Patents

Literature

137results about How to "Avoid dead ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-conditioner

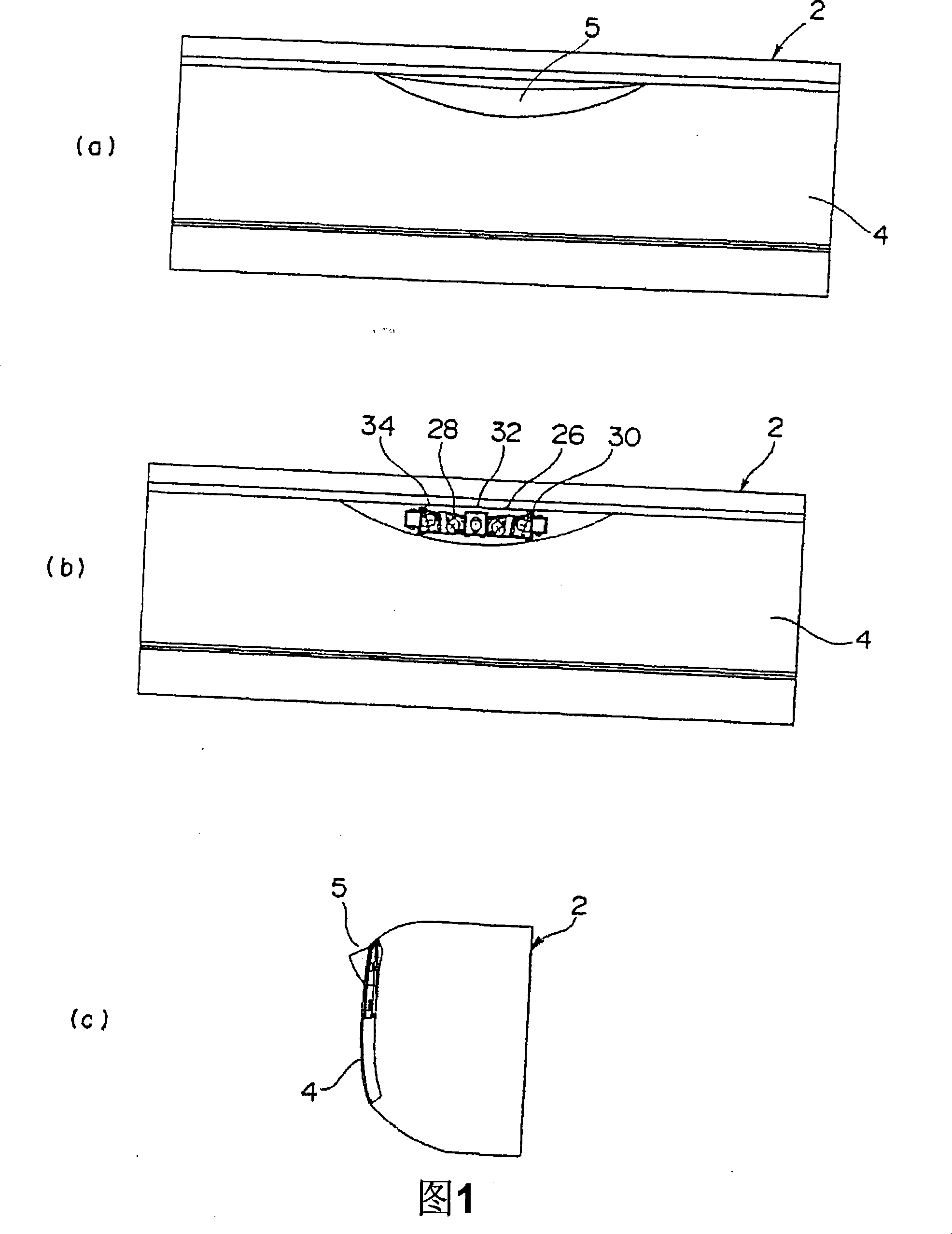

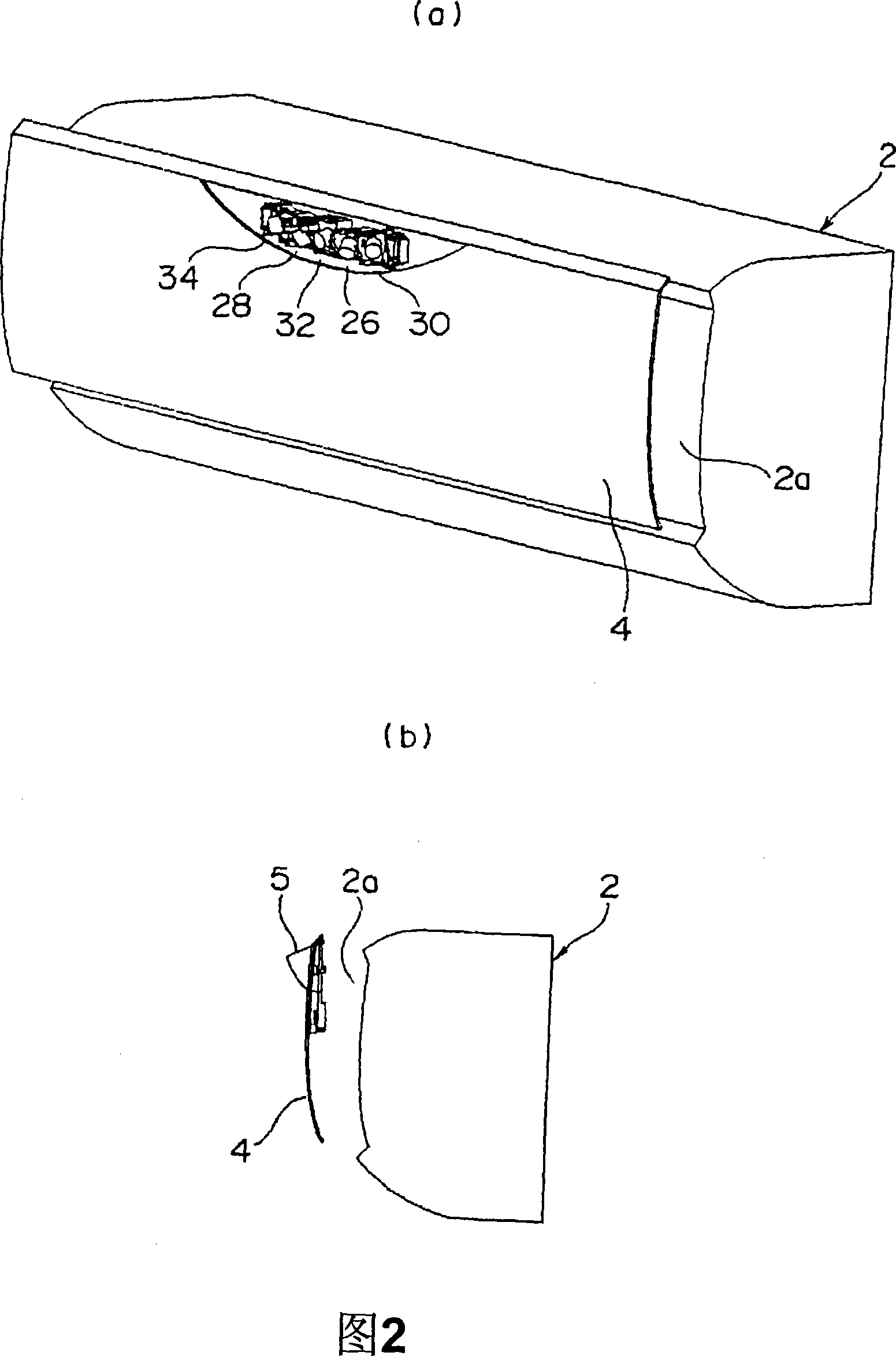

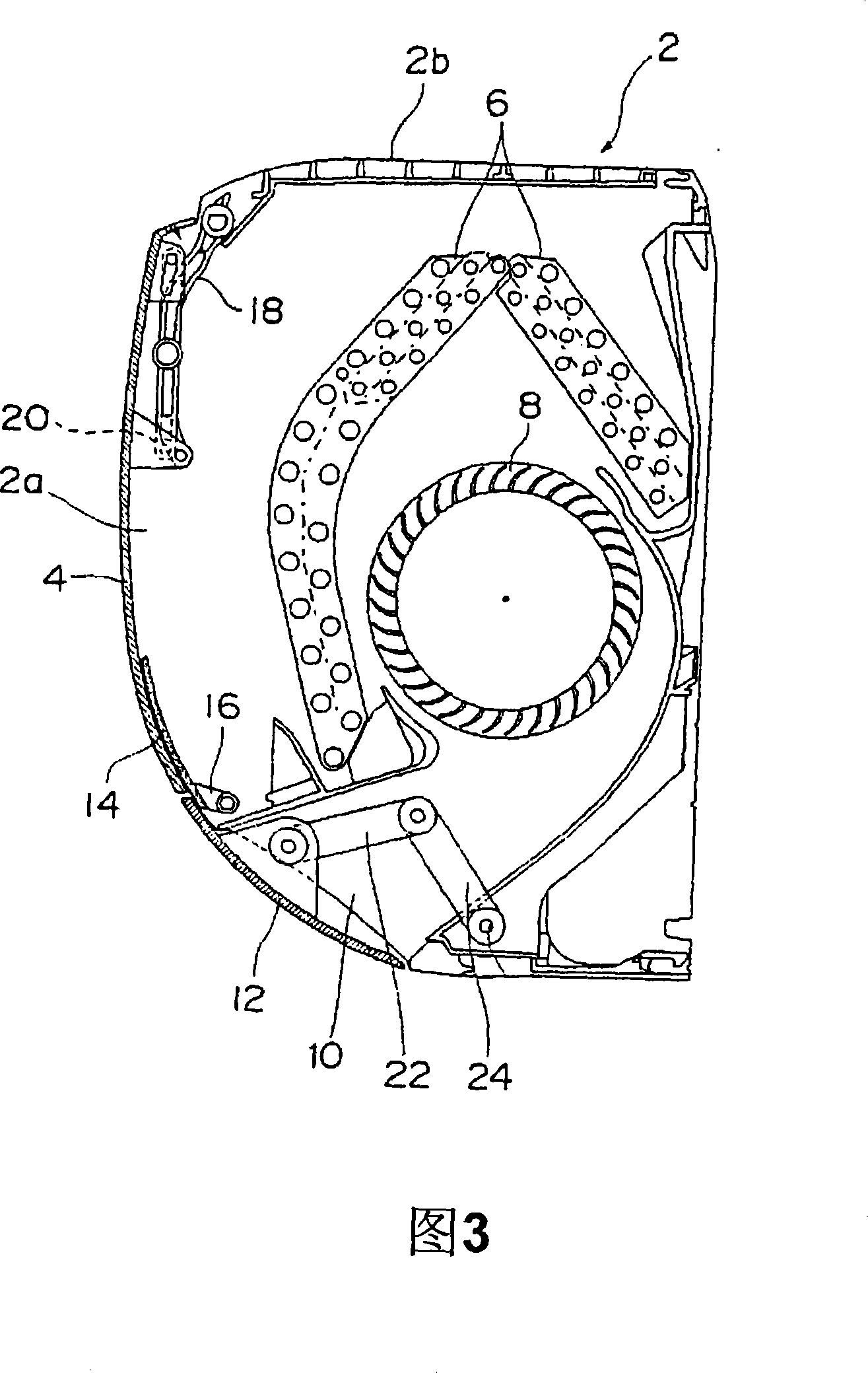

ActiveCN101165424AExpand your field of visionAvoid dead endsSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringField of view

The present invention provides an air conditioner having an indoor device for allocating the human body detecting sensor to the position with sufficient view field. At lease one human body detecting sensor (26, 28, 30, 32, 34) is installed on the upper side of the indoor device for insuring if a person is detecting to control the running of the air conditioner.

Owner:PANASONIC CORP

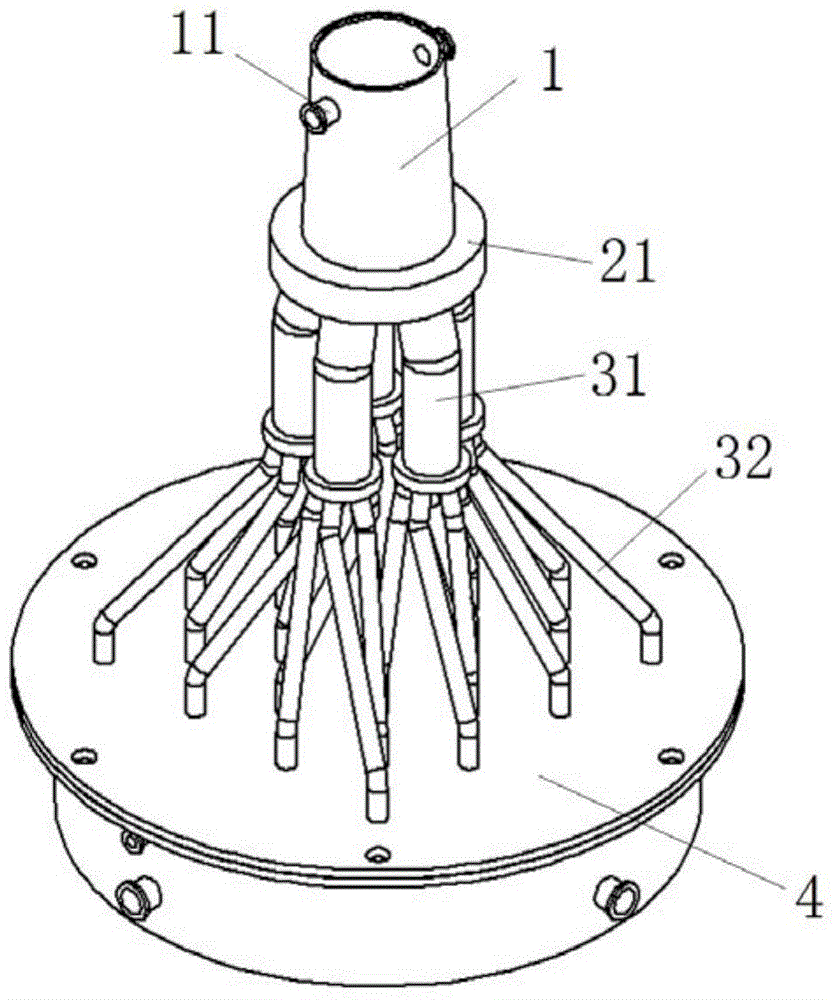

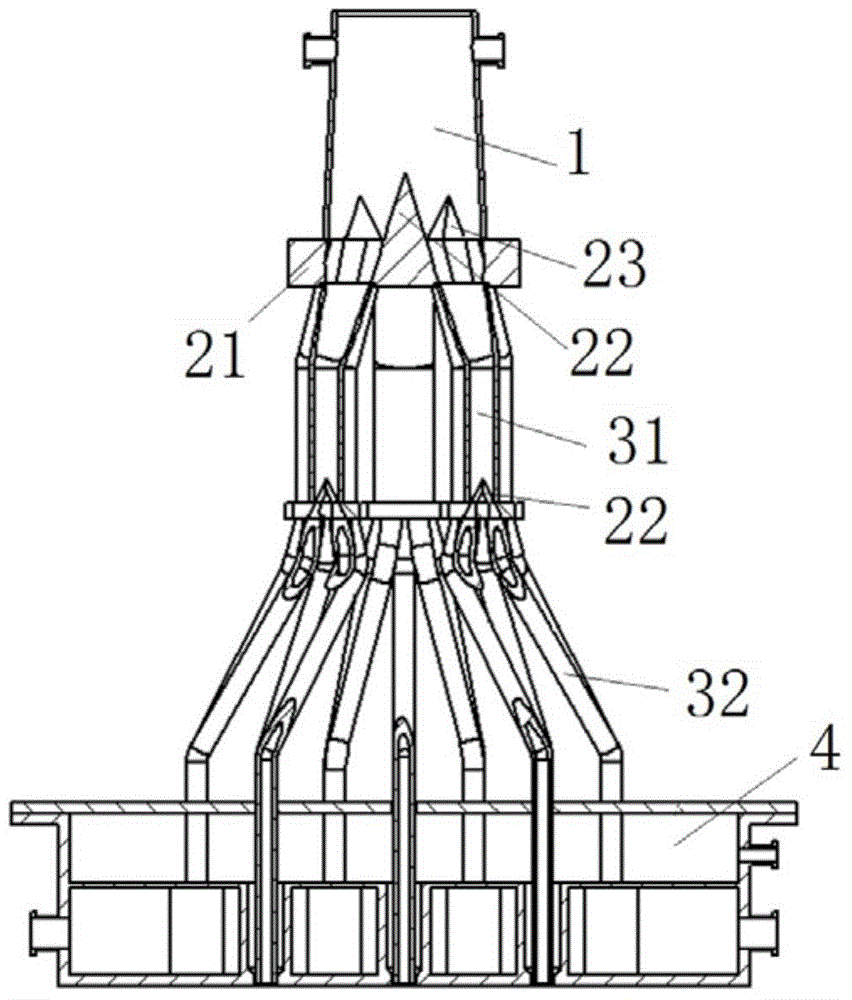

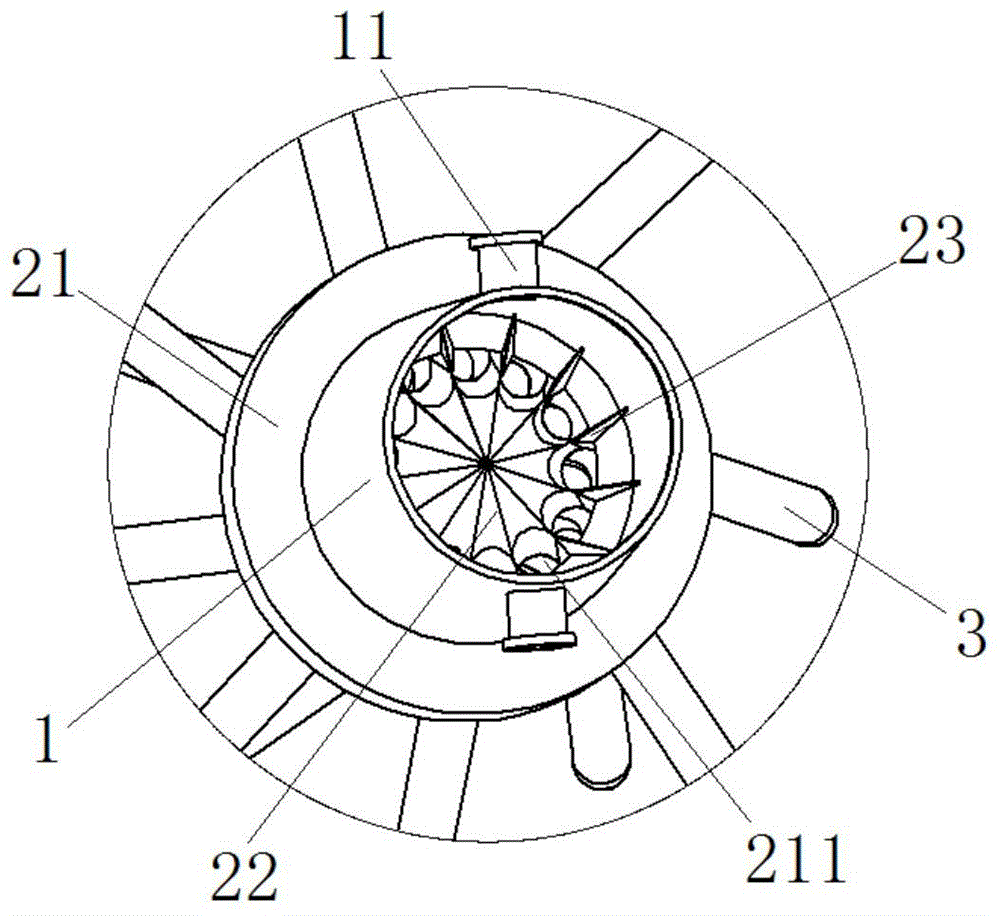

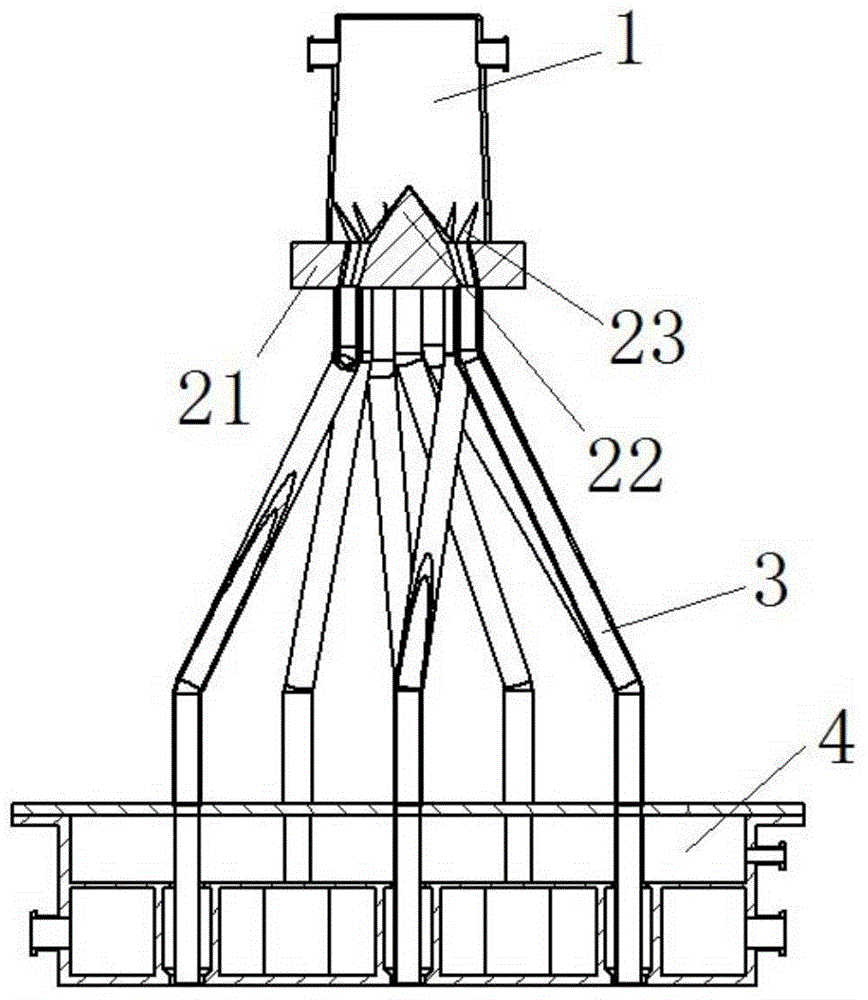

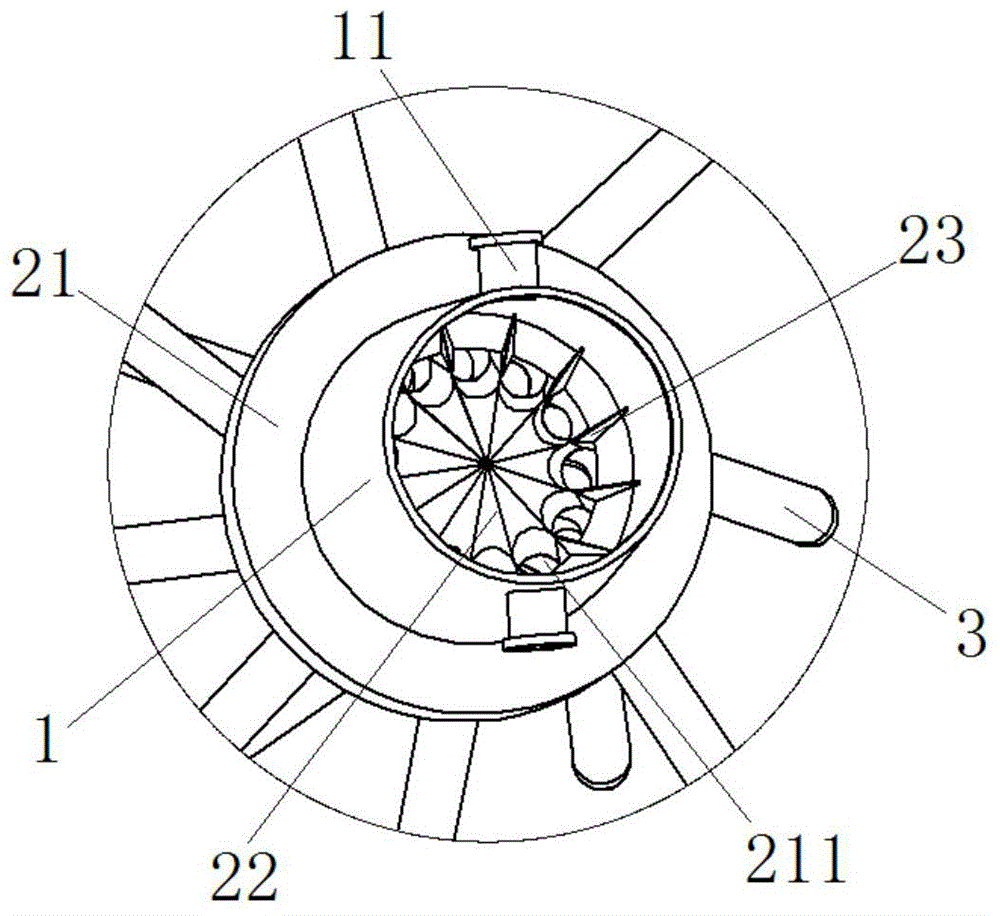

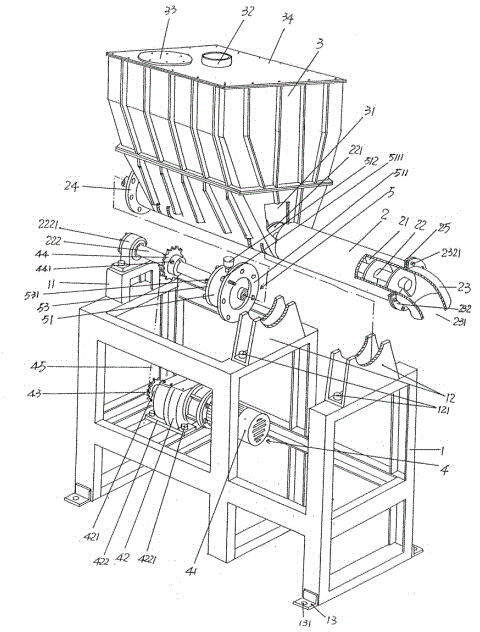

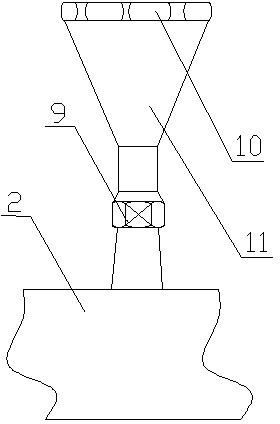

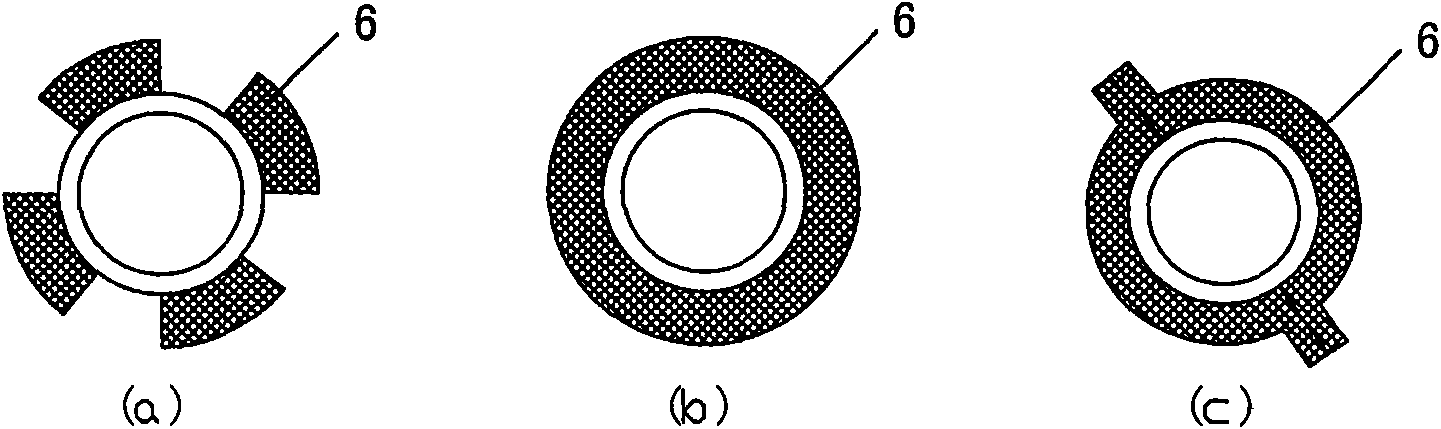

Gasification nozzle and gasifier

ActiveCN104804772AEvenly distributedAvoid dead endsSpray nozzlesCombined combustion mitigationEngineeringMechanical engineering

