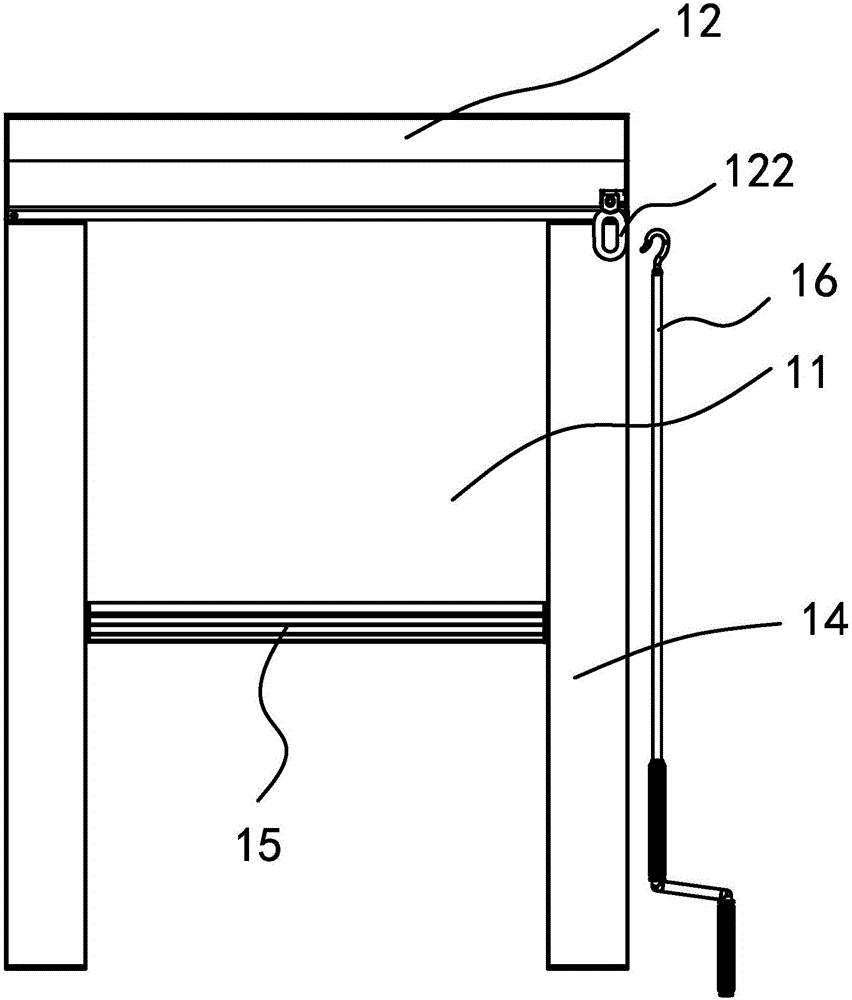

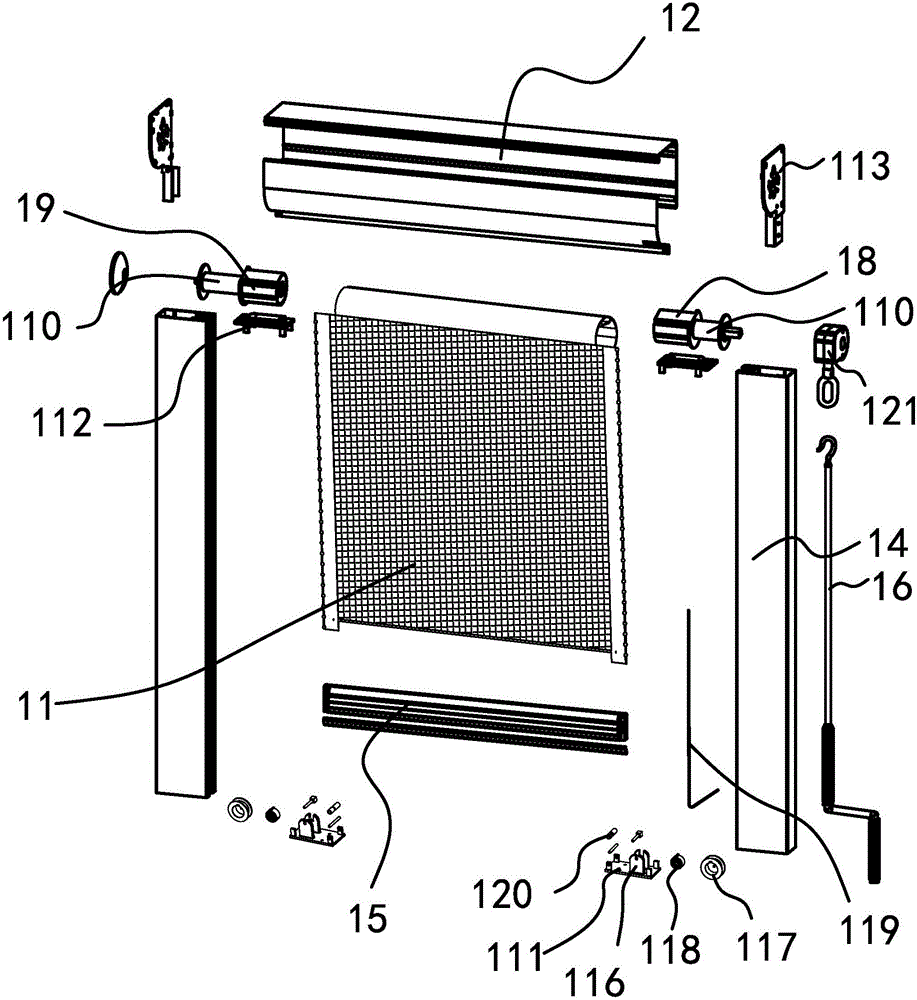

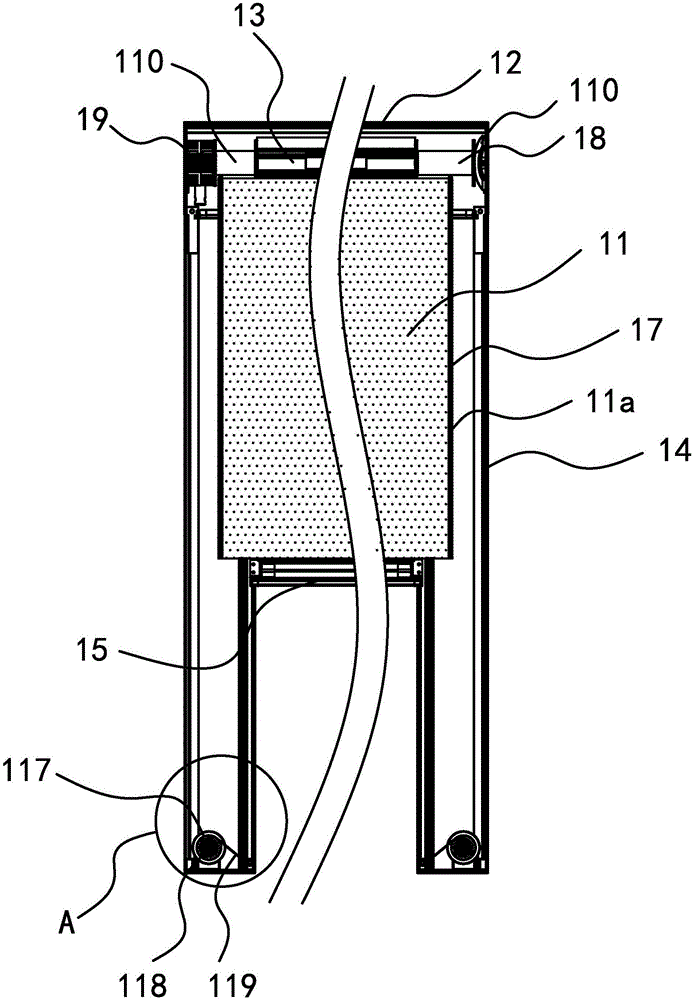

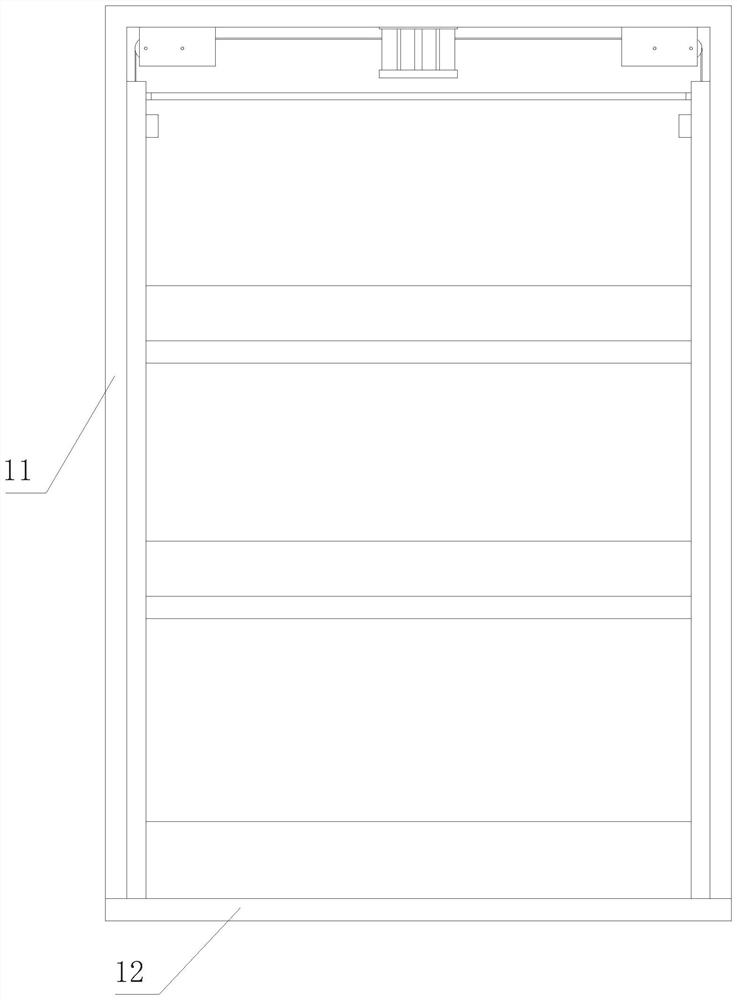

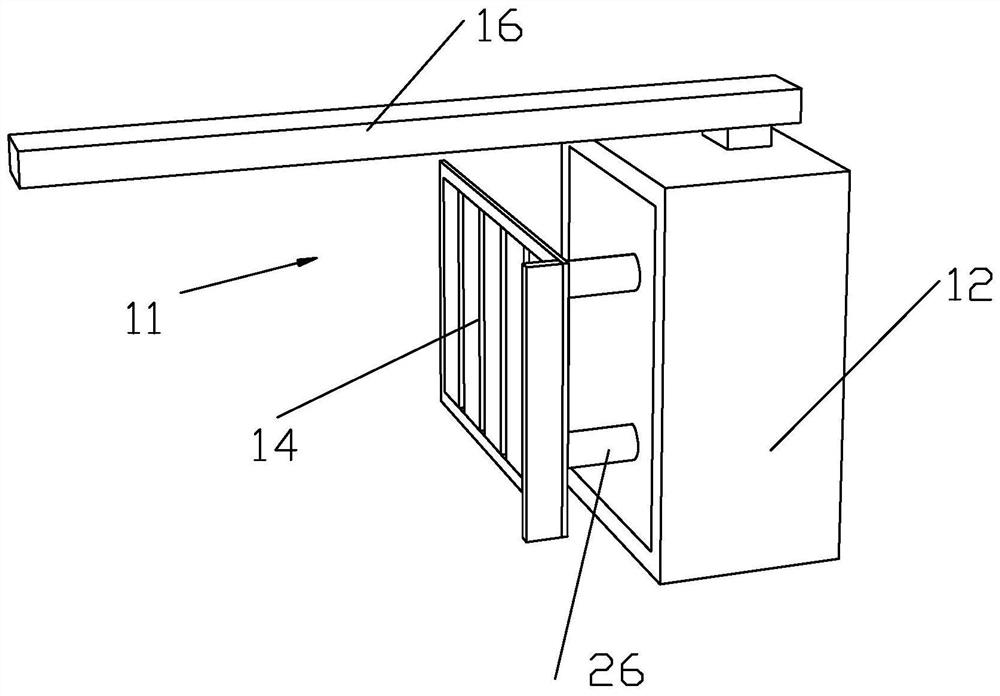

Wind-resistant and sun-shading curtain

ActiveCN103291203AGuaranteed liftingCause the problem of unsmooth liftingLight protection screensCurtain rodsMechanical engineeringEngineering

