Paper feeding device and work method thereof

A working method and paper feeding technology, which is applied in the directions of transportation and packaging, object separation, pile separation, etc., can solve the problems of unsmooth adjustment of the paper feeding knife up and down, the unqualified rate of scratched printed products, and the influence of paper knife use accuracy, etc. Achieve the effect of increasing the thickness, preventing scratches on printed products, and improving the rate of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

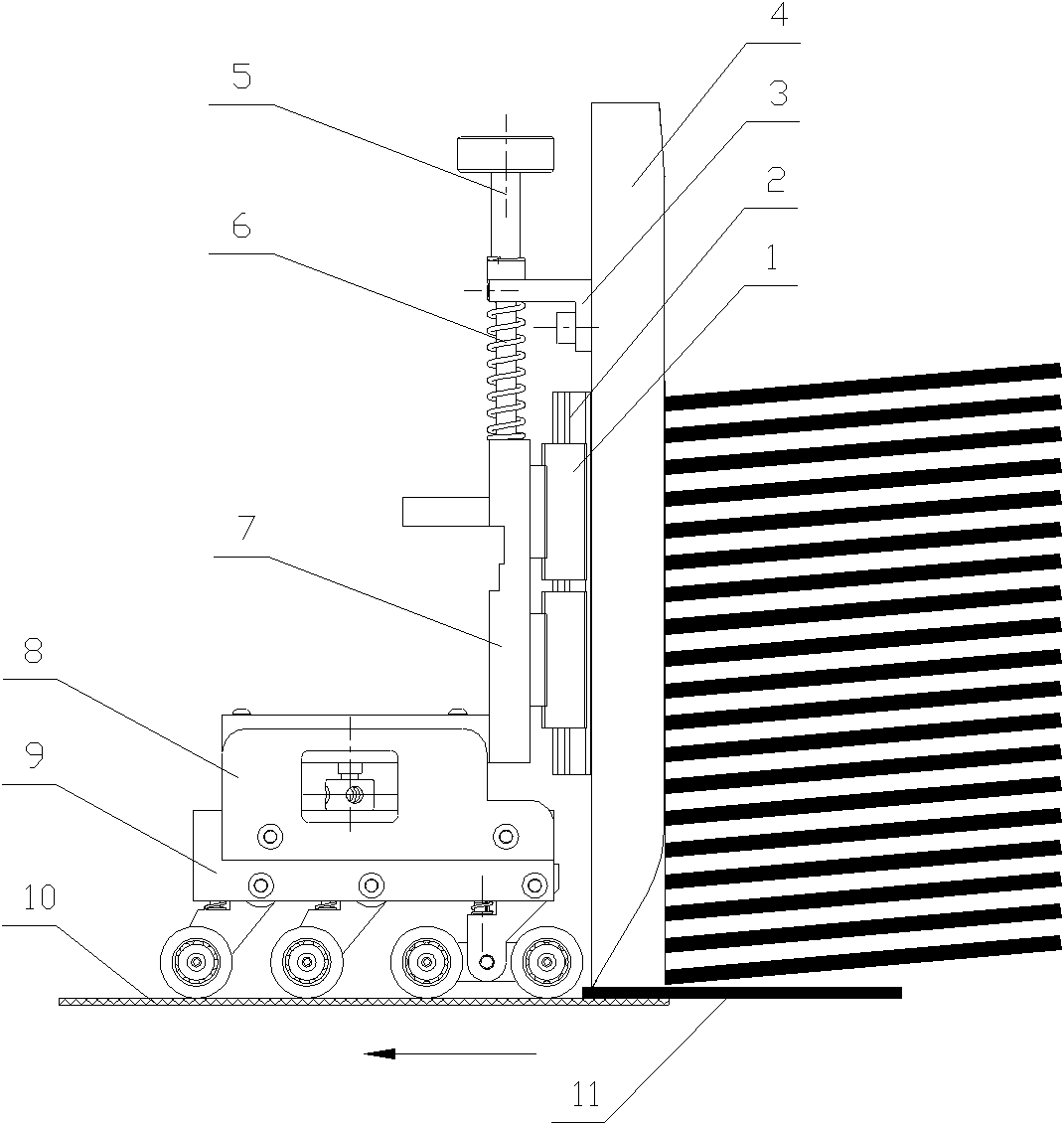

[0027] Embodiment 1: a kind of paper feeding device (see Picture 1-1 ), which is characterized in that it includes a slider 1, a linear guide rail 2, an adjustment support plate 3, a paper feed knife 4, an adjustment bolt 5, a spring 6 and an adjustment seat 7; the linear guide rail 2 is connected with the paper feed knife 4; the The slider 1 is fixedly connected with the adjustment seat 7; the slider 1 is in clearance fit with the linear guide rail 2; the adjustment bolt 5 is threaded with the upper part of the adjustment seat 7; the spring 6 is set on the adjustment bolt 5 and installed on the adjustment support plate 3 and the adjustment seat 7; the adjustment support plate 3 is fixedly connected with the paper feeding knife 4.