The invention discloses a gasification nozzle. The gasification nozzle comprises a conveying portion for conveying a material, and an injection portion connected to the tail end of the conveying portion and used for injecting the material, the conveying portion comprises a conveying main pipe (1) and at least two-stage conveying branch pipes, the conveying main pipe is connected with a first stage conveying branch pipe (31) through a diverter, and adjacent two stage conveying branch pipes are connected through a diverter. At least one diverter comprises a substrate, and the substrate is provided with through holes (211); and each of the diverters comprises polyhedral cone, the side surfaces of the polyhedral cone and parts of the wall of the conveying main pipe or parts of the wall of the previous-stage conveying branch pipe of the adjacent two-stage conveying branch pipes form the guiding surfaces of all the through holes, and the side surfaces of the polyhedral cone cover the top surface of the substrate. The invention also discloses a gasifier provided with the gasification nozzle. The material is uniformly diverted in the gasification nozzle to prevent powder accumulation and obstruction of the material in order to improve the production efficiency of a gasification furnace.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

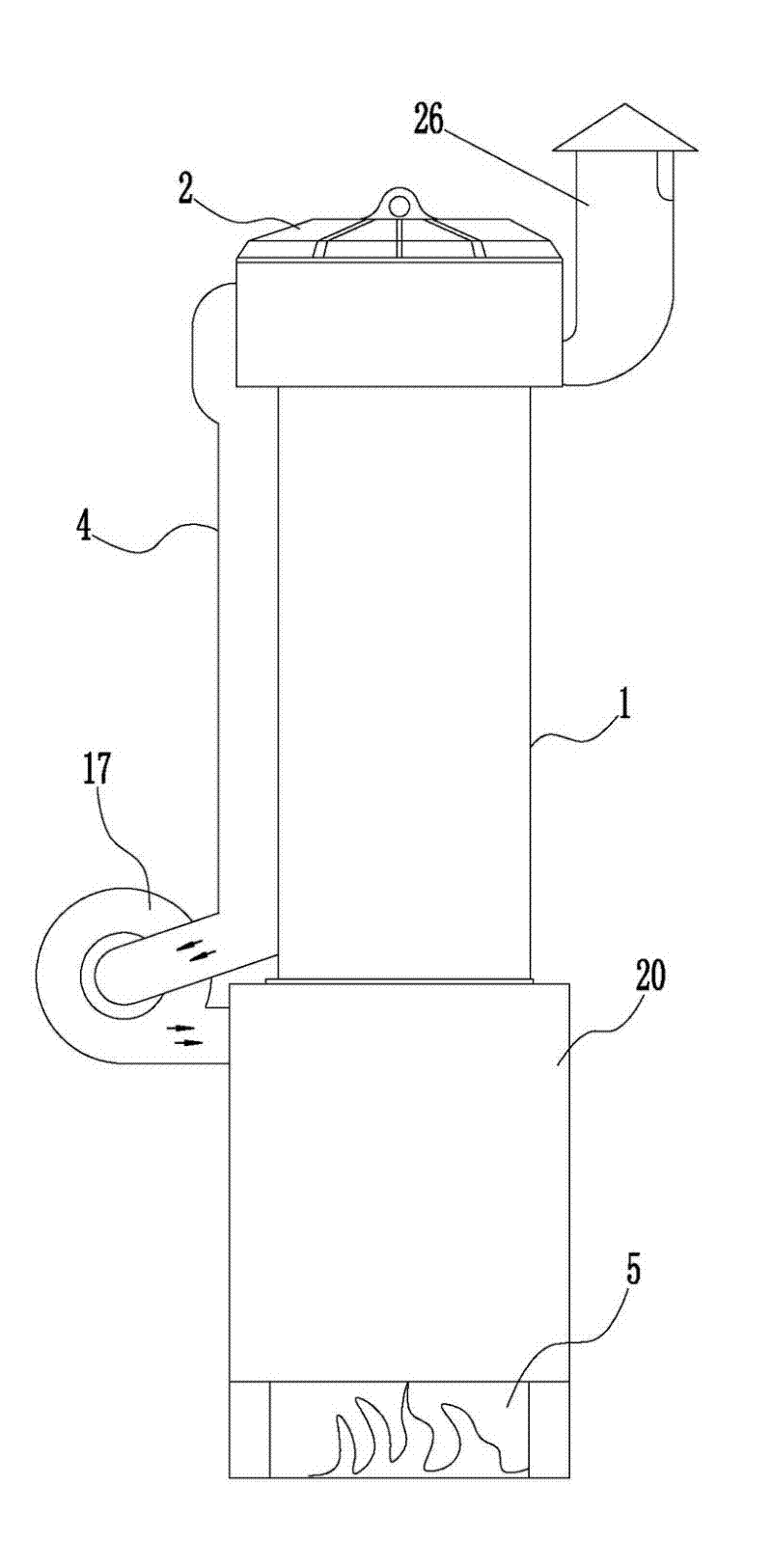

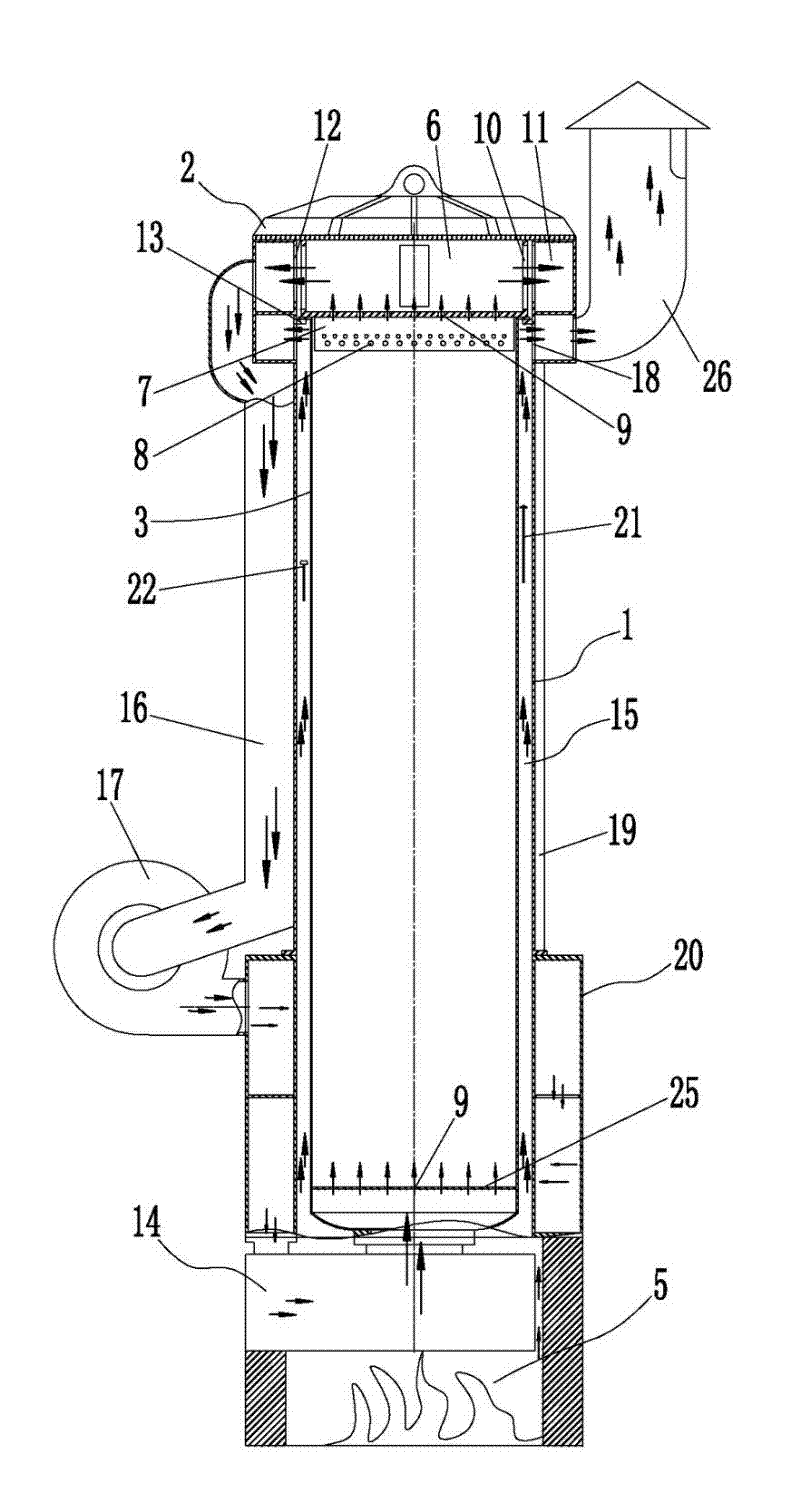

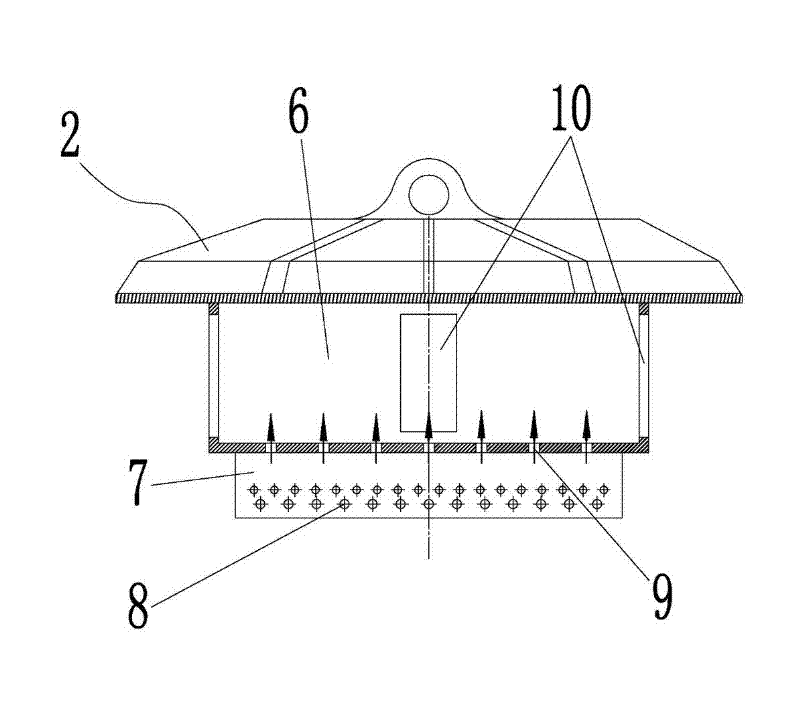

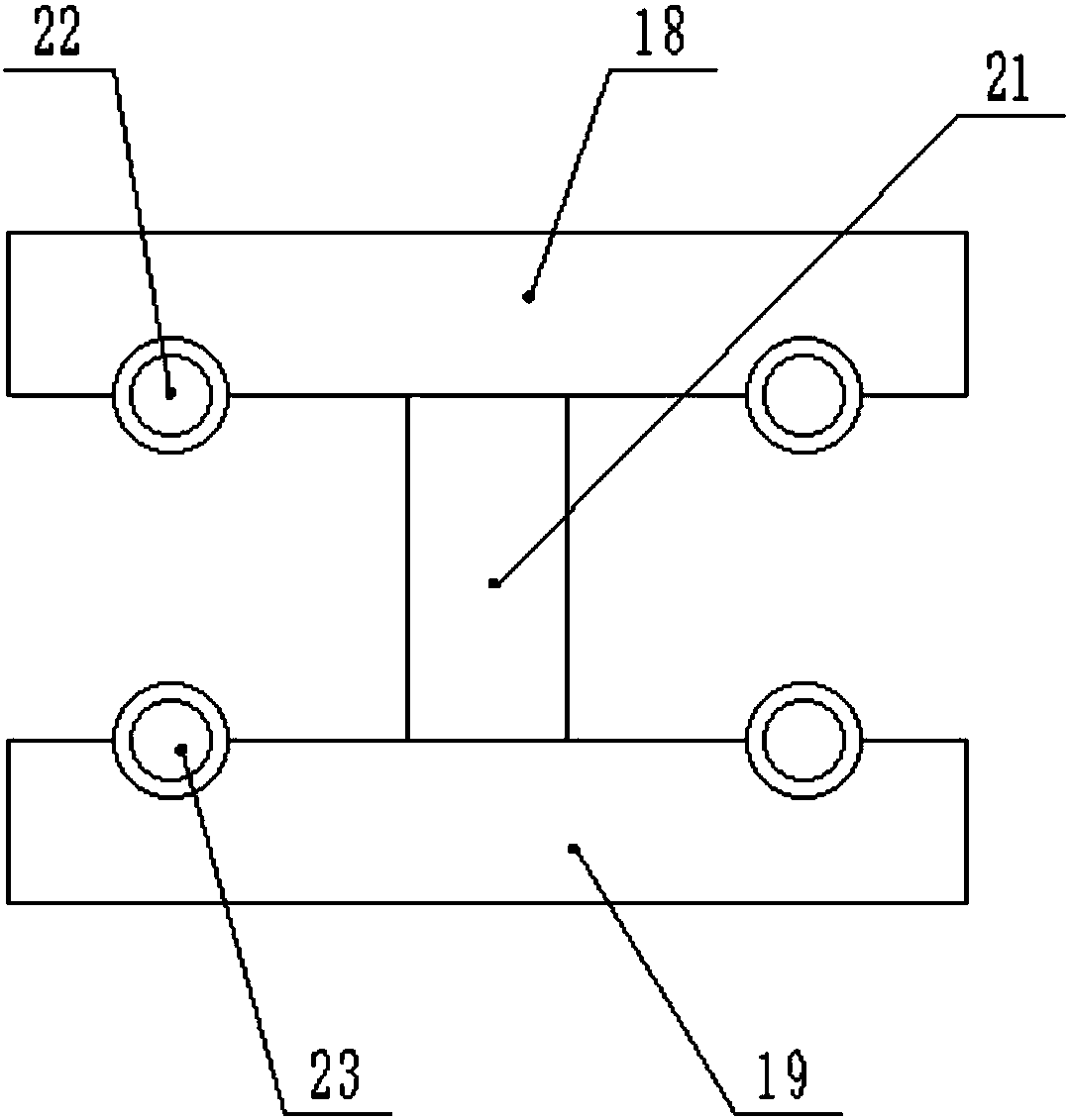

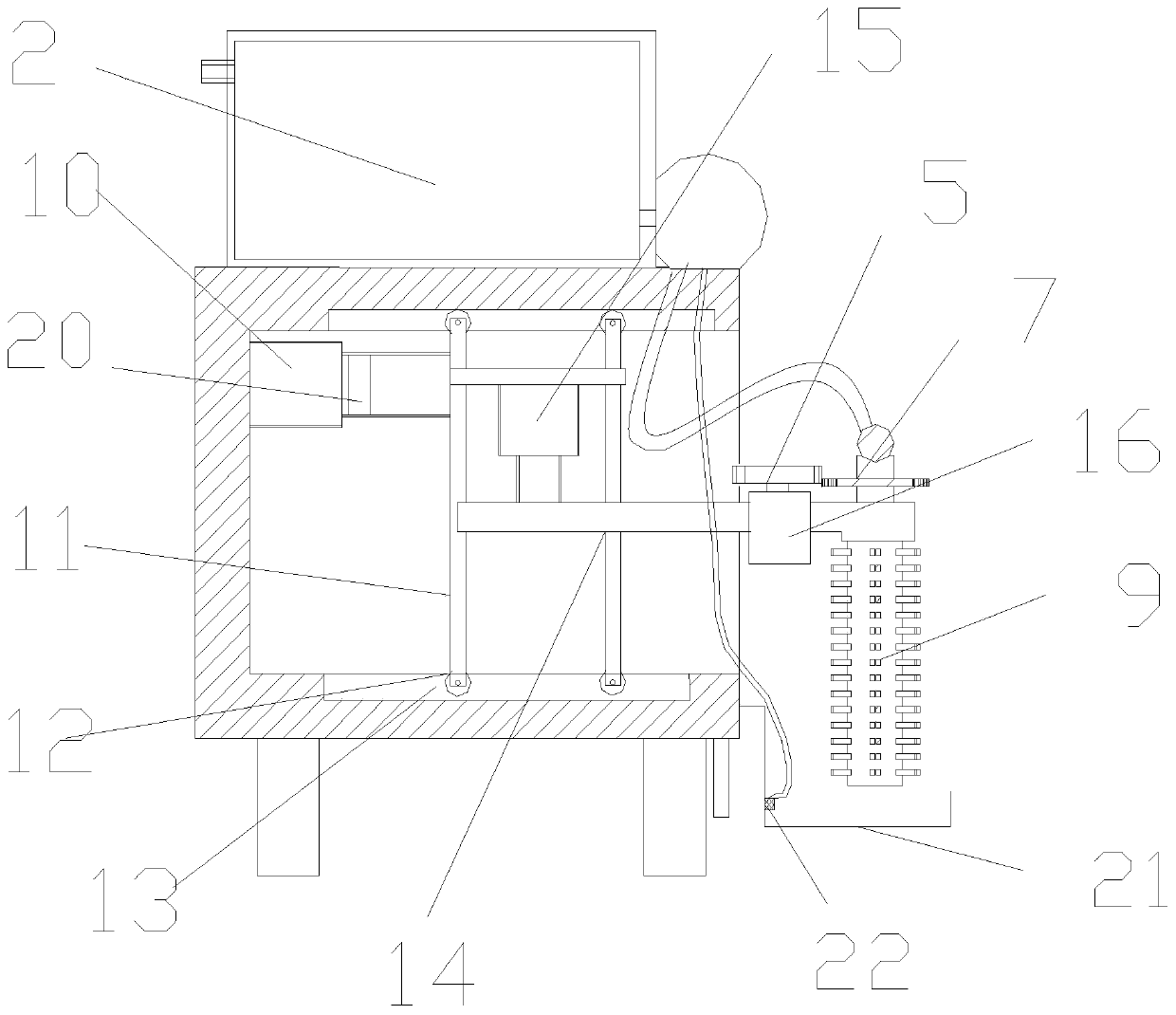

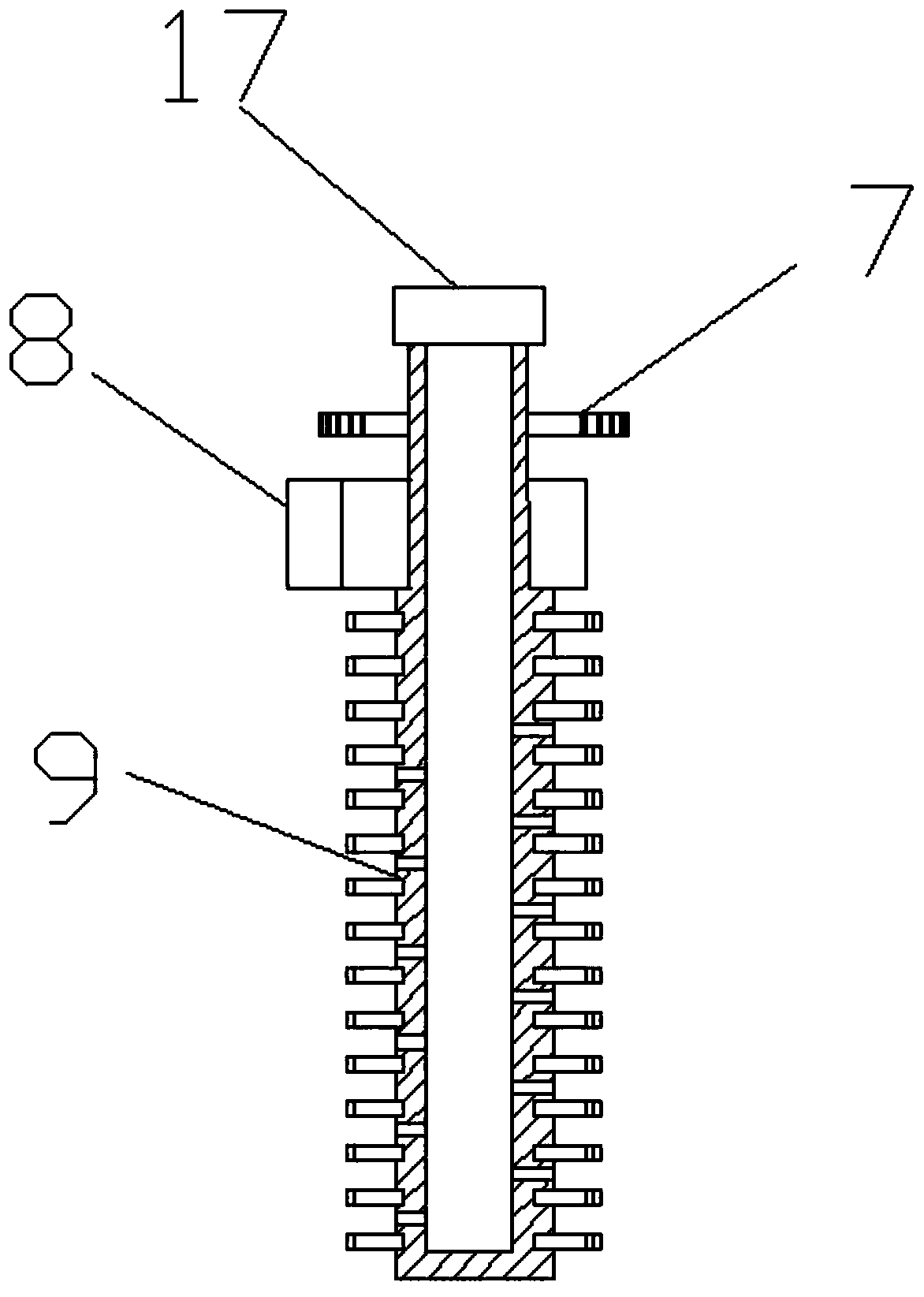

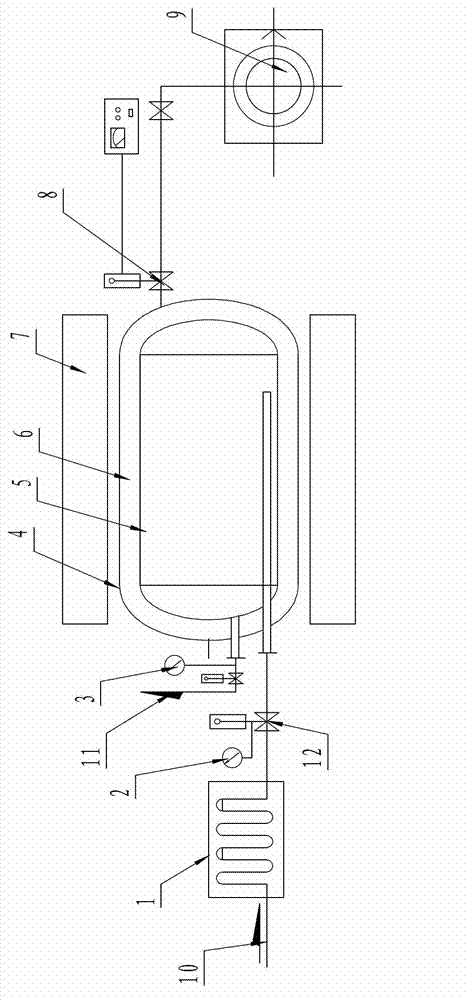

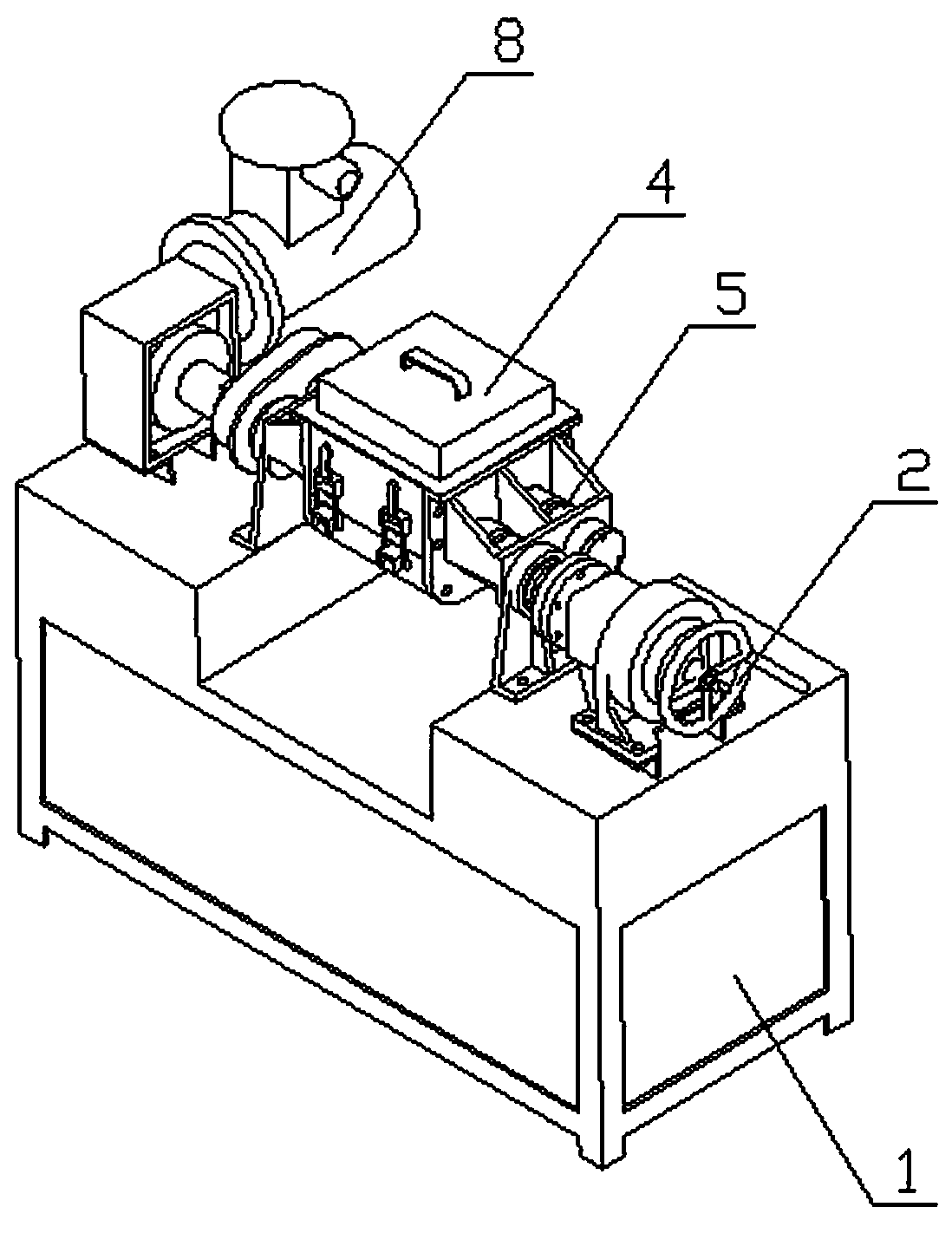

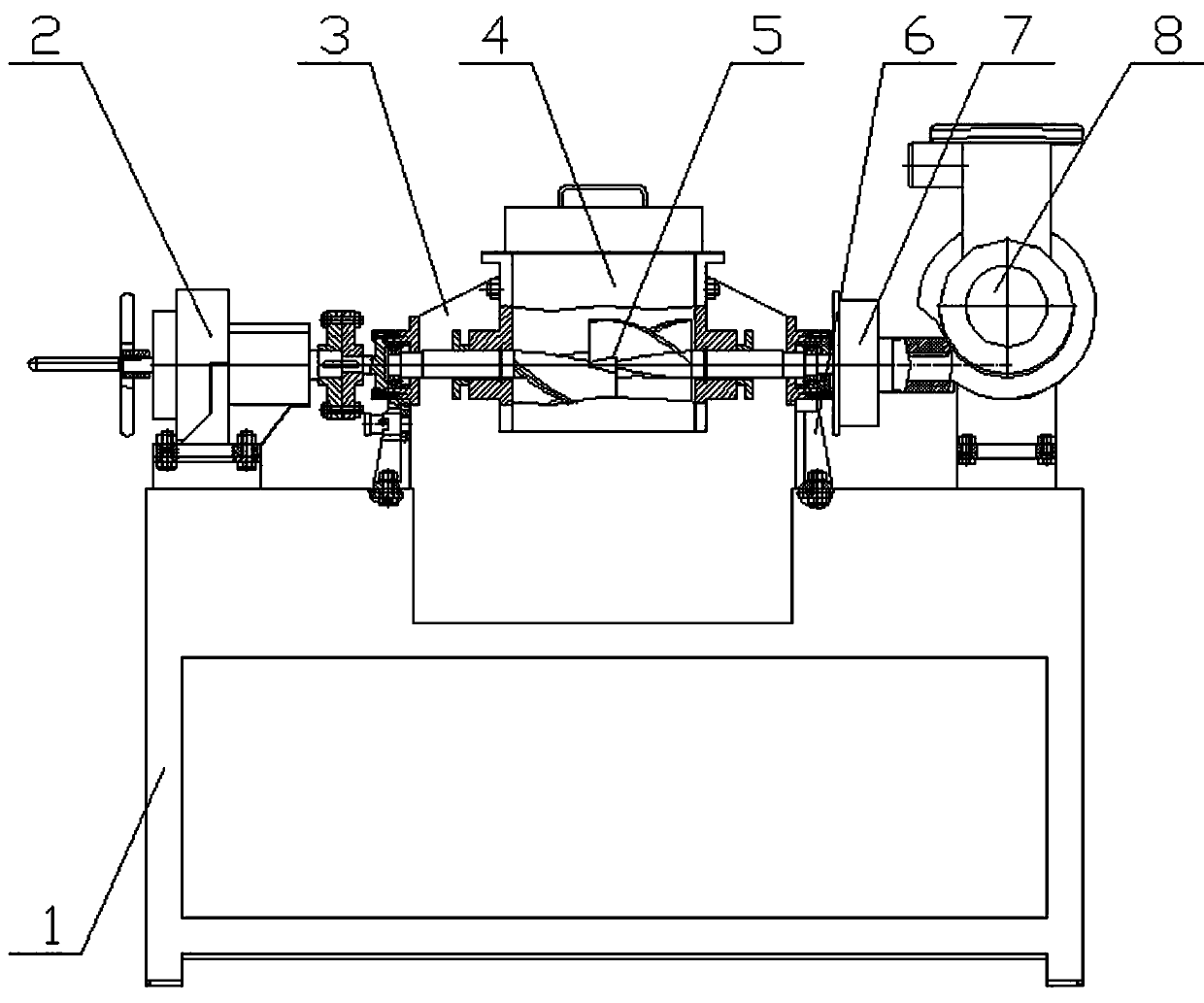

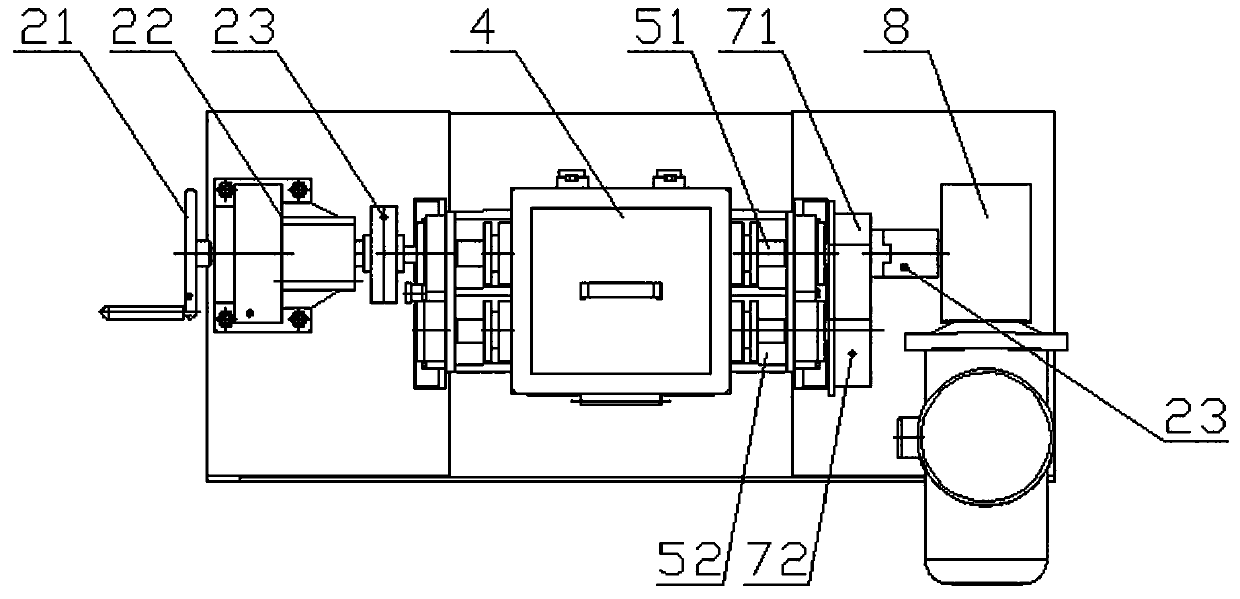

Tempering Furnace

ActiveCN102213544AEasy to control temperatureImprove tempering qualityVertical furnacesHearthEnergy conservation

The invention relates to a tempering furnace. The furnace comprises a furnace body, the top of which is provided with a furnace cover, an inner container is arranged in the furnace body, an air circulating and heating device is arranged on the furnace body, and a hearth is arranged at the bottom end of the furnace body. By properly arranging the furnace cover, the inner container, the air circulating and heating device and the like, the tempering furnace provided by the invention achieves omidirectional