Owner:NINGBO XIANFENG NEW MATERIAL

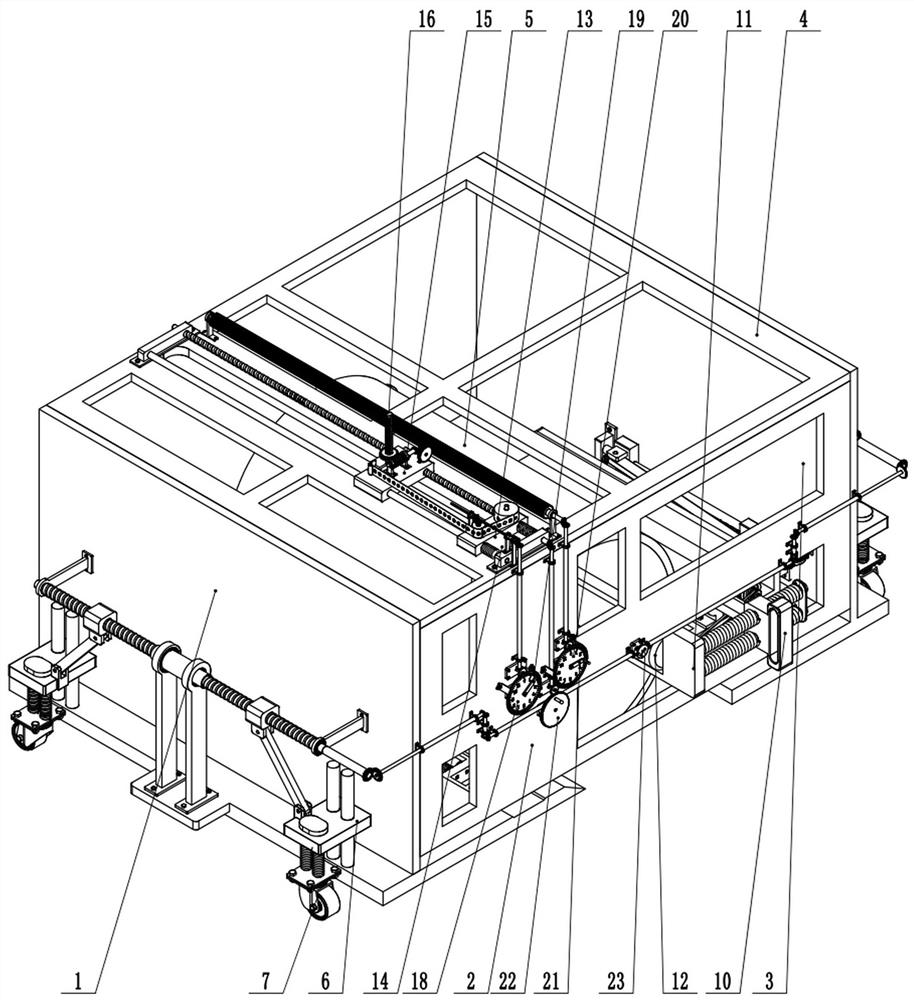

Paper feeding device and work method thereof

Owner:MASTERWORK GROUP CO LTD

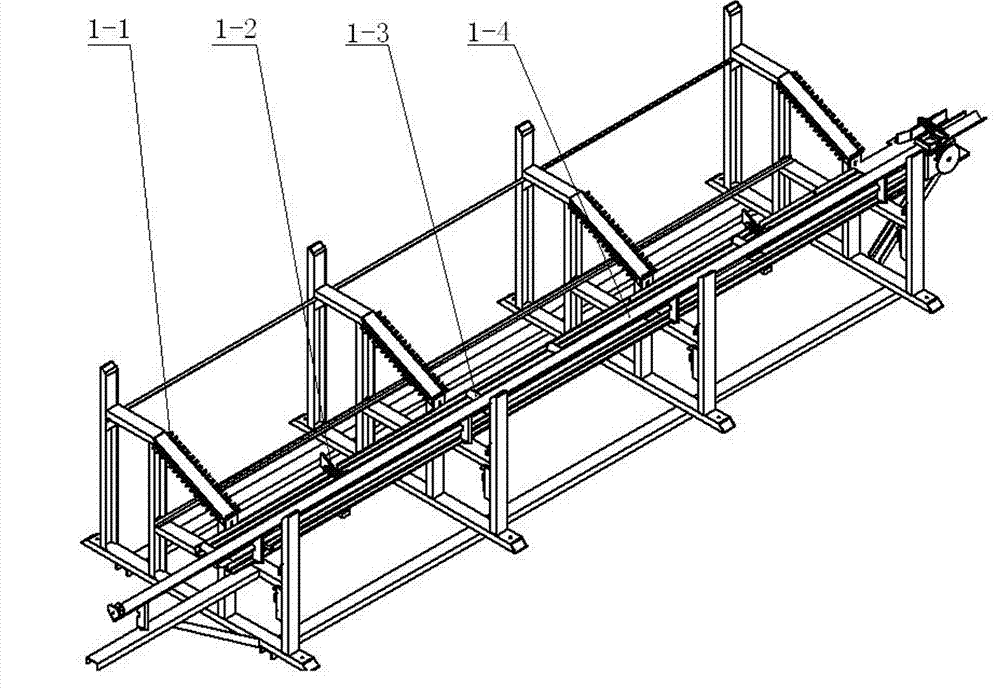

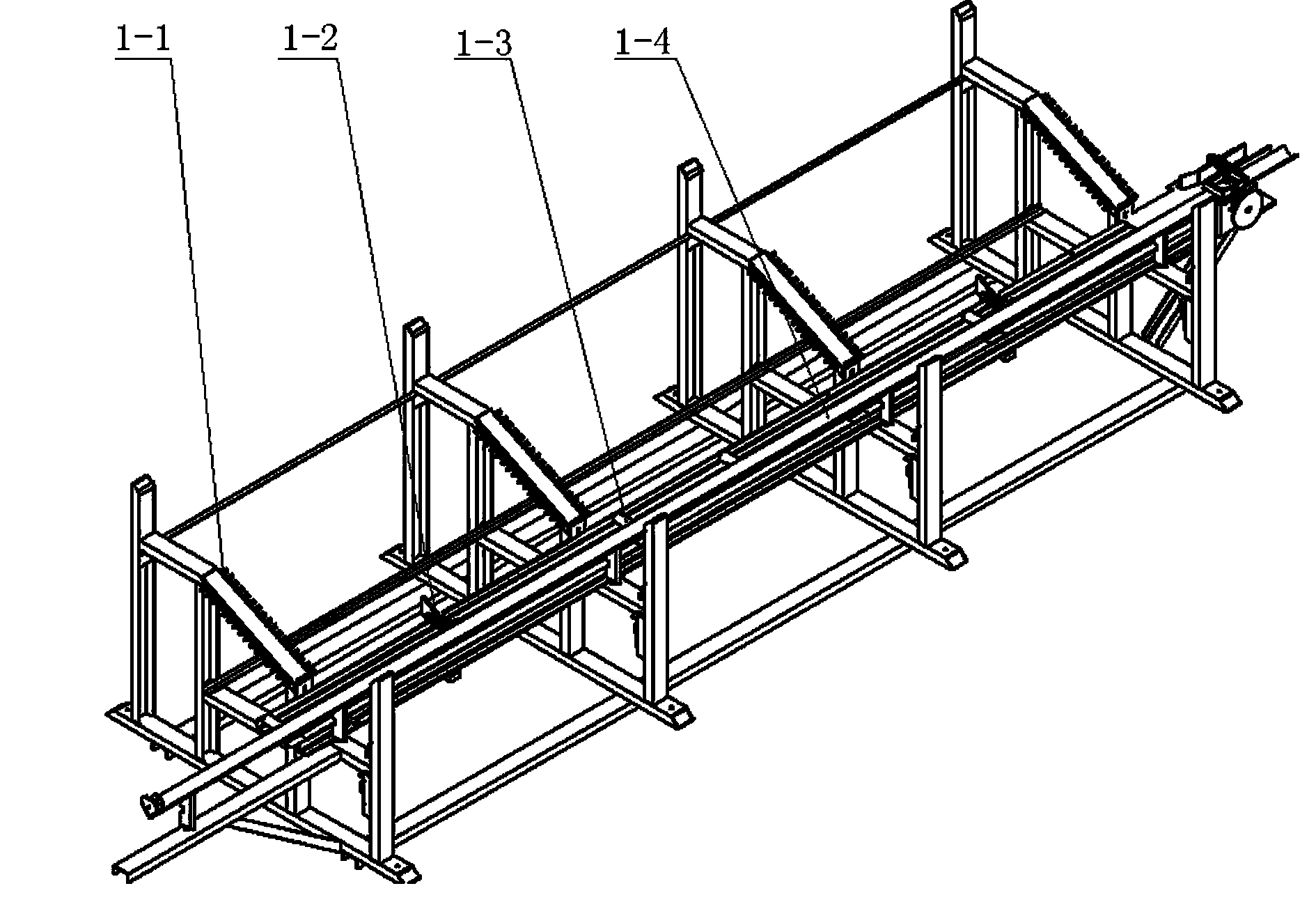

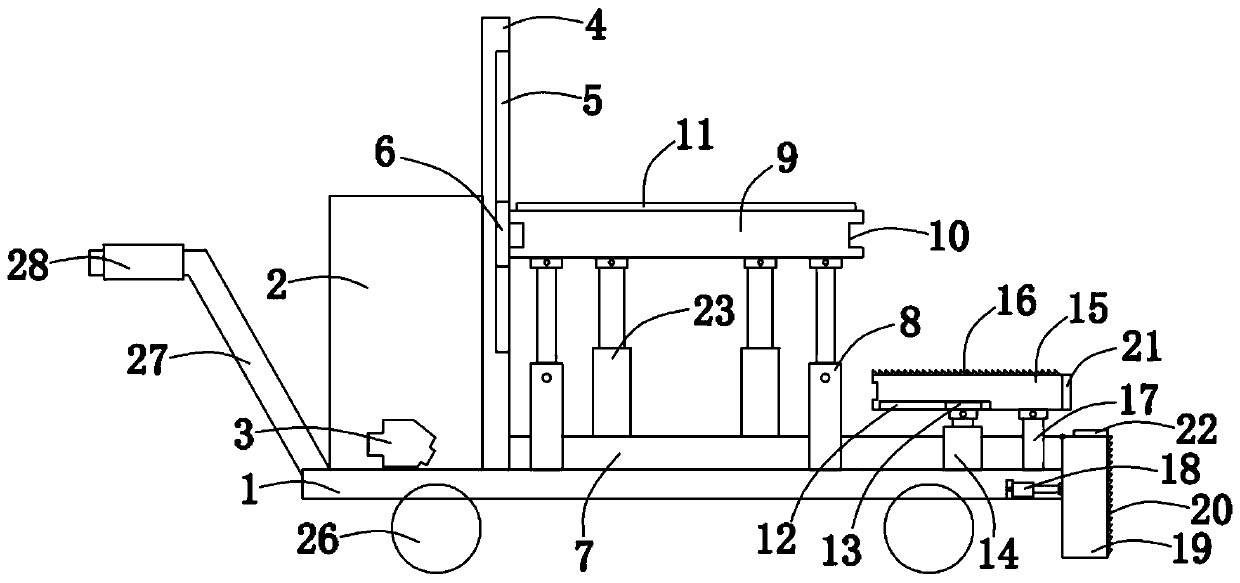

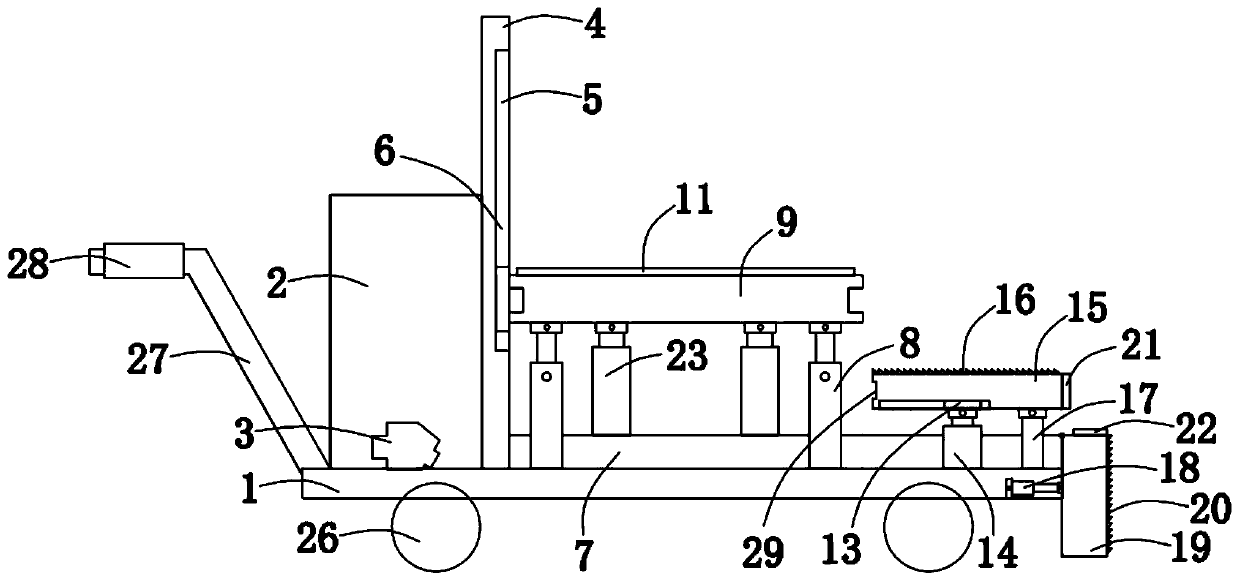

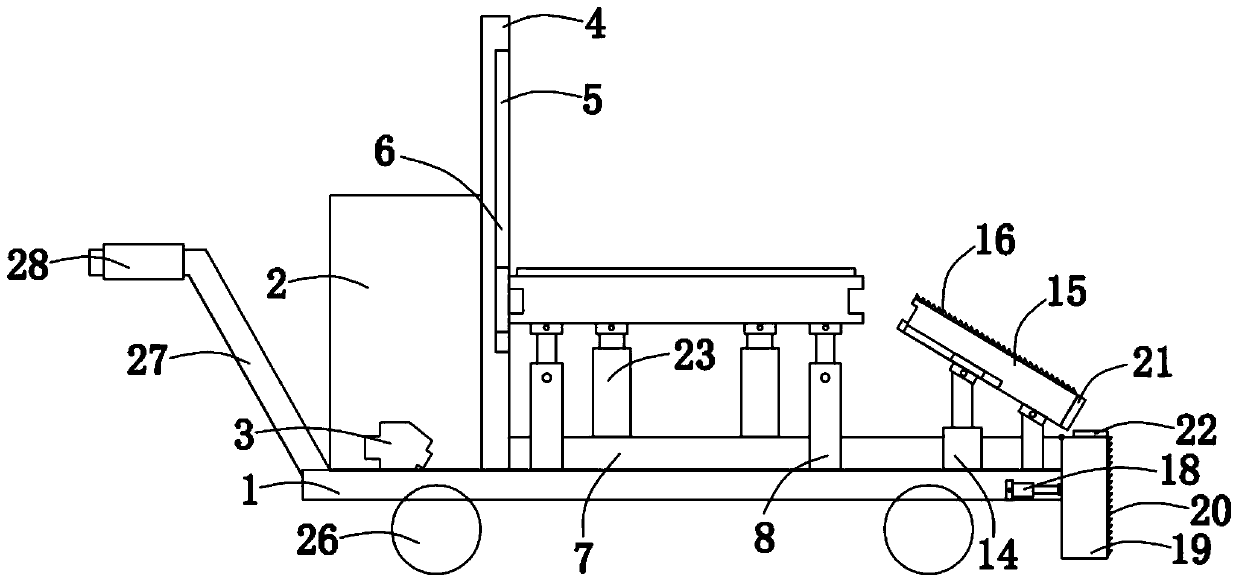

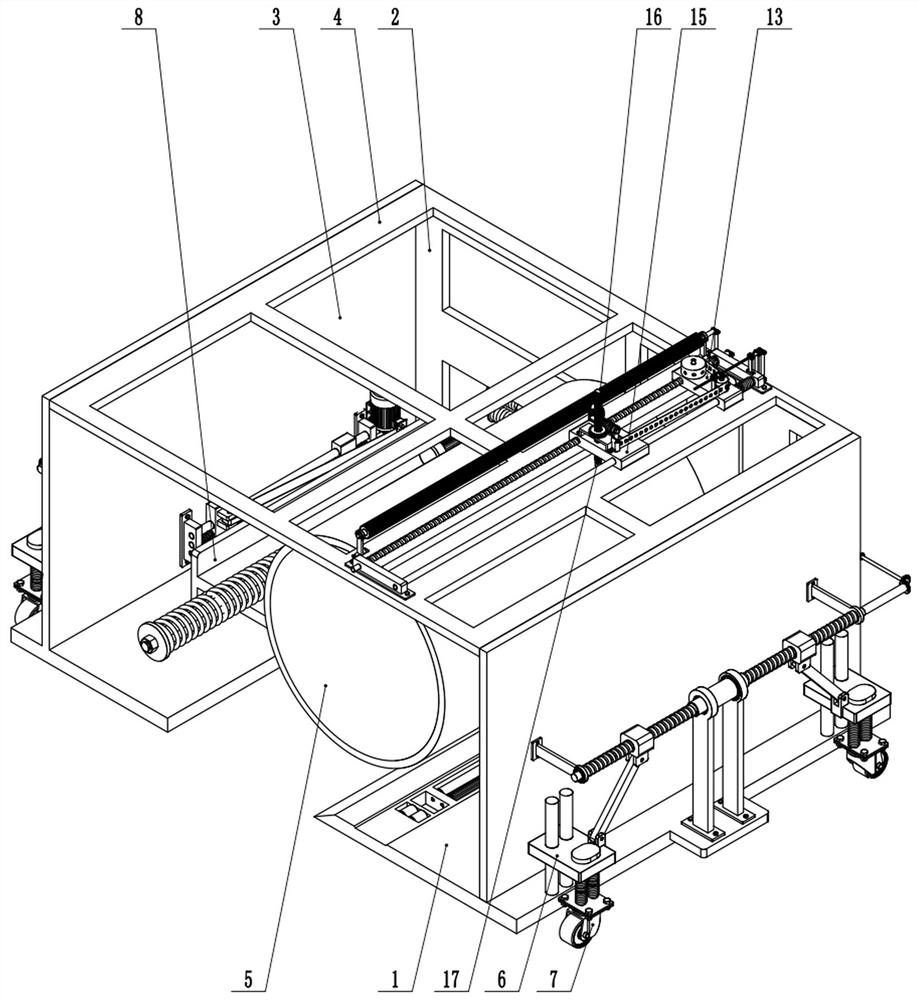

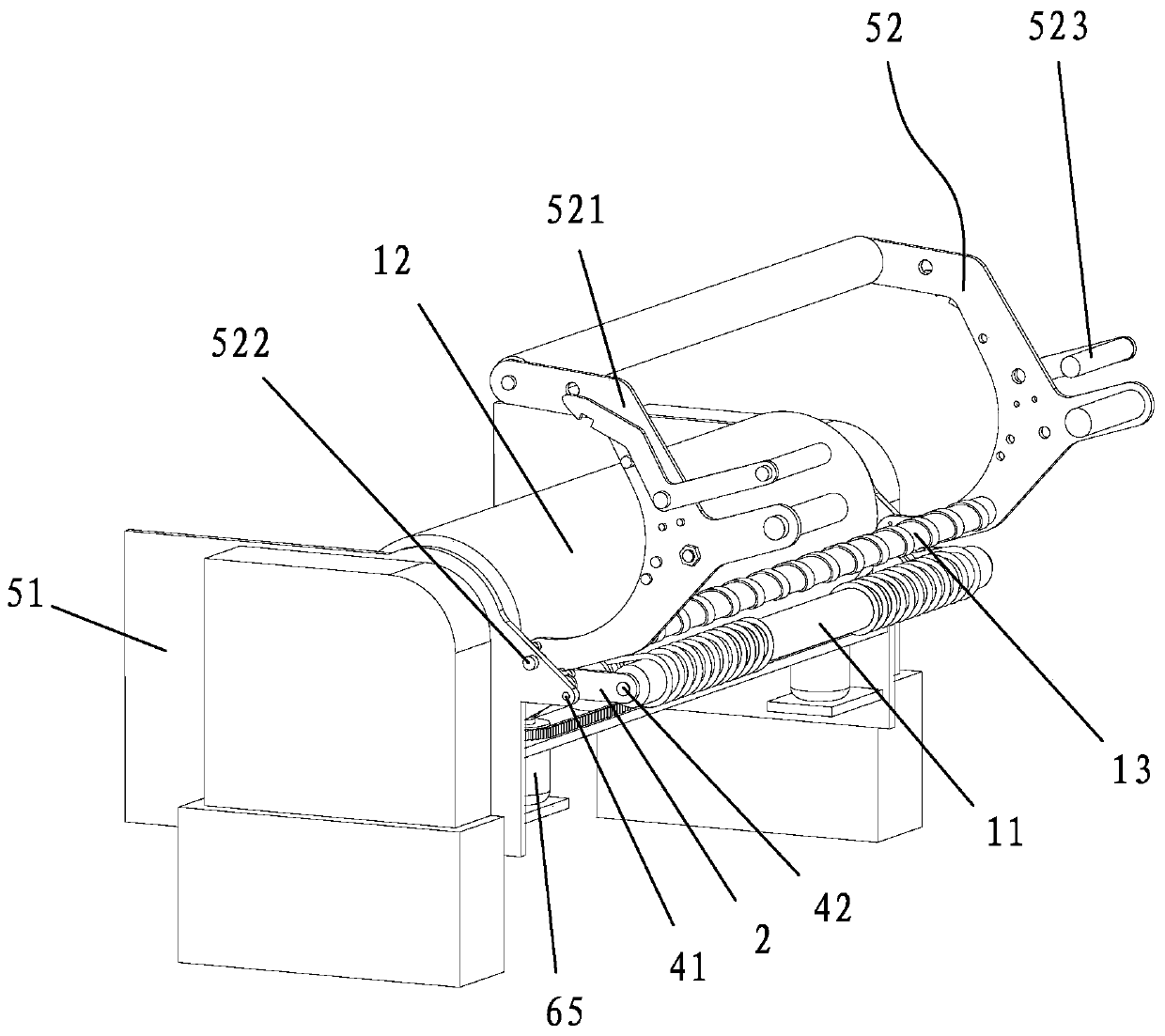

Automatic pipe cutting machine

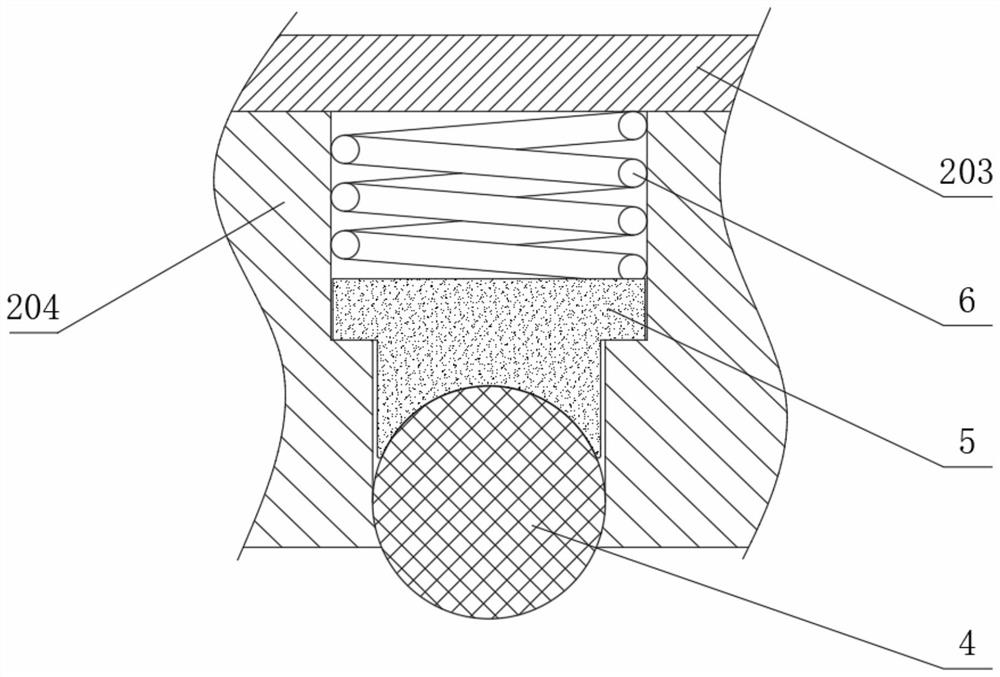

ActiveCN102784959AMove down smoothlyBalance downTube shearing machinesShearing machine accessoriesEngineeringSurface plate

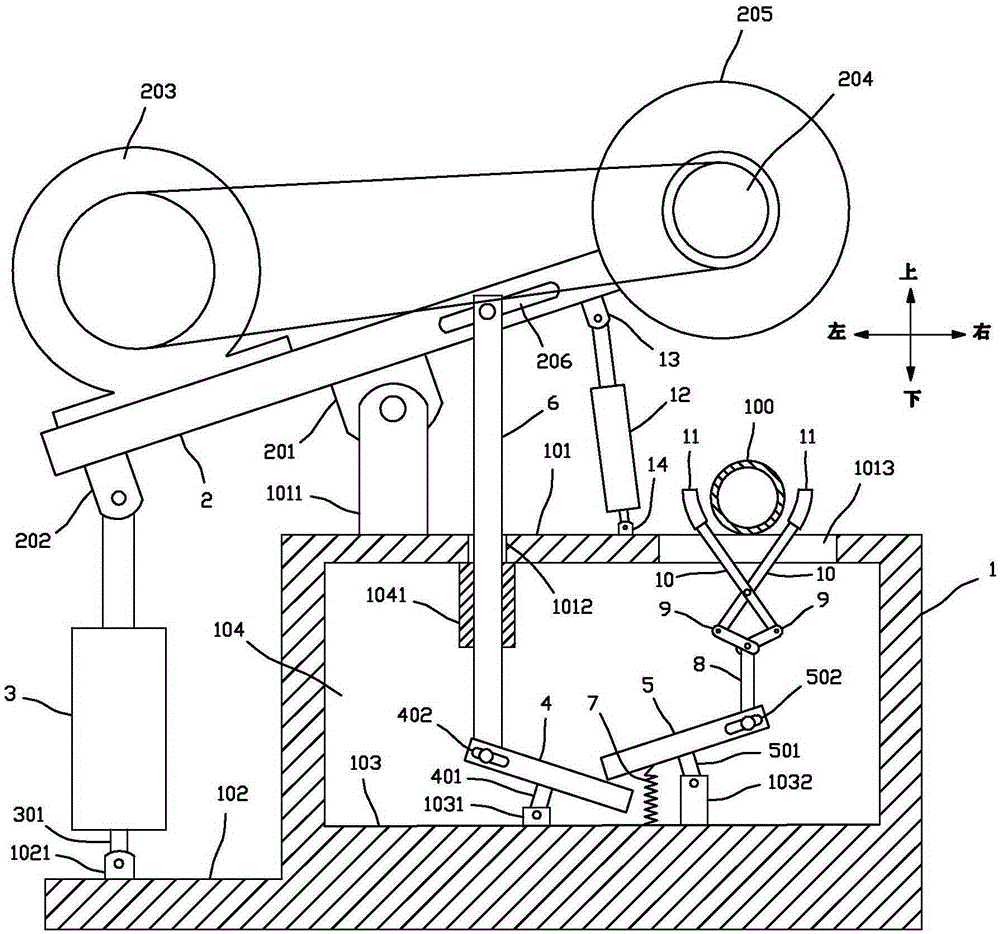

The invention discloses an automatic pipe cutting machine, belonging to the technical field of pipe cutting equipment and mainly solving the problem that the existing pipe cutting machine is not suitable for cutting square pipes. The automatic pipe cutting machine is mainly characterized by comprising a material storing and distributing frame, a material taking mechanism, a material feeding track, a material pulling system, a cutting system and a cut material blanking system, wherein a bearing is installed on the inclined track; the outside diameter of the bearing is higher than the surface of the inclined track; the material taking mechanism is an automatic material taking mechanism which is composed of a power source, a mounting base, an L-shaped plate, a material retention locating rod and an inclined panel; the power source is fixed on the mounting base; the L-shaped plate is fixed on a stretched rod of the power source; an upper folded adjusting plate of the L-shaped plate is provided with a horizontal adjusting groove; and the material retention locating rod and the inclined panel are fixed on the horizontal adjusting groove of the upper folded adjusting plate. The automatic pipe cutting machine disclosed by the invention is capable of discharging a material to an automatic material taking position smoothly and evenly, is aligned with the center of a material inlet track and a cutting center, can adapt to cutting characteristics of rectangular pipes in different specifications, and is mainly suitable for automatic cutting of rectangular pipes.

Owner:SHENZHEN QIHONGFU TECH

Oil containment device

InactiveCN106884418AQuick inflationHigh oil containment efficiencyWater cleaningGeneral water supply conservationWater solubleHigh pressure

The invention provides an oil containment device, and belongs to the technical field of offshore oil containment equipment. The oil containment device comprises a plurality of exhaust hoses and a plurality of quick charging devices. A plurality of exhaust holes are formed in the side walls of the exhaust hoses. Each quick charging device comprises a high-pressure air tank and a plurality of mounting shells. Each high-pressure air tank comprises a plurality of air outlets, wherein the air outlets are sealed by metal films. The lower ends of the mounting shells are fixedly connected to the high-pressure air tanks, connecting sleeves are fixedly connected to the upper ends of the mounting shells, and the exhaust hoses are arranged in the connecting sleeves in a penetrating mode. Ejector rods are arranged in the mounting shells in a sliding connection mode, water-soluble stop blocks are further fixedly connected with the interiors of the mounting shells, the ejector rods abut against the water-soluble stop blocks in a press mode under the action of springs, and when the water-soluble stop blocks dissolve, the ejector rods can penetrate through the metal films. The oil containment device can conduct quick oil containment and is higher in efficiency.

Owner:ZHEJIANG OCEAN UNIV

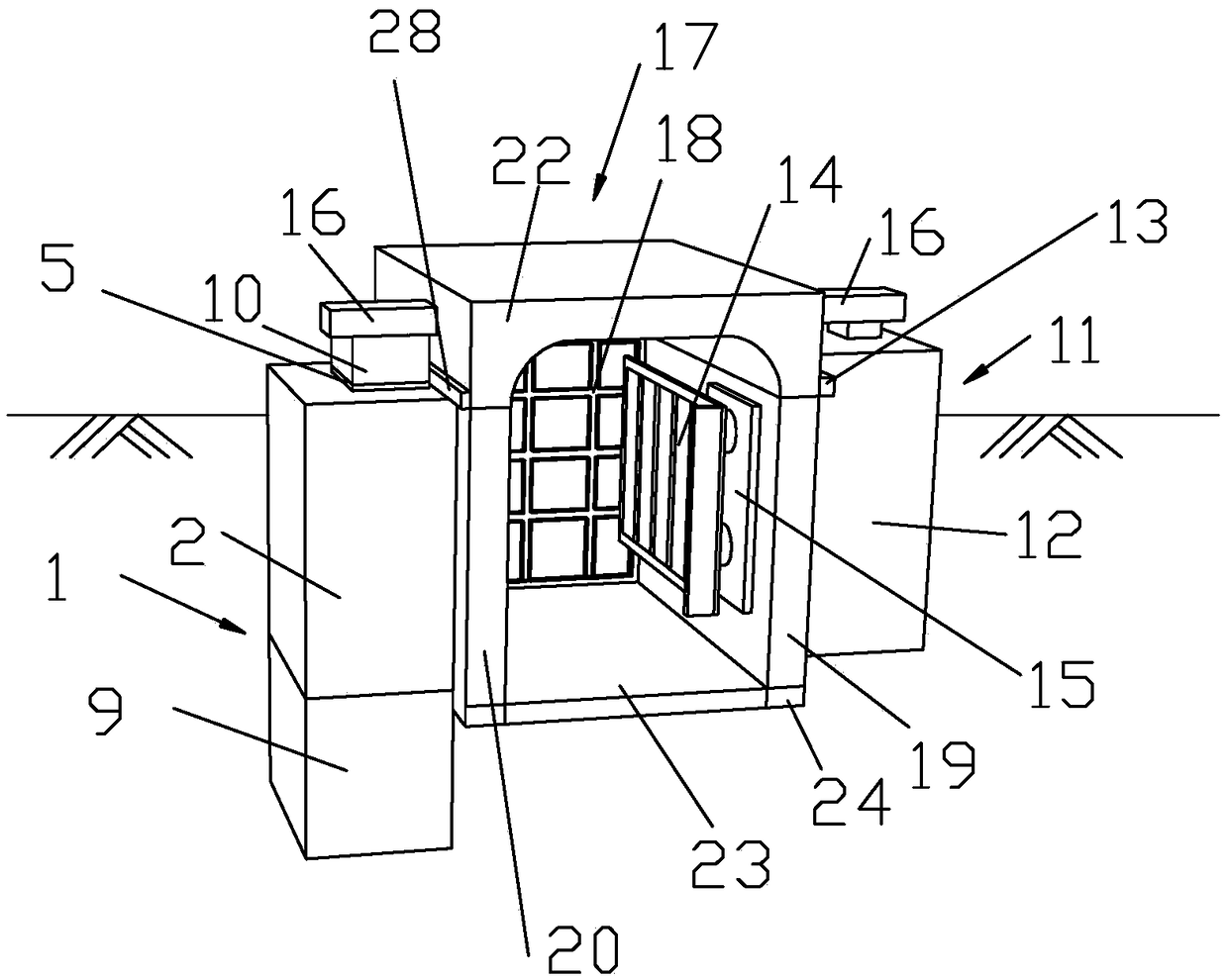

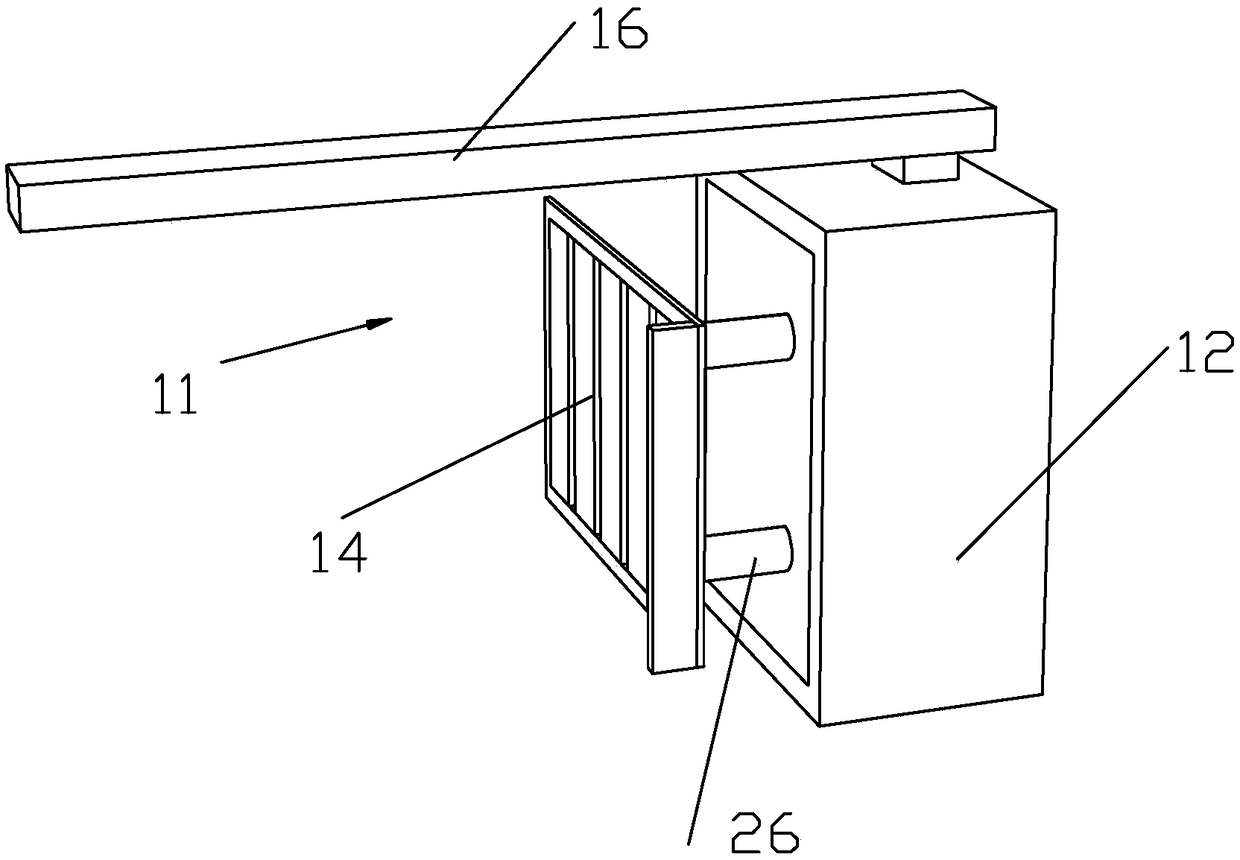

Wind resisting window shade

InactiveCN104989260ACause the problem of unsmooth liftingSimple processLight protection screensEngineeringInjection moulding

The invention provides a wind resisting window shade. The wind resisting window shade comprises cord fabric, a window cover and a reel pipe assembly which is rotationally assembled in the window cover. The cord fabric is externally wound around the coil pipe assembly. The coil pipe assembly rotates to drive the cord fabric to be unfolded or folded. The two ends of the window cover are each downwards fixedly connected with a side rail. Longitudinal openings are formed in the sides, facing the cord fabric, of the side rails. The side rails are internally provided with clamping structures in the longitudinal direction. Gaps are arranged on the sides, facing the cord fabric, of the clamping structures. Upper openings of the gaps are communicated with the window cover. The two side edges of the cord fabric penetrate through the longitudinal openings of the side rails on the same side and the gaps of the clamping structures to stretch into inner cavities of the side rails and to be transversely and fixedly connected to flexible positioning pieces, and the outer diameter of the flexible positioning pieces is larger than the width of a gap between two clamping strips. The flexible positioning pieces are a plurality of beads arranged on the two side edges of the cord fabric in an injection molding mode. The flexible positioning pieces are formed in the injection molding mode, the technology is simple, and the work hours and the machining cost can be obviously reduced.