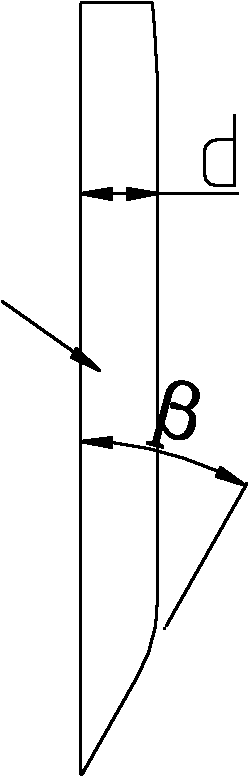

[0028] The shape of the working end surface of the paper feeding knife 4 is arc-shaped, and its arc radius RA is 500 mm; the two sides are arc-shaped, and its arc radius RB is 1 mm; the thickness d of the paper feeding knife is 30 mm; the angle of ...

Embodiment 2

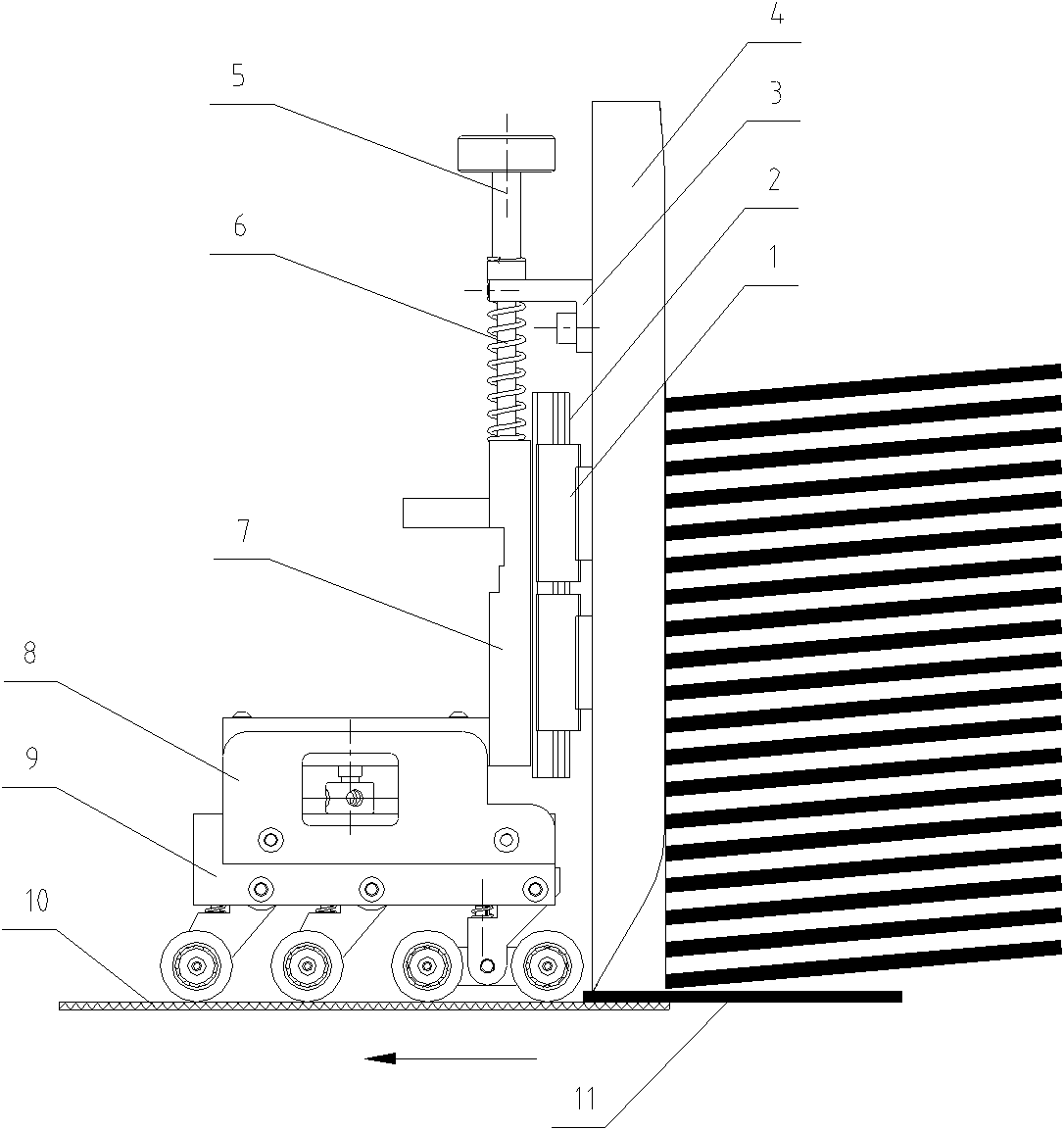

[0040] Embodiment 2: a kind of paper feeding device (see Figure 1-2 ), which is characterized in that it includes a slider 1, a linear guide rail 2, an adjustment support plate 3, a paper knife 4, an adjustment bolt 5, a spring 6 and an adjustment seat 7; the linear guide rail 2 is connected to the adjustment seat 7; the slide The block 1 is fixedly connected with the paper feeding knife 4; the slider 1 is in clearance fit with the linear guide rail 2; the adjustment bolt 5 is threaded with the upper part of the adjustment seat 7; the spring 6 is set on the adjustment bolt 5 and installed on the adjustment support plate 3 and the adjustment seat 7; the adjustment support plate 3 is fixedly connected with the paper feeding knife 4.

[0041] The shape of the working end surface of the paper feeding knife 4 is arc-shaped, and its arc radius RA is 600 mm; the two sides are arc-shaped, and its arc radius RB is 2 mm; the thickness d of the paper feeding knife is 40 mm; the angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com