tempering of a workpiece which is suspended below the furnace cover by the process of uniformly heating, cycling and preheating the gas in the furnace, thus avoiding tempering blind spot in the furnace, obviously decreasing the temperature deviation in the furnace, and effectively improving the tempering quality of the workpiece in the furnace. Moreover, the tempering furnace maximally utilizes the heat created by burning the fuel, and further improves the furnace tempering effect. The tempering furnace of the invention has the advantages of reasonable and simple structure, low production cost, simplicity of operation, convenience of maintenance, high efficiency and energy conservation, and is suitable for popularization.

Owner:LISHUI HUAYI AUTOMATION TECH

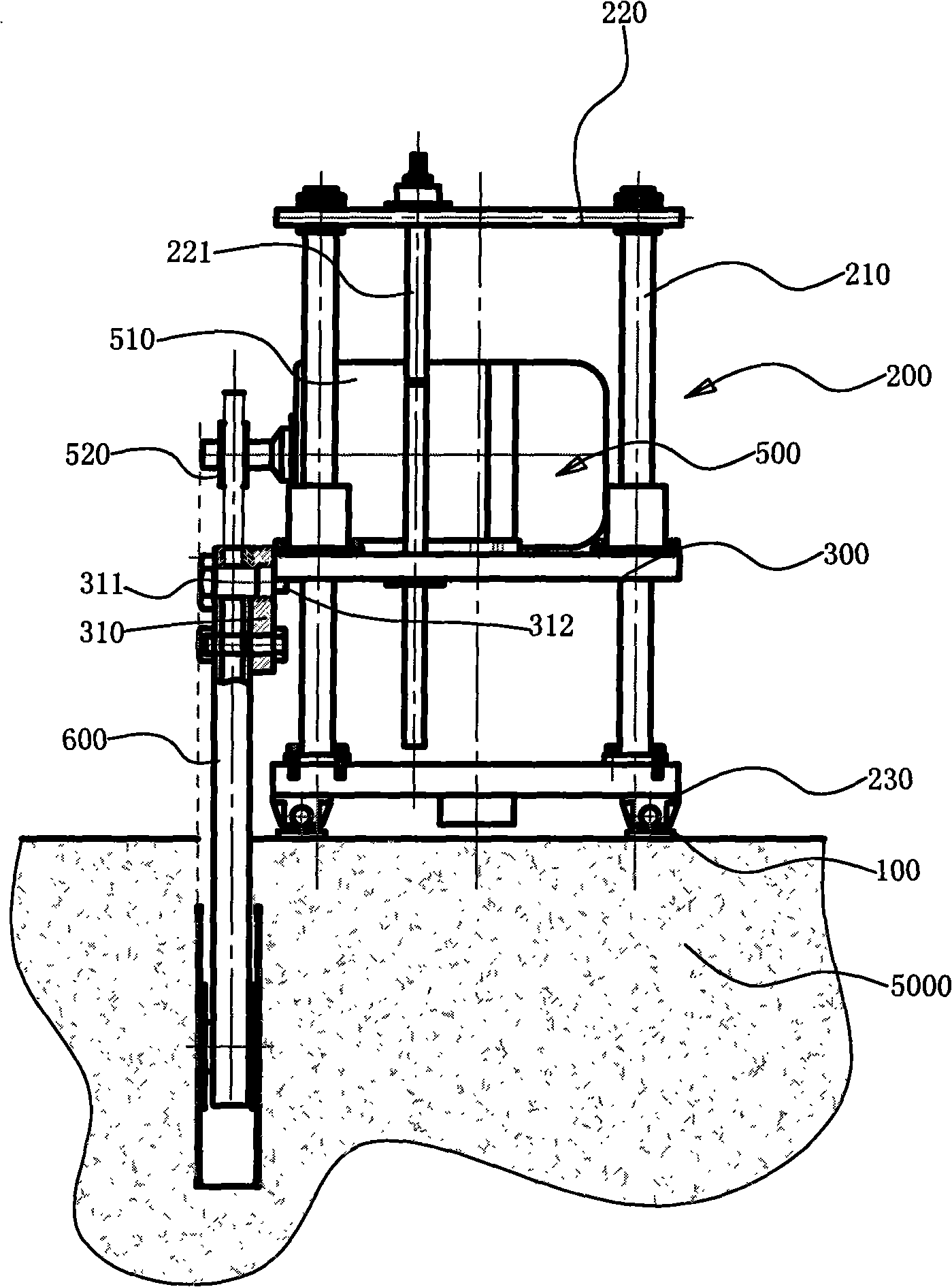

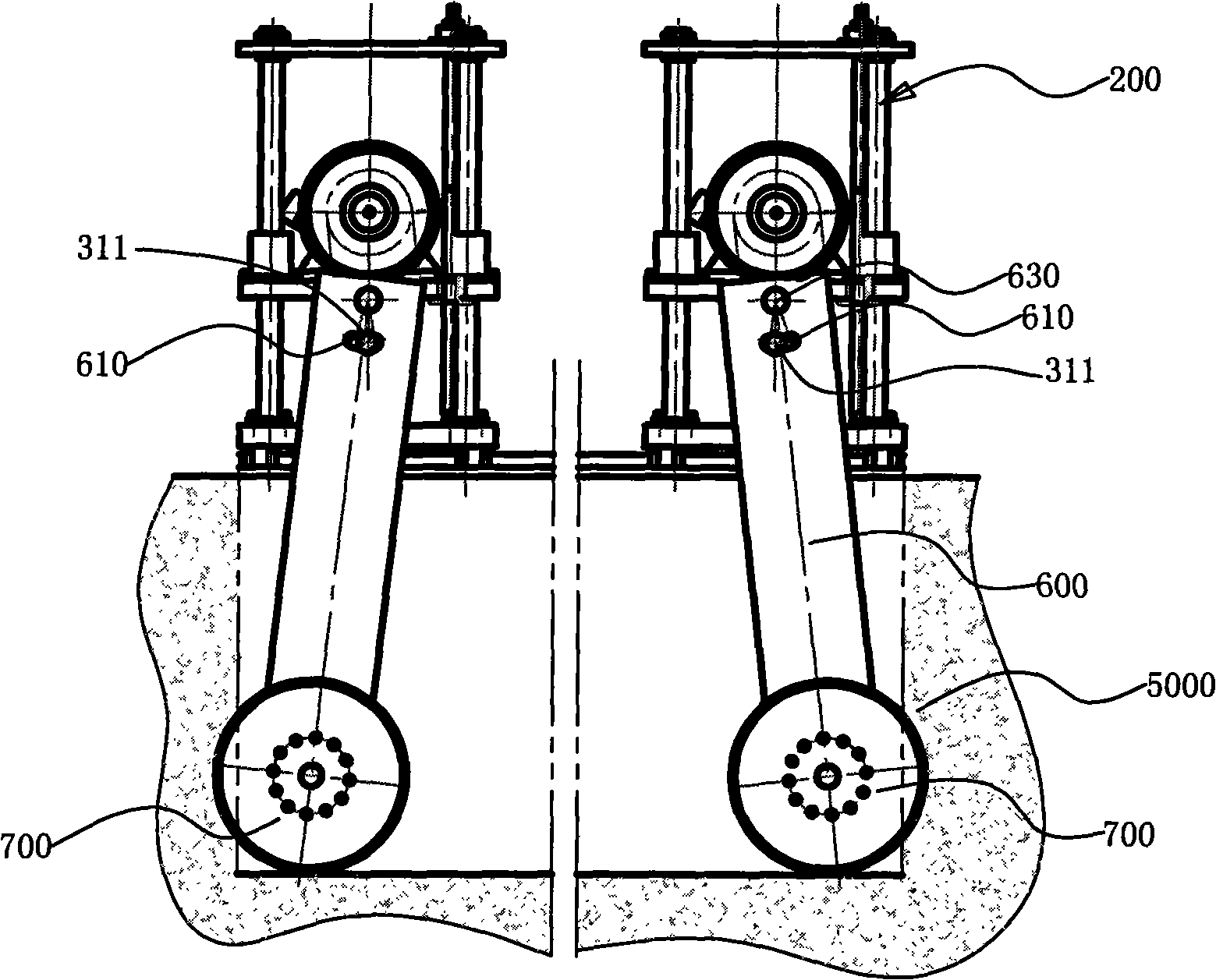

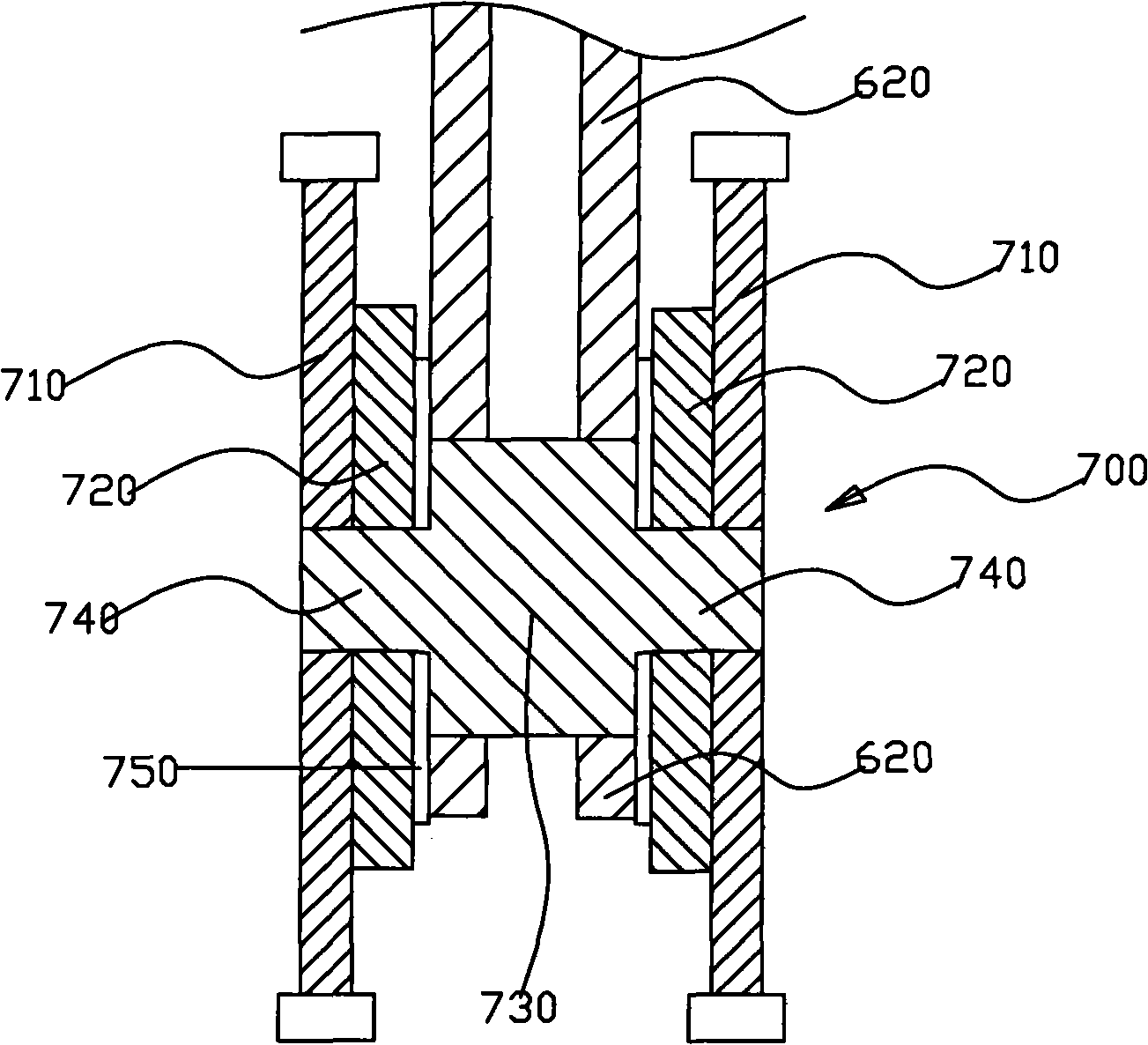

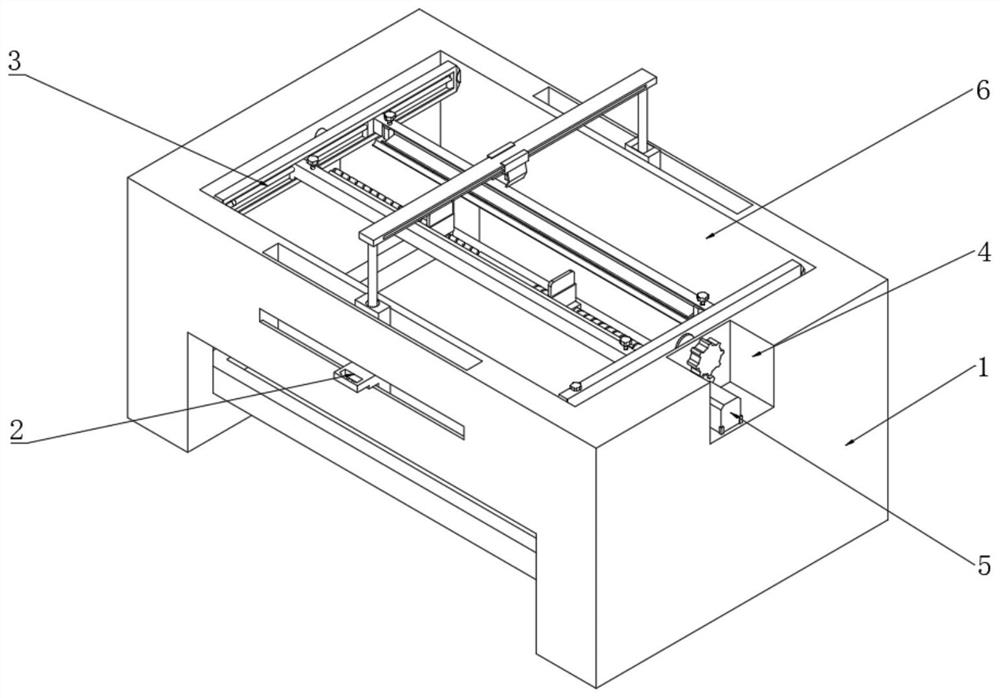

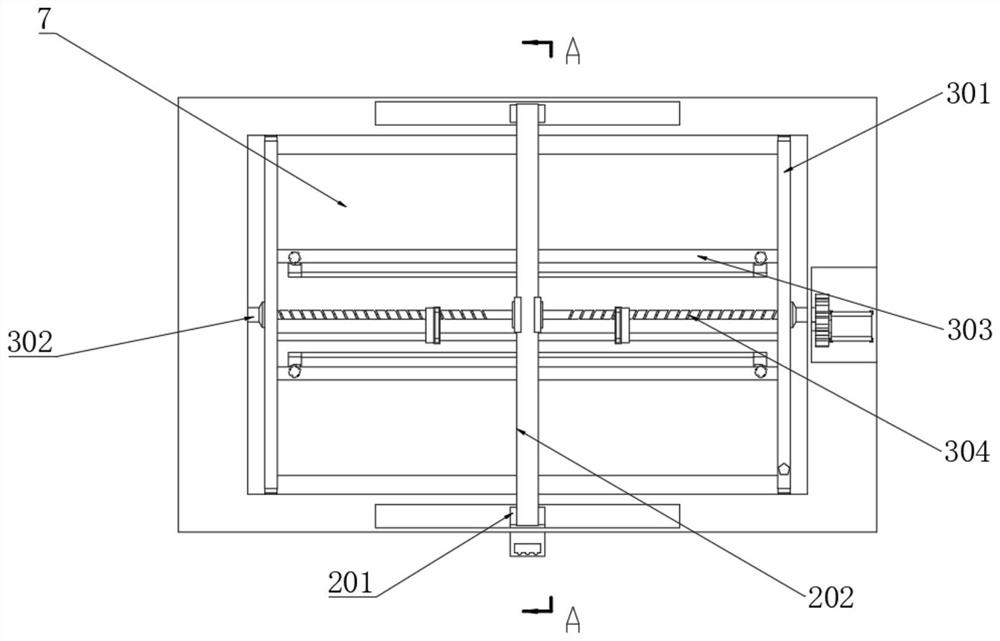

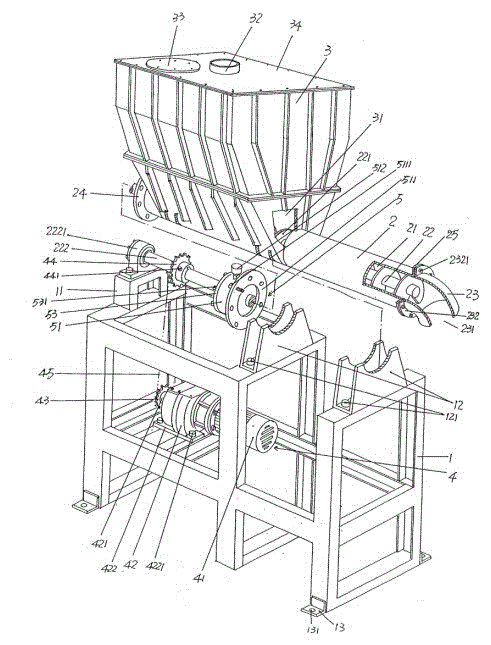

Mining and cutting method for mine and equipment therefor

The invention discloses a stone mine exploiting and cutting method, an exploiting method and a device thereof. The device includes a bracket, a bearing frame and a cutting unit; the bearing frame can be connected with the bracket in a sliding way; the cutting unit includes a main cutting arm and a cutting part; the first end part of the main cutting arm is connected with the bearing frame; the second end part of the cutting arm extends out of the bracket; the cutting part is connected with the second end part of the main cutting arm to lead the rotating axes of two disk saws to be arranged outside the bracket. As the distance between the two disk saws is not less than the distance between the left and the right of the main cutting arm, a cutter inlet space can be formed after removing a mine core between two cutting gaps for a cutter to enter the cutting part again; the axes of the disk saws can be lower than tracks and can be arranged in the mine; the cutting part even can be completely cut into the mine after the cutter enters the cutting part for a plurality of times. The device can carry out horizontal and vertical cutting of a plurality of angles, thereby being capable of realizing cave exploitation and preferably fetching stones and being capable of fully utilizing the texture structure of the stone to exploit.

