Automatic quantitative liquid outlet cover and using method thereof

An automatic, liquid outlet technology used in packaging, closing, transportation and packaging, which can solve problems such as unstable bottle grip, pouring out excess liquid, and pouring out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0026] The technical scheme of the specific implementation of the present invention is as follows:

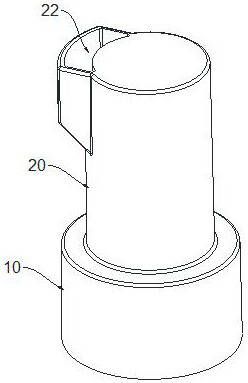

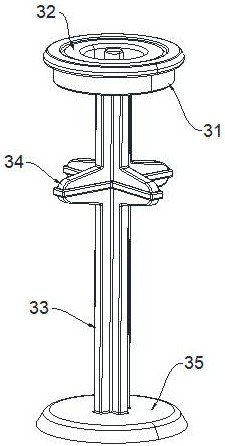

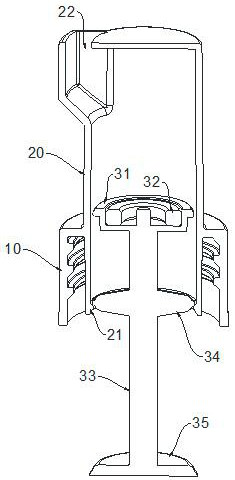

[0027] like Figure 1 to Figure 4 As shown, the present invention provides an automatic quantitative cover for liquid discharge, including a main cover body 10; a liquid pouring pipe 20 is pierced through the top wall of the main cover body 10, and the liquid pouring pipe 20 is coaxial with the main cover body 10; The two ends of the liquid pipe 20 are respectively: a first end facing the same direction as the opening of the main cover 10, and a second end facing away from the opening of the main cover 10; the first end of the liquid pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com