Turnover type material rapid welding device

A rapid welding and flipping technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as overall efficiency impact, position offset, flipping operation, etc., to reduce personnel injuries, improve stability, and avoid transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

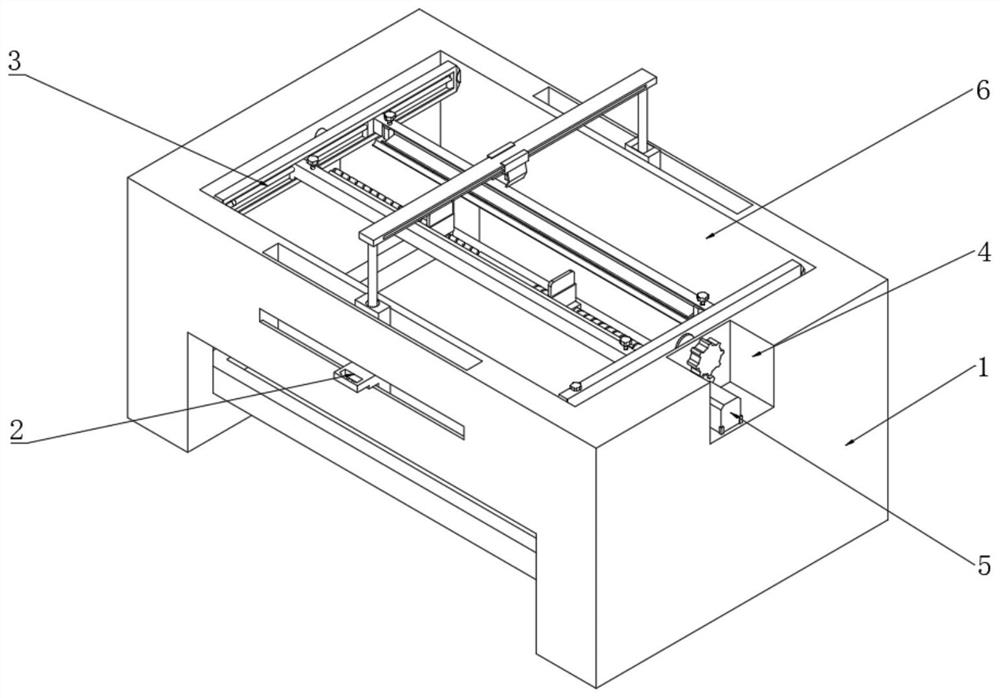

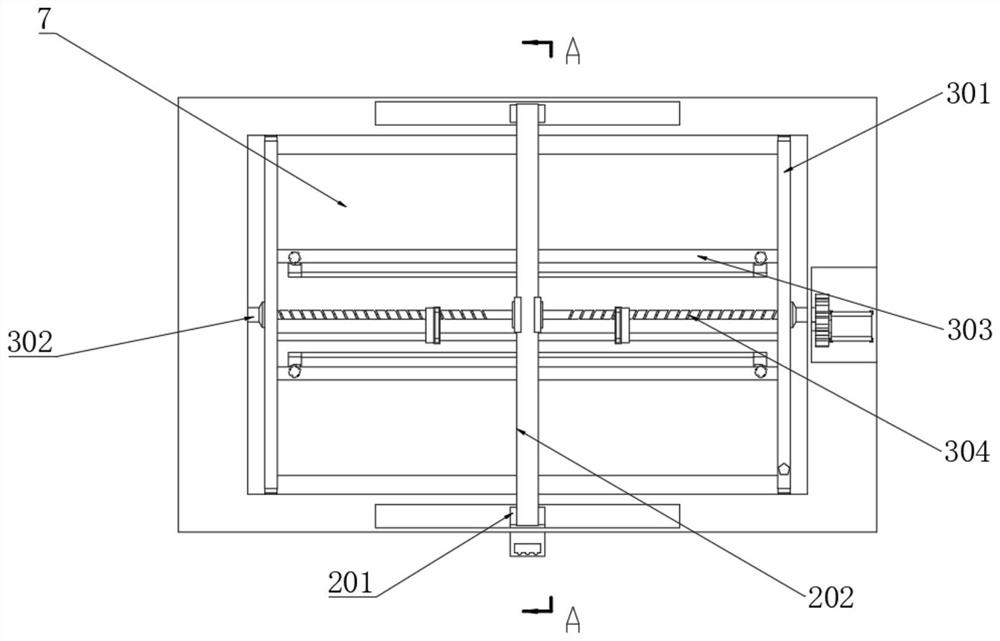

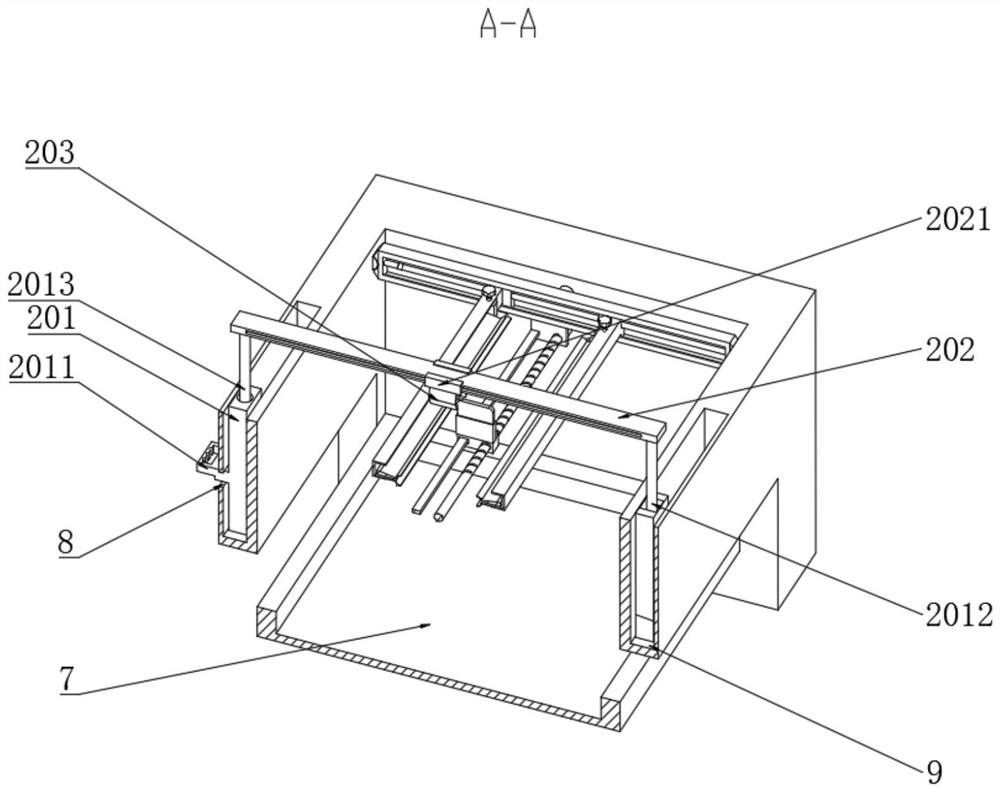

[0041] Such as Figures 1 to 15 As shown, a reversible material rapid welding device includes a workbench 1, a processing turning groove 6 is opened inside the workbench 1, a derivation groove 4 is opened on one side of the workbench 1, and a turning motor 5 is fixedly installed inside the derivation groove 4 , the output end of the turnover motor 5 is fixedly installed with a driving wheel 11, the outer surface of the driving wheel 11 is provided with teeth on half a circle, the two ends of the inner wall of the processing turning groove 6 are rotated and installed with turning components 3, and the two sides of the workbench 1 are respectively provided with displacement chutes 9. A welding assembly 2 is slidably installed inside the displacement chute 9, and the welding assembly 2 is located above the turning assembly 3;

[0042] The welding assembly 2 includes a sliding mounting seat 201. There are two sliding mounting seats 201. One of the sliding mounting seats 201 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com