Owner:江显秋

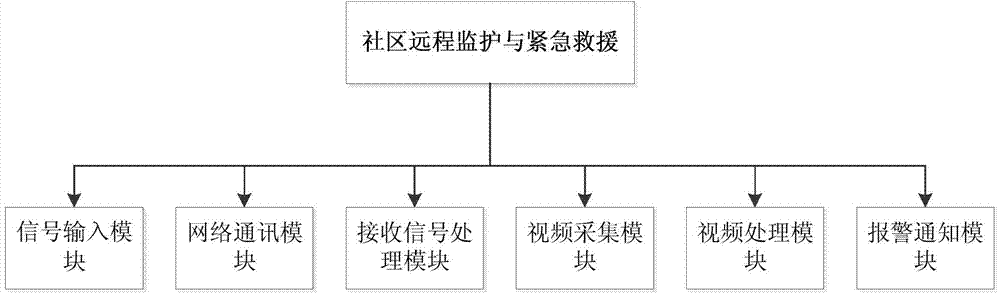

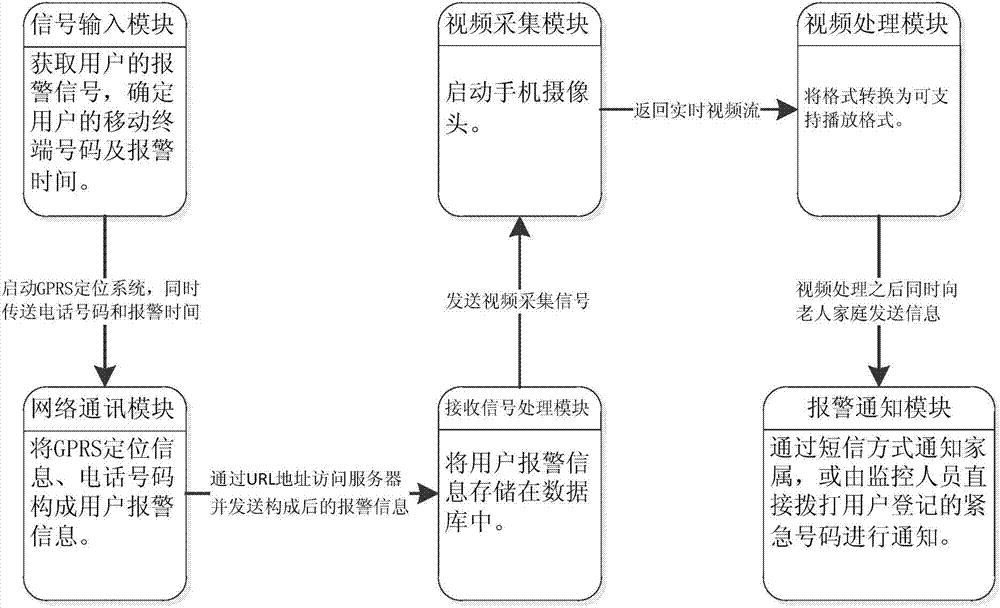

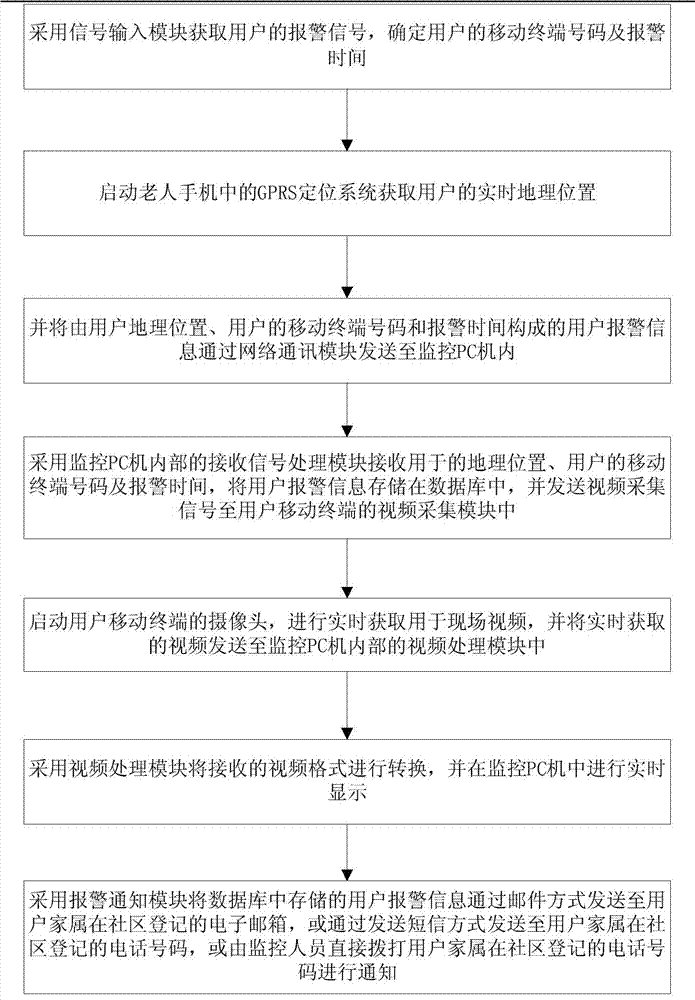

Community resident remote monitoring and emergency rescue monitoring device and method

InactiveCN103942918AProtection securityAvoid dead endsClosed circuit television systemsAlarmsAlarm messageEmergency rescue

The invention relates to a community resident remote monitoring and emergency rescue monitoring device and method and belongs to the technical field of internet information. A user can transmit an alarm signal to a monitoring center through a mobile phone end, the monitoring center can process alarm information after receiving the signal, manual errors of the monitoring center can be reduced, and the safety of community users is ensured to the largest extent. The monitoring center can obtain the detailed position information of community users giving an alarm, dead corners in the community monitoring are avoided, and security personnel can arrive on the scene at the first time. The monitoring center can obtain mobile phone video information of the community users giving the alarm, the security personnel can further judge the position of the users according to the specific ambient environment shot by a mobile phone camera, and the safety of the community users can be further ensured. The monitoring center can send a short message to family members of the users at the first time after receiving the alarm signal.

Owner:NORTHEASTERN UNIV

Method for quickly carrying out pesticide application/fertilizer supplementation on adult fruit tree by adopting trunk penetration mode

InactiveCN101861807ALow costIncrease profitHorticulture methodsPlant protectionFruit treeEcological environment

The invention provides a method for quickly carrying out pesticide application / fertilizer supplementation on an adult fruit tree by adopting a trunk penetration mode. In the method, sponge section totally sucking pesticide liquor or fertilizer liquor is fixedly tied on a fruit tree trunk, 60-80cm away from the ground, wherein the side of the sponge section attached to the trunk is in direct contact with the trunk, and the rest is completely shaded by a plastic film to isolate the sponge section from atmosphere. The sponge section fully absorbing the pesticide liquor or the fertilizer liquor is attached to the trunk of the fruit tree, and by utilizing a tree penetration and inverse penetration principle, medicaments are gradually absorbed by the tree to take effect so that the medicaments and trace element fertilizers can penetrate into the fruit tree through the fruit tree trunk to generate disease-resistant and pest suppression juice or fertilizing factors in the fruit tree so as to realize the effects of quickly and efficiently killing pests and supplementing nutrition. The method has low environmental pollution and can effectively protect the ecological environment and guarantee the health of operating personnel.

Owner:XIAMEN YIZHUANG MODERN AGRI

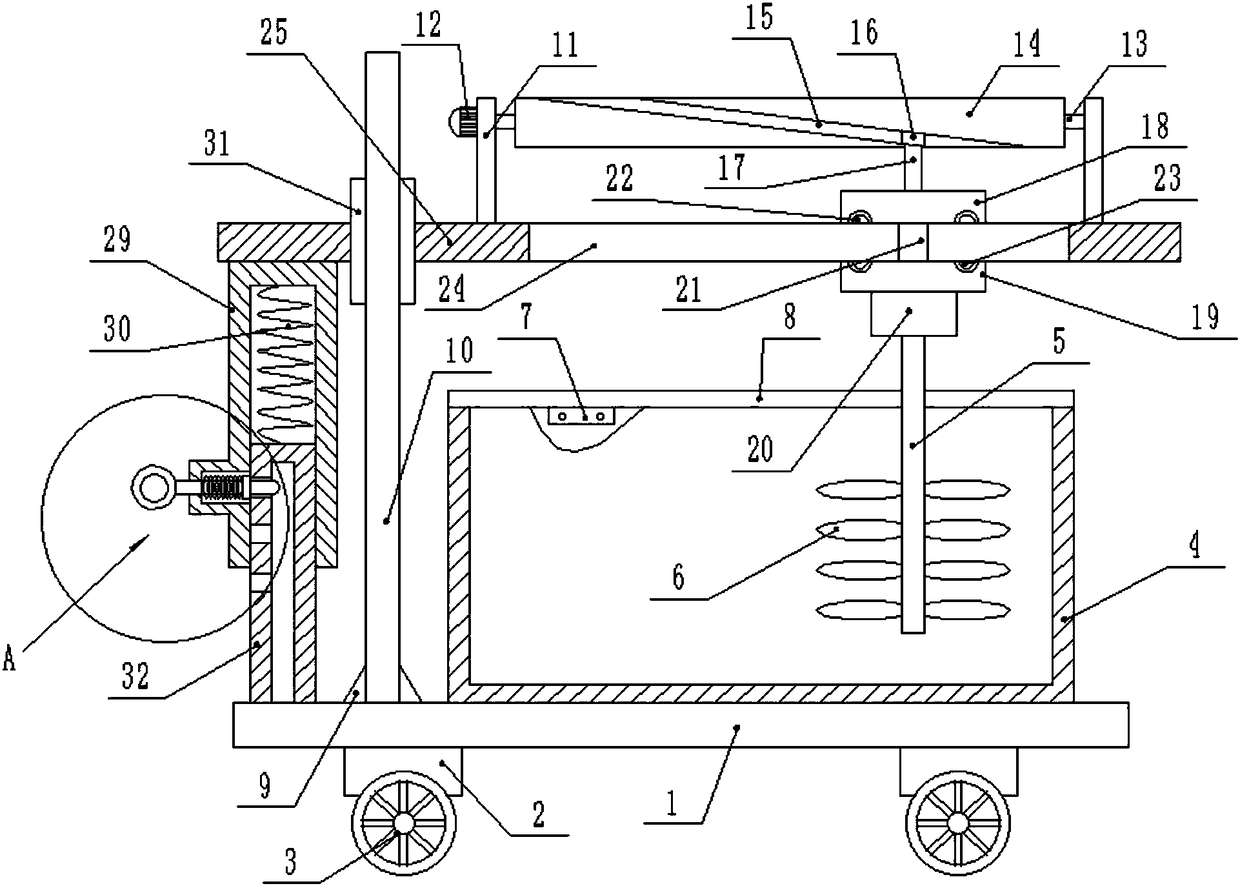

Manually-pulled lifting type horizontal swinging automatic dough kneading device

InactiveCN108477252AReasonable structureInnovative designMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsReciprocating motionEngineering

The invention discloses a manually-pulled lifting type horizontal swinging automatic dough kneading device. The manually-pulled lifting type horizontal swinging automatic dough kneading device comprises a bottom plate, wherein a dough kneading tank is mounted at the middle part of the upper end of the bottom plate; a guiding column is fixedly mounted on the left side of the upper end of the bottomplate; a lifting plate is arranged at the upper end of the guiding column; a fixing frame is mounted on the right side of the upper end of the lifting plate; a rotating shaft is connected between thefixing frame; a rotating roller is mounted outside the rotating shaft; a limiting groove is formed in the outer side of the rotating roller; a limiting block is mounted in the limiting groove; a limiting column is connected to the lower end of the limiting block; an upper guiding block is connected to the lower end of the limiting column; a connecting column is mounted at the middle part of the lower end of the upper guiding block, and penetrates through a moving groove in the middle part of the lifting plate, and then a lower guiding block is connected to the connecting column; a lifting cylinder is connected to the left side of the lower end of the lifting plate; a telescopic spring is connected to the upper end of the inner part of the lifting cylinder; and a fixing cylinder is connected to the lower end of the telescopic spring. Through the adoption of the manually-pulled lifting type horizontal swinging automatic dough kneading device disclosed by the invention, adjusting of theup-and-down position of a stirring shaft is realized, dead angles of dough kneading are avoided, besides, the left-and-right reciprocating motion of the stirring shaft is also realized, and the doughkneading quality is improved.

Owner:广西东创智能科技有限公司

Method for three-dimensional mixed culture of escargots and fish

InactiveCN106508735AGuaranteed normal growthIncrease proteinClimate change adaptationAnimal feeding stuffOxygenAnimal waste

A method for three-dimensional mixed culture of escargots and fish includes the following steps that (1) a medium-low-yield abandoned terrace in a mountainous area is transformed into a micro running water pond, and the water level of the pond is 0.8-1.6 meters; (2) the pond is sterilized and disinfected, escargot species and fry are introduced and placed in the pond, the quantity of the placed escargot species per mu is 80-120 kg, and the quantity of the placed fry per mu is 8,000-10,000; (3) the escargot species and the fry are placed in the pond at the same time, after 1-3 days, the escargot species and the fry can be fed with grass and animal waste, the escargot species and the fry are fed with grass two times every day, respectively in the morning and evening, and animal waste can be placed in the pond every 3-5 days; (4) feeding management of the escargot species and the fry is enhanced, and through biological oxygenation or mechanical oxygenation, the problem of insufficient oxygen dissolving in aquatic water is solved; (5) the pH value of water is adjusted and kept to be 7-8; (6) disease control is carried out; and (7) escargots and fish are harvested and sold in the market.

Owner:宾阳县阳光农村产业农民专业合作社

Environment-friendly textile fabric surface cleaning device

InactiveCN111282920AEffective electrostatic adsorptionImprove protectionDispersed particle filtrationElectrostatic cleaningActivated carbonSurface cleaning

The invention discloses an environment-friendly textile fabric surface cleaning device, and relates to the technical field of textile fabrics. The environment-friendly textile fabric surface cleaningdevice comprises a clean box, wherein a dust removal box is installed to the bottom of the inner side of the clean box in a welded manner, a suction fan and an activated carbon layer are installed tothe bottom of the inner side of the dust removal box in a welded manner, an air inlet pipe is fixedly mounted at the air inlet end of the suction fan, an air outlet pipe is fixedly installed at the air outlet end of the suction fan, one end of the air outlet pipe extends to one side of the clean box, an ash inlet groove is fixedly installed on the outer surface of the top of the dust removal box,and one end of the ash inlet groove extends into the dust removal box. According to the environment-friendly textile fabric surface cleaning device, the electrostatic adsorption effect of objects suchas wool balls on the fabric can be effectively achieved, the environment can be better protected, the problem of dead corners in the cleaning process can be effectively avoided, and the cleaning areaand cleanliness are greatly increased.

Owner:李洁洁

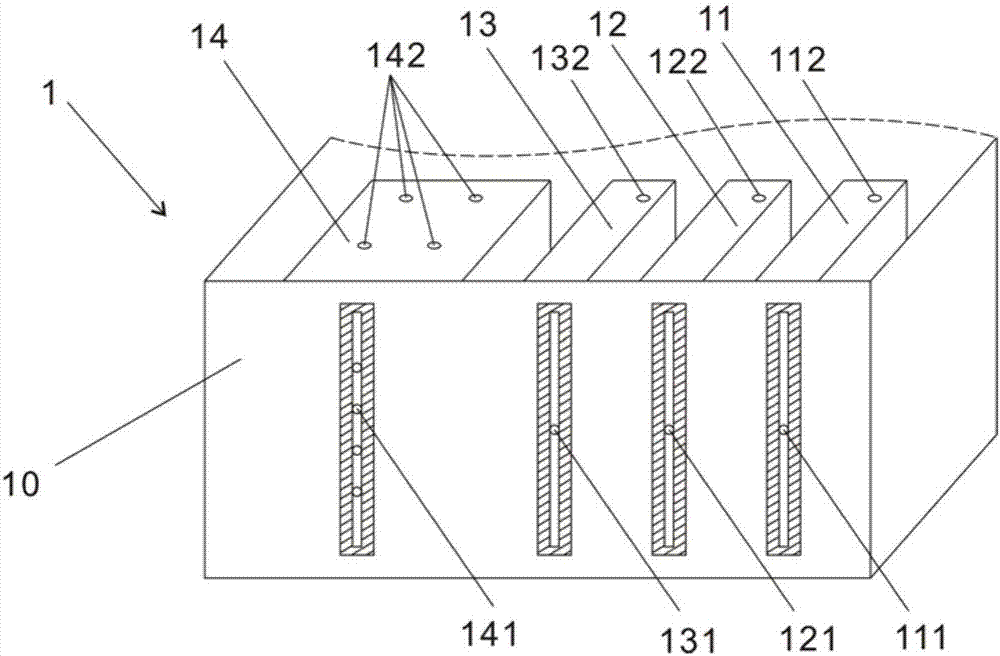

Method for manufacturing viscose fibers by ultrasonic polymerization reduction of wood-cotton composite pulp

InactiveCN102041565AAvoid dead endsEliminate the disadvantages of uneven responseArtificial filaments from viscoseViscose fiberMaterials science

The invention provides a method for manufacturing viscose fibers by ultrasonic polymerization reduction of wood-cotton composite pulp, which is a method for producing the viscose fibers directly from the wood-cotton mixed pulp by ultrasonic polymerization reduction of an ultrasonic polymerization reduction pipe. The method comprises the following steps of: replacing the traditional reaction kettle by using the ultrasonic polymerization reduction pipe, and soaking the wood-cotton pulp into alkali to obtain paste; performing polymerization reduction on the paste under the action of an ultrasonic instrument; and squeezing the paste after the polymerization reduction to obtain alkali fibers, and finally preparing the alkali fibers into the viscose fibers. The method overcomes the defects of the prior art, and has more uniform polymerization reduction, low energy consumption, a little equipment, small floor space and stable product quality; and the polymerization reduction effect of ultrasonic on a polymer is applied in the manufacturing of the viscose fibers for the first time, so the polymerization reduction method in the polymerization reduction manufacturing of the viscose fibers is enriched.

Owner:YIBIN HIEST FIBER +1

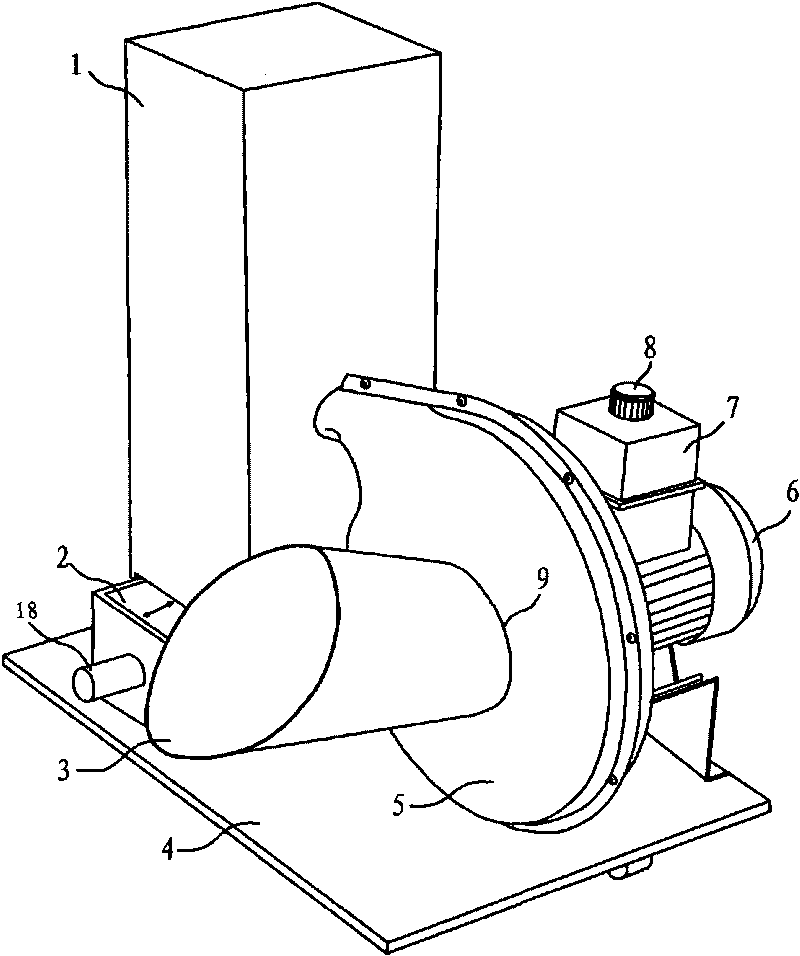

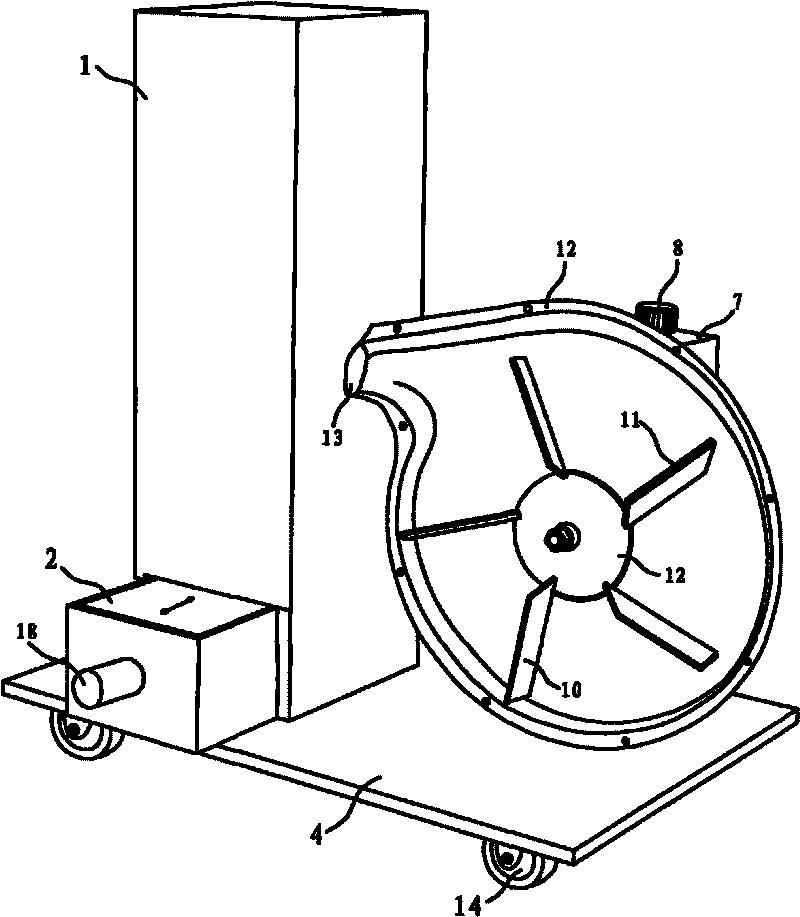

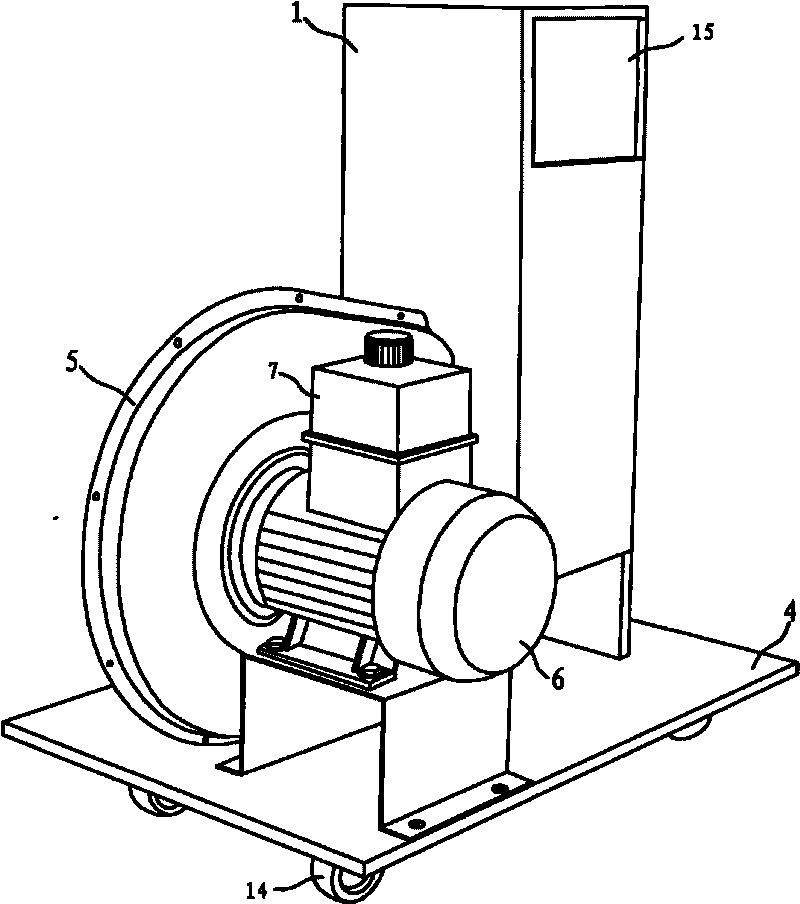

Single wheat/rice plant threshing device

The invention relates to a single wheat / rice plant threshing device comprising a centrifugal fan type thresher, a separating container and a mounting base. The centrifugal fan type thresher comprises a power mechanism, impellers, a volute casing and a wheat / rice ear inlet bucket. The impellers are arranged in the volute casing in a matching way and is connected with the rotating shaft of the power mechanism; the volute casing is provided with an air inlet and an air outlet, wherein the air inlet is butted with the wheat / rice ear inlet bucket, and the air outlet is communicated with the middle part of the separating container; the included angle Alpha between the air outlet direction and the horizontal direction is more than or equal to -30 DEG and less than or equal to 30 DEG; a wheat / rice bran discharge opening is arranged on the top of the separating container; and a movable wheat / rice kernel collecting slot which is matched with the separating container in shape is arranged at the bottom of the separating container. The single wheat / rice plant threshing device has novel and compact structure, small volume, light weight, low manufacturing cost, high threshing ratio, high intactness keeping ratio, high cleaning ratio, low breaking ratio, low retaining and adulterating ratio and low splashing ratio, has no dead corner for the residual and less wheat / rice kernel flow and collision link, is easy to use, consumes less power and can ensure the high purity and the high quality of the wheat / rice kernels and the material.