Owner:NINGBO XIANFENG NEW MATERIAL

A stirring device suitable for liquid medicine and chemical material liquid

ActiveCN104307405BEasy to operateOperation time savingRotary stirring mixersMixer accessoriesEngineeringPiston rod

The invention provides a stirring device applicable to liquid medicines and chemical feed liquids and solves the problem of tedious operation of a conventional stirring device. The stirring device applicable to liquid medicine and chemical feed liquid comprises a stirring shaft and a tank body provided with a liquid inlet opening; the stirring shaft is vertically arranged in the tank body, and the upper end of the stirring shaft extends out of the tank body; a plurality of stirring paddles are arranged on the outer edge of the lower end of the stirring shaft; a liquid outlet pipe is arranged at the bottom of the tank body; a motor is arranged at the top of the tank body and drives the stirring shaft to rotate through a transmission mechanism; a joint pin is arranged on the outer edge of the liquid outlet pipe; a cover plate is hinged to the joint pin, and a torsional spring having the tendency of enable the cover plate to seal the liquid outlet pipe is arranged between the joint pin and the cover plate; the stirring shaft is hollow, and a mandril is inserted in the stirring shaft; an air cylinder which can enable the lower end of the mandril to be propped against the cover plate and enable the cover plate to overcome the torsion of the torsional spring and to rotate around the hinge point is arranged at the top of the tank body; the piston rod of the air cylinder is connected with the upper end of the mandril. The stirring device applicable to liquid medicine and chemical feed liquid has the advantages that the operation is simple and time is saved.

Owner:珠海君瑞恒医药科技有限公司

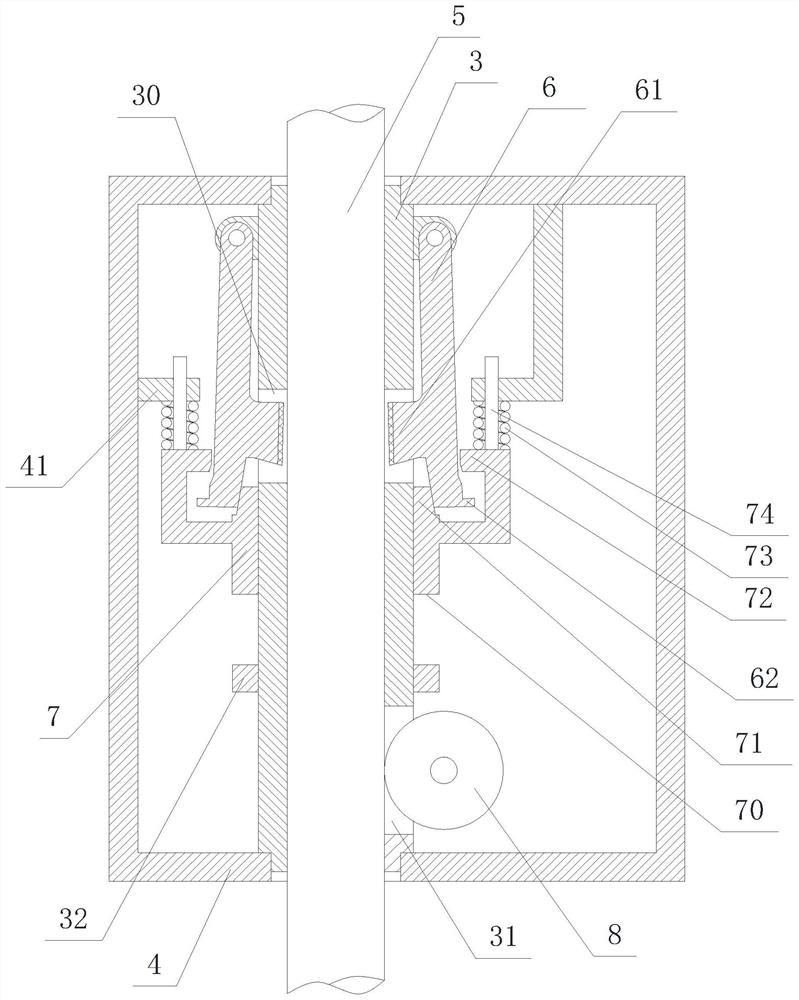

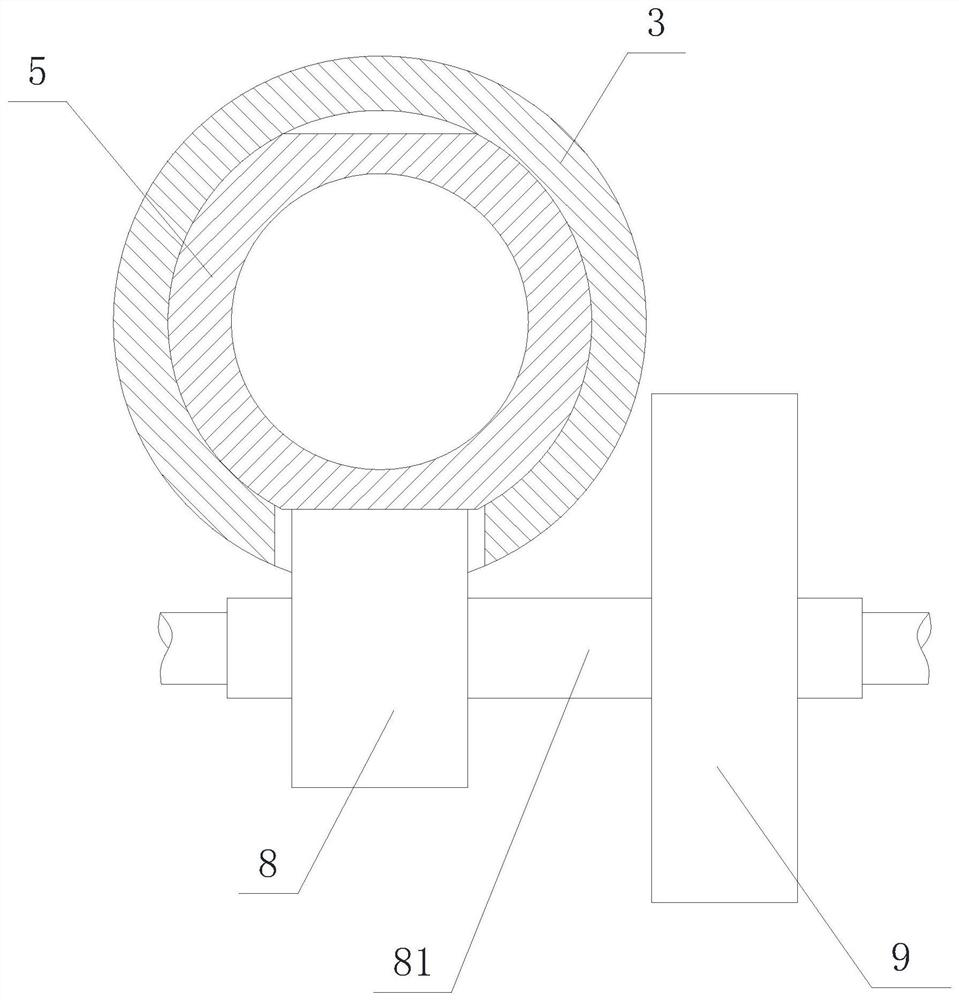

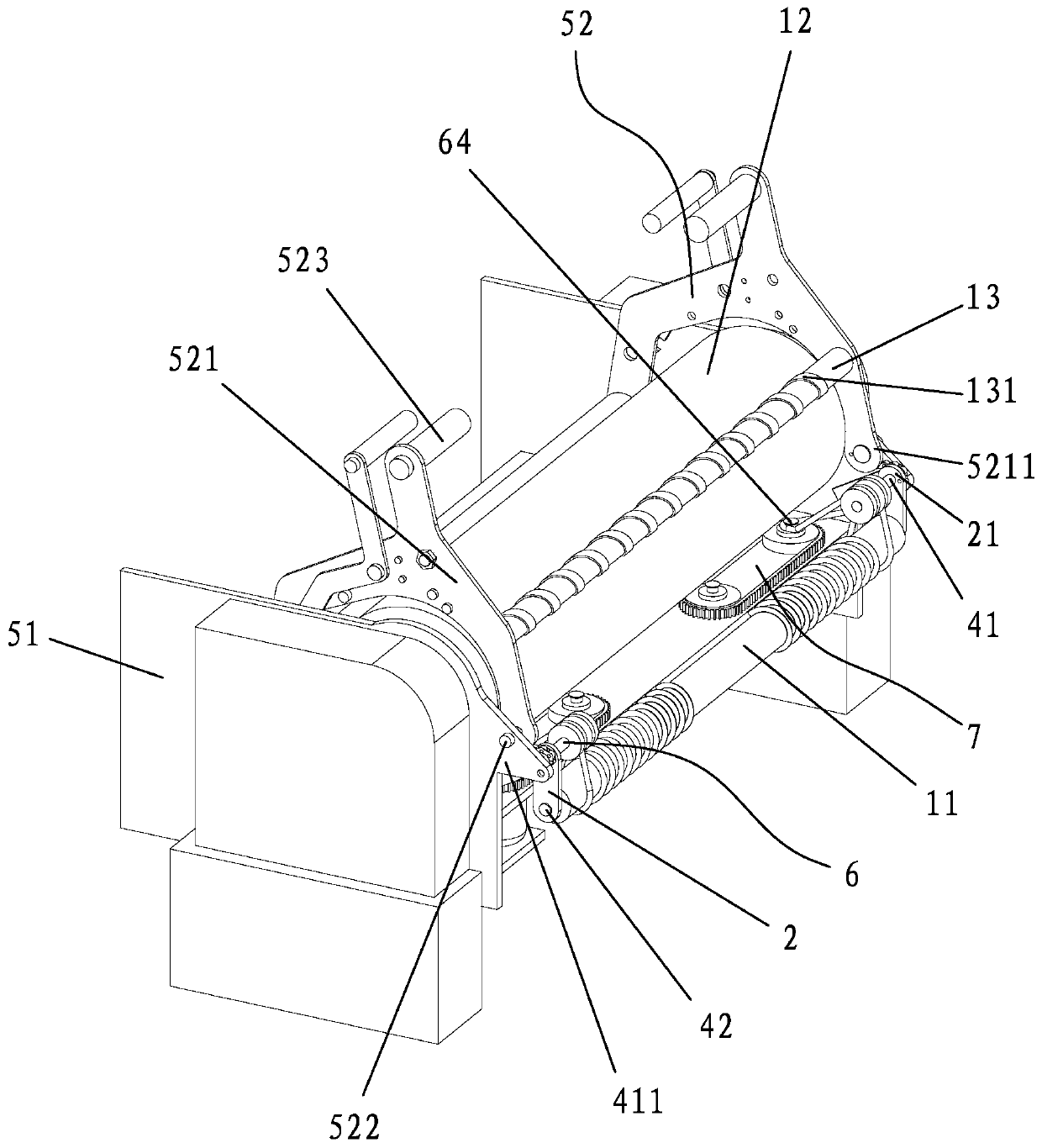

Pipe cutting device

InactiveCN105313156ASimple and efficient operationSimplify control proceduresMetal working apparatusProgram controlMechanical transmission

The invention discloses a pipe cutting device which comprises an air cylinder, a first rotary plate, a transmission rod, a second rotary plate, a third rotary plate, a first driving rod, two second driving rods, two third driving rods and two clamping heads, wherein a cutting wheel is mounted on the first rotary plate. When the air cylinder drives the first rotary plate to rotate, the cutting wheel moves up and down. When the first rotary plate rotates, the first rotary plate passes through the transmission rod, the second rotary plate, the third rotary plate, the first driving rod, the two second driving rods and the two third driving rods successively to drive the two clamping heads to meet each other or separate from each other, so that the two clamping heads clamp or loosen a pipe to be cut. Moreover, the pipe cutting device is provided with a hydraulic damper. When the first rotary plate rotates so that the cutting wheel moves down, the hydraulic damper can apply damping force to the first rotary plate. When the pipe cutting device cuts the pipe, a clamping mechanism is driven to automatically clamp the pipe in a mechanical transmission way, and manual control or programmed control is not needed.

Owner:NINGBO FUSHI AUTOMOBILE COMPONENTS

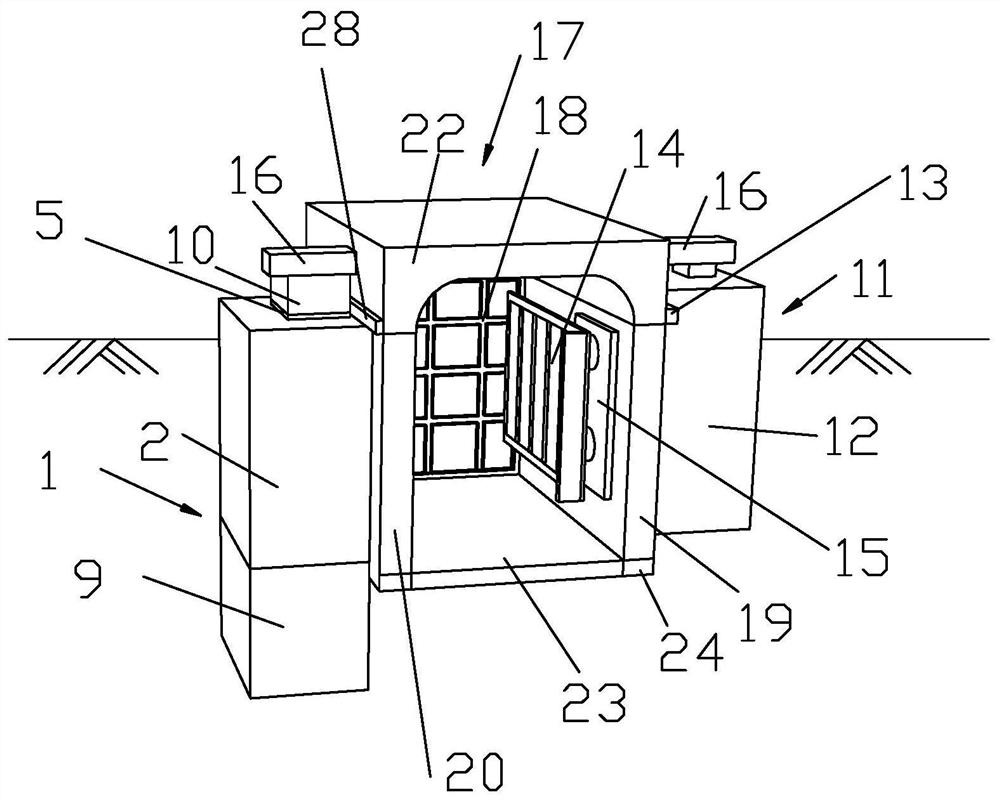

Construction method of automatic sewage interception closed conduit

The invention discloses a technical solution of a construction method of an automatic sewage interception closed conduit. The construction method comprises the following steps: 1, making a slag removal device; 2, making a moving device; 3, making a conduit body; and 4, implementing on-site construction. The construction method provided by the invention is not only simple in structural compositionbut also low in closed conduit maintenance cost; the construction method provided by the invention, which is enough in structural intensity, can collect solid waste and residues in the closed conduit,so as to prevent the closed conduit from getting blocked by the solid waste in discharge, and to enhance underwater and rainwater discharge functions of the closed conduit; and therefore, a risk of flood due to river blockage can be avoided.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

