Automatic vending machine

A vending machine and aisle technology, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problems of small diameter and easy falling of goods, Achieve the effect of avoiding dumping and solving self-falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

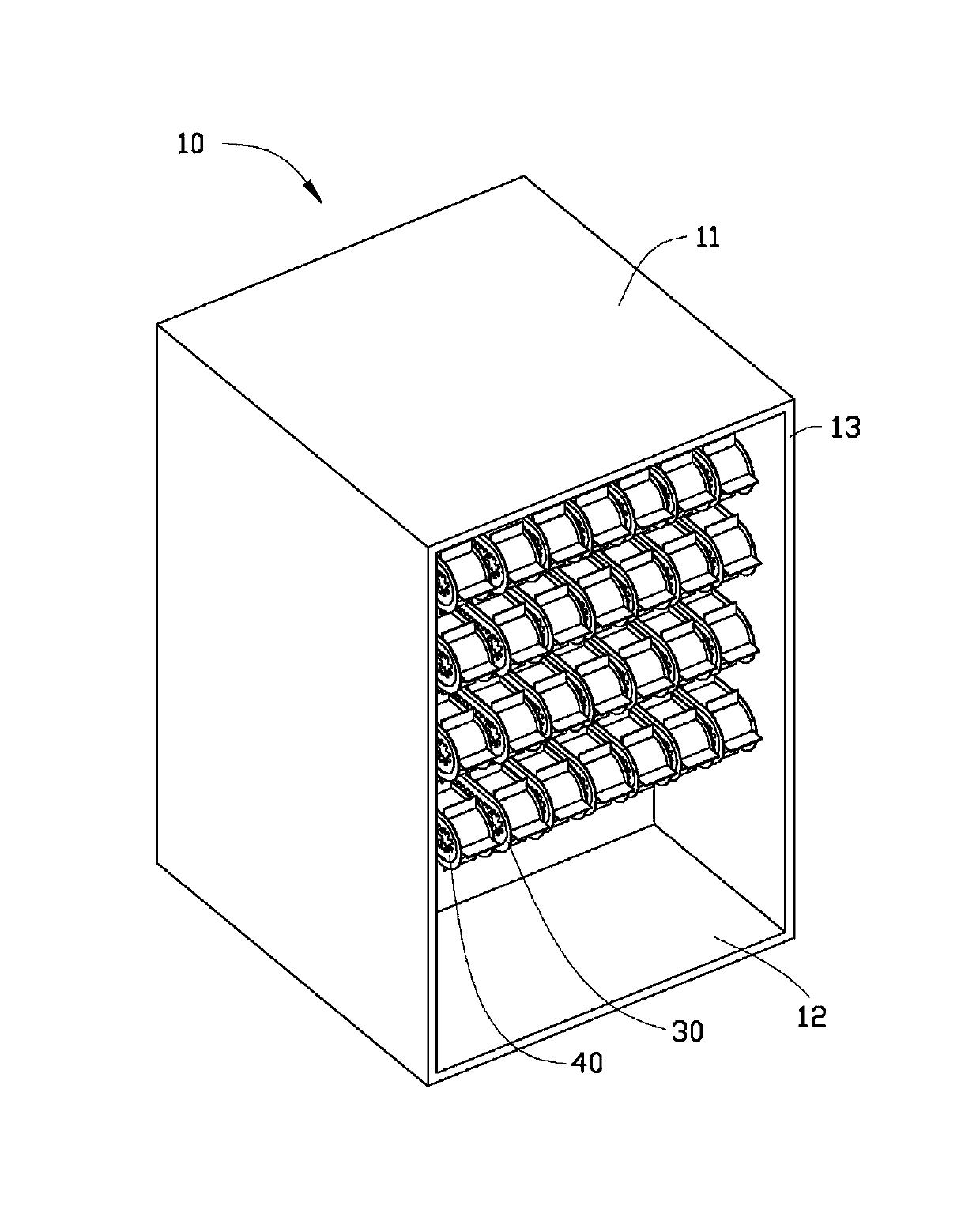

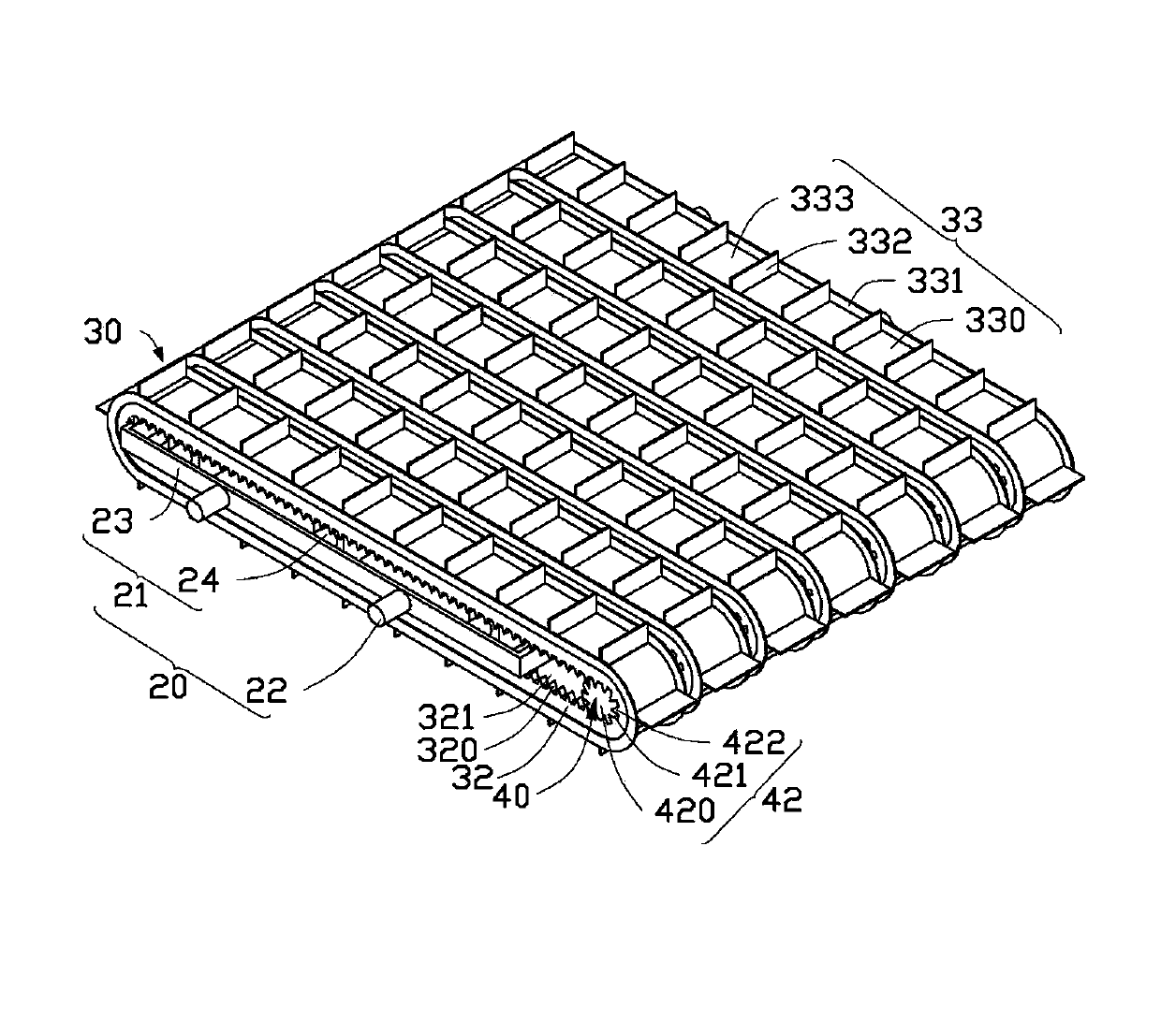

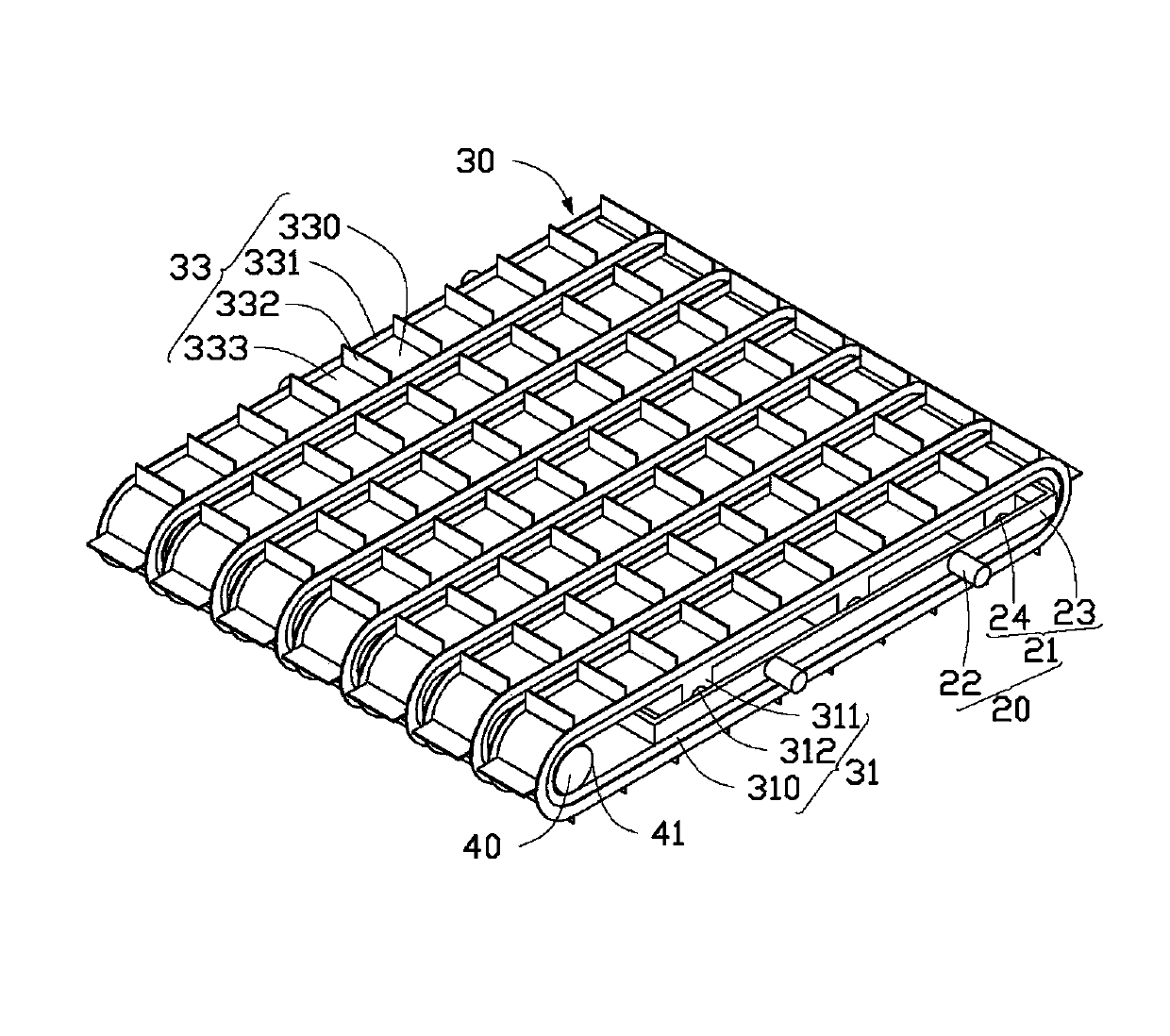

[0020] Please also see figure 1 and figure 2 , an automatic vending machine comprising a cabinet 10, a cargo aisle support 20 fixed to the cabinet 10, a conveying device 30 placed on the aisle support 20, and a driving device 40 for driving the conveying device 30 to rotate .

[0021] see figure 1 , the cabinet 10 includes a top plate 11 , a bottom plate 12 parallel to the top plate, and two side plates 13 vertically connecting the top plate 11 and the bottom plate 12 .

[0022] Please also see figure 2 and image 3 , the cargo aisle bracket 20 includes a bracket body 21 and a fixing column 22 extending from the bracket body 21 . The bracket body 21 includes four side bars 23 and three support bars 24 fixedly connected with the side bars 23 . The four side bars 23 and the three support bars 24 can increase the stability of the cargo rack 20 . The fixing column 22 corresponds to the side panel 13 of the cabinet 10 , and the fixing column 22 is fixed on the side panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com