Owner:HENAN AGRICULTURAL UNIVERSITY

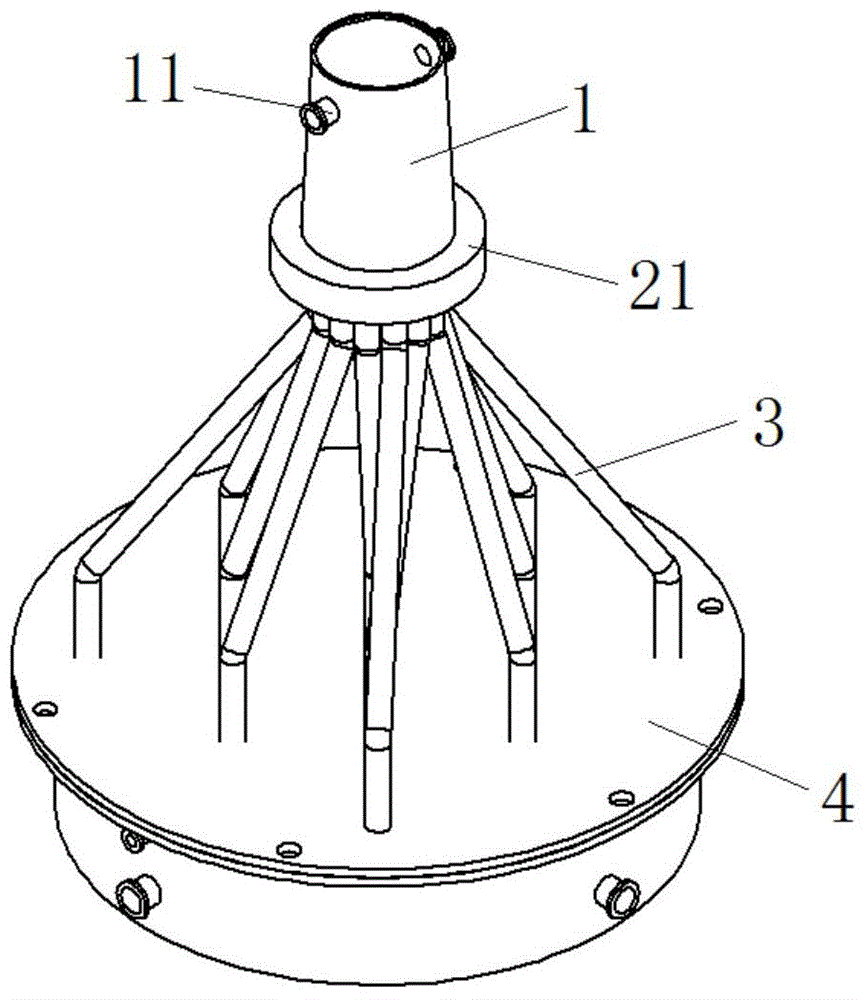

Gasification nozzle and gasifier

InactiveCN104804773AEvenly distributedAvoid dead endsCombined combustion mitigationGranular/pulverulent flues gasificationEngineeringNozzle

The invention discloses a gasification nozzle. The gasification nozzle comprises a conveying portion for conveying a material, and an injection portion connected to the tail end of the conveying portion and used for injecting the material, wherein the conveying portion comprises a conveying main pipe and a plurality of conveying branch pipes connected with the conveying main pipe through a diverter. The diverter comprises a substrate, the conveying main pipe is connected to the top surface of the substrate, all the conveying branch pipes are connected to the bottom surface of the substrate, and the substrate is provided with a plurality of through holes making the conveying main pipe connected with all the conveying branch pipes; the diverter also comprises a polyhedral cone with the cone base connected to the top surface of the substrate and the cone top positioned in the conveying main pipe, all side surfaces of the polyhedral cone and parts of the sidewall of the conveying total main respectively form a guiding surface of all the through holes, and the side surfaces of the polyhedral cone cover the top surface of the substrate. The invention also discloses a gasifier comprising the gasification nozzle. The material is uniformly diverted in the gasification nozzle to prevent powder accumulation and obstruction of the material in order to improve the production efficiency of a gasification furnace.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

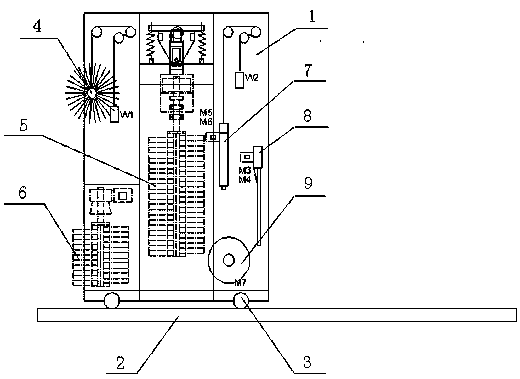

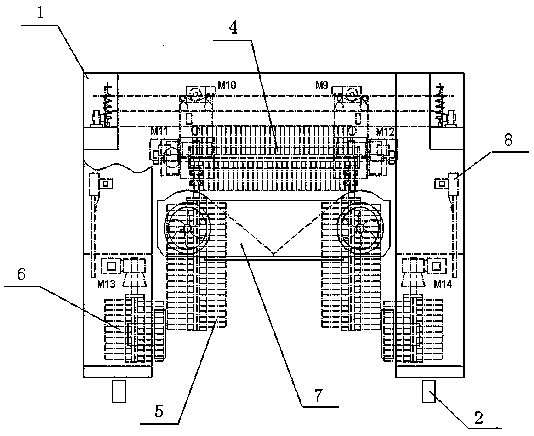

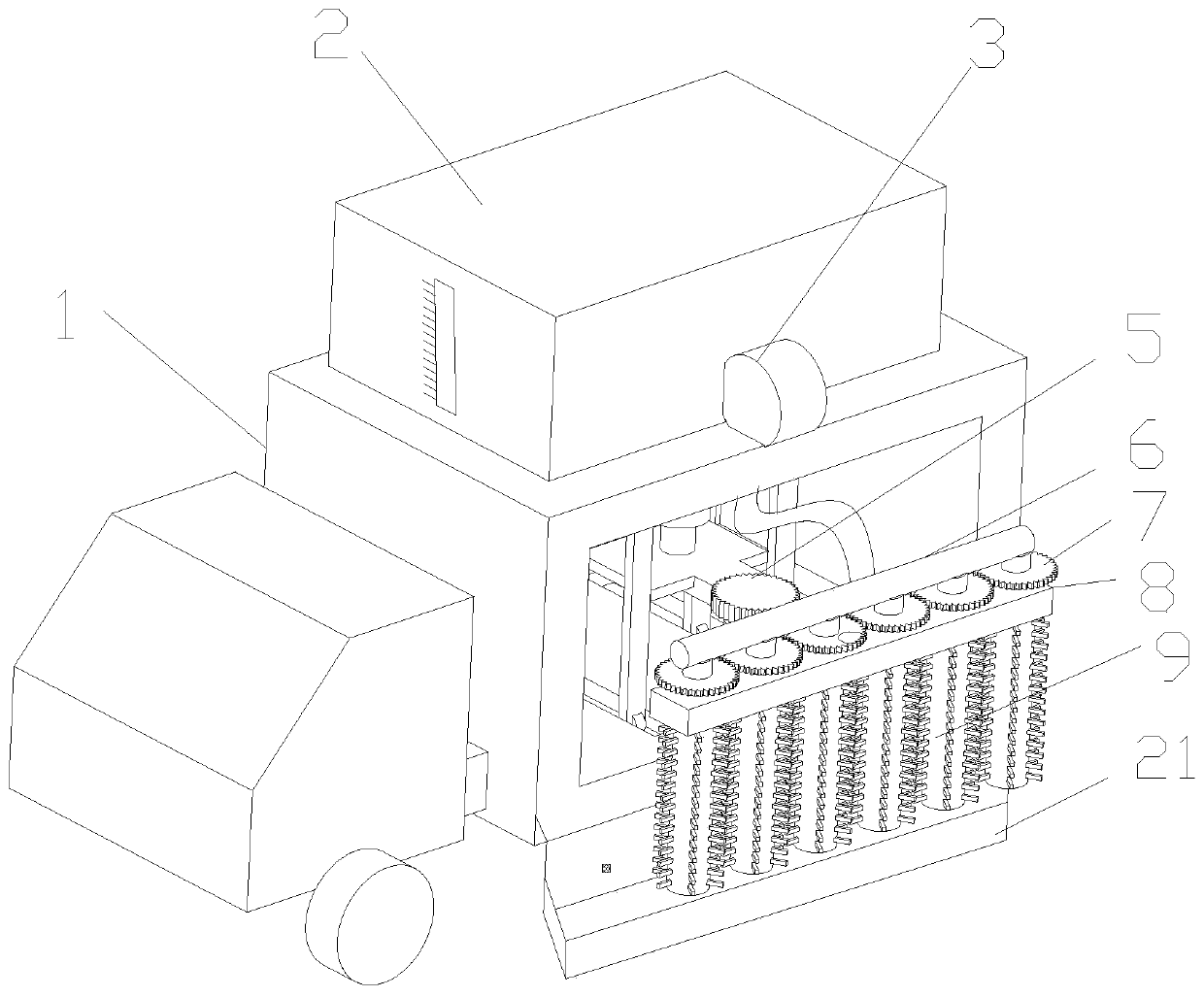

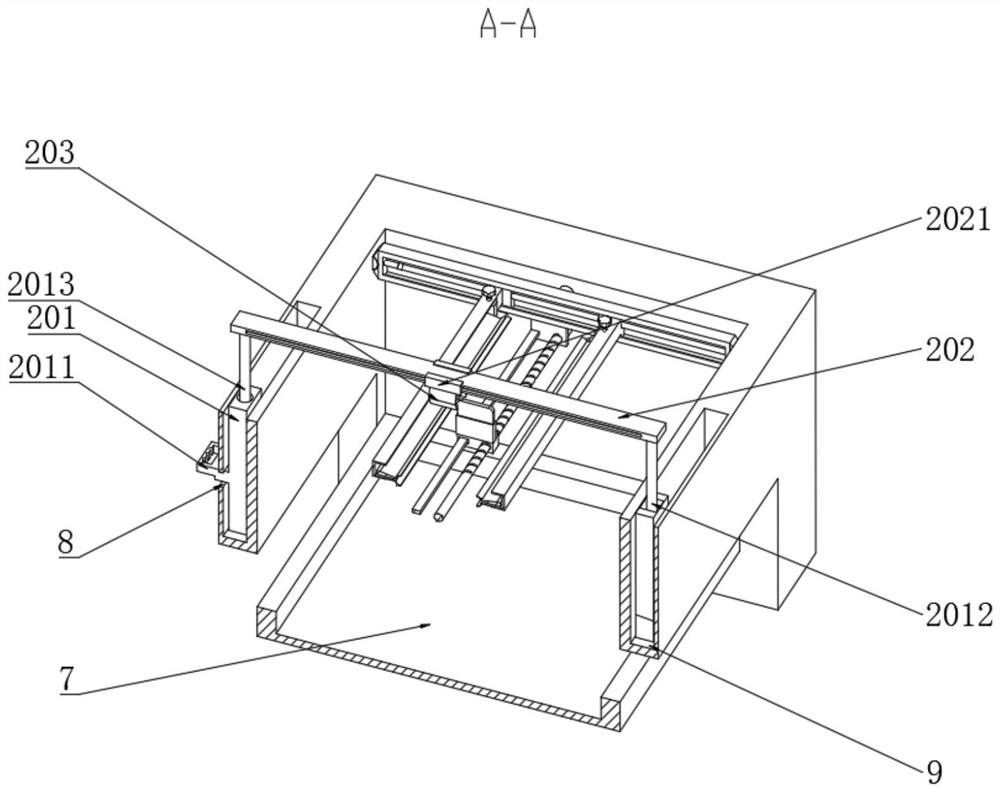

Mobile gantry car washing machine

PendingCN109131237AAvoid blind spotsImprove cleaning effectCleaning apparatus with conveyorsVehicle drying apparatusAutomotive engineeringEngineering

The invention discloses a mobile gantry car washing machine, which comprises a gantry frame, a guide rail, a roller, and a transverse brush mechanism, a large vertical brush mechanism, a small vertical brush mechanism, a transverse wind knife mechanism and a cross wind knife mechanism arranged in the gantry frame. The mobile gantry car washing machine clean the vehicle by moving the gantry, thereis no need for the vehicle to drive into the position to be washed, the gantry frame moves forward or backward on the guide rails, which can be used for cleaning vehicles with different widths and heights. The mobile gantry car washing machine also has the function of cleaning the wheel hub, achieves the comprehensive scrubbing effect, avoids the dead corner, enhances the cleaning effect, simultaneously carries on the blowing drying treatment to the vehicle after the vehicle washes, and may complete the entire body length blowing drying. The blowing drying effect is good, the work efficiency is high, and the mobile gantry car washing machine may replace the manual drying and saves the labor force.

Owner:常熟市中协无纺机械设备有限公司

Finishing processing technique

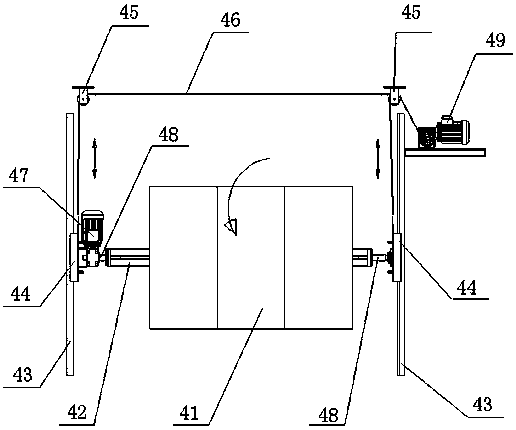

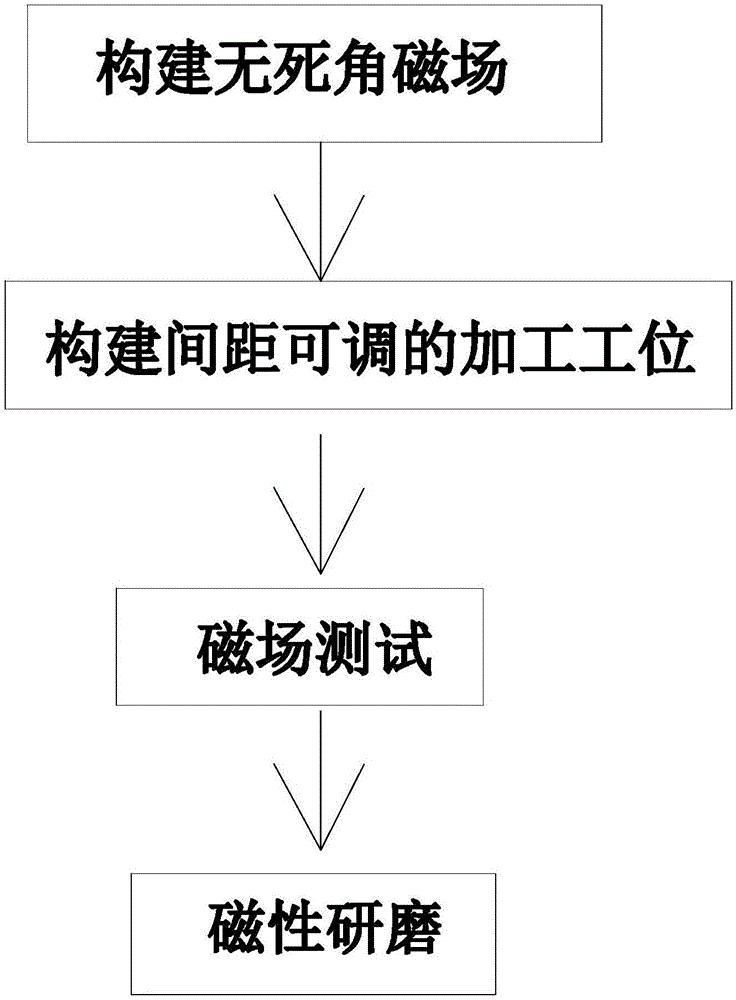

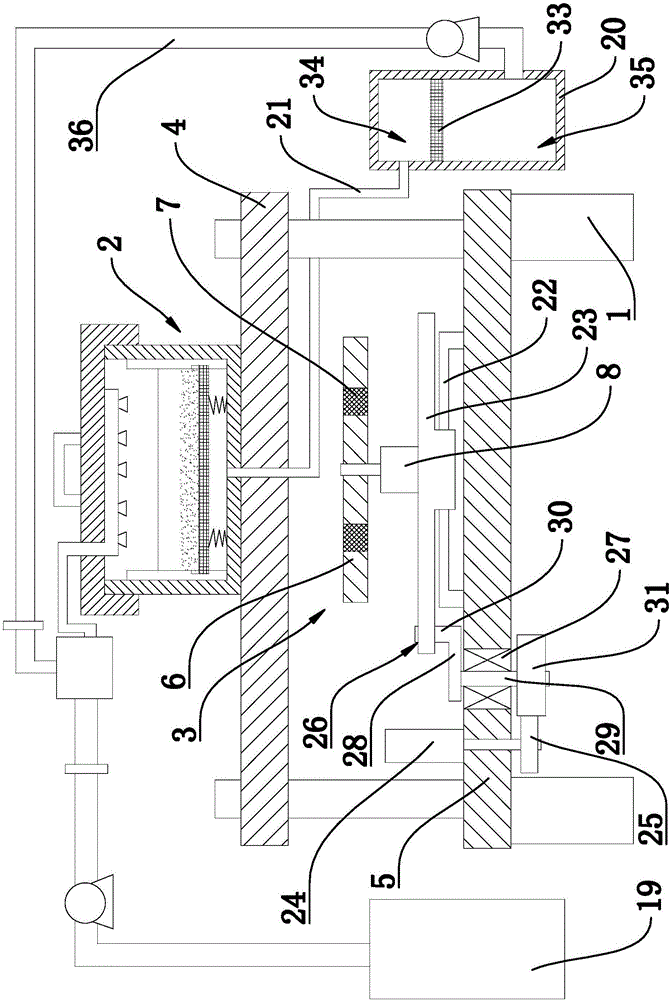

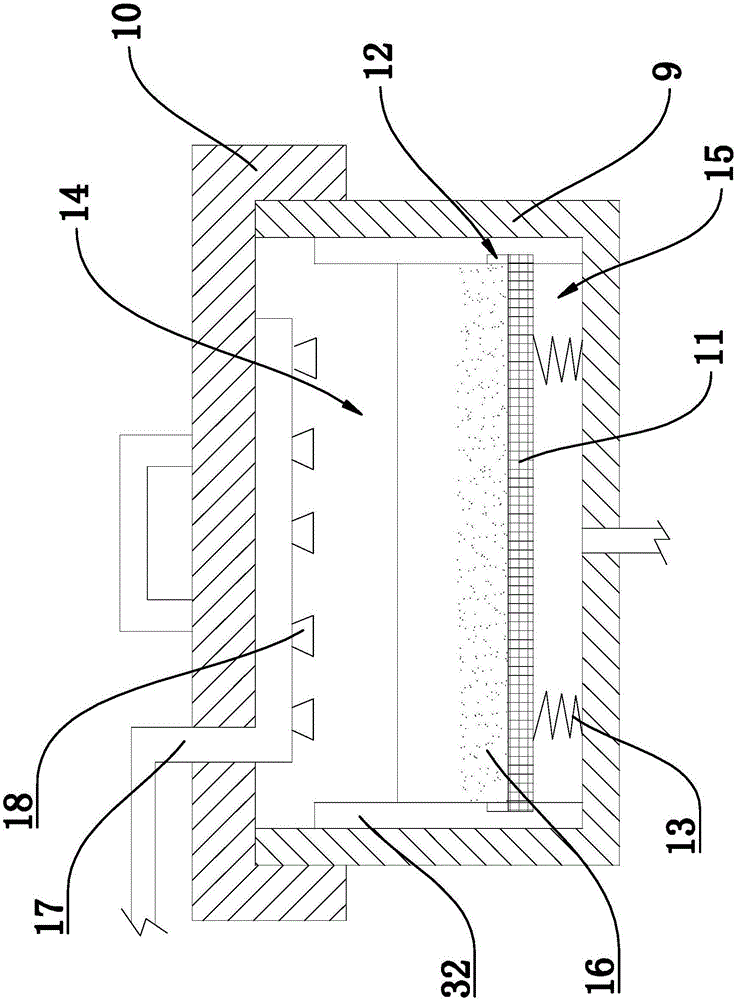

A finishing processing technique comprises the following steps that A, a no-dead-corner magnetic field is constructed, specifically, at least one pair of magnets is mounted on a rotary plate, a first motor is mounted on a sliding plate, one end of the sliding plate is in transmission connection with a second motor, the second motor can drive the sliding plate to slide transversely and horizontally, and the rotary plate is mounted on the first motor; B, machining stations with the interval being adjustable are constructed, specifically, a machining box is provided for the position above the magnetic rotary plate and mounted on a first liftable supporting table; C, a magnetic field test is conducted, specifically, a magnetic abrasive is added into a machining cavity, grinding liquid is pumped into the machining cavity, the magnetic abrasive is soaked in the grinding liquid, and the first motor is started to drive the magnetic rotary plate to rotate, so that the magnetic field is formed and can be adjusted through ascending and descending of the first supporting table; and D, magnetic grinding is conducted, specifically, a to-be-machined part is put into the machining cavity, and the second motor is started and drives the sliding plate to transversely slide back and forth, so that the magnetic field is distributed movably, and the part is subjected to finishing processing by colliding the part surface with the magnetic abrasive.

Owner:HAINING SHENGXIANG WIRE

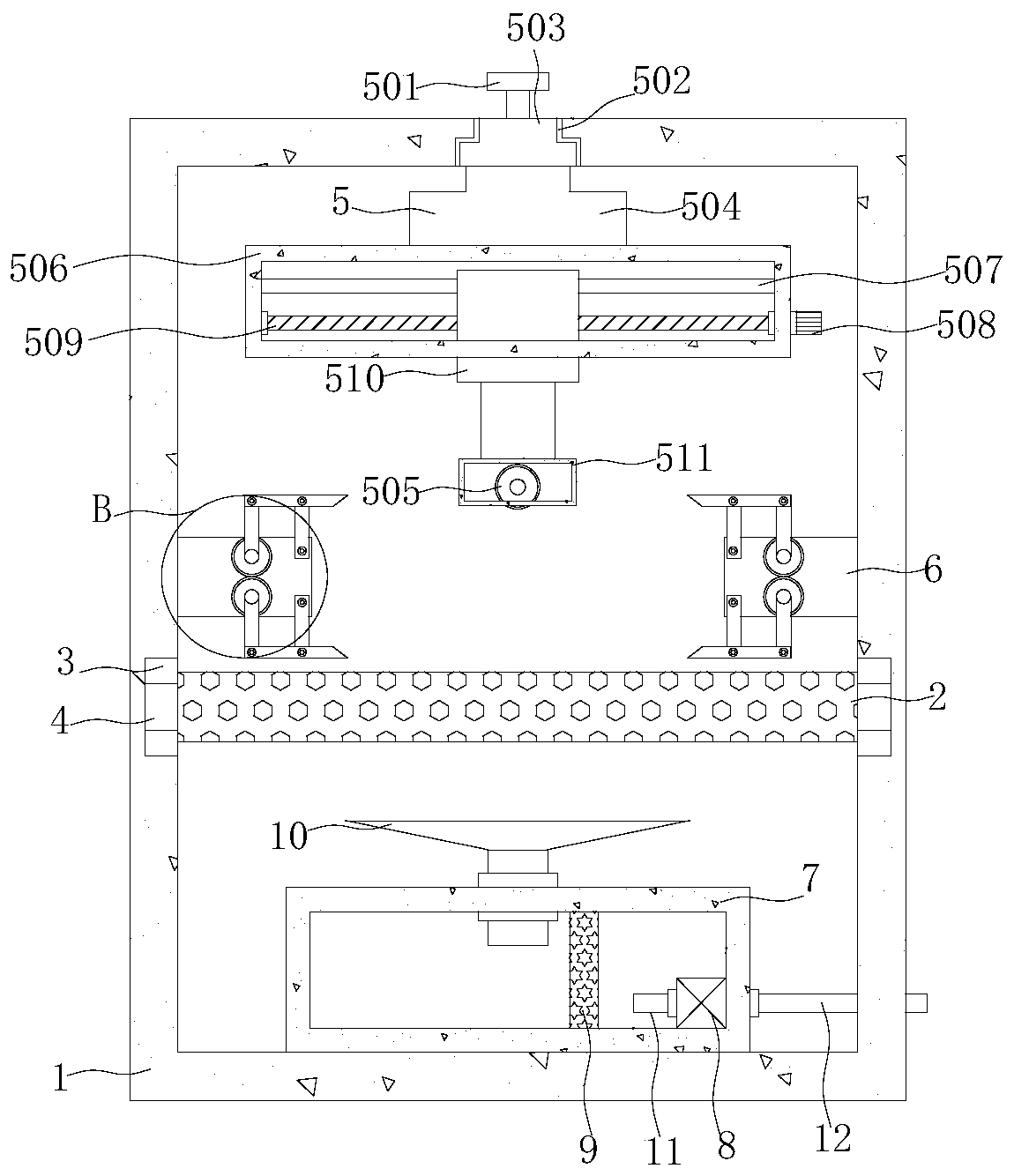

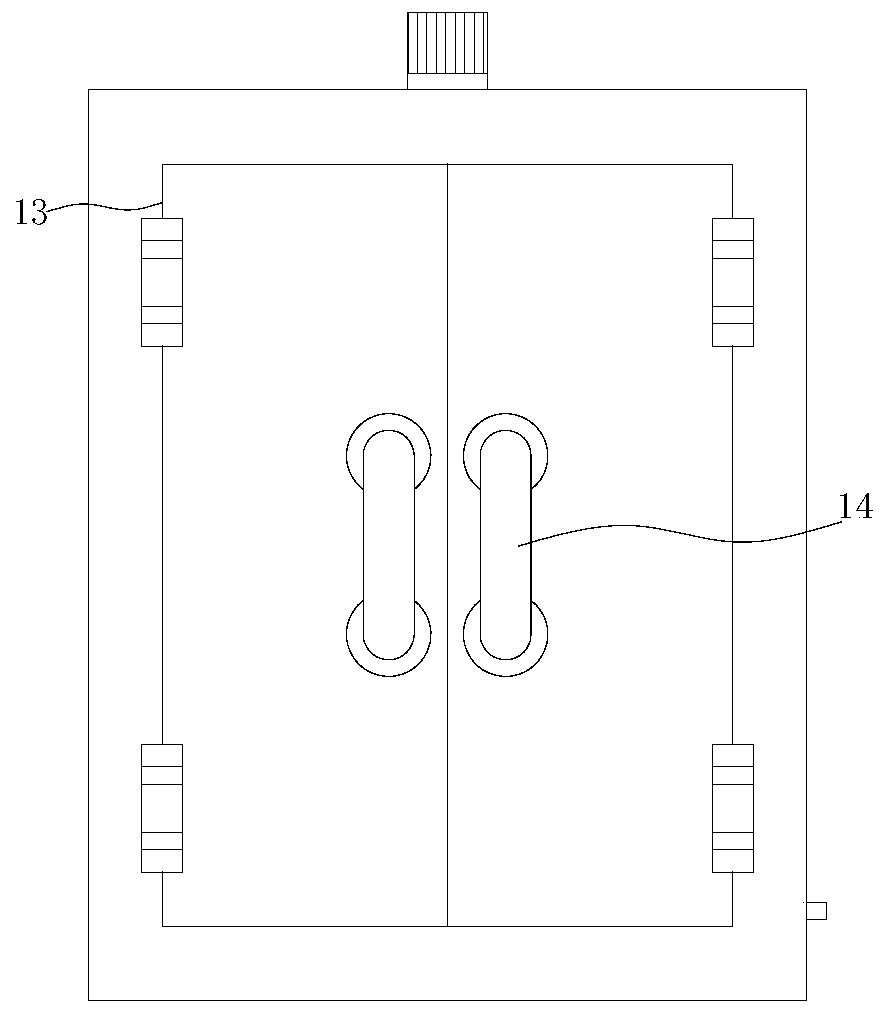

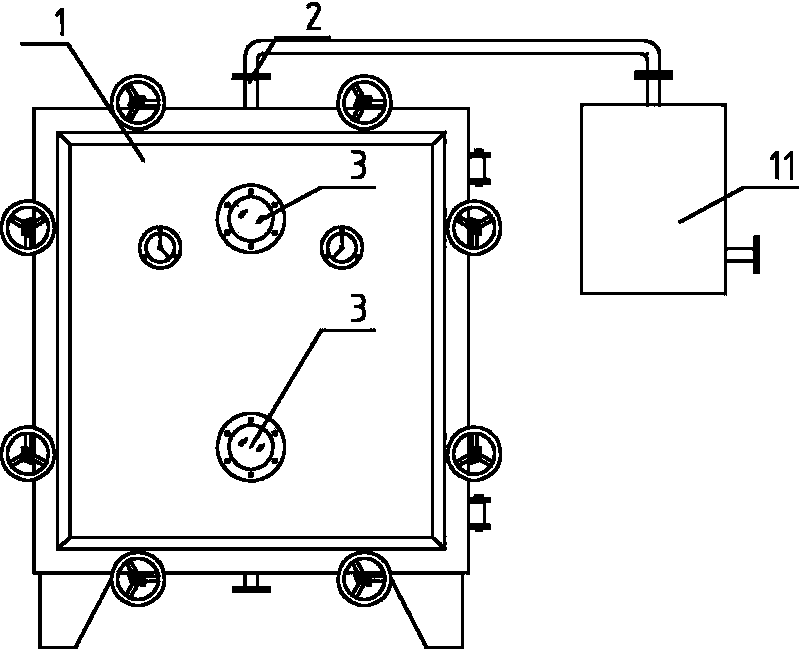

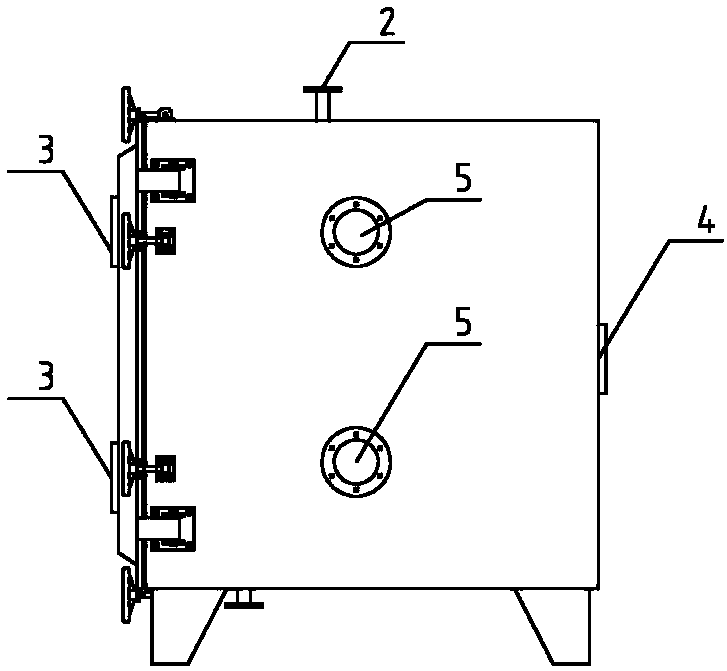

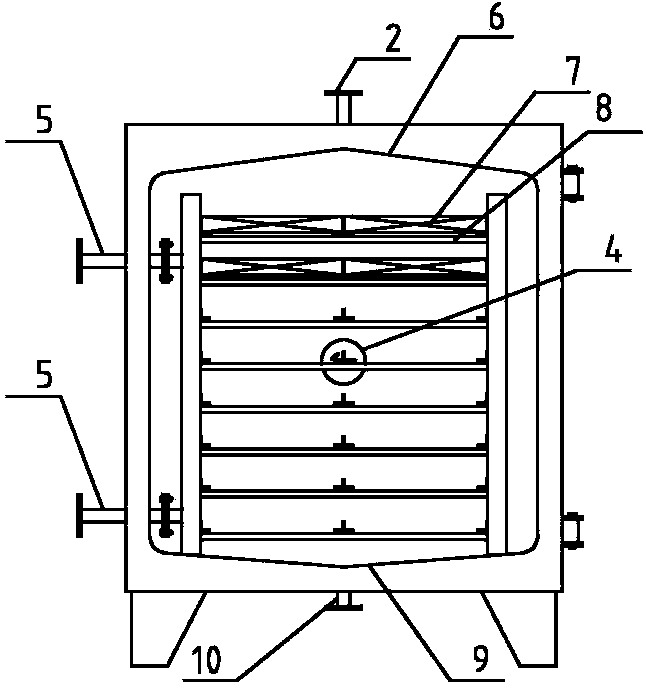

Improved low-temperature vacuum drying oven

InactiveCN103411397AAvoid standing waterAvoid scorchingDrying using combination processesDrying chambers/containersThermodynamicsEngineering

The invention discloses an improved low-temperature vacuum drying oven. The improved low-temperature vacuum drying oven comprises an oven body, drying trays and at least one layer of drying rack, the inner top of the top of the oven box is semi-elliptical, the inner bottom of the bottom of the oven body is concave, and the concave portion of the inner bottom is provided with a drainage pipe; the drying racks are arranged inside the oven body, both the upper end and the lower end of the drying racks are provided with a steam pipe, the connector opening of each steam pipe is provided with a quick connector, and the drying trays are arranged on the drying racks. The improved low-temperature vacuum drying oven improves vacuum-pumping efficiency, avoids dead angles, solves the problem that materials at the top layer is not easy to dry, improves drying efficiency, solves the problems that materials are easy to be scorched at the contact position of the bottom of the drying tray and a heat dissipating coil pipe, improves drying efficiency on the whole and reduces drying energy loss.

Owner:NANJING JIAXI DRYING EQUIP

Highway bridge guardrail maintenance equipment

PendingCN111364398AAvoid secondary pollutionAvoid dead endsRoad cleaningGear wheelElectric machinery

The invention discloses highway bridge guardrail maintenance equipment. The equipment comprises a compartment and brush rollers; a translation frame is arranged in the carriage in a sliding manner; adisplacement sensor can monitor large deformation of the guardrail; a second hydraulic rod is fixedly arranged on and connected with a translation frame; the bottom of the second hydraulic rod is fixedly connected with a lifting frame; the lifting frame is arranged in the translation frame in a liftable sliding manner; the outer end of the lifting frame is fixedly connected with a mounting frame;a plurality of brush rollers are rotationally arranged on the mounting frame; the brush rollers are coaxially and fixedly connected with driven gears; every two adjacent driven gears are engaged witheach other; a motor is fixedly installed on the side wall of the mounting frame; an output shaft of the motor is coaxially and fixedly connected with a driving gear, which is mounting with one of thedriven gears; and a square tray is fixed to the bottom of the compartment and used for recycling cleaning water resources. The equipment is simple in structure, complete in function, convenient to operate, high in cleaning quality, capable of recycling water resources and convenient to popularize and implement.

Owner:SHAANXI RAILWAY INST

Turnover type material rapid welding device

InactiveCN114406591AReduce work intensityReduce operating proceduresWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelElectric machinery

The invention provides a turnover type material rapid welding device, and relates to the technical field of material welding, the turnover type material rapid welding device comprises a workbench, a machining turnover groove is formed in the workbench, a derivation groove is formed in one side of the workbench, a turnover motor is fixedly installed in the derivation groove, and a driving wheel is fixedly installed at the output end of the turnover motor; teeth are arranged on a half circle of the outer surface of the driving wheel, overturning assemblies are rotationally installed at the two ends of the inner wall of the machining overturning groove, materials needing to be welded can be overturned in situ in a unified mode through the overturning assemblies, and therefore the positions of the materials do not need to be adjusted and matched after single-face welding is completed; by means of the device, the problem that due to the fact that materials cannot be turned over in situ, the welding position needs to be adjusted again, and the working intensity of operators is increased is effectively solved, and the operation procedures of the operators are reduced.

Owner:许桂娜

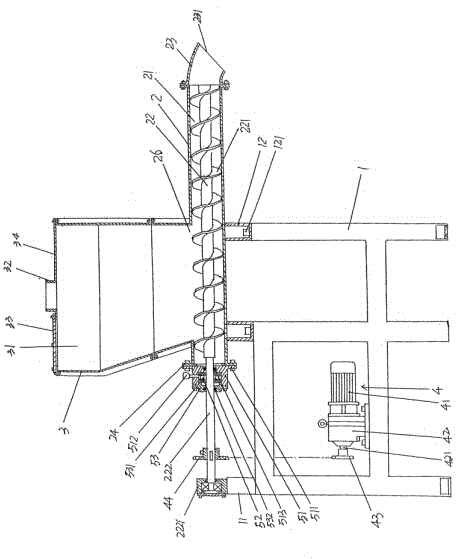

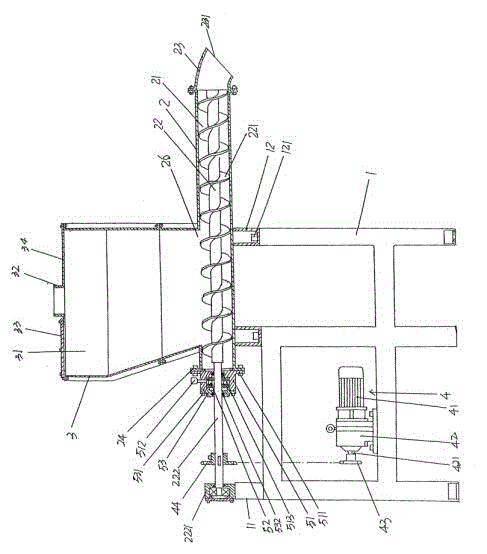

Sagger automatic continuous charging device for electronic kiln

The invention discloses a sagger automatic continuous charging device for an electronic kiln, and belongs to the technical field of electronic kiln auxiliary facilities. The sagger automatic continuous charging device comprises a rack, a spiral material conveying tube, a material storage box and a power transmission mechanism. The rack is supported on a terrace. The spiral material conveying tube is fixed on the top of the rack, a screw rod shaft is matched in a tube cavity of the spiral material conveying tube, and a spiral sheet is formed on the screw rod shaft. A closed end is formed at the left end of the spiral material conveying tube, and an opened end is formed at the right end of the spiral material conveying tube. The material storage box is fixedly connected with the top of the rack, and the bottom of a material storage box cavity is communicated with the tube cavity of the spiral material conveying tube. The power transmission mechanism is connected with the screw rod shaft. The sagger automatic continuous charging device for the electronic kiln is characterized in that the opened end of the spiral material conveying tube is connected with a bend connector in a matched mode, the bend connector is communicated with the tube cavity, a bend connector discharging opening of the bend connector faces downwards, the left end of the screw rod shaft stretches out of the tube cavity to form a screw rod shaft extension shaft section, the screw rod shaft extension shaft section is supported on the top of the rack, and the power transmission mechanism is connected with the screw rod shaft extension shaft section. Discharging smoothness is guaranteed, the spiral sheet can be prevented from scraping the inner wall of the tube cavity, and accordingly materials can be accurately led into a sagger.

Owner:SUZHOU HUIKE EQUIP CO LTD

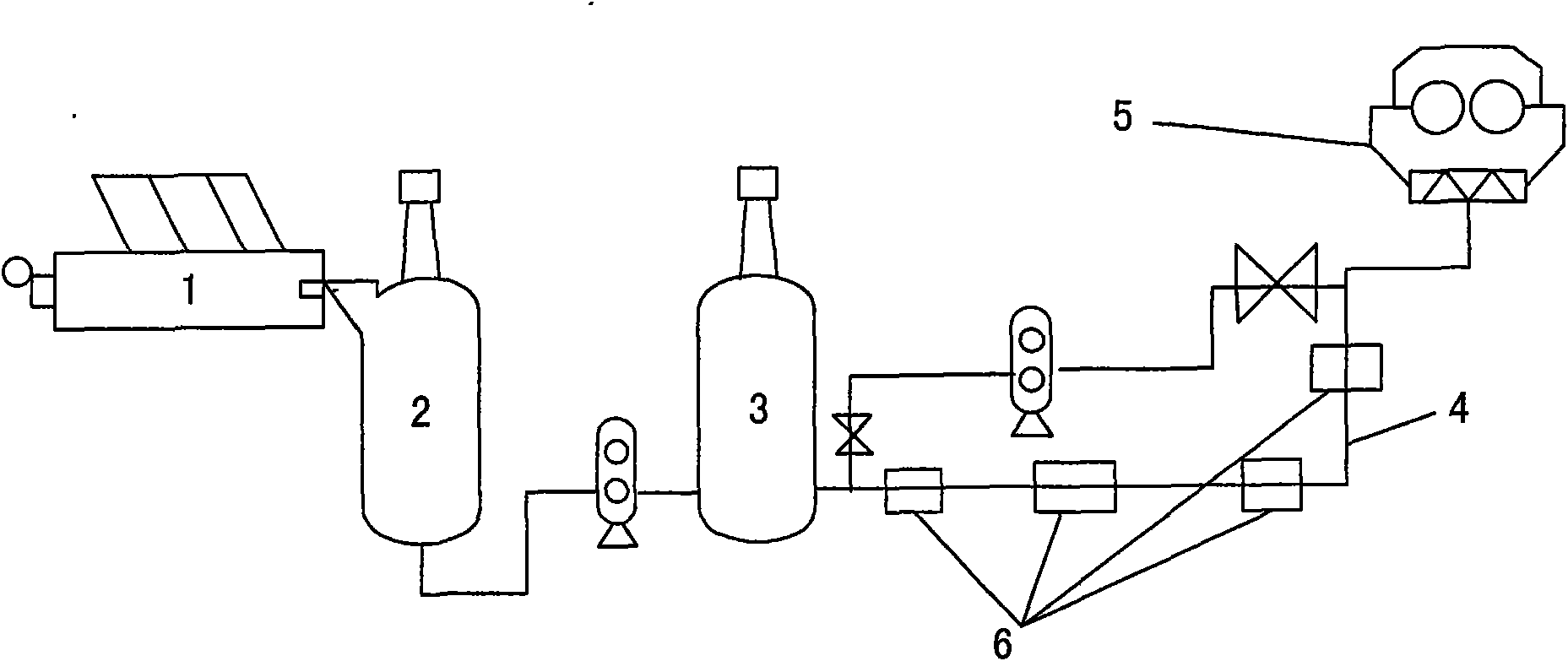

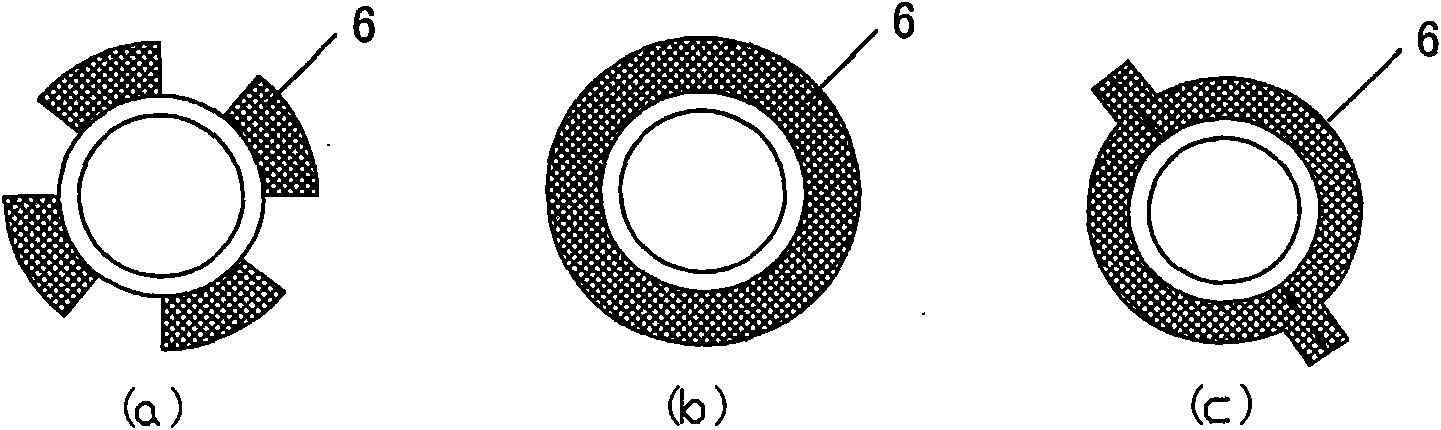

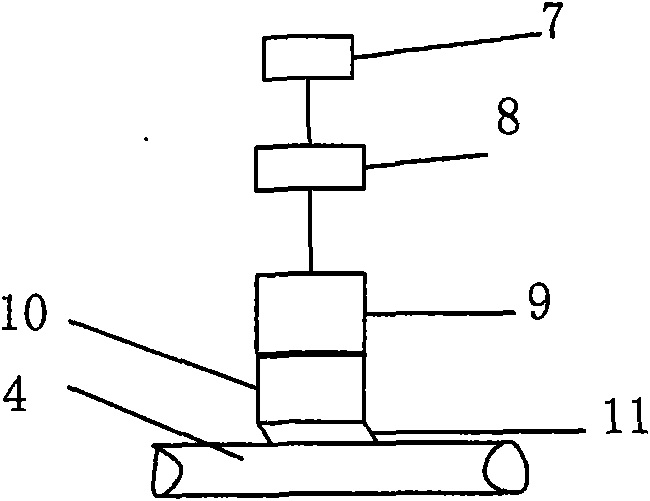

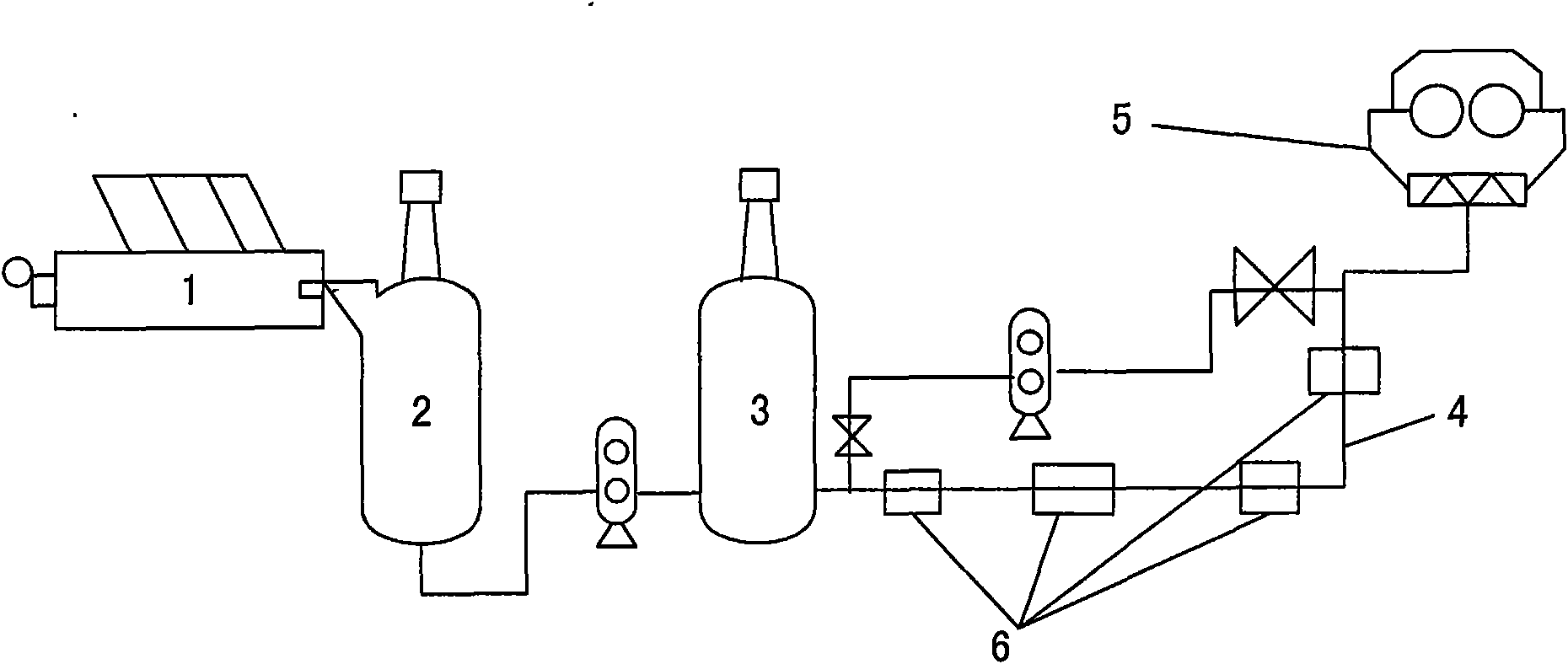

Dual-injection type injecting and dust-removing device and process

ActiveCN103990331AIncrease temperatureGuaranteed temperatureDispersed particle filtrationTemperature controlGas supply

The invention discloses a dual-injection type injecting and dust-removing device and process. The dual-injection type injecting and dust-removing device comprises two injection gas transmission pipes and an injection pipe, wherein one injection gas transmission pipe is connected to an upper nozzle which is formed in the upper part of a filter cartridge of a dust remover; the other injection gas transmission pipe is connected to a lower nozzle which is formed in the lower part of the filter cartridge of the dust remover; the injection gas transmission pipe for supplying gas to the lower nozzle is connected to a dust-containing gas inlet pipeline of the dust remover; the injection gas transmission pipe for supplying the gas to the upper nozzle is connected to a gas outlet pipe of a gas purification chamber of the dust remover or an external gas supply device; the temperatures in the injection gas transmission pipes are controlled to be 350-750 DEG C; the pressures in the injection gas transmission pipes are controlled to be 0.5-2.5MP; the two injection gas transmission pipes are used for injecting alternately; the ratio of the injection times of the upper nozzle to the injection times of the lower nozzle is 1 to (0.5-4). By adopting the combined manners of internal injection and back blowing as well as external injecting and peeling at the bottom of the filter cartridge of the dust remover and controlling the selection of injection temperature and injection manners, the working efficiency of the device is improved and the operation cost is reduced.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

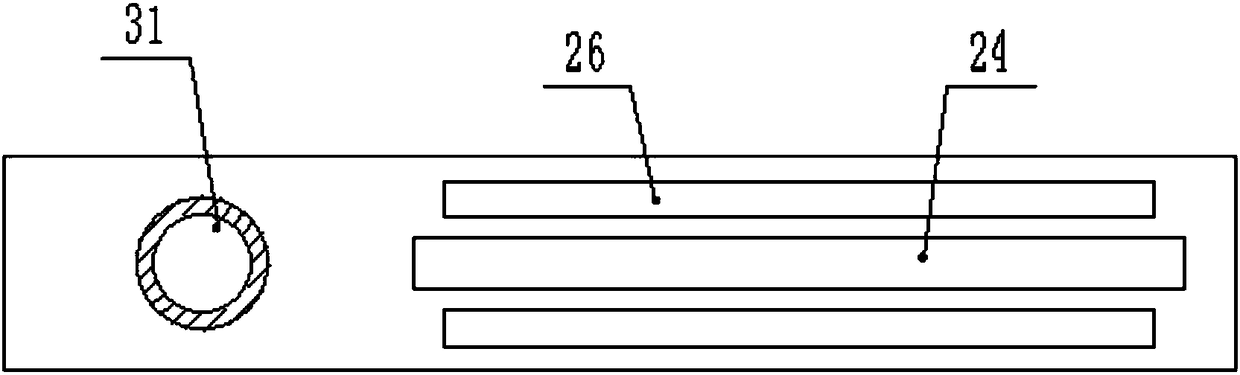

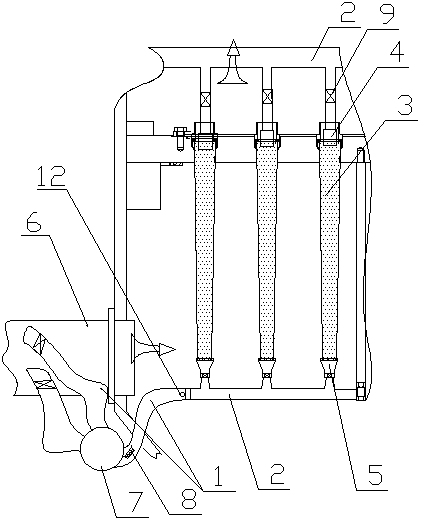

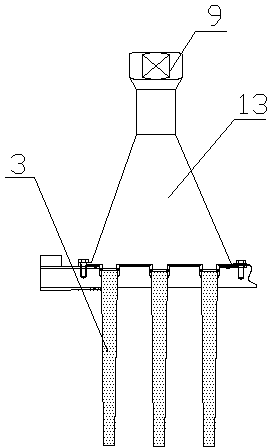

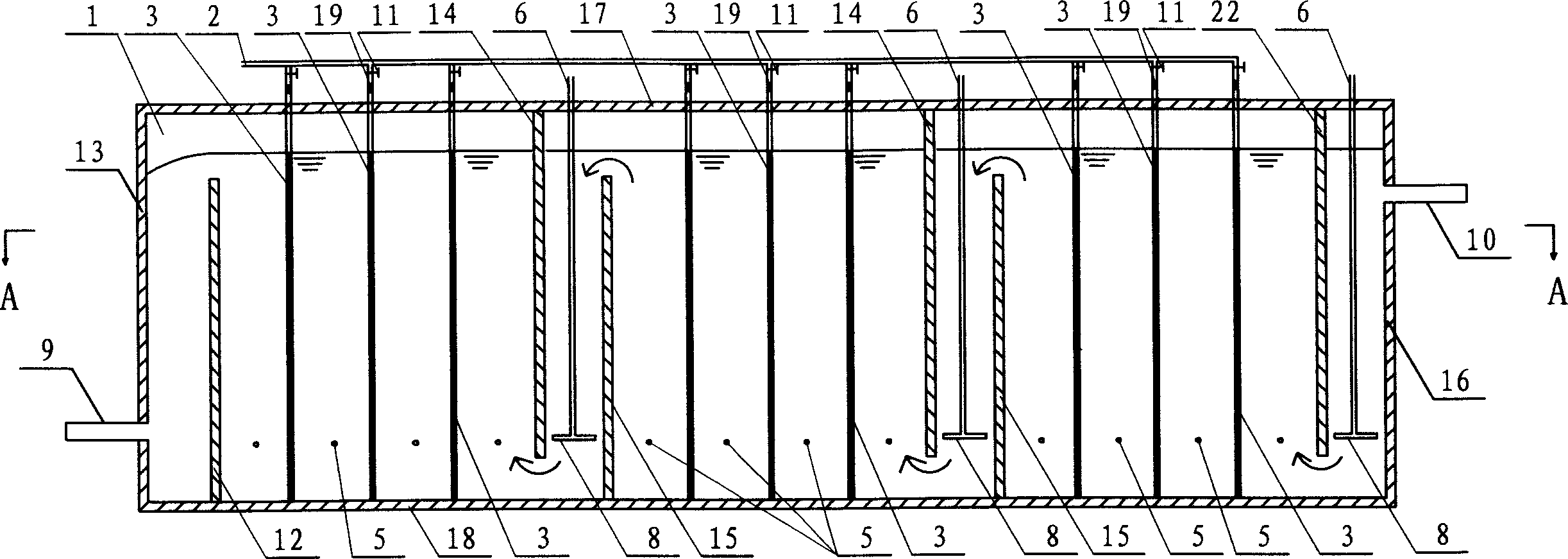

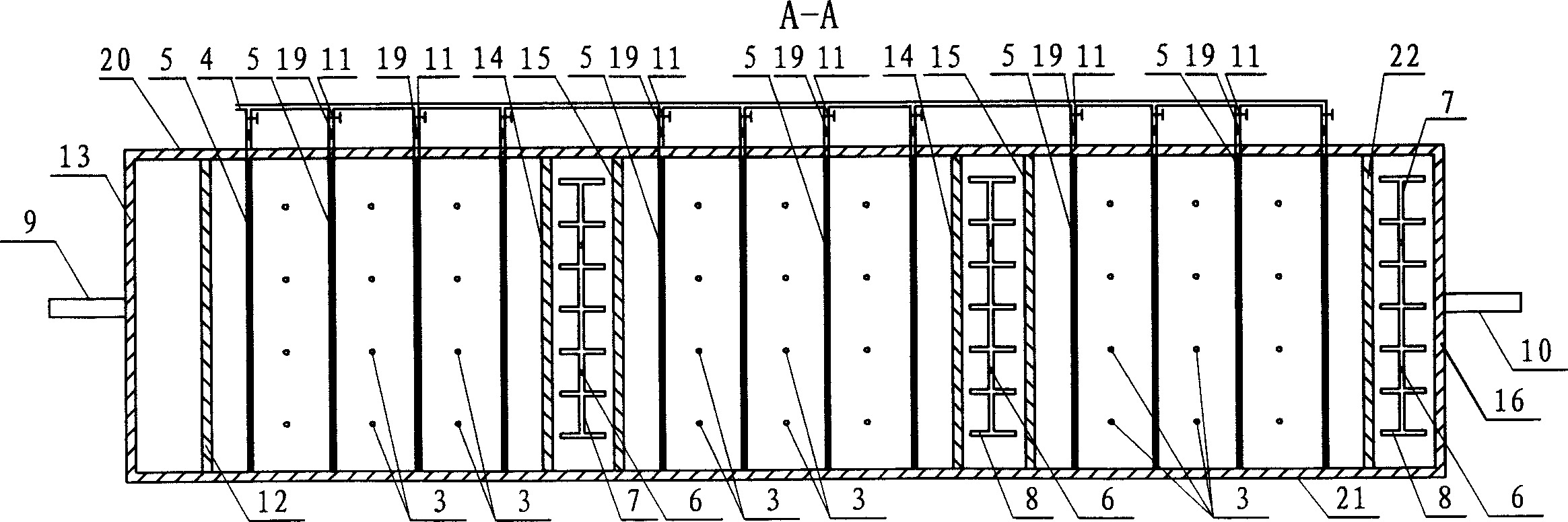

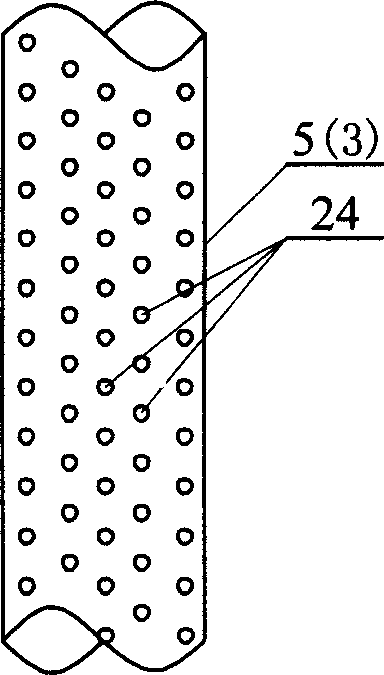

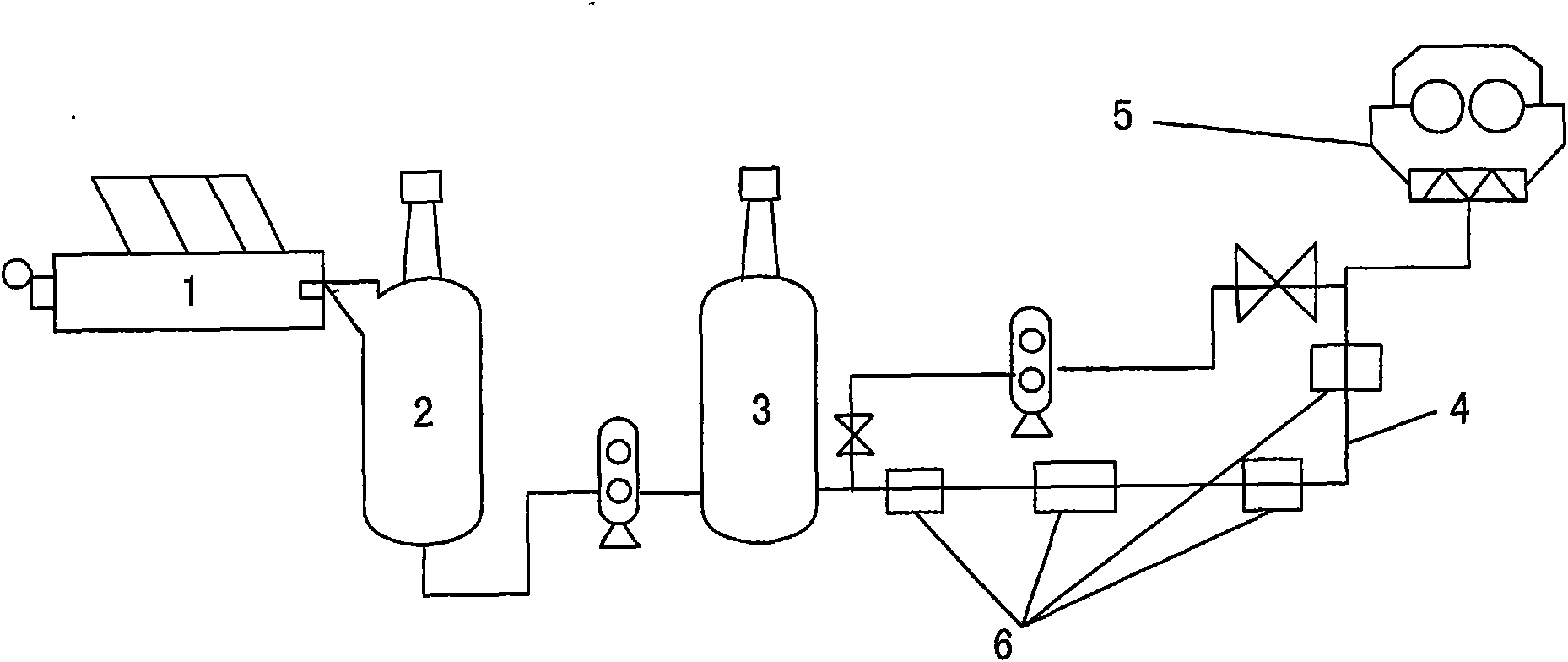

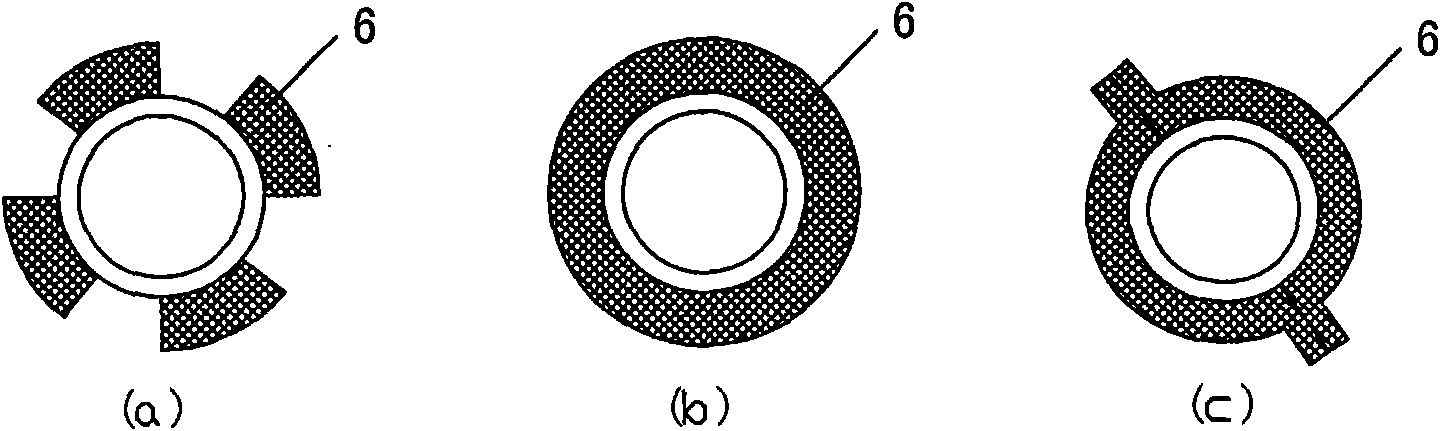

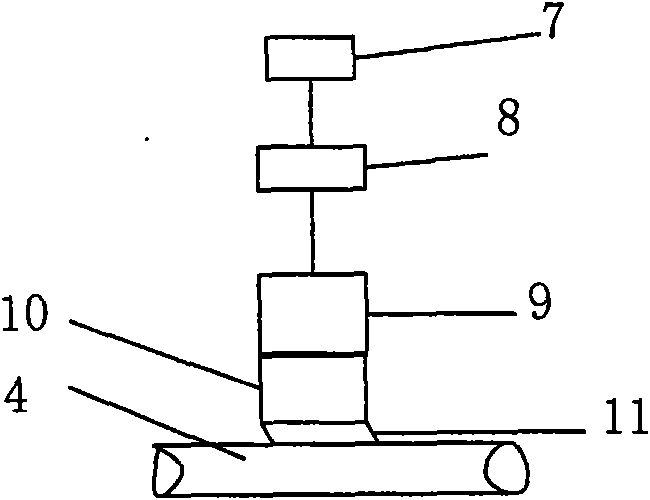

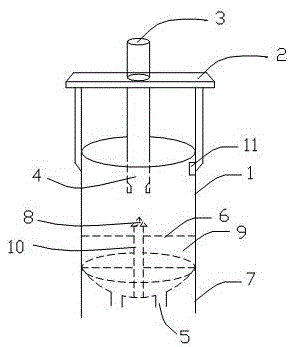

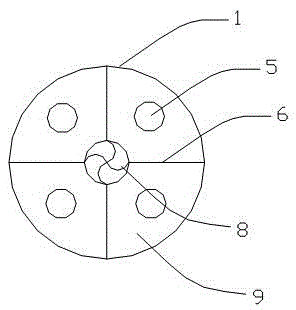

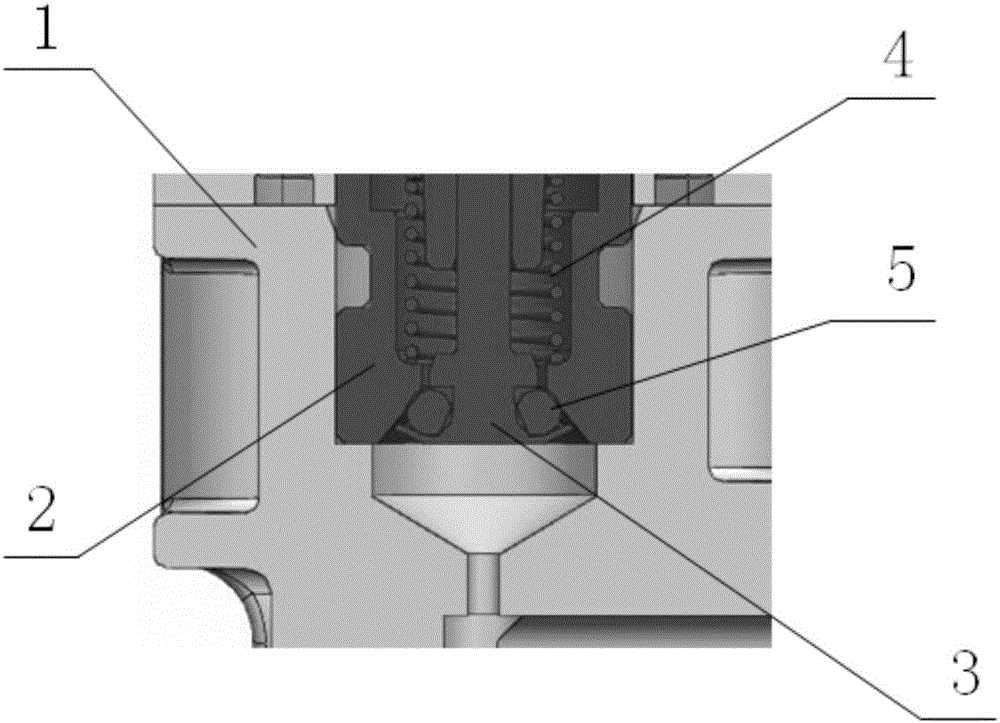

Porous multi-site provided reactor for water treatment

InactiveCN1644527AAvoid "dead ends"Improve reaction efficiencyWater/sewage treatment by oxidationMulti siteOrganic matter

A micro-porous multi-point adding reactor for water treatment relates a device for improving organic matter efficiency of oxidant oxide water in water treatment. A horizontal medicament adding tube5 is arranged parallelly on the bottom of a water pool, the vertical medicament adding tube3 and the horizontal medicament adding tube5 are arranged vertically in the water pool1, the ozone aerating offtake8 is arranged horizontally on the ozone horizontal tube7, a mico-pore24 is opened on the horizontal medicament reacting tube5 and the vertical medicament adding tube3, the aperture of the micro-pore24 is 0.5mum-0.5mm. It achieves to decrease hydrogen peroxide reacting consumption, improve contact of hydroxy radical and water organic matter, and lower water treating cost.

Owner:HARBIN INST OF TECH

Method for manufacturing viscose through ultrasonic polymerization reduction of plant fibers

InactiveCN102041570AAvoid dead endsEliminate the disadvantages of uneven responseArtificial filaments from viscoseChemistryUltrasound

The invention provides a method for manufacturing viscose through ultrasonic polymerization reduction of plant fibers, which is a viscose manufacturing method through direct polymerization reduction of the plant fibers by an ultrasonic polymerization reduction pipe. In the method, the ultrasonic polymerization reduction pipe replaces the traditional reaction kettle, and the plant fibers are subjected to alkali steeping to form pulp gruel; the pulp gruel is subjected to polymerization reduction under the action of an ultrasonoscope; the pulp gruel subjected to polymerization reduction is squeezed to form alkali fibers; and the alkali fibers are prepared into the viscose finally. The method overcomes the defects of the prior art, the polymerization reduction is more uniform, the energy consumption is low, a few pieces of equipment are used, the occupied space is small and the product quality is stable; and the polymerization reduction of ultrasonic waves on polymers is applied to the manufacturing of the viscose for the first time, so a polymerization reduction method for the manufacturing of the viscose through polymerization reduction is increased.

Owner:YIBIN HIEST FIBER +1

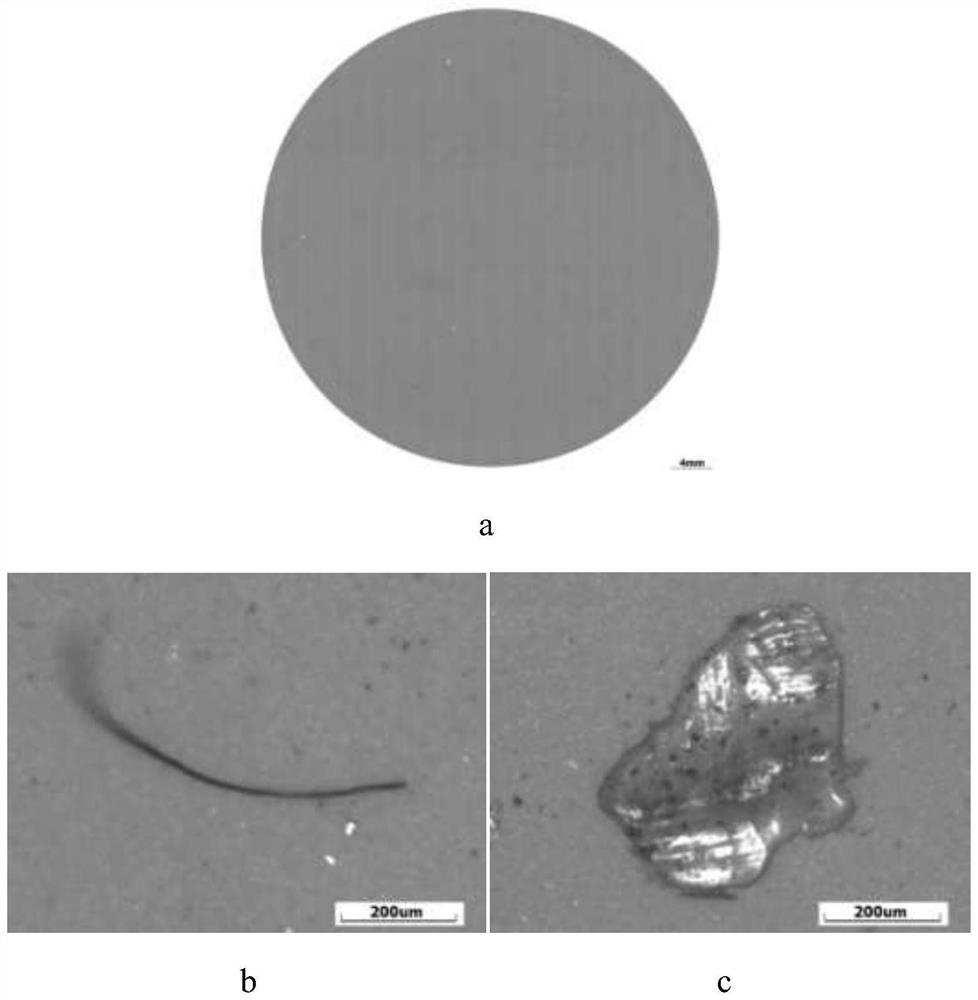

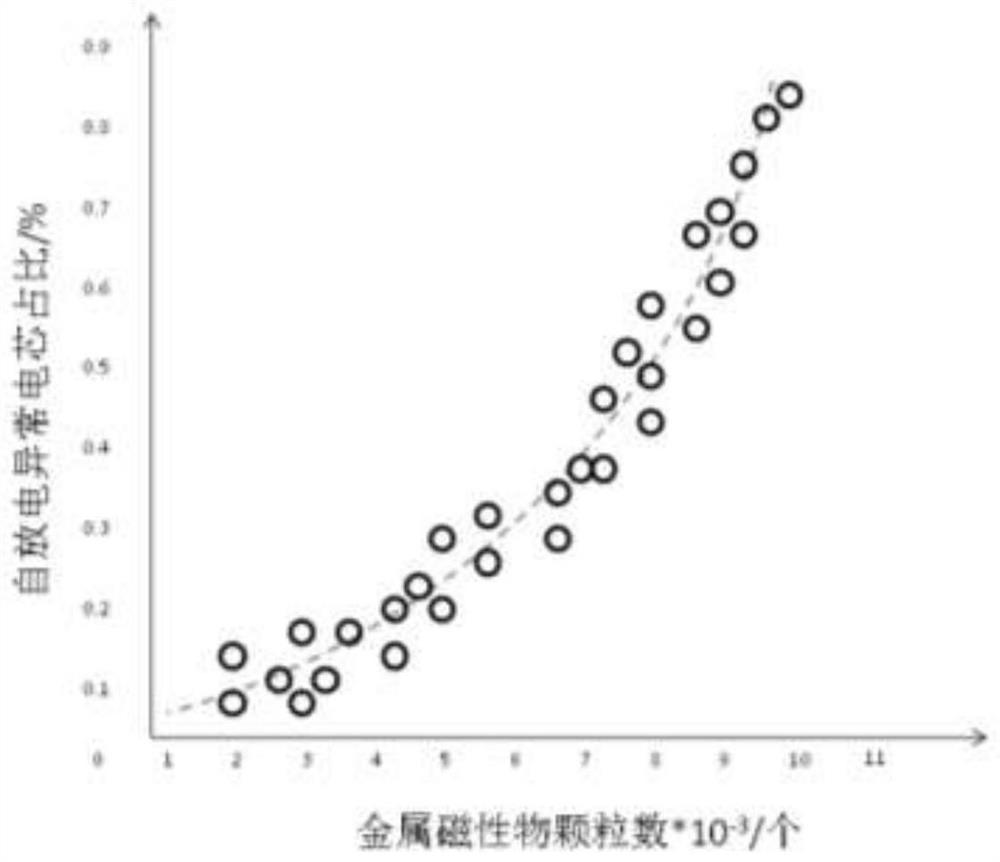

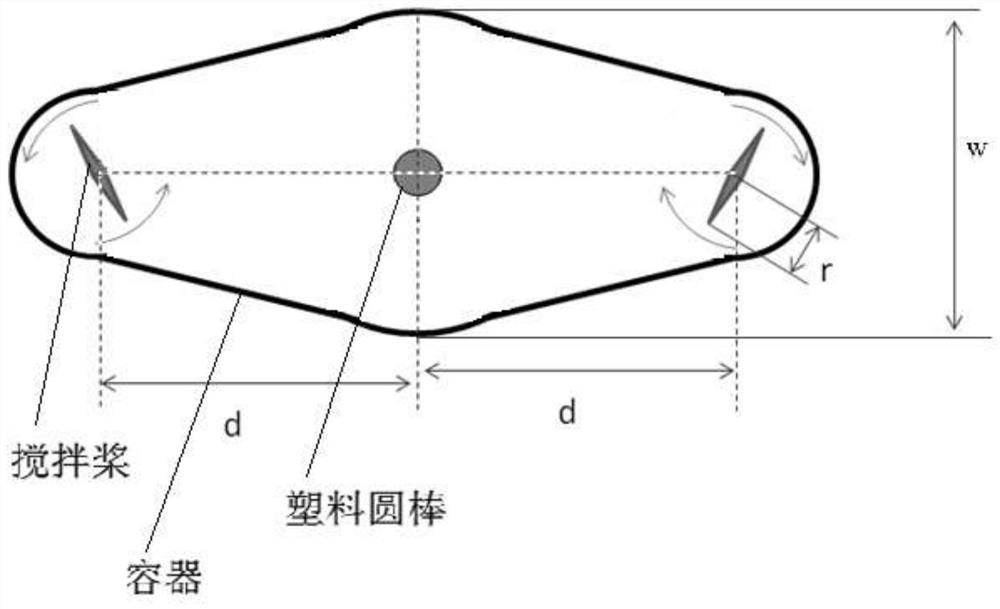

Method for detecting metal magnetic impurities in positive electrode material

InactiveCN111638173AImprove adsorption capacityEfficient enrichmentPreparing sample for investigationParticle size analysisElectrical batteryPhysisorption

The invention discloses a method for detecting metal magnetic impurities in a positive electrode material. The method comprises the following steps: S1, putting a sample solution into a container, inserting a plastic round rod filled with a magnetic rod into the sample solution, and carrying out continuous stirring by using a stirrer in each of two sides of the plastic round rod to perform dynamicadsorption; S2, after stirring is finished, taking out the plastic round rod filled with the magnetic rod, firstly washing off physically adsorbed particles, then taking out the magnetic rod, and dispersing residual particles on the surface of the plastic round rod into a solvent A to obtain an adsorption solution; and S3, adding a hydrochloric acid aqueous solution into the adsorption liquid, carrying out stirring and filtering, taking a filter cake, and detecting the total particle number and the metal particle number. The magnetic rod can adsorb magnetic metal particles without dead angles, the physically adsorbed particles on the magnetic rod are reduced, and the purpose of rapidly and accurately detecting the magnetic particles in the positive and negative electrode materials of thebattery is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

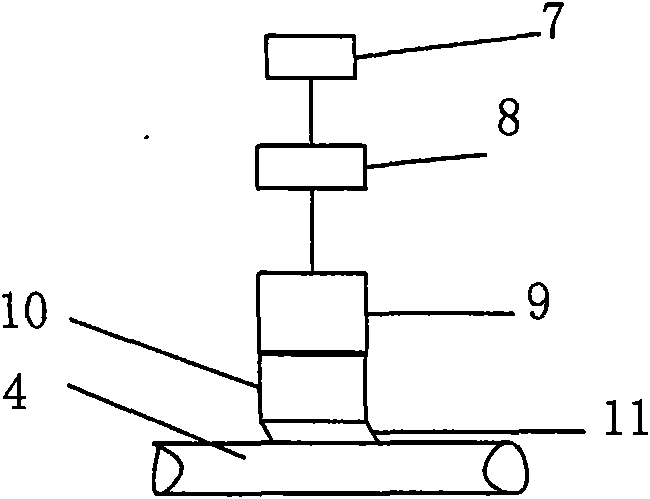

Equipment for averagely distributing separated ore pulp

InactiveCN105417480AAvoid dead endsDead stop preventionLiquid flow controllersLiquid dispensingPulp and paper industryMechanical engineering

The invention discloses equipment for averagely distributing separated ore pulp. The equipment comprises a pulp inlet pipe, a barrel upper frame, a pulp barrel, a necking funnel, a pulp separating head, a pulp separating column, a liquid level detecting device and pulp outlet pipes; the barrel upper frame is fixedly connected above the pulp barrel; one end of the pulp inlet pipe is fixedly connected to the barrel upper frame, and the other end of the pulp inlet pipe is vertically suspended in the pulp barrel; an outlet of the pulp inlet pipe is communicated with the necking funnel; the pulp separating column is arranged in the center of the bottom wall of the pulp barrel; the pulp separating head is arranged at the top end of the pulp separating column, and is rotationally connected relative to the pulp separating column; the pulp outlet pipes are uniformly distributed on the bottom wall of the pulp barrel; the section of the bottom wall of the pulp barrel is arched; ore pulp flows out of the necking funnel; the pulp separating head automatically rotates under the impact of the ore pulp to disperse the ore pulp; the ore pulp uniformly drops to the lower part of the pulp barrel; as the section of the bottom wall of the pulp barrel is arched, the stop of the ore pulp at the bottom of the pulp barrel is prevented; one end of the pulp inlet pipe is fixedly connected to the barrel upper frame to prevent the shaking of the pulp inlet pipe; and the device can uniformly distribute the ore pulp without needing any driving device, and is high in efficiency and high in practicability.

Owner:吴振宇

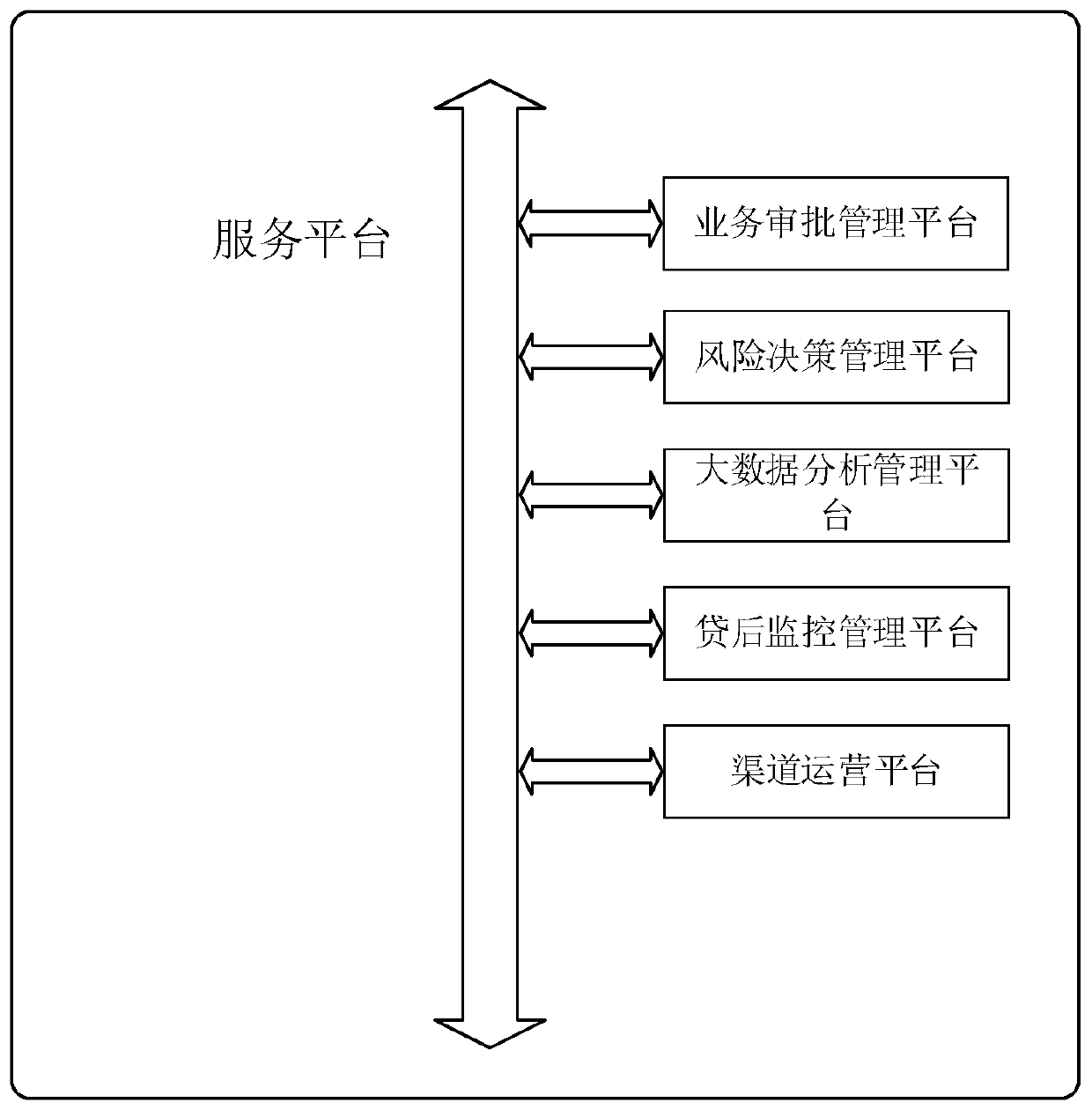

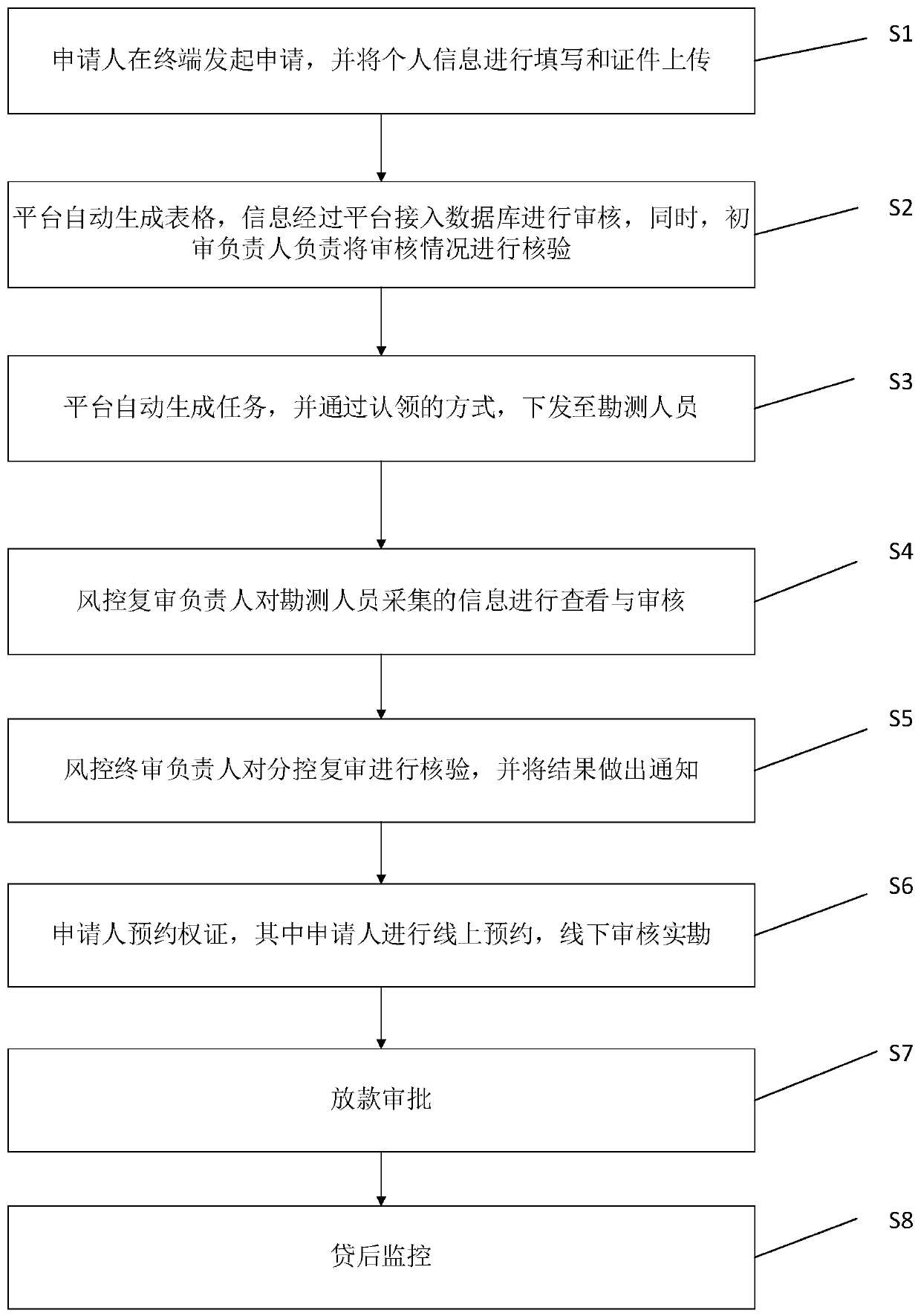

Intelligent financial service platform and method

The invention discloses an intelligent financial service platform and method, and the platform comprises a business approval management platform used for standardizing a business process, guaranteeingthe smoothness of any link from the rear part to the end part of the business, and enabling a responsible person to be clear; a risk decision management platform for assessing the risk of the borrowers and providing online and offline omnibearing monitoring; a big data analysis management platform for carrying out risk control on the borrowers in all directions based on the big data technology onthe basis of auditing of traditional risk control personnel; a post-loan monitoring management platform used for automatically checking the fund condition, transaction, disposal and flow direction ofeach business, and timely avoiding the risk prediction bad operation; and a channel operation platform which enriches the data of the database of the platform and an external third-party database through daily maintenance and operation, and continuously increases the risk control capability of the platform. The invention has the advantages of high efficiency, low cost, accurate target and low risk level.

Owner:重庆斐耐科技有限公司

Interlayer vacuumizing method for cryogenic vessel and special device thereof

InactiveCN103047535AImprove pumping qualityReduce pumping timePressure vesselsNitrogenInlet pressure

The invention discloses an interlayer vacuumizing method for a cryogenic vessel, which belongs to vessels used for accommodating or storing compressed, liquefied or cured gases, particularly a manufacturing method of a cryogenic vessel, which comprises insulation measures. The interlayer vacuumizing method for the cryogenic vessel is characterized in that the outer cylinder body of the cryogenic vessel is heated by heating equipment, N2 heated to 350-370 DEG C is continuously injected into the inner container of the cryogenic vessel, and the inlet pressure is controlled to be 0.4 Mpa; and the outlet pressure is 0.2 Mpa, and in the state of heating the outer cylinder body and the inner container of the cryogenic vessel, a vacuum pump is used to vacuumize an interlayer between the outer cylinder body and the inner container of the cryogenic vessel. According to the invention, hot nitrogen higher than 350 DEG C is adopted to heat the inner container, and a heating furnace is adopted to heat the outer cylinder body so as to heat the inner container and the outer cylinder body at the same time, so that the bleeding rate of a substance in the interlayer is increased in the heated state to facilitate decomposing remaining water molecules and other substances, the vacuumizing efficiency and the vacuity of the interlayer are both improved and the qualified index of the bleeding rate is improved.

Owner:SHANDONG HONGDA TECH GRP

Method for manufacturing viscose through ultrasonic polymerization reduction of bamboo and cotton composite pulp

InactiveCN102041568AAvoid dead endsEliminate the disadvantages of uneven responseArtificial filaments from viscoseViscoseEnergy consumption

The invention provides a method for manufacturing viscose through ultrasonic polymerization reduction of bamboo and cotton composite pulp, which is a viscose manufacturing method through direct polymerization reduction of bamboo and cotton mixed pulp gruel by an ultrasonic polymerization reduction pipe. In the method, the ultrasonic polymerization reduction pipe replaces the traditional reaction kettle, and bamboo and cotton pulp is subjected to alkali steeping to form pulp gruel; the pulp gruel is subjected to polymerization reduction under the action of an ultrasonoscope; the pulp gruel subjected to polymerization reduction is squeezed to form alkali fibers; and the alkali fibers are prepared into the viscose finally. The method overcomes the defects of the prior art, the polymerization reduction is more uniform, the energy consumption is low, a few pieces of equipment are used, the occupied space is small and the product quality is stable; and the polymerization reduction of ultrasonic waves on polymers is applied to the manufacturing of the viscose for the first time, so a polymerization reduction method for the manufacturing of the viscose through polymerization reduction is increased.

Owner:YIBIN HIEST FIBER +1

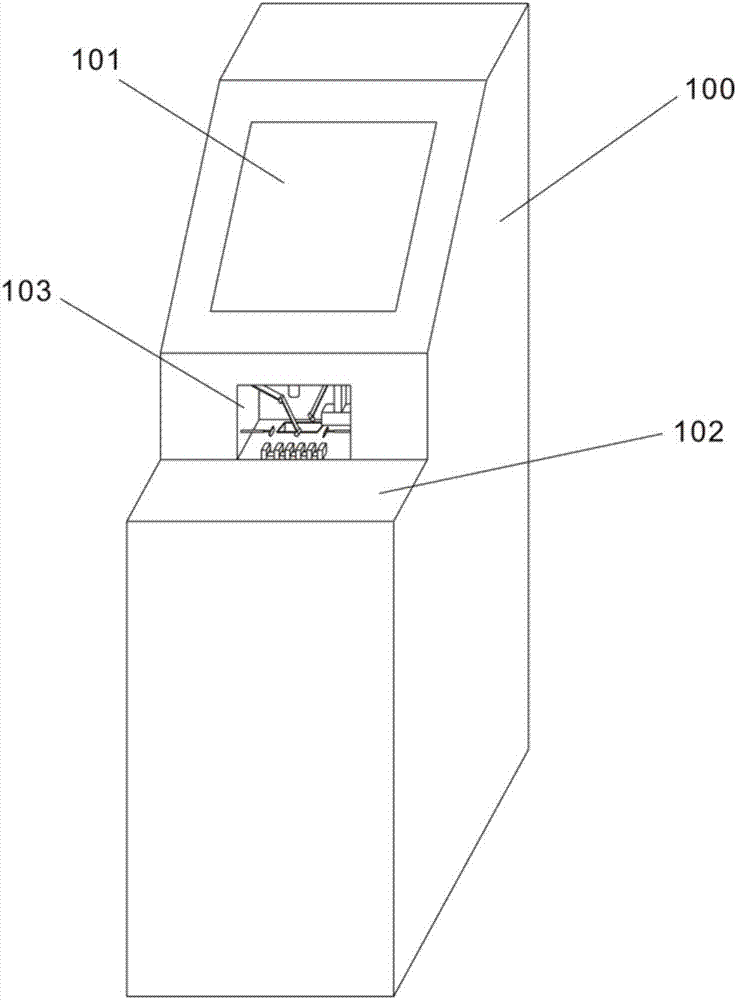

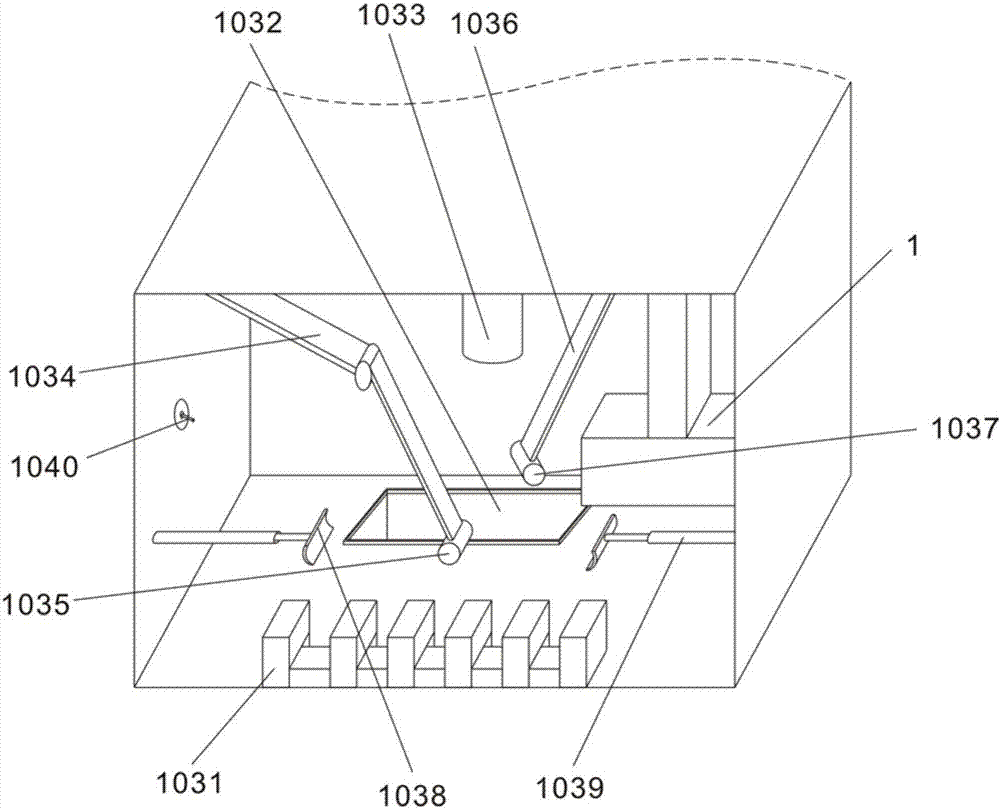

Nail polish nozzle, nail polish box, manicure vending machine and manicure technology

PendingCN107307564ASave spaceFast printingApparatus for meter-controlled dispensingManicure/pedicureSpray nozzlePulp and paper industry

The invention discloses a nail polish nozzle, a nail polish box, a manicure vending machine and a manicure technology, and the nail polish nozzle comprises four nail polish nozzles which are arranged in the nail polish box; the nail polish box comprises nail polish accommodation cavities and polish inlets, and the nail polish accommodation cavities are communicated with the nail polish nozzles; the manicure vending machine comprises a machine body, a touch display screen and a working table, and the working table further comprises a palm placing table and a manicure operation table which are separated by a closing door, and the palm placing table is located at the front end and the manicure operation table is located at the rear end. According to the manicure machine, the printing speed is high, cleaning, trimming, polishing, jet printing and drying can be completed by one step, the dead corner problem is avoided, and the manicure machine has the advantages that the full automation degree is high, layering outgoing of polish can be realized, and the printing effect is improved greatly.

Owner:SHENZHEN ZHUOBANGYUAN TECH CO LTD

Automatic continuous charging device for saggers used in electronic kilns

The invention discloses a sagger automatic continuous charging device for an electronic kiln, and belongs to the technical field of electronic kiln auxiliary facilities. The sagger automatic continuous charging device comprises a rack, a spiral material conveying tube, a material storage box and a power transmission mechanism. The rack is supported on a terrace. The spiral material conveying tube is fixed on the top of the rack, a screw rod shaft is matched in a tube cavity of the spiral material conveying tube, and a spiral sheet is formed on the screw rod shaft. A closed end is formed at the left end of the spiral material conveying tube, and an opened end is formed at the right end of the spiral material conveying tube. The material storage box is fixedly connected with the top of the rack, and the bottom of a material storage box cavity is communicated with the tube cavity of the spiral material conveying tube. The power transmission mechanism is connected with the screw rod shaft. The sagger automatic continuous charging device for the electronic kiln is characterized in that the opened end of the spiral material conveying tube is connected with a bend connector in a matched mode, the bend connector is communicated with the tube cavity, a bend connector discharging opening of the bend connector faces downwards, the left end of the screw rod shaft stretches out of the tube cavity to form a screw rod shaft extension shaft section, the screw rod shaft extension shaft section is supported on the top of the rack, and the power transmission mechanism is connected with the screw rod shaft extension shaft section. Discharging smoothness is guaranteed, the spiral sheet can be prevented from scraping the inner wall of the tube cavity, and accordingly materials can be accurately led into a sagger.

Owner:SUZHOU HUIKE EQUIP CO LTD

Wet mixing machine capable of facilitating material clearing for chemicals

InactiveCN110449063AEasy to cleanImprove uniformityRotary stirring mixersTransportation and packagingEngineering

The invention discloses a wet mixing machine capable of facilitating material clearing for chemicals. The machine comprises a working platform, a material mixing pot is arranged above the upper side of the working platform through a frame, the material mixing pot is connected with the working platform through a rotary supporting mechanism, and the material mixing pot is connected with a rotating device for controlling rotation of the material mixing pot; and the interior of the material mixing pot is provided with a stirring device, the stirring device is connected with a power device, the power device is located outside the material mixing pot, and the connection place of the stirring device and the power device is located on the rotary central axis of the material mixing pot. According to the machine provided by the invention, the material mixing pot and the stirring device are arranged, so that mixing of the chemicals is realized; the rotating device is arranged, so that turning ofthe material mixing pot for material clearing is realized; an open-close pot bottom of the material mixing pot is designed, so that timely clearing of the material mixing pot is facilitated, and the difficult problems that an original machine uses great labor to pour materials and materials are difficult to clear are solved; mixing of the chemicals can be automatically completed by controlling a motor, and the uniformity of the mixed chemicals is high; and separation of human and machine is realized in the whole wet mixing process, safety of workers is ensured, and the efficiency of mixing thechemicals is improved.

Owner:河南中南工业有限责任公司

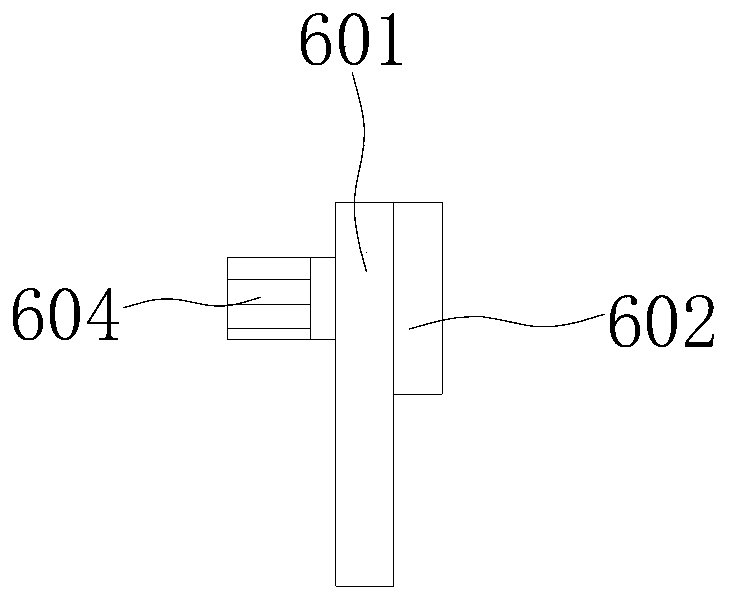

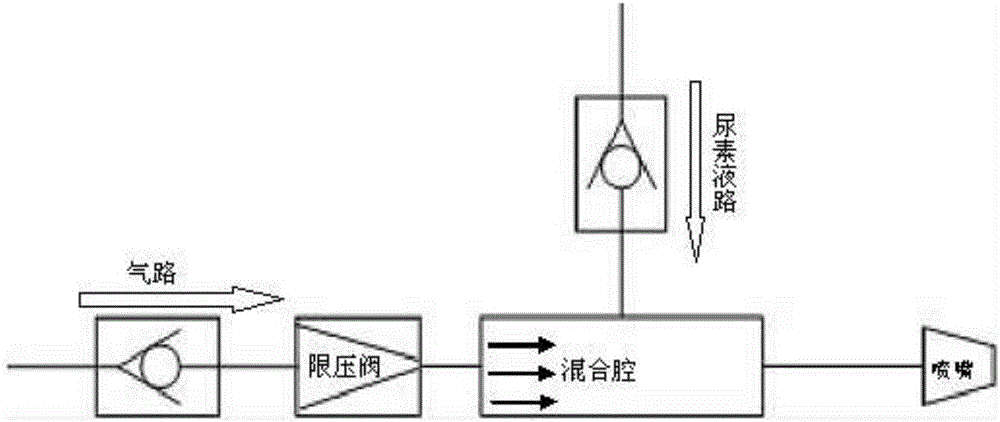

Urea injection device for engine SCR system

ActiveCN106593586AAvoid direct contactEasily brokenGas treatmentInternal combustion piston enginesFailure rateEngineering

The invention relates to a urea injection device for an engine SCR system. The urea injection device comprises a urea liquid way, a gas way, a mixing chamber and a nozzle. One inlet end of the mixing chamber communicates with the gas way, and the other inlet end of the mixing chamber communicates with the urea liquid way. The outlet end of the mixing chamber communicates with the nozzle. A gas way one-way valve is arranged on the gas way. A liquid way one-way valve is arranged on the urea liquid way. Gas in the gas way enters the mixing chamber in the horizontal flowing direction. A urea solution in the urea liquid way is vertically injected into the mixing chamber. By the adoption of the urea injection device for the engine SCR system, the problem that the urea at the urea pump mixing chamber is attached to the wall of the gas way one-way valve and crystallized is solved effectively, the whole vehicle failure rate can be lowered, and the stability and reliability of the SCR injection system are improved. The invention further relates to the engine SCR system with the urea injection device.

Owner:WEICHAI POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com