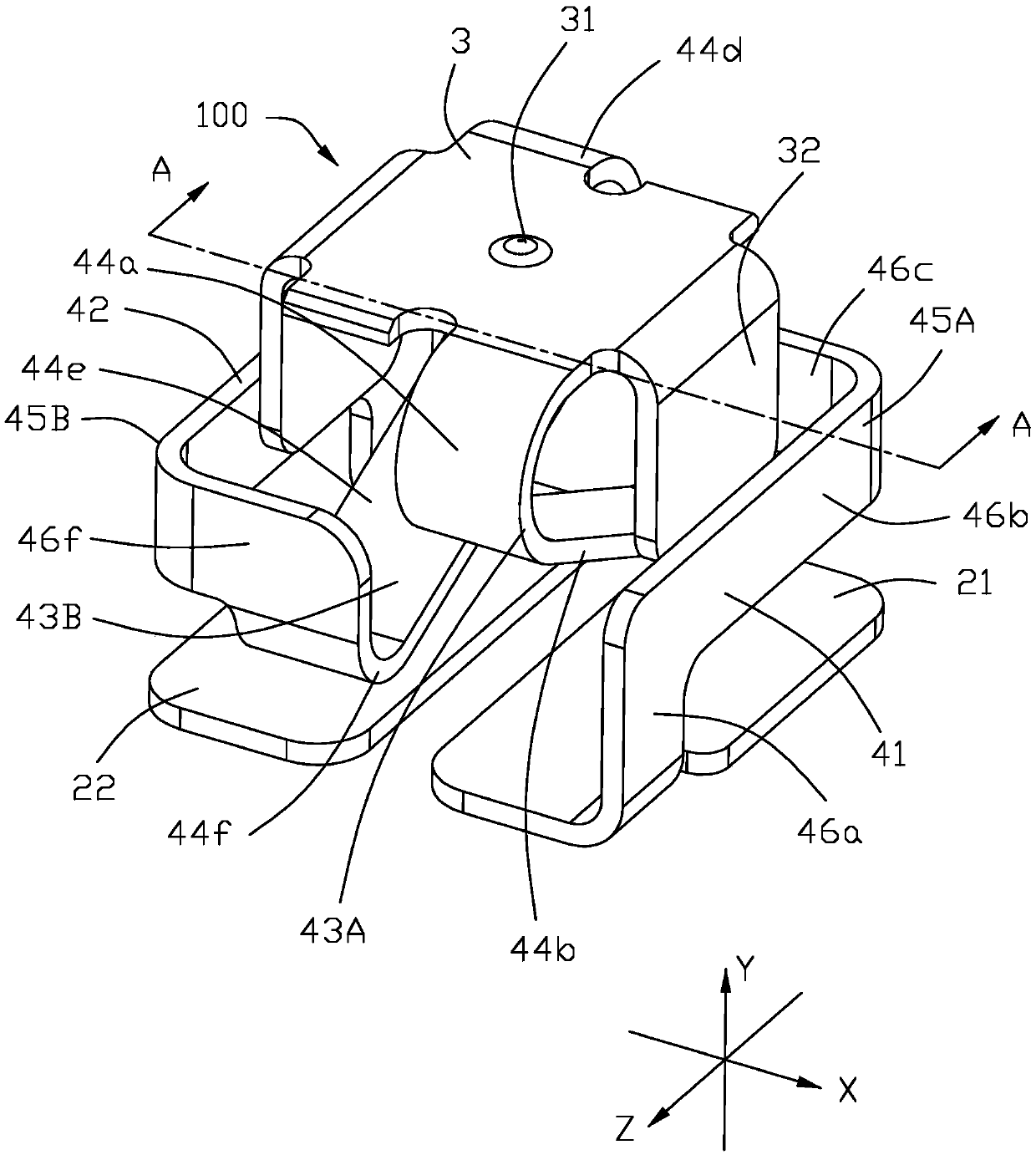

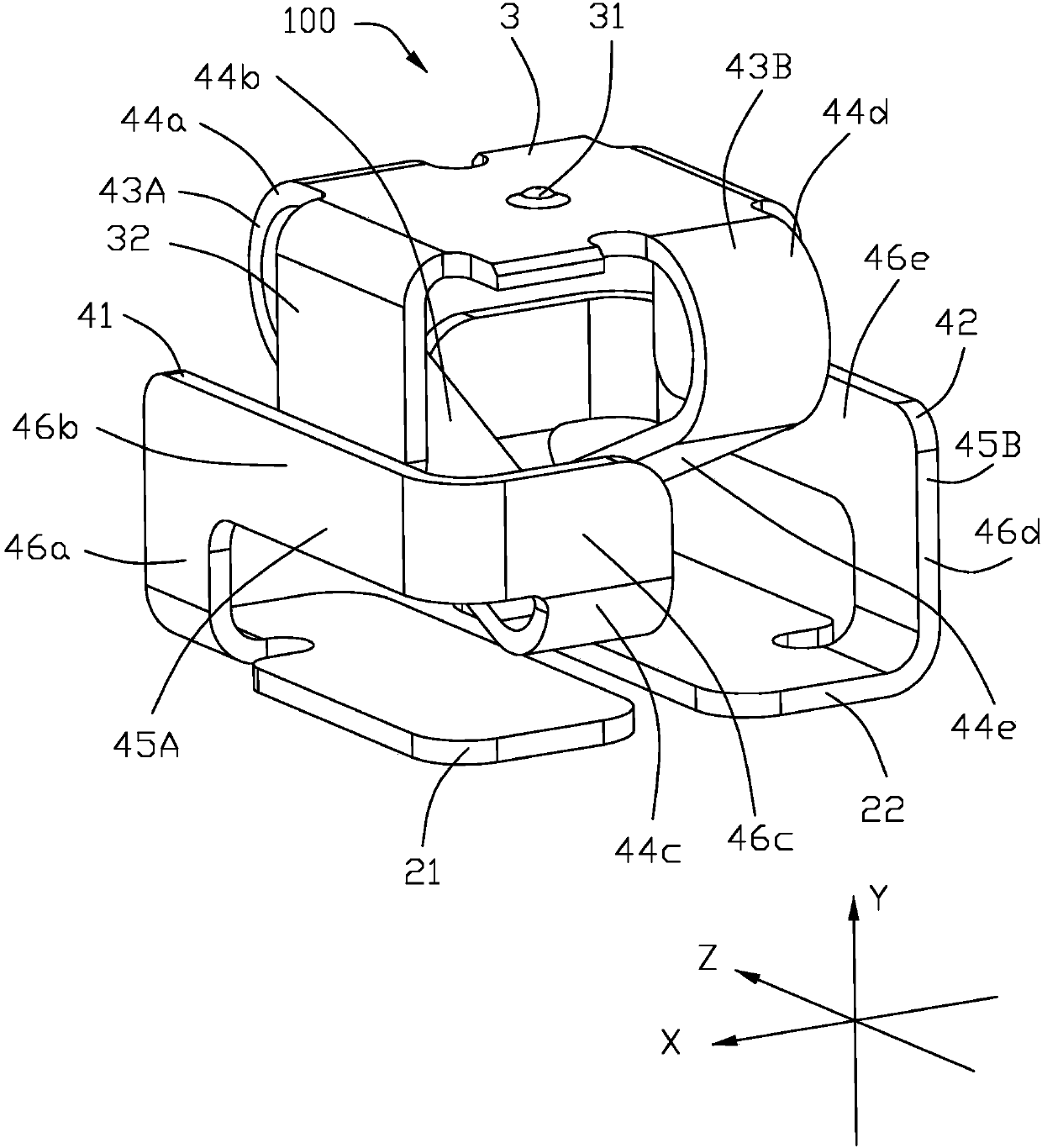

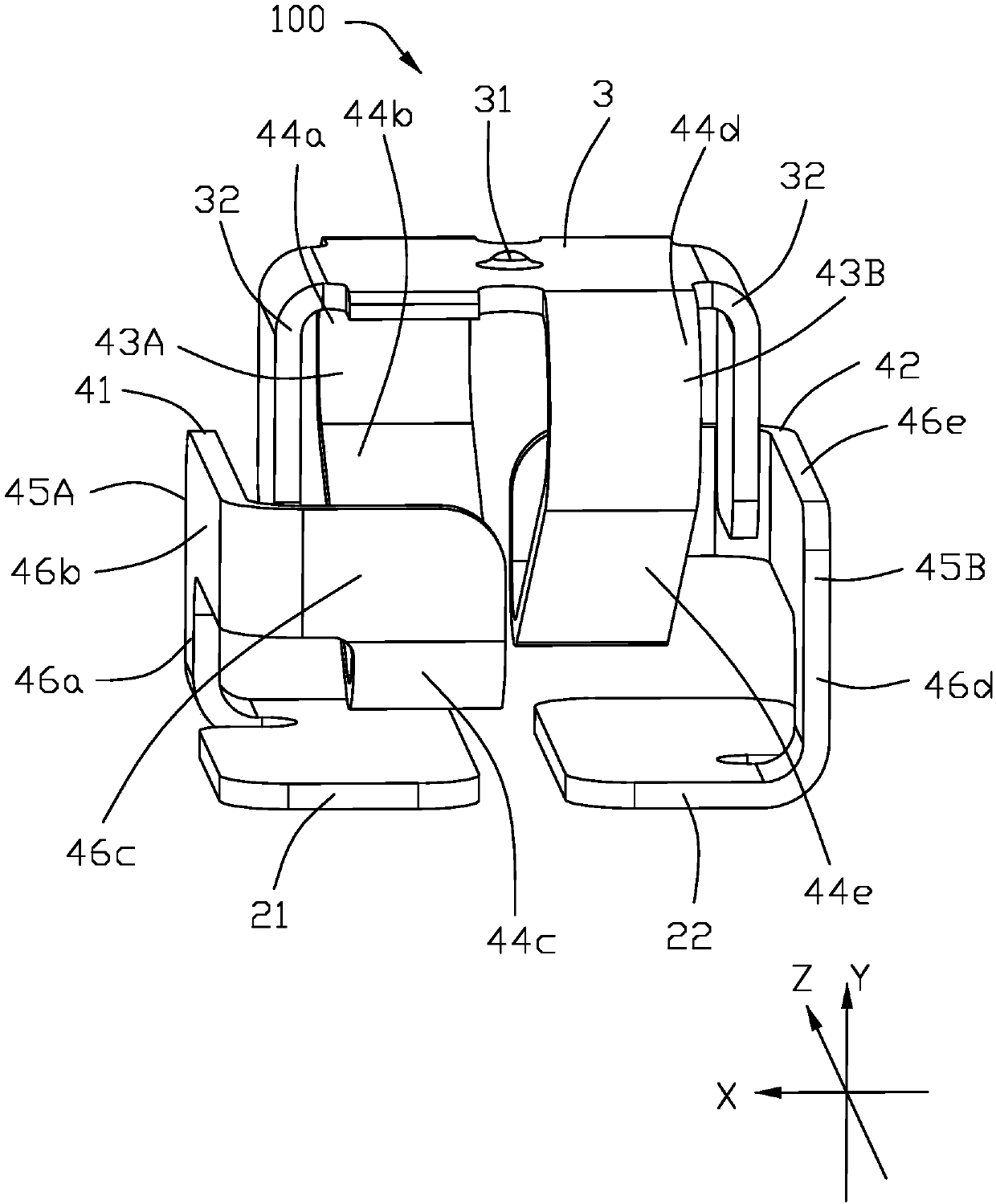

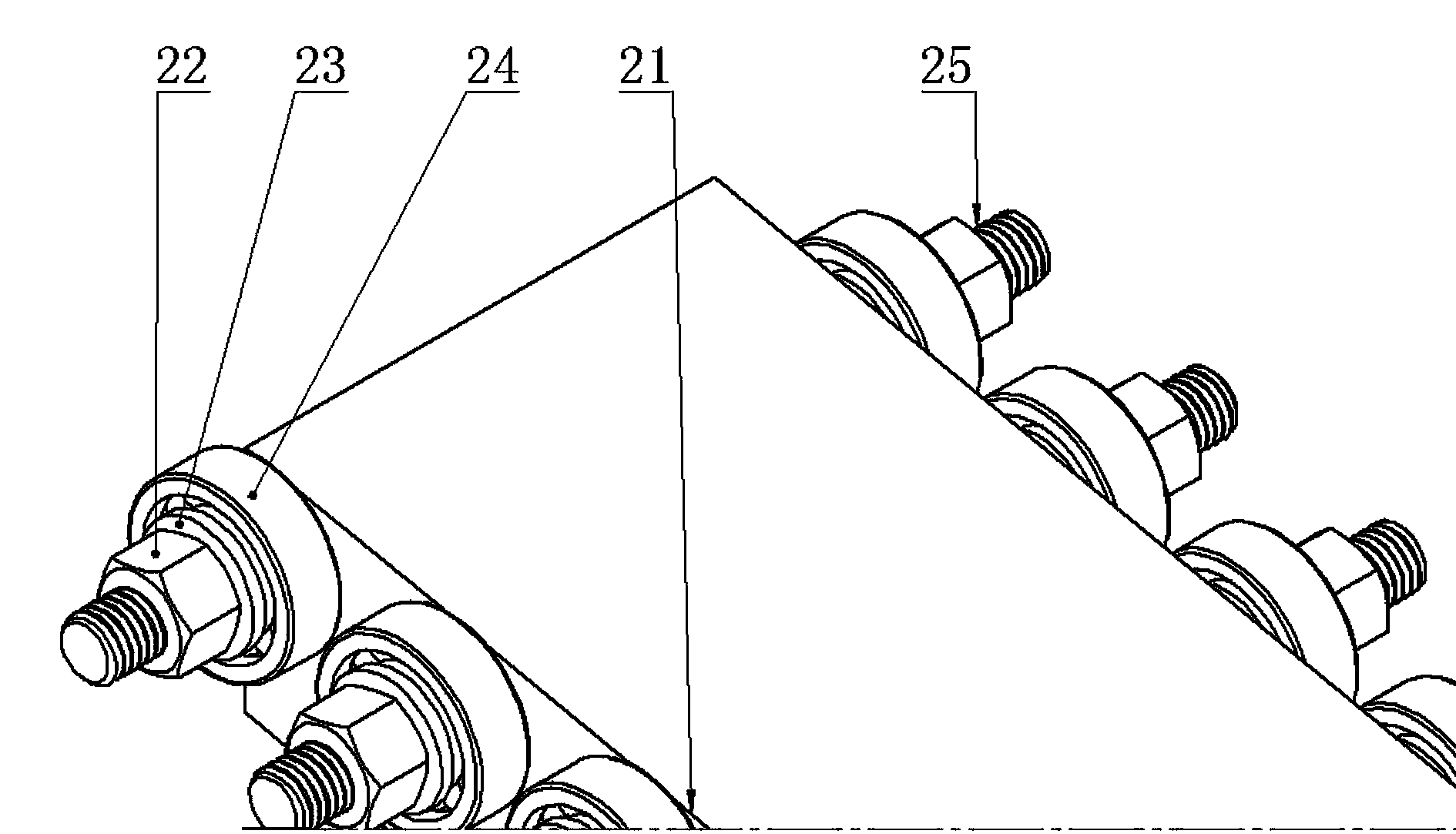

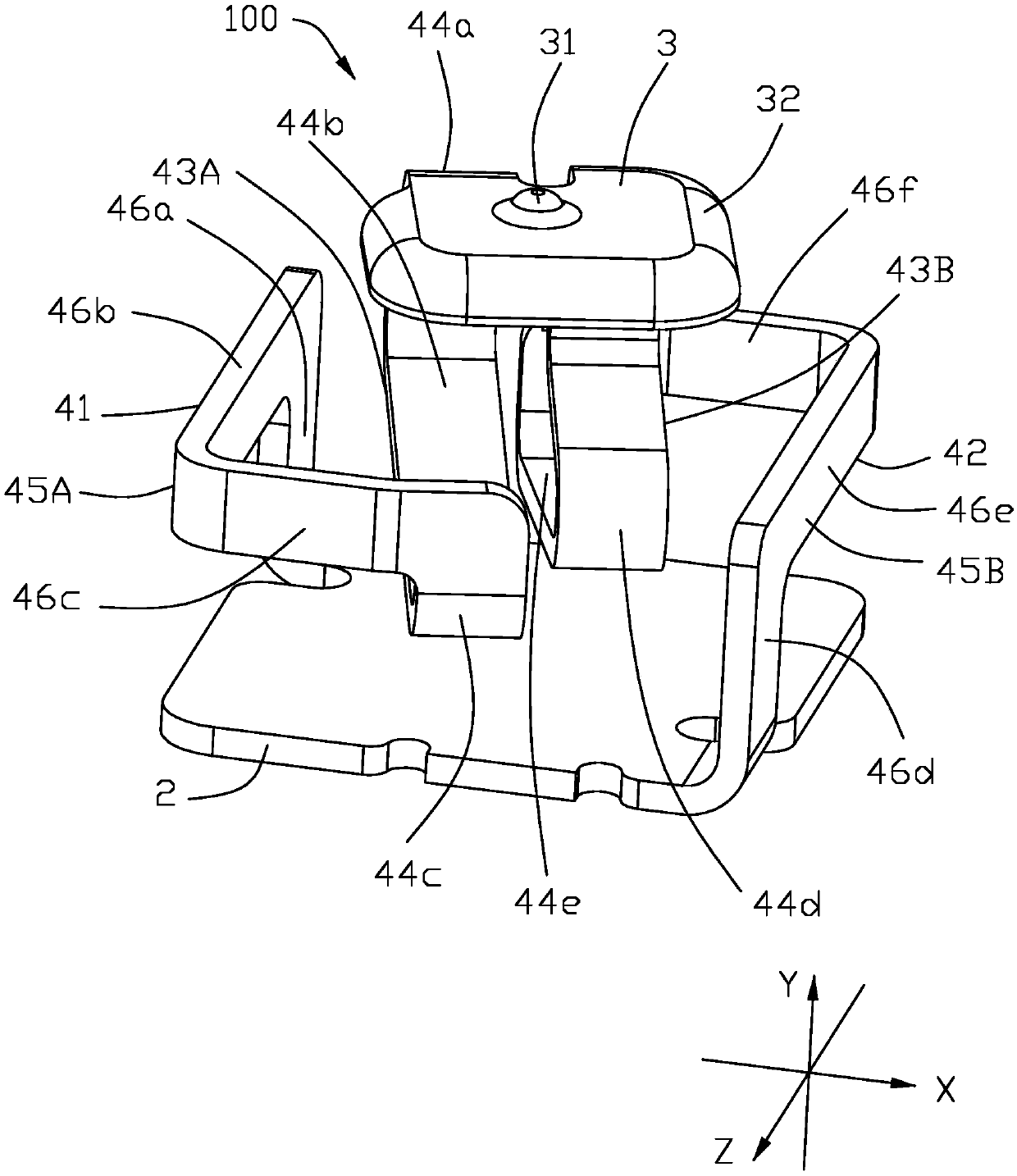

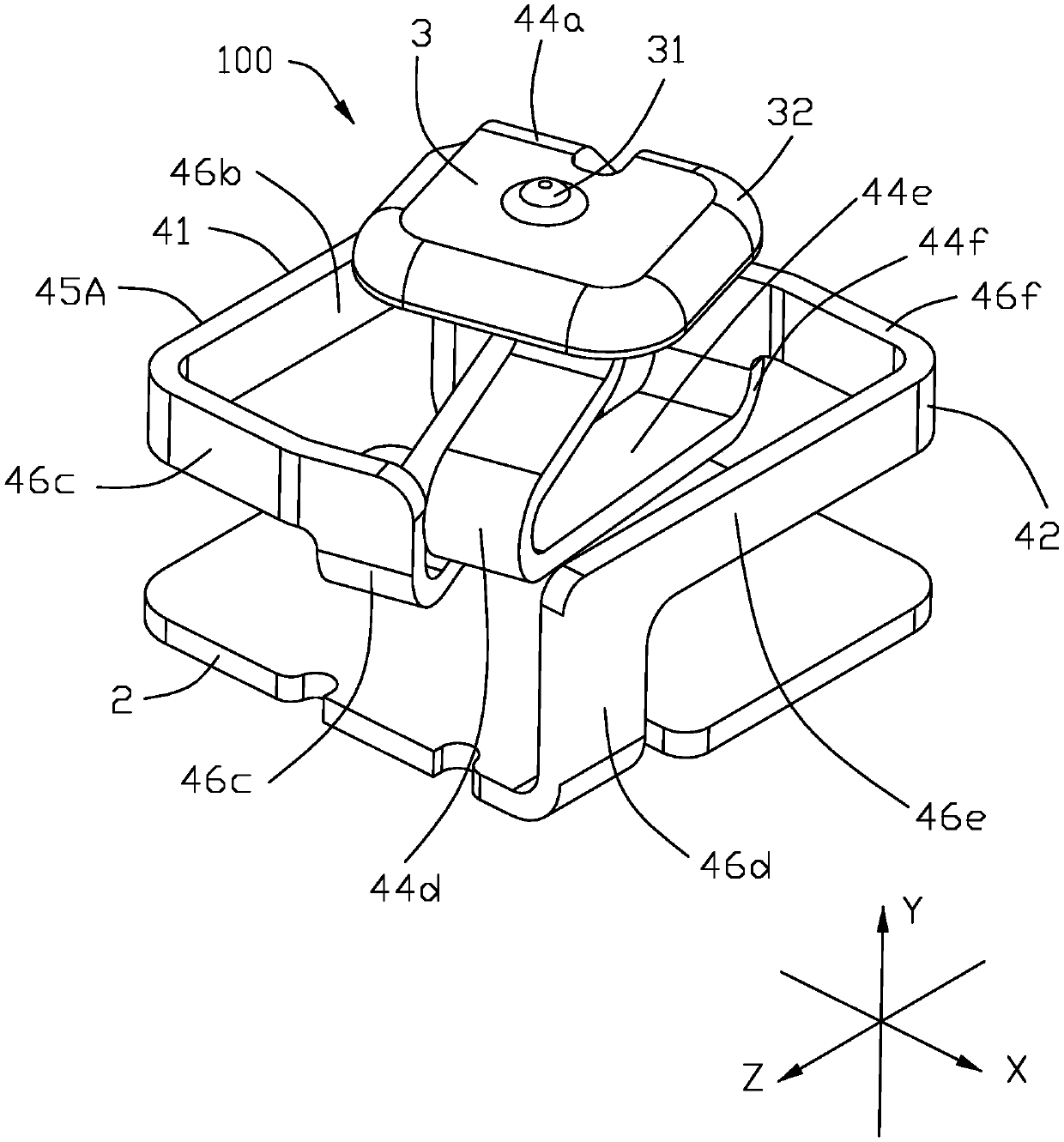

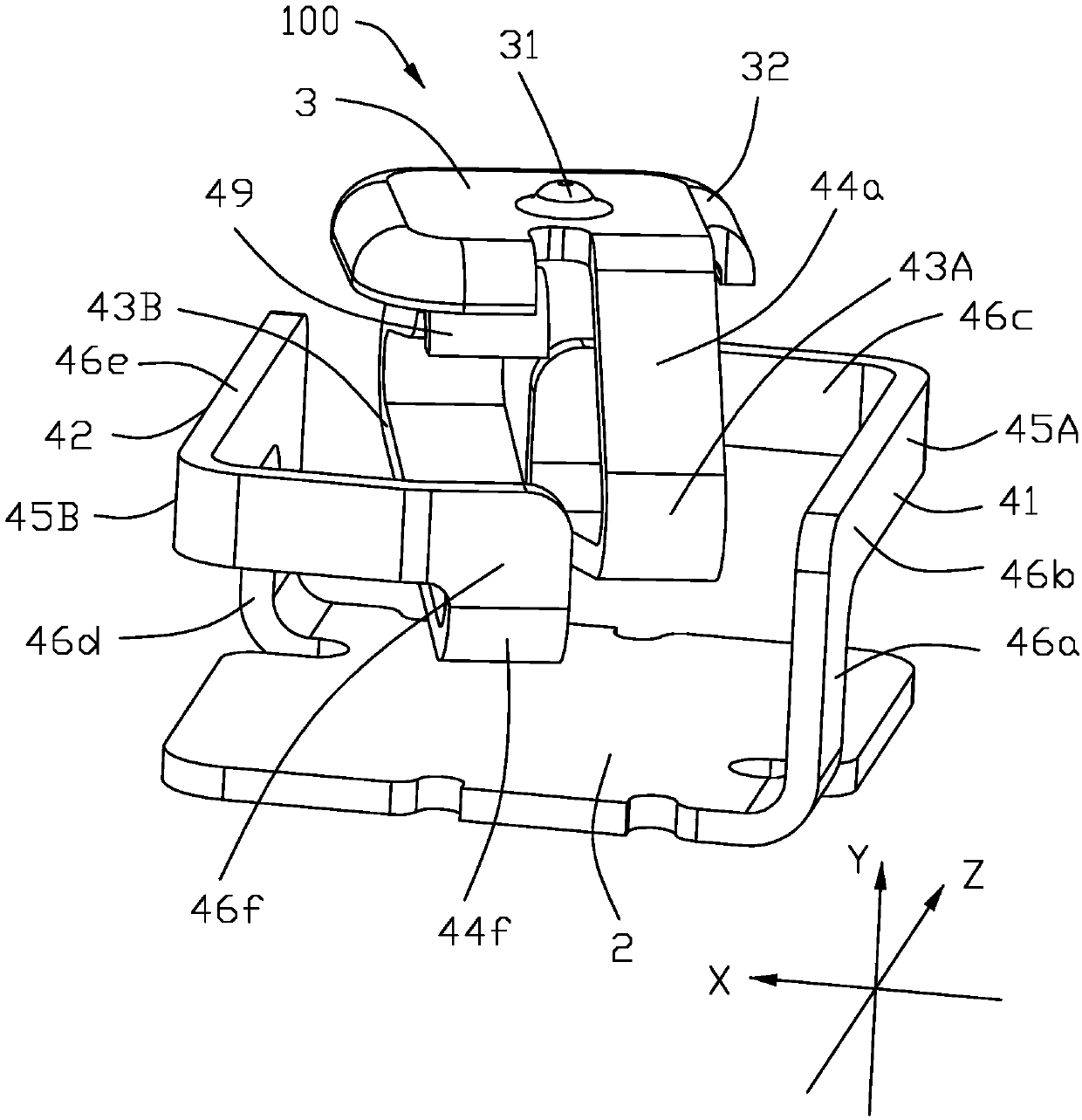

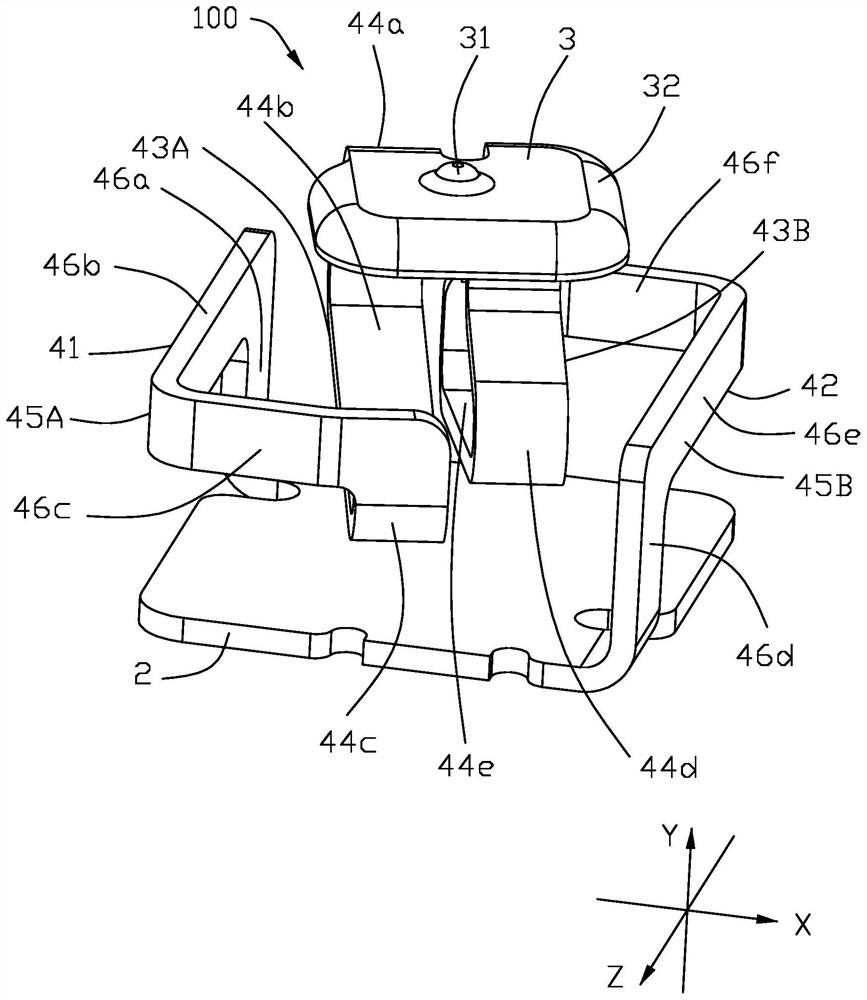

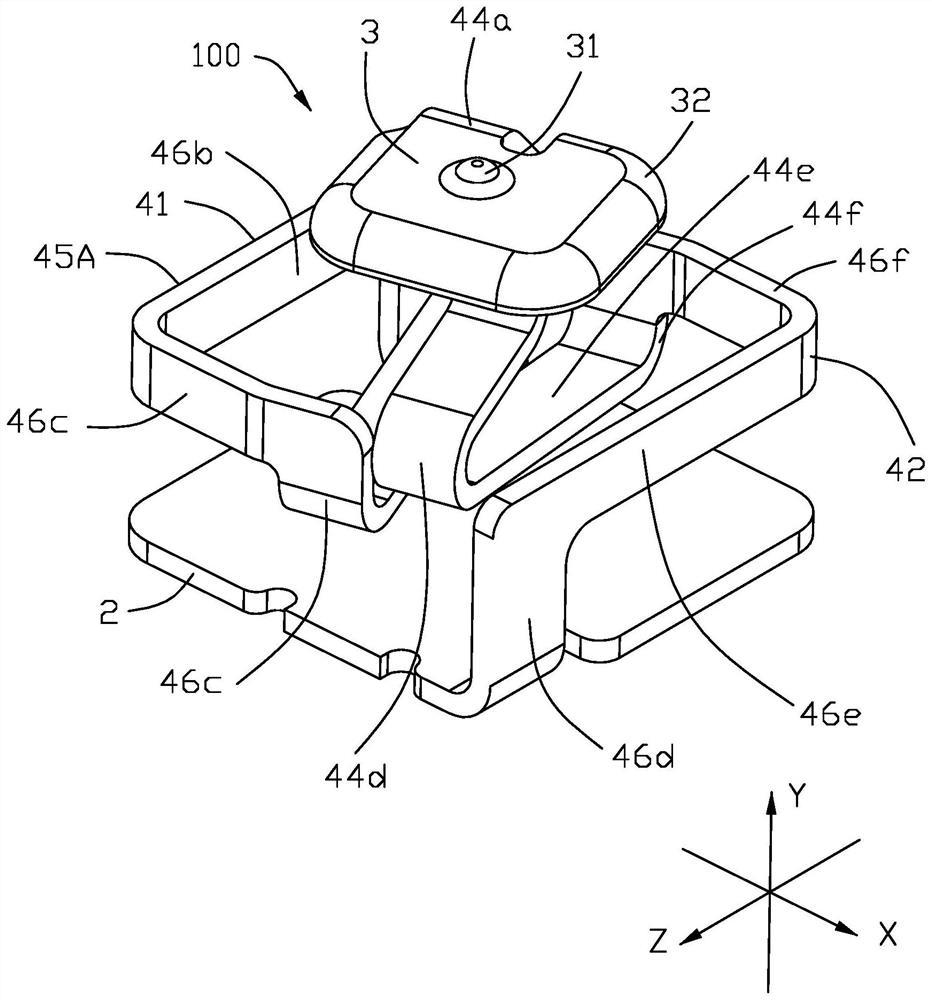

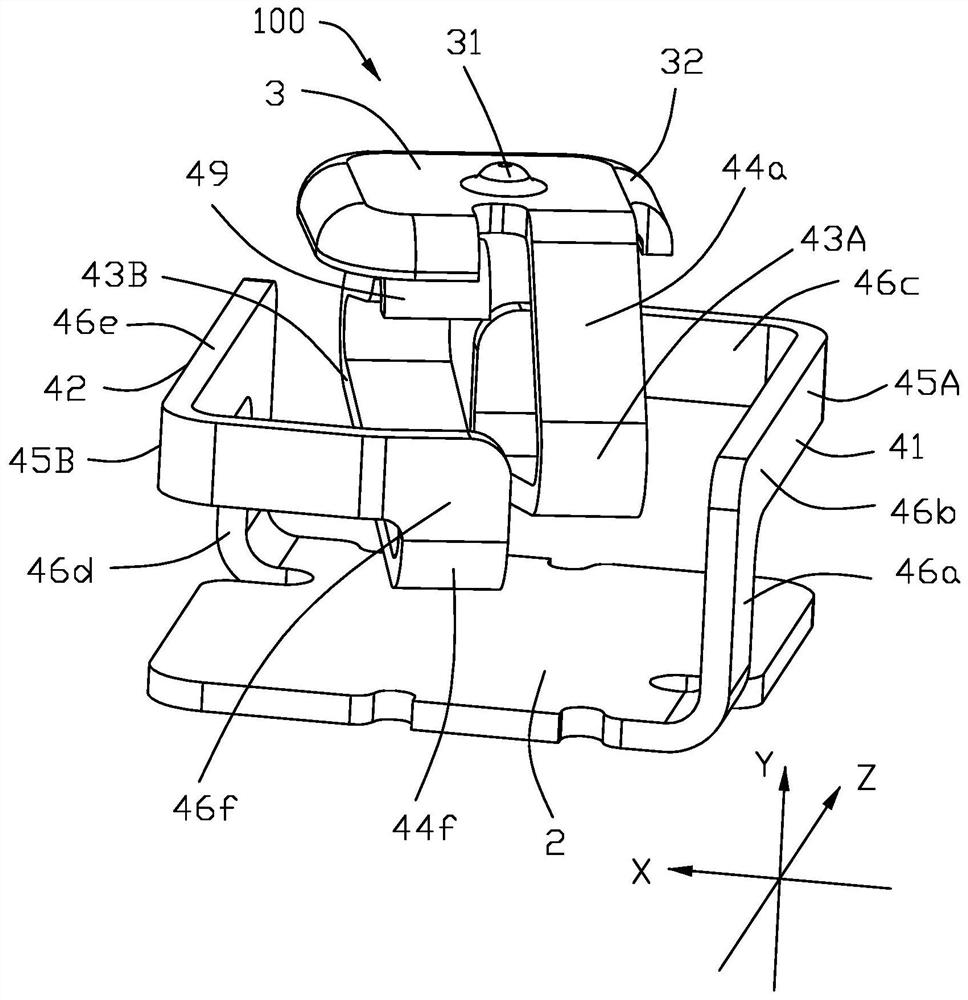

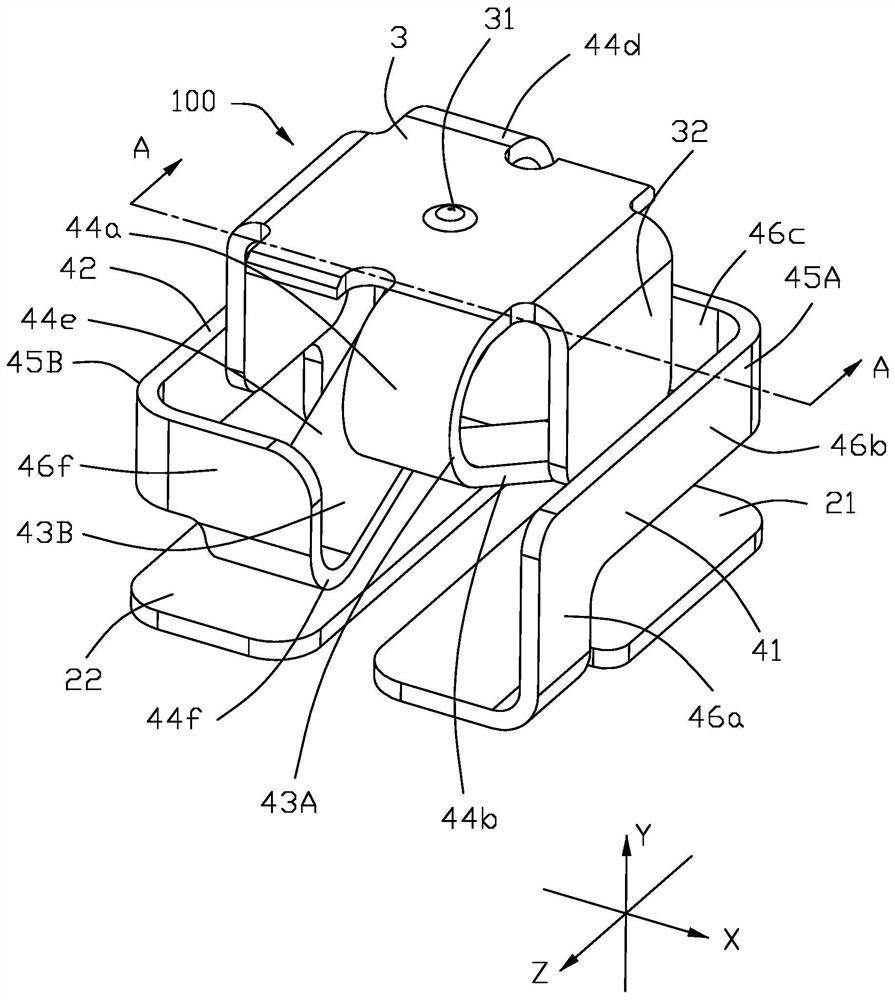

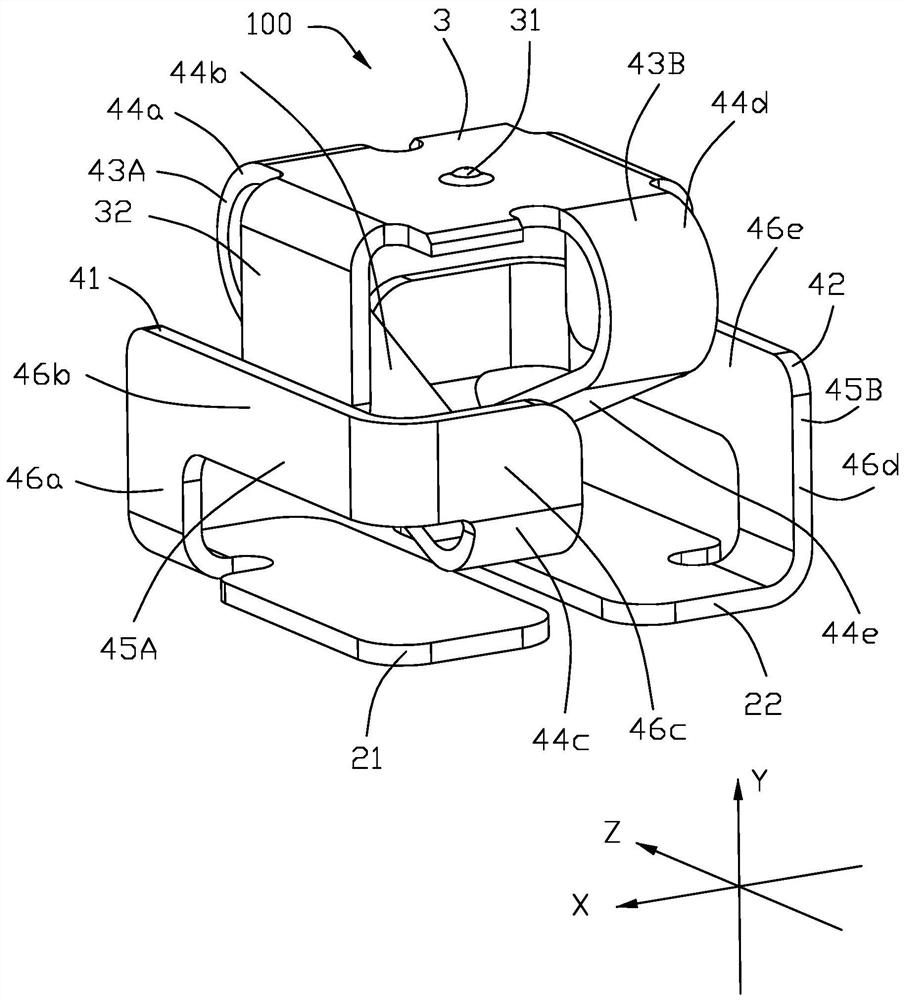

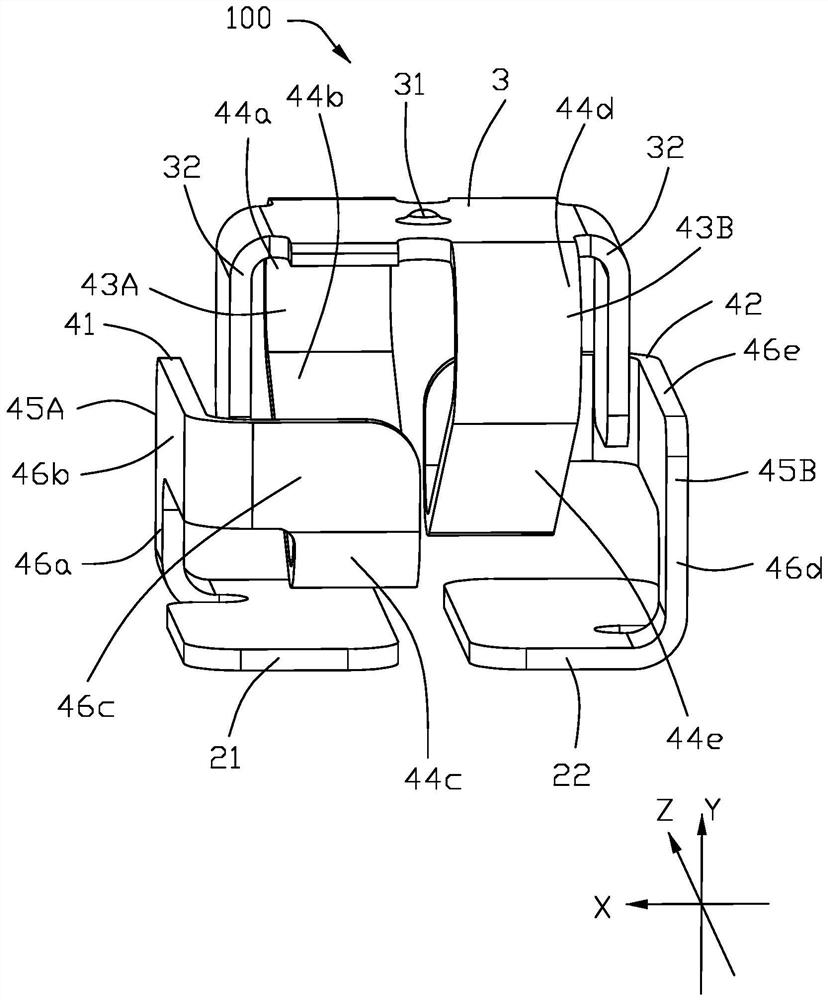

Crimping connector and manufacturing method thereof

ActiveCN110061372AExtended service lifeBending steps are simpleContact member manufacturingFixed connectionsEngineeringUltimate tensile strength

The invention provides a crimping connector. The crimping connector comprises a substrate, a press plate and two elastic parts, wherein the press plate is arranged on the substrate, the two elastic parts are continuously bent to connect the substrate and the press plate, one end of each of the two elastic parts is connected to a peripheral edge of the press plate, the other ends of the two elasticparts are respectively connected with peripheral edges of the substrate, and each elastic part has elasticity in a vertical direction so that the press plate elastically moves along the vertical direction. Since the two elastic parts are respectively connected to edges of two opposite edges of the press plate and are arranged in a staggered way, the crimping connector is better in structural strength, pressure borne by the press plate can be uniformly allocated to the two elastic parts, the two elastic parts can give balanced elastic support to the press plate, the press plate is enabled to stably move downwards, and longer service lifetime of the two elastic parts is also ensured; and during manufacturing, the bending step of the elastic parts is simple, and the crimping connector is easy to manufacture.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

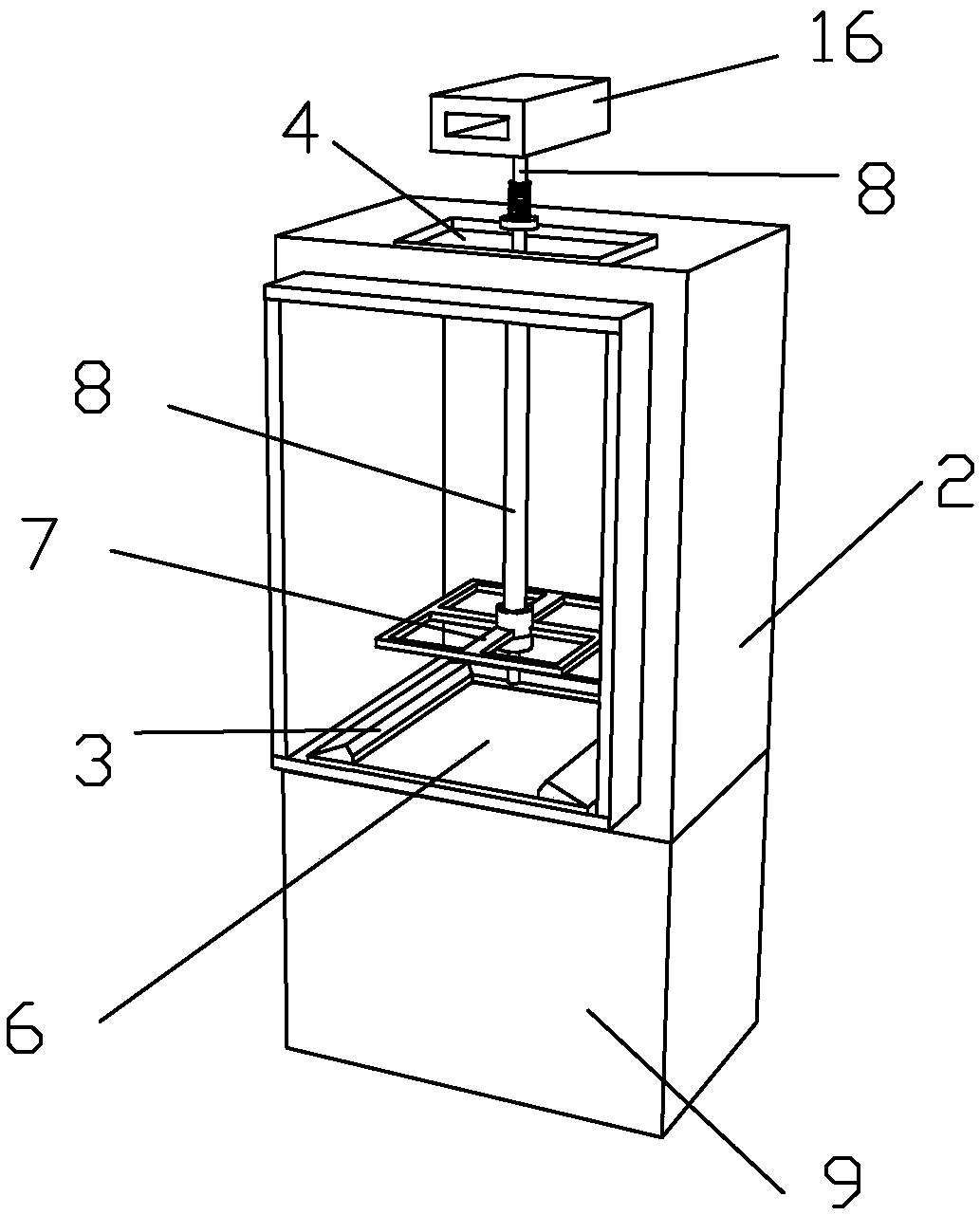

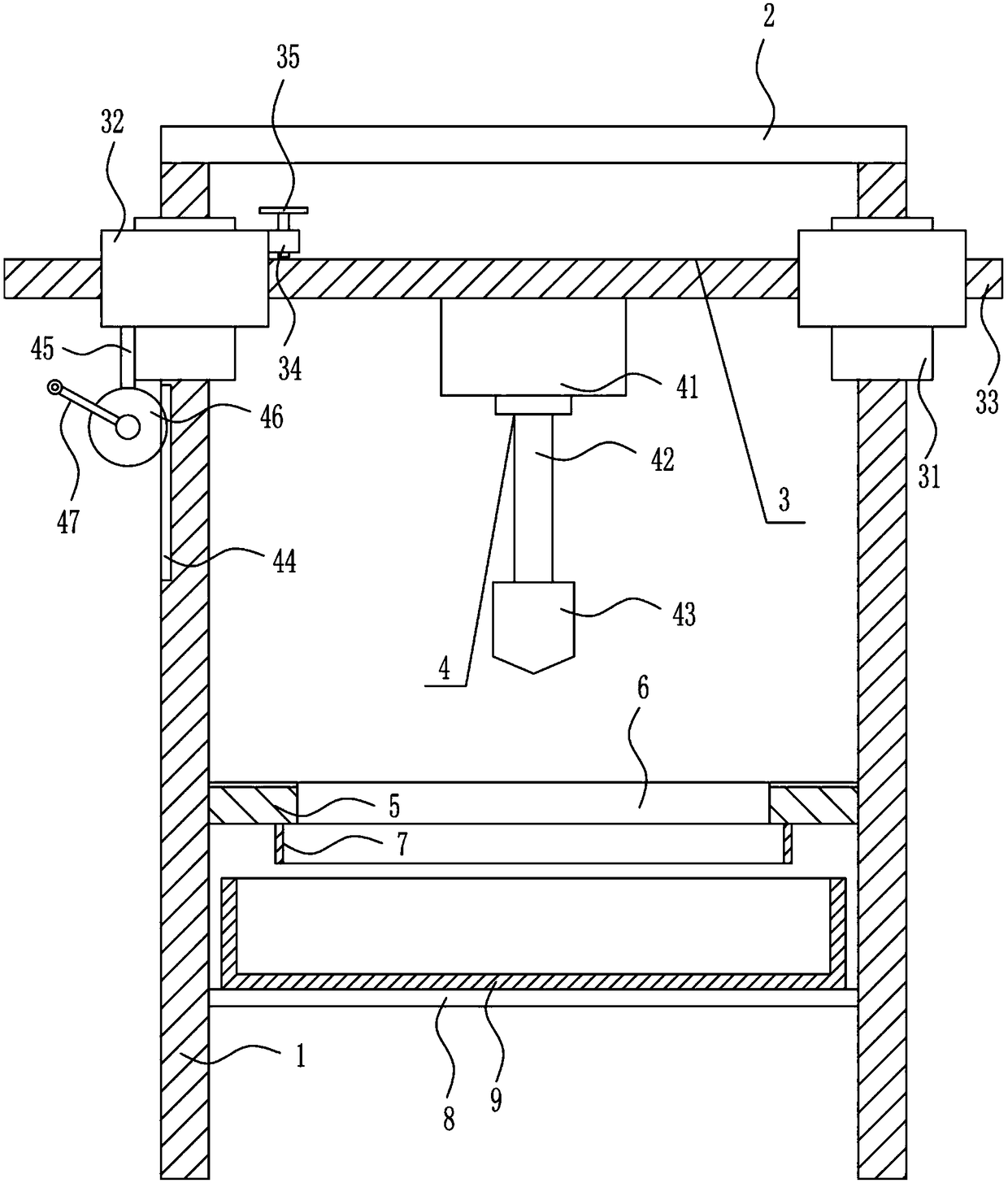

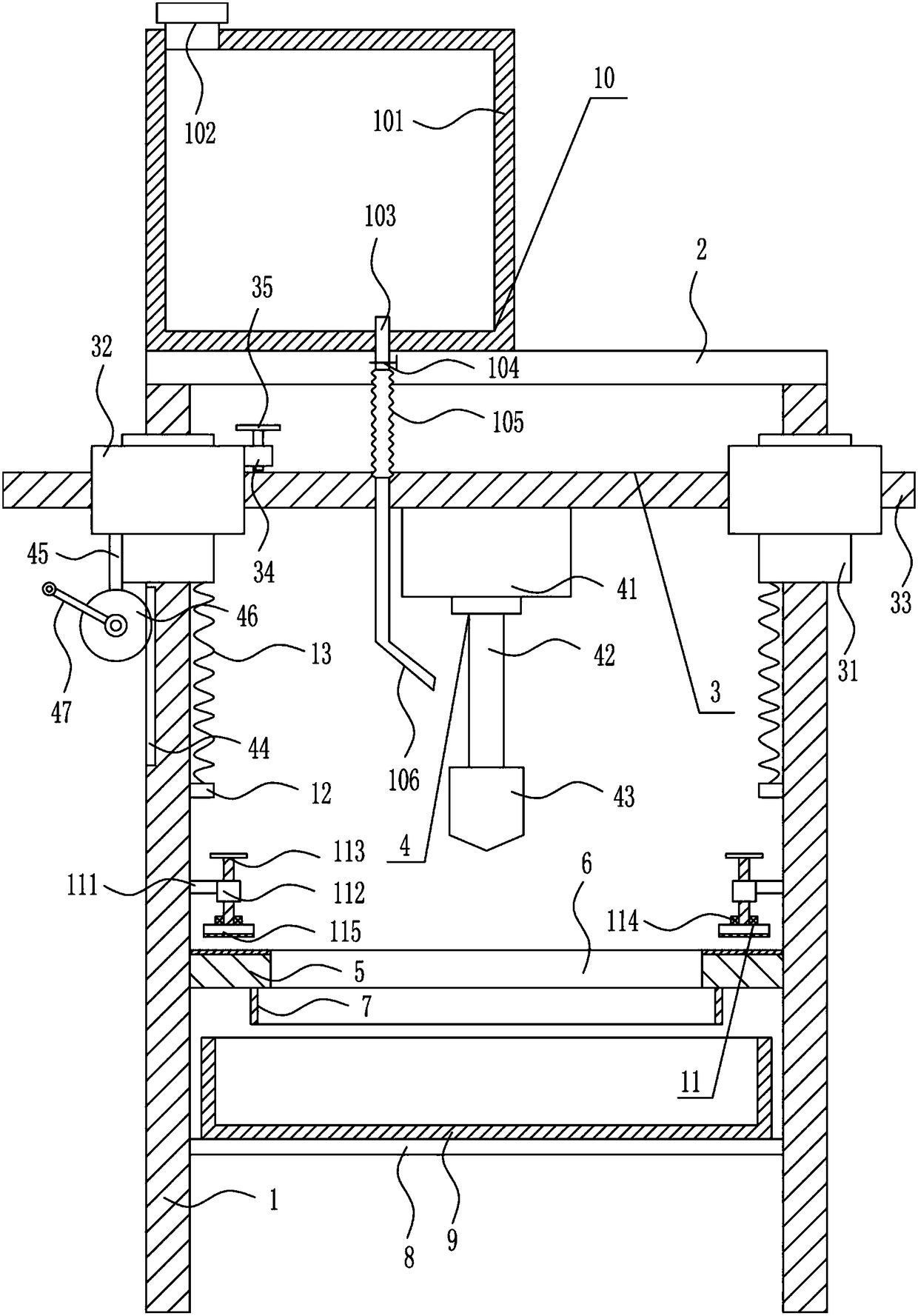

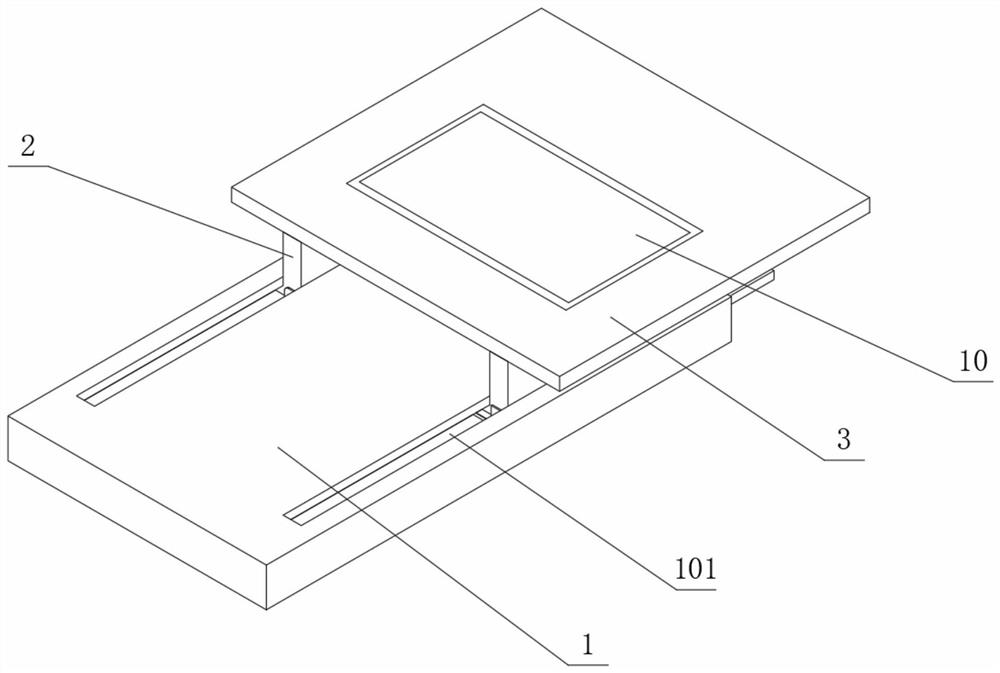

Fixed type ceramic tile floor drilling equipment for construction engineering

InactiveCN108582509ARealize the drilling operationEasy to useWorking accessoriesStone-like material working toolsMoving partsCeramic tiles

The invention relates to drilling equipment, in particular to fixed type ceramic tile floor drilling equipment for construction engineering. According to the technical purposes of the fixed type ceramic tile floor drilling equipment for the construction engineering, the drilling process can be defined, the consumed time is short, and operation is easy and convenient. The fixed type ceramic tile floor drilling equipment for the construction engineering comprises supporting legs, a connecting plate, adjusting mechanisms, drilling mechanisms, an operating table, a guiding frame and the like; theconnecting plate is arranged on the tops of the left and right side supporting legs; the adjusting mechanisms are installed on the supporting legs; the drilling mechanisms are installed on moving parts of the adjusting mechanisms; the position, close to the middle lower portion, between the left and right side supporting legs is connected with the operating table; and the middle portion of the operating table is provided with a through hole. According to the fixed type ceramic tile floor drilling equipment for the construction engineering, due to mutual cooperation between the adjusting mechanisms and the drilling mechanisms, drilling is performed on ceramic tile floors placed on the operating table; and meanwhile due to optimization of a spraying mechanism and a fixed mechanism, the effects that the drilling process can be defined, the consumed time is short, and operation is easy and convenient are achieved.

Owner:李子轩

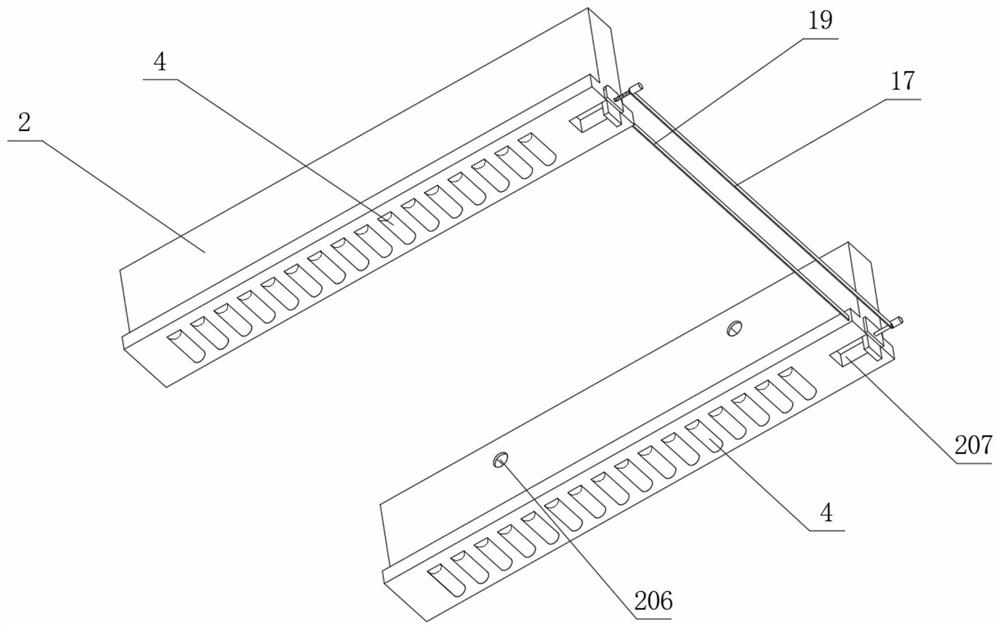

Pyrography machine lower plate seat capable of automatically adjusting levelness

The invention relates to a pyrography machine lower plate seat capable of automatically adjusting levelness, which comprises a horizontal bottom plate, two parallel sliding chutes are formed in the top end of the bottom plate, a supporting seat in sliding connection with the sliding chutes is arranged in the sliding chutes, and a drawing board in clamping connection with the supporting seat is arranged at the top end of the supporting seat; a plurality of roller grooves are formed in the bottom end of the supporting seat in the length direction of the sliding grooves, rollers are arranged in the roller grooves, and shaft sleeves connected with the roller grooves in an up-down sliding mode are arranged between the roller grooves and the rollers. According to the pyrography machine lower plate seat capable of automatically adjusting the levelness, the rollers moving up and down in the roller grooves are used for keeping parallel to an upper plate, the situation that the lower plate seat cannot be tightly attached to the upper plate after being heated and deformed is effectively prevented, and the pyrography effect is guaranteed; the base plate is supported by a base capable of automatically adjusting the horizontal position, the base corrects the height difference of the four corners of the base by recognizing the inclined direction, the adjusting mode is accurate and reliable, and the levelness of the base and the drawing board on the base is effectively guaranteed.

Owner:福建欣弘机电设备有限公司

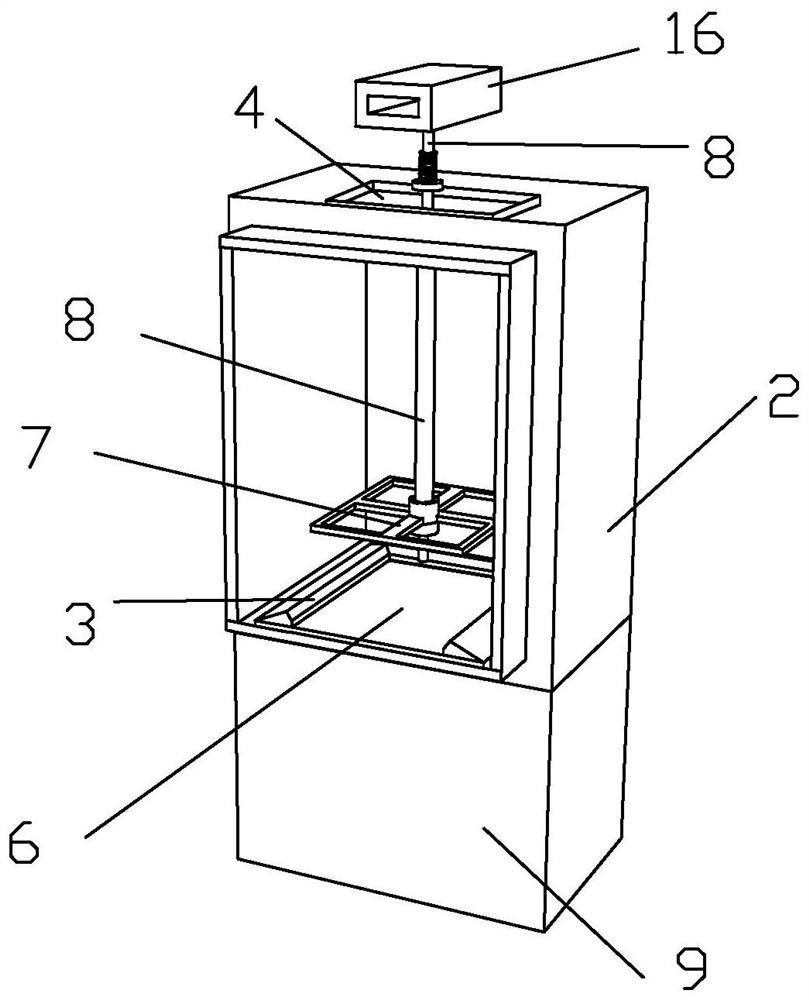

An intelligent lifting cabinet

ActiveCN112056801BAvoid damageImprove running synchronicityKitchen cabinetsDismountable cabinetsControl engineeringStructural engineering

The invention provides a lifting cabinet, which includes a fixed cabinet and a lifting cabinet. An overspeed limiting device is provided on the fixed cabinet and the lifting cabinet for quality inspection. The overspeed limiting device includes a knife rod vertically arranged on the The limiter on the guide rod, when the running speed of the lifting cabinet is greater than a predetermined value, the limiter locks the guide rod to brake the lifting cabinet; the intelligent lifting cabinet of the present invention has a compact structure and a purely mechanical structure Design, high stability, good braking performance, which improves the overall safety of intelligent lifting cabinets.

Owner:德扬精密制造科技(无锡)有限公司

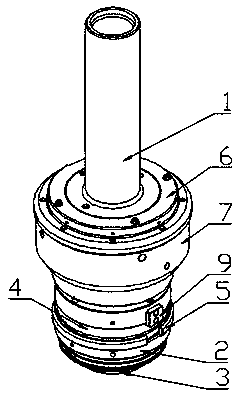

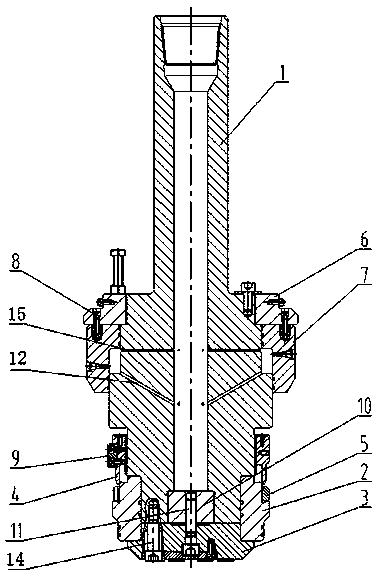

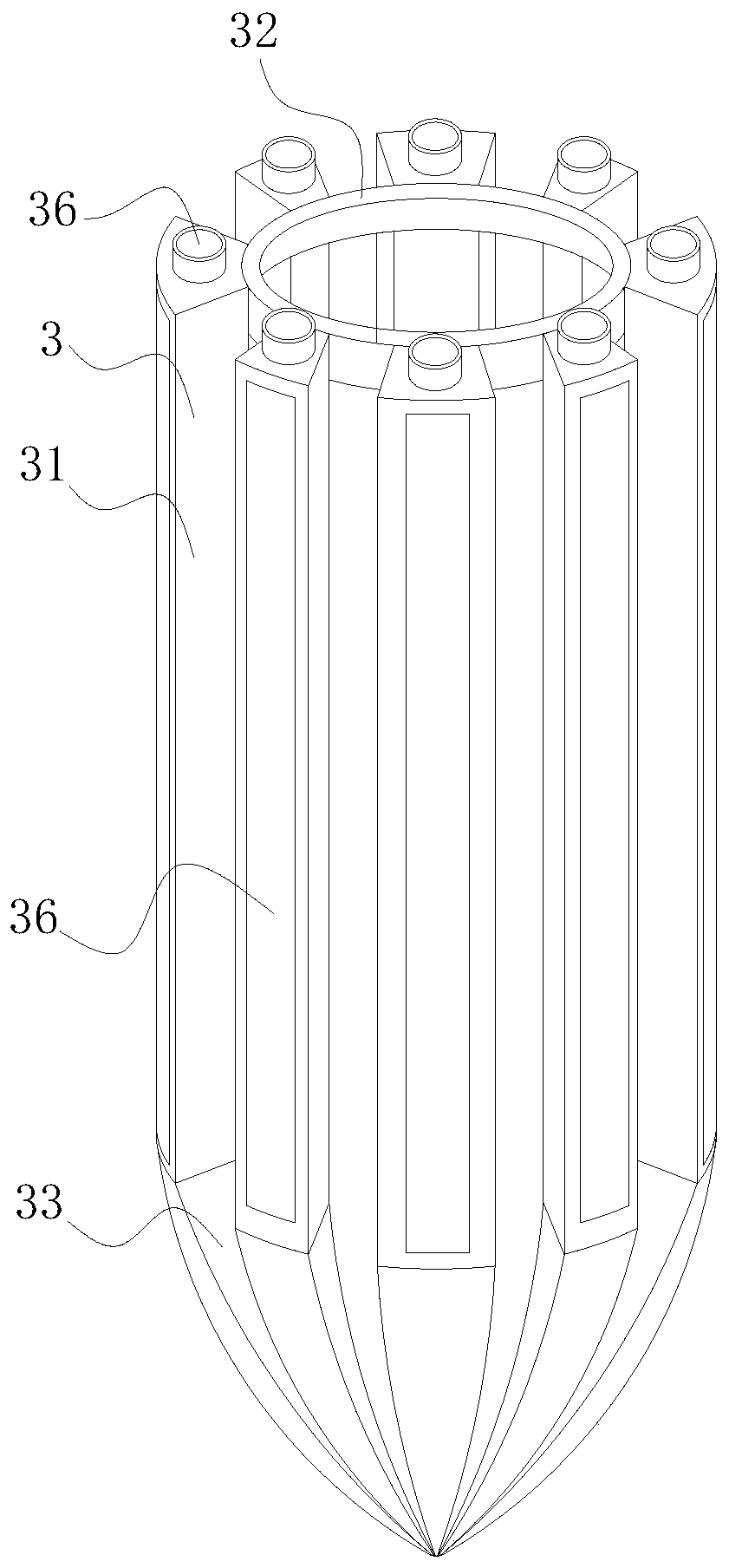

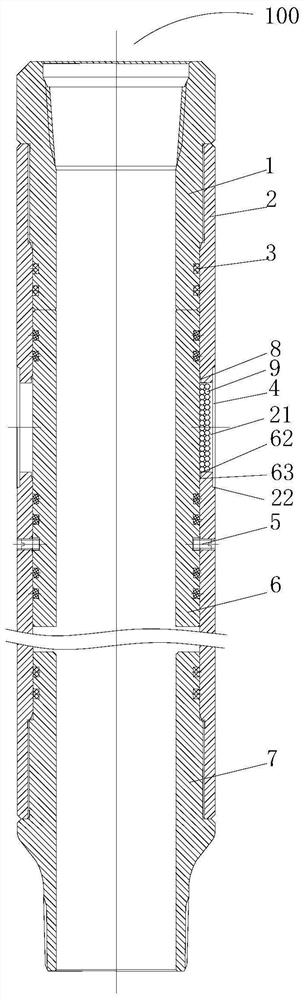

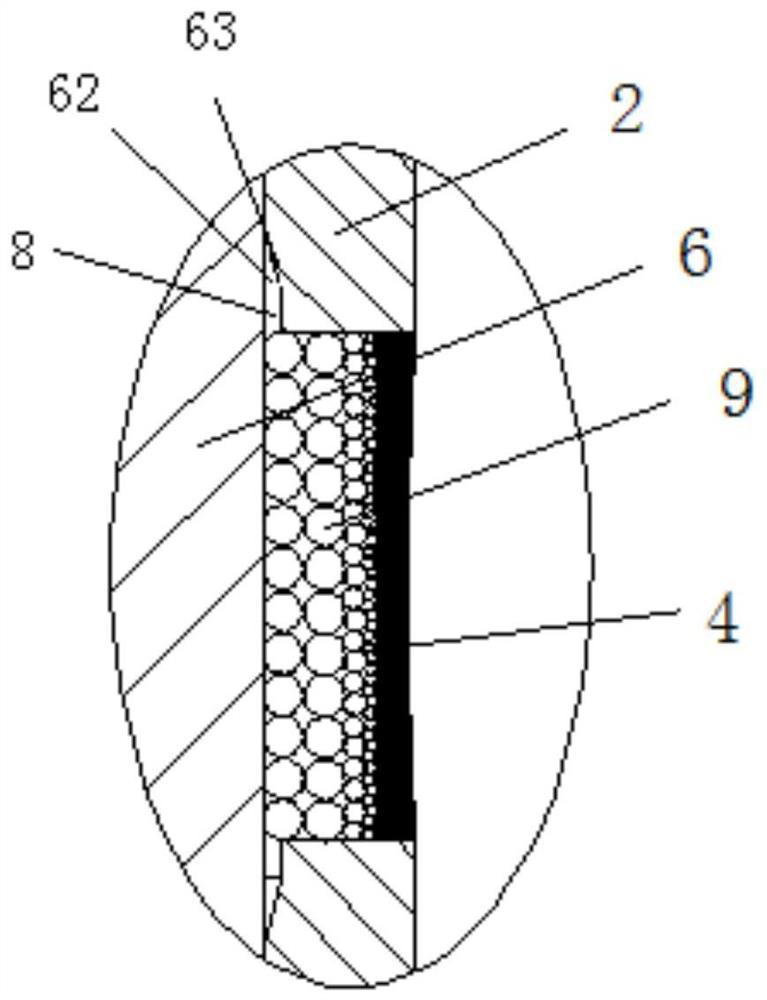

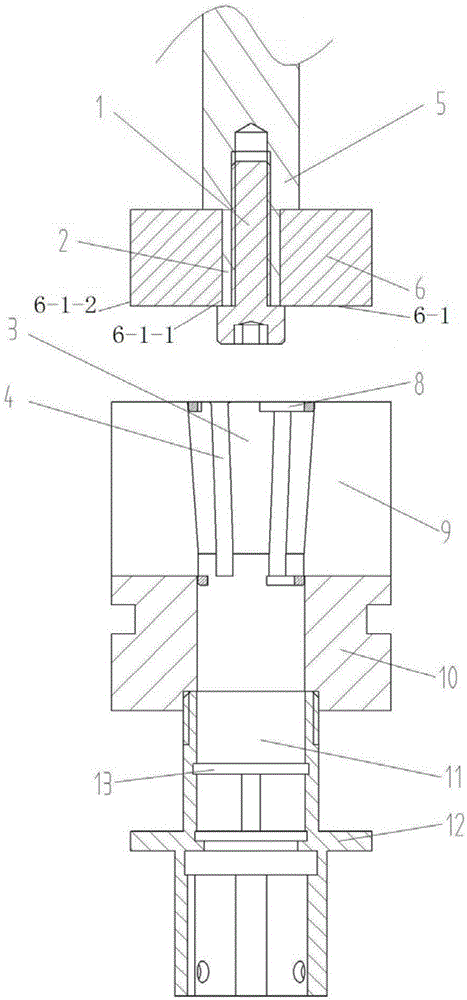

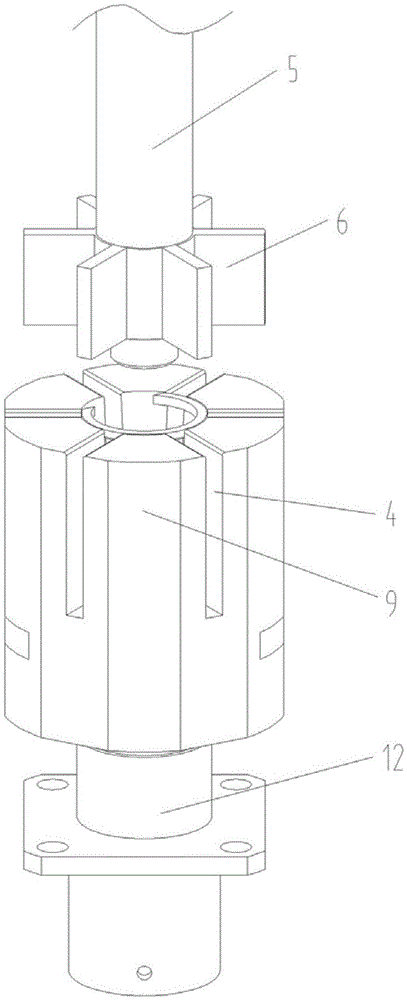

Subsea tree cap running tool

The invention discloses an underwater tree cap feeding tool. The underwater tree cap feeding tool comprises a tool body, a drive connection mechanism and a connection and separation mechanism; an overall shape of the tool body is of a cylindrical structure, and the top of the tool body in the height direction is a connecting part for being connected with a drill rod; the drive connection mechanismis installed at the middle part of the tool body in the height direction in a sleeving mode, the drive connection mechanism is used for driving an actuation ring of an underwater tree cap, so that the underwater tree cap is connected with an underwater horizontal type Christmas tree in a locked mode; the drive connection mechanism includes an actuating piston, a piston driving structure and a temporary limiting structure before driving; the connection and separation mechanism is installed at the bottom part of the tool body in the height direction in a sleeving mode, and the connection and separation mechanism is used for connecting with or separating from the underwater tree cap; and the connection and separation mechanism includes a lower baffle ring, a locking ring, a drive ring, and adriving structure for the drive ring. The underwater tree cap feeding tool has the advantages of simple structure, reliable performance and convenient use, and is suitable for being popularized and used.

Owner:CHONGQING QIANWEI SCI & TECH GRP

Automatic pipe cutting machine

ActiveCN102784959BMove down smoothlyBalance downTube shearing machinesShearing machine accessoriesStructural engineeringMachine

The invention discloses an automatic pipe cutting machine, belonging to the technical field of pipe cutting equipment and mainly solving the problem that the existing pipe cutting machine is not suitable for cutting square pipes. The automatic pipe cutting machine is mainly characterized by comprising a material storing and distributing frame, a material taking mechanism, a material feeding track, a material pulling system, a cutting system and a cut material blanking system, wherein a bearing is installed on the inclined track; the outside diameter of the bearing is higher than the surface of the inclined track; the material taking mechanism is an automatic material taking mechanism which is composed of a power source, a mounting base, an L-shaped plate, a material retention locating rod and an inclined panel; the power source is fixed on the mounting base; the L-shaped plate is fixed on a stretched rod of the power source; an upper folded adjusting plate of the L-shaped plate is provided with a horizontal adjusting groove; and the material retention locating rod and the inclined panel are fixed on the horizontal adjusting groove of the upper folded adjusting plate. The automatic pipe cutting machine disclosed by the invention is capable of discharging a material to an automatic material taking position smoothly and evenly, is aligned with the center of a material inlet track and a cutting center, can adapt to cutting characteristics of rectangular pipes in different specifications, and is mainly suitable for automatic cutting of rectangular pipes.

Owner:SHENZHEN QIHONGFU TECH

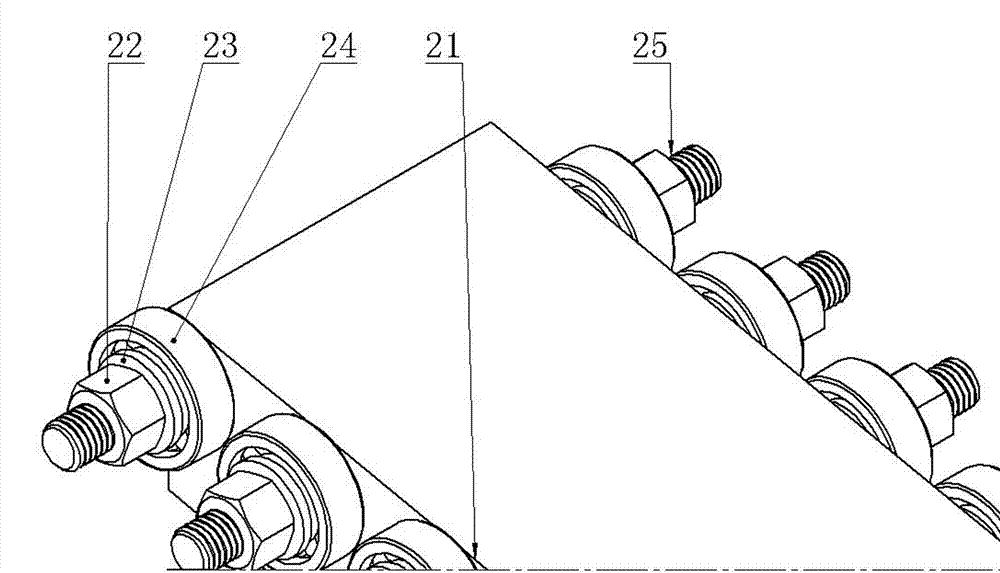

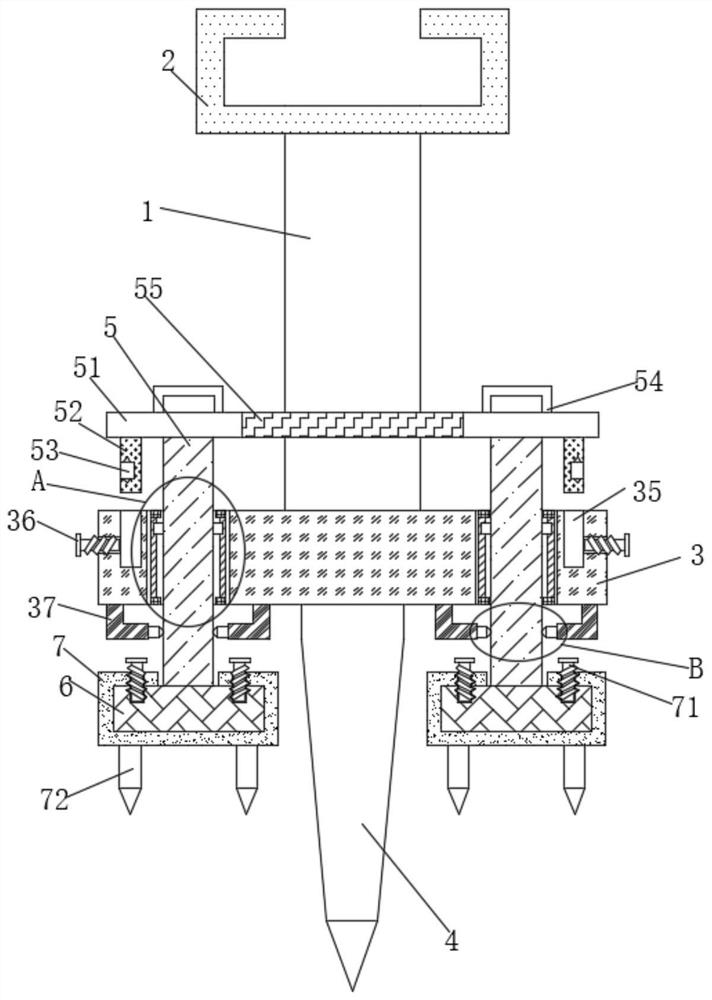

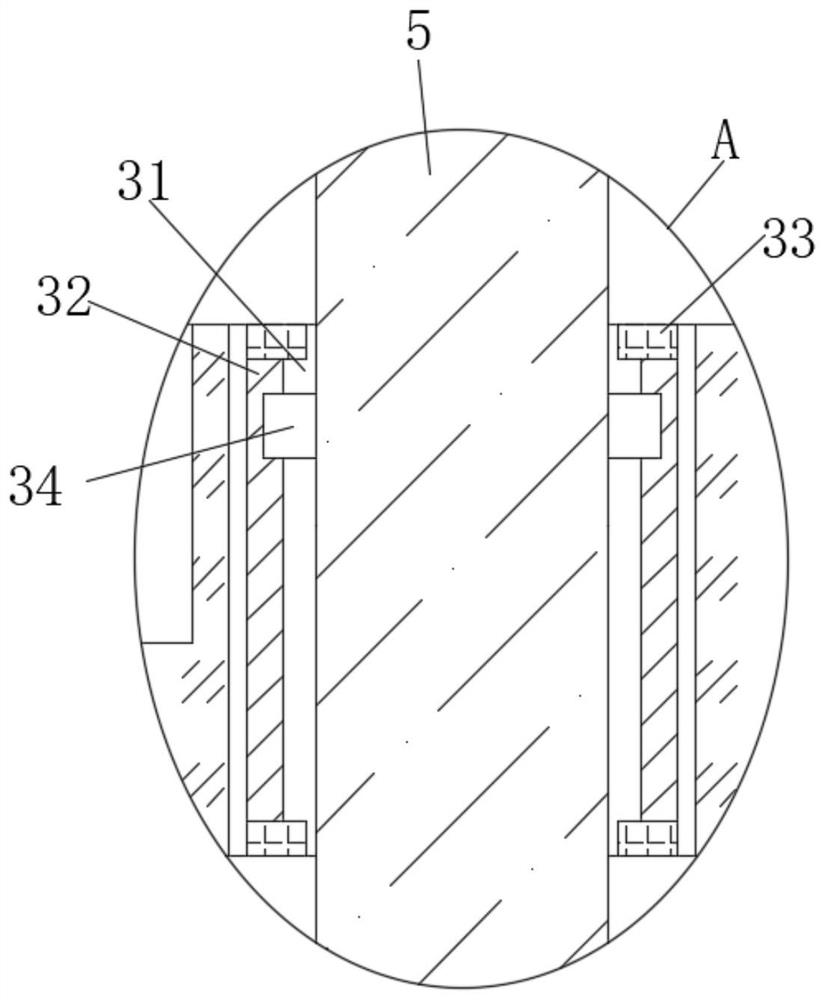

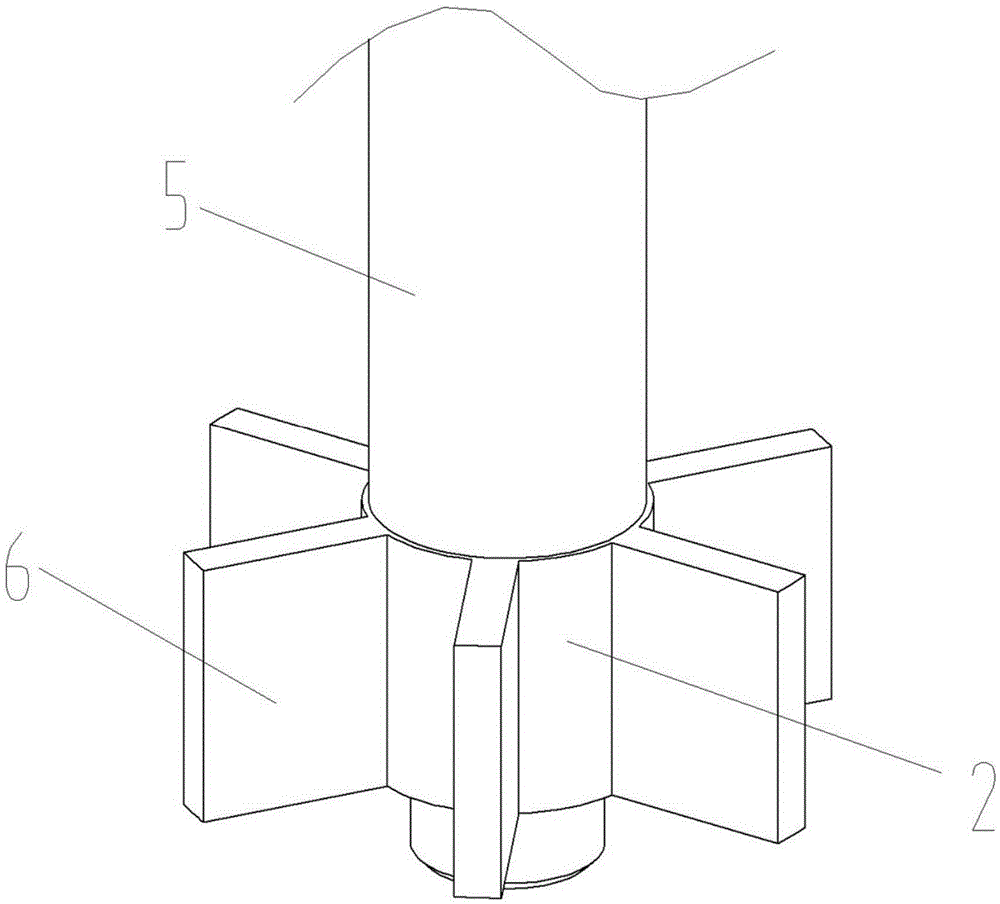

Convenient and rapid supporting pile for steel plate group laying

InactiveCN112982378APrevent left and right tiltMove down smoothlyBulkheads/pilesFour-slideSteel plates

The invention relates to the technical field of supporting piles, in particular to a convenient and rapid supporting pile for steel plate group laying. The pile comprises a supporting column, a supporting disc is fixedly mounted at the top end of the supporting column, a bottom plate is fixedly mounted at the bottom end of the supporting column, a positioning column is fixedly mounted at the position, close to the middle, of the bottom end of the bottom plate, and movable grooves are formed in the positions, close to the two sides, in the bottom plate; sliding rails are fixedly mounted on the inner walls of the two sides of the two movable grooves, limiting blocks are fixedly mounted at the two ends of the four sliding rails, sliding blocks are slidably connected to the outer surfaces of the four sliding rails, the outer surfaces of one sides of the four sliding blocks are fixed to the outer surfaces of the corresponding sides of corresponding movable rods, fixing grooves are formed in the positions, close to the two sides, of the top end of the bottom plate, and fixing bolts are movably connected to the two sides of the bottom plate through threads. By arranging four positioning rods, on one hand, the ground can be further positioned and fixed, on the other hand, the bottom plate and the supporting column can be supported from left and right, and thus left-right inclination of the bottom plate and the supporting column can be prevented to a certain extent.

Owner:郎斌斌

Adjustable mechanical equipment maintenance platform

InactiveCN109702696AEasy to useThe lifting process is stableWork benchesOther workshop equipmentPhysical strengthEngineering

The invention discloses an adjustable mechanical equipment maintenance platform. The adjustable mechanical equipment maintenance platform comprises a base, a worktable, a first auxiliary plate and a second auxiliary plate; a tool box is arranged on the left side of the upper end of the base; a connecting plate is placed in the tool box; a vertical plate is arranged on the right side of the tool box and positioned on the base; a first chute is formed in the right side of the vertical plate; a first slide block is slidingly connected into the first chute; a first slide rail and a second slide rail are arranged at the lower end of the worktable in sequence from inside to outside; multiple sets of first hydraulic cylinders are arranged at the upper end of a flat plate; the upper ends of the first hydraulic cylinders are connected into the first slide rail through bearings; two sets of extension rods are arranged on two sides of the upper end of the base; and the shifting-up or the shifting-down of mechanical equipment from the worktable can be easily finished without needing manual hoisting of the mechanical equipment, so that the physical strength is saved, the maintenance use is convenient, and the defects of need of manual hoisting of the mechanical equipment in a traditional equipment maintenance platform is solved.

Owner:淮北雷德机电科技有限公司

Crimping connector and manufacturing method thereof

ActiveCN110061378AExtended service lifeBending steps are simpleContact member manufacturingCoupling contact membersEngineeringMechanical engineering

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

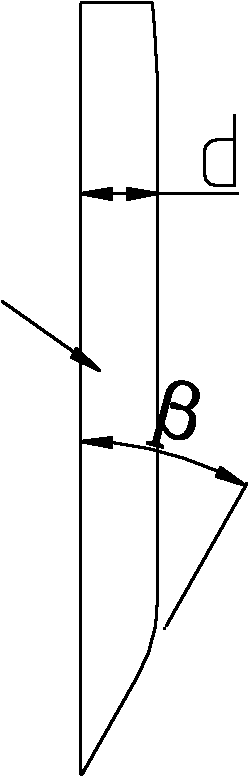

Method for preparing finger spindle compact spinning knitted flannel

ActiveCN102797078AIncrease productivityReduce consumptionDrafting machinesContinuous wound-up machinesDyeingYarn

The invention discloses a method for preparing finger spindle compact spinning knitted flannel. The method comprises the following steps of: dyeing fibers, mixing and opening the fibers, carding machine, gilling in two passes, combing machine, gilling in two passes, drawing, roving, finger spindle compact spinning fine complexing, two-for-one twisting and forming finished knitted flannel, wherein 1) a negative pressure device is additionally arranged at a front roller outlet, so that the fibers can move according to a specified motion track, and short fibers which influence smoothness of resultant yarns are adsorbed; and 2) the spinning spindle used in the process of twisting the fibers out of the front roller is a spindle with a spindle end finger, wherein the spindle comprises a spindle body, and is characterized in that the spindle end finger is arranged at the tail end of the spindle, and the other end of the spindle end finger is connected with a yarn guide hook. According to the technical scheme, due to the combination, the twist required by tight yarns with the specified smoothness is reduced, the production efficiency is correspondingly improved by 10 to 30 percent, the consumption is synchronously reduced, and the yarn breakage is reduced by 50 percent.

Owner:JIANGSU REGAL LEYE TECHNOLOGY CO.,LTD.

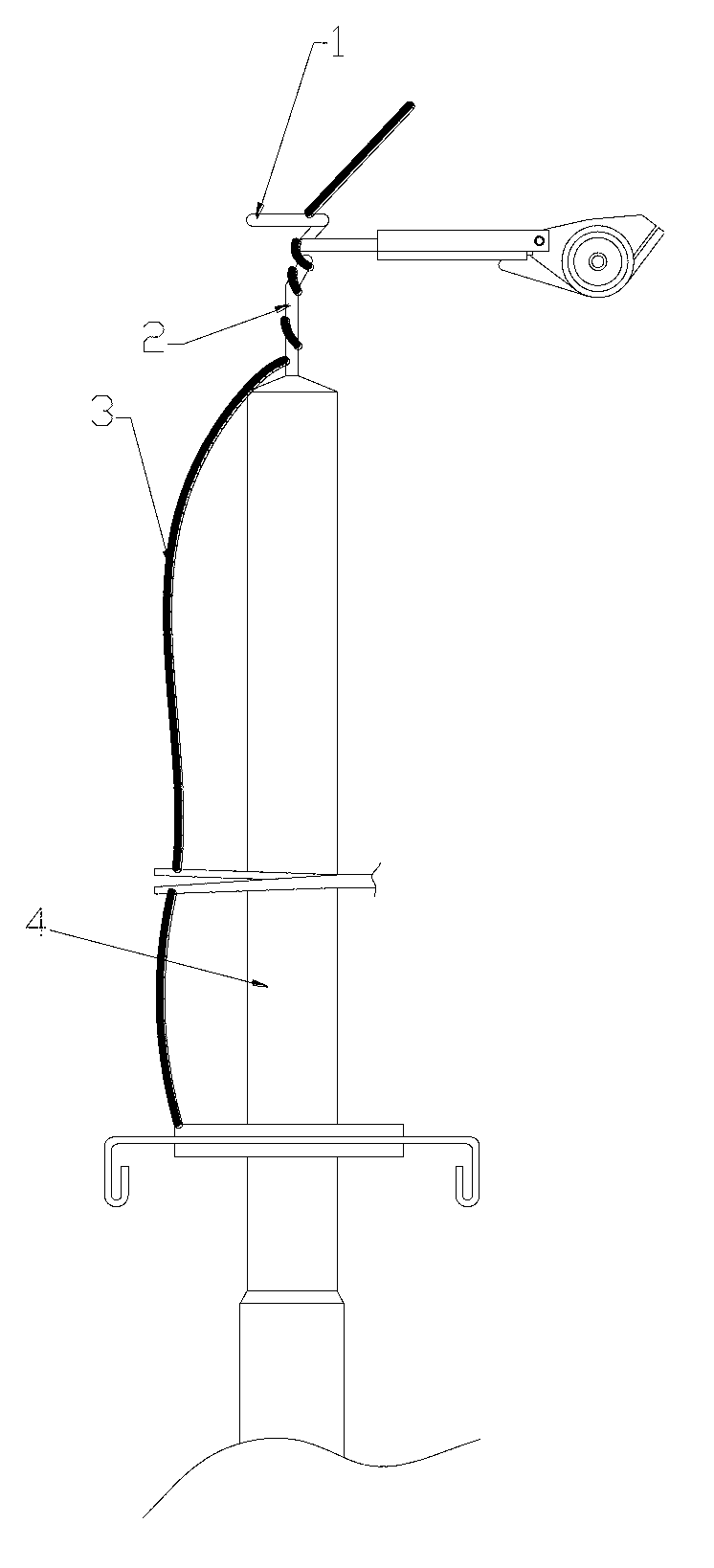

Clinical angiograpnic injection device for cardiovascular medicine department and injection method thereof

PendingCN113975543AMove down smoothlyAchieve a fixed effectAutomatic syringesIntravenous devicesBiomedical engineeringInjections methods

The invention discloses a clinical angiograpnic injection device for a cardiovascular medicine department, the clinical angiograpnic injection device for the cardiovascular medicine department comprises a bottom cavity and a connecting rod fixedly connected to the bottom cavity, wherein the top end of the connecting rod is fixedly connected with a displayer through a cross rod; and a walking part, wherein the walking part comprises a mounting cavity, a supporting rod and walking wheels; circular rings are arranged on the outer surface of the bottom cavity in an annular array mode, the multiple supporting rods are slidably connected into the circular rings respectively, the mounting cavity is fixedly connected to the lower ends of the supporting rods, the walking wheels are rotationally connected into the mounting cavity, and the walking part is used for moving the angiograpnic injection device. When a push rod and a sealing plug fixed to the push rod move downwards, liquid located on the lower side of the sealing plug flows upwards through the through hole in the sealing plug, so that the downward movement of the push rod is buffered, and the piston rod can stably and smoothly move downwards for injection.

Owner:李庆勇

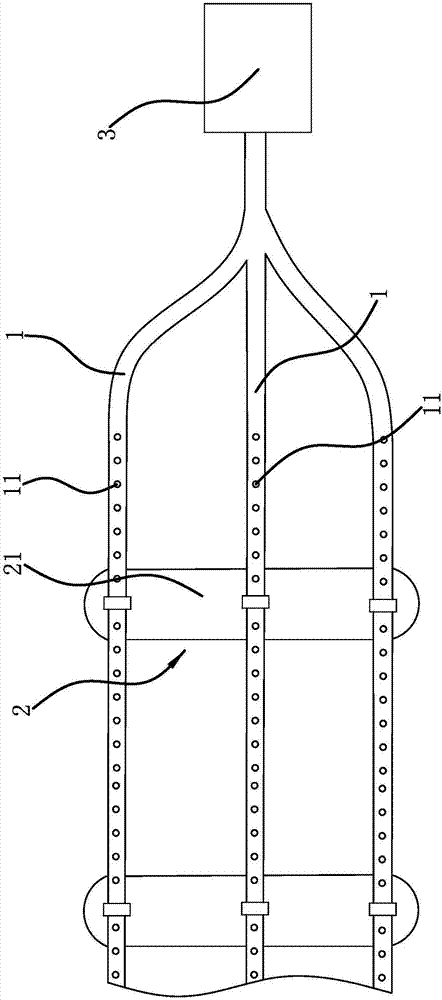

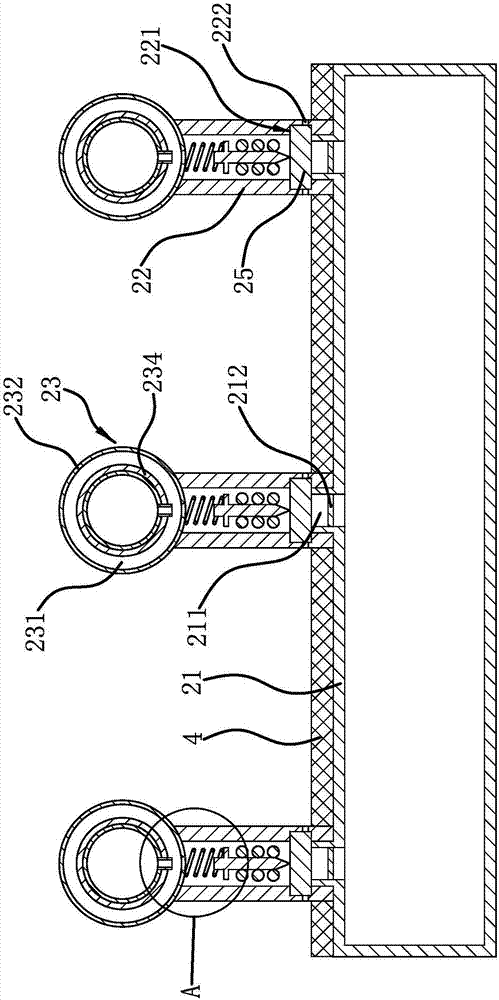

A minimally invasive laparoscopic retractor

InactiveCN110179508BAvoid secondary damagePrevent closureEnemata/irrigatorsSurgeryApparatus instrumentsSubcutaneous tissue

The invention belongs to the technical field of medical appliances, and specifically discloses a minimally invasive laparoscopic retractor. The minimally invasive laparoscopic retractor comprises a sleeve ring, a conductor, a support tube and a movable tube; the conductor is composed of a plurality of conduction rods and a conduction ring; the support tube is composed of a plurality of support rods and a support ring; the lower end of each of the support rods is fixedly connected with a rubber block; a cavity is formed inside each of the rubber blocks; two arcuate elastic pieces are fixedly connected with the interior of each of the cavity; third grooves, which are in one-to-one correspondence with sliding rods, are formed on a surface of the movable tube; second guide grooves communicatethrough the third grooves; ejector cores are connected with the interior of the third grooves in a sliding way; and the ejector cores are fixedly connected to the inner walls of the second guide grooves by evenly distributed springs. The minimally invasive laparoscopic retractor is capable of avoiding influence on surgery by effectively preventing closure of an opening during operation, thereby reducing the probability of secondary injury to subcutaneous tissue caused by medical instruments during the operation; moreover, the minimally invasive laparoscopic retractor is also capable of allowing more quickly and conveniently cleaning of a patient's wound with physiological saline.

Owner:THE SECOND HOSPITAL OF HEBEI MEDICAL UNIV

Crimp connector and method of making the same

ActiveCN110061378BExtended service lifeBending steps are simpleContact member manufacturingCoupling contact membersEngineeringMechanical engineering

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

A measuring device for road and bridge construction

ActiveCN111561854BSmooth rotationEasy to cutMechanical diameter measurementsMechanical thickness measurementsDrive wheelArchitectural engineering

A measuring device for road and bridge construction, comprising L-shaped left side panels and right side panels placed symmetrically from left to right, the left side panels and right side panels are fixedly connected by the top panel and the rear panel; the left side of the right panel is set There is a push plate that can move left and right, a drive wheel is set on the left side of the push plate, a pull plate that can move back and forth is set on the top and back of the push plate, a reset plate is set on the left side of the back side of the pull plate, and a drive wheel is set on the front side of the reset plate that can rotate left and right. The reset wheel; the left and right positions of the top plate corresponding to the limit groove are provided with an initial block and a measuring plate that can move back and forth in sequence, an initial plate is set at the bottom of the initial block, and a lifting rod that can move up and down is set in the middle of the measuring plate. A marking pen is provided at the bottom of the lifting rod. The invention effectively solves the problems of difficult and non-standard marking of pipelines existing in the current road and bridge construction.

Owner:车先锋

Fracturing nipple and fracturing string comprising fracturing nipple

PendingCN113803023AAvoid premature ruptureAvoid enteringFluid removalWell/borehole valve arrangementsThermodynamicsEngineering

The invention provides a fracturing nipple and a fracturing string comprising the fracturing nipple. The fracturing nipple comprises an outer barrel, an inner sliding sleeve, a fracturing sleeve, and a supporting body; a fracturing hole capable of communicating the inside and the outside is formed in the wall of the outer barrel; the inner sliding sleeve is arranged in the inner cavity of the outer barrel and can close the fracturing hole; the inner sliding sleeve can move relative to the outer barrel so as to release the closing of the fracturing hole; the fracturing sleeve is arranged on the outer wall of the outer barrel, can block the fracturing hole and can be damaged under the action of pressure; and the fracturing hole is filled with the supporting body which is used for supporting the fracturing sleeve and can fall off under the action of pressure. According to the fracturing nipple and the fracturing string comprising the fracturing nipple, impurities in a shaft are effectively prevented from entering the inner sliding sleeve, cement paste is effectively prevented from entering the inner sliding sleeve from the fracturing hole in the well cementation and paste replacement process, and then normal and smooth opening of the inner sliding sleeve is protected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Assembly tool for elastic ring installation and its push rod and guide sleeve

InactiveCN104209919BReduce manufacturing difficultyWon't scratchMetal-working hand toolsEngineeringMechanical engineering

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Anti-scale steam boiler convenient to clean

PendingCN114001345AReduce humidityReduced scale productionBoiler cleaning apparatusPhysicsThreaded pipe

The invention discloses an anti-scale steam boiler convenient to clean and relates to the technical field of boiler equipment, the anti-scale steam boiler comprises a boiler, a threaded pipe is slidably connected to the center of the upper surface of the boiler in a penetrating mode, a first connecting pipe is fixedly connected to the lower end of the threaded pipe, and a first through hole is formed in the circumferential side face of the first connecting pipe in a penetrating mode; and the lower end of the first through hole is fixedly connected with a second connecting pipe, a first threaded groove is formed in the upper end of the inner wall of the second connecting pipe, scraping rods are fixedly connected to the front side face and the rear side face of the second connecting pipe, through grooves are formed in the side faces of the scraping rods, and second through holes are formed in the lower end of the inner wall of the second connecting pipe and the inner walls, close to the second connecting pipe, of the through grooves in a penetrating mode. The technical problems that an industrial boiler is generally large in size, the interior of a boiler shell cavity is deep, a long tool needs to be used when a filtering device is taken out, meanwhile, the problem that scale falls into a boiler shell due to the fact that the filtering device inclines laterally when the filtering device is taken out is solved, the operation of taking out the scale is tedious, errors are prone to occurring, labor is consumed, and the efficiency is low are solved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

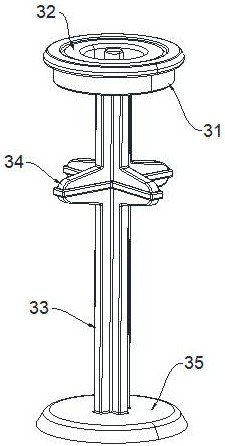

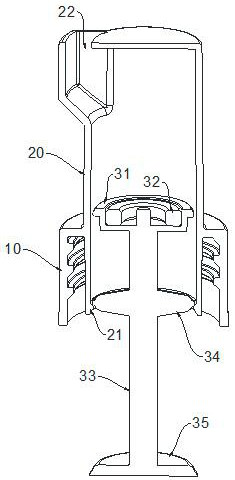

Automatic quantitative liquid outlet cover and using method thereof

The invention discloses an automatic quantitative liquid outlet cap and a using method thereof.The automatic quantitative liquid outlet cap is a bottle cap, the bottle cap is installed on a bottle opening of a bottle, liquid in the bottle can be poured out without taking down the bottle cap from the bottle opening, the liquid in the bottle can be prevented from being poured out at a time, and the bottle cap is convenient to use. And the amount of liquid poured out each time can be almost the same, so that quantitative liquid discharging can be basically realized.

Owner:TECHNIMARK PRECISION CASTING SUZHOU CO LTD

A construction method of automatic sewage interception culvert

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

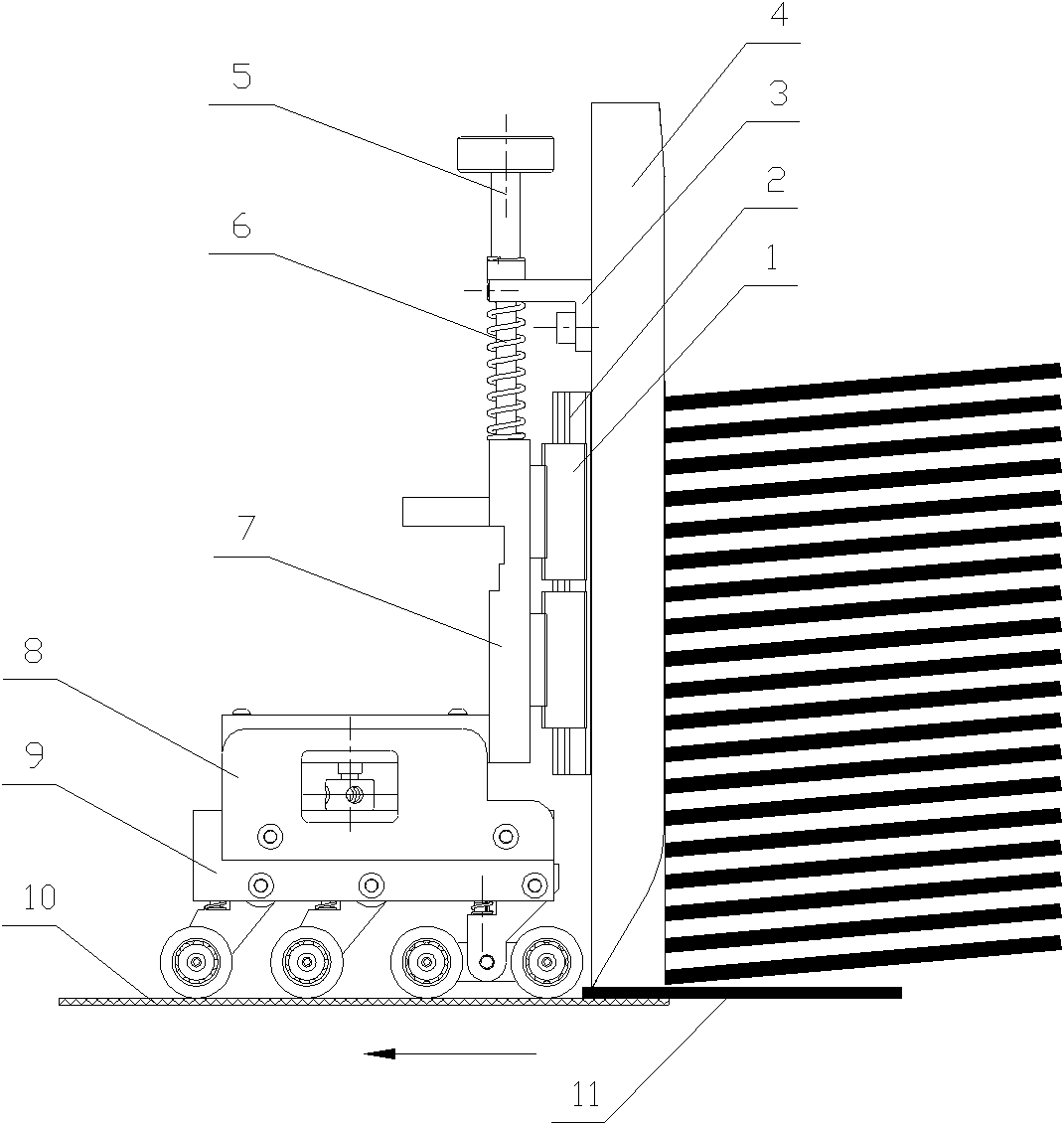

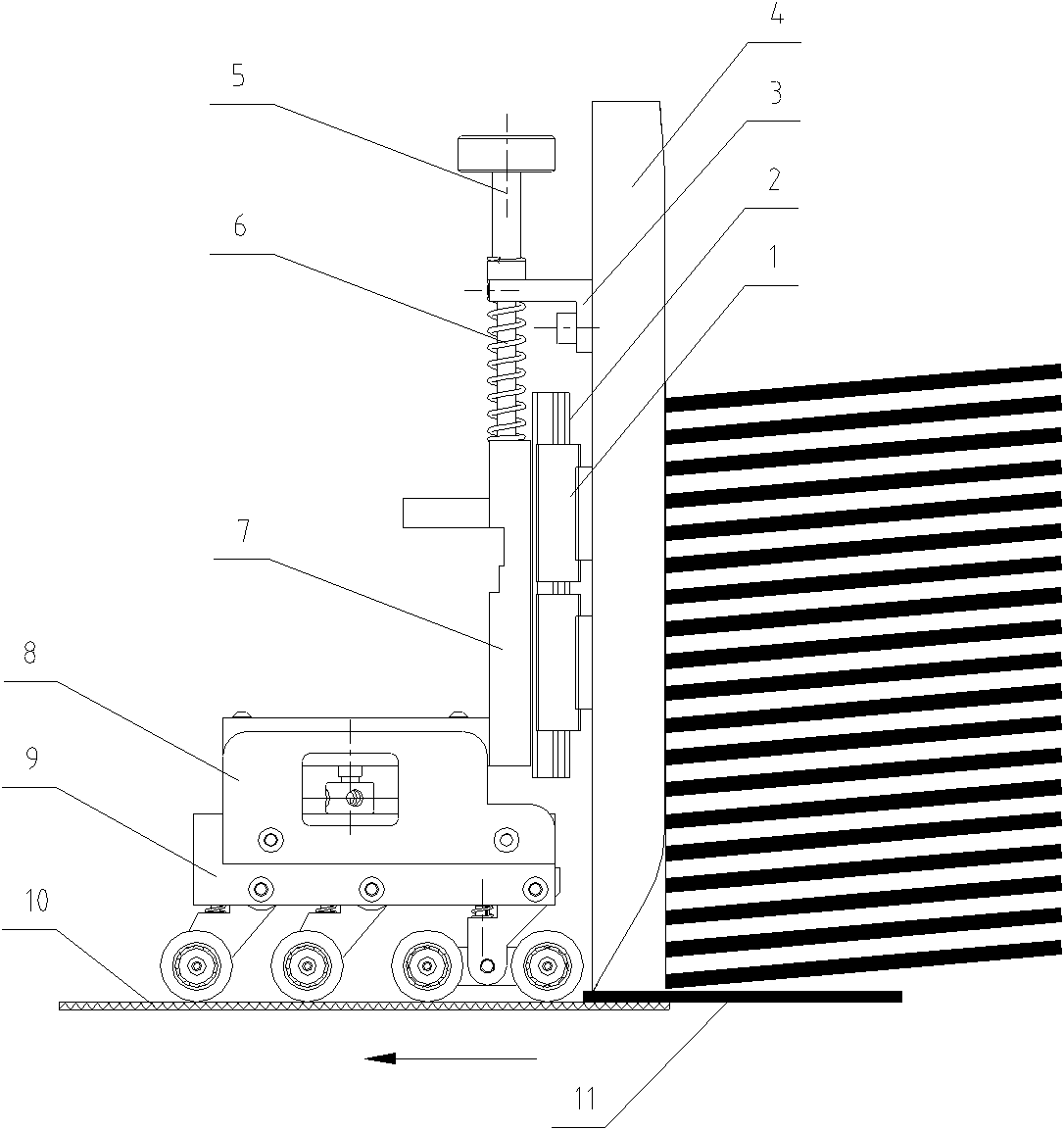

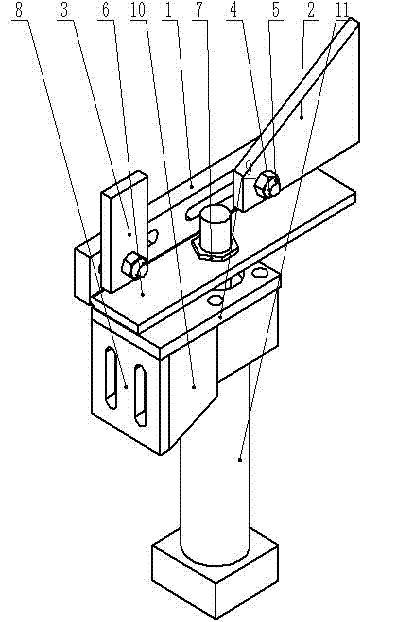

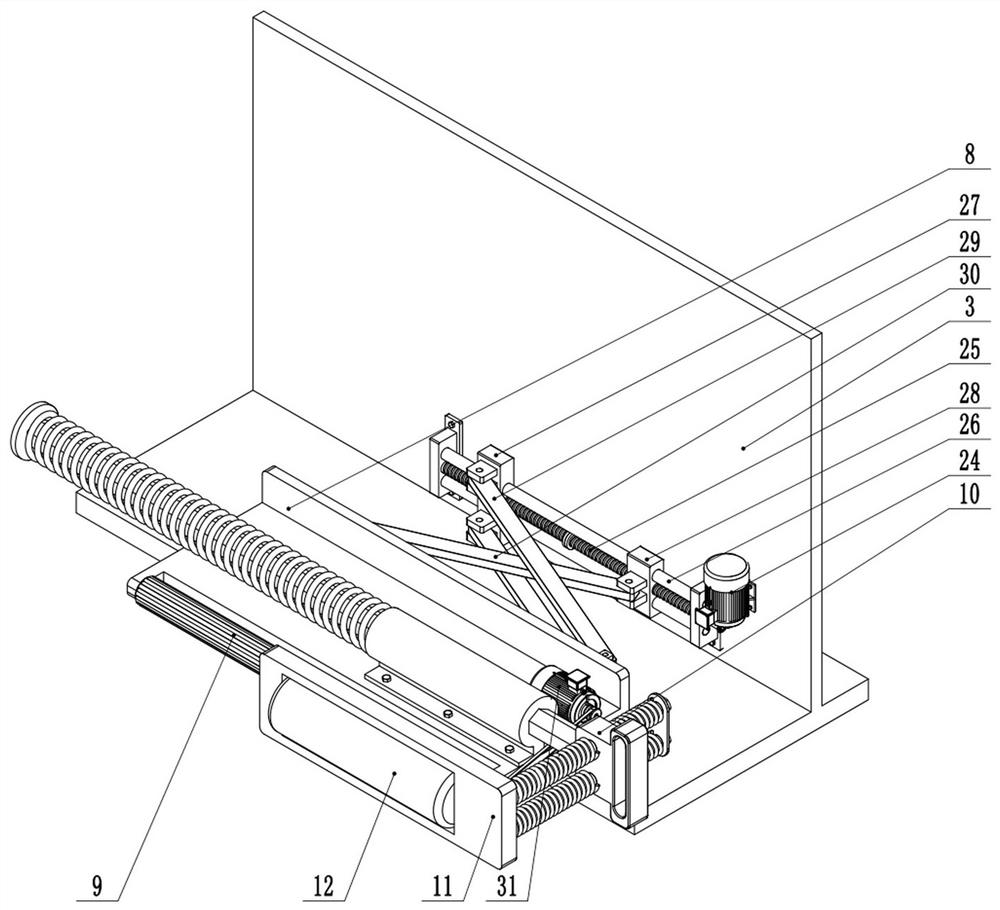

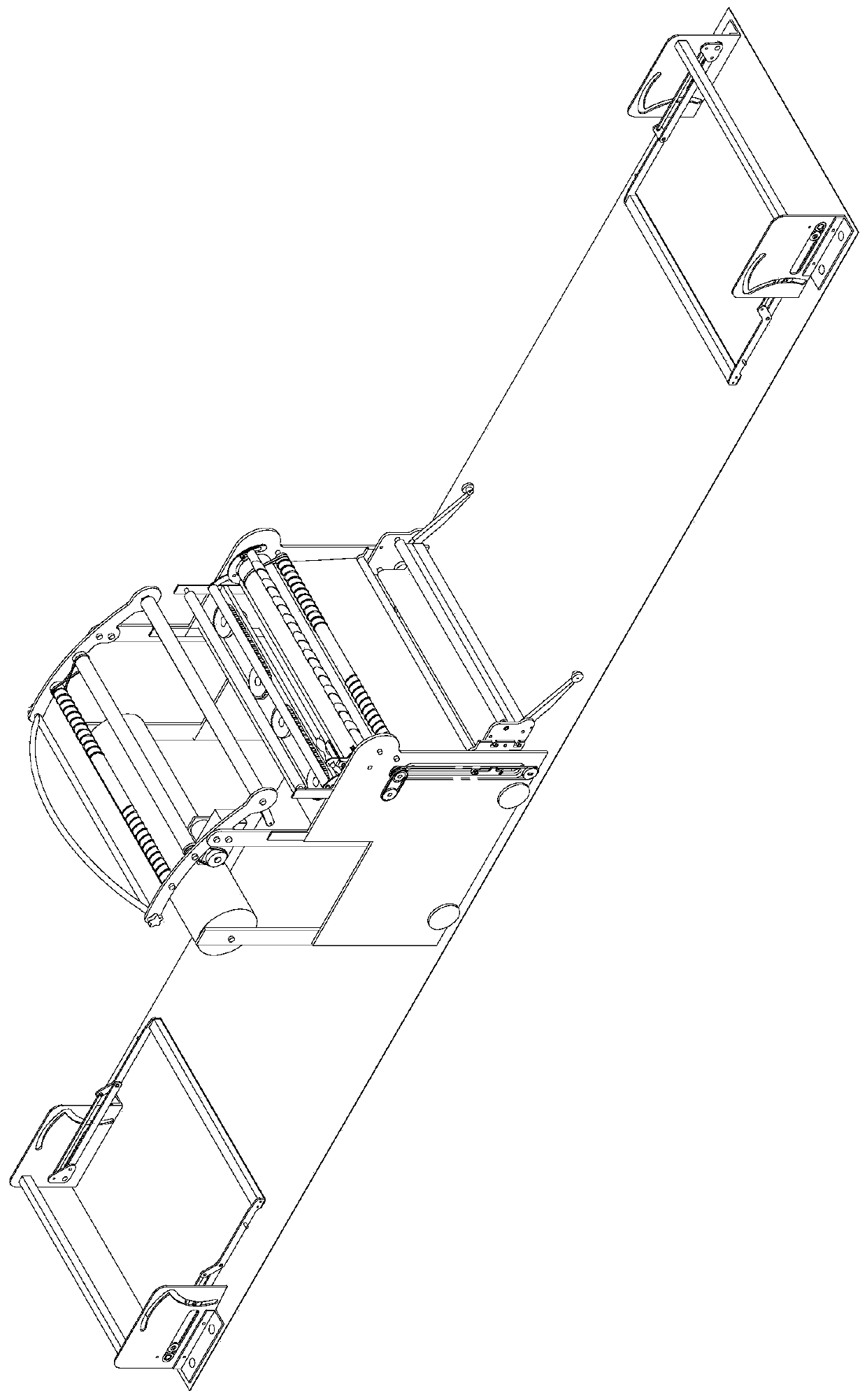

Moving device of roller, conveying mechanism and cloth paving machine

PendingCN110589541AMove down smoothlyEasy to move downUnfolding thin materialsWebs handlingEngineeringMechanical engineering

Owner:石狮市卓诚机械自动化设备有限责任公司

Crimp connector and manufacturing method thereof

ActiveCN110061372BExtended service lifeBending steps are simpleContact member manufacturingFixed connectionsEngineeringMechanical engineering

The present invention provides a crimping connector, which includes a base plate, a press plate located above the base plate, and two elastic parts that are continuously bent to connect the base plate and the press plate. One end of the two elastic parts is respectively connected to the periphery of the press plate. The other ends of the elastic parts are respectively connected to the peripheral edge of the base, and the elastic parts are elastic in the up and down direction to allow the pressure plate to move elastically in the up and down direction. The structural strength is better, so that the pressure on the pressure plate can be evenly distributed to the two elastic parts, and the two elastic parts can give the pressure plate a balanced elastic support, ensuring the smooth downward movement of the pressure plate, and also ensuring the two Longer service life of the elastic part; during manufacture, the bending step of the elastic part is simple and easy to manufacture.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com