Anti-scale steam boiler convenient to clean

A steam boiler and anti-scaling technology, which is applied in the direction of boiler cleaning equipment, etc., can solve the problems of cumbersome operation of scale, prone to errors, deep furnace shell cavity, etc., and achieve the effect of improving cleaning effect, reducing scale production, and avoiding the existence of dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

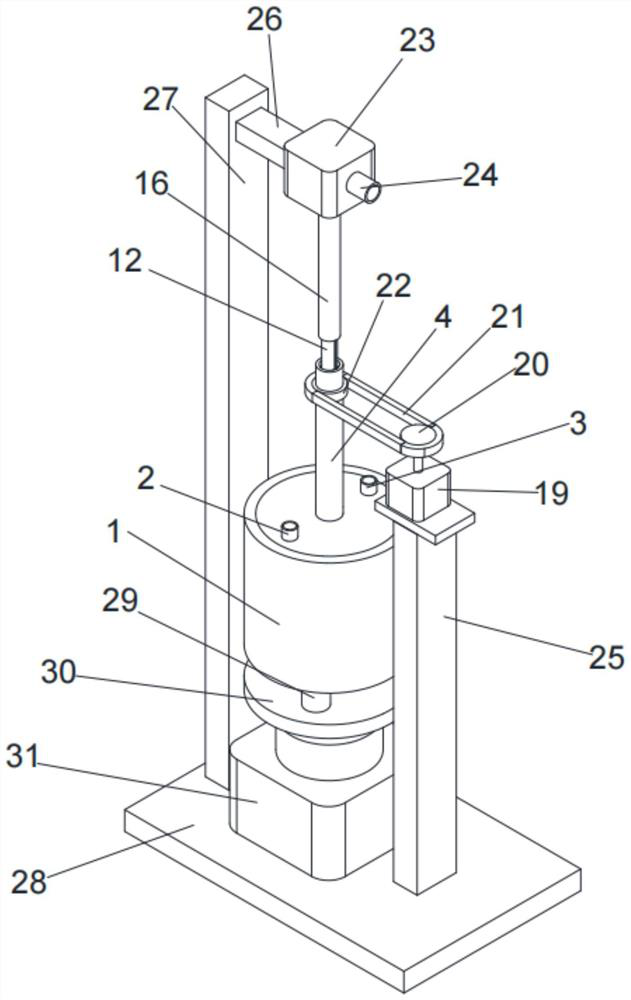

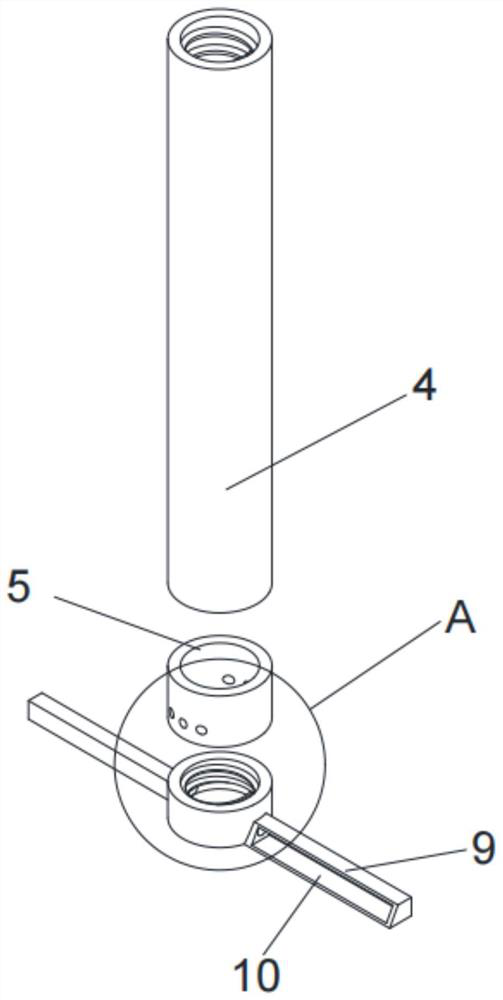

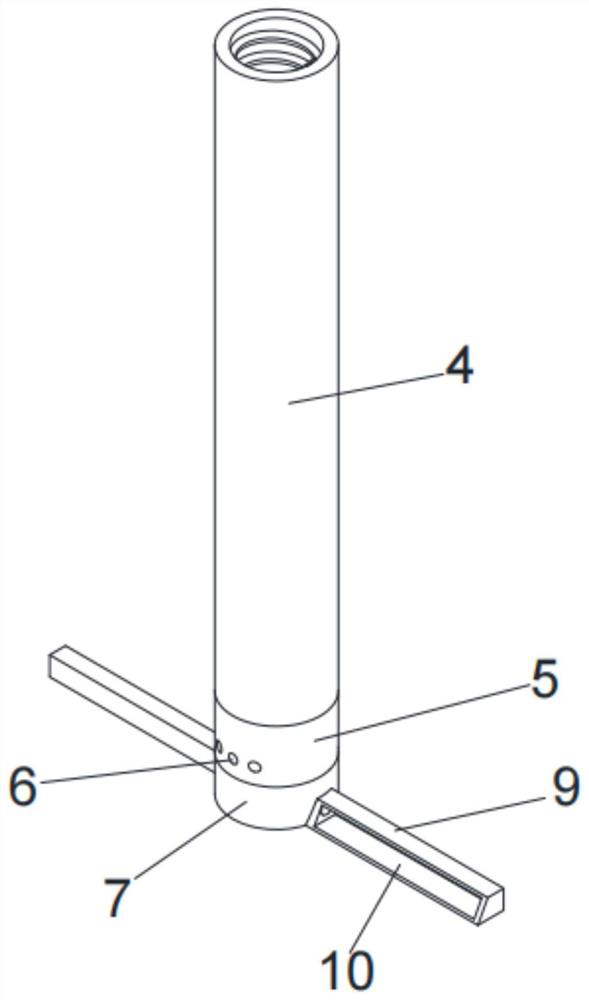

[0027] see Figure 1-Figure 6, the present invention provides a technical solution, including a boiler 1, the center of the upper surface of the boiler 1 is slidably connected with a threaded pipe 4, the lower end of the threaded pipe 4 is fixedly connected with a connecting pipe-5, and the circumferential side of the connecting pipe-5 is opened There is a through hole one 6, the lower end of the through hole one 6 is fixedly connected with a connecting pipe two 7, the upper end of the inner wall of the connecting pipe two 7 is provided with a thread groove one 8, and the front and rear sides of the connecting pipe two 7 are fixedly connected with a scraper rod 9, The side of the scraper rod 9 is provided with a through groove 10, the lower end of the inner wall of the connecting pipe 2 7 and the inner wall of the through groove 10 close to the connecting pipe 2 7 are provided with a through hole 2 11, and the inside of the threaded pipe 4 is provided with a hollow rod 1 12, T...

Embodiment 2

[0030] see figure 1 , on the basis of Embodiment 1, the present invention provides a technical solution: the lower surface of the boiler 1 is fixedly connected with a support leg 29, the lower end of the support leg 29 is fixedly connected with a support plate 30, and the upper end of the push rod of the push rod motor 31 is fixed At the center of the lower surface of the connecting support plate 30 , the lower surface of the push rod motor 31 is fixedly connected to the upper surface of the bottom plate 28 .

[0031] In this embodiment: after the bottom of the inner wall of the boiler 1 is cleaned, the height of the boiler 1 can be adjusted by the push rod motor 31, so that the scraper rod 9 stuck with the cleaning liquid can scrape the scale on the inner wall of the boiler 1 , to facilitate multi-directional cleaning, improve the cleaning effect, and avoid dead angles.

[0032] Working principle: In the initial state, the scraper rod 9 is located at the upper